Drivers for the Adoption of Eco-Innovations in the German Fertilizer Supply Chain

Abstract

:1. Introduction

2. Theoretical Framework

2.1. Technology Push or Market Pull

2.2. Perceived Need for Action to Mitigate Climate Change

2.3. Regulation Awareness and Knowledge on Eco-Innovations

3. The Fertilizer Supply Chain and Its Existing Eco-Innovations

3.1. The Fertilizer Supply Chain in Germany

3.2. Eco-Innovations in the Fertilizer Supply Chain

3.2.1. Stabilized Nitrogen Fertilizers (SNF)

- (1)

- SNF, first introduced in the 1950s can be formulated in three different ways. The first is to add a coating to the granular which allows for a controlled release of the nitrogen (N). The second way is to supply Nin a less soluble from that needs to be converted chemically or biologically to a more soluble and plant available from (sometimes called “delayed release”). The third way is to add an inhibiting chemical that blocks or at least delays the transformation of urea/ammonium N into nitrate nitrogen [74].

- (2)

- (3)

- It has been estimated that stabilized N fertilizers comprise only 8%–10% of the fertilizers used in Europe [79,80], 1% in the USA, and only 0.25% in the world [81]. The market share of these products in German agriculture is still very limited. Legal requirements have led to a faster adoption rate of this technology, especially in areas with high livestock intensity, while in other regions market penetration is developing rather slowly. Only about 10% of the total SNF production is used on agricultural crops [70], the remainder is used for non-agricultural markets (e.g., lawns, golf courses, fruit trees, and vegetables [80]).

3.2.2. Fertigation (FG)

- (1)

- FG is defined as application of soluble fertilizer via the irrigation water [82]. This technology was initially developed in the 1970s in Israel [82]. As nutrients are applied in a water soluble form they are immediately accessible for plant uptake right after application, allowing the farmers greater control over nutrient availability to the crop. When nutrients are applied shortly before they are actually needed, it is possible to reduce losses of nutrients to the environment and also to make the producers less dependent on weather conditions.

- (2)

- In Germany, the need for irrigation is not so widespread compared to Mediterranean countries, but with changes in rainfall patterns due to climate change, FG might become important to enable high yields in the future. The benefits of FG are two-fold: (1) a reduction of fertilizer and water needed for crop production; and (2) the application of nutrients can be controlled at the precise times they are needed [83,84]. However, FG also has some disadvantages like high investment costs, organic fertilizer cannot be used, and a supply of high quality water resources must be guaranteed.

- (3)

- At the moment, market adoption of FG in Germany is rather low. Due to its high investment costs for the irrigation infrastructure, FG is only profitable for crops with high profit margins (like strawberries, tomatoes, or herbs). However, experiments in regions with frequent drought stress periods with potatoes have shown promising results [85]. Assuming climate would become warmer and drier, FG seems to be a viable option for many regions in Europe [86].

3.2.3. Fertilizers Made from Secondary Raw Materials (FSRM)

- (1)

- FSRM are fertilizers made from so-called “secondary raw materials”, such as sewage sludge, compost or other organic substances like horn meal, crop residues, or various non-usable leftovers from food production.

- (2)

- If these materials are used as fertilizers they need to comply with the German fertilizer regulation [87] which, at the moment, bans the use of bone meal, meat meal, animal meal, and blood-based products. However, such FSRM products are expected to become especially important when non-renewable raw materials like rock-phosphate become scarce and regulations regarding the closing of nutrient cycles become mandatory. Additionally, with new filtering, removing, or cleaning technologies [88], many of the above-mentioned materials could also be used as base materials for fertilizer production. This will result in a reduction of the use of non-renewable resources as source material for mineral fertilizer production.

- (3)

- Overall these materials are quite often used in German agriculture, but often there is a lack of awareness of these products reflected by the fact that most farmers are neglecting them when calculating fertilizer compositions [87].

