Introduction of Microbial Biopolymers in Soil Treatment for Future Environmentally-Friendly and Sustainable Geotechnical Engineering

Abstract

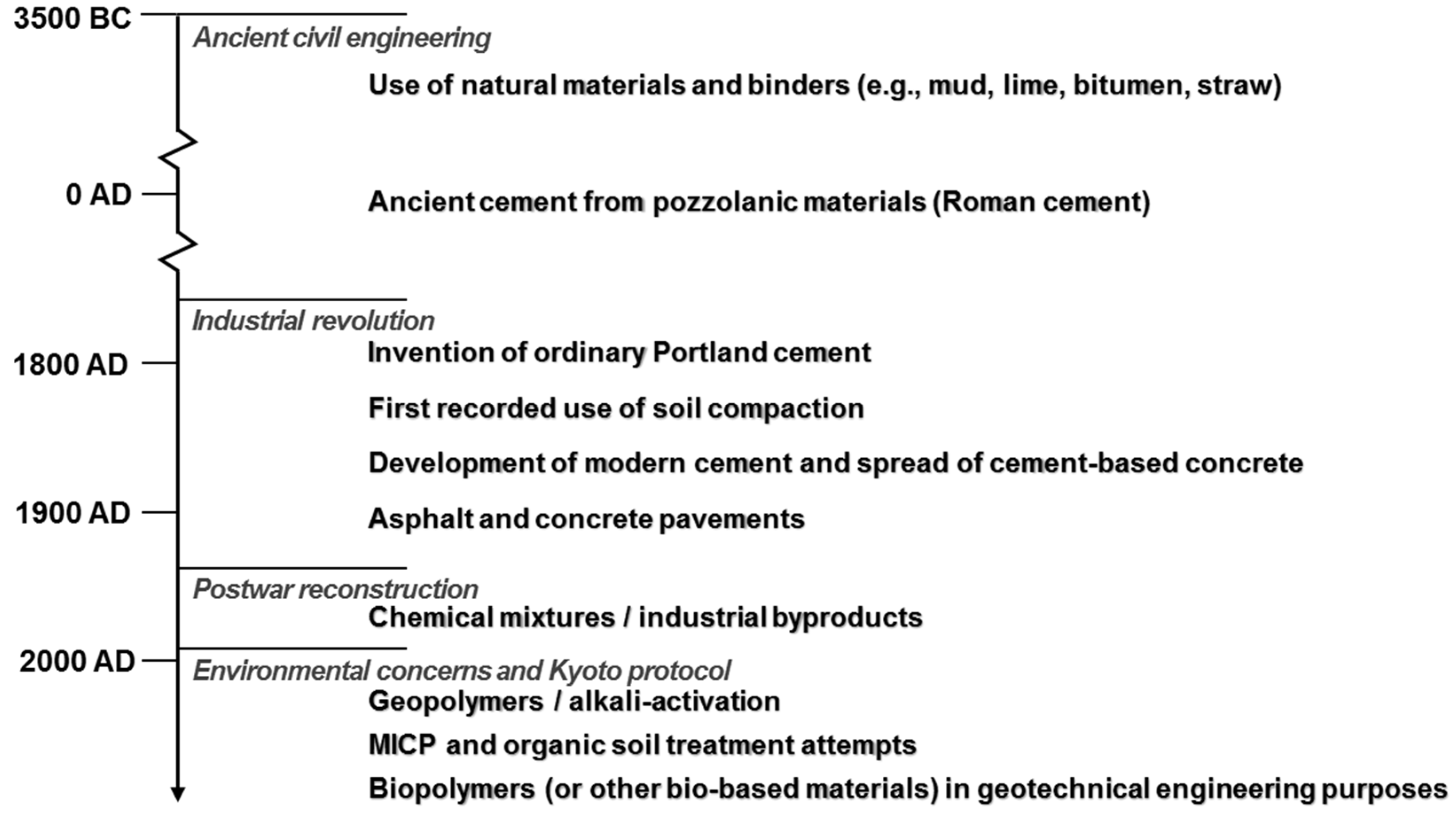

:1. Introduction

2. Environmental Concerns Affecting Soil Treatment in Geotechnical Engineering

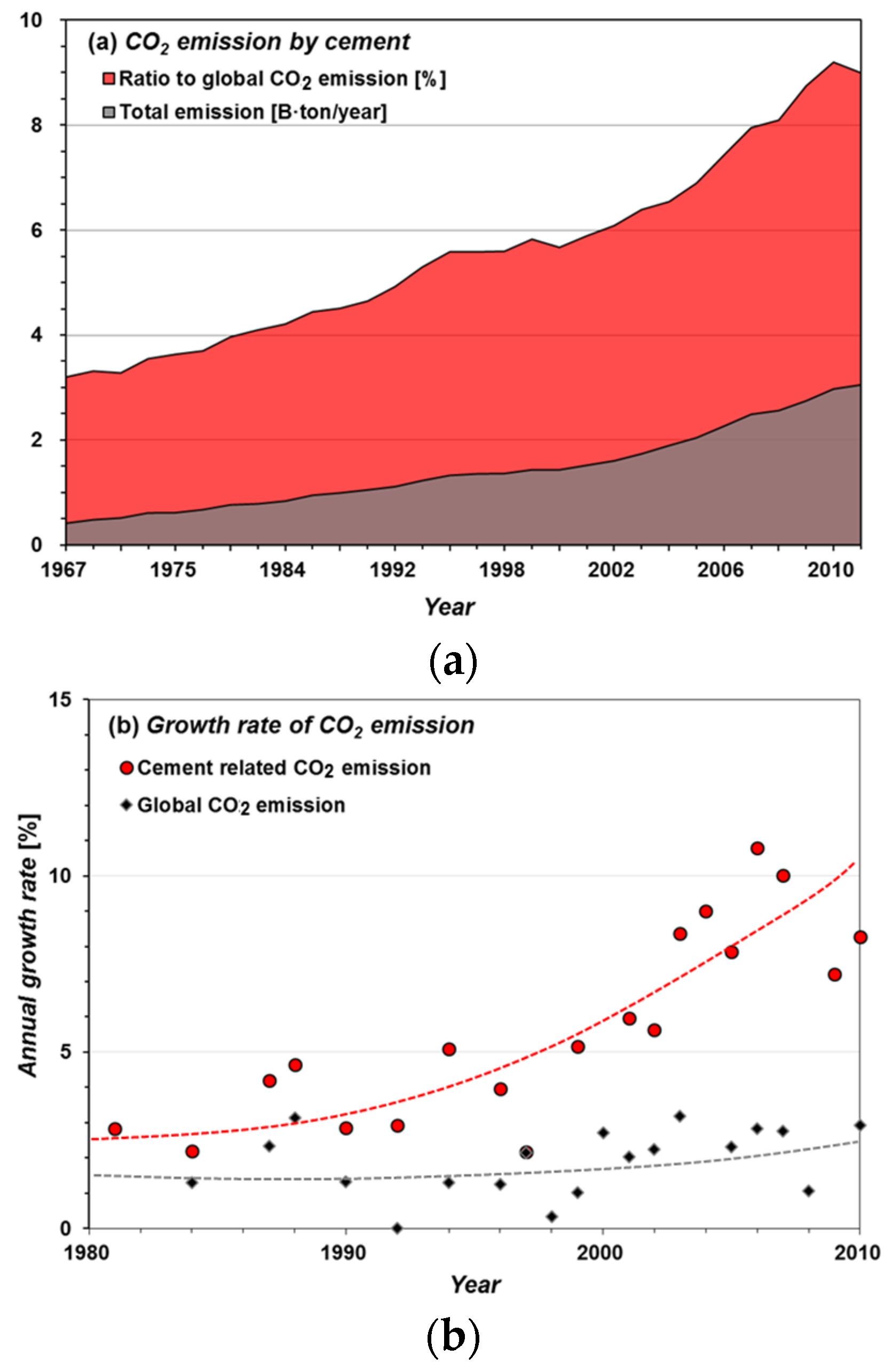

2.1. CO2 Emissions related to Cement Usage in Civil and Geotechnical Engineering

2.2. Other Environmental Concerns from the Use of Cement

2.3. Soil Treatment Methods with Environmentally-Friendly Aspects

3. Application of Biological Approaches to Geotechnical Engineering

3.1. Attempts with Bio-Mineralization

3.2. Biopolymers: Definition and Usage

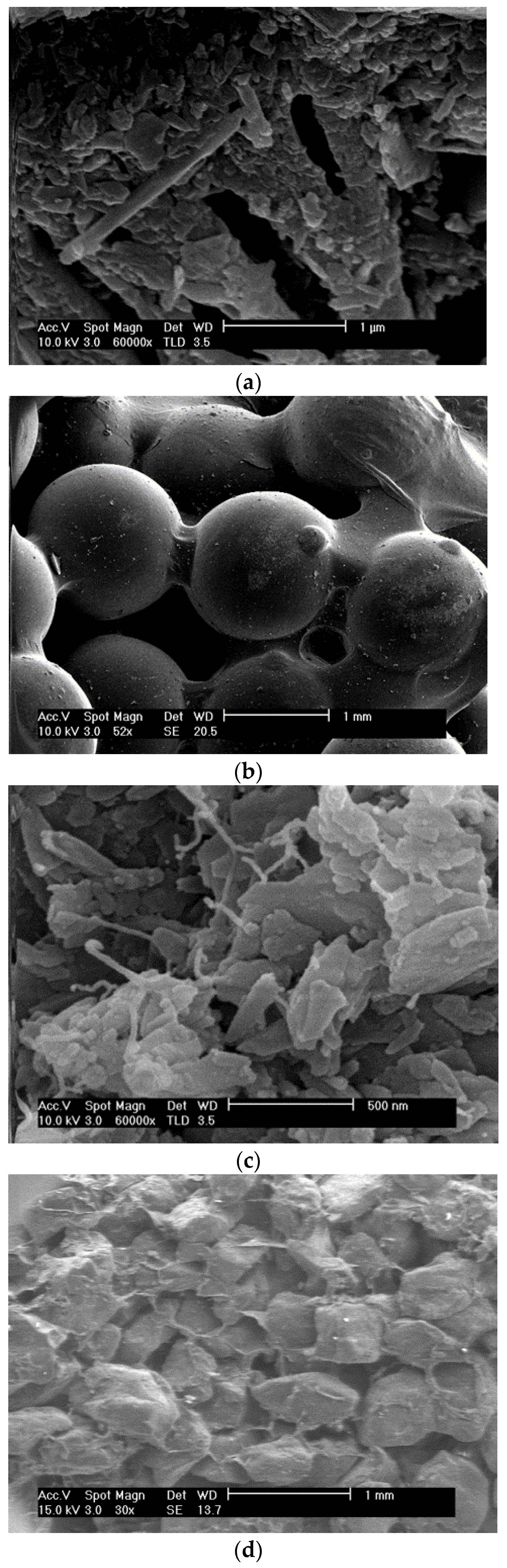

3.3. Biopolymers in Geotechnical Engineering

3.3.1. Cellulose and Starch

3.3.2. Chitosan

3.3.3. Curdlan

3.3.4. Beta-Glucan

3.3.5. Xanthan Gum

