Experimental and Analytical Studies on the Utilization of Biowastes Available in an Educational Institution in India

Abstract

:1. Introduction

2. Materials and Methods

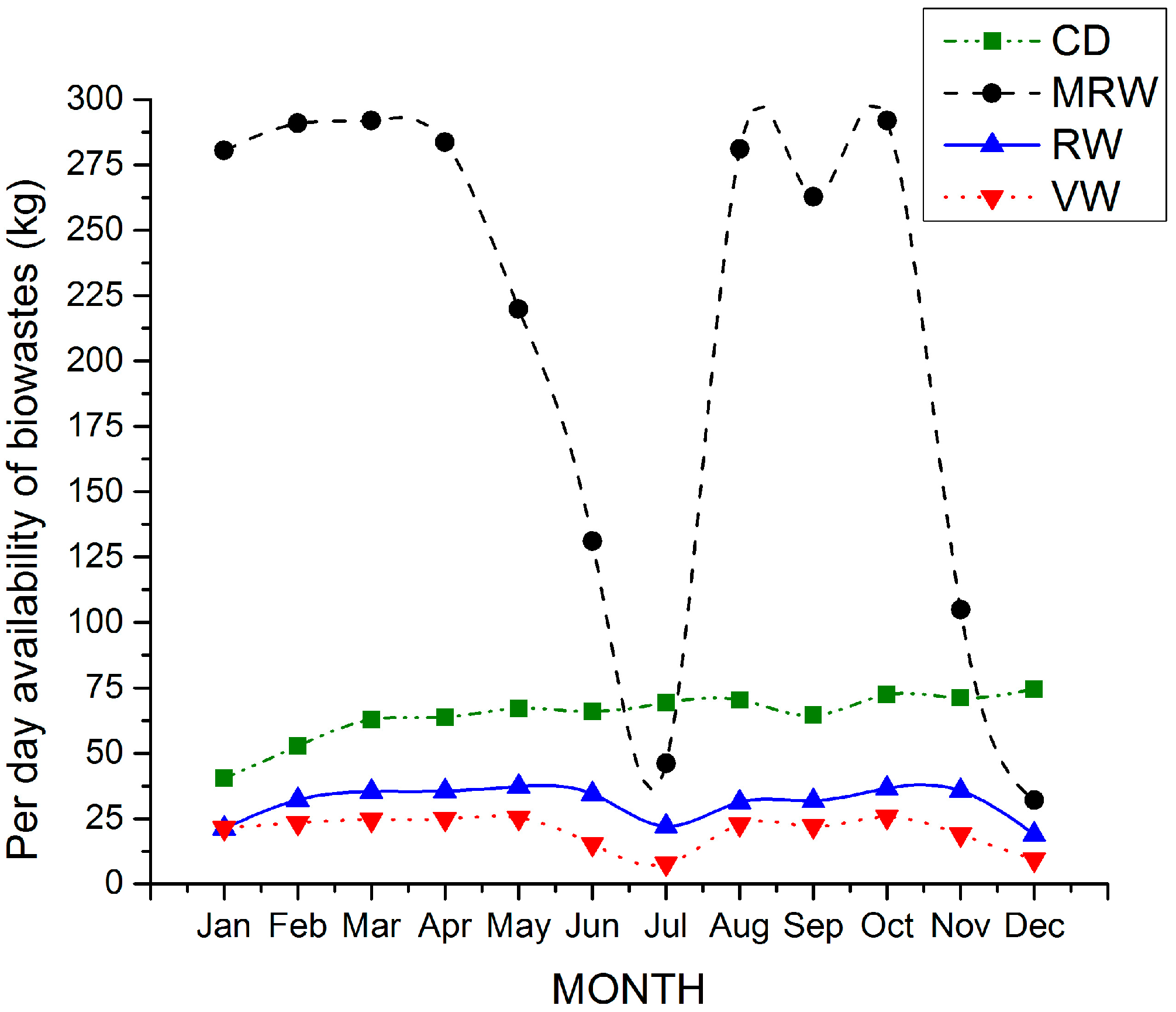

2.1. Identification and Characterization of Feedstock

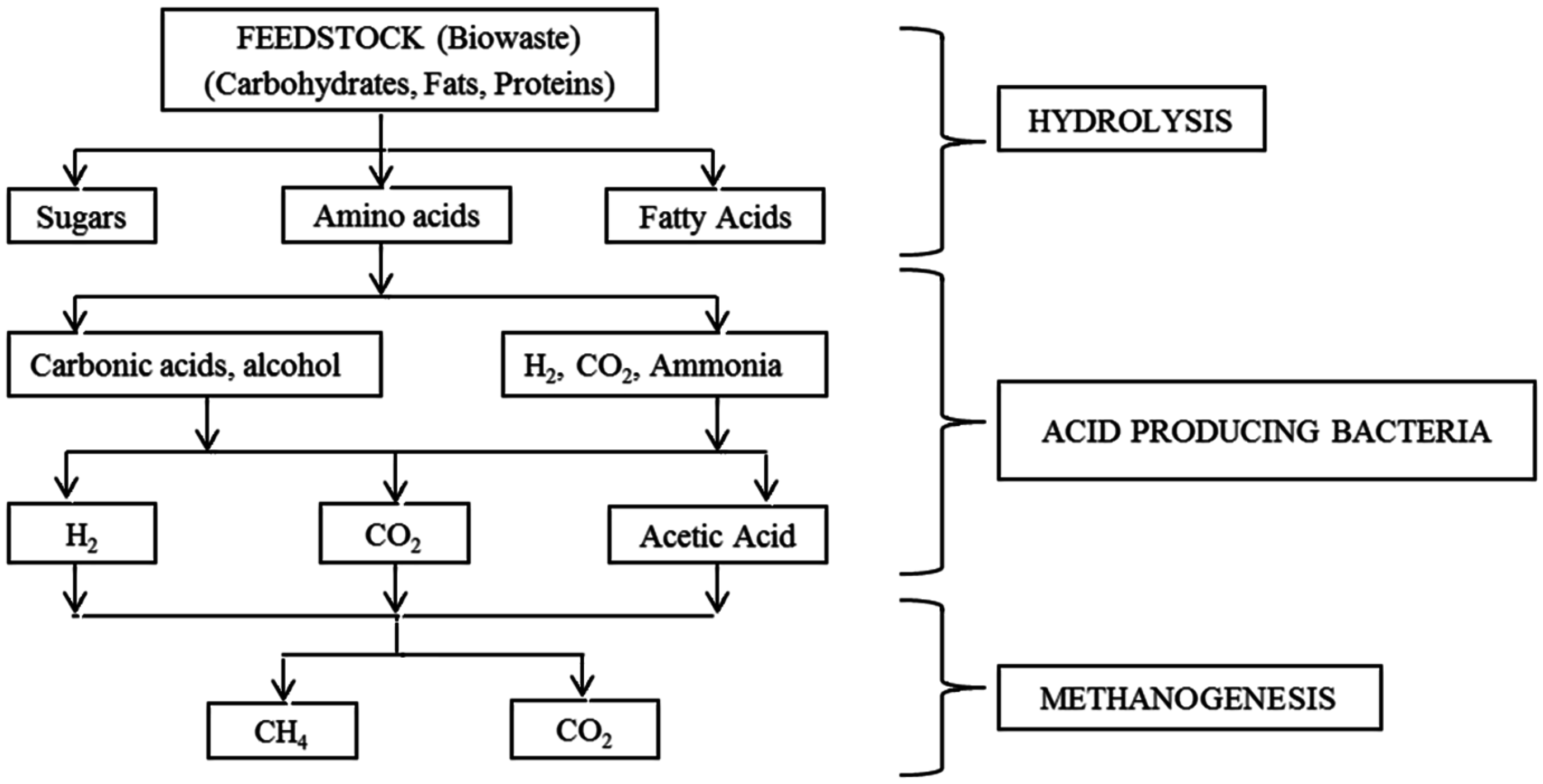

2.2. Simulation of the Anaerobic Digestion Process

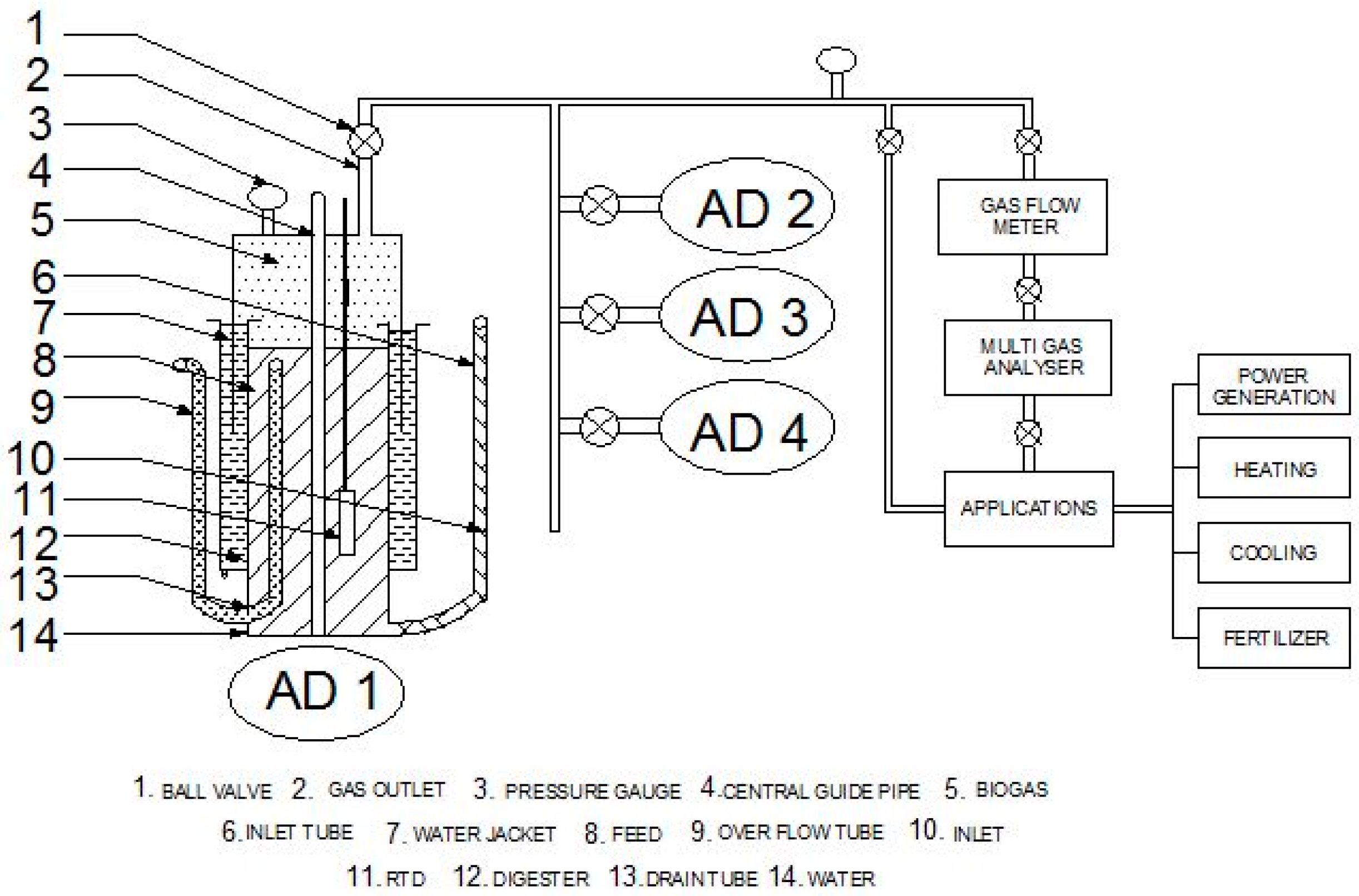

2.3. Experimental Setup

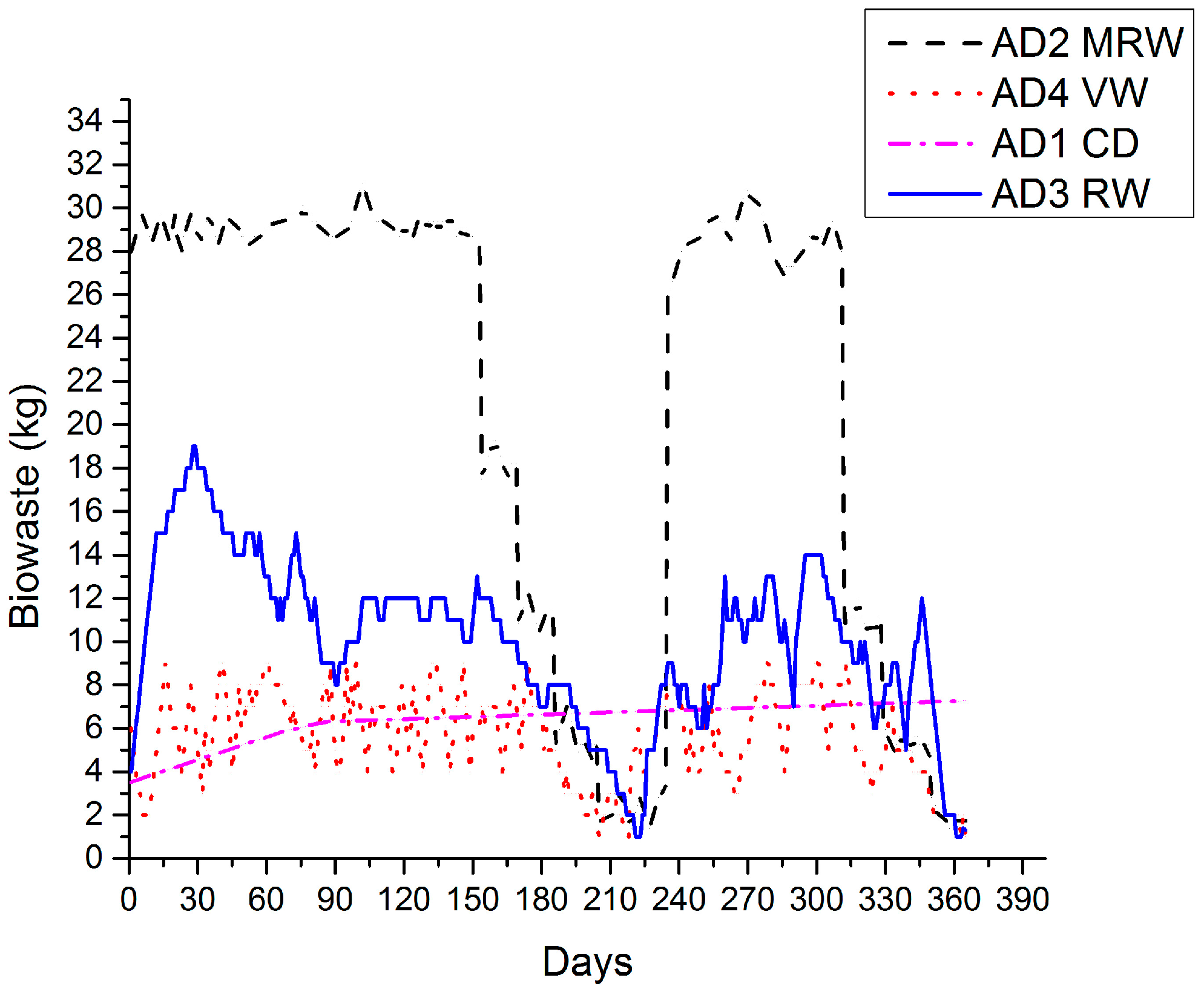