4. Methods

4.1. Step One: Exploratory Interview with Experts in the Fertilizer Sector

4.2. Step Two: Questionnaire with Actors across the Fertilizer Supply Chain

4.3. Measurement Used in the Questionnaire

5. Results

5.1. Technology Push or Market Pull

5.2. Perceived Need for Action

5.3. Regulation Awareness

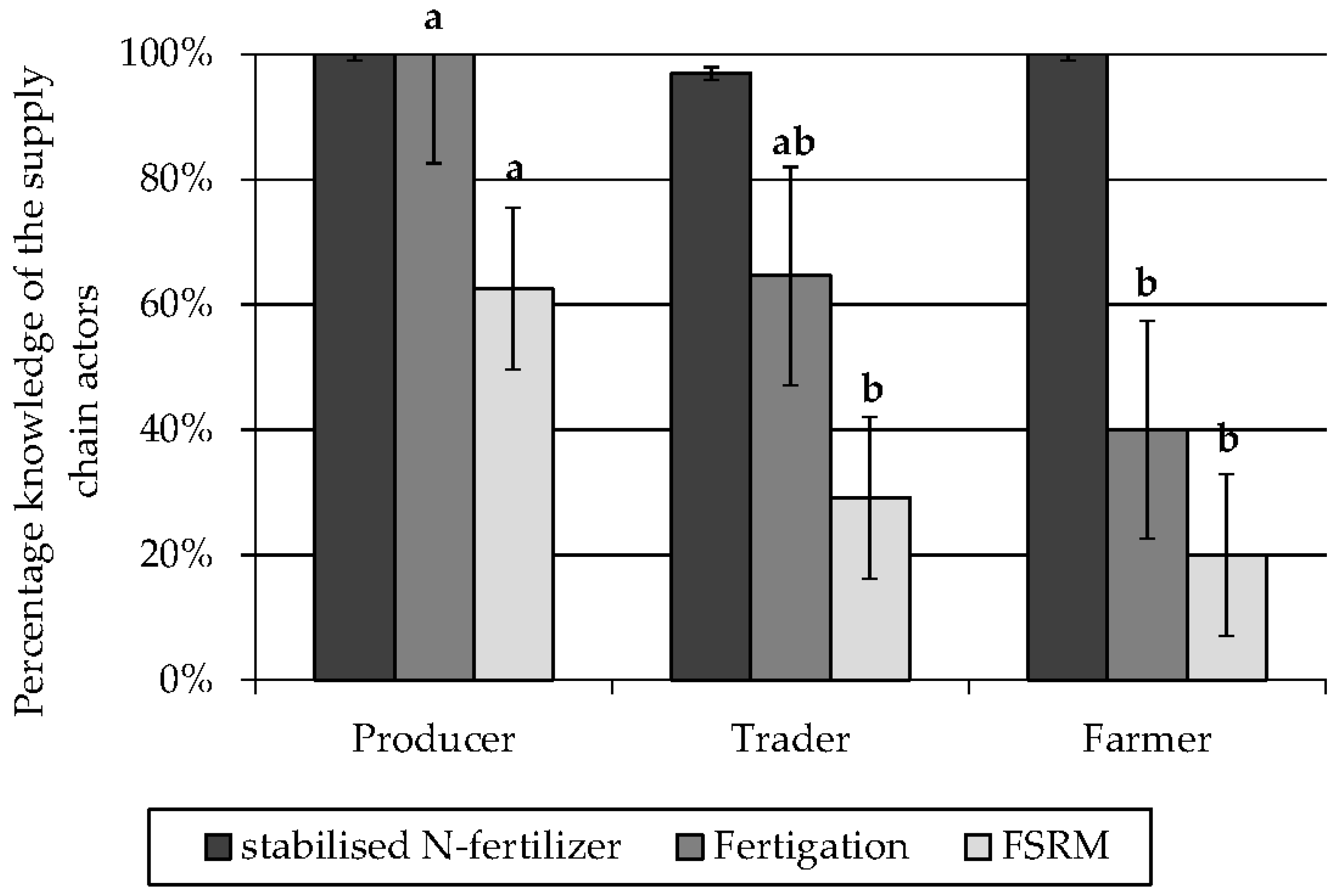

5.4. Knowledge about Eco-Innovations and Awareness for Changes

6. Discussion and Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| FG | Fertigation |

| FSRM | Fertilizer made from secondary raw materials |

| GMO | Genetically modified plants |

| SNF | Stabilized nitrogen fertilizer |

| N | nitrogen |

References

- United Nations, Department of Economic and Social Affairs, Population Division (2015). World Population Prospects: The 2015 Revision, Key Findings and Advance Tables; Working Paper No. ESA/P/WP.241; United Nations: New York, NY, USA, 2015. [Google Scholar]

