Optimization Model for Mitigating Global Warming at the Farm Scale: An Application to Japanese Rice Farms

Abstract

:1. Introduction

2. Materials and Methods

2.1. Agri-Environmental Direct Payment Program in Japan

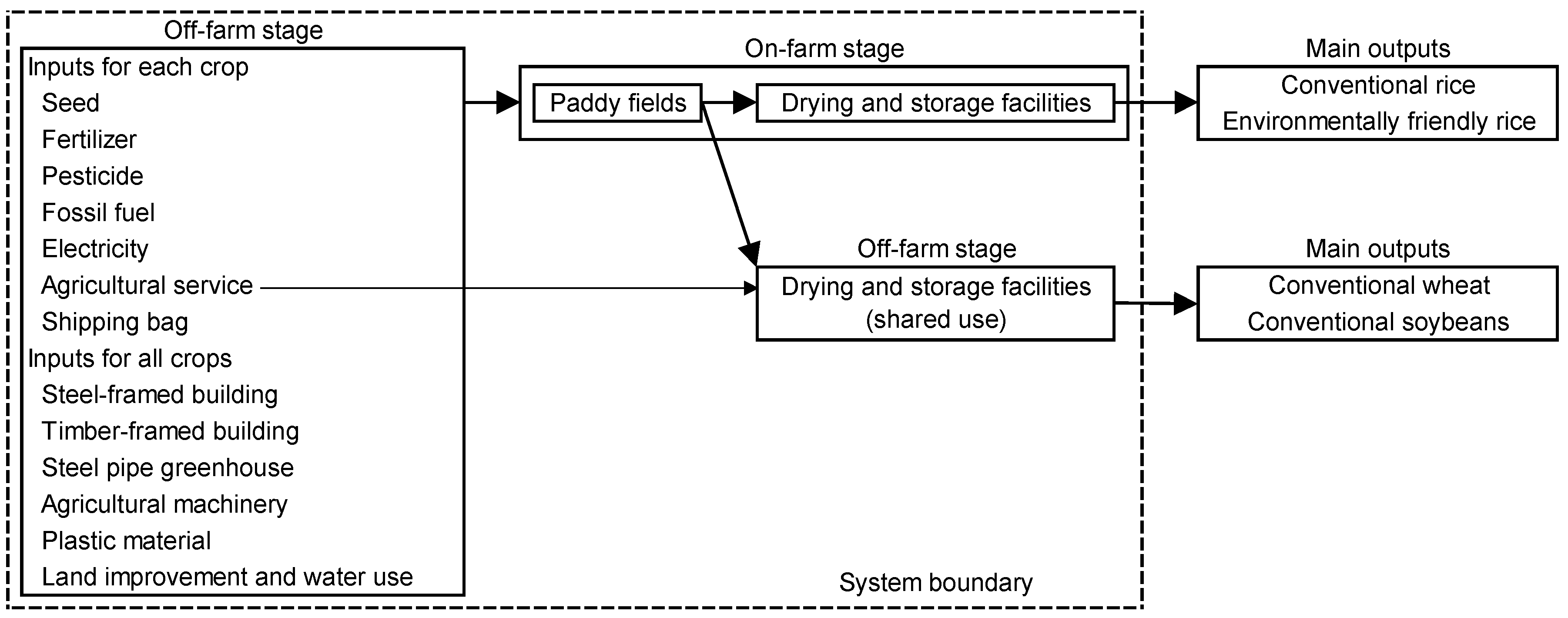

2.2. Farm Modeling

2.3. Linear Programming Model

2.4. Life Cycle Assessment

2.5. Eco-Efficiency

3. Results

3.1. Global Warming Impact in the Modeled Farm

3.2. Model-Optimized Results

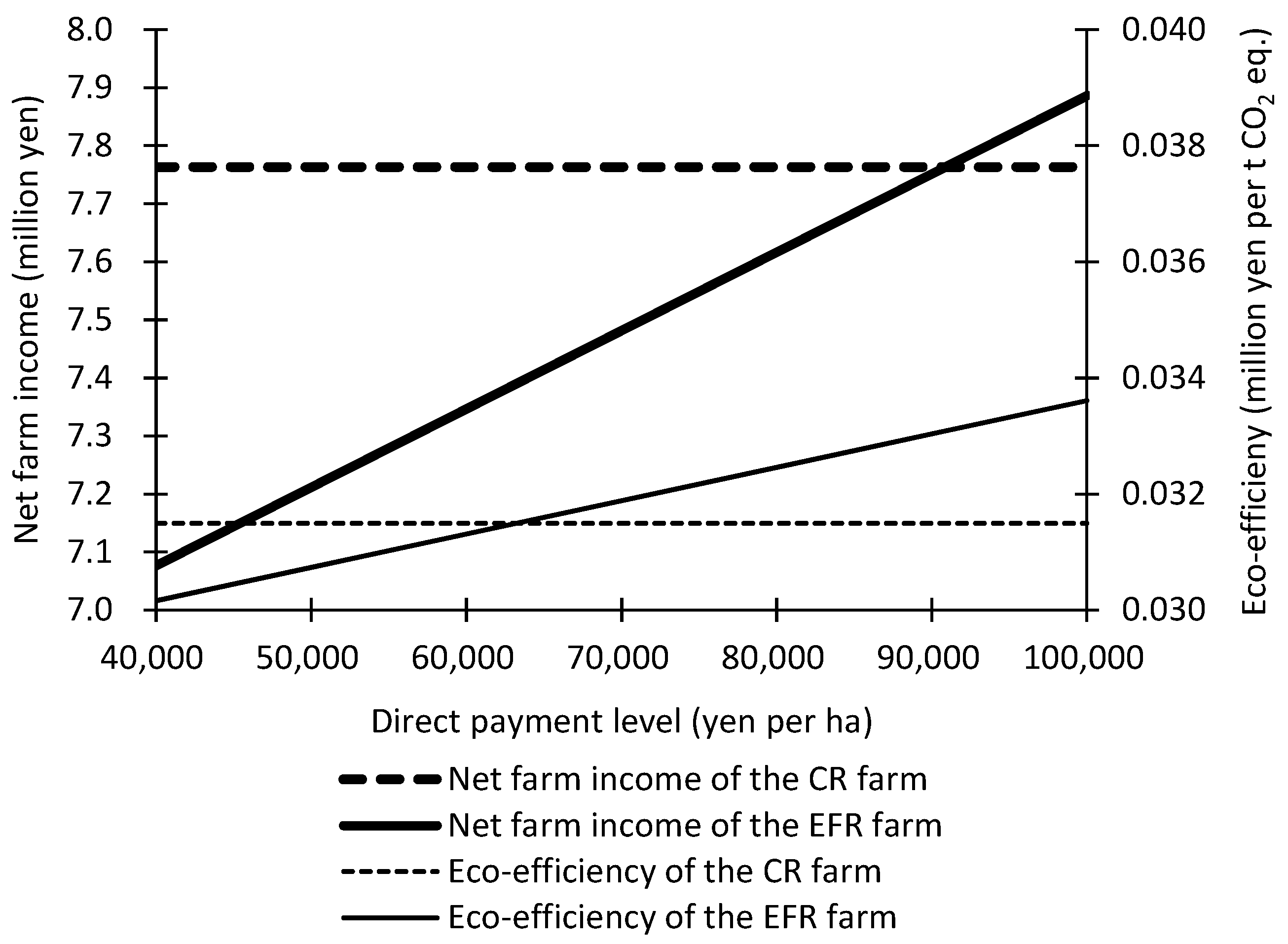

4. Discussion

4.1. Comparison between Two Modeled Farms

4.2. Sensitivity Analysis on the CO2 Equivalence Factors

4.3. Eco-Efficiency Measurement Methodologies

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Latacz-Lohmann, U.; Hodge, I. European agri-environmental policy for the 21st century. Aust. J. Agric. Resour. Econ. 2003, 47, 123–139. [Google Scholar] [CrossRef]

- Organisation for Economic Co-Operation and Development. Evaluation of Agricultural Policy Reforms in the European Union; OECD Publishing: Paris, France, 2011. [Google Scholar]

- Wilkins, R.J. Eco-efficient approaches to land management: A case for increased integration of crop and animal production systems. Philos. Trans. R. Soc. B 2008, 363, 517–525. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Agriculture, Forestry and Fisheries of Japan. The Direct Payment Program for Environmentally Friendly Agriculture. Available online: http://www.maff.go.jp/j/seisan/kankyo/kakyou_chokubarai/mainp.html (accessed on 11 August 2014). (In Japanese)

- Nishizawa, E. Agri-environmental policies in Japan and environmentally friendly agriculture in the Shiga region. In Economic Analysis of Agri-Environmental Policies; Nishizawa, E., Ed.; Nippon Hyoron Sha: Tokyo, Japan, 2014; pp. 99–120. (In Japanese) [Google Scholar]

- Stocker, T.F.; Qin, D.; Plattner, G.-K.; Tignor, M.M.B.; Allen, S.K.; Boschung, J.; Nauels, A.; Xia, Y.; Bex, V.; Midgley, P.M. (Eds.) Climate Change 2013: The Physical Science Basis; Cambridge University Press: Cambridge, UK, 2013.

