Release of Heavy Metals from the Pyrite Tailings of Huangjiagou Pyrite Mine: Batch Experiments

Abstract

:1. Introduction

2. Materials and Methods

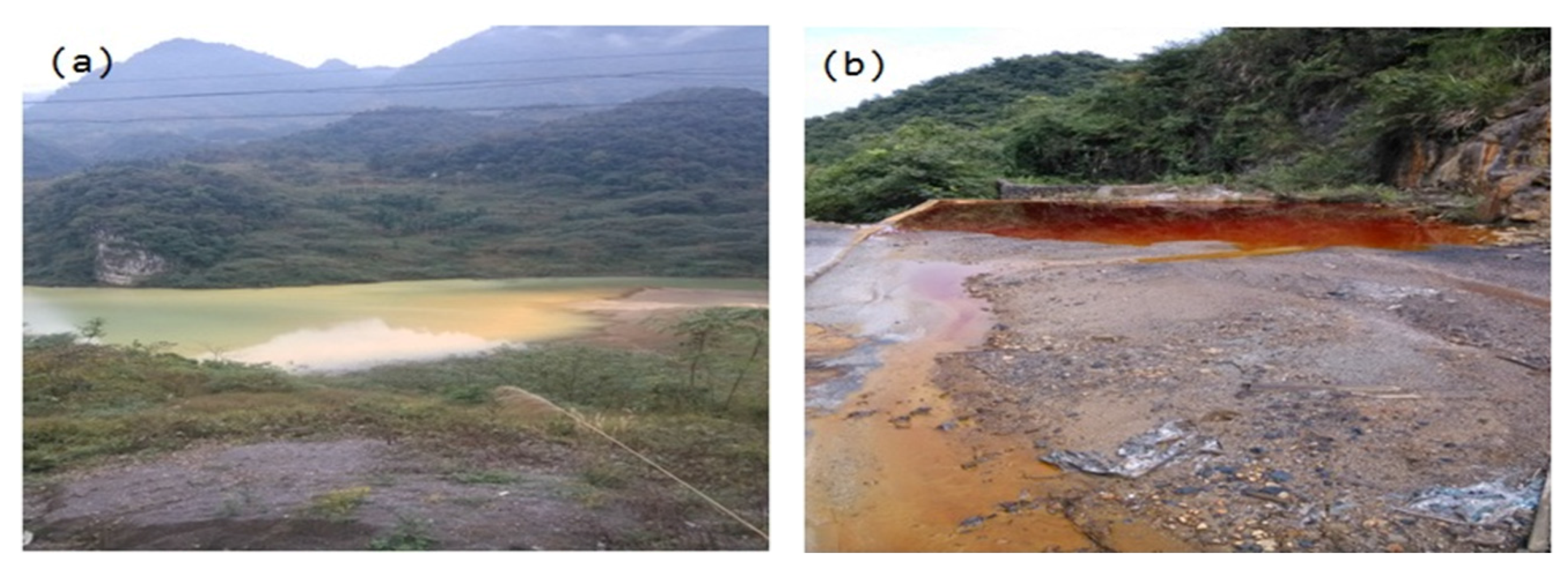

2.1. Study Area Description and Samples Collection

2.2. Batch Experiments

| Experiment Name | Liquid Extractant (L) | Initial pH of Extractant | Temperature (°C) | LS Ratio (L·kg−1) | Soaking Time (h) |

