Thermodynamic Analyses of Biomass Gasification Integrated Externally Fired, Post-Firing and Dual-Fuel Combined Cycles

Abstract

:1. Introduction

2. Descriptions of Systems

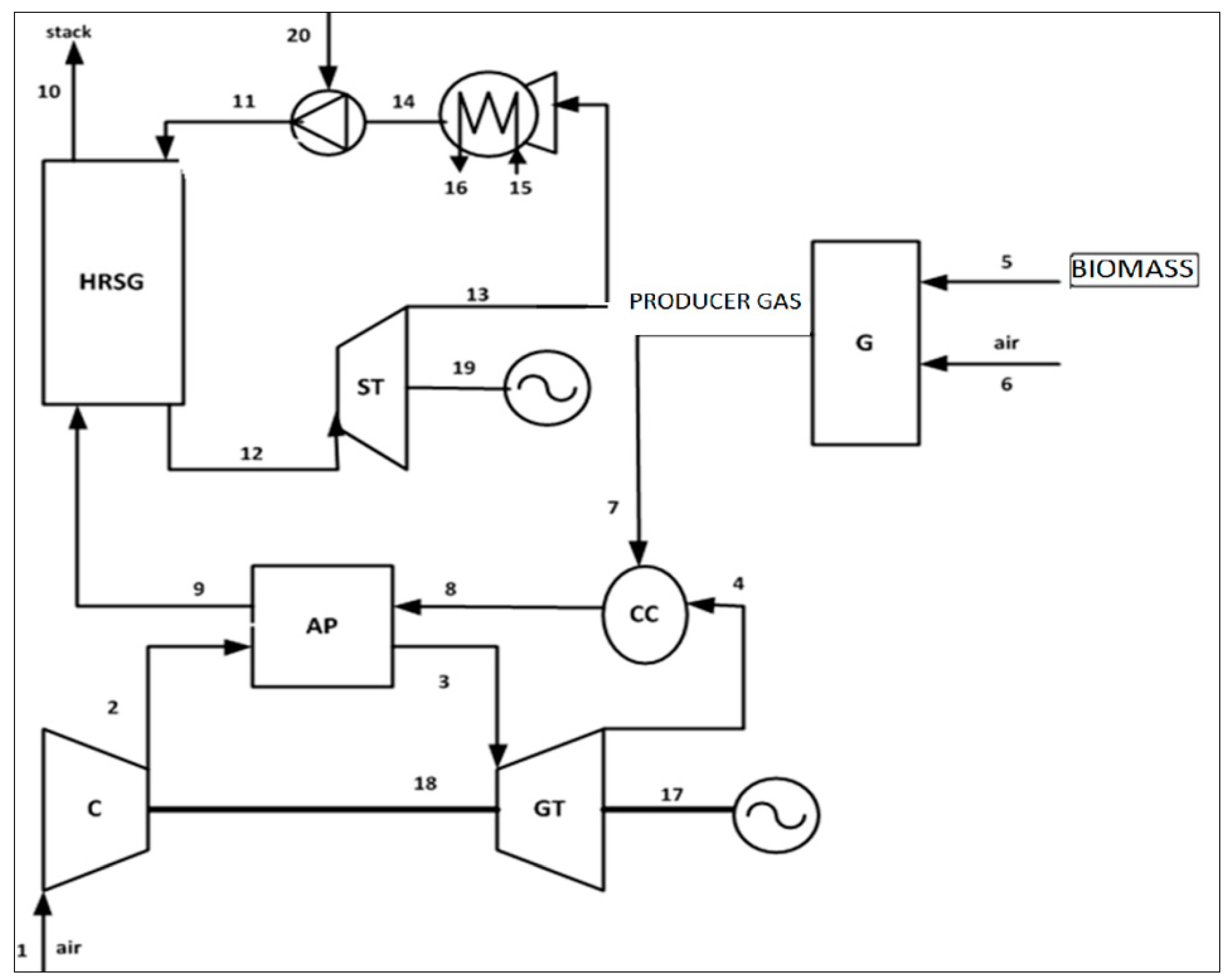

- BGI-EFCC (Figure 1): Wood fuel is put into the gasifier, and producer gas from the gasifier and heated air from the gas turbine enter the combustion chamber. Exhaust gases from the combustion chamber heat the compressed air in a heat exchanger and then produce steam for the steam cycle in a heat recovery steam generator (HRSG).

- BGI-DFCC (Figure 2): This cycle uses a fuel mix of natural gas and biomass (wood) [12]. Air exiting the compressor passes through the pre-heater to the combustion chamber. Natural gas fuel is put into the combustion chamber. The producer gas from a downdraft gasifier is conveyed to the post-combustion unit where it mixes with the combustion gases from the gas turbine. Combustion exhaust gases from the post combustion unit preheat the airflow and pass through a HRSG, in which steam for the steam cycle is produced.