- Greenhouse Gas Inventory Office of Japan. National Greenhouse Gas Inventory Report of Japan; National Institute for Environmental Studies: Tsukuba, Japan, 2014. [Google Scholar]

- Food and Agriculture Organization of the United Nations. FAOSTAT: Emissions-Agriculture. Available online: http://faostat3.fao.org/download/G1/*/E (accessed on 22 January 2015).

- Yagi, K.; Tsuruta, H.; Minami, K. Possible options for mitigating methane emission from rice cultivation. Nutr. Cycl. Agroecosyst. 1997, 49, 213–220. [Google Scholar] [CrossRef]

- Itoh, M.; Sudo, S.; Mori, S.; Saito, H.; Yoshida, T.; Shiratori, Y.; Suga, S.; Yoshikawa, N.; Suzue, Y.; Mizukami, H.; et al. Mitigation of methane emissions from paddy fields by prolonging midseason drainage. Agric. Ecosyst. Environ. 2011, 141, 359–372. [Google Scholar] [CrossRef]

- Chono, S.; Maeda, S.; Kawachi, T.; Imagawa, C.; Buma, N.; Takeuchi, J. Optimization model for cropping-plan placement in paddy fields considering agricultural profit and nitrogen load management in Japan. Paddy Water Environ. 2012, 10, 113–120. [Google Scholar] [CrossRef] [Green Version]

- Senthilkumar, K.; Lubbers, M.T.M.H.; de Ridder, N.; Bindraban, P.S.; Thiyagarajan, T.M.; Giller, K.E. Policies to support economic and environmental goals at farm and regional scales: Outcomes for rice farmers in Southern India depend on their resource endowment. Agric. Syst. 2011, 104, 82–93. [Google Scholar] [CrossRef]

- Glithero, N.J.; Ramsden, S.J.; Wilson, P. Farm systems assessment of bioenergy feedstock production: Integrating bio-economic models and life cycle analysis approaches. Agric. Syst. 2012, 109, 53–64. [Google Scholar] [CrossRef] [PubMed]

- Nakashima, T. Life cycle assessment integrated into positive mathematical programming: A conceptual model for analyzing area-based farming policy. Jpn. Agric. Res. Q. 2010, 44, 301–310. [Google Scholar] [CrossRef]

- Louhichi, K.; Kanellopoulos, A.; Janssen, S.; Flichman, G.; Blanco, M.; Hengsdijk, H.; Heckelei, T.; Berentsen, P.; Lansink, A.O.; van Ittersum, M. FSSIM, a bio-economic farm model for simulating the response of EU farming systems to agricultural and environmental policies. Agric. Syst. 2010, 103, 585–597. [Google Scholar] [CrossRef] [Green Version]

- Schader, C.; Lampkin, N.; Christie, M.; Nemecek, T.; Gaillard, G.; Stolze, M. Evaluation of cost-effectiveness of organic farming support as an agri-environmental measure at Swiss agricultural sector level. Land Use Policy 2013, 31, 196–208. [Google Scholar] [CrossRef]

- Berentsen, P.B.M.; Giesen, G.W.J. An environmental–economic model at farm level to analyse institutional and technical change in dairy farming. Agric. Syst. 1995, 49, 153–175. [Google Scholar] [CrossRef]

- Berentsen, P.B.M.; Tiessink, M. Potential effects of accumulating environmental policies on Dutch dairy farms. J. Dairy Sci. 2003, 86, 1019–1028. [Google Scholar] [CrossRef]

- Van Calker, K.J.; Berentsen, P.B.M.; de Boer, I.M.J.; Giesen, G.W.J.; Huirne, R.B.M. An LP-model to analyse economic and ecological sustainability on Dutch dairy farms: Model presentation and application for experimental farm “de Marke”. Agric. Syst. 2004, 82, 139–160. [Google Scholar] [CrossRef]

- Zimmermann, A. Optimization of sustainable dairy-cow feeding systems with an economic-ecological LP farm model using various optimization processes. J. Sustain. Agric. 2008, 32, 77–94. [Google Scholar] [CrossRef]

- Shiga Prefecture. Handbook on Agricultural Management, 2012 ed.; Shiga Prefecture: Otsu, Japan, 2012. (In Japanese) [Google Scholar]

- Shiga Prefecture. Direct Payments for Environmentally Friendly Agriculture. Available online: http://www.pref.shiga.lg.jp/g/kodawari/kodawarishien.html (accessed on 26 August 2014). (In Japanese)

- Ministry of Agriculture, Forestry and Fisheries of Japan. The Implementation Status of the Direct Payment Program for Environmentally Friendly Agriculture in 2013. Available online: http://www.maff.go.jp/j/seisan/kankyo/kakyou_chokubarai/pdf/25_jisseki2.pdf (accessed on 23 February 2016). (In Japanese)

- Shiga Prefecture; Shiga Prefecture. personal communication, 2013–2014.