- Goodman, D.; Watts, M. Globalising Food: Agrarian Questions and Global Restructuring; Routledge Psychology Press: London, UK; New York, NY, USA, 1997. [Google Scholar]

- Smith, P.; Martino, D.; Cai, Z.; Gwary, D.; Janzen, H.; Kumar, P.; McCarl, B.; Ogle, S.; O’Mara, F.; Rice, C. Greenhouse gas mitigation in agriculture. Philos. Trans. R. Soc. Lond. B 2008, 363, 789–813. [Google Scholar] [CrossRef] [PubMed]

- Pretty, J. Agricultural sustainability: Concepts, principles and evidence. Philos. Trans. R. Soc. Lond. B 2008, 363, 447–465. [Google Scholar] [CrossRef] [PubMed]

- Tillmann, D.; Cassman, K.G.; Matson, P.A.; Naylor, R.; Polasky, S. Agricultural sustainability and intensive production practices. Nature 2002, 418, 671–677. [Google Scholar] [CrossRef] [PubMed]

- Pretty, J.; Hine, R. Reducing Food Poverty with Sustainable Agriculture: A Summary of New Evidence; University of Essex: Colchester, UK, 2001. [Google Scholar]

- FAO. World Agriculture towards 2030/50, the 2012 Revision; ESA Working Paper No. 12-03; FAO: Rome, Italy, 2012. [Google Scholar]

- Wood, S.; Cowie, A. A review of greenhouse gas emission factors for fertiliser production. IEA Bioenergy Task 2004, 38, 2–20. [Google Scholar]

- Jenssen, T.K.; Kongshaug, G. Energy Consumption and Greenhouse Gas Emissions in Fertiliser Production; International Fertiliser Society: Colchester, UK, 2003. [Google Scholar]

- Smith, P.; Martino, D.; Cai, Z.; Gwary, D.; Janzen, H.; Kumar, P.; McCarl, B.; Ogle, S.; O’Mara, F.; Rice, C.; et al. Policy and technological constraints to implementation of greenhouse gas mitigation options in agriculture. Agric. Ecosyst. Environ. 2007, 118, 6–28. [Google Scholar] [CrossRef]

- Wegner, J.; Theuvsen, L. Handlungsempfehlungen zur Minderung von Stickstoffbedingten Treibhausgasemissionen in der Landwirtschaft; WWF Deutschland: Berlin, Germany, 2010. [Google Scholar]

- EFMA. Production of Phospohoric Acid; EFMA European Fertilizer Manufacturers’ Association: Brussel, Belgium, 2000. [Google Scholar]

- EFMA. Production of NPK Fertzilizers by the Nitrophosphate Route; EFMA European Fertilizer Manufacturers’ Association: Brussel, Belgium, 2000. [Google Scholar]

- Spiertz, H. Food production, crops and sustainability: Restoring confidence in science and technology. Curr. Opin. Environ. Sustain. 2010, 2, 439–443. [Google Scholar] [CrossRef]

- Ekins, P. Eco-innovation for environmental sustainability: Concepts, progress and policies. Int. Econ. Econ. Policy 2010, 7, 267–290. [Google Scholar] [CrossRef]

- Kemp, R.; Schot, J.; Hoogma, R. Regime shifts to sustainability through processes of niche formation: The approach of strategic niche management. Technol. Anal. Strateg. Manag. 1998, 10, 175–198. [Google Scholar] [CrossRef]

- Rennings, K. Redefining innovation-eco-innovation research and the contribution from ecological economics. Ecol. Econ. 2000, 32, 319–332. [Google Scholar] [CrossRef]

- Kemp, R.; Pearson, P. Final Report of the MEI Project Measuring Eco Innovation; UM Merit: Maastricht, The Netherlands, 2008. [Google Scholar]

- Carruthers, G.; Vanclay, F. The intrinsic features of environmental management systems that facilitate adoption and encourage innovation in primary industries. J. Environ. Manag. 2012, 110, 125–134. [Google Scholar] [CrossRef] [PubMed]