|---|---|---|---|---|---|

| Initial pH | 0.05 | 2.00, 3.00, 4.00, 5.00, 6.00, 7.00 | 25 | 20 | 8 |

| Temperature | 0.05 | 2.00 | 15, 25, 35, 45 | 20 | 8 |

| LS ratio | 0.05 | 2.00 | 25 | 1, 2, 5, 10, 20, 30, 50 | 8 |

| Soaking time | 0.05 | 2.00 | 25 | 5 | 1, 2, 4, 8, 12, 24, 48, 72, 96, 120 |

2.3. Analytic Method

2.4. Quality Control

2.5. Data Analysis and Processing

3. Results and Discussion

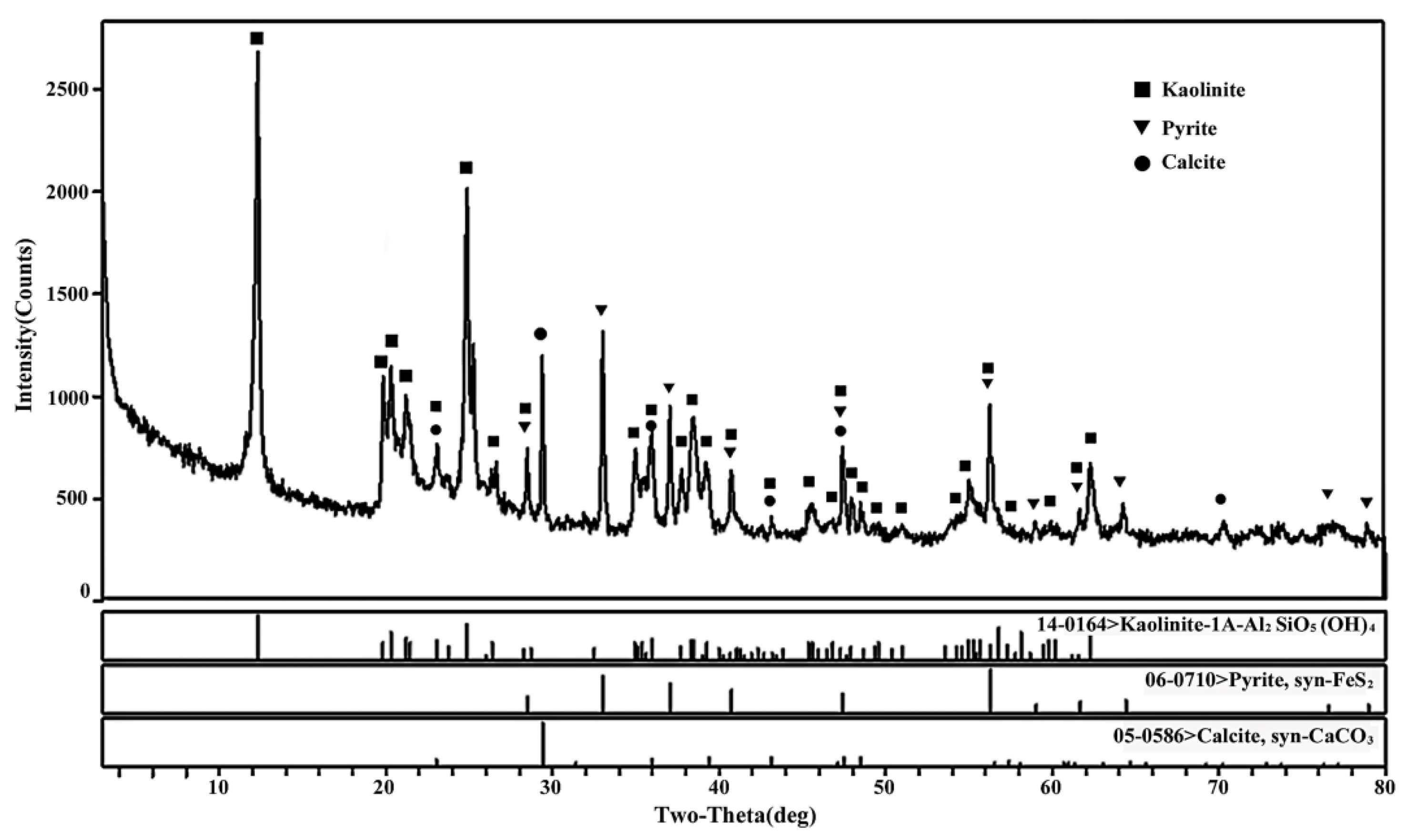

3.1. Characteristics of Pyrite Tailings

| Element | Content (mg·kg−1) | Element | Content (mg·kg−1) |

|---|---|---|---|

| Fe | 68,500.00 | Zn | 98.00 |

| Al | 145,588.24 | Hg | 0.29 |

| Cu | 118.00 | Mn | 115.00 |

| Ni | 63.50 | Cr | 319.00 |

| Cd | 1.12 | Ca | 17,928.57 |

3.2. Released Amounts of Heavy Metals under Different Initial pH of Extractant Conditions

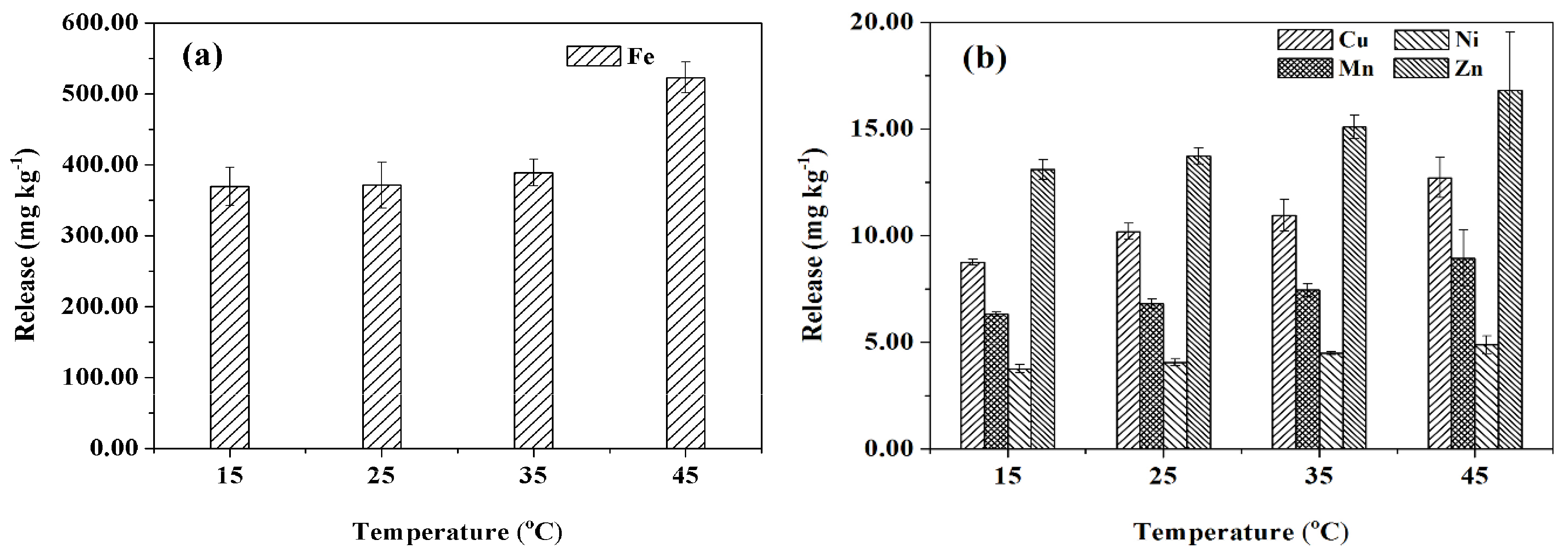

3.3. Released Amounts of Heavy Metals under Different Temperature Conditions

