1. Introduction

With the ability of enhancing sustainability of road traffic [

1] and promoting low-carbon economic transition of transportation, electric vehicles (EVs) have attracted much attention all around the world. Many countries have been stepped up policies and standards to support the development of EVs and related facilities, especially in United States, Japan, and European countries. In 2010, the topic of “Research on the effect of electric vehicle charging on power grid and its orderly charging” was officially proposed by Chinese government, which marked that electric vehicles had become one of the main research hotspots in China [

2]. However, lagged construction of repowering facilities has become the bottleneck to fast development of EV [

3]. Therefore, it is badly in need of rapid development of EV energy supplying stations and the related facilities, to provide important energy supply and maintenance service for the normal operation of EV.

Recently, the main energy supplying mode of EV is the battery charging mode [

4]. Because of it is easy to conduct and has a lower one-time investment, battery charging stations (BCS) for EV belonging to the battery charging mode have been developed rapidly. However, along with the increase of EVs, drawbacks of BCS become prominent such as long charging time and poor endurance. Taking BAIC BJEV EV200 as an example, the maximum endurance mileage is 200 km with 6–8 h charging time [

5]. Based on this context, battery swapping mode returns into the view of the public in China. In July 2015, the company BAIC BJEV signed a strategic cooperation agreement with Sinopec’s Beijing oil to declare that the two sides will build the swapping services for EV based on the gas station network [

6]. Compared to the charging mode, battery swapping mode has its unique advantages, including the control ability of charging time and charging power for depleted batteries to achieve orderly charging, short waiting time for EV users of less than 5 min [

7], storage ability to provide different kinds of auxiliary services, and convenient management. To promote development of BSS, the optimal planning and operating methods of BSS should be researched first and the potential economic benefit should be fully considered in the process to promote investment for BSS and cost recovery.

To date, some studies have been done regarding the optimal planning and operation of BSS. There are two main types in the existing works. Articles in the first type optimize the planning and operation of BSS with the goal of satisfying the requirements of EV users which mainly focus on the “service” attribute of BSS [

8], involving minimizing waiting time and travelling time of EV users, meeting swapping demand [

9], and ensuring BSS service availability [

10]. The other type primarily concerns the “power” attribute of BSS, e.g. the influence of BSS on power grid or the revenue obtained by the interaction between BSS and power grid. A dynamic operation model of BSS based on the short term battery management with responding actively to the price fluctuation was built in [

7] and results show that BSS can acquire additional revenue in electricity market. Charging model of double objective optimization considering load shifting to minimizing the charging cost and reducing the load fluctuation was presented in [

11] and the simulation results show that 30% of the optimized charging cost can be saved with the sharpening peak effect. To determine the capacity of BSS with consideration of the efficiency of photovoltaic (PV) energy, multi-objective model of PV-based BSS towards benefits of economy and environment was provided in [

12]. EV users’ swapping behaviors were studied in [

13] to determine the swapping load impacts on the power grid side and generation side.

In addition, as an effective method to increase the flexibility of power system, demand side management (DSM) has been paid much attention. Due to the controllability of EV charging time, charging mode of EV has been researched as a form of responsive demand [

14]. Nowadays, most studies in this aspect mainly focus on the mechanism of charging and discharging pricing [

15]. Based on EV charging demand varying in response to the electricity price, the optimal pricing and dispatch problem of smart grid retailers are formulated as a Stackelberg game in [

16]. A model to optimize time-of-use electricity price for the purpose of making use of orderly charge behavior by EV and realizing peak-shaving and valley-filling for power systems was presented in [

17]. As an integrated form of EV batteries, BSS offers a better new form of responsive demand. There have been some applications of BSS as a kind of controllable resource in demand side. The application of BSS to the system frequency regulation as responsive demand was studies in [

18]. A multi-objective bi-level optimization model of real-time charging/discharging dispatch with coordination of BSS and grid is established in [

19]. However, the cost of BSS responding to the dispatch of dispatch center was not considered in [

19] and it just dealt with the operation of BSS not involving the BSS optimal planning.