- Aguilar-Gallegos, N.; Muñoz-Rodríguez, M.; Santoyo-Cortés, H.; Aguilar-Ávila, J.; Klerkx, L. Information networks that generate economic value: A study on clusters of adopters of new or improved technologies and practices among oil palm growers in Mexico. Agric. Syst. 2015, 135, 122–132. [Google Scholar] [CrossRef]

- Tepic, M.; Trienekens, J.H.; Hoste, R.; Omta, S.W.F. The influence of networking and absorptive capacity on the innovativeness of farmers in the Dutch pork sector. Int. Food Agribus. Manag. Rev. 2012, 15, 1–34. [Google Scholar]

- Martino, G.; Polinori, P. Networks and organisational learning: Evidence from broiler production. Br. Food J. 2011, 113, 871–885. [Google Scholar] [CrossRef]

- Amankwah, K.; Klerkx, L.; Oosting, S.J.; Sakyi-Dawson, O.; van der Zijpp, A.J.; Millar, D. Diagnosing constraints to market participation of small ruminant producers in northern Ghana: An innovation systems analysis. NJAS Wagening. J. Life Sci. 2012, 60–63, 37–47. [Google Scholar] [CrossRef]

- Totin, E.; van Mierlo, B.; Saïdou, A.; Mongbo, R.; Agbossou, E.; Stroosnijder, L.; Leeuwis, C. Barriers and opportunities for innovation in rice production in the inland valleys of Benin. NJAS Wagening. J. Life Sci. 2012, 60–63, 57–66. [Google Scholar] [CrossRef]

- Edquist, C. Systems of innovation: Perspectives and challenges. In Oxford Handbook of Innovation; Fagerberg, J., Mowery, D., Nelson, R., Eds.; Oxford University Press: Oxford, UK, 2005; pp. 181–208. [Google Scholar]

- Lundvall, B.A. National Systems of Innovation, towards a Theory of Innovation and Interactive Learning; Pinter Publishers: London, UK, 1992. [Google Scholar]

- Malerba, F. Sectoral systems of innovation and production. Res. Policy 2002, 31, 247–264. [Google Scholar] [CrossRef]

- Anandajayasekeram, P.; Gebremedhin, B. Integrating Innovation Systems Perspective and Value Chain Analysis in Agricultural Research for Development: Implications and Challenges; Working Paper No. 16, Improving Productivity and Market Success of Ethiopian Farmers Project (IPMS); International Livestock Research Institute (ILRI): Ad-dis Ababa, Ethiopia, 2009. [Google Scholar]

- Mylan, J.; Geels, F.W.; Gee, S.; McMeekin, A.; Foster, C. Eco-innovation and retailers in milk, beef and bread chains: Enriching environmental supply chain management with insights from innovation studies. J. Clean. Prod. 2015, 107, 20–30. [Google Scholar] [CrossRef]

- Klerkx, L.; Aarts, N.; Leeuwis, C. Adaptive management in agricultural innovation systems: The interactions between innovation networks and their environment. Agric. Syst. 2010, 103, 390–400. [Google Scholar] [CrossRef]

- Cohen, W.M.; Levinthal, D.A. Absorptive capacity: A new perspective on learning and innovation. Adm. Sci. Q. 1990, 35, 128–152. [Google Scholar] [CrossRef]

- Keskin, H. Market orientation, learning orientation, and innovation capabilities in SMEs: An extended model. Eur. J. Innov. Manag. 2006, 9, 396–417. [Google Scholar] [CrossRef]

- Lund Vinding, A. Absorptive capacity and innovative performance: A human capital approach. Econ. Innov. New Technol. 2006, 15, 507–517. [Google Scholar] [CrossRef]

- Gellynck, X.; Cárdenas, J.; Pieniak, Z.; Verbeke, W. Association between innovative entrepreneurial orientation, absorptive capacity, and farm business performance. Agribusiness 2015, 31, 91–106. [Google Scholar] [CrossRef]

- Van Rijn, F.; Bulte, E.; Adekunle, A. Social capital and agricultural innovation in Sub-Saharan Africa. Agric. Syst. 2012, 108, 112–122. [Google Scholar] [CrossRef]

