1. Introduction

Laterites and lateritic soils, described as Fe

2O

3-Al

2O

3-SiO

2-H

2O matrices, are made from kaolinite in which a high proportion of Al

3+ is replaced by Fe

2+ or Fe

3+. This replacement induces important transformation of the structure of the kaolinite: reduction of the crystallinity, increase of the crystal layer and the amorphous phase with consequent increase in the vulnerability to chemical attack [

1,

2,

3,

4,

5].

Ambrost

et al. [

6], described the antagonism between hematite and kaolinite in the matrix of laterite: the corrosion of the kaolinite is followed by a complete destruction of the crystal giving place to hematite or goethite organized into thin lamellar structures; the crystals of Al-rich hematite or Al-rich goethite formed maintain a clear trace of the shapes of former kaolinite platelets. They postulated that, in the deep layers of laterites fed by Fe

3+ solutions, the protons necessary to dissolve kaolinite are generated by a reaction similar to the oxidation–hydrolysis step of ferrolysis [

6]. Several papers [

3,

4,

5] have shown that, at the places where iron oxides are invading the pores of a soft clay matrix, this matrix soon becomes corroded. Ambrost

et al. [

6] indicated that the protons released by the precipitation of 1 cm

3 of ferrihydrite may solubilize about 1.5 cm

3 of kaolinite. On the other hand, the precipitation of ferrihydrite from Fe

3+ solutions has been shown to be accelerated by interfaces such as those of silica or kaolinite particles. In the presence of kaolinite, the release of Al

3+ species into solution and the precipitation of Fe

3+ hydroxide were observed to be two simultaneous processes [

4,

5,

6].

The increase in iron accumulation led to firstly the production of nodule nuclides that progressively grow with the iron content and, finally, laterite concrete is formed with amorphous silica which acts as binder [

4,

5,

6].The induration of lateritic soils is specific in the tropical regions. The fluctuation of temperature and humidity, grain size, kinetics of precipitation and equilibrium conditions, involving the activity of water, are factors controlling the formation of indurated matrices of laterites. Mottles and concretions with essentially hematite and goethite are a very small size in the first steps of the induration. During the last steps, the goethite phase appears in quite well formed crystals of about 1 micrometer. However, hematite and goethite are generally present with tiny particles of 100 Å, suggesting more impact of dehydration and water activity. For Schwertmann, 1999 [

7], rapid release of Fe and low concentration of organic compound favors hematite formation while high concentration of organic compounds favors goethite. For kinetic reasons, goethite is more common than hematite, and also hematite, once appeared, does not rehydrate to form coarse goethite. The driving force of the migration and accumulation of iron will be suggested to be the difference in size of pores which tends to be accentuated as the concretion process [

8]. For Schellmann

et al. [

7], the chemical and mineralogical results have shown that the primary minerals are generally not fully dissolved but partially transformed in secondary minerals which are more stable. On the other hand, the iron content of laterites will enhance the kinetic of transformation of kaolinite with structure already affected. Various literature discusses the formation and transformations of ferrihydrite under different chemical conditions [

9,

10,

11].

It is expected that the disordered structure of the laterites will allow their dissolution in high alkaline solution and the geopolymerization, reaction products of the laterites and laterites soils in alkali activated media will provide mechanical properties comparable to hardened hydrated composites but with significant reduction of greenhouse footprint [

12]. It is easier in tropical areas to have laterites, generally at the surface, than struggle for clays for which exploitation will be detrimental for the environment because they are covered in most cases by laterites or various types of soils.

A sustainable material should be locally sourced and produced using renewable resources, with negligible transport costs and environmental impact, having thermal efficiency, financial viability and low energy required in the manufacturing process [

12]. These are requirements that can be easily fulfilled with the manufacturing of geopolymers based on laterites rather than metakaolin. In this paper, the understanding of the geopolymerization process adapted to the specific characteristics of laterites is our goal. A suitable production process for stable and durable inorganic polymer cements and composites with good mechanical strength, low porosity and high density achieved on the basis of the local requirements in agreement with the international standards is proposed.