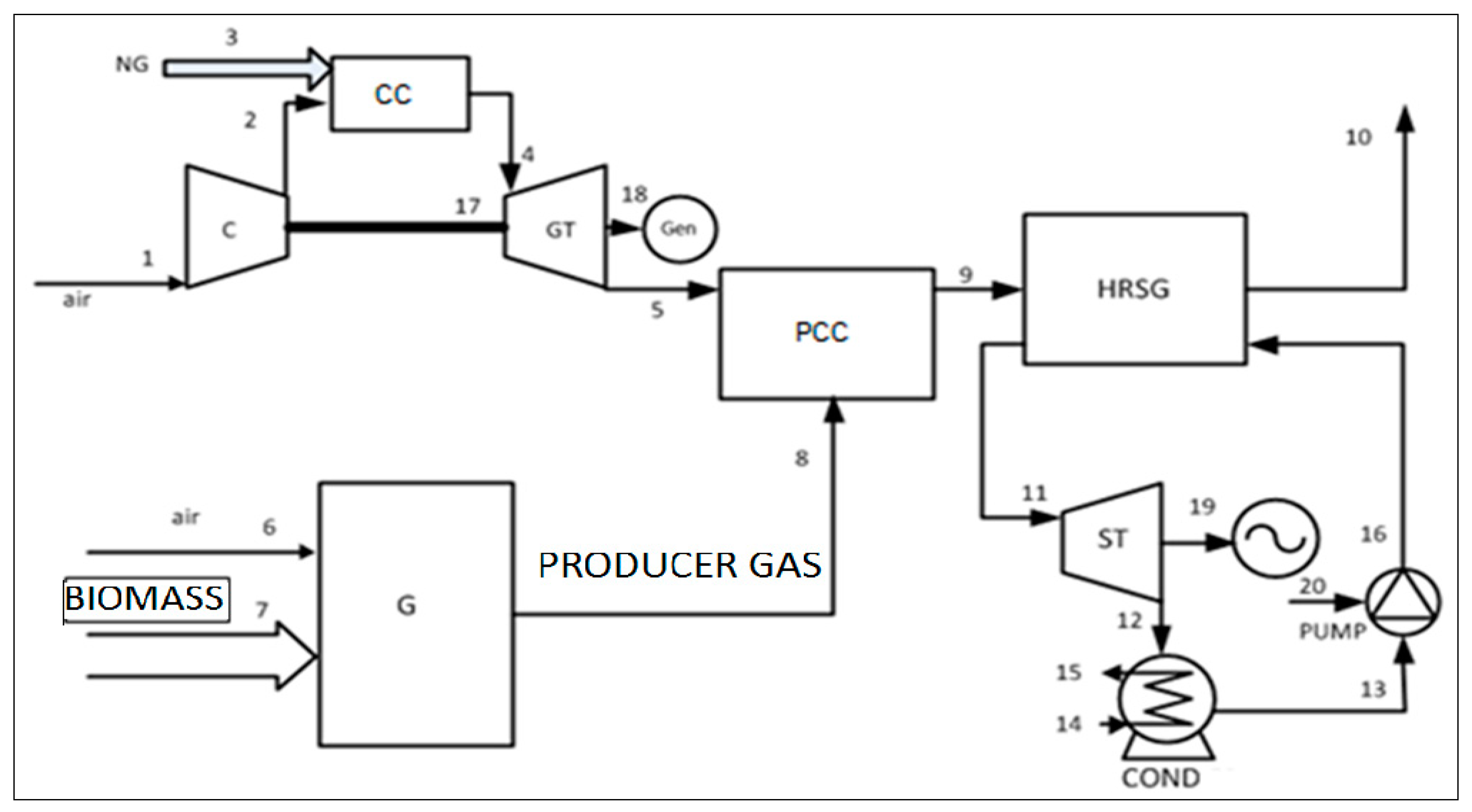

- BGI-PFCC (Figure 3): This cycle also uses a fuel mix of natural gas and biomass (wood). The producer gas from a downdraft gasifier flows to the post-combustion unit, where it is combusted using the oxygen content of the combustion gases exiting the gas turbine. Unlike Figure 2, the exhaust gases from post combustion unit flow to the heat recovery steam generator.

3. Analyses

| Component | Exergy of Fuel | Exergy of Product |

|---|---|---|

| Compressor | ||

| Air Pre-heater | ||

| Gas Turbine | ||

| Combustion Chamber | ||

| Gasifier | ||

| HRSG | ||

| Steam Turbine | ||

| Condenser | ||

| Pump |

| Component | Exergy of Fuel | Exergy of Product |

|---|---|---|

| Compressor | ||

| Air Pre-heater | ||

| Gas Turbine | ||

| Combustion Chamber | ||

| Post Combustion Chamber | ||

| Gasifier | ||

| HRSG | ||

| Steam Turbine | ||

| Condenser | ||

| Pump |

| Component | Exergy of Fuel | Exergy of Product |

|---|---|---|

| Compressor | ||

| Gas Turbine | ||

| Combustion Chamber | ||

| Post Combustion Chamber | ||

| Gasifier | ||

| HRSG | ||

| Steam Turbine | ||

| Condenser | ||

| Pump |

| Constituent | Present Model | Experiment [23] | Zainal Equilibrium Model [22] |