- Geels, F.W.; Schot, J. Typology of sociotechnical transition pathways. Res. Policy 2007, 36, 399–417. [Google Scholar] [CrossRef]

- Jansen, J.J.P.; van den Bosch, F.A.J.; Volberda, H.W. Managing potential and realized absorptive capacity: How do organizational antecedents matter? Acad. Manag. J. 2005, 48, 999–1015. [Google Scholar] [CrossRef]

- Dinar, A.; Karagiannis, G.; Tzouvelekas, V. Evaluating the impact of agricultural extension on farms’ performance in Crete: A nonneutral stochastic frontier approach. Agric. Econ. 2007, 36, 135–146. [Google Scholar] [CrossRef]

- Horbach, J.; Rammer, C.; Rennings, K. Determinants of eco-innovations by type of environmental impact—The role of regulatory push/pull, technology push and market pull. Ecol. Econ. 2012, 78, 112–122. [Google Scholar] [CrossRef]

- Horbach, J. Determinants of environmental innovation—New evidence from German panel data sources. Res. Policy 2008, 37, 163–173. [Google Scholar] [CrossRef]

- Frondel, M.; Horbach, J.; Rennings, K. What triggers environmental management and innovation? Empirical evidence for Germany. Ecol. Econ. 2008, 66, 153–160. [Google Scholar] [CrossRef]

- Davis, F.D. Perceived usefulness, perceived ease of use, and user acceptance of information technology. MIS Q. 1989, 13, 319–340. [Google Scholar] [CrossRef]

- Rogers, E.M. Diffusion of Innovations, 5th ed.; Free Press: New York, NY, USA, 2003; p. 576. [Google Scholar]

- Dolinska, A.; d’Aquino, P. Farmers as agents in innovation systems. Empowering farmers for innovation through communities of practice. Agric. Syst. 2016, 142, 122–130. [Google Scholar] [CrossRef]

- Heemskerk, W. Participatory Approaches in Agricultural Research and Development. 2005. Available online: http://betuco.be/voorlichting/Participatory%20Approaches%20in%20agricultural%20research%20and%20Development.pdf (accessed on 15 July 2016).

- Morgan, K.; Murdoch, J. Organic vs. conventional agriculture: Knowledge, power and innovation in the food chain. Geoforum 2000, 31, 159–173. [Google Scholar] [CrossRef]

- Sivertsson, O.; Tell, J. Barriers to business model innovation in Swedish agriculture. Sustainability 2015, 7, 1957–1969. [Google Scholar] [CrossRef]

- Rehfeld, K.; Rennings, K.; Ziegler, A. Determinants of environmental product innovations and the role of integrated product policy—An empirical analysis. Ecol. Econ. 2007, 61, 91–100. [Google Scholar] [CrossRef]

- Pannell, D. Social and economic challenges in the development of complex farming systems. Agrofor. Syst. 1999, 45, 395–411. [Google Scholar] [CrossRef]

- Olesen, J.E.; Bindi, M. Consequences of climate change for European agricultural productivity, land use and policy. Eur. J. Agron. 2002, 16, 239–262. [Google Scholar] [CrossRef]

- Woolthuis, R.K.; Lankhuizen, M.; Gilsing, V. A system failure framework for innovation policy design. Technovation 2005, 25, 609–619. [Google Scholar] [CrossRef]

- Van Mierlo, B.; Arkesteijn, M.; Leeuwis, C. Enhancing the reflexivity of system innovation projects with system analyses. Am. J. Eval. 2010, 31, 143–161. [Google Scholar] [CrossRef]

- Smith, K. Innovation as a systemic phenomenon: Rethinking the role of policy. Enterp. Innov. Manag. Stud. 2000, 1, 73–102. [Google Scholar] [CrossRef]

- Carlsson, B.; Jacobsson, S. In search of useful public policies: Key lessons and issues for policy makers. In Technological Systems and Industrial Dynamics; Carlsson, B., Ed.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1997. [Google Scholar]

- Krott, M. Forest Policy Analysis; Springer Science & Business Media: Dortrecht, The Netherlands, 2005. [Google Scholar]

- Lemaire, D. The Stick: Regulation as a Tool of Government; Transaction Publishers: London, UK, 1998. [Google Scholar]