In the case of laterites, it is here necessary to note that the term describes a range of aluminosilicates in which iron accumulation could be at the stage of nodule nuclides, nodules or larger and coarse iron crusts. Their reactivity and behavior during the polycondensation should be linked to the degree of iron accumulation. Taking in account the goethite-diaspore and hematite-corundum profiles describe as solid solutions of crystallized iron-rich oxihydroxides [

3,

4,

5], the substitution of Al

3+ in goethite (Al-goethite) and hematite (Al-hematite) are additional parameters that make the particularity of laterites as aluminosilicates, a particularity that may affect the traditional mechanism of geopolymerisation. To the particle size distribution, reactive amorphous/vitreous phase and the Si/Al, key factors governing the suitability of a solid precursor for geopolymerization of classical aluminosilicates, additional elements as the degree of laterization and the form of iron (ferrihydrite, hematite or goethite) should be considered for laterite materials.

It is expected that lateritic soils can be potential candidates as solid precursors for the geopolymerization. The structure of kaolinite already dissolved/destructed by iron accumulation should be favorable for polycondensation. So, even though all the parameters listed here will not be elucidated in this work, hypotheses described in the above introductive part are used to develop geopolymer matrices with the objectives to verify the effective factors affecting the geopolymerization of this class of aluminosilicates. The present study also intends to confirm whether good geopolymeric products can be obtained from laterites or lateritic soils.

2. Materials and Experimental Methods

2.1. Materials

Two samples of laterites were considered for this study, both collected in Yaoundé town in Cameroon: (i) a red soil (from Mvogbetsi, south west of Yaoundé) with very fine nodules commonly used as additive in the fired clay products and for compressed earth blocks, and (ii) a mix of brown and yellowish soil with high proportion of coarse aggregates. The two materials were collected, dried and ground to fine particles (<80 µm) from Nkolbisson, in the south of Yaoundé, Cameroon. A river sand, semi-crystalline matrix with alpha-quartz as principal mineral, was also collected. The sand has particle size < 500 µm.

Table 1 shows the chemical and mineralogical compositions of the three solid precursors.

Table 1.

Chemical and mineralogical compositions of laterite 1, laterite 2 and river.

Table 1.

Chemical and mineralogical compositions of laterite 1, laterite 2 and river.

| | Laterite 1 | Laterite 2 | River Sand |

|---|

| TiO2 | 1.73 | 4.38 | 0.41 |

| Na2O | 0.57 | 2.37 | 2.6 |

| SiO2 | 46.70 | 31.7 | 59.3 |

| CaO | − | − | 9.22 |

| Al2O3 | 23.04 | 10.6 | 10.7 |

| K2O | 0.13 | 1.98 | 2.14 |

| Fe2O3 | 9.68 | 35.2 | 3.02 |

| MgO | 0.05 | 0.07 | 3.02 |

| L.O.I | 17.50 | 11.3 | 9.12 |

| Minerals | Kaolinite, quartz, ilmenite, hematite, goethite | Kaolinite, quartz, ilmenite, hematite, goethite | Quartz, plagioclase, ilmenite |

Laterite from Mvogbetsi, hereafter L1, with SiO

2/(Al

2O

3 + Fe

2O

3) = 1.43 can be classified as iron-rich aluminosilicate (lateritic soil). Here, the iron accumulation seems to be at the initial stage where kaolinite maintains a stable and ordered structure. Ngon Ngon

et al. [

4] described the material as clayey laterite; the minerals identified are anatase, halloysite, kaolinite, hematite, goethite, quartz and rutile. The laterite from Nkolbisson, hereafter L2, with SiO

2/(Al

2O

3 + Fe

2O

3) = 0.68 is a real ferruginous soil intermediate between the initial stage and the iron crust (

Figure 1a). The difference with L1 is that it is not yet at the level of iron crust; the minerals identified are anatase, kaolinite, ilmenite, hematite, goethite and quartz. The degree of dissolution of kaolinite and subsequent iron accumulation are different for L1 and L2 samples, so that it can be assumed they were collected with the consideration that Laterite 2 could be the subsequent stage of the iron accumulation of Laterite 1 (

Figure 1).