3.3.6. Agar Gum

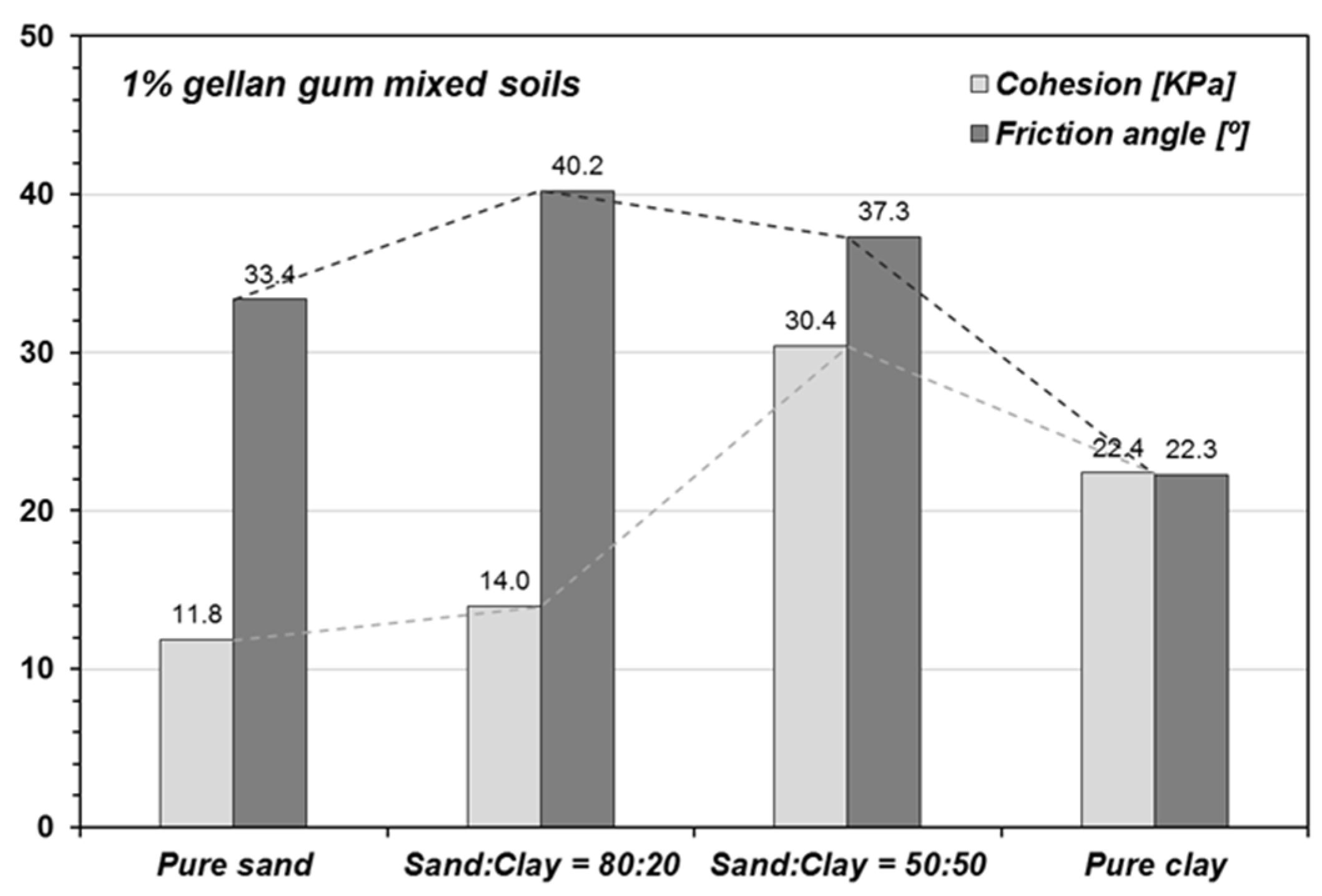

3.3.7. Gellan Gum

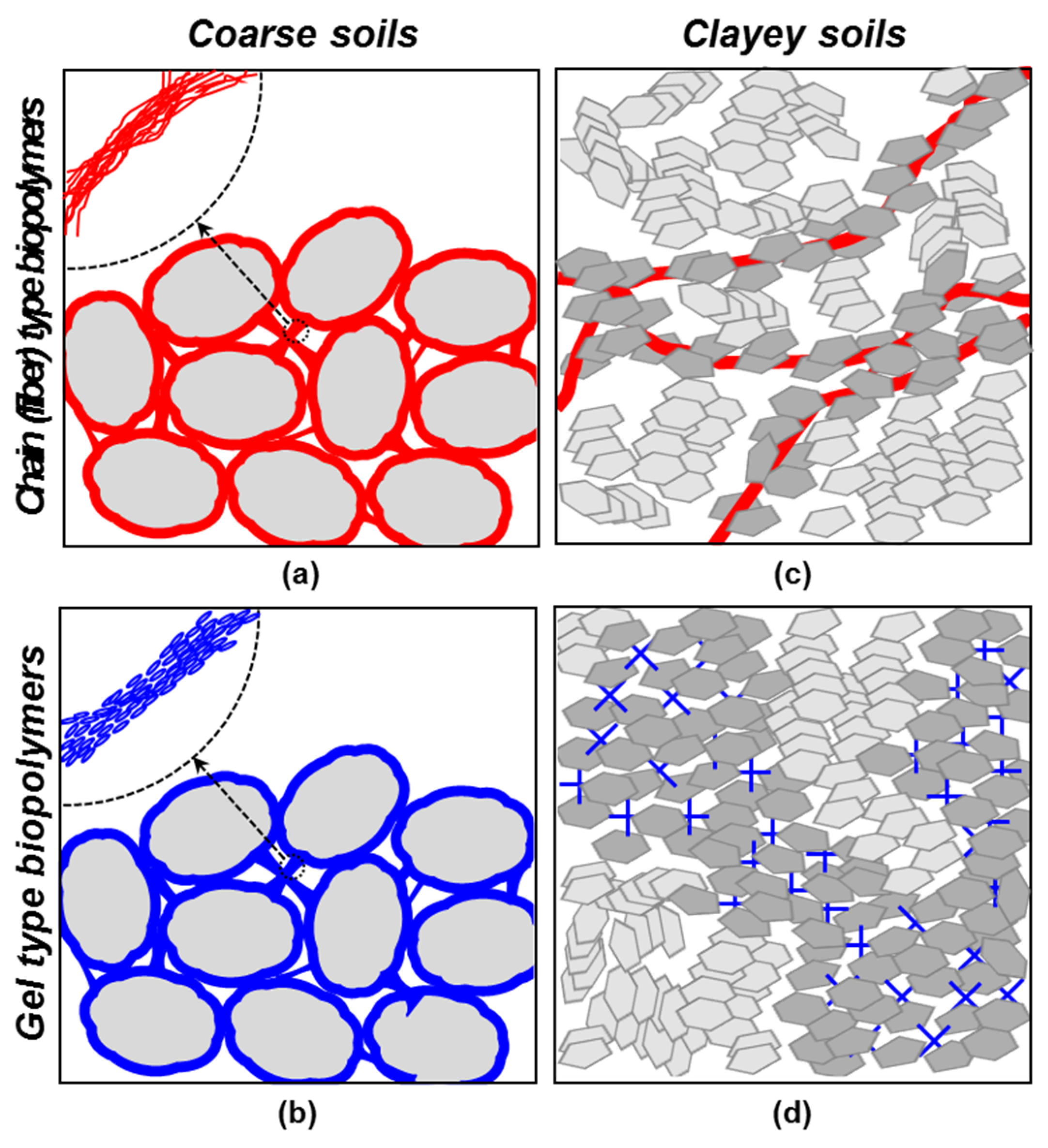

4. Mechanisms of Soil–Biopolymer Interaction

4.1. How Biopolymers Strengthen Soil

4.2. Hydro-Dependency and Clogging Effect of Biopolymers

5. Discussion

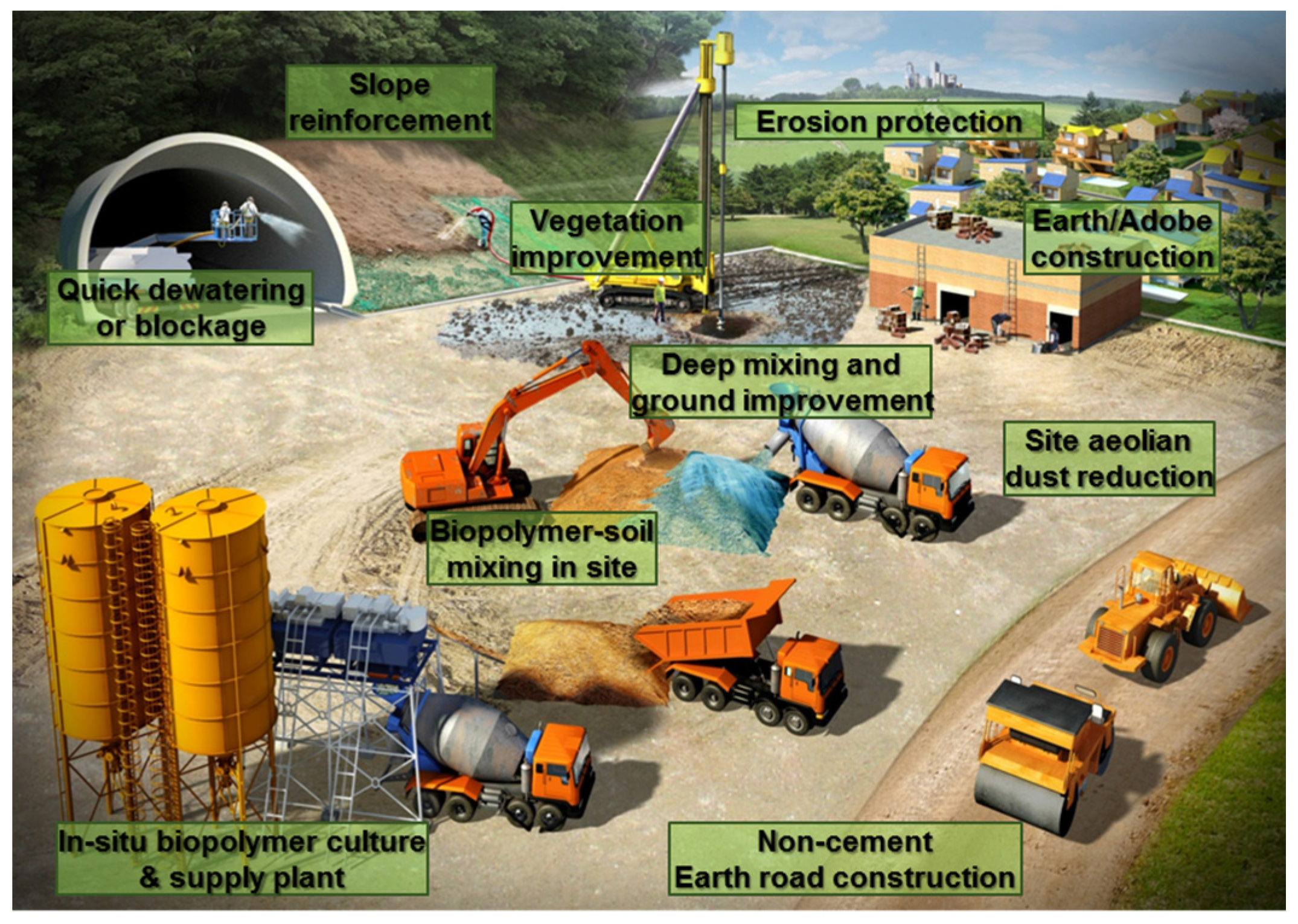

5.1. Opportunities for Biopolymers in Geotechnical Engineering

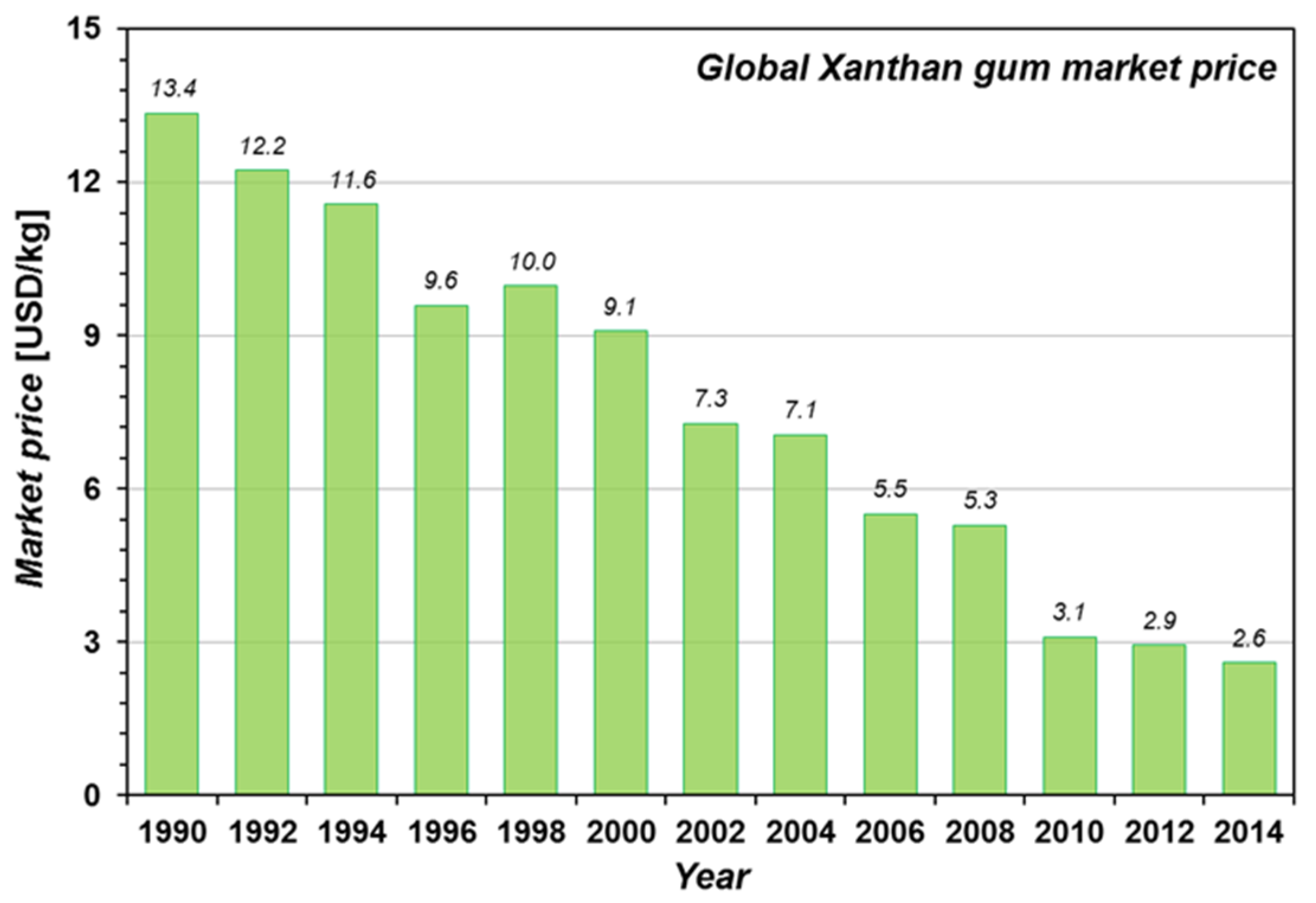

5.2. Economic Feasibility of Biopolymers: Global market of Biopolymers

5.3. Biopolymer Competitiveness in Global Carbon Emission Trading

5.4. Further Challenges for Practical Implementation of Biopolymer Technology

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Potts, D.T. Mesopotamian Civilization: The Material Foundations; Cornell University Press: Ithaca, NY, USA, 1997; p. 366. [Google Scholar]