- Shiga Prefecture. Handbook on Agricultural Management, 2002 ed.; Shiga Prefecture: Otsu, Japan, 2002. (In Japanese) [Google Scholar]

- Shiga Prefecture. Technical Guide on Rice Production; Shiga Prefecture: Otsu, Japan, 2010. (In Japanese) [Google Scholar]

- Ministry of Agriculture, Forestry and Fisheries of Japan. Summary of the Income Stabilization Program for Farmers in 2014. Available online: http://www.maff.go.jp/j/kobetu_ninaite/keiei/pdf/26pamph_all.pdf (accessed on 11 August 2014). (In Japanese)

- Kurosawa, M.; Tezuka, T. Awareness of farmers approaching the sustainable agriculture to improve regional environment: Case study of environmentally conscious agriculture in Shiga Prefecture. J. Rural Plan. Assoc. 2005, 24, 61–66, (In Japanese with English Abstract). [Google Scholar] [CrossRef]

- Ministry of Agriculture, Forestry and Fisheries of Japan. Statistics of Production Costs of Crops. Available online: http://www.maff.go.jp/j/tokei/kouhyou/noukei/seisanhi_nousan/ (accessed on 29 August 2014). (In Japanese)

- Oishi, W. Linear programming program “XLP” for farming planning. Agric. Inf. Res. 2006, 15, 319–330, (In Japanese with English Abstract). [Google Scholar] [CrossRef]

- Guinée, J.B. (Ed.) Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002.

- Nishimura, S.; Yonemura, S.; Sawamoto, T.; Shirato, Y.; Akiyama, H.; Sudo, S.; Yagi, K. Effect of land use change from paddy rice cultivation to upland crop cultivation on soil carbon budget of a cropland in Japan. Agric. Ecosyst. Environ. 2008, 125, 9–20. [Google Scholar] [CrossRef]

- Shiga Prefecture. Technical Guide on Soil Preparation; Shiga Prefecture: Otsu, Japan, 2001. (In Japanese) [Google Scholar]

- Nansai, K.; Kondo, Y.; Kagawa, S.; Suh, S.; Nakajima, K.; Inaba, R.; Tohno, S. Estimates of embodied global energy and air-emission intensities of Japanese products for building a Japanese input-output life cycle assessment database with a global system boundary. Environ. Sci. Technol. 2012, 46, 9146–9154. [Google Scholar] [CrossRef] [PubMed]

- Shiga Prefecture. Technical Guide on Environmentally Friendly Agriculture; Shiga Prefecture: Otsu, Japan, 2010. (In Japanese) [Google Scholar]

- Ministry of Education, Culture, Sports, Science and Technology of Japan. Food Composition Database. Available online: http://fooddb.mext.go.jp/index.pl (accessed on 29 August 2014). (In Japanese)

- Owa, N. Nutrient balances of crops in Japan. Kanhonokenren News 1996, 33, 428–445. (In Japanese) [Google Scholar]

- Houghton, J.T.; Meira Filho, L.G.; Callander, B.A.; Harris, N.; Kattenberg, A.; Maskell, K. (Eds.) Climate Change 1995: The Science of Climate Change; Cambridge University Press: Cambridge, UK, 1996.

- Verfaillie, H.A.; Bidwell, R. Measuring Eco-Efficiency: A Guide to Reporting Company Performance; World Business Council for Sustainable Development: Geneva, Switzerland, 2000. [Google Scholar]

- Breiling, M.; Hashimoto, S.; Sato, Y.; Ahamer, G. Rice-related greenhouse gases in Japan, variations in scale and time and significance for the Kyoto Protocol. Paddy Water Environ. 2005, 3, 39–46. [Google Scholar] [CrossRef]

- Harada, H.; Kobayashi, H.; Shindo, H. Reduction in greenhouse gas emissions by no-tilling rice cultivation in Hachirogata polder, northern Japan: Life-cycle inventory analysis. Soil Sci. Plant Nutr. 2007, 53, 668–677. [Google Scholar] [CrossRef]

- Hokazono, S.; Hayashi, K. Variability in environmental impacts during conversion from conventional to organic farming: A comparison among three rice production systems in Japan. J. Clean. Prod. 2012, 28, 101–112. [Google Scholar] [CrossRef]

- Koga, N.; Tajima, R. Assessing energy efficiencies and greenhouse gas emissions under bioethanol-oriented paddy rice production in northern Japan. J. Environ. Manag. 2011, 92, 967–973. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Xia, X.; Zhang, Q.; Liu, J. Life cycle assessment of a rice production system in Taihu region, China. Int. J. Sustain. Dev. World Ecol. 2010, 17, 157–161. [Google Scholar] [CrossRef]