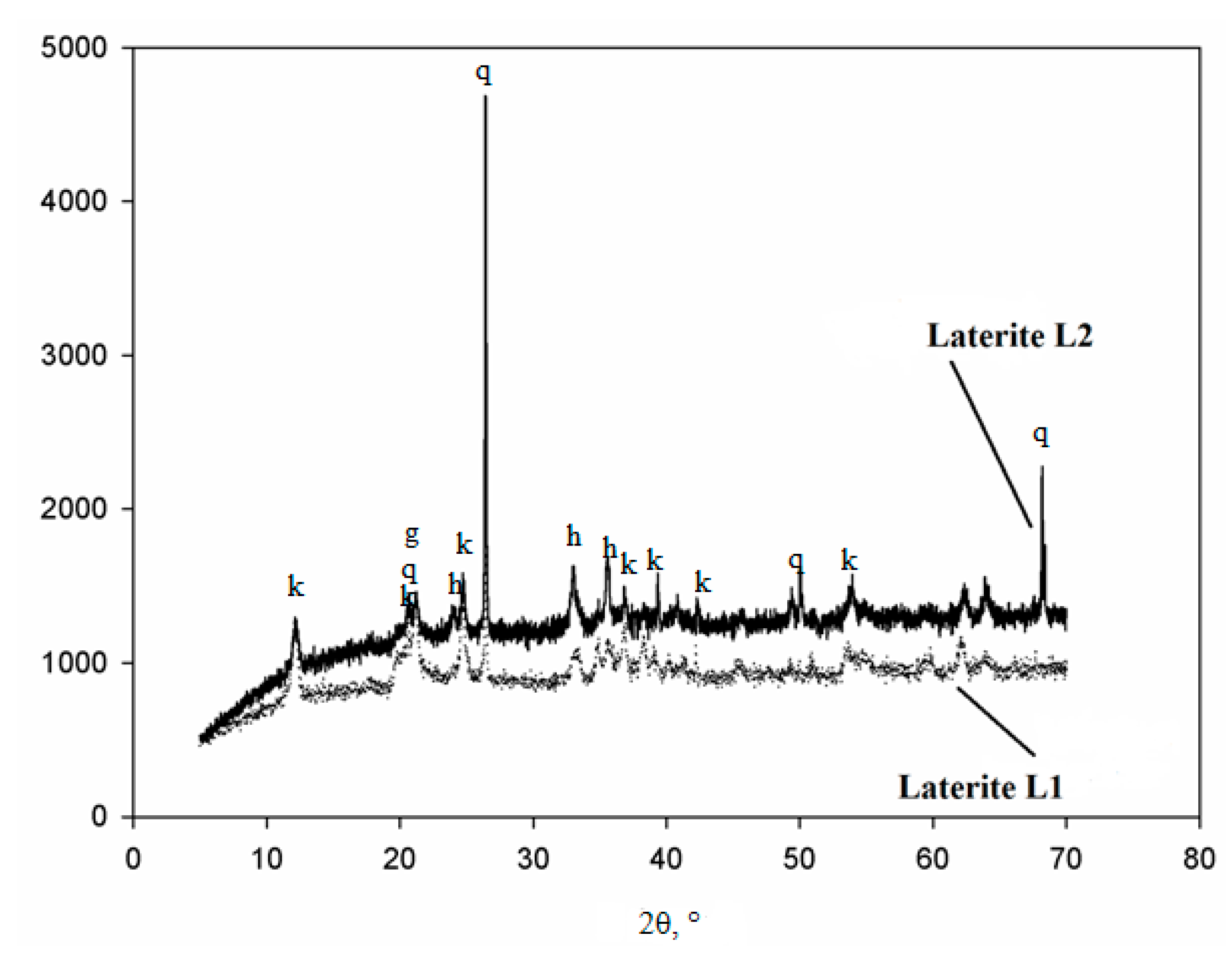

Figure 1.

X-ray diffraction patterns of Laterite 1 and Laterite 2 showing the difference in the amorphous content: k = kaolin, h = hematite, g = goethite.

Figure 1.

X-ray diffraction patterns of Laterite 1 and Laterite 2 showing the difference in the amorphous content: k = kaolin, h = hematite, g = goethite.