- Kemp, B.J. Ancient Egypt: Anatomy of a Civilization; Routledge: London, UK, 1989; p. 437. [Google Scholar]

- Yang, F.; Zhang, B.; Ma, Q. Study of Sticky Rice-Lime Mortar Technology for the Restoration of Historical Masonry Construction. Acc. Chem. Res. 2010, 43, 936–944. [Google Scholar] [CrossRef] [PubMed]

- Delatte, N.J. Lessons from Roman Cement and Concrete. J. Prof. Issues Eng. Deucation Pract. 2001, 127, 109–115. [Google Scholar] [CrossRef]

- Sherwood, P.T. Soil Stabilization with Cement and Lime; HMSO: London, UK, 1993. [Google Scholar]

- Hargreaves, D. The Global Cement Report 10th Edition; International Cement Review: Surrey, UK, 2013. [Google Scholar]

- Maclaren, D.C.; White, M.A. Cement: Its Chemistry and Properties. J. Cemical Educ. 2003, 80, 623. [Google Scholar] [CrossRef]

- Larson, A. Sustainability, Innovation, and Entrepreneurship; University of Virginia: Charlottesville, VA, USA, 2011. [Google Scholar]

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O. Carbon Dioxide Emissions from the Global Cement Industry. Ann. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- Metz, B.; Davidson, O.; Coninck, H.D.; Loos, M.; Meyer, L. Carbon Dioxide Capture and Storage; Intergovernmental Panel on Climate Change: New York, NY, USA, 2005. [Google Scholar]

- Oss, H.G.V. Cement Statistics and Information; US Geological Survey: Reston, VA, USA, 2014.

- Rapier, R. Global Carbon Dioxide Emissions - Facts and Figures; Consumer Energy Repor, 2012. [Google Scholar]

- Plank, J. Applications of biopolymers in construction engineering. In Biopolymers Online; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005. [Google Scholar]

- U.S. Energy Information Administration. International Energy Statistics; U.S. Department of Energy: Washington, DC, USA, 2015.