|---|---|---|---|

| H2 | 18.01 | 15.23 | 21.06 |

| CO | 18.77 | 23.04 | 19.61 |

| CH4 | 0.68 | 1.58 | 0.64 |

| CO2 | 13.84 | 16.42 | 12.01 |

| N2 | 48.7 | 42.31 | 46.68 |

| O2 | 0.00 | 1.42 | 0.00 |

| Stream | T (K) | P (kPa) | (kg/s) |

|---|---|---|---|

| (a) Parameter Values for Key Streams in the BGI-EFCC Plant * | |||

| 2 | 590.50 | 910.70 | 16.55 |

| 4 | 878.80 | 103.66 | 16.55 |

| 8 | 1520 | 102.54 | 21.02 |

| 10 | 384.30 | 101.13 | 21.02 |

| 12 | 850.00 | 8000.00 | 3.87 |

| (b) Parameter Values for Key Streams in the BGI-DFCC Plant * | |||

| 2 | 590.50 | 910.70 | 16.89 |

| 6 | 886.10 | 103.66 | 17.05 |

| 10 | 1283.00 | 102.54 | 19.60 |

| 12 | 384.60 | 101.13 | 19.60 |

| 13 | 850.00 | 8000.00 | 3.61 |

| (c) Parameter Values for Key Streams in the BGI-PFCC * | |||

| 2 | 590.50 | 910.70 | 17.27 |

| 5 | 893.90 | 102.14 | 17.62 |

| 9 | 940.00 | 101.13 | 17.96 |

| 10 | 384.90 | 101.13 | 19.96 |

| 12 | 850.00 | 8000.00 | 3.30 |

4. Results and Discussion

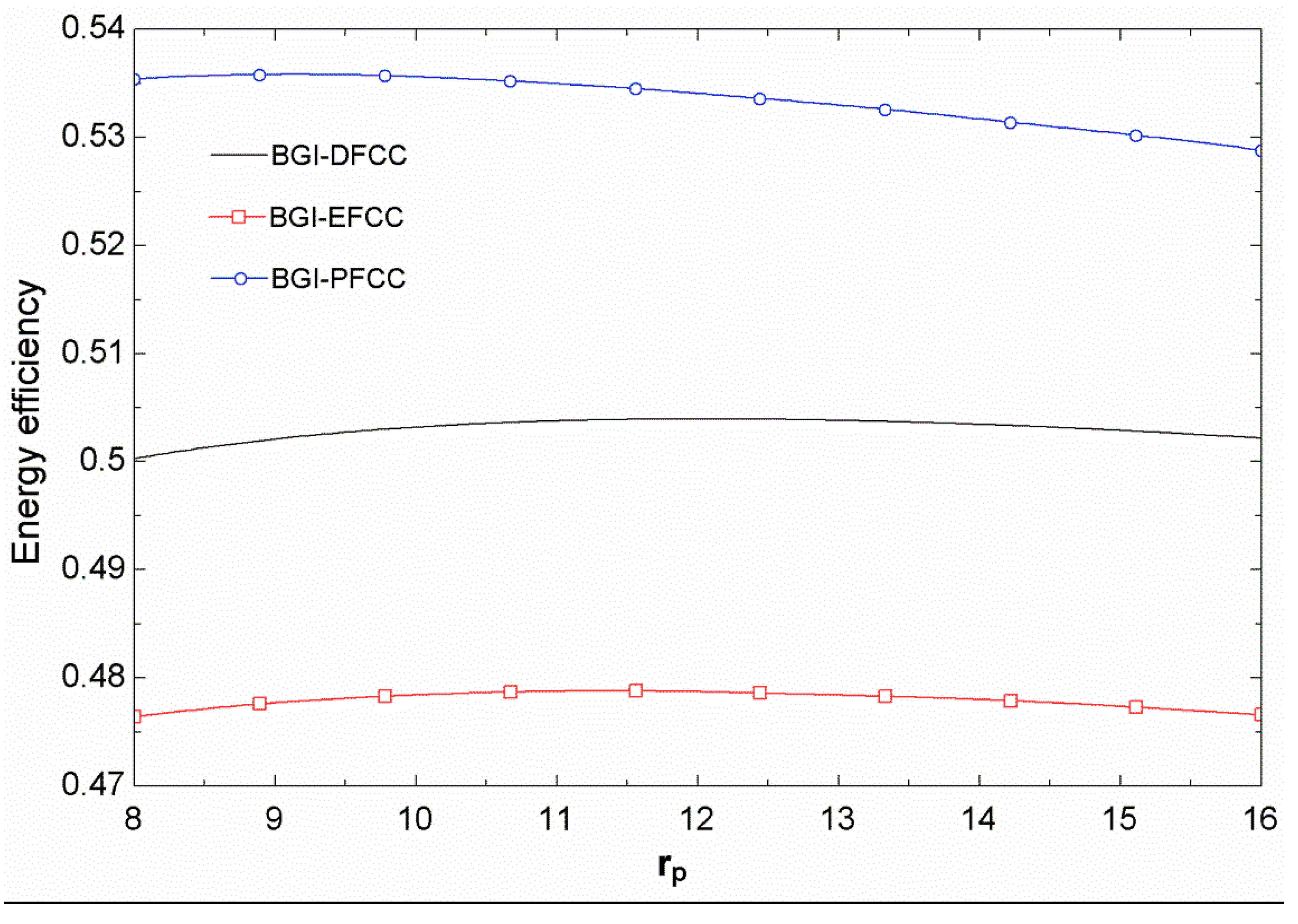

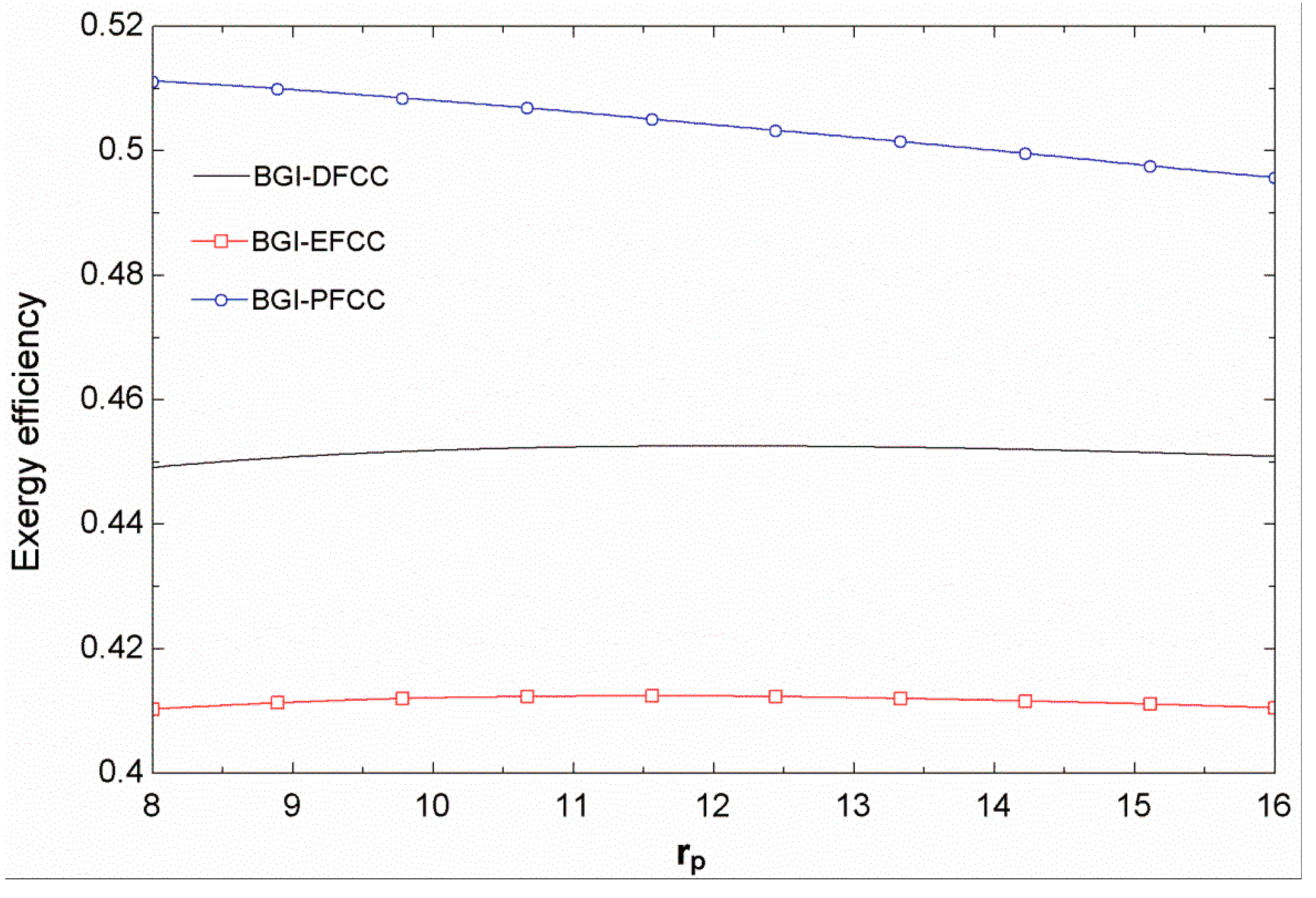

Relations between Performance and Operating Parameters