The activation of the solid precursors was done using a mix of sodium hydroxide and sodium silicate in the volume ratio 1:1. The sodium hydroxide (8 M) was prepared by dissolving an appropriate amount of NaOH pellets (99.6 wt%) from Aldrich into deionized water. The sodium silicate was a high viscous liquid, with SiO2/Na2O = 2.99, SiO2 = 26.45 wt%, Na2O = 9.14 wt% and L.O.I = 60 wt%, produced by Ingessil, Verona, Italy.

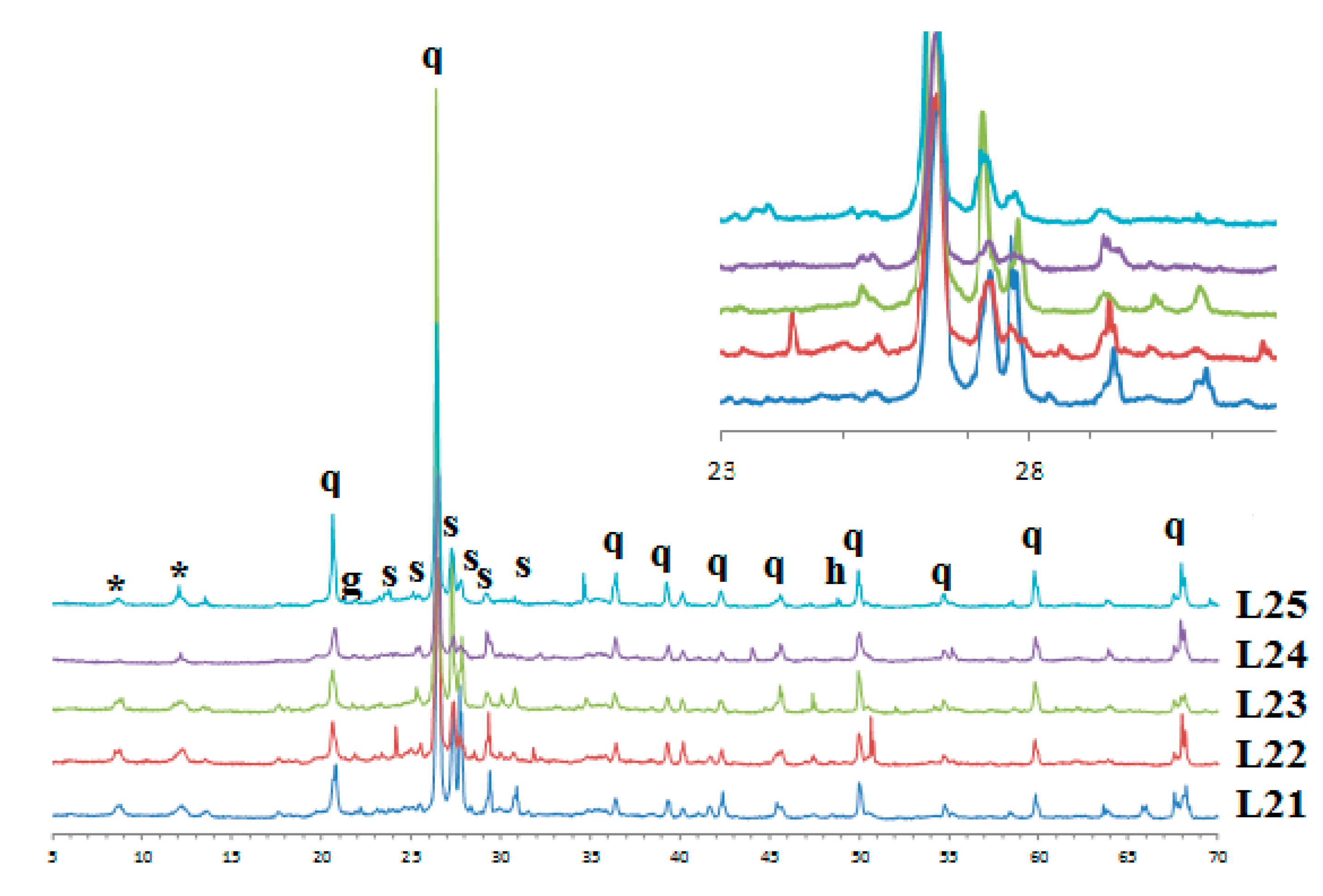

2.2. Compositions Design of Laterite Based Geopolymers

Laterite 1, with high silica content (46.70 wt%), was used to prepare the amorphous fraction of the laterite based geopolymer matrices. Fine powder of Laterite 1 prepared as described above was calcined at 700 °C for 4 h to allow the completion of the loss of structural hydroxyl groups of the residual kaolinite. This amorphous fraction was used from 15–35 wt% on the basis of the literature that describes 3–30 wt% amorphous phase in indurated lateritic blocks [

13]. In their work studying the domains of existence of geopolymers, Prud’Homme

et al. [

14] gave similar consideration about the amorphous phase which in their case was between 25 and 40 molar% of soluble silica. They also recognized the impacts of some impurities in the physic-mechanical properties of geopolymers confirming our projection on the use of river sand which here acts as catalytic agents by promoting interfacial reactions and reinforcements. It was not to this extent our intention to speculate on the iron phases, apart from recognizing their action, as described in the literature, in increasing the disorder in kaolinite allowing their reactivity in the geopolymerization context. The formulations were established as described in

Table 2.

Table 2.

Design of the formulations of laterite based geopolymers.

