Stand-Alone Solar Organic Rankine Cycle Water Pumping System and Its Economic Viability in Nepal

Abstract

:1. Introduction

2. Description of Experimental Setup

| Characteristics of solar collectors | |||

|---|---|---|---|

| Collector | Evacuated tubular | ||

| Type | Heat pipe | ||

| Manufacturer | Apack Inc. | ||

| No. of tubes | 10 | ||

| Heat capacity (kCal/m2.day) | 3342.47 | ||

| Gross area (m2) | 2.55 | ||

| Collector efficiency (%) | 72.95 | ||

| Filled with water (kg) | 62.8 | ||

| Characteristics of evaporator | |||

| Evaporator | Unit | Hot side | Cold side |

| (Model: CB60-14H-F, Alfa Laval) | |||

| Fluid Name | - | Water | R245fa |

| Temperature In | °C | 115 | 52 |

| Temperature Out | °C | 105 | 109 |

| Flow rate | kg/s | 0.45 | 0.08 |

| Operating Pressure | bar | 5 | 15 |

| Characteristics of condenser | |||

| Condenser | Unit | Hot side | Cold side |

| (Model: CB76-50E, Alfa Laval) | |||

| Fluid Name | - | R245fa | Water |

| Temperature In | °C | 77 | 22 |

| Temperature Out | °C | 50 | 25 |

| Flow rate | kg/s | 0.08 | 0.13 |

| Operating Pressure | bar | 4 | 5 |

| Characteristics of scroll expander | |||

| Model | E15022A-SH | ||

| Type | Scroll | ||

| Manufacturer | Airsquared | ||

| Maximum operating temperature (°C) | 175 | ||

| Maximum operating pressure(bar) | 13.8 | ||

| Volume ratio | 3.5 | ||

| Maximum speed(rpm) | 3600 | ||

| Characteristics of working fluid feed pump | |||