2.4. Experimental Procedure

3. Results and Discussion

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Ziana, Z.; Rajesh, P. Production and Analysis of Biogas from Kitchen Waste. Int. Res. J. Eng. Technol. 2015, 2, 622–632. [Google Scholar]

- Agrahari, R.P.; Tiwari, G.N. The Production of Biogas Using Kitchen Waste. Int. J. Energy Sci. 2013, 3, 408–413. [Google Scholar] [CrossRef]

- Gwavuya, S.G.; Abele, S.; Barfuss, I.; Zeller, M.; Müller, J. Household energy economics in rural Ethiopia: A cost-benefit analysis of biogas energy. Renew. Energy 2012, 48, 202–209. [Google Scholar] [CrossRef]

- Rajendran, K.; Aslanzadeh, S.; Johansson, F.; Taherzadeh, M.J. Experimental and economical evaluation of a novel biogas digester. Energy Convers. Manag. 2013, 74, 183–191. [Google Scholar] [CrossRef]

- Walekhwa, P.N.; Lars, D.; Mugisha, J. Economic viability of biogas energy production from family-sized digesters in Uganda. Biomass Bioenergy 2014, 70, 26–39. [Google Scholar] [CrossRef]

- Liu, Y.; Kuang, Y.; Huang, N.; Wu, Z.C.; Xu, L. Popularizing household-scale biogas digesters for rural sustainable energy development and greenhouse gas mitigation. Renew. Energy 2008, 33, 2027–2035. [Google Scholar]

- Antognoni, S.; Ragazzi, M.; Ionescu, G.; Passamani, G.; Zanoni, S.; Rada, E.C.; Torretta, V. Respirometric index as a tool for biogas generation production from poultry manure. Manag. Environ. Qual. 2016, 27, 269–280. [Google Scholar] [CrossRef]