- Taylor, H.F.W. Cement Chemistry; Thomas Telford Publishing: London, UK, 1997. [Google Scholar]

- Hansen, P.J. Effect of high pH on the growth and survival of marine phytoplankton: Implications for species succession. Aquat. Microb. Ecol. 2002, 28, 279–288. [Google Scholar] [CrossRef]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Resour. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Water Environment Federation. Urban Runoff Quality Manaement; Water Environment Federation: Alexandria, VA, USA, 1998. [Google Scholar]

- Parliamentary Office of Science and Technology. Urban Flooding; Postnote: London, UK, 2007.

- Burton, G.A.; Pitt, R. Stormwater Effects Handbook: A Toolbox for Watershed Managers, Scientists, and Engineers; Lewis Publishers: Boca Raton, FL, USA, 2002. [Google Scholar]

- Schueler, T.R. Watershed Protection Techniques: A Quarterly Bulletin on Urban Watershed Restoration and Protection Tools; Center for Watershed Restoration: Silver Spring, MD, USA, 1994. [Google Scholar]

- Solecki, W.D.; Rosenzweig, C.; Parshall, L.; Pope, G.; Clark, M.; Cox, J.; Wiencke, M. Mitigation of the heat island effect in urban New Jersey. Glob. Environ. Chang. B Environ. Hazards 2005, 6, 39–49. [Google Scholar] [CrossRef]

- Regents, A.B.O. Urban Climate—Climate Study and UHI via the Internet Wayback Machine; Arizona State University: Tempe, AZ, USA, 2006. [Google Scholar]

- Arnfield, A.J. Two decades of urban climate research: A review of turbulence, exchanges of energy and water, and the urban heat island. Int. J. Climatol. 2003, 23, 1–26. [Google Scholar] [CrossRef]

- Kurn, D.; Bretz, S.; Huang, B.; Akbari, H. The Potential for Reducting Urban Air Temperatures and Energy Consumption through Vegetative cooling. In ACEEE Summer Study on Energy Efficiency in Buildings; American Council for an Energy Efficient Economy: Pacific Grove, CA, USA, 1994. [Google Scholar]

- McPherson, E.G.; Simpson, J.R.; Peper, P.J.; Maco, S.E.; Xiao, Q. Municipal forest benefits and costs in five US cities. J. For. 2005, 103, 411–416. [Google Scholar]

- Torring, M. Management of concrete demolition waste. In Concrete Technology for a Sustainable Development in the 21st Century; CRC Press: Boca Raton, FL, USA, 2000; pp. 321–331. [Google Scholar]

- Meijer, E.; Kromhout, H.; Heederik, D. Respiratory effects of exposure to low levels of concrete dust containing crystalline silica. Am. J. Ind. Med. 2001, 40, 133–140. [Google Scholar] [CrossRef] [PubMed]

- Gotoh, T.; Nishimura, T.; Nakata, M.; Nakaguchi, Y.; Hiraki, K. Air Pollution by Concrete Dust from the Great Hanshin Earthquake. J. Environ. Qual. 2002, 31, 718–723. [Google Scholar] [CrossRef] [PubMed]

- Basu, D.; Misra, A. Sustainability in Geotechnical Engineering. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013.

- Barrett, R.J. Use of Plastic Filters in Coastal Structures. In Proceedings of the 16th International Conference on Coastal Engineers, Tokyo, Japan, September 1966; pp. 1048–1067.

- Ward, I.M. The Orientation of Polymers to Produce high Performance Materials. In Proceedings of the Symposium on Polymer Grid Reinforcement in Civil Engineering, London, UK, 22–23 March 1984.

- Eith, A.W.; Koerner, R.M. Field Evaluation of GEonet Flow Rate (Transmissivity) Under Increasing Load. J. Geotext. Geomembr. 1992, 11, 153–166. [Google Scholar] [CrossRef]

- Narjary, B.; Aggarwal, P.; Singh, A.; Chakraborty, D.; Singh, R. Water availability in different soils in relation to hydrogel application. Geoderma 2012, 187–188, 94–101. [Google Scholar] [CrossRef]

- Kulicke, W.M.; Kniewske, R.; Klein, J. Preparation, characterization, solution properties and rheological behaviour of polyacrylamide. Prog. Polym. Sci. 1982, 8, 373–468. [Google Scholar] [CrossRef]

- Malik, M.; Letey, J. Adsorption of Polyacrylamide and Polysaccharide Polymers on Soil Materials. Soil Sci. Soc. Am. J. 1991, 55, 380–383. [Google Scholar] [CrossRef]

- Laird, D.A. Bonding Between Polyacrylamide and Clay Mineral Surfaces. Soil Sci. 1997, 162, 826–832. [Google Scholar] [CrossRef]

- Fox, D.; Bryan, R.B. Influence of a polyacrylamide soil conditioner on runoff generation and soil erosion: Field tests in Baringo District, Kenya. Soil Technol. 1992, 5, 101–119. [Google Scholar] [CrossRef]

- Orts, W.J.; Roa-Espinosa, A.; Sojka, R.E.; Glenn, G.M.; Imam, S.H.; Erlacher, K.; Pedersen, J.S. Use of synthetic polymers and biopolymers for soil stabilization in agricultural, construction, and military applications. J. Mater. Civ. Eng. 2007, 19, 58–66. [Google Scholar] [CrossRef]

- Karol, R.H. Chemical Grouting and Soil Stabilization, 3rd ed.; CRC Press: New York, NY, USA, 2003. [Google Scholar]

- Burnotte, F.; Lefebvre, G.; Grondin, G. A case record of electroosmotic consolidation of soft clay with improved soilelectrode contact. Can. Geotech. J. 2004, 41, 1038–1053. [Google Scholar] [CrossRef]

- Lefebvre, G.; Burnotte, F. Improvements of electroosmotic consolidation of soft clays by minimizing power loss at electrodes. Can. Geotech. J. 2002, 39, 399–408. [Google Scholar] [CrossRef]

- Ou, C.Y.; Chien, S.C.; Chang, H.H. Soil improvement using electroosmosis with the injection of chemical solutions: Field tests. Can. Geotech. J. 2009, 46, 727–733. [Google Scholar] [CrossRef]

- Duxon, P.; Jimenez, A.F.; Provis, J.L.; Lukey, G.C.; Palomo, A.; Deventer, J.S.J.V. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Kim, D.; Lai, H.T.; Chilingar, G.V.; Yen, T.F. Geopolymer formation and its unique properties. Environ. Geol. 2006, 51, 103–111. [Google Scholar] [CrossRef]

- Hench, L.L. Sol-Gel Silica. Properties, Processing and Technology Transfer; Noyes Publications: Park Ridge, NJ, USA, 1998. [Google Scholar]

- Rovnaník, P. Effect of curing temperature on the development of hard structure of metakaolin-based geopolymer. Constr. Build. Mater. 2010, 24, 1176–1183. [Google Scholar] [CrossRef]

- Van Jaarsveld, J.G.S.; van Deventer, J.S.J.; Lukey, G.C. The effect of composition and temperature on the properties of fly ash- and kaolinite-based geopolymers. Chem. Eng. J. 2002, 89, 63–73. [Google Scholar] [CrossRef]