| Model | 2SF22ES | ||

| Type | Plunger | ||

| Manufacturer | CAT PUMPS | ||

| Maximum operating pressure(bar) | 140 | ||

| Flow rate (l/m) | 8.3 | ||

| Characteristics of Heat transfer fluid(HTF) pump | |||

| Model | A979641P11515 | ||

| Type | CRN1-2 F-FGJ-G-F-HQQE | ||

| Manufacturer | GRUNDFOS | ||

| Maximum operating pressure(bar) | 25 | ||

| Maximum operating temperature (°C) | 180 | ||

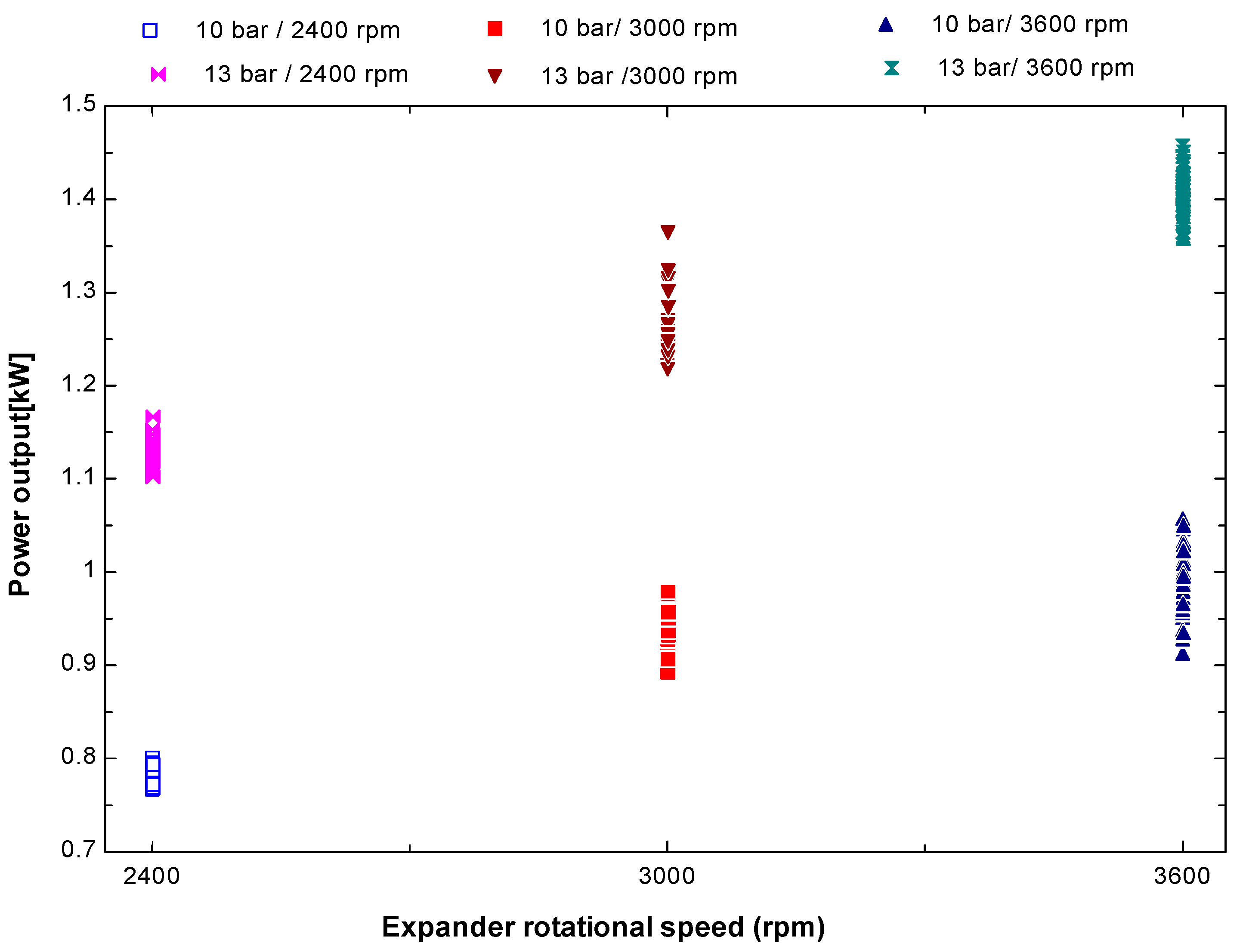

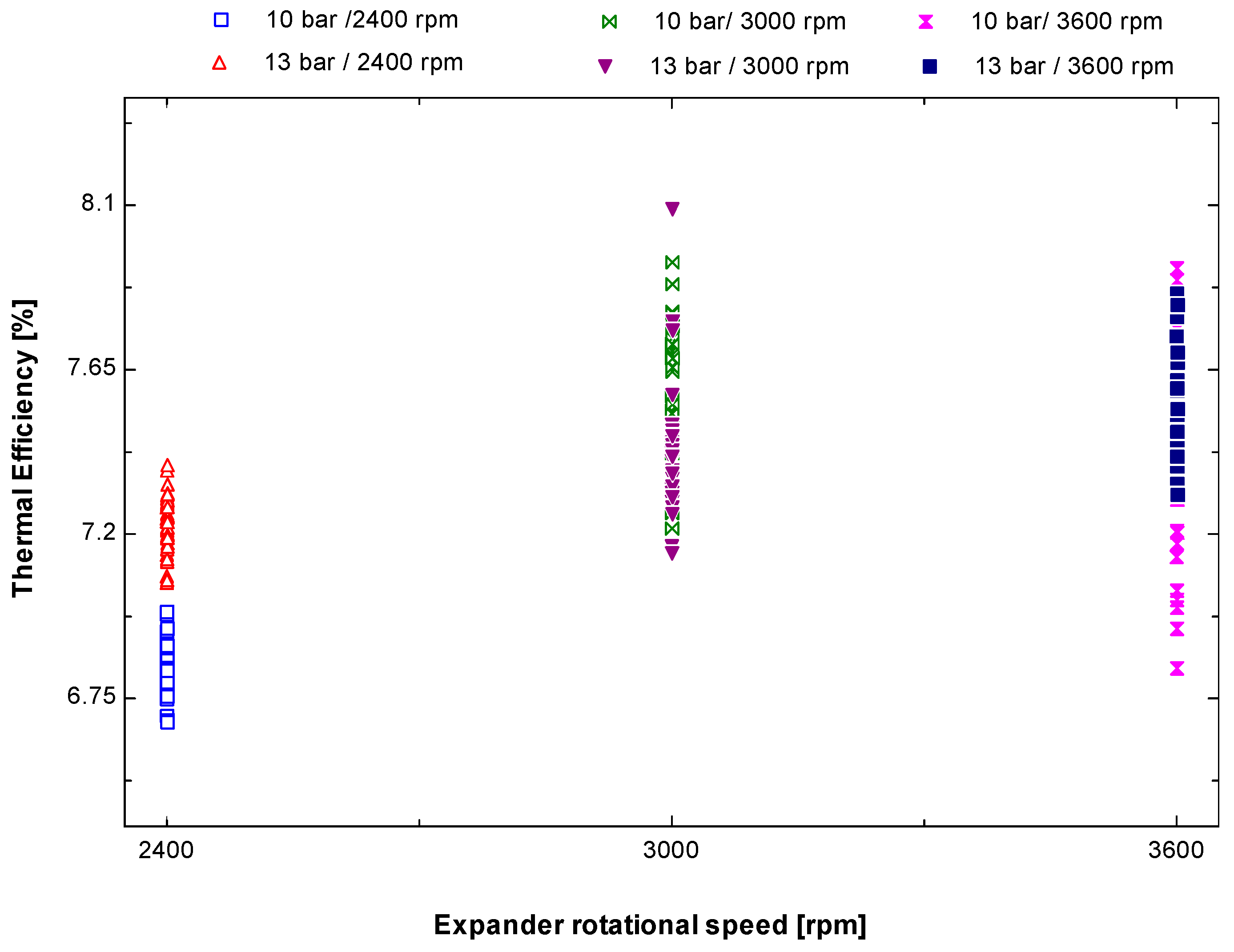

3. Results and Discussion

| Parameters | Instrument | Uncertainty range |

|---|---|---|

| Temperature | K type thermocouples | ±1.1 °C |

| Pressure | Transducers | ±0.044% full scale |

| Mass flow | Flow meter | ±0.4 (L/min) full scale |

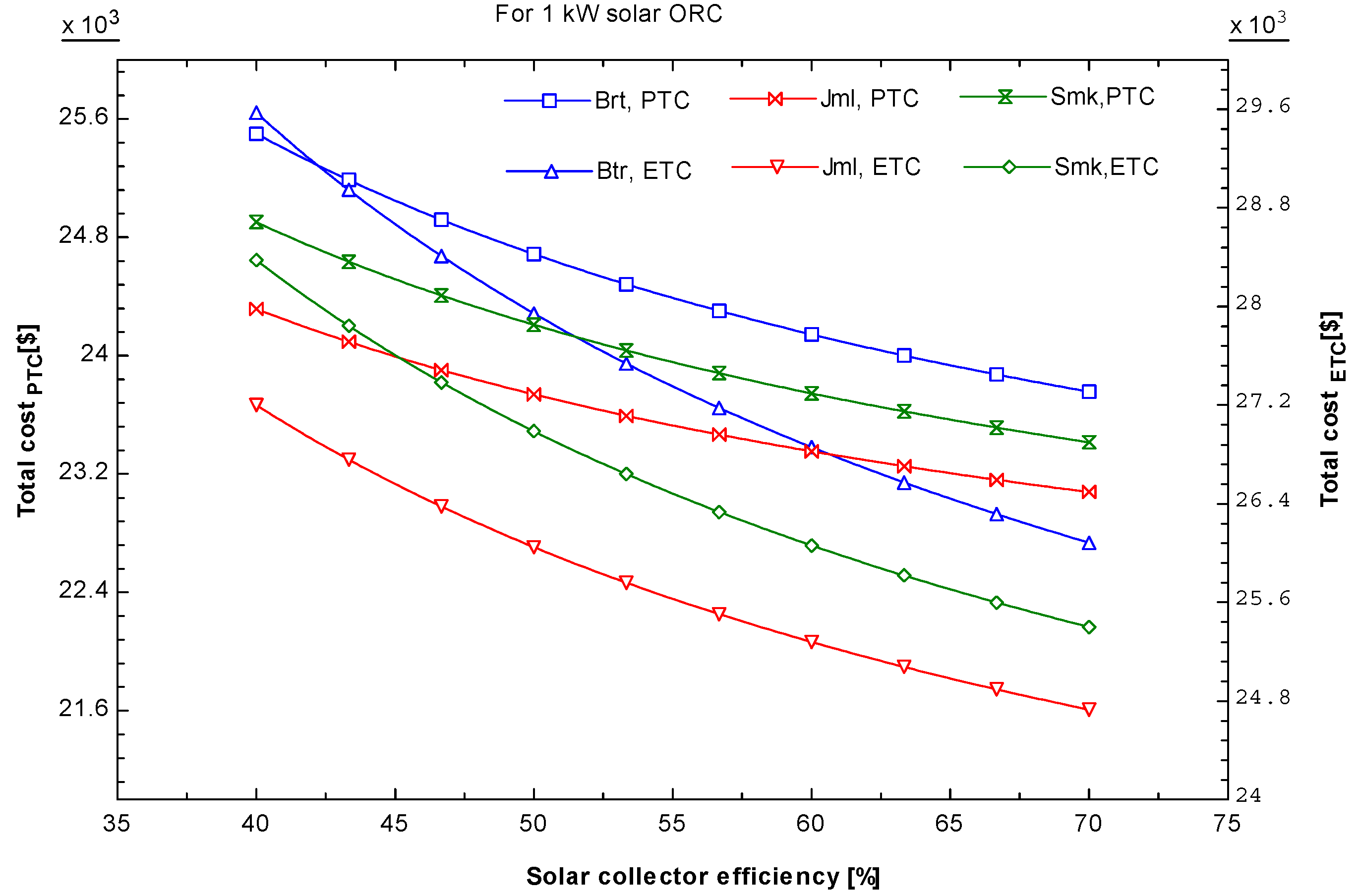

4. Economic Viability of Solar ORC Water Pumping System

| Component Cost item | Biratnagar | Jumla | Simikot | |||

|---|---|---|---|---|---|---|

| 1 kW | 5 kW | 1 kW | 5 kW | 1 kW | 5 kW | |

| Solar collector arrays with installation cost($) | 13,577 | 66,897 | 13,057 | 64,292 | 13,316 | 65,582 |

| ORC unit with power block ($) | 10,615 | 52,301 | 10,208 | 50,265 | 10,410 | 51,273 |

| Labor cost ($) | 494 | 2433 | 475 | 2338 | 484 | 2385 |

| Battery Storage System($) | 2130 | 10650 | 2130 | 10650 | 2130 | 10650 |

| Water Pumping system($) | 900 | 2700 | 900 | 2700 | 900 | 2700 |

| Total cost , PTC ($) | 27,715 | 378,240 | 74,250 | 364,035 | 75,660 | 371,070 |