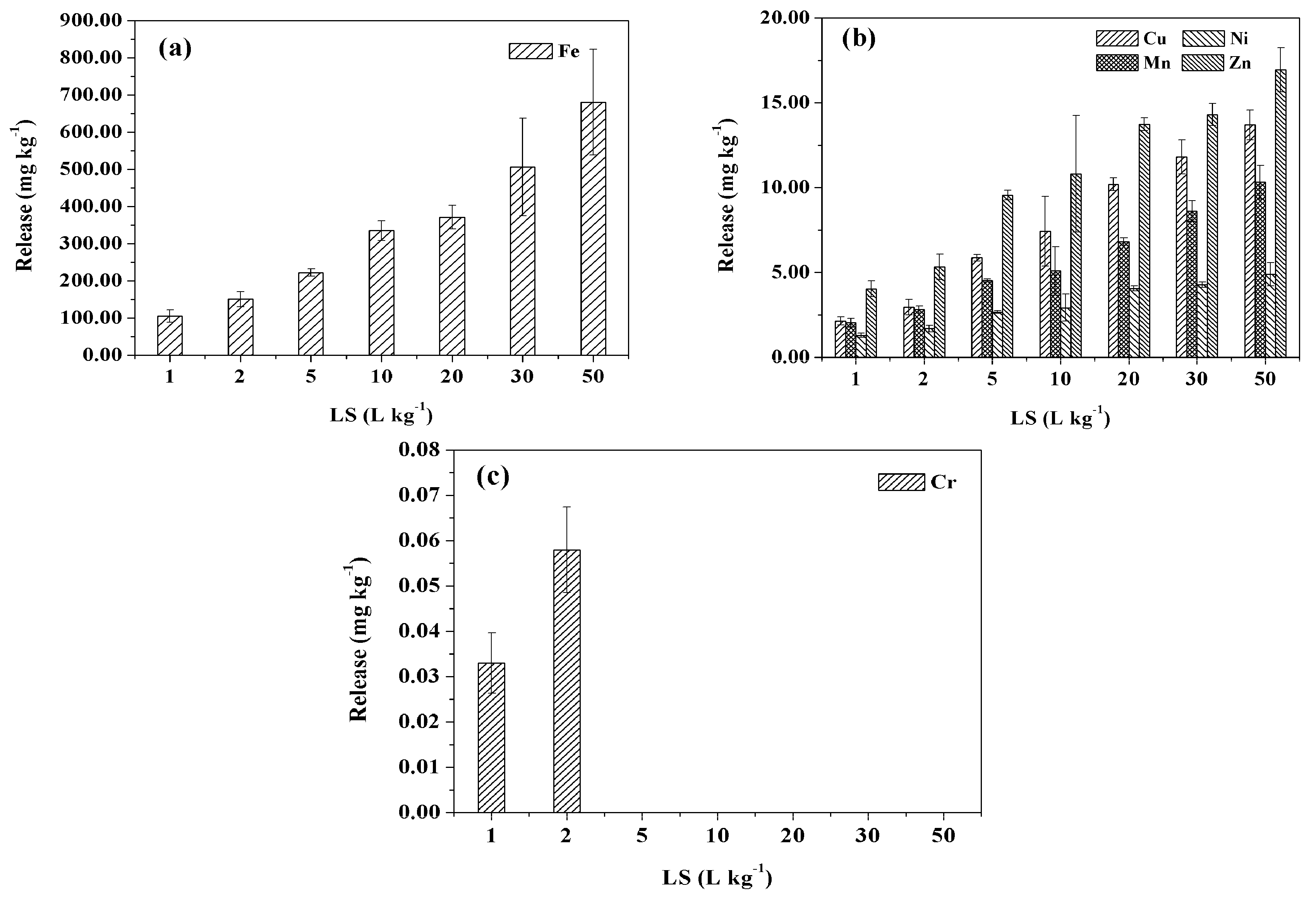

3.4. Released Amounts of Heavy Metals under Different LS Ratio Conditions

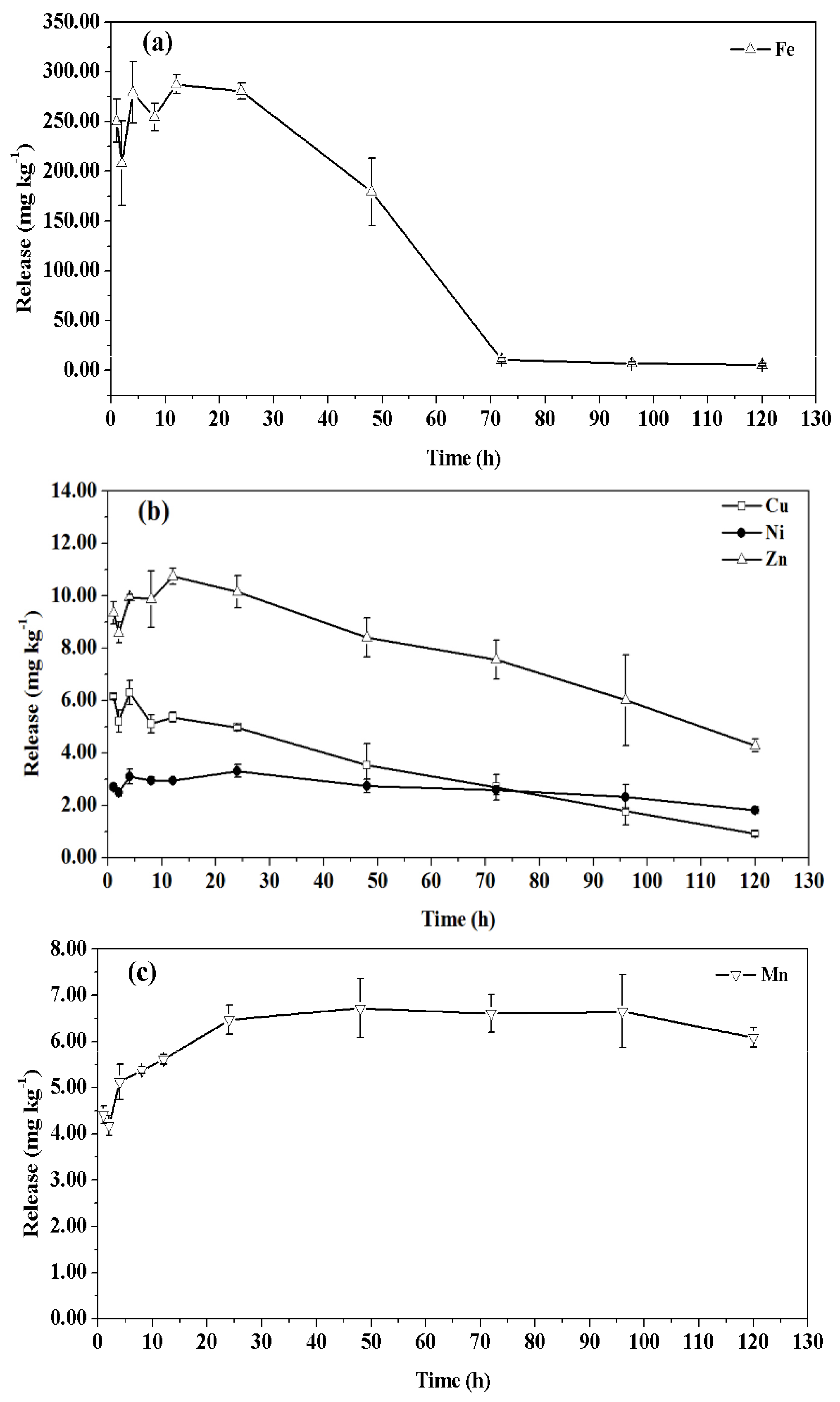

3.5. Released Amounts of Heavy Metals under Different Soaking Time Conditions

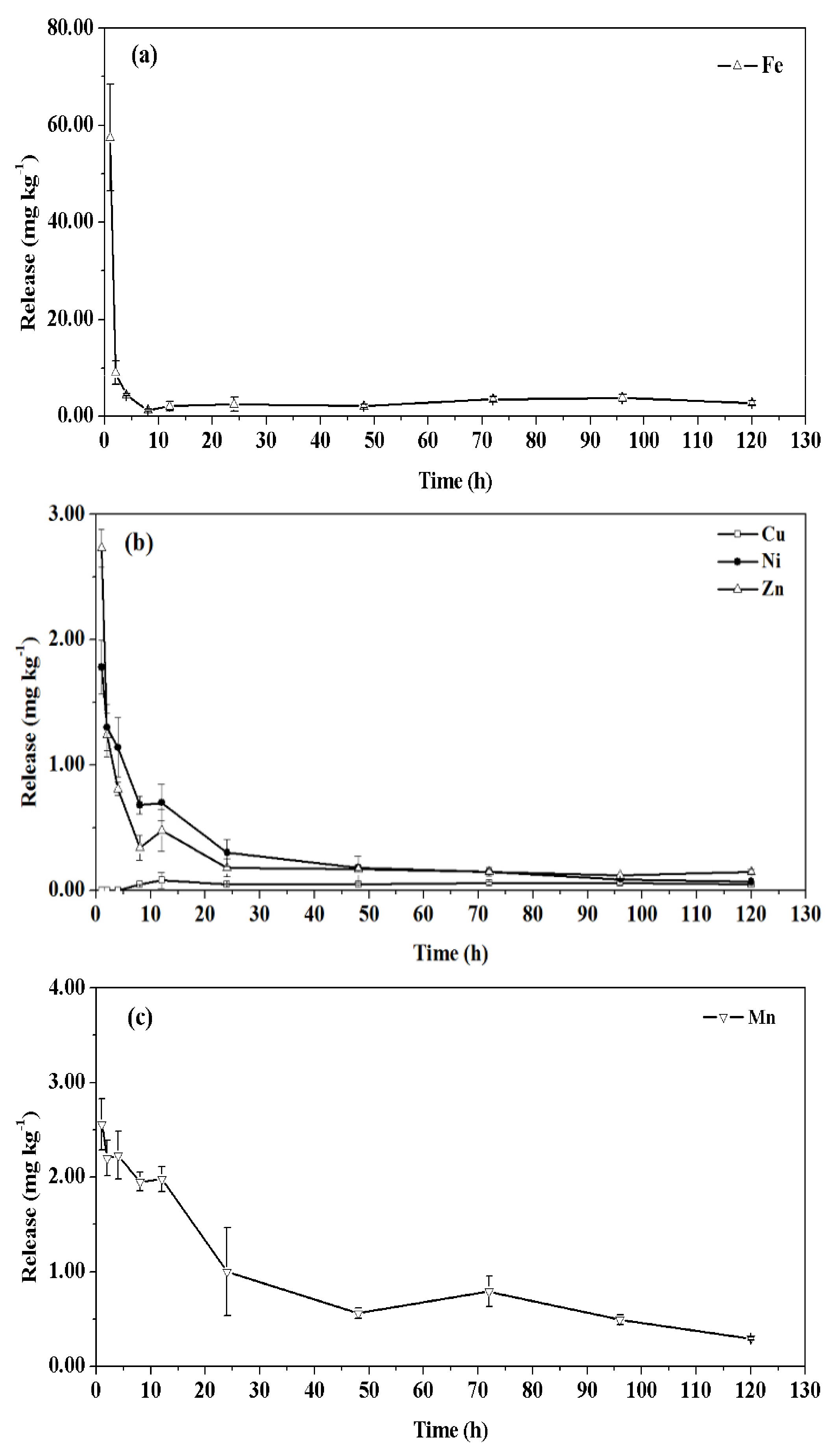

3.6. Released Amounts of Heavy Metals after Adding Calcium Carbonate

| Soaking Time (h) | Reduced Percentage (%) | ||||

|---|---|---|---|---|---|

| Fe | Cu | Mn | Ni | Zn | |

| 1 | 77.06 | 100.00 | 41.95 | 34.07 | 70.80 |

| 2 | 95.68 | 100.00 | 47.37 | 48.00 | 85.58 |

| 4 | 98.43 | 100.00 | 56.53 | 63.23 | 91.86 |

| 8 | 99.51 | 99.02 | 63.75 | 76.95 | 96.56 |

| 12 | 99.27 | 98.51 | 64.71 | 76.27 | 95.53 |

| 24 | 99.13 | 99.00 | 84.54 | 90.94 | 98.23 |

| 48 | 98.83 | 98.59 | 91.67 | 93.43 | 97.98 |

3.7. Implication of the Study