Table 2.

Design of the formulations of laterite based geopolymers.

| | L11 | L12 | L13 | L14 | L15 | L21 | L22 | L23 | L24 | L25 |

|---|

| Laterite 1 | 17 | 16 | 15 | 14 | 13 | | | | | |

| Laterite 2 | | | | | | 17 | 16 | 15 | 14 | 13 |

| Calcined Laterite 1 | 3 | 4 | 5 | 6 | 7 | 3 | 4 | 5 | 6 | 7 |

| River sand | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| NaH: Na2SiO3 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 |

2.3. Preparation of Laterite Based Geopolymers

Each powder of laterite prepared was mixed to the appropriate amount of calcined Laterite 1 following the formulation considered (

Table 2). River sand was then added and the resultant composite homogenized using ball mill. The alkaline solution was added to the homogeneous powders and a semi-wet pastes obtained. The pastes were pressed using uniaxial type hydraulic press at 40 MPa (Nanneti, Italy). Discs of 40 mm diameter and thickness from 6–9 mm were obtained. The specimens were sealed in plastic for 7 days then the curing continued at room temperature.

2.4. Characterization of Laterites Based Geopolymers

The crystalline phases present in the sintered specimens were identified using the X-ray diffractometer (Philips, mod. PW3710) and a spectroscopy electron microscope (SEM) (Philips mod. XL30). XRD analysis was performed on the flat polished surface to insure the investigations on the real bulk structure of the products. The specimens were scanned from 2θ = 5–70°, at a scanning speed of 2°/min with Cu Kα radiation, λ = 0.154 nm at 40 kV and 40 mA.

Fourier transformed infrared spectroscopy, FT-IR, (Avatar 330 FTIR, Thermo Nicolet) was performed on selected samples analyzing surface and bulk areas. A minimum of 32 scans between 4000 and 400 cm−1 were averaged for each spectrum at intervals of 1 cm−1.