- Shiga Prefecture. Guide for Producing Salable Wheat and Soybeans; Shiga Prefecture: Otsu, Japan, 2012. (In Japanese) [Google Scholar]

- Biswas, W.K.; Barton, L.; Carter, D. Global warming potential of wheat production in Western Australia: A life cycle assessment. Water Environ. J. 2008, 22, 206–216. [Google Scholar] [CrossRef]

- Charles, R.; Jolliet, O.; Gaillard, G.; Pellet, D. Environmental analysis of intensity level in wheat crop production using life cycle assessment. Agric. Ecosyst. Environ. 2006, 113, 216–225. [Google Scholar] [CrossRef]

- Pelletier, N.; Arsenault, N.; Tyedmers, P. Scenario modeling potential eco-efficiency gains from a transition to organic agriculture: Life cycle perspectives on Canadian canola, corn, soy, and wheat production. Environ. Manag. 2008, 42, 989–1001. [Google Scholar] [CrossRef] [PubMed]

- Tuomisto, H.L.; Hodge, I.D.; Riordan, P.; Macdonald, D.W. Comparing global warming potential, energy use and land use of organic, conventional and integrated winter wheat production. Ann. Appl. Biol. 2012, 161, 116–126. [Google Scholar] [CrossRef]

- Castanheira, É.G.; Freire, F. Greenhouse gas assessment of soybean production: Implications of land use change and different cultivation systems. J. Clean. Prod. 2013, 54, 49–60. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Cumulative energy and global warming impact from the production of biomass for biobased products. J. Ind. Ecol. 2003, 7, 147–162. [Google Scholar] [CrossRef]

- Korsaeth, A.; Jacobsen, A.Z.; Roer, A.-G.; Henriksen, T.M.; Sonesson, U.; Bonesmo, H.; Skjelvåg, A.O.; Strømman, A.H. Environmental life cycle assessment of cereal and bread production in Norway. Acta Agric. Scand. A 2012, 62, 242–253. [Google Scholar] [CrossRef]

- Hokazono, S.; Hayashi, K. Life cycle assessment of organic paddy rotation systems using land- and product-based indicators: A case study in Japan. Int. J. Life Cycle Assess. 2015, 20, 1061–1075. [Google Scholar] [CrossRef]

- Fujie, T. Factors influencing the adoption of environmentally friendly agriculture in the Shiga region. In Economic Analysis of Agri-Environmental Policies; Nishizawa, E., Ed.; Nippon Hyoron Sha: Tokyo, Japan, 2014; pp. 123–152. (In Japanese) [Google Scholar]

- Nansai, K. Estimation Methods of Sectoral Energy Consumption and Greenhouse Gas Emissions Based on 2005 Input-Output Tables, Revised Edition (August 2013). Available online: http://www.cger.nies.go.jp/publications/report/d031/jpn/pdf/6/3EID2005_Method_jp.pdf (accessed on 2 June 2016). (In Japanese)

- Kuosmanen, T.; Kortelainen, M. Measuring eco-efficiency of production with data envelopment analysis. J. Ind. Ecol. 2005, 9, 59–72. [Google Scholar] [CrossRef]

- Iribarren, D.; Vázquez-Rowe, I.; Moreira, M.T.; Feijoo, G. Further potentials in the joint implementation of life cycle assessment and data envelopment analysis. Sci. Total Environ. 2010, 408, 5265–5272. [Google Scholar] [CrossRef] [PubMed]

- Vázquez-Rowe, I.; Iribarren, D.; Moreira, M.T.; Feijoo, G. Combined application of life cycle assessment and data envelopment analysis as a methodological approach for the assessment of fisheries. Int. J. Life Cycle Assess. 2010, 15, 272–283. [Google Scholar] [CrossRef]

- Tatari, O.; Kucukvar, M. Eco-efficiency of construction materials: Data envelopment analysis. J. Constr. Eng. Manag. 2012, 138, 733–741. [Google Scholar] [CrossRef]

- Jan, P.; Dux, D.; Lips, M.; Alig, M.; Dumondel, M. On the link between economic and environmental performance of Swiss dairy farms of the alpine area. Int. J. Life Cycle Assess. 2012, 17, 706–719. [Google Scholar] [CrossRef]

- Mohammadi, A.; Rafiee, S.; Jafari, A.; Keyhani, A.; Dalgaard, T.; Knudsen, M.T.; Nguyen, T.L.T.; Borek, R.; Hermansen, J.E. Joint life cycle assessment and data envelopment analysis for the benchmarking of environmental impacts in rice paddy production. J. Clean. Prod. 2015, 106, 521–532. [Google Scholar] [CrossRef]