- García, J.; Davies, S.; Villa, R.; Gomes, D.M.; Coulon, F.; Wagland, S.T. Compositional analysis of excavated landfill samples and the determination of residual biogas potential of the organic fraction. Waste Manag. 2016, 55, 336–344. [Google Scholar] [CrossRef] [PubMed]

- Moedinger, F.; Ast, F.; Ragazzi, M.; Foldori, P.; Rada, E.C.; Binnig, R. Innovative biogas multi-stage biogas plant and novel analytical system first project experiences. Energy Procedia 2012, 18, 672–680. [Google Scholar] [CrossRef]

- Irene, P.; Marianna, G.; Erasmo, C.; Ivet, F. Technical, economic and environmental assessment of household biogas digesters for rural communities. Renew. Energy 2014, 62, 313–318. [Google Scholar]

- Lemea, M.M.V.; Rochaa, M.H.; Loraa, E.E.S.; Venturinia, O.J.; Lopesb, B.M.; Ferreirab, C.H. Techno-economic analysis and environmental impact assessment of energy recovery from Municipal Solid Waste (MSW) in Brazil. Resour. Conserv. Recycl. 2014, 87, 8–20. [Google Scholar] [CrossRef]

- Torretta, V.; Ionescu, G.; Raboni, M.; Merler, G. The mass and energy balance of an integrated solution for municipal solid waste treatment. In WIT Transactions on Ecology and the Environment; WIT Press: Boston, MA, USA, 2014; Volume 180, pp. 151–161. [Google Scholar]

- Rada, E.C. Energy from municipal solid waste. In WIT Transactions on Ecology and the Environment; WIT Press: Boston, MA, USA, 2014; Volume 190, pp. 945–958. [Google Scholar]

- Consonni, S.; Giugliano, M.; Massarutto, A.; Ragazzi, M.; Saccani, C. Material and energy recovery in integrated waste management systems: Project overview and main results. Waste Manag. 2011, 31, 2057–2065. [Google Scholar] [CrossRef] [PubMed]

- Karthik, R.; Kankanala, H.R.; Martinsson, R.; Taherzadeh, M.J. Uncertainty over techno-economic potentials of biogas from municipal solid waste (MSW): A case study on an industrial process. Appl. Energy 2014, 125, 84–92. [Google Scholar]

- Wilkie, A.C.; Graunke, R.E.; Cornejo, C. Food Waste Auditing at Three Florida Schools. Sustainability 2015, 7, 1370–1387. [Google Scholar] [CrossRef]

- Galli, F.; Brunori, G.; Di Iacovo, F.; Innocenti, S. Co-Producing Sustainability: Involving Parents and Civil Society in the Governance of School Meal Services. A Case Study from Pisa, Italy. Sustainability 2014, 6, 1643–1666. [Google Scholar] [CrossRef]

- Rojas, A.; Valley, W.; Mansfield, B.; Orrego, E.; Chapman, G.E.; Harlap, Y. Toward Food System Sustainability through School Food System Change: Think&EatGreen@School and the Making of a Community-University Research Alliance. Sustainability 2011, 3, 763–788. [Google Scholar]

- Rada, E.C.; Bresciani, B.; Girelli, S.; Ragazzi, M.; Schiavon, M.; Torretta, V. Analysis and Measures to Improve Waste Management in Schools. Sustainability 2016, 8, 840. [Google Scholar] [CrossRef]

- Gaida, D.; Christian, W.; Michael, B.; Thomas, B. MATLAB Toolbox for Biogas Plant Modelling and Optimization; Computing Center: Gummersbach, Germany, 2011. [Google Scholar]

- American Public Health Association (APHA). Standard Methods for the Examination of Water and Wastewater, 19th ed.; APHA: Washington, DC, USA, 1995. [Google Scholar]

- Batstone, D.J.; Keller, J.; Angelidaki, I.; Kalyuzhnyi, S.V.; Pavlostathis, S.G.; Rozzi, A.; Sanders, W.T.M.; Siegrist, H.; Vavilin, V.A. The IWA Anaerobic Digestion Model No 1 (ADM1). Water Sci. Technol. 2002, 45, 65–73. [Google Scholar] [PubMed]

- Singh, R.; Malik, R.K.; Tauro, P. Anaerobic Digestion of cattle dung at Various retention times—A pilot plant study. Agric. Wastes 1985, 12, 313–316. [Google Scholar] [CrossRef]

- Abubaker, J.; Risberg, K.; Pell, M. Biogas residues as fertilisers—Effects on wheat growth and soil microbial activities. Appl. Energy 2012, 99, 126–134. [Google Scholar] [CrossRef]