- Jang, E.; Park, M.; Roh, T.; Han, K. Policy instruments for eco-innovation in Asian countries. Sustainability 2015, 7, 12586. [Google Scholar] [CrossRef]

- Cleff, T.; Rennings, K. Determinants of environmental product and process innovation-evidence from the Mannheim Innovation panel and a follow-up telephone survey. In Innovation-Oriented Environmental Regulation; Hemmelskamp, J., Rennings, K., Leone, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2000; pp. 331–347. [Google Scholar]

- Brunnermeier, S.B.; Cohen, M.A. Determinants of environmental innovation in US manufacturing industries. J. Environ. Econ. Manag. 2003, 45, 278–293. [Google Scholar] [CrossRef]

- Green, K.; McMeekin, A.; Irwin, A. Technological trajectories and R & D for environmental innovation in UK firms. Futures 1994, 26, 1047–1059. [Google Scholar]

- Lieberman, M.B.; Montgomery, D.B. First-mover advantages. Strateg. Manag. J. 1988, 9, 41–58. [Google Scholar] [CrossRef]

- Demirel, P.; Kesidou, E. Stimulating different types of eco-innovation in the UK: Government policies and firm motivations. Ecol. Econ. 2011, 70, 1546–1557. [Google Scholar] [CrossRef]

- Kottila, M.-R. Knowledge sharing in organic food supply chains. J. Chain Netw. Sci. 2009, 9, 133–144. [Google Scholar] [CrossRef]

- Simatupang, T.M.; Wright, A.C.; Sridharan, R. The knowledge of coordination for supply chain integration. Bus. Process Manag. J. 2002, 8, 289–308. [Google Scholar] [CrossRef]

- Skipper, J.B.; Craighead, C.W.; Byrd, T.A.; Rainer, R.K. Towards a theoretical foundation of supply network interdependence and technology-enabled coordination strategies. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 39–56. [Google Scholar]

- Lindner, R.K.; Pardey, P.G.; Jarrett, F.G. Distance to information source and the time lag to early adoption of trace element fertilisers. Aust. J. Agric. Econ. 1982, 26, 98–113. [Google Scholar] [CrossRef]

- Porter, M.E.; van der Linde, C. Toward a new conception of the environment-competitiveness relationship. J. Econ. Perspect. 1995, 9, 97–118. [Google Scholar] [CrossRef]

- Garbade, P.J.P.; Omta, S.W.F.; Fortuin, F.T.J.M.; Hall, R.; Leone, G. The impact of the product generation life cycle on knowledge valorization at the public private research partnership, the Centre for Biosystems Genomics. NJAS Wagening. J. Life Sci. 2013, 67, 1–10. [Google Scholar] [CrossRef]

- IVA. Wichtige Zahlen Düngemittel, Produktion, Markt, Landwirtschaft; Industrieverband Agrar e.V.; Pflanzenernährung: Frankfurt am Main, Germany, 2014. [Google Scholar]

- Statistisches Bundesamt. Fachserie 3 Reihe 1 Ausgewählte Zahlen der Landwirtschaftszählung/Agrarstrukturerhebung 2010; Statistisches Bundesamt: Wiesbaden, Germany, 2013. [Google Scholar]

- Renni, R.; Heffer, P. Anticipated impact of modern biotechnology on nutient use efficieny: Consequences for the fertilizer industry. In Proceedings of the TFI/FIRT Fertilizer Outlook and Technology Conference, Savannah, GA, USA, 16–18 November 2010.

- Lusk, J.L.; Roosen, J.; Fox, J.A. Demand for beef from cattle administered growth hormones or fed genetically modified corn: A comparison of consumers in France, Germany, the United Kingdom, and the United States. Am. J. Agric. Econ. 2003, 85, 16–29. [Google Scholar] [CrossRef]

- Schönthaler, K.; von Andrian-Werburg, S.; van Rüth, P.; Hempen, S. Monitoringbericht 2015 zur Deutschen Anpassungsstrategie an den Klimawandel; Bericht der Interministeriellen Arbeitsgruppe Anpassungsstrategie der Bundesregierung; Bundesumweltministerium: Berlin, Germany, 2015. [Google Scholar]

- Watson, C.J.; Laughlin, R.J. Nitrogen Use Efficiency—Best Management Practices, 2010. Available online: http://www.fertilizer-assoc.ie/wp-content/uploads/2014/10/Fertiliser-Association-of-Ireland-Watson.pdf (accessed on 15 July 2016).