5. Conclusions

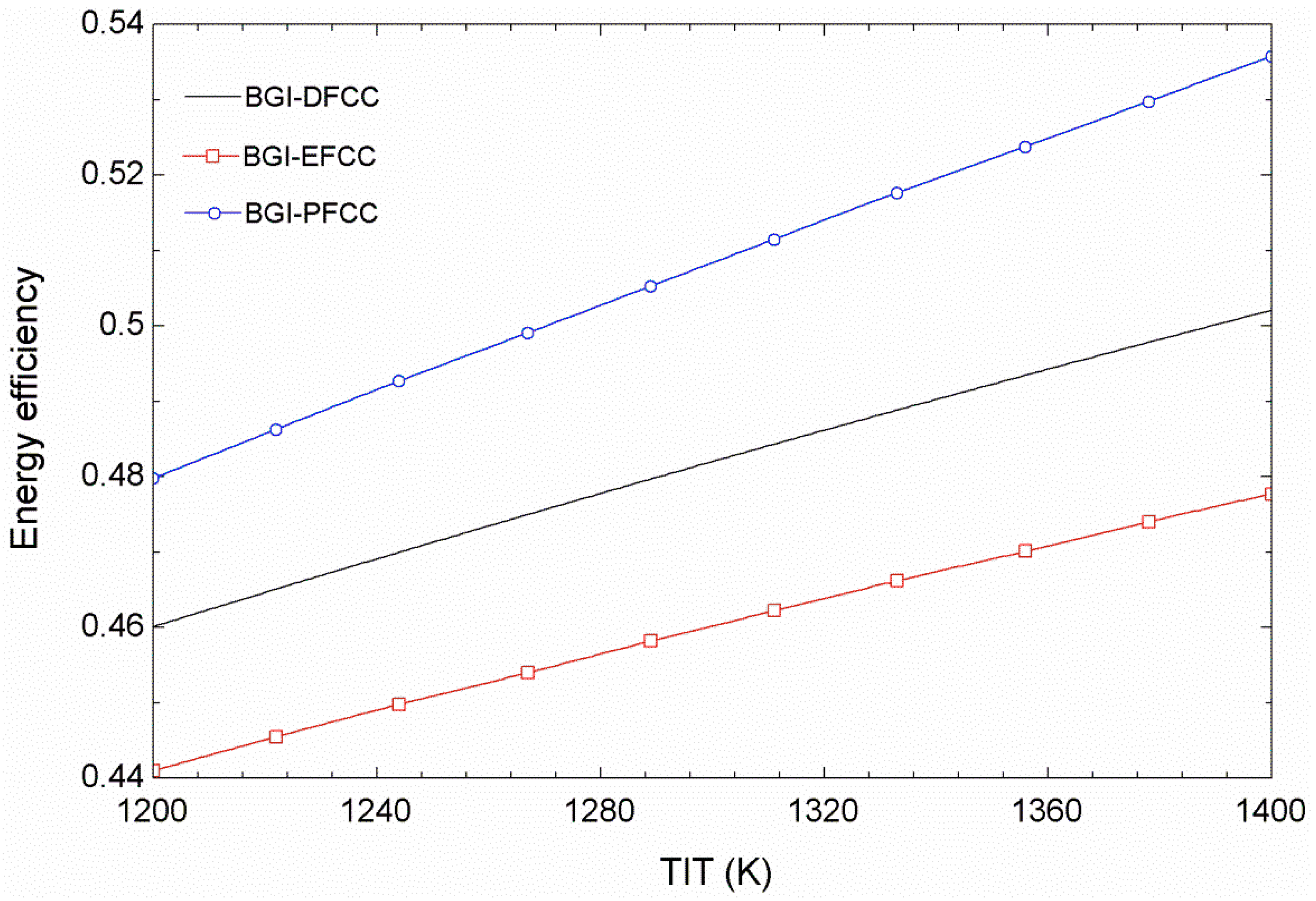

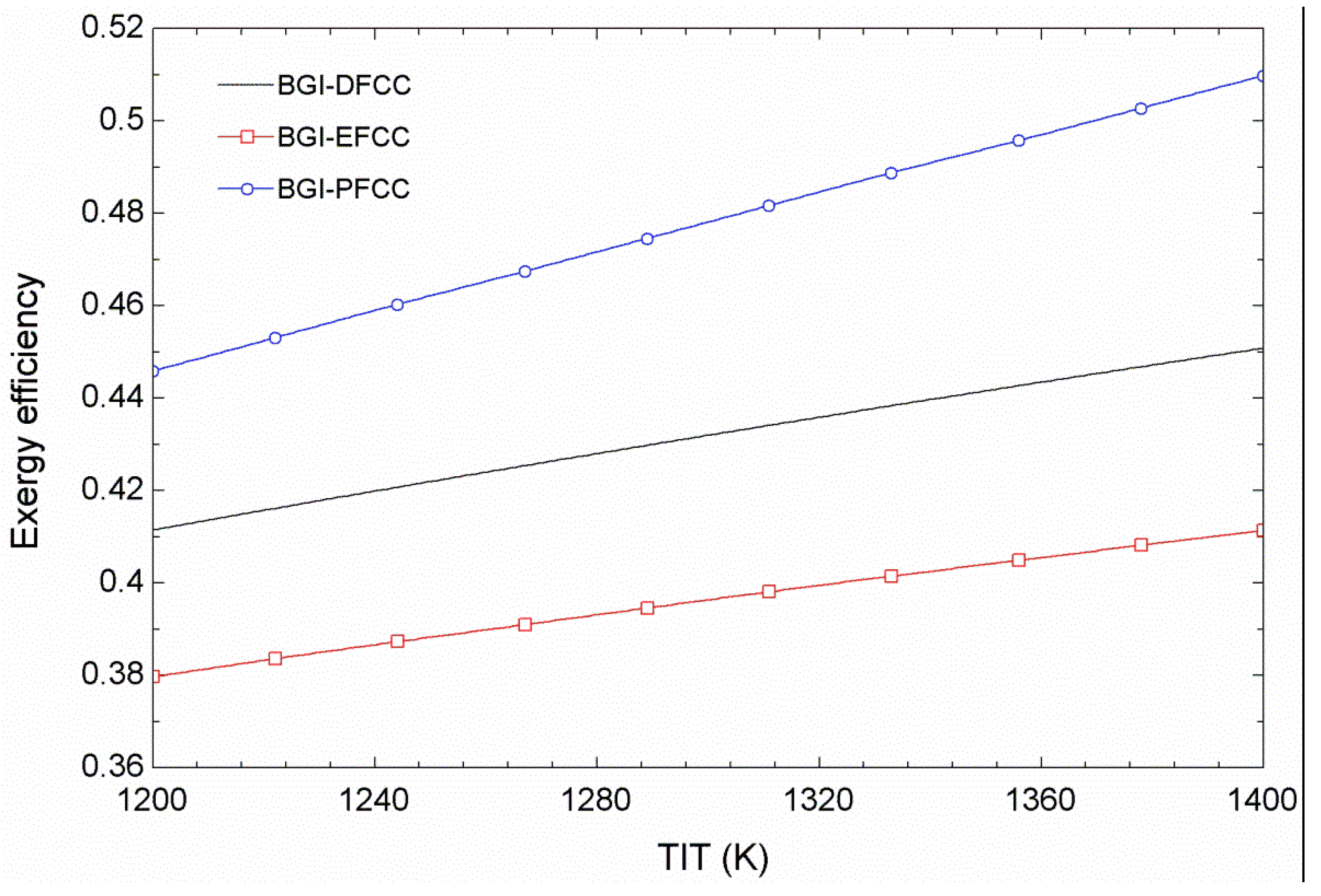

- The BGI-PFCC energy efficiency is about 3% and 6% points higher than those of the BGI-DFCC and BGI-EFCC, respectively. Correspondingly, the exergy loss in BGI-PFCC is lower relative to the BGI-DFCC and BGI-EFCC. The energy and exergy efficiencies of the three biomass fired configurations are maximized at particular values of the compressor pressure ratios, and increasing the TIT raises the energy and exergy efficiencies for the BGI-PFCC, BGI-EFCC, and BGI-DFCC.