| O&M cost, PTC ($) | 554 | 7565 | 1485 | 7281 | 1513 | 7421 |

| Total cost, ETC($) | 26,085 | 126,840 | 25,600 | 124,470 | 25,850 | 125,645 |

| O&M cost, ETC ($) | 522 | 2537 | 512 | 2489 | 517 | 2513 |

Theory for Economic Analysis of the Investigated System

5. Results and Discussion

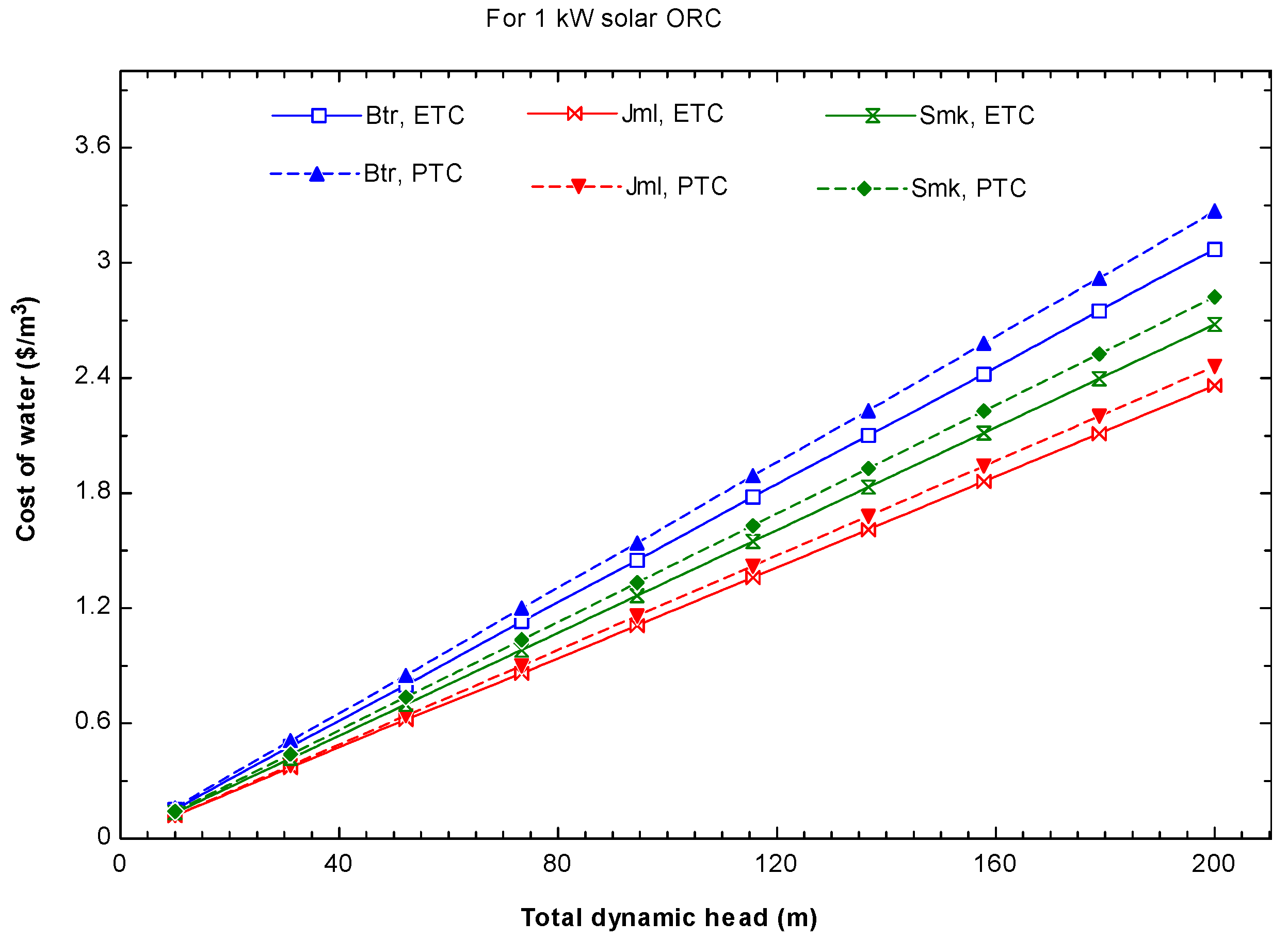

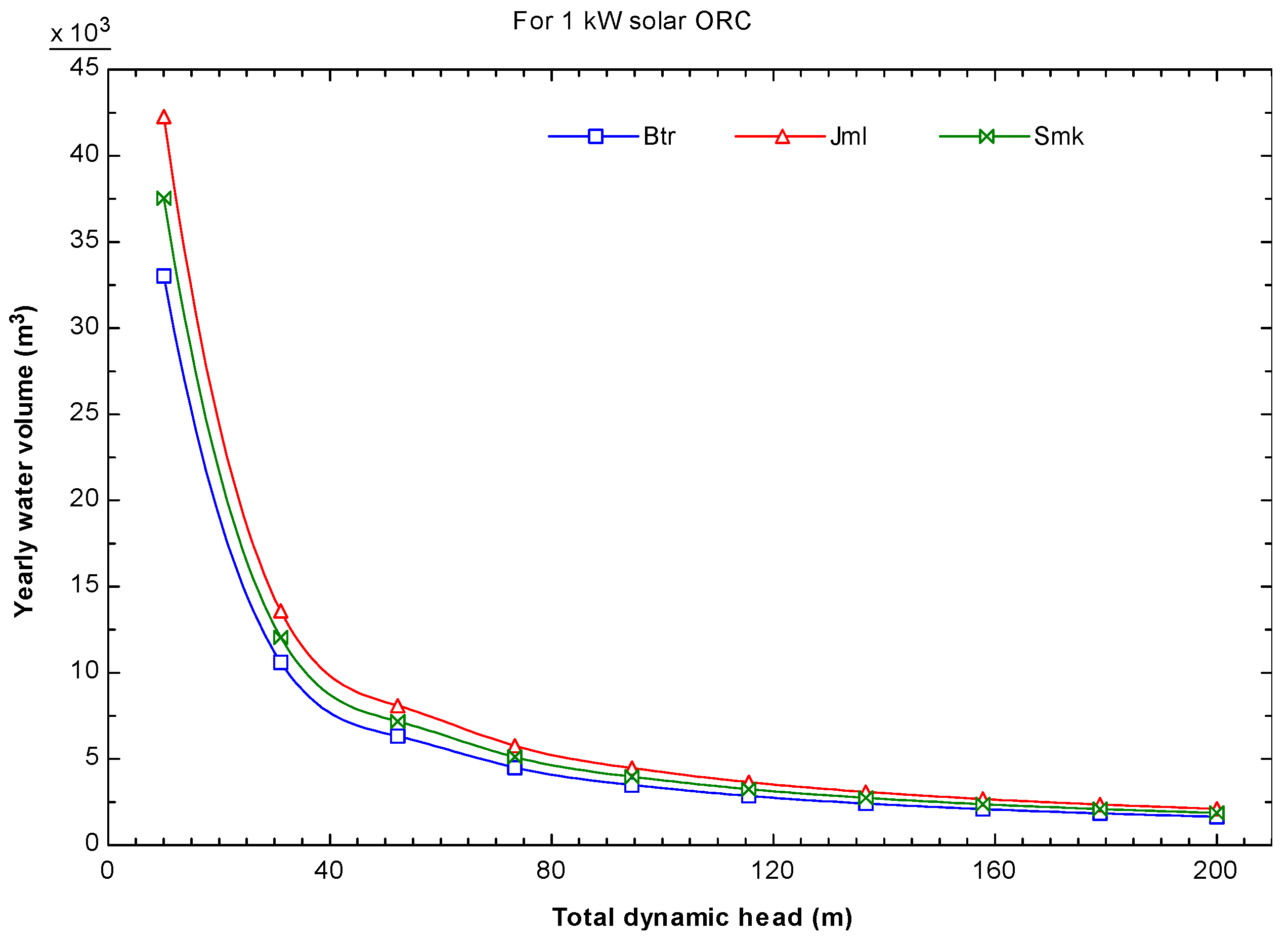

5.1. Estimation of Cost of Water

| Economic parameters | Biratnagar | Jumla | Simikot | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PTC | ETC | PTC | ETC | PTC | ETC | |||||||

| 1 kW | 5 kW | 1 kW | 5 kW | 1 kW | 5 kW | 1 kW | 5 kW | 1 kW | 5 kW | 1 kW | 5 kW | |

| NPV($) | 19,952.1 | 97,890.74 | 18,676.91 | 91,281.92 | 19,164.71 | 93,877.97 | 18,362.67 | 89,627.27 | 19,468.94 | 95,319.14 | 18,443.4 | 90,001.5 |

| IRR (%) | 8.08 | 8.13 | 8.04 | 8.07 | 8.03 | 8.09 | 8.05 | 8.08 | 8.02 | 8.07 | 8.01 | 8.04 |

| PI | 1.6 | 1.61 | 1.59 | 1.6 | 1.59 | 1.6 | 1.59 | 1.6 | 1.59 | 1.6 | 1.59 | 1.59 |

| PBP(yrs) | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Cost of water ($/m3) | 2.47 | 2.38 | 2.32 | 2.23 | 1.86 | 1.79 | 1.78 | 1.71 | 2.13 | 2.05 | 2.02 | 1.94 |