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Garcíaa, C.; Ballesterb, A.; Gonzálezb, F.; Blázquezb, M.L. Pyrite behaviour in a tailings pond. Hydrometallurgy 2005, 76, 25–36. [Google Scholar] [CrossRef]

- Malmström, M.E.; Gleisner, M.; Herbert, R.B. Element discharge from pyritic mine tailings at limited oxygen availability in column experiments. Appl. Geochem. 2006, 21, 184–202. [Google Scholar] [CrossRef]

- Heikkinen, P.M.; Räisänen, M.L. Trace metal and As solid-phase speciation in sulphide mine tailings: Indicators of spatial distribution of sulphide oxidation in active tailings impoundments. Appl. Geochem. 2009, 24, 1224–1237. [Google Scholar] [CrossRef]

- Wang, S.; Mulligan, C. Enhanced mobilization of arsenic and heavy metals from mine tailings by humic acid. Chemosphere 2009, 74, 274–279. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, P.C.S.; Neiva, A.M.R.; Silva, M.M.V.G.; Antunes, I.M.H.R. Metal and metalloid leaching from tailings into streamwater and sediments in the old Ag–Pb–Zn Terramonte mine, northern Portugal. Environ. Earth. Sci. 2014, 71, 2029–2041. [Google Scholar] [CrossRef]