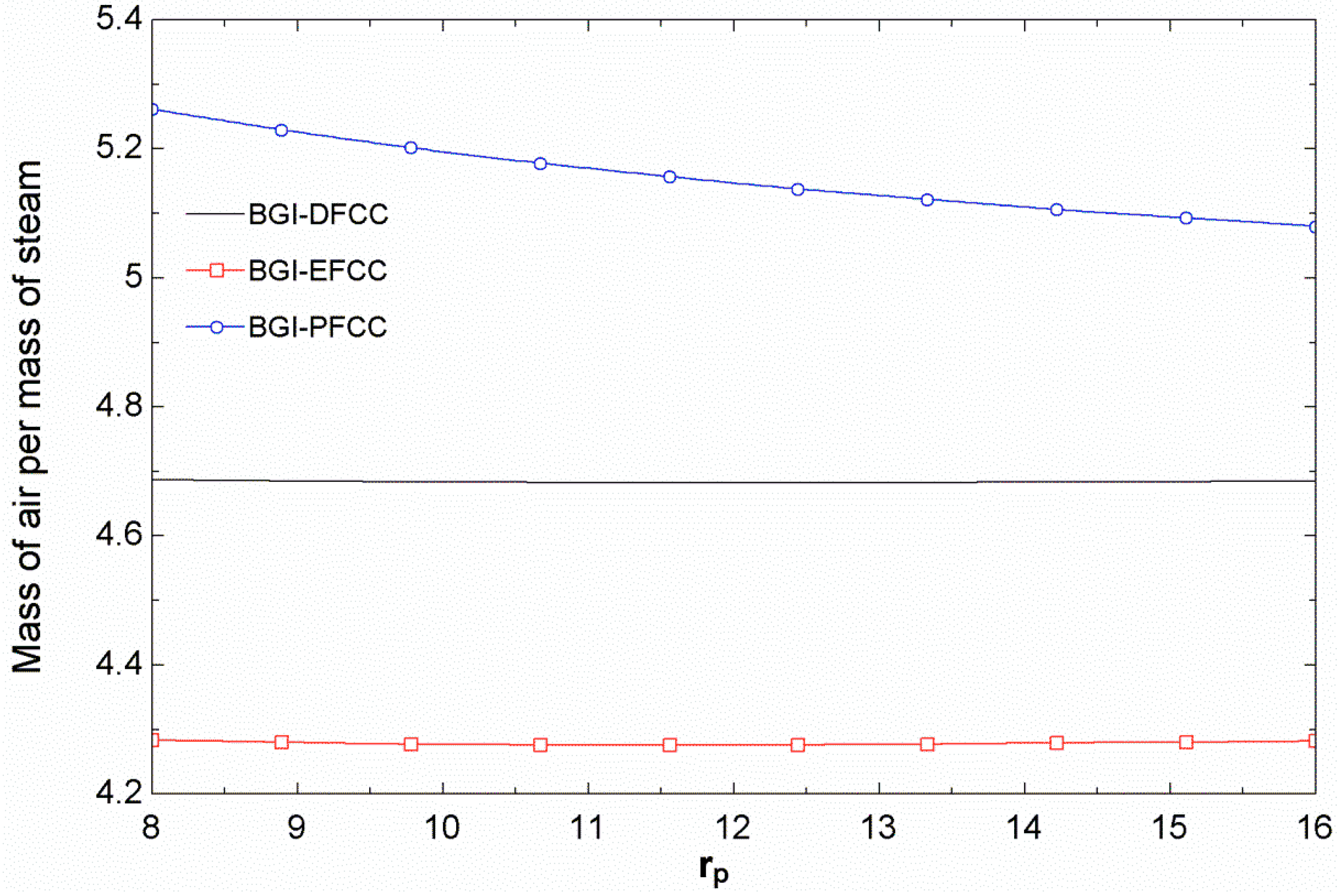

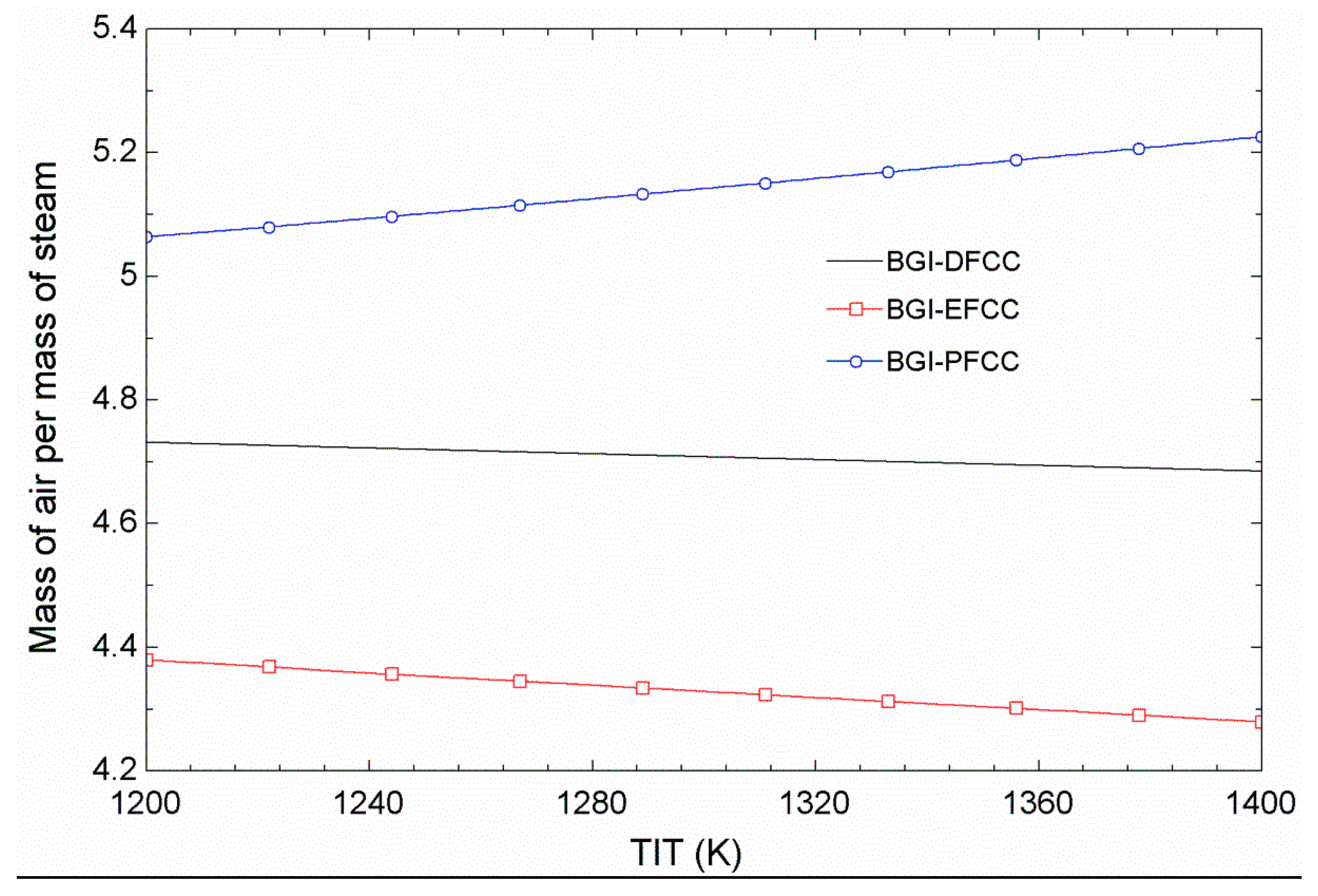

- The mass of air per mass of steam is highest for the BGI-PFCC, but increasing the pressure ratio reduces this value for the BGI-PFCC and increases it slightly for the BGI-DFCC and BGI-EFCC. Increasing TIT raises the mass of air per mass of steam for the BGI-PFCC and decreases it slightly for the other cycles.