- Hanafi, M.M.; Eltaib, S.M.; Ahmad, M.B.; Omar, S.R.S. Evaluation of controlled-release compound fertilizers in soil. Commun. Soil Sci. Plant Anal. 2002, 33, 1139–1156. [Google Scholar] [CrossRef]

- Bellarby, J.; Foereid, B.; Hastings, A.; Smith, P. Cool Farming: Climate Impacts of Agriculture and Mitigation Potential; Greenpeace: Amsterdam, The Netherlands, 2008; pp. 12–36. [Google Scholar]

- Brentrup, F.; Pallière, C. GHG Emissions and Energy Efficiency in European Nitrogen Fertiliser Production and Use; International Fertiliser Society: Colchester, UK, 2008. [Google Scholar]

- Hasler, K.; Bröring, S.; Omta, S.W.F.; Olfs, H.W. Life cycle assessment (LCA) of different fertilizer product types. Eur. J. Agron. 2015, 69, 41–51. [Google Scholar] [CrossRef]

- Lammel, J. Cost of the different options available to the farmers: Current situation and prospects. In IFA—International Workshop on Enhanced-Efficiency Fertilizers; IVA-International Fertilizer Association: Frankfurt, Germany, 2005. [Google Scholar]

- Shaviv, A. Controlled release fertilizers. In IFA—International Workshop on Enhanced-Efficiency Fertilizers; IVA-International Fertilizer Association: Frankfurt, Germany, 2005. [Google Scholar]

- Hall, A. Benefits of enhanced-efficiency fertilizer for the environment. In IFA International Workshop on Enhanced-Efficiency Fertilizers; IVA-International Fertilizer Association: Frankfurt, Germany, 2005. [Google Scholar]

- Goldberg, D.; Shmueli, M. The effect of distance for tricklers on the soil salinity and growth and yield of sweet corn in an arid zone. HortScience 1971, 6, 565–567. [Google Scholar]

- Kafkafi, U. Global aspects of fertigation usage. In Fertigation: Optimizing the Utilization of Water and Nutrients; Imas, P., Price, R., Eds.; International Potash Institute: Horgen, Switzerland, 2008; pp. 8–22. [Google Scholar]

- Bhattarai, S.P.; Huber, S.; Midmore, D.J. Aerated subsurface irrigation water gives growth and yield benefits to zucchini, vegetable soybean and cotton in heavy clay soils. Ann. Appl. Biol. 2004, 144, 285–298. [Google Scholar] [CrossRef]

- Darwish, T.; Atallah, T.; Hajhasan, S.; Haidar, A. Nitrogen and water use efficiency of fertigated processing potato. Agric. Water Manag. 2006, 85, 95–104. [Google Scholar] [CrossRef]

- Nunes, J.P.; Seixas, J.; Pacheco, N.R. Vulnerability of water resources, vegetation productivity and soil erosion to climate change in Mediterranean watersheds. Hydrol. Process. 2008, 22, 3115–3134. [Google Scholar] [CrossRef]

- DüMV. Verordnung über das Inverkehrbringen von Düngemitteln, Bodenhilfsstoffen, Kultursubstraten und Pflanzenhilfsmitteln (Düngemittelverordnung—DüMV); Bundesministeriums der Justiz.: Berlin, Germany, 2012. [Google Scholar]

- De-Bashan, L.E.; Bashan, Y. Recent advances in removing phosphorus from wastewater and its future use as fertilizer (1997–2003). Water Res. 2004, 38, 4222–4246. [Google Scholar] [CrossRef] [PubMed]

- Konietschke, F.; Hothorn, L.A.; Brunner, E. Rank-based multiple test procedures and simultaneous confidence intervals. Electron. J. Stat. 2012, 6, 738–759. [Google Scholar] [CrossRef]

- R Development Core Team. R: A Language and Environment for Statistical Computing. R Foundation for Statistical Computing. Available online: http://www.r-project.org (accessed on 24 May 2016).