- Bakharev, T. Resistance of geopolymer materials to acid attack. Cem. Concr. Rese. 2005, 35, 658–670. [Google Scholar] [CrossRef]

- Sigel, A.; Sigel, H.; Sigel, R.K.O. Biomineralization: From Nature to Application; Wiley: Hoboken, NJ, USA, 2008; Volume 4. [Google Scholar]

- Lear, G.; Lewis, G.D. Microbial Biofilms: Current Research and Applications; Caister Academic Press: Norwich, UK, 2012. [Google Scholar]

- DeJong, J.; Fritzges, M.; Nüsslein, K. Microbially Induced Cementation to Control Sand Response to Undrained Shear. J. Geotech. Geoenviron. Eng. 2006, 132, 1381–1392. [Google Scholar]

- Whiffin, V.S.; van Paassen, L.A.; Harkes, M.P. Microbial Carbonate Precipitation as a Soil Improvement Technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- Stockes-Fischer, S.; Galinat, J.K.; Ban, S.S. Microbiological precipitation of CaCO3. Soil Biol. Biochem. 1999, 31, 1563–1571. [Google Scholar] [CrossRef]

- Fujita, Y.; Ferris, F.G.; Lawson, R.D.; Colwell, F.S.; Smith, R.W. Calcium Carbonate Precipitation by Ureolytic Subsurface Bacteria. Geomicrobiol. J. 2000, 17, 305–318. [Google Scholar] [CrossRef]

- Mortensen, B.M.; Haber, M.J.; DeJong, J.T.; Caslake, L.G.; Nelson, D.C. Effects of environmental factors on microbial induced calcium carbonate precipitation. J. Appl. Microbiol. 2011, 111, 338–349. [Google Scholar] [CrossRef] [PubMed]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Neupane, D.; Yasuhara, H.; Kinoshita, N.; Unno, T. Applicability of Enzymatic Calcium Carbonate Precipitation as a Soil-Strengthening Technique. J. Geotech. Geoenviron. Eng. 2013, 139, 2201–2211. [Google Scholar] [CrossRef]

- Fujita, Y.; Taylor, J.L.; Gresham, T.L.; Delwiche, M.E.; Colwell, F.S.; Mcling, T.L.; Mcling, L.M.; Petzke, L.M.; Smith, R.W. Stimulation of microbial urea hydrolysis in groundwater to enhance calcite precipitation. Environ. Sci. Technol. 2008, 42, 3025–3032. [Google Scholar] [CrossRef] [PubMed]

- Renforth, R.; Manning, D.A.C.; Lopez-Capel, E. Carbonate precipitation in artificial soils as a sink for atmospheric carbon dioxide. Appl. Geochem. 2009, 24, 1757–1764. [Google Scholar] [CrossRef]

- Ramakrishnan, V.; Bang, S.S.; Deo, K.S. A novel technique for repairing cracks in high performance concrete using bacteria. In Proceedings of the International Conference on High Performance High Strength Concrete, Perth, Australia, 10–12 August 1998; Curtin University of Technology: Perth, Australia, 1998; pp. 597–618. [Google Scholar]

- Ramachandran, S.K.; Ramakrishnan, V.; Band, S.S. Remediation of concrete using micro-organisms. ACI Mater. J. 2001, 98, 3–9. [Google Scholar]

- Rong, H.; Qian, C.; Wang, R. A cementation method of loose particles based on microbe-based cement. Sci. China Technol. Sci. 2011, 54, 1722–1729. [Google Scholar] [CrossRef]

- Yasuhara, H.; Neupane, D.; Hayashi, K.; Okamura, M. Experiments and predictions of physical properties of sand cemented by enzymatically-induced carbonate precipitation. Soils Found. 2012, 52, 539–549. [Google Scholar] [CrossRef]

- Pham, V.; Paassen, L.V.; Nakano, A.; Kanayama, M.; Heimovaara, T. Microbially induced carbonate precipitation (MICP) by denitrification as ground improvement method—Process control in sand column experiments. In Paper presented at the EGU General Assembly 2013, Vienna, Austria, 7–12 April 2013.

- FuWei, Y.; BingJian, Z.; ChangChu, P.; YuYao, Z. Traditional mortar represented by sticky rice lime mortar—One of the great inventions in ancient China. Sci. China Ser. E Technol. Sci. 2009, 52, 1641–1647. [Google Scholar]

- US National Library of Medicine. Medical Subject Headings (Polynucleotides). Available online: http://www.nlm.nih.gov/mesh/2011/mesh_browser/MBrowser.html (accessed on 31 August 2011).

- Kalia, S.; Averous, L. Biopolymers: Biomedical and Environmental Applications; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Belitz, H.D.; Grosch, W.; Schieberle, P. Food Chemistry, 4th revised and extended edition ed.; Springer: Leipzig, Germany, 2009. [Google Scholar]

- Saha, D.; Bhattacharya, S. Hydrocolloids as thickening and gelling agents in food: A critical review. J. Food Sci. Technol. 2010, 47, 587–597. [Google Scholar] [CrossRef] [PubMed]

- Lorenzo, G.; Zaritzky, N.; Califano, A. Rheological analysis of emulsion-filled gels based on high acyl gellan gum. Food Hydrocoll. 2012, 30, 672–680. [Google Scholar] [CrossRef]

- Velde, K.V.D.; Kiekens, P. Biopolymers: Overview of several properties and consequences on their applications. Polym. Test. 2002, 21, 433–442. [Google Scholar] [CrossRef]

- Cole, D.; Ringelberg, D.; Reynolds, C. Small-scale mechanical properties of biopolymers. J. Geotech. Geoenviron. Eng. 2012, 138, 1063–1074. [Google Scholar] [CrossRef]

- De Muynck, W.; de Belie, N.; Verstraete, W. Microbial carbonate precipitation in construction materials: A review. Ecol. Eng. 2010, 36, 118–136. [Google Scholar] [CrossRef]

- Adibkia, K.; MR, S.S.; Nokhodchi, A.; Javadzedeh, A.; Barzegar-Jalali, M.; Barar, J.; Mohammadi, G.; Omidi, Y. Piroxicam nanoparticles for ocular delivery: Physicochemical characterization and implementation in endotoxin-induced uveitis. J. Drug Target. 2007, 15, 407–416. [Google Scholar] [CrossRef] [PubMed]

- Barrére, G.C.; Barber, C.E.; Daniels, M.J. Molecular cloning of genes involved in the production of the extracellular polysaccharide xanthan by Xanthomonas campestris pv. campestris. Int. J. Biol. Macromol. 1986, 8, 372–374. [Google Scholar] [CrossRef]

- Chang, Y.J.; Lee, S.; Yoo, M.A.; Lee, H.G. Structural and biological characterization of sulfated-derivatized oat β-glucan. J. Agric. Food Chem. 2006, 54, 3815–3818. [Google Scholar] [CrossRef] [PubMed]

- Daniel, J.; Whistler, R.L.; Voragen, A.C.J.; Pilnik, W. Starch and other polysaccharides. In Ullmann's Encyclopedia of Industrial Chemistry; VCH Verlagsgesellschaft mbH: Weinheim, Germany, 1994; Volume A25. [Google Scholar]

- Harada, T.; Misaki, A.; Saito, H. Curdlan: A bacterial gel-forming β-1, 3-glucan. Arch. Biochem. Biophys. 1968, 124, 292–298. [Google Scholar] [CrossRef]