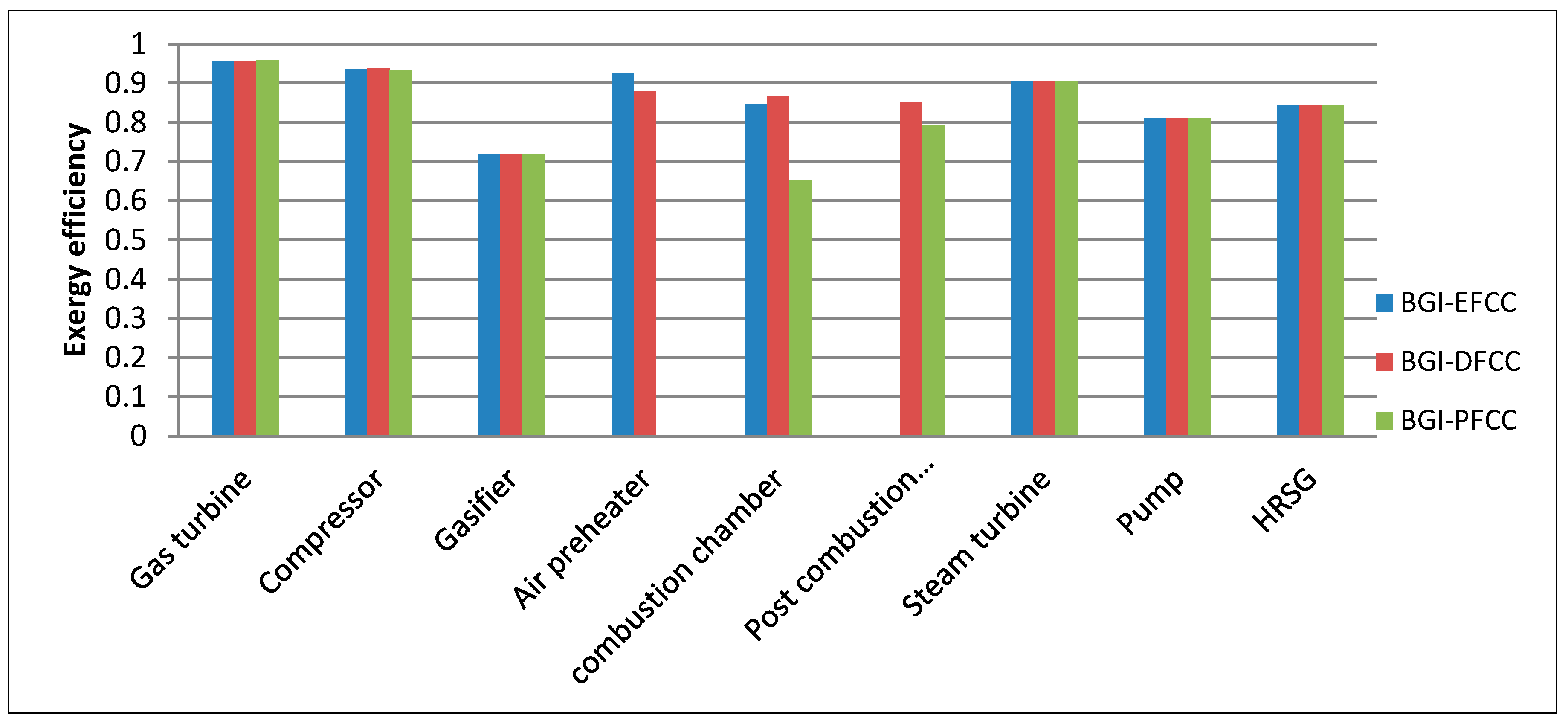

- The exergy efficiencies for the components of the three configurations, determined for the maximum energy efficiency condition, indicate that the gas turbine exergy efficiency is the highest for three configurations, the BGI-PFCC exhibits the highest gas turbine exergy efficiency, the BGI-DFCC combustion chamber has the highest exergy efficiency, and the lowest exergy efficiency is for the BGI-PFCC. The post combustion chamber of the BGI-DFCC exhibits the highest exergy efficiency, while the heat exchanger exergy efficiency is highest for the BGI-EFCC.

- Thermodynamic analysis for three cycles show that the BGI-PFCC is the more efficient cycle, followed in order by the BGI-DFCC and the BGI-EFCC plants. Also, the air preheater is a costly component in the BGI-DFCC and BGI-EFCC plants and is a negative feature of these plants. On the contrary, the BGI-EFCC plant has the highest exergy efficiencies for the air preheater and HRSG and only uses biomass. This last point makes the efficiencies of biomass plants comparatively low, but the enhanced availability, renewability and environmental characteristics can justify their uses. The results may prove beneficial for designers and engineers of such systems.

Author Contributions

Nomenclature

| AP | Air pre-heater |

| BGI-DFCC | Biomass gasification integrated dual-fuel combined cycle |

| BGI-EFCC | Biomass gasification integrated externally fired combined cycle |

| BGI-PFCC | Biomass gasification integrated post-firing combined cycle |

Exergy rate (kW) | |

| G | Gasifier |

| GT | Gas turbine |

Enthalpy of formation (kJ/kmol) | |

| HRSG | Heat recovery steam generator |

| K | Equilibrium constant (-) |

| LHV | Lower heating value (kJ/kg) |

Mass flow rate (kg/s) | |

| n | Number of kmoles |

| P | Pump |

| Pi | Pressure at state i; partial pressure for species i (kPa) |

| PCC | Post combustion chamber |

| rp | Pressure ratio (-) |

| Ti | Temperature at state i (K) |

| TIT | Gas turbine inlet temperature (K) |

Net power (kW) | |

| x | Steam quality (-) |

Greek Letters

Energy efficiency (-) | |

Isentropic efficiency of compressor (-) | |

Isentropic efficiency of gas turbine (-) | |

Isentropic efficiency of steam turbine (-) | |

Exergy efficiency (-) |

Subscripts

| C | Compressor |

| CC | Combustion chamber |

| COND | Condenser |

| F | Fuel |

| GT | Gas turbine |

| in | Input |

| is | Isentropic |

| i | Index for thermodynamic state point |

| P | Product |

| ST | Steam turbine |

Conflicts of Interest

References

- Al Kassir, A.; Gomez, J.G.; Mohamad, A.A.; Correa, E.M.C. A study of energy production from cork residues: Sawdust, sandpaper dust and triturated wood. Energy 2010, 35, 382–386. [Google Scholar] [CrossRef]

- Abuadala, A.; Dincer, I. Investigation of a multi-generation system using hybrid steam biomass gasification for hydrogen, power and heat. Int. J. Hydrog. Energy 2010, 35, 13146–13157. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Manna, D.; Paul, B.; Datta, A. Biomass integrated gasification combined cycle power generation with supplementary biomass firing: Energy and exergy based performance analysis. Energy 2011, 36, 2599–2610. [Google Scholar] [CrossRef]