5.2. Sensitivity Analysis

| Influencing Parameters | Scenarios | Reasons |

|---|---|---|

| Base case | No variation on systems parameters | |

| Capital cost (CC) | Increased by 30% | Increase in components cost |

| Decreased by 30% | Decrease in components cost | |

| Operating cost (OC) | Increased by 30% | Labor cost increases |

| High O&M cost | ||

| Less durability of the system components | ||

| Decreased by 30% | Low O&M costs | |

| Longer component life | ||

| Decrease in labor cost | ||

| System productivity(SP) | Increased by 30% | Improvement in solar collector and ORC efficiency |

| Higher solar insolation | ||

| Optimized system performance | ||

| Decreased by 30% | Poor collector and ORC efficiency | |

| Low solar insolation | ||

| Not optimized system | ||

| Interest rate (IR) | Increased by 30% | Unstable country's GDP and political instability |

| Ineffective banking system | ||

| High inflation rate | ||

| Supply/demand pattern un matched | ||

| Decreased by 30% | GDP increased and political stable | |

| Decrease in inflation rate | ||

| Government subsidizing policy | ||

| Supply/demand pattern matched |

6. Conclusions

- The solar ORC water pumping system can be used in drip irrigation, for pumping water for drinking and irrigation, and for organic farming to generate income in rural Nepalese villages.