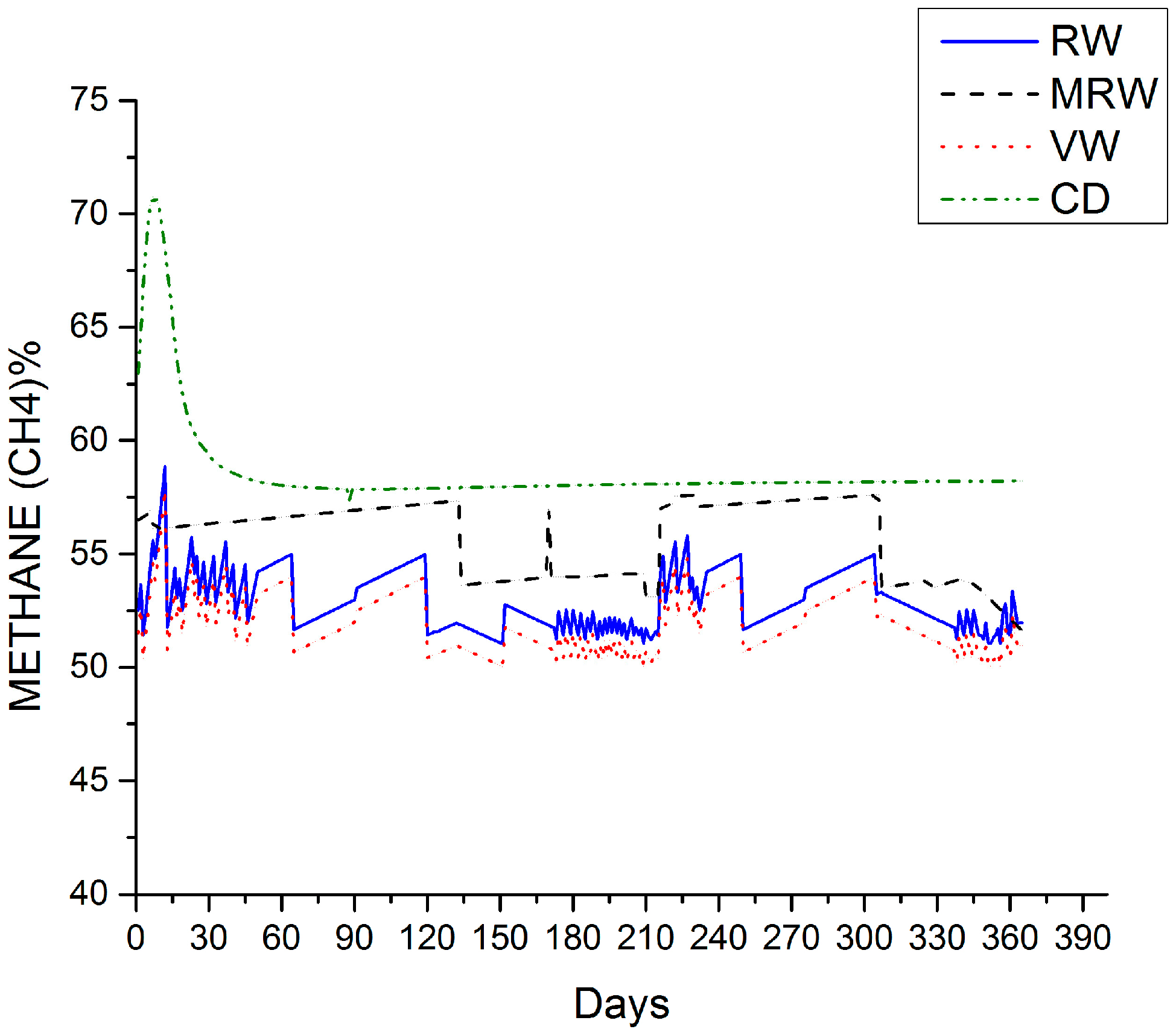

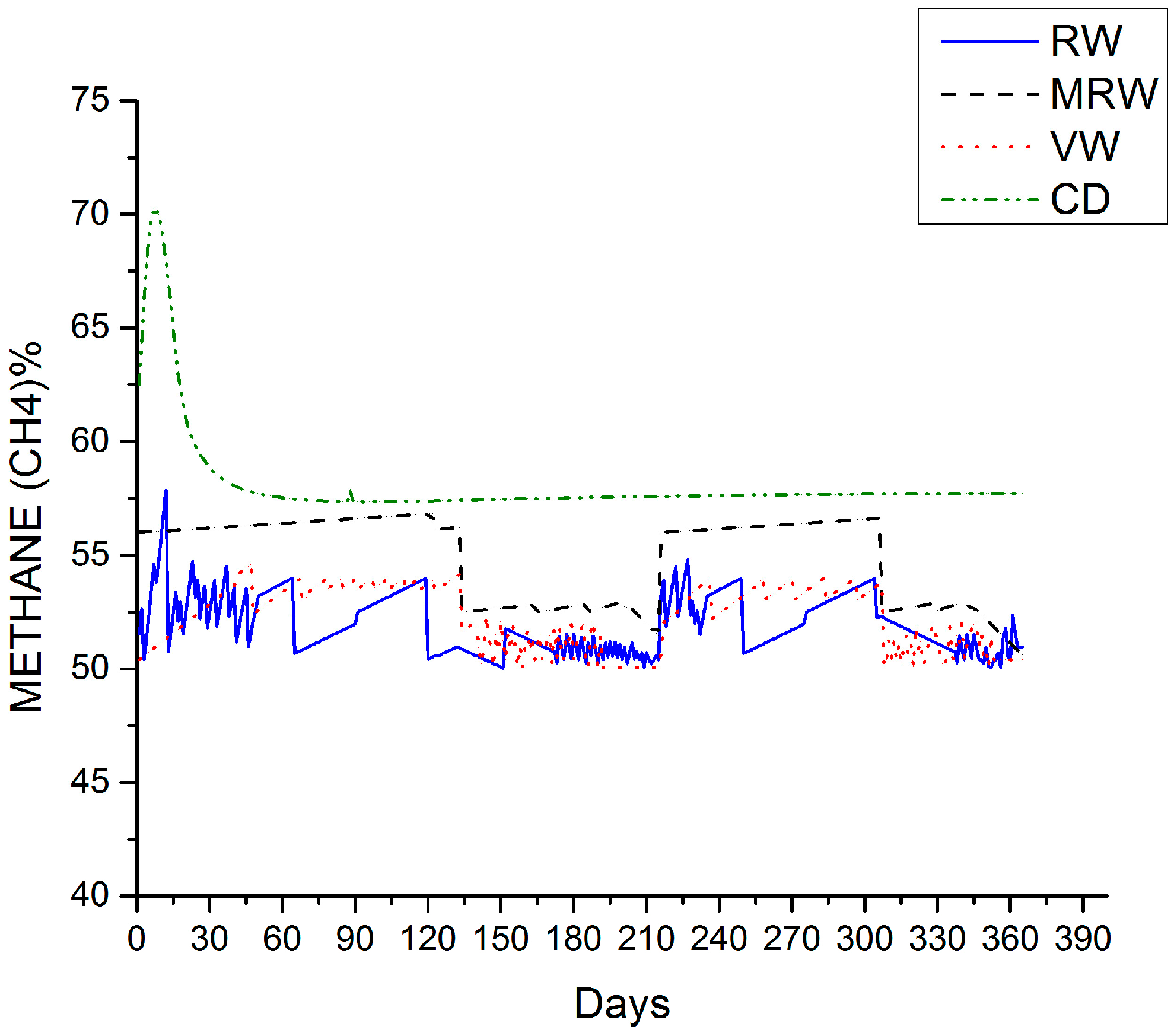

| Sl.No. | FEED | pH | TS | VS |

|---|---|---|---|---|

| % | % | |||

| 1 | Cow Dung (CD) | 6.50 | 15.98 | 64.99 |

| 2 | Mixed Rice Waste (MRW) | 4.91 | 20.25 | 90.15 |

| 3 | Rice Waste (RW) | 6.61 | 30.28 | 90.11 |

| 4 | Vegetable Waste (VW) | 6.35 | 10.55 | 90.45 |

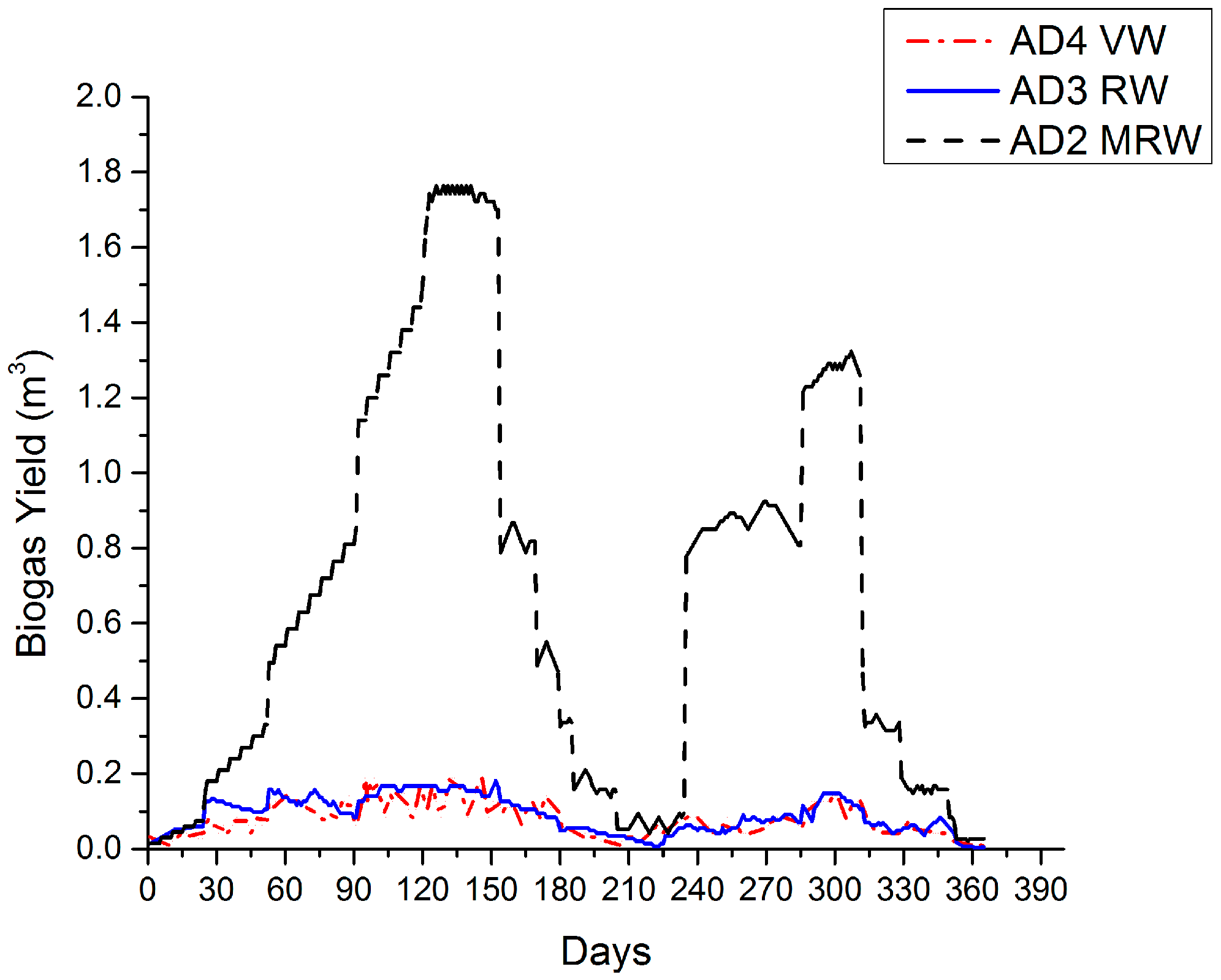

| Digester | Digester Size | Feedstock | Test Duration | Mixing Ratio |

|---|---|---|---|---|

| (Days) | (Feed + Water) | |||

| AD 1 | 1 m3 | Cow dung (CD) | 365 | 1:1 |

| AD 2 | 2 m3 | Mixed Rice Waste (MRW) | 365 | 1:1 |

| AD 3 | 0.25 m3 | Rice waste (RW) | 365 | 1:1 |

| AD 4 | 0.25 m3 | Vegetable waste (VW) | 365 | 1:1 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glivin, G.; Sekhar, S.J. Experimental and Analytical Studies on the Utilization of Biowastes Available in an Educational Institution in India. Sustainability 2016, 8, 1128. https://doi.org/10.3390/su8111128

Glivin G, Sekhar SJ. Experimental and Analytical Studies on the Utilization of Biowastes Available in an Educational Institution in India. Sustainability. 2016; 8(11):1128. https://doi.org/10.3390/su8111128

Chicago/Turabian StyleGlivin, Godwin, and S. Joseph Sekhar. 2016. "Experimental and Analytical Studies on the Utilization of Biowastes Available in an Educational Institution in India" Sustainability 8, no. 11: 1128. https://doi.org/10.3390/su8111128