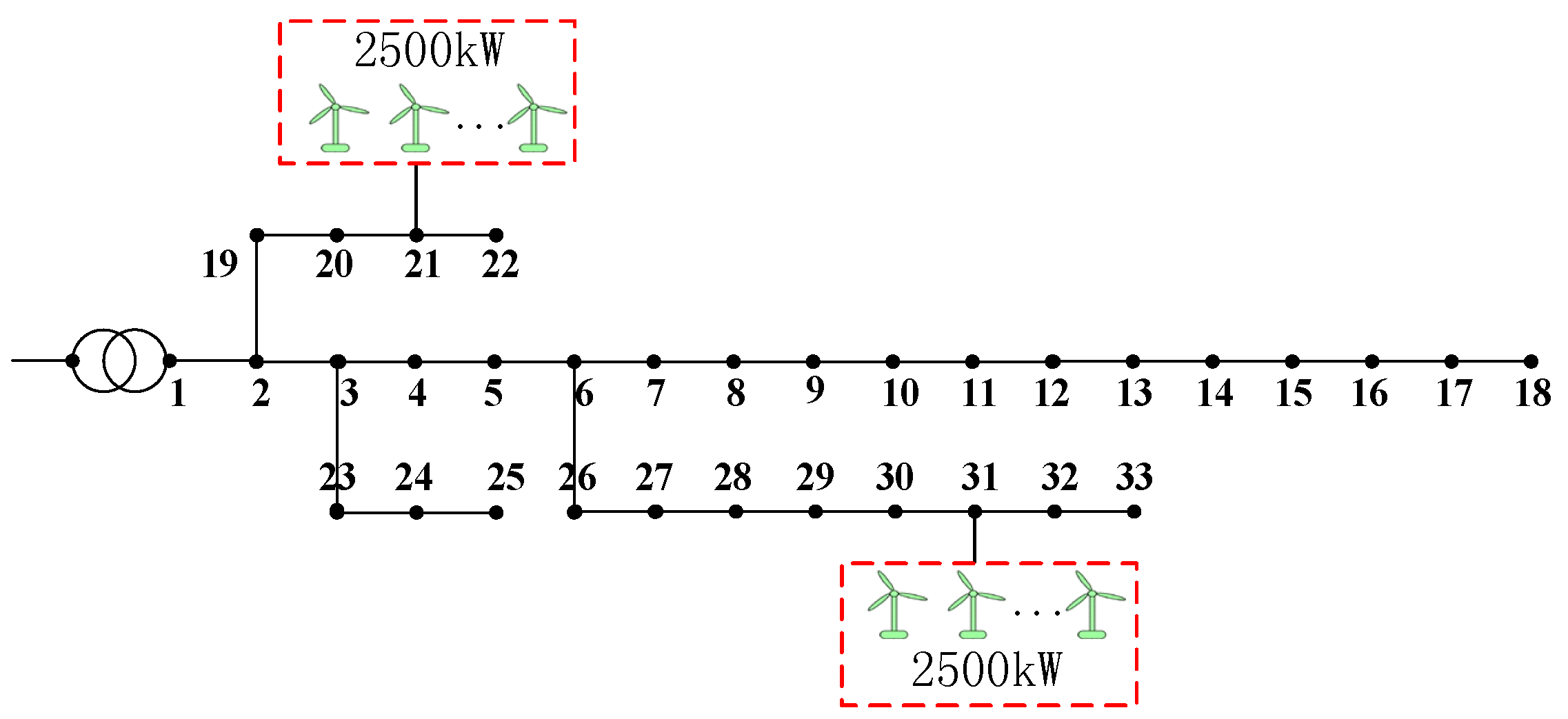

In this paper, the process of BSS participating in DSM in distribution network with DG is considered into the optimal planning of BSS. Compared to the former studies, the main contributions and differences of this paper can be summarized as follows. (1) The optimal sizing and location of BSS are decided separately in this paper in order to reduce the complexity of the problem and difficulty of solving. (2) Both the economic profits of BSS and distribution company (DisCo) [

20] are considered in the process of optimal planning of BSS and a bi-level programming model of BSS is presented realizing the decomposing of BSS optimal planning and DisCo economic dispatching. (3) Besides the planning variables containing optimal numbers of batteries and chargers initially purchased and optimal location, the operating variables, including contract price and dispatched power of BSS participating in DSM, can also be decided through the proposed model.

The rest of this paper is organized as follows.