- Hassan, H.; Al-Oraimi, S.; Taha, R. Evaluation of open-graded friction course mixtures containing cellulose fibers and styrene butadiene rubber polymer. J. Mater. Civ. Eng. 2005, 17, 416–422. [Google Scholar] [CrossRef]

- Wan, M.W.; Petrisor, I.G.; Lai, H.T.; Kim, D.; Yen, T.F. Copper adsorption through chitosan immobilized on sand to demonstrate the feasibility for in situ soil decontamination. Carbohydr. Polym. 2004, 55, 249–254. [Google Scholar] [CrossRef]

- Fahnestock, K.J.; Austero, M.S.; Schauer, C.L. Natural Polysaccharides: From Membranes to Active Food Packaging. In Biopolymers: Biomedical and Environmental Applications; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Maher, M.; Ho, Y. Mechanical Properties of Kaolinite/Fiber Soil Composite. J. Geotech. Eng. 1994, 120, 1381–1393. [Google Scholar] [CrossRef]

- Sivakumar Babu, G.; Vasudevan, A. Strength and Stiffness Response of Coir Fiber-Reinforced Tropical Soil. J. Mater. Civ. Eng. 2008, 20, 571–577. [Google Scholar] [CrossRef]

- Annabi, M.; Houot, S.; Francou, C.; Poitrenaud, M.; Bissonnais, Y.L. Soil Aggregate Stability Improvement with Urban Composts of Different Maturities. Soil Sci. Soc. Am. J. 2007, 71, 413–423. [Google Scholar] [CrossRef]

- Zobel, H.F. Molecules to granules: A comprehensive starch review. Starch 1988, 40, 1. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. FAO Statistical Yearbook 2009; FAO Economic and Social Development Department, Ed.; FAO: Rome, Italy, 2009. [Google Scholar]

- Francis, H.P.; DeBoer, E.D.; Wermers, V.L. High Temperature Drilling Fluid Component. U.S. Patent 4,652,384, 24 March 1987. [Google Scholar]

- Jose, A.; Carvalho, F. Starch as Source of Polymeric Materials. In Biopolymers: Biomedical and Environmental Applications; Wiley: Salem, MA, USA, 2011. [Google Scholar]

- Sahoo, D.; Nayak, P.L. Chitosan: The Most Valuable Derivative of Chitin. In Biopolymers: Biomedical and Environmental Applications; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Nascimento, T.; Rego, C.; Oliveira, H. Potential use of chitosan in the control of grapevine trunk diseases. Phytopathol. Mediterr. 2007, 46, 218–224. [Google Scholar]

- Cheung, W.H.; Ng, J.C.Y.; McKay, G. Kinetic analysis of the sorption of copper(II) ions on chitosan. J. Chem. Technol. Biotechnol. 2003, 78, 562–571. [Google Scholar] [CrossRef]

- Renault, F.; Sancey, B.; Badot, P.M.; Crini, G. Chitosan for coagulation/flocculation processes—An eco-friendly approach. Eur. Polym. J. 2009, 45, 1337–1348. [Google Scholar] [CrossRef]

- Khachatoorian, R.; Petrisor, I.G.; Kwan, C.C.; Yen, T.F. Biopolymer plugging effect: Laboratory-pressurized pumping flow studies. J. Petroleum Sci. Eng. 2003, 38, 13–21. [Google Scholar] [CrossRef]

- McIntosh, M.; Ston, B.A.; Stanisich, V.A. Curdlan and other bacterial (1→3)-[beta]-d-glucans. Appl. Microbiol. Biotechnol. 2005, 68, 163–173. [Google Scholar] [CrossRef] [PubMed]

- Ivanov, V.; Chu, J. Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev. Environ. Sci. Biotechnol. 2008, 7, 139–153. [Google Scholar] [CrossRef]

- Bacic, A.; Fincher, G.B.; Stone, B.A. Chemistry Biochemistry and Biology of (1–3)-[beta]-glucans and Related Polysaccharides, 1st ed.; Academic Press: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Chang, I.; Cho, G.C. Strengthening of Korean residual soil with β-1,3/1,6-glucan biopolymer. Constr. Build. Mater. 2012, 30, 30–35. [Google Scholar] [CrossRef]

- Chang, I.; Cho, G.C. Geotechnical behavior of a beta-1,3/1,6-glucan biopolymer-treated residual soil. Geomech. Eng. 2014, 7, 633–647. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Shin, H.D.; Cho, G.C. Soil treatment using microbial biopolymers for anti-desertification purposes. Geoderma 2015, 253–254, 39–47. [Google Scholar] [CrossRef]

- Bouazza, A.; Gates, W.P.; Ranhith, P.G. Hydraulic conductivity of biopolymer-treated silty sand. Geotechnique 2009, 59, 71–72. [Google Scholar] [CrossRef]

- Nugent, R.A.; Zhang, G.; Gambrell, R.P. Effect of exopolymers on the liquid limit of clays and its engineering implications. Transp. Res. Rec. J. Transp. Res. Board 2009, 2101, 34–43. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- McHugh, D.J. A Guide to the Seaweed Industry; Food and Agriculture Organization of The United Nations: Rome, Italy, 2003. [Google Scholar]

- Khatami, H.; O’Kelly, B. Improving mechanical properties of sand using biopolymers. J. Geotech. Geoenviron. Eng. 2012, 139, 1402–1406. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Cho, G.C. Soil strengthening using thermo-gelation biopolymers. Constr. Build. Mater. 2015, 77, 430–438. [Google Scholar] [CrossRef]

- Imeson, A. Food Stabilisers, Thickeners and Gelling Agents; Wiley-Blackwell Publishing: Chichester, UK, 2009; p. 368. [Google Scholar]

- Huang, M.; Kennedy, J.F.; Li, B.; Xu, X.; Xie, B.J. Characters of rice starch gel modified by gellan, carrageenan, and glucomannan: A texture profile analysis study. Carbohydr. Polym. 2007, 69, 411–418. [Google Scholar] [CrossRef]

- Tang, J.; Tung, M.A.; Zeng, Y. Gelling Properties of Gellan Solutions Containing Monovalent and Divalent Cations. J. Food Sci. 1997, 62, 688–692. [Google Scholar] [CrossRef]

- Ferruzzi, G.G.; Pan, N.; Casey, W.H. Mechanical properties of gellan and polyacrlamide gels with implications for soil stabilization. Soil Sci. 2000, 165, 778–792. [Google Scholar] [CrossRef]

- Chang, C.; Duan, B.; Cai, J.; Zhang, L. Superabsorbent hydrogels based on cellulose for smart swelling and controllable delivery. Eur. Polym. J. 2010, 46, 92–100. [Google Scholar] [CrossRef]

- Bueno, V.B.; Bentini, R.; Catalani, L.H.; Petri, D.F.S. Synthesis and swelling behavior of xanthan-based hydrogels. Carbohydr. Polym. 2013, 92, 1091–1099. [Google Scholar] [CrossRef] [PubMed]

- Yakimets, I.; Paes, S.S.; Wellner, N.; Smith, A.C.; Wilson, R.H.; Mitchell, J.R. Effect of Water Content on the Structural Reorganization and Elastic Properties of Biopolymer Films: A Comparative Study. Biomacromolecules 2007, 8, 1710–1722. [Google Scholar] [CrossRef] [PubMed]