- Holmström, H.; Öhlander, B. Oxygen penetration and subsequent reactions in flooded sulphidic mine tailings: A study at Stekenjokk, northern Sweden. Appl. Geochem. 1999, 14, 747–759. [Google Scholar] [CrossRef]

- Lundgren, T. The dynamics of oxygen transport into soil covered mining waste deposits in Sweden. J. Geochem. Explor. 2001, 74, 163–173. [Google Scholar] [CrossRef]

- Mohana, D.; Chander, S. Removal and recovery of metal ions from acid mine drainage using lignite—A low cost sorbent. J. Hazard. Mater. 2006, B137, 1545–1553. [Google Scholar] [CrossRef] [PubMed]

- Moreno, L.; Neretnieks, I. Long-term environmental impact of tailings deposits. Hydrometallurgy 2006, 83, 176–183. [Google Scholar] [CrossRef]

- Bernier, L.R. The potential use of serpentinite in the passive treatment of acid mine drainage: Batch experiments. Environ. Geol. 2005, 47, 670–684. [Google Scholar] [CrossRef]

- Kalin, M.; Fyson, A.; Wheeler, W.N. The chemistry of conventional and alternative treatment systems for the neutralization of acid mine drainage. Sci. Total Environ. 2006, 366, 395–408. [Google Scholar] [CrossRef] [PubMed]

- Ríos, C.A.; Williams, C.D.; Roberts, C.L. Removal of heavy metals from acid mine drainage (AMD) using coal fly ash, natural clinker and synthetic zeolites. J. Hazard. Mater. 2008, 156, 23–35. [Google Scholar] [CrossRef] [PubMed]

- Ouakibi, O.; Hakkou, R.; Benzaazoua, M. Phosphate carbonated wastes used as drains for acidic mine drainage passive treatment. Procedia Eng. 2014, 83, 407–414. [Google Scholar] [CrossRef]

- Ouyang, Y.T.; Liu, Y.; Zhu, R.L.; Ge, F.; Xu, T.Y.; Luo, Z.; Liang, L.B. Pyrite oxidation inhibition by organosilane coatings for acid mine drainage control. Miner. Eng. 2015, 72, 57–64. [Google Scholar] [CrossRef]