- Masuda, K. Measuring eco-efficiency of wheat production in Japan: A combined application of life cycle assessment and data envelopment analysis. J. Clean. Prod. 2016, 126, 373–381. [Google Scholar] [CrossRef]

| Item | Characteristics |

|---|---|

| Farmland area | 27 ha (1 ha privately owned; 26 ha leased) |

| Planted crops | CR or EFR (VEV, EV, MV, and LV) CW (MV) and CS (MV and LV) under the rice production adjustment program |

| Cropping patterns | Continuous rice cultivation every year Rice–wheat–soybean rotation every two years |

| Labor force | Two family members Minimum number of temporary workers for mechanical weeding at paddy field dikes in early June, early July, late July, mid-August, and late September |

| Entrusted operations | Chemical control of pests and diseases in CR production Chemical pest control in EFR production Chemical disease control in CW production Grain drying in CW and CS production |

| CR | EFR | |

|---|---|---|

| Pesticide application | Chemical seed disinfection Fungicide injection into nursery soil at seeding Herbicide application soon after transplanting Two chemical pest and disease control treatments | Hot water disinfection for seeds Use of fungicide and insecticide mixtures in nursery boxes Herbicide application at the time of transplanting One chemical pest control treatment |

| Fertilization | Chemical fertilizers Soil amendments | Organic-inorganic compound fertilizers Soil amendments |

| Period of midseason drainage 2 | 7 days | 14 days |

| CR | EFR | CW | CS | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| VEV | EV | MV | LV | VEV | EV | MV | LV | MV | MV | LV | |

| Yield 1 | 5.1 | 5.4 | 5.7 | 5.1 | 4.6 | 4.9 | 5.2 | 4.6 | 3.6 | 2.0 | 2.0 |

| Gross income 2 | 0.95 | 1.10 | 1.07 | 0.95 | 0.92 | 1.06 | 1.04 | 0.92 | 0.04 | 0.18 | 0.18 |

| Subsidy 3 | 0.075 | 0.075 | 0.075 | 0.075 | 0.115 | 0.115 | 0.115 | 0.115 | 0.796 | 0.539 | 0.539 |

| Production cost 4 | 0.31 | 0.32 | 0.31 | 0.31 | 0.37 | 0.37 | 0.37 | 0.36 | 0.32 | 0.27 | 0.27 |

| Crop income 5 | 0.71 | 0.86 | 0.84 | 0.72 | 0.67 | 0.81 | 0.79 | 0.67 | 0.52 | 0.44 | 0.44 |

| CR | EFR | CW | CS | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VEV | EV | MV | LV | VEV | EV | MV | LV | MV | MV | LV | ||

| January | Early | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.6 | 0 | 0 |

| Middle | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Late | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| February | Early | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Middle | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Late | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| March | Early | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.6 | 0 | 0 |

| Middle | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Late | 4.4 | 1.5 | 2.5 | 2.5 | 5.3 | 1.5 | 3.4 | 3.4 | 0 | 0 | 0 | |

| April | Early | 6.5 | 2.7 | 8.3 | 8.3 | 6.5 | 3.6 | 8.3 | 8.3 | 0 | 0 | 0 |

| Middle | 5.8 | 7.6 | 5.7 | 5.7 | 5.8 | 7.6 | 5.7 | 5.7 | 0 | 0 | 0 | |

| Late | 17.6 | 9.6 | 6.9 | 5.3 | 17.6 | 9.6 | 6.9 | 5.3 | 0 | 0 | 0 | |

| May | Early | 5.6 | 4.7 | 14.8 | 16.5 | 4.0 | 4.7 | 14.8 | 16.5 | 1.6 | 0 | 0 |

| Middle | 3.0 | 9.8 | 4.6 | 4.6 | 3.0 | 9.0 | 3.0 | 3.0 | 0 | 0 | 0 | |

| Late | 4.0 | 10.8 | 4.0 | 4.0 | 4.0 | 10.0 | 4.0 | 4.0 | 0 | 0 | 0 | |

| June | Early | 11.3 | 11.3 | 10.5 | 10.5 | 11.3 | 11.3 | 10.5 | 10.5 | 5.0 | 0 | 0 |