Section 2 gives the mechanism of BSS participating in DSM. The optimal sizing and locating mode of BSS considering DSM is introduced in

Section 3. Solving method of the bi-level model is shown in

Section 4. The simulation of the proposed model for testing is provided in

Section 5.

Section 6 discusses the suggestions for BSS operators and DisCo. Finally,

Section 7 is devoted to the conclusions and future research.

2. Mechanism of BSS Participating in Demand Side Management

Typically, without the limitation of external conditions, the rule of “First-In First-Out” is applied as the charging strategy of BSS,

i.e., the swapped batteries are charged as soon as possible to satisfy the swapping demand in the next period [

21]. However, this may result in the increase of system load peak–valley ratio and reduce the benefit of DisCo. Therefore, some measures must be adopted to control the charging process of BSS. In this paper, the charging process of BSS is guided by DSM. In essence, the charging power of BSS is dispatched by DisCo as a form of DSM.

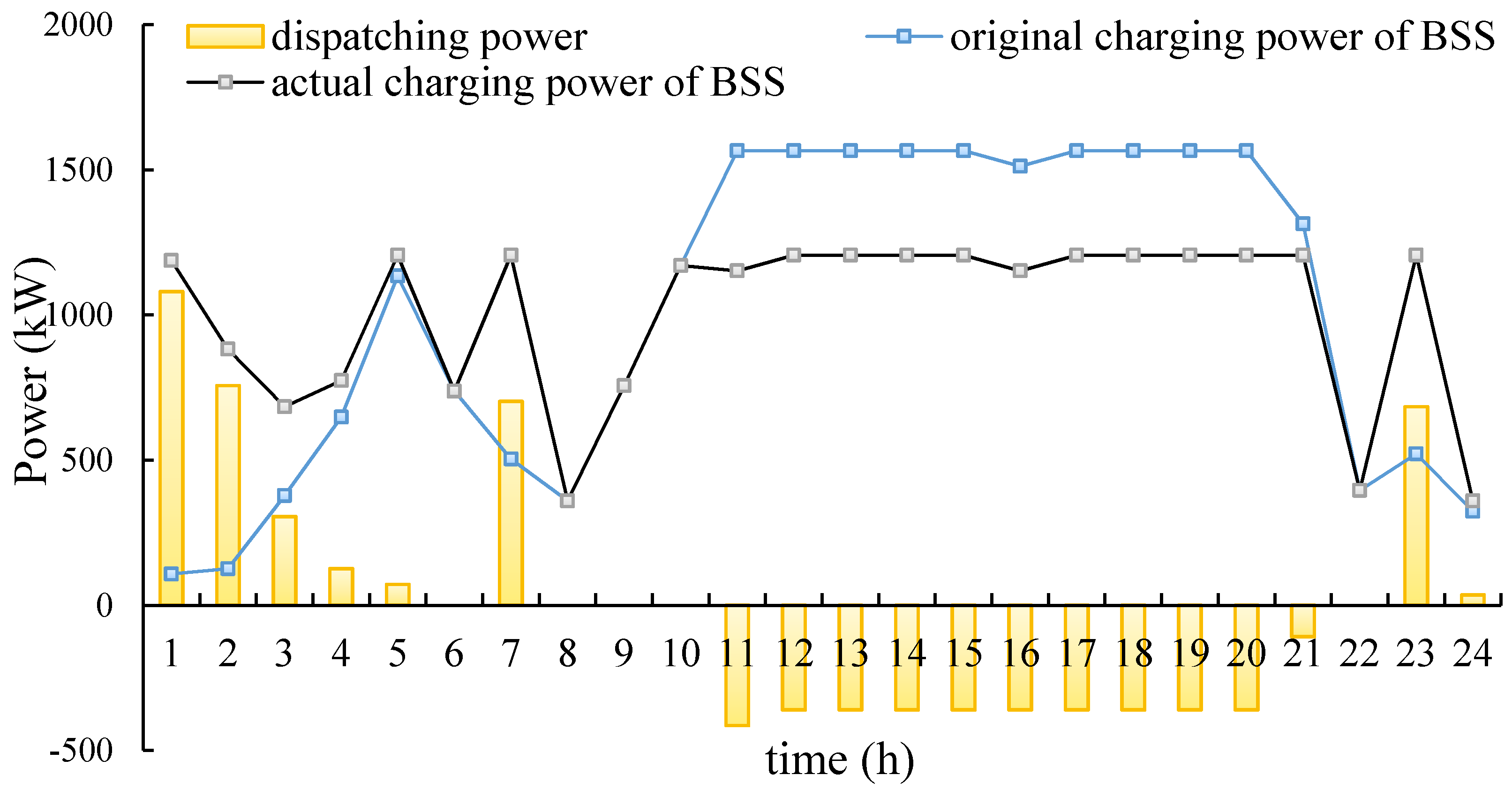

Through dispatching BSS, DisCo will profit in peak load shifting and valley load filling. Meanwhile, original charging power of BSS will be changed due to the dispatching by DisCo. More batteries and chargers need to be reserved in BSS, which will increase the initial configuration cost of BSS. Therefore, DisCo should pay some compensation for dispatching BSS. Contract price is one of the effective compensation methods [

20]. The mechanism of BSS participating in DSM is that in the market environment, BSS offers contract price of participating in DSM to DisCo and according to the system load curve and spot electricity price of the upper grid, DisCo decides how much power of BSS in each period is dispatched to minimize its operation cost. The profit of BSS participating in DSM is calculated as Equation (1).

where

T is the total number of periods in the research; Δ

t is the time interval (1 h);

cR is contract price of DisCo dispatching unit power of BSS (¥/kWh); and

PR.t is the dispatched power of BSS in time

t.

PR.t greater than zero means the charging power of BSS in time

t needs to increase. Similarly,

PR.t less than zero means the charging power of BSS in time

t needs to decrease.