- Gnanapragasm, N.V.; Reddy, B.V.; Rosen, M.A. Optimum conditions for a natural gas combined cycle power generation system based on available oxygen when using biomass as supplementary fuel. Energy 2009, 34, 816–826. [Google Scholar] [CrossRef]

- Consonni, S.; Larson, E.D. Biomass-gasifier/aeroderivative gas turbine combined cycles. Part A—Technologies and performance modeling. J. Eng. Gas Turbines Power 1996, 118, 507–515. [Google Scholar] [CrossRef]

- Faaij, A.; van Ree, R.; Waldheim, L.; Olsson, E.; Oudhuis, A.; van Wijk, A.; Daey-Ouwens, C.; Turkenburg, W. Gasification of biomass wastes and residues for electricity production. Biomass Bioenerg. 1997, 12, 387–407. [Google Scholar] [CrossRef]

- Rodrigues, M.; Andre, P.C.F.; Walter, A. Techno-economic analysis of co-fired biomass integrated gasification/combined cycle systems with inclusion of economies of scale. Energy 2003, 28, 1229–1258. [Google Scholar] [CrossRef]

- Rosen, M.A.; Dincer, I. Exergoeconomic analysis of power plants operating on various fuels. Appl. Therm. Eng. 2003, 23, 643–658. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Pisa, J. Exergoeconomic evaluation and optimization of energy system—Application to the CGAM problem. Energy 1994, 19, 287–321. [Google Scholar] [CrossRef]

- Soltani, S.; Mahmoudi, S.M.S.; Yari, M.; Rosen, M.A. Thermodynamic analyses of an externally fired gas turbine combined cycle integrated with a biomass gasification plant. Energy Convers. Manag. 2013, 70, 107–115. [Google Scholar] [CrossRef]

- Datta, A.; Ganguly, R.; Sarkar, L. Energy and exergy analyses of an externally fired gas turbine (EFGT) cycle integrated with biomass gasifier for distributed power generation. Energy 2010, 35, 341–350. [Google Scholar] [CrossRef]

- Franco, A.; Giannini, N. Perspectives for the use of biomass as fuel in combined cycle power plants. Int. J. Therm. Sci. 2005, 44, 163–177. [Google Scholar] [CrossRef]

- Spath, P. Innovative Ways of Utilizing Biomass in a Cofiring Scenario with a Gas Turbine Integrated Combined Cycle System. Power Milestone Completion Report; National Renewable Energy Laboratory: Golden, CO, USA, 1995. [Google Scholar]

- Walter, A.; Rodrigues, M.; Overend, R. Feasibility of co-firing (Biomass + Natural Gas). In Proceedings of The Fourth Biomass Conference of the Americas, Oakland, CA, USA, 29 August–2 September 1998; Elsevier: Oxford, UK, 1999; Volume 2, pp. 1321–1327. [Google Scholar]

- Walter, A.; Llagostera, J.; Gallo, W.L.R. Impact of gas turbine de-rating on the performance and economics of BIG-GT cycles. In Proceedings of the Advanced Energy Systems Division, ASME International Mechanical Engineering Congress and Exposition, Anaheim, CA, USA, 15–20 November 1998; pp. 67–72.

- Robert, H.P.; Don, W.G. Perry’s Chemical Engineers Hand Book, 6th ed.; McGraw Hill: New York, NY, USA, 1984. [Google Scholar]

- Cocco, D.; Deiana, P.; Cau, G. Performance evaluation of small size externally fired gas turbine (EFGT) power plants integrated with direct biomass dryers. Energy 2006, 31, 1459–1471. [Google Scholar] [CrossRef]

- Moran, M.J.; Shapiro, H.N.; Boettner, D.D.; Bailey, M.B. Fundamentals of Engineering Thermodynamics, 7th ed.; Wiley: New York, NY, USA, 2011. [Google Scholar]

- Dincer, I.; Rosen, M.A. Exergy: Energy, Environment and Sustainable Development, 2nd ed.; Elsevier: Oxford, UK, 2013. [Google Scholar]

- Kotas, T.J. The Exergy Method of Energy Plant Analysis; Butterworths: London, UK, 1985. [Google Scholar]

- Szargut, J.; Styrylska, T. Approximate evaluation of exergy of fuels. Brennst. Warme Kraft 1964, 16, 589–596. [Google Scholar]

- Zainal, Z.A.; Ali, R.; Lean, C.H. Prediction of performance of downdraft gasifier using equilibrium modeling for different biomass materials. Energy Convers. Manag. 2001, 42, 1499–1515. [Google Scholar] [CrossRef]

- Alauddin, Z.A. Performance and Characteristics of a Biomass Gasifier System. Ph.D. Thesis, University of Wales, College of Cardiff, Cardiff, UK, 1996. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soltani, S.; Athari, H.; Rosen, M.A.; Mahmoudi, S.M.S.; Morosuk, T. Thermodynamic Analyses of Biomass Gasification Integrated Externally Fired, Post-Firing and Dual-Fuel Combined Cycles. Sustainability 2015, 7, 1248-1262. https://doi.org/10.3390/su7021248

Soltani S, Athari H, Rosen MA, Mahmoudi SMS, Morosuk T. Thermodynamic Analyses of Biomass Gasification Integrated Externally Fired, Post-Firing and Dual-Fuel Combined Cycles. Sustainability. 2015; 7(2):1248-1262. https://doi.org/10.3390/su7021248

Chicago/Turabian StyleSoltani, Saeed, Hassan Athari, Marc A. Rosen, Seyed Mohammad Seyed Mahmoudi, and Tatiana Morosuk. 2015. "Thermodynamic Analyses of Biomass Gasification Integrated Externally Fired, Post-Firing and Dual-Fuel Combined Cycles" Sustainability 7, no. 2: 1248-1262. https://doi.org/10.3390/su7021248

APA StyleSoltani, S., Athari, H., Rosen, M. A., Mahmoudi, S. M. S., & Morosuk, T. (2015). Thermodynamic Analyses of Biomass Gasification Integrated Externally Fired, Post-Firing and Dual-Fuel Combined Cycles. Sustainability, 7(2), 1248-1262. https://doi.org/10.3390/su7021248