- Kuyucak, N. Role of microorganisms in mining: Generation of acid rock drainage and its mitigation and treatment. Eur. J. Miner. Process. Environ. Prot. 2002, 2, 179–196. [Google Scholar]

- Hallberg, K.B.; Johnson, D.B. Microbiology of a wetland ecosystem constructed to remediate mine drainage from a heavy metal mine. Sci. Total Environ. 2005, 338, 53–66. [Google Scholar] [CrossRef] [PubMed]

- Whitehead, P.G.; Prior, H. Bioremediation of acid mine drainage: An introduction to the Wheal Jane wetlands project. Sci. Total Environ. 2005, 338, 15–21. [Google Scholar] [CrossRef] [PubMed]

- Natarajan, K.A. Microbial aspects of acid mine drainage and its bioremediation. Trans. Nonferrous Met. Soc. China 2008, 18, 1352–1360. [Google Scholar] [CrossRef]

- Sánchez-Andrea, I.; Triana, D.; Sanz, J.L. Bioremediation of acid mine drainage coupled with domestic wastewater treatment. Water Sci. Technol. 2012, 66, 2425–2431. [Google Scholar] [CrossRef] [PubMed]

- Lottermoser, B.G. Mine Wastes, 3rd ed.; Springer-Verlag: Berlin, Germany; Heidelberg, Germany, 2010; pp. 3–12. [Google Scholar]

- Cappuyns, V.; Alian, V.; Vassilieva, E.; Swennen, R. pH dependent leaching behavior of Zn, Cd, Pb, Cu and As from mining wastes and slags: Kinetics and mineralogical control. Waste Biomass Valori. 2014, 5, 355–368. [Google Scholar] [CrossRef]

- Gleisner, M.; Herbert, R.B. Sulfide mineral oxidation in freshly processed tailings: Batch experiments. J. Geochem. Explor. 2002, 76, 139–153. [Google Scholar] [CrossRef]

- Doye, I.; Duchesne, J. Neutralisation of acid mine drainage with alkaline industrial residues: Laboratory investigation using batch-leaching tests. Appl. Geochem. 2003, 18, 1197–1213. [Google Scholar] [CrossRef]

- Malviya, R.; Chaudhary, R. Leaching behavior and immobilization of heavy metals in solidified/stabilized products. J. Hazard. Mater. 2006, 137, 207–217. [Google Scholar] [CrossRef] [PubMed]

- Cappuyns, V.; Swennen, R. The application of pHstat leaching tests to assess the pH-dependent release of trace metals from soils, sediments and waste materials. J. Hazard. Mater. 2008, 158, 185–195. [Google Scholar] [CrossRef] [PubMed]

- Yue, M.; Zhao, F. Leaching experiments to study the release of trace elements from mineral separates from Chinese coals. Int. J. Coal Geol. 2008, 73, 43–51. [Google Scholar] [CrossRef]

- Lee, P.K.; Kang, M.J.; Jo, H.Y.; Choi, S.H. Sequential extraction and leaching characteristics of heavy metals in abandoned tungsten mine tailings sediments. Environ. Earth Sci. 2012, 66, 1909–1923. [Google Scholar] [CrossRef]

- Zheng, S.; Zheng, X.; Chen, C. Leaching behavior of heavy metals and transformation of their speciation in polluted soil receiving simulated acidrain. PLoS ONE 2012, 22, e49664. [Google Scholar]

- Guo, Y.G.; Huang, P.; Zhang, W.G.; Yuan, X.W.; Fan, F.X.; Wang, H.L.; Liu, J.S.; Wang, Z.H. Leaching of heavy metals from Dexing copper mine tailings pond. Trans. Nonferrous Met. Soc. China 2013, 23, 3068–3075. [Google Scholar] [CrossRef]

- Al-Abed, S.R.; Jegadeesan, G.; Purandare, J.; Allen, D. Leaching behavior of mineral processing waste: Comparison of batch and column investigations. J. Hazard. Mater. 2008, 153, 1088–1092. [Google Scholar] [CrossRef] [PubMed]

- Dong, J.; Yu, M.; Bian, Z.; Zhao, Y.; Cheng, W. The safety study of heavy metal pollution in wheat planted in reclaimed soil of mining areas in Xuzhou, China. Environ. Earth Sci. 2012, 66, 673–682. [Google Scholar] [CrossRef]