| Middle | 0 | 0 | 4.8 | 4.8 | 0 | 0 | 4.8 | 4.8 | 4.6 | 2.3 | 0 | |

| Late | 4.6 | 3.0 | 0 | 0 | 4.6 | 3.0 | 0 | 0 | 2.0 | 11.1 | 1.3 | |

| July | Early | 8.0 | 9.6 | 8.0 | 8.0 | 8.0 | 9.6 | 8.0 | 8.0 | 0 | 0 | 12.1 |

| Middle | 3.0 | 3.0 | 4.6 | 3.0 | 3.0 | 3.0 | 4.6 | 3.0 | 0 | 2.6 | 0 | |

| Late | 8.0 | 8.0 | 8.0 | 9.6 | 8.0 | 8.0 | 8.0 | 9.6 | 0 | 7.6 | 7.6 | |

| August | Early | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 0 | 0 | 2.6 |

| Middle | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 0 | 1.9 | 1.9 | |

| Late | 21.3 | 8.6 | 3.0 | 3.0 | 21.3 | 8.6 | 3.0 | 3.0 | 0 | 0 | 0 | |

| September | Early | 0 | 10.6 | 3.0 | 3.0 | 0 | 10.6 | 3.0 | 3.0 | 0 | 1.9 | 1.9 |

| Middle | 0 | 5.1 | 11.2 | 3.0 | 0 | 5.1 | 11.2 | 3.0 | 0 | 1.9 | 0 | |

| Late | 0 | 0 | 10.1 | 15.2 | 0 | 0 | 10.1 | 15.2 | 0 | 5.0 | 6.9 | |

| October | Early | 0 | 0 | 0 | 6.1 | 0 | 0 | 0 | 6.1 | 8.9 | 0 | 0 |

| Middle | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 6.4 | 0 | 0 | |

| Late | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 8.1 | 4.0 | 0 | |

| November | Early | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 8.1 | 5.0 | 0 |

| Middle | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Late | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 9.1 | |

| December | Early | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 0 | 0 | 0 |

| Middle | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 0 | 0 | 0 | |

| Late | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| CR | EFR | CW | CS | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| VEV | EV | MV | LV | VEV | EV | MV | LV | MV | MV | LV | |

| Fossil fuel (L) 1 | |||||||||||

| Gasoline | 126.0 | 131.0 | 136.0 | 141.0 | 121.0 | 126.0 | 131.0 | 136.0 | 25.0 | 15.0 | 15.0 |

| Diesel oil | 182.0 | 182.0 | 182.0 | 182.0 | 182.0 | 182.0 | 182.0 | 182.0 | 185.0 | 161.0 | 161.0 |

| Premixed fuel (25:1) | 15.8 | 15.8 | 15.8 | 15.8 | 14.8 | 14.8 | 14.8 | 14.8 | 7.2 | 6.4 | 6.4 |

| Motor oil | 20.0 | 20.0 | 20.0 | 20.0 | 20.0 | 20.0 | 20.0 | 20.0 | 10.0 | 10.0 | 10.0 |

| Kerosene | 180.0 | 150.0 | 90.0 | 90.0 | 180.0 | 150.0 | 90.0 | 90.0 | 0 | 0 | 0 |

| Production cost (thousand yen) 2 | |||||||||||

| Seed | 16.5 | 18.0 | 16.5 | 16.5 | 16.5 | 18.0 | 16.5 | 16.5 | 30.4 | 31.5 | 32.5 |

| Chemical fertilizer | 107.5 | 107.5 | 107.5 | 107.5 | 125.9 | 125.9 | 125.9 | 125.9 | 97.2 | 79.4 | 79.4 |

| Organic fertilizer | 0 | 0 | 0 | 0 | 50.8 | 50.8 | 50.8 | 50.8 | 0 | 0 | 0 |

| Pesticide | 58.3 | 58.3 | 58.3 | 58.3 | 64.6 | 64.6 | 64.6 | 64.6 | 28.6 | 53.1 | 53.1 |

| Fossil fuel | 64.8 | 62.9 | 58.2 | 58.9 | 63.9 | 62.0 | 57.3 | 58.0 | 26.2 | 22.7 | 22.7 |

| Electricity | 0.9 | 0.8 | 0.6 | 0.6 | 0.9 | 0.8 | 0.6 | 0.6 | 0.001 | 0 | 0 |

| Agricultural service | 34.6 | 34.6 | 34.6 | 34.6 | 17.3 | 17.3 | 17.3 | 17.3 | 126.0 | 63.0 | 63.0 |

| Shipping bag | 12.7 | 13.5 | 14.3 | 12.7 | 11.5 | 12.3 | 13.0 | 11.5 | 0 | 5.3 | 5.3 |

| Others | 19.6 | 19.6 | 19.6 | 19.6 | 19.6 | 19.6 | 19.6 | 19.6 | 14.7 | 15.7 | 15.7 |

| Nitrogen input (kg N) 3 | |||||||||||

| Chemical fertilizer | 80.0 | 80.0 | 80.0 | 80.0 | 40.0 | 40.0 | 40.0 | 40.0 | 148.0 | 20.0 | 20.0 |