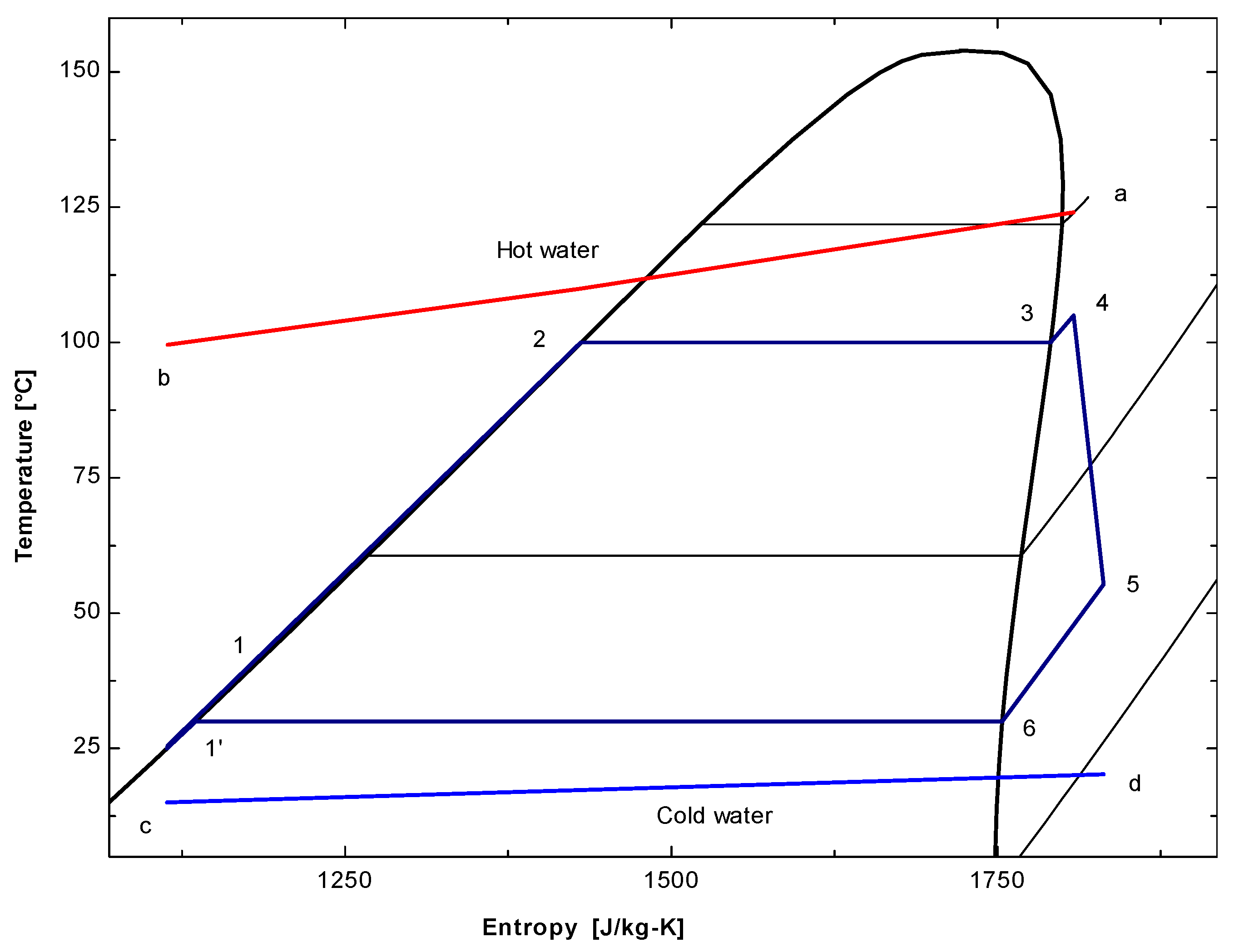

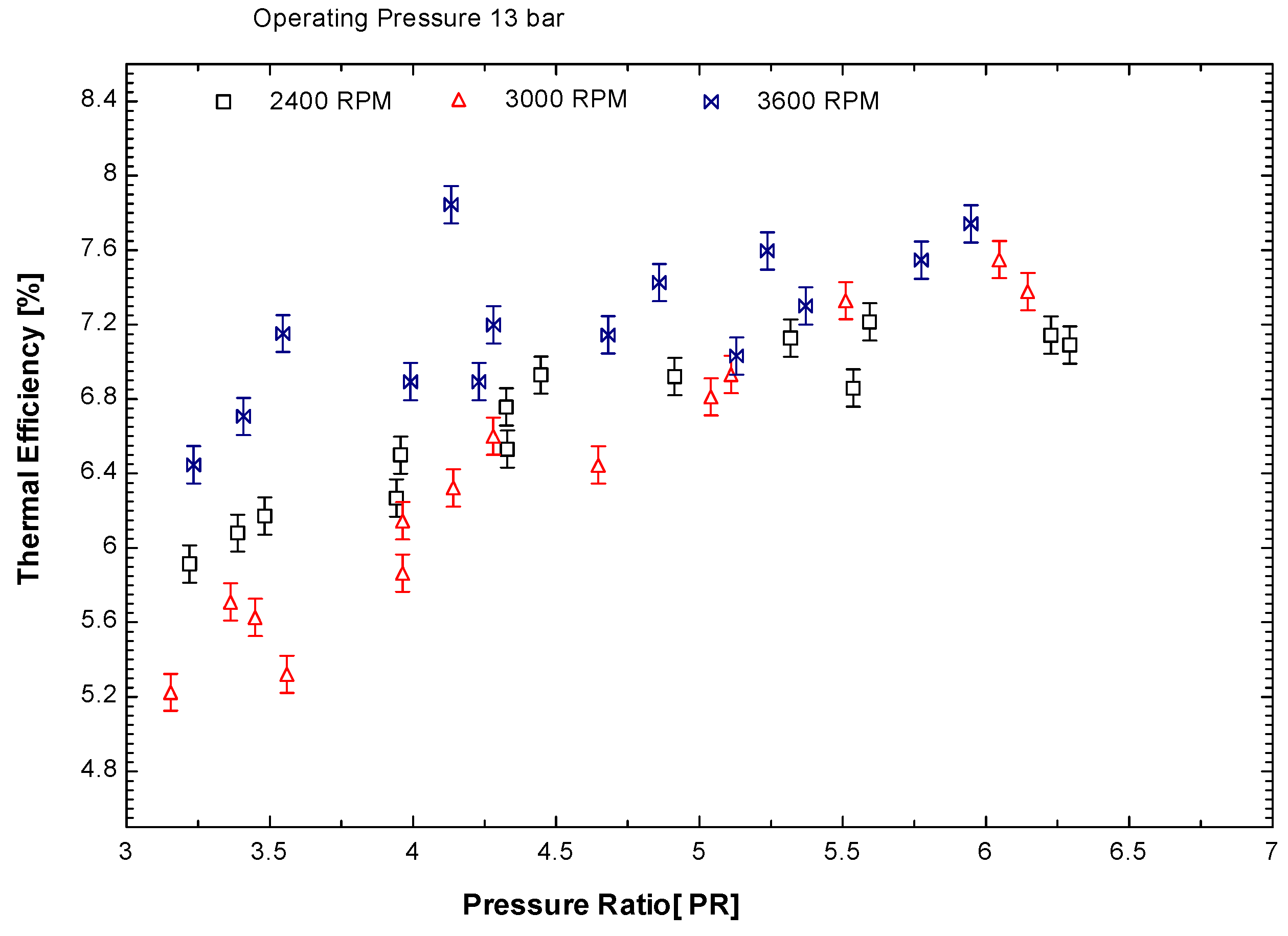

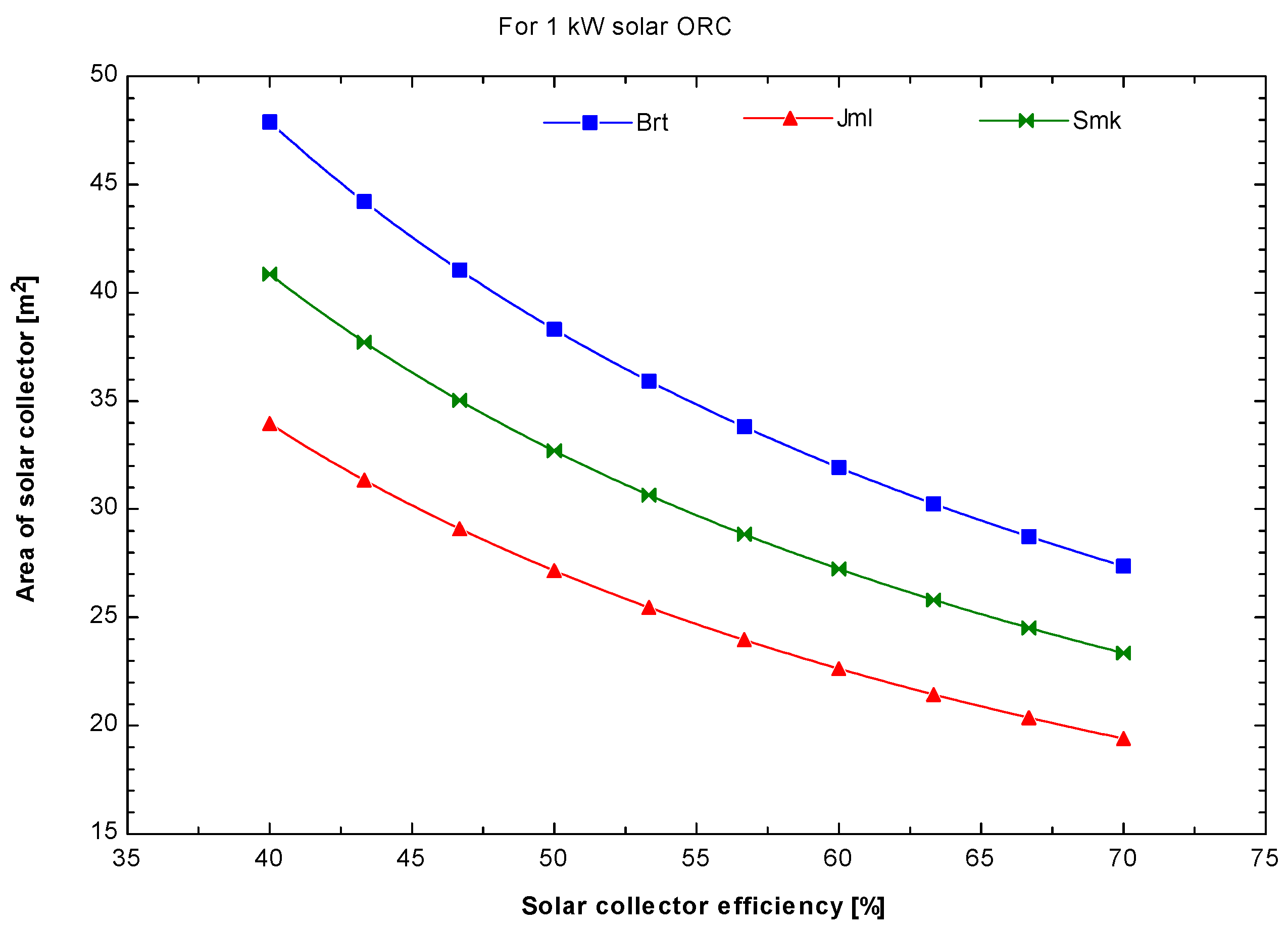

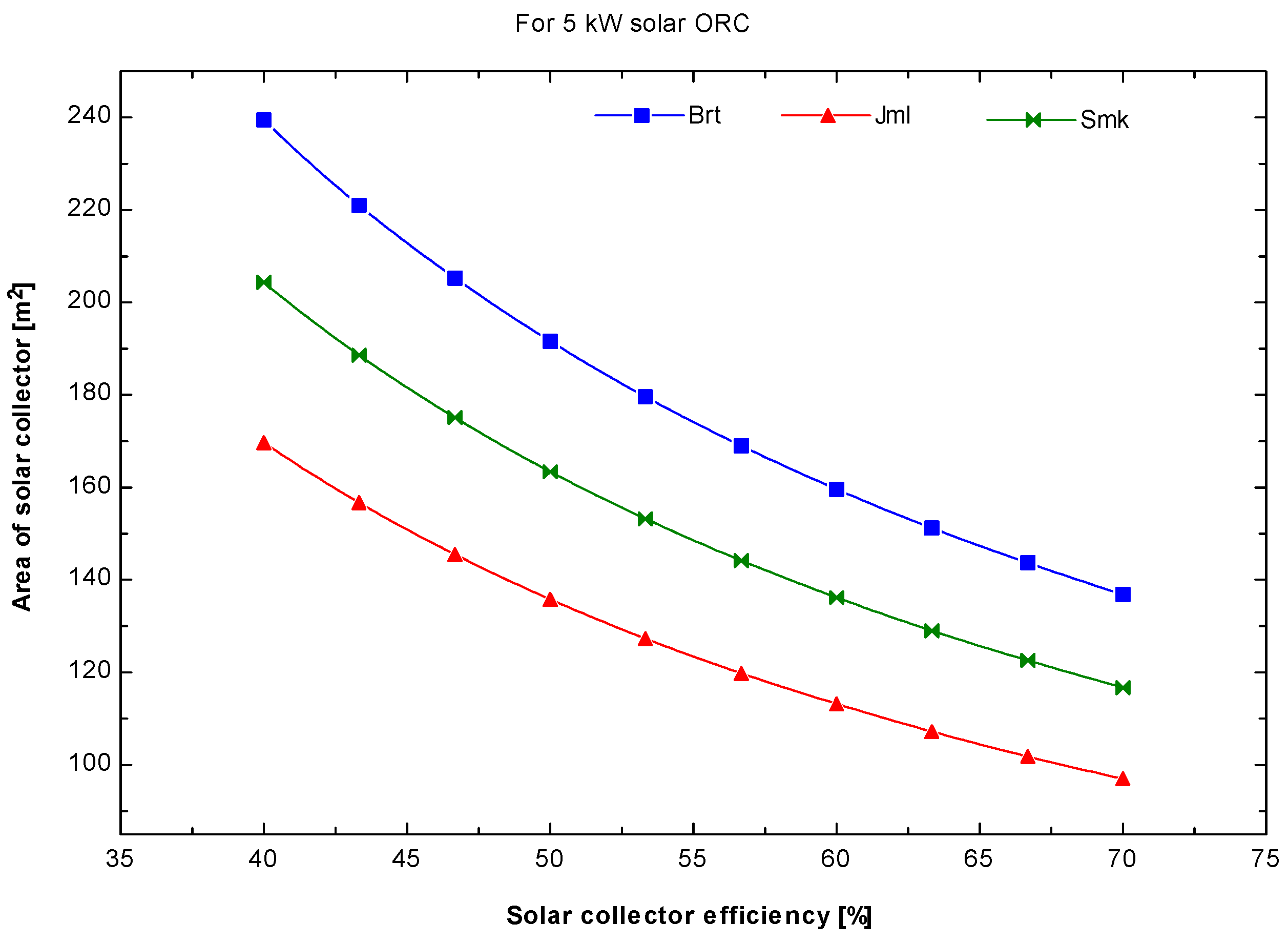

- The technology can use a PTC or ETC for converting solar energy into power generation using R245fa as a refrigerant. The ORC based on a low temperature of 120 °C has an efficiency of around 8%. The efficiency is reduced when the solar collector efficiency is reduced, so a collector with high solar collecting efficiency is recommended.

- The stand-alone solar ORC water pumping system can be effective when there is no sunshine hours and on cloudy days because of the battery storage system.

- The specific cost of water ranges from $1.86/m3 to $2.47/m3 for the 1-kW system and from $1.71/m3 to $2.38/m3 for the for 5-kW system using the PTC. The maximum volumes of water pumped are 2806 m3 and 14,208 m3 yearly for 1-kW and 5-kW systems, respectively, in Jumla when the total dynamic head is 150 m. The cost of water is low when there is high solar insolation and more sunshine during the year. The results showed that Jumla has the lowest cost of water, followed by Simikot and Biratnagar.