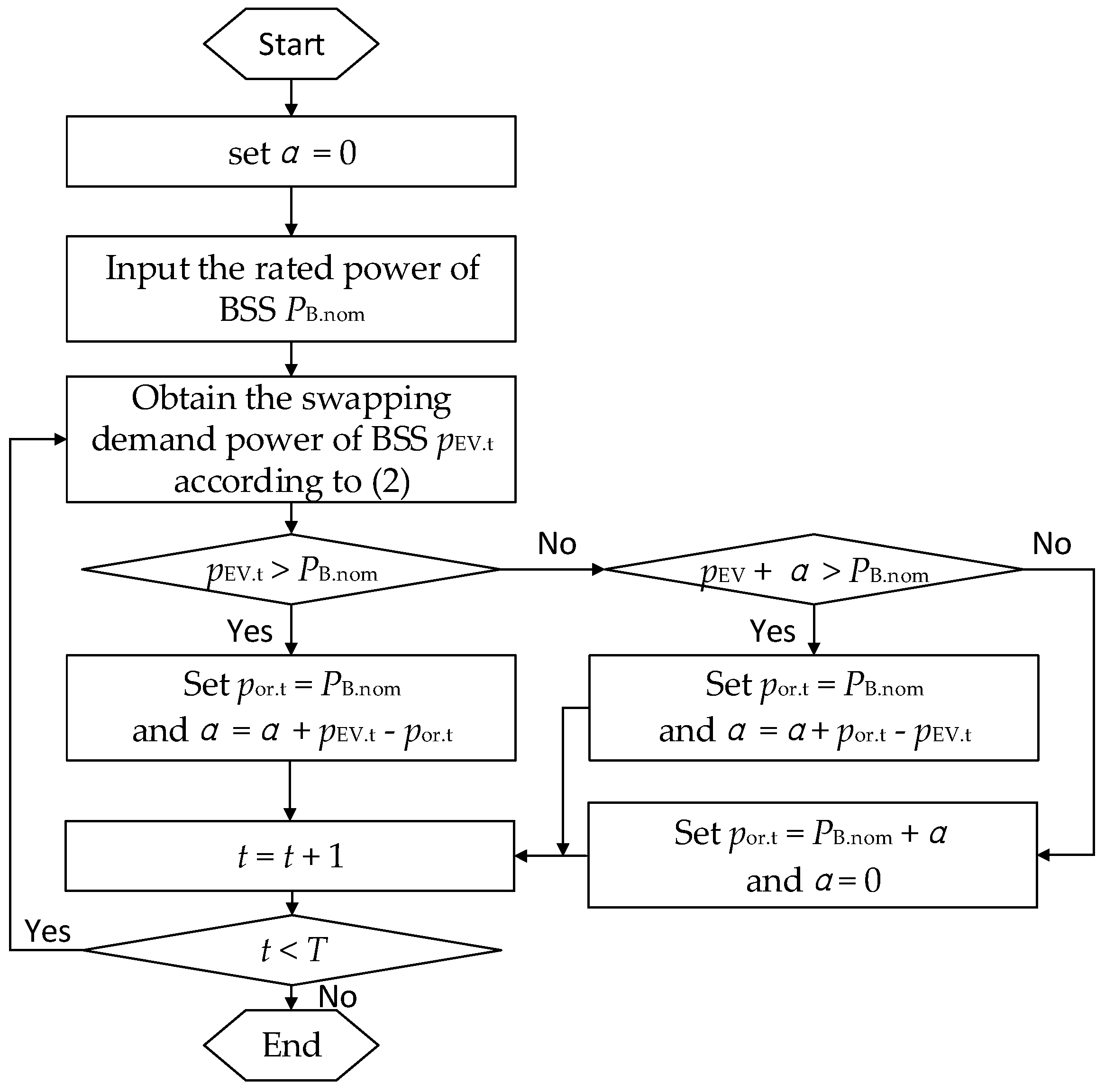

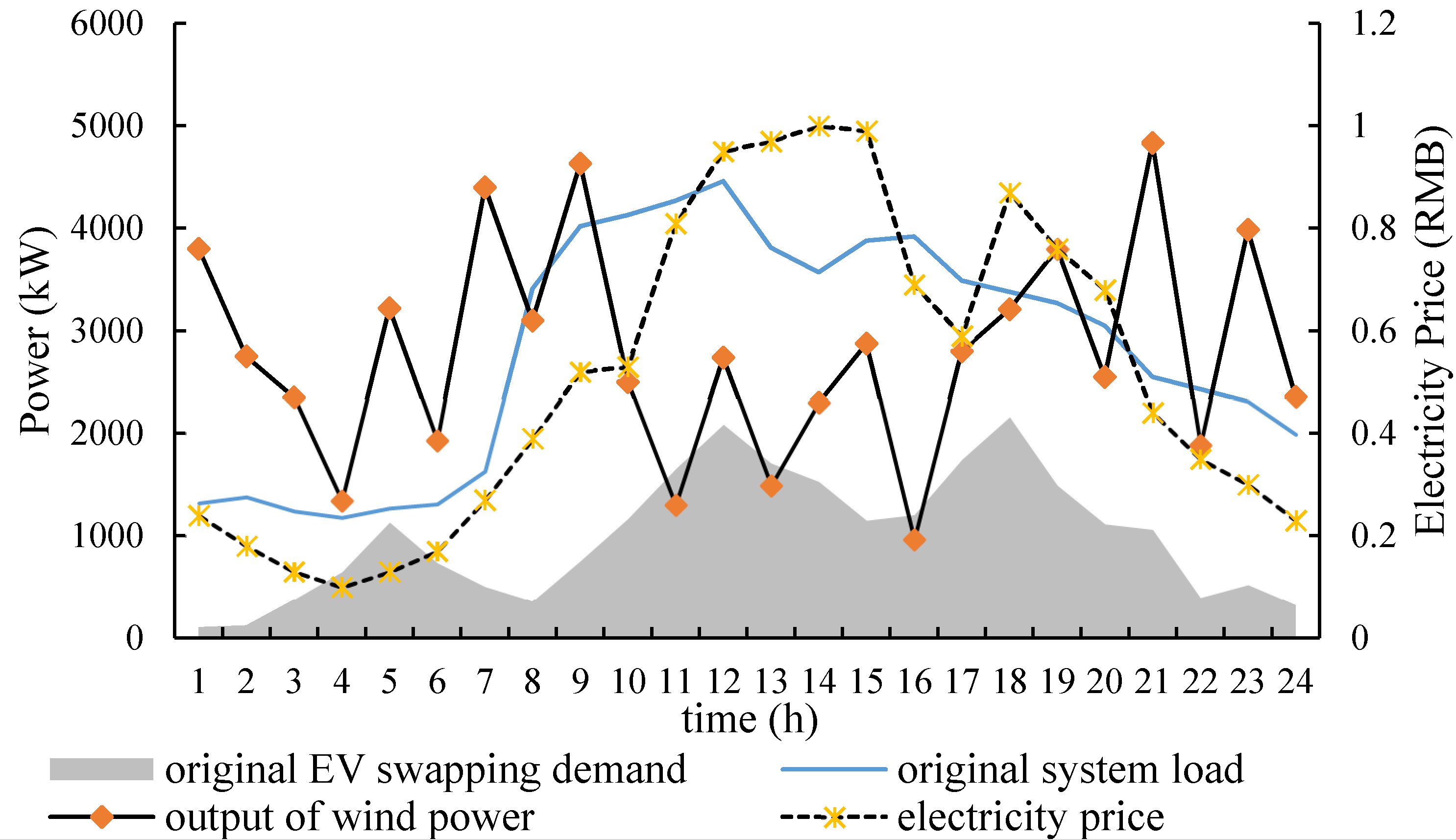

The dispatched power of BSS in each time is based on the original charging power. Therefore, the original charging power curve of BSS must be obtained. Because the rule “First-In First-Out” is applied, the original charging power curve is determined by battery swapping demand and the rated power of BSS. The swapping demand power is calculated by Equation (2) and the calculation process of BSS original charging power in period

t is shown in

Figure 1.

where

pEV.t is swapping power of EV in time

t;

SB is the rated capacity of EV battery;

Lt is the number of EVs coming to the BSS for battery swapping in time

t which can be obtained through the hourly swapping demand model of BSS in [

22];

SOCl is the value of battery state of charge (SOC) when the swapped battery

l starts to charge; and

TB is the number of periods required to charge a battery. In order to prevent the battery from permanent damage and prolong the lifetime, EV battery cannot be in full-charged state. Therefore, 95% is the upper boundary of SOC.

In

Figure 1,

α is set to store the swapping demand power that cannot be charged immediately due to the restriction of BSS rated power;

PB.nom is the rated power of BSS; and

por.t expresses the original charging power of BSS in time

t.

Generally, an EV battery is charged using constant current-constant voltage mode. Recently, the constant power charging mode has also become popular in charging EV batteries [

23]. Therefore, in order to provide better support for grid, the constant power charging mode is adopted in this paper.