| Organic fertilizer | 0 | 0 | 0 | 0 | 40.0 | 40.0 | 40.0 | 40.0 | 0 | 0 | 0 |

| Nitrogen fixation by legumes | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 121.1 | 121.1 |

| Crop residue | 30.2 | 32.1 | 34.0 | 30.2 | 27.4 | 29.1 | 30.9 | 27.4 | 19.5 | 9.6 | 9.6 |

| Magnesium carbonate fertilizer (t) 4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.0 | 1.0 | 1.0 |

| Item | Cost |

|---|---|

| Steel-framed building | 1.53 |

| Timber-framed building | 0.28 |

| Steel pipe greenhouse | 0.26 |

| Agricultural machinery | 10.49 |

| Plastic material | 0.28 |

| Land improvement and water use | 1.03 |

| Others 2 | 2.69 |

| CR | EFR | CW | CS | FCC | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VEV | EV | MV | LV | VEV | EV | MV | LV | MV | MV | LV | ||

| Seed | 53 | 58 | 53 | 53 | 53 | 58 | 53 | 53 | 98 | 101 | 104 | |

| Fertilizer | 1205 | 1205 | 1205 | 1205 | 1560 | 1560 | 1560 | 1560 | 1904 | 1338 | 1338 | |

| Pesticide | 278 | 278 | 278 | 278 | 308 | 308 | 308 | 308 | 137 | 253 | 253 | |

| Fossil fuel | 1718 | 1643 | 1476 | 1492 | 1698 | 1623 | 1456 | 1472 | 751 | 641 | 641 | |

| Electricity | 26 | 23 | 18 | 18 | 27 | 24 | 18 | 18 | 0.04 | 0 | 0 | |

| Agricultural service | 121 | 121 | 121 | 121 | 61 | 61 | 61 | 61 | 441 | 220 | 220 | |

| Shipping bag | 45 | 48 | 51 | 45 | 41 | 44 | 46 | 41 | 0 | 19 | 19 | |

| CH4 from rice paddy fields | 3804 | 3804 | 3804 | 3804 | 2644 | 2644 | 2644 | 2644 | 0 | 0 | 0 | |

| Nitrogen fixation by legumes | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 366 | 366 | |

| Crop residue | 184 | 196 | 207 | 184 | 167 | 177 | 188 | 167 | 119 | 58 | 58 | |

| Steel-framed building | 6439 | |||||||||||

| Timber-framed building | 879 | |||||||||||

| Steel pipe greenhouse | 4584 | |||||||||||

| Agricultural machinery | 44,817 | |||||||||||

| Plastic material | 975 | |||||||||||

| Land improvement and water use | 3587 | |||||||||||

| Total | 7435 | 7376 | 7213 | 7200 | 6560 | 6499 | 6335 | 6325 | 3449 | 2997 | 3000 | 61,282 |

| CR Farm | EFR Farm | |

|---|---|---|

| Land use (ha) | ||

| CR (VEV) | 0 | |

| CR (EV) | 5.0 | |

| CR (MV) | 8.5 | |

| CR (LV) | 0 | |

| EFR (VEV) | 0 | |

| EFR (EV) | 5.0 | |

| EFR (MV) | 8.5 | |

| EFR (LV) | 0 | |

| CW (MV) | 13.5 | 13.5 |

| CS (MV) | 8.6 | 8.6 |

| CS (LV) | 4.9 | 4.9 |

| Temporary workers (hours) | ||

| Early June | 43.5 | 43.5 |

| Early July | 0 | 0 |

| Late July | 35.5 | 35.5 |

| Mid-August | 0 | 0 |

| Late September | 0 | 0 |

| Economic, environmental, and integrated indicators | ||

| Net farm income (million yen) | 7.76 | 7.08 |

| GWP (t CO2 eq.) | 246.5 | 234.6 |

| Eco-efficiency (million yen per t CO2 eq.) | 0.031 | 0.030 |

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masuda, K. Optimization Model for Mitigating Global Warming at the Farm Scale: An Application to Japanese Rice Farms. Sustainability 2016, 8, 593. https://doi.org/10.3390/su8070593

Masuda K. Optimization Model for Mitigating Global Warming at the Farm Scale: An Application to Japanese Rice Farms. Sustainability. 2016; 8(7):593. https://doi.org/10.3390/su8070593

Chicago/Turabian StyleMasuda, Kiyotaka. 2016. "Optimization Model for Mitigating Global Warming at the Farm Scale: An Application to Japanese Rice Farms" Sustainability 8, no. 7: 593. https://doi.org/10.3390/su8070593