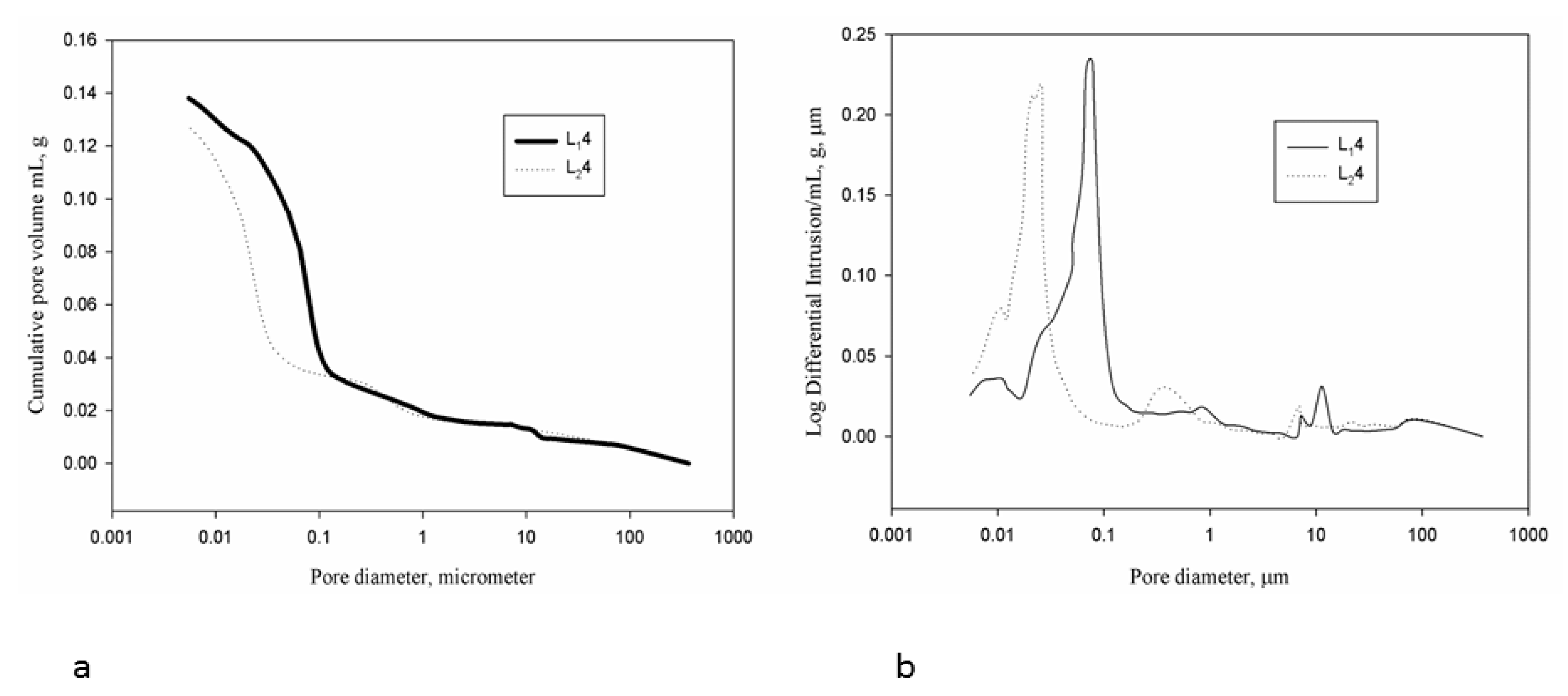

For the evaluation of porosity and pore size distribution, we used a Mercury Intrusion Porosimetry (MIP) for its simplicity, quickness and wide measuring range of pore diameter (from 360–0.005 μm in the case under study).

The Mercury Intrusion Porosimeter (MIP) used was an Auto pore IV 9500, 33000 psi (228 MPa) having two low-pressure ports and one high-pressure chamber. Pieces collected from the mechanical test (biaxial flexural strength test) were used to prepare specimens of ~1 cm3 of volume for the MIP. The sample is weighed and a file is created in which its characteristics are recorded together with analysis conditions and other parameters for the analysis. The measurement includes (1) low-pressure step done with a penetrometer from 0–50 psi (345 kPa), resolution 0.01 psi, pore diameter 360–3.6 μm and transducer accuracy of ±1 of full scale and (2) high-pressure step from atmospheric pressure to 33,000 psi (228 MPa), resolution 0.2 psi from 3000–33,000 psi and 0.1 psi from the atmospheric pressure to 3000 psi, pore diameter 6–0.005 μm and transducer accuracy of ±1 of full scale. When the sample information, analysis conditions, penetrometer properties, and report options are set, the data portion of the sample file is created automatically by the Auto pore software.