4. Solving Method

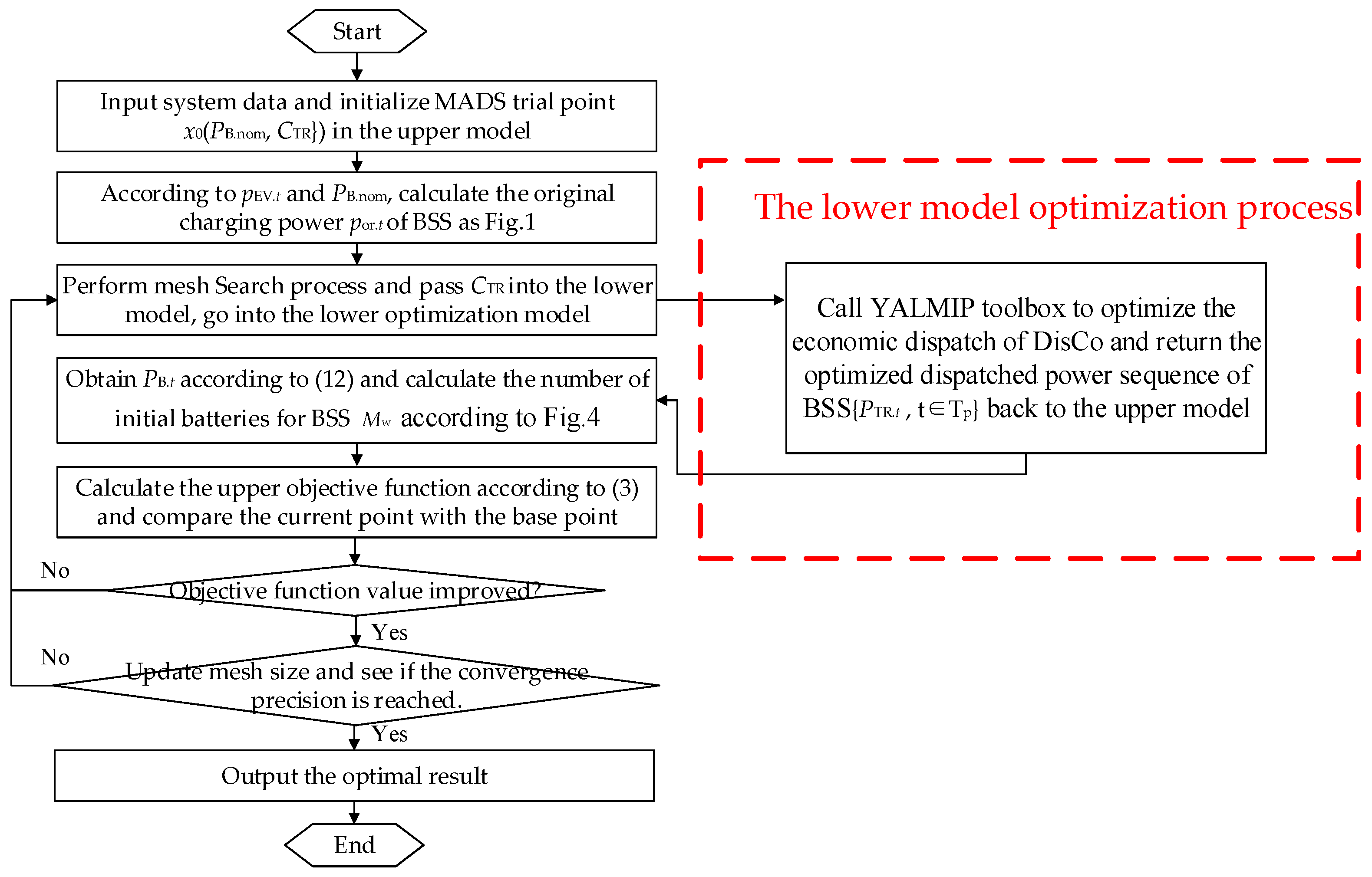

As shown in

Figure 3, the proposed optimal planning model of BSS considering DSM contains two sub-problems. The model solving process is that the upper model passes the initialized BSS rated power and contract price to the lower model; then based on the original charging power of BSS, the lower model optimizes economic dispatch of distribution system with the given rated power and contract price of BSS and the dispatched power of BSS in each time can be obtained and be returned back to the upper model; the upper optimization process is go on and by iteratively, the optimal solution can be obtained eventually.

In the upper model, for the complex relationships among BSS rated power, contract price and the operation cost of DisCo are hard to determine directly, the lower optimization process can be regarded as “black box” from the upper model’s perspective. Therefore, as an effective “black box” optimization algorithm, Mesh Adaptive Direct Search (MADS) is adopted to solve the upper model. MADS was first proposed by Audet and Dennis in 2004 [

30]. MADS can be divided into Search process and Poll process (more details can be seen in [

31]). Compared to the traditional heuristic algorithm, MADS is suitable for optimization problems with more complex objective functions and can greatly shorten the calculation time.

The lower model is a problem of economic dispatch, which is an integer optimization linear programming and solved by the MATLAB toolbox YALMIP. YALMIP is a modeling language for advanced modeling and solution of convex and nonconvex optimization problems in MATLAB [

32].

To satisfy the constraint of EV swapping demands in Equation (9), the minimum value of batteries initially purchased in BSS

Mw can be obtained by the actual charging power of BSS

pB.t and the swapping power of BSS

pEV.t. The calculation process is shown in

Figure 4.

The solving flowchart of the proposed bi-level model is shown in

Figure 5, in which

Tp expresses one scheduling period (24 h in this paper).

7. Conclusions

The main contribution of this paper is to propose a new method for sizing and locating BSS in which the capacity and location of BSS are decided separately. Firstly, considering the economic profits of both BSS and DisCo, a bi-level programming model of BSS for EV considering DSM is built to plan the rated power of BSS; meanwhile, the contract price and dispatched power of BSS for DSM can be obtained in the process. Subsequently, with the objective of minimizing the net loss of distribution system, the optimal locating model of BSS is put forward.

This paper provides a new operation way for BSS to gain more profits, which can promote the constructions of BSS and lay a foundation on the rapid development of EVs. In the future, we plan to expand our research in the following ways. With the increase of EV battery life-time, the function of V2G is required to be combined with the proposed model in the future work. Moreover, the “service” attribute of BSS should also be considered with the “power” attribute, especially in the method of locating BSS.