- Davidovits, J. Geopolymer Chemistry and Applications; Geopolymer Institute: Saint-Quentin, France, 2008; p. 585. [Google Scholar]

- DeJong, J.T.; Fritzges, M.B.; Nusslein, K. Microbially Induced Cementation to Control Sand Response to Undrained Shear. J. Geotech. Geoenviron. Eng. 2006, 132, 1381–1392. [Google Scholar] [CrossRef]

- Koerner, R.M. Designing With Geosynthetics, 6th ed.; Xlibris Publishers: Dartford, UK, 2012; p. 914. [Google Scholar]

- Oh, J.E.; Monteiro, P.J.M.; Jun, S.S.; Choi, S.; Clark, S.M. The evolution of strength and crystalline phases for alkali-activated ground blast furnace slag and fly ash-based geopolymers. Cem. Concr. Res. 2010, 40, 189–196. [Google Scholar] [CrossRef]

- Niaounakis, M. Biopolymers: Reuse, Recycling, And Disposal, 1st ed.; Elsevier/WA: Oxford, UK; Waltham, MA, USA, 2013; p. 432. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from Renewable Resources: Opportunities and Challenges in the Green Materials World. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Krishna Leela, J.; Sharma, G. Studies on xanthan production from Xanthomonas campestris. Bioprocess Eng. 2000, 23, 687–689. [Google Scholar] [CrossRef]

- Guerrero-Lemus, R.; Martinez-Duart, J.M. Renewable energies and CO₂: Cost Analysis, Environmental Impacts and Technological Trends, 2012 ed.; Springer: London, UK; New York, NY, USA, 2013; p. 373. [Google Scholar]

- Minke, G. Building with earth-30 years of research and development at the University of Kassel. In Proceedings of the International Symposium on Earthen Structures, Bangalore, Bangalore, India, 22–24 August 2007; Interline Publishing: Karnataka, India, 2007. [Google Scholar]

- Mark, J.E.; Erman, B.; Eirich, F.R. Science and Technology of Rubber; Academic Press: San Diego, CA, USA, 1994. [Google Scholar]

- Gong, J.P.; Katsuyama, Y.; Kurokawa, T.; Osada, Y. Double-Network Hydrogels with Extremely High Mechanical Strength. Adv. Mater. 2003, 15, 1155–1158. [Google Scholar] [CrossRef]

- Nakayama, A.; Kakugo, A.; Gong, J.P.; Osada, Y.; Takai, M.; Erata, T.; Kawano, S. High Mechanical Strength Double-Network Hydrogel with Bacterial Cellulose. Adv. Funct. Mater. 2004, 14, 1124–1128. [Google Scholar] [CrossRef]

| Biopolymer | Composition | Characteristics |

|---|---|---|

| Cellulose | β-(1 → 4)-d-glucose linkages | - Hydrophilic |

| - Properties depend on the chain length | ||

| Starch | d-glucose residues linked by α-(1, 4) glucosidic bonds | - Soluble in heated water |

| - Viscous, gelatinization | ||

| Chitosan | P-(1,4)-2-amino-2-deoxy-d-glucose | - Soluble in acidic solvents |

| - Bioadhesive for (-) charged surfaces | ||

| - Biodegradable | ||

| Xanthan | C35H49O29 | - High viscous rheology |

| Curdlan | (C6H10O5)n | - Gel formation via heating in aqueous solutions |

| Beta-Glucan | d-glucose monomers linked by β-glycosidic bonds | - Capable of immune activation in humans |

| - Cholesterol absorption capabilities | ||

| Polyacrylamide | (C3H5NO)n | - Water absorbent, gel formation |

| - Thickener |

| Properties | Cement | Chemicals | Geosynthetics | Geopolymer | MICP | Biopolymer |

|---|---|---|---|---|---|---|

| Soil Competitiveness | Course grained soils Fine grained soils | Course grained soils | Course grained soils | Course grained soils Fine grained soils | Course grained soils | Course grained to Fine grained soils |

| Method/Construction | Deep mixing, injection, grouting, direct mixing spray | Injection, grouting, spray | In-situ installation | Deep mixing, injection grouting, direct mixing Spray | Direct microbe and nutrient injection in to ground | Direct mixing, injection, spraying exo-cultivated biopolymers |

| Main Materials | Cement Water | Chemically synthesized polymers | Various synthesized materials | Pozzolanic materials, water, cement | Micro-organisms urea, starch | Biopolymers, water |

| Major Reactions | Hydration | Solidification, chemical bonding | Tensile reinforcement | Pozzolanic reactions | Biological calcite precipitation | Hydrogen-/ionic- bonding, gelation |

| Advantages | Strong, durable Numerous case studies | Strong, durable Quick isolation Numerous case studies | Quick, Easy to use | Strong, durable Good waste sink Lower carbon footprint than cement | No carbon footprint Possible use with material remediation | Environment-friendly Smaller concentrations Stronger in fine soils |

| Disadvantages/ Challenges | Large carbon footprint Disruption of local ecosystem. Disposal Problems | High price Environmental impacts. Washout and durability problems | Heterogeneous method Use limited to shallow depths | Similar environmental problems as cement | Ammonia byproduct Limitations in fine soils | High price High sensitivity (hydrophilic) to presence of water |

| Compressive Strength (MPa) (average) | 2 a | 0.8 (acrylic polymer-treated sand) | - | 10 c | 1.8 (shear strength) d | 4.3 f |

| Price for Soil Treatment (average) | 45.5 USD/ton a | 200 USD/ton b | 2 USD/m2 | 30 USD/ton c | 90 USD e | 28 g – 250 f USD/ton |

| Soil Treatment Material | Cement | Xanthan Gum |

|---|---|---|

| Market price of material | 98.5 USD/ton a | 2,700 USD/ton b |

| Required amount for 1 ton soil treatment (≥ 2.5 MPa) | 100 kg (10% to soil 1 ton) | 5 kg (0.5% to soil 1 ton) |

| Material price for 1 ton soil treatment | 9.85 USD | 13.50 USD |

| CO2 emission per 1 kg material production (kg CO2) | +1.25 | −4.97 |

| CO2 emission related to 1 ton soil treatment (kg CO2) | +125 | −24.85 |

| CO2 emission trade related to 1 ton soil treatment c | +2.75 USD | −0.55 USD |

| Total cost for 1 ton soil treatment (with carbon trade exchange considerations) | 12.50 USD | 12.95 USD |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, I.; Im, J.; Cho, G.-C. Introduction of Microbial Biopolymers in Soil Treatment for Future Environmentally-Friendly and Sustainable Geotechnical Engineering. Sustainability 2016, 8, 251. https://doi.org/10.3390/su8030251

Chang I, Im J, Cho G-C. Introduction of Microbial Biopolymers in Soil Treatment for Future Environmentally-Friendly and Sustainable Geotechnical Engineering. Sustainability. 2016; 8(3):251. https://doi.org/10.3390/su8030251

Chicago/Turabian StyleChang, Ilhan, Jooyoung Im, and Gye-Chun Cho. 2016. "Introduction of Microbial Biopolymers in Soil Treatment for Future Environmentally-Friendly and Sustainable Geotechnical Engineering" Sustainability 8, no. 3: 251. https://doi.org/10.3390/su8030251