- European Commission. Common Agricultural Policy towards 2020. Assessment of Alternative Policy Options; European Commission: Brussels, Belgium, 2013. [Google Scholar]

- EMAS. Gesetz zur Ausführung der Verordnung (EG) Nr. 1221/2009 des Europäischen Parlaments und des Rates vom 25. November 2009 über die Freiwillige Teilnahme von Organisationen an Einem Gemeinschaftssystem für Umweltmanagement und Umweltbetriebsprüfung und zur Aufhebung der Verordnung (EG) Nr. 761/2001, Sowie der Beschlüsse der Kommission 2001/681EG und 2006/193/EG, 2009. Available online: http://www.gesetze-im-internet.de/bundesrecht/uag/gesamt.pdf (accessed on 14 July 2016).

- ISO International Standard. Environmental Management Systems—Requirements with Guidance for Use; International Organization of Standardization: Geneva, Switzerland, 2000. [Google Scholar]

- Narrod, C.; Roy, D.; Okello, J.; Avendaño, B.; Rich, K.; Thorat, A. Public-private partnerships and collective action in high value fruit and vegetable supply chains. Food Policy 2009, 34, 8–15. [Google Scholar] [CrossRef]

- Sligo, F.; Massey, C. Risk, trust and knowledge networks in farmers’ learning. J. Rural Stud. 2007, 23, 170–182. [Google Scholar] [CrossRef]

- Lambrecht, E.; Taragola, N.; Kühne, B.; Crivits, M.; Gellynck, X. Networking and innovation within the ornamental plant sector. Agric. Food Econ. 2015, 3, 1–20. [Google Scholar] [CrossRef] [Green Version]

| Supply Chain Position | |||

|---|---|---|---|

| Producers (n = 12) | Traders (n = 34) | Farmers (n = 11) | |

| First user of new technologies | 4.37/1.85 | 4.08/1.61 | 3.54/1.63 |

| New technologies are better | 5.00/1.60 | 4.41/1.21 | 4.00/1.18 |

| Supply Chain Position | |||

|---|---|---|---|

| Producers (n = 12) | Traders (n = 34) | Farmers (n = 11) | |

| Qualitative statement | “Climate change in Germany will result in more dry periods and extreme weather scenarios (like tornados, extreme rainfall events or extreme frost events in winter).” | “What climate change?” | “Would buy with environmental motivation, if that would be honored or paid.” |

| More frequently extreme weather scenarios | 6.00/1.10 | 4.96/1.74 | 5.82/0.87 |

| Fertilization has to be adapted to weather scenarios | 6.38/0.74 a | 5.22/1.27 b | 5.54/1.13 a,b |

| Supply Chain Position | |||

|---|---|---|---|

| Producers (n = 12) | Traders (n = 34) | Farmers (n = 11) | |

| Qualitative statement | “The nutrient surplus will be further regulated (finally to achieve a balanced input/output nutrient ratio) by the European government, because existing regulations have not lowered the nitrate emissions to ground water bodies.” | “…cannot be influenced or changed.” | “We have no choice!” |

| Further restriction of N and P 1 use | 4.58/1.68 | 4.73/1.42 | 5.18/0.87 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasler, K.; Olfs, H.-W.; Omta, O.; Bröring, S. Drivers for the Adoption of Eco-Innovations in the German Fertilizer Supply Chain. Sustainability 2016, 8, 682. https://doi.org/10.3390/su8080682

Hasler K, Olfs H-W, Omta O, Bröring S. Drivers for the Adoption of Eco-Innovations in the German Fertilizer Supply Chain. Sustainability. 2016; 8(8):682. https://doi.org/10.3390/su8080682

Chicago/Turabian StyleHasler, Kathrin, Hans-Werner Olfs, Onno Omta, and Stefanie Bröring. 2016. "Drivers for the Adoption of Eco-Innovations in the German Fertilizer Supply Chain" Sustainability 8, no. 8: 682. https://doi.org/10.3390/su8080682

APA StyleHasler, K., Olfs, H.-W., Omta, O., & Bröring, S. (2016). Drivers for the Adoption of Eco-Innovations in the German Fertilizer Supply Chain. Sustainability, 8(8), 682. https://doi.org/10.3390/su8080682