The mechanical properties of the laterite based-geopolymer specimens were assessed by the measurement of the biaxial flexural strength through the piston on the three balls test. This test was preferred to the uni-axial bending test because thin plates structures such as structural materials for building and construction are subjected to multi-axial stress states due to complex loading configuration and the geometry structures [

15]. The biaxial flexural strength test has an advantage in that it is capable of generating constant equi-axial flexural stress within the area of the loading ring, which is necessary and useful for the investigations of the stochastic nature of the strength of a brittle material [

15]. The stress inside the loading ring is identical in all directions, which means cracks would initiate in any direction.

For the piston on the three balls, we modified Kirstein and Woolley’s analysis and developed the equation for the maximum biaxial flexural strength:

where

P is the ultimate sustained load,

a is the radius of the support ring,

b is the effective radius of the contact of the loading ball on the specimen,

R is the specimen radius,

t is the specimen thickness and

ν is the Poisson’s ratio.

Jihwan

et al. [

15] claimed that this solution should approximately be independent from the number of supporting balls, so it can be applied to axi- but also to non-strictly axi-symmetric testing configurations.

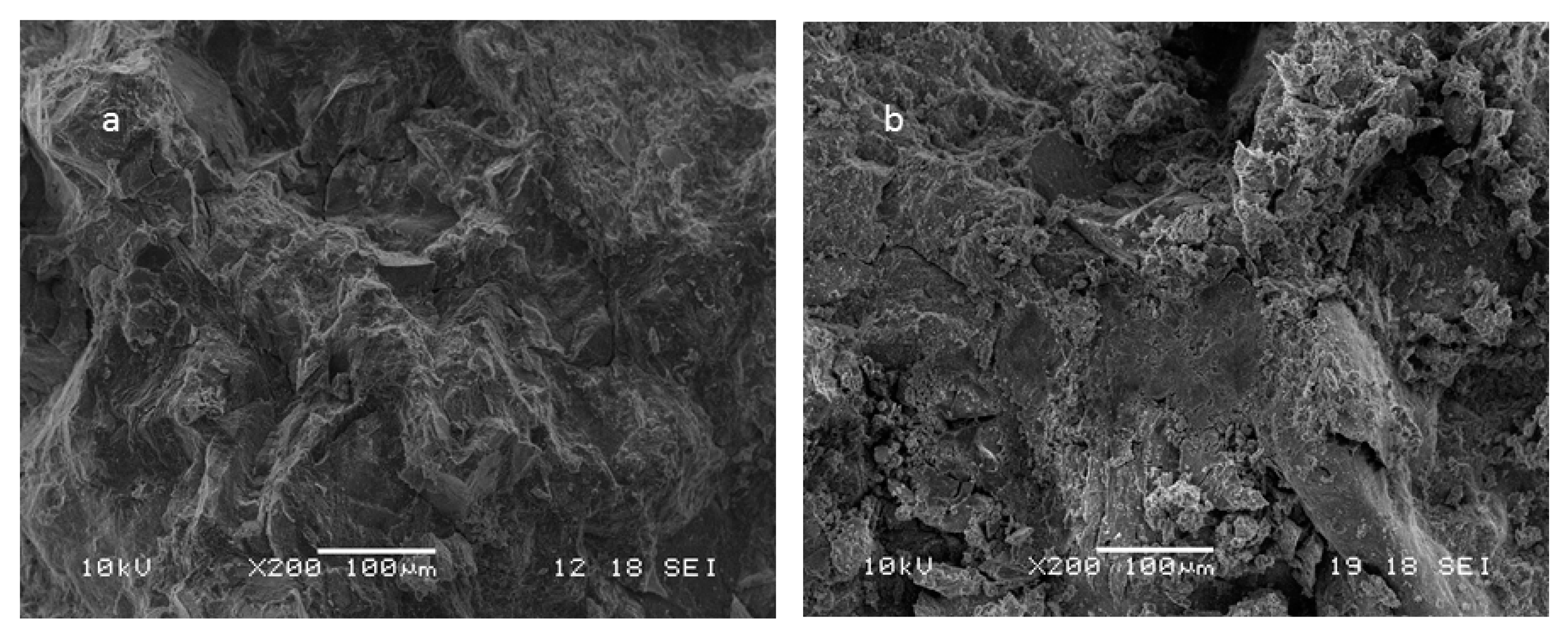