- The system is more profitable when the influencing parameters vary. When the capital cost, interest rate, and operating cost are decreased, the system is highly feasible and the payback period is only six years. The investment is also acceptable when the productivity of the system increases.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bhandari, H.; Pandey, S. Economics of groundwater irrigation in Nepal: Some farm-level evidences. J. Agric. Appl. Econ. 2006, 38, 185–199. [Google Scholar]

- Shah, T.; Singh, O.P.; Mukherji, A. Some aspects of South Asia's groundwater irrigation economy: Analyses from a survey in India, Pakistan, Nepal Terai and Bangladesh. Hydrogeol. J. 2006, 14, 286–309. [Google Scholar] [CrossRef]

- Hossain, M.A.; Hassan, M.S.; Mottalib, M.A.; Hossain, M. Feasibility of solar pump for sustainable irrigation in Bangladesh. Int. J. Energy Environ. Eng. 2015, 6, 147–155. [Google Scholar] [CrossRef]

- Poudyal, K.N.; Bhattarai, B.K.; Sapkota, B.; Kjeldstad, B. Estimation of global solar radiation using clearness index and cloud transmittance factor at trans-Himalayan region in Nepal. Energy Power Eng. 2012. [Google Scholar] [CrossRef]

- Baral, S.; Kim, K.C. Existing and Recommended Renewable Energy Conversion Technologies for Electricity Generation in Nepal. Energy Power 2014, 4, 16–28. [Google Scholar]

- Bhandari, R.; Stadler, I. Electrification using solar photovoltaic systems in Nepal. Appl. Energy 2011, 88, 458–465. [Google Scholar] [CrossRef]

- Adhikari, K.R.; Bhattarai, B.K.; Gurung, S. Estimation of Global Solar Radiation for Four Selected Sites in Nepal Using Sunshine Hours, Temperature and Relative Humidity. J. Power Energy Eng. 2013, 1, 1–9. [Google Scholar] [CrossRef]

- Nepal, R. Roles and potentials of renewable energy in less-developed economies: the case of Nepal. Renew. Sustain. Energy Rev. 2012, 16, 2200–2206. [Google Scholar] [CrossRef]

- Mainali, B.; Silveira, S. Renewable energy markets in rural electrification: Country case Nepal. Energy Sustain. Dev. 2012, 16, 168–178. [Google Scholar] [CrossRef]

- Rai, S. Sustainable dissemination of solar home systems for rural development: experiences in Nepal. Energy Sustain. Dev. 2004, 8, 47–50. [Google Scholar] [CrossRef]

- AEPC. Training Manual on Solar PV Pumping System; Alternative Energy Promotion Center: Lalitpur Sub Metropolitan City, Nepal, 2014. [Google Scholar]

- Gopal, C.; Mohanraj, M.; Chandramohan, P.; Chandrasekar, P. Renewable energy source water pumping systems—A literature review. Renew. Sustain. Energy Rev. 2013, 25, 351–370. [Google Scholar] [CrossRef]

- Wong, Y.W.; Sumathy, K. Solar thermal water pumping systems: a review. Renew. Sustain. Energy Rev. 1999, 3, 185–217. [Google Scholar] [CrossRef]

- Qiblawey, H.M.; Banat, F. Solar thermal desalination technologies. Desalination 2008, 220, 633–644. [Google Scholar] [CrossRef]

- Delgado-Torres, A.M.; García-Rodríguez, L. Status of solar thermal-driven reverse osmosis desalination. Desalination 2007, 216, 242–251. [Google Scholar] [CrossRef]

- Delgado-Torres, A.M. Solar thermal heat engines for water pumping: An update. Renew. Sustain. Energy Rev. 2009, 13, 462–472. [Google Scholar] [CrossRef]

- Tchanche, B.F.; Papadakis, G.; Lambrinos, G.; Frangoudakis, A. Fluid selection for a low-temperature solar organic Rankine cycle. Appl. Therm. Eng. 2009, 29, 2468–2476. [Google Scholar]

- Baral, S.; Kim, K.C. Thermodynamic modeling of the solar organic Rankine cycle with selected organic working fluids for cogeneration. Distrib. Gener. Altern. Energy J. 2014, 29, 7–34. [Google Scholar] [CrossRef]

- Baral, S.; Kim, D.; Yun, E.; Kim, K.C. Energy, exergy and performance analysis of small-scale organic Rankine cycle systems for electrical power generation applicable in rural areas of developing countries. Energies 2015, 8, 684–713. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Solar thermal collectors and applications. Prog. Energy Combust. Sci. 2004, 30, 231–295. [Google Scholar] [CrossRef]

- Quoilin, S.; Orosz, M.; Hemond, H.; Lemort, V. Performance and design optimization of a low-cost solar organic Rankine cycle for remote power generation. Sol. Energy 2011, 85, 955–966. [Google Scholar] [CrossRef]

- Yunus, A.C.; Cimbala, J.M. Fluid Mechanics: Fundamentals and Applications (International Edition); McGraw Hill Publication: New York, NY, USA, 2006; pp. 185–201. [Google Scholar]

- Grunfos USA. Available online: https://us.grundfos.com (accessed on 5 August 2015).

- Kosmadakis, G.; Manolakos, D.; Kyritsis, S.; Papadakis, G. Economic assessment of a two-stage solar organic Rankine cycle for reverse osmosis desalination. Renew. Energy 2009, 34, 1579–1586. [Google Scholar] [CrossRef]

- Baral, S.; Kim, D.; Yun, E.; Kim, K.C. Experimental and Thermoeconomic Analysis of Small-Scale Solar Organic Rankine Cycle (SORC) System. Entropy 2015, 17, 2039–2061. [Google Scholar] [CrossRef]

- Trading Economics. Nepal Interest Rate 2003–2005. Available online: http://www.tradingeconomics.com/nepal/interest-rate (accessed on 6 August 2015).

- Park, C.S. Fundamentals of Engineering Economics; Prentice Hall: Upper Saddle River, NJ, USA, 2004. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baral, S.; Kim, K.C. Stand-Alone Solar Organic Rankine Cycle Water Pumping System and Its Economic Viability in Nepal. Sustainability 2016, 8, 18. https://doi.org/10.3390/su8010018

Baral S, Kim KC. Stand-Alone Solar Organic Rankine Cycle Water Pumping System and Its Economic Viability in Nepal. Sustainability. 2016; 8(1):18. https://doi.org/10.3390/su8010018

Chicago/Turabian StyleBaral, Suresh, and Kyung Chun Kim. 2016. "Stand-Alone Solar Organic Rankine Cycle Water Pumping System and Its Economic Viability in Nepal" Sustainability 8, no. 1: 18. https://doi.org/10.3390/su8010018