- Lin, H.; Zhou, Y.H.; Dong, Y.B.; Xu, W.J.; Xu, J.M.; Wang, L. Influence of flotation reagents for the release of heavy metals in lead-zinc tailings by bioleaching. China Environ. Sci. 2015, 35, 3387–3395. [Google Scholar]

- Ma, L.; Wang, B.; Yang, J. Spatial-temporal distribution of acid rain in Sichuan Province. Environ. Sci. Manag. 2008, 33, 26–29. [Google Scholar]

- Aydogan, S.; Aras, A.; Canbazoglu, M. Dissolution kinetics of sphalerite in acidic ferric chloride leaching. Chem. Eng. J. 2005, 114, 67–72. [Google Scholar] [CrossRef]

- Chen, T.; Lei, C.; Yan, B.; Xiao, X.M. Metal recovery from the copper sulfide tailing with leaching and fractional precipitation technology. Hydrometallurgy 2014, 147, 178–182. [Google Scholar] [CrossRef]

- Schwab, P.; Zhu, D.; Banks, M.K. Heavy metal leaching from mine tailings as affected by organic amendments. Bioresour. Technol. 2007, 98, 2935–2941. [Google Scholar] [CrossRef] [PubMed]

- Bigham, J.M.; Schwertmann, U.; Traina, S.J.; Winland, R.L.; Wolf, M. Schwertmannite and the chemical modeling of iron in acid sulfate waters. Geochim. Cosmochim. Acta 1996, 60, 2111–2121. [Google Scholar] [CrossRef]

- Sidenko, N.V.; Sherriff, B.L. The attenuation of Ni, Zn and Cu by secondary Fe phases of different crystallinity from surface and ground water of two sulfide mine tailings in Manitoba, Canada. Appl. Geochem. 2005, 20, 1180–1194. [Google Scholar] [CrossRef]

- Jiang, M.Q.; Jin, X.Y.; Lu, X.Q.; Chen, Z.L. Adsorption of Pb (II), Cd (II), Ni (II) and Cu (II) onto natural kaolinite clay. Desalination 2010, 252, 33–39. [Google Scholar] [CrossRef]

- Kamel, M.M.; Ibrahm, M.A.; Ismael, A.M.; El-Motaleeb, M.A. Adsorption of some heavy metal ions from aqueous solutions by using kaolinite clay. Ass. Univ. Bull. Environ. Res. 2004, 7, 101–109. [Google Scholar]

- Yavuz, Ö.; Altunkaynak, Y.; Güzel, F. Removal of copper, nickel, cobalt and manganese from aqueous solution by kaolinite. Water Res. 2003, 37, 948–952. [Google Scholar] [CrossRef]

- Akcil, A.; Koldas, S. Acid Mine Drainage (AMD): Causes, treatment and case studies. J. Clean. Prod. 2006, 14, 1139–1145. [Google Scholar] [CrossRef]

- Doye, I.; Duchesne, J. Column leaching test to evaluate the use of alkaline industrial wastes to neutralize acid mine tailings. J. Environ. Eng. 2005, 131, 1221–1229. [Google Scholar] [CrossRef]

- Mylona, E.; Xenidis, A.; Paspaliaris, I. Inhibition of acid generation from sulphidic wastes by the addition of small amounts of limestone. Miner. Eng. 2000, 13, 1161–1175. [Google Scholar] [CrossRef]

- Komnitsas, K.; Bartzas, G.; Paspaliaris, I. Efficiency of limestone and red mud barriers: Laboratory column studies. Miner. Eng. 2004, 17, 183–194. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, L.; Zhou, X.; Luo, H.; Deng, J.; Dai, L.; Ju, Z.; Zhu, Z.; Zou, L.; Ji, L.; Li, B.; et al. Release of Heavy Metals from the Pyrite Tailings of Huangjiagou Pyrite Mine: Batch Experiments. Sustainability 2016, 8, 96. https://doi.org/10.3390/su8010096

Fan L, Zhou X, Luo H, Deng J, Dai L, Ju Z, Zhu Z, Zou L, Ji L, Li B, et al. Release of Heavy Metals from the Pyrite Tailings of Huangjiagou Pyrite Mine: Batch Experiments. Sustainability. 2016; 8(1):96. https://doi.org/10.3390/su8010096

Chicago/Turabian StyleFan, Liangqian, Xi Zhou, Hongbing Luo, Jie Deng, Li Dai, Zhengfu Ju, Zhiming Zhu, Likou Zou, Lin Ji, Bei Li, and et al. 2016. "Release of Heavy Metals from the Pyrite Tailings of Huangjiagou Pyrite Mine: Batch Experiments" Sustainability 8, no. 1: 96. https://doi.org/10.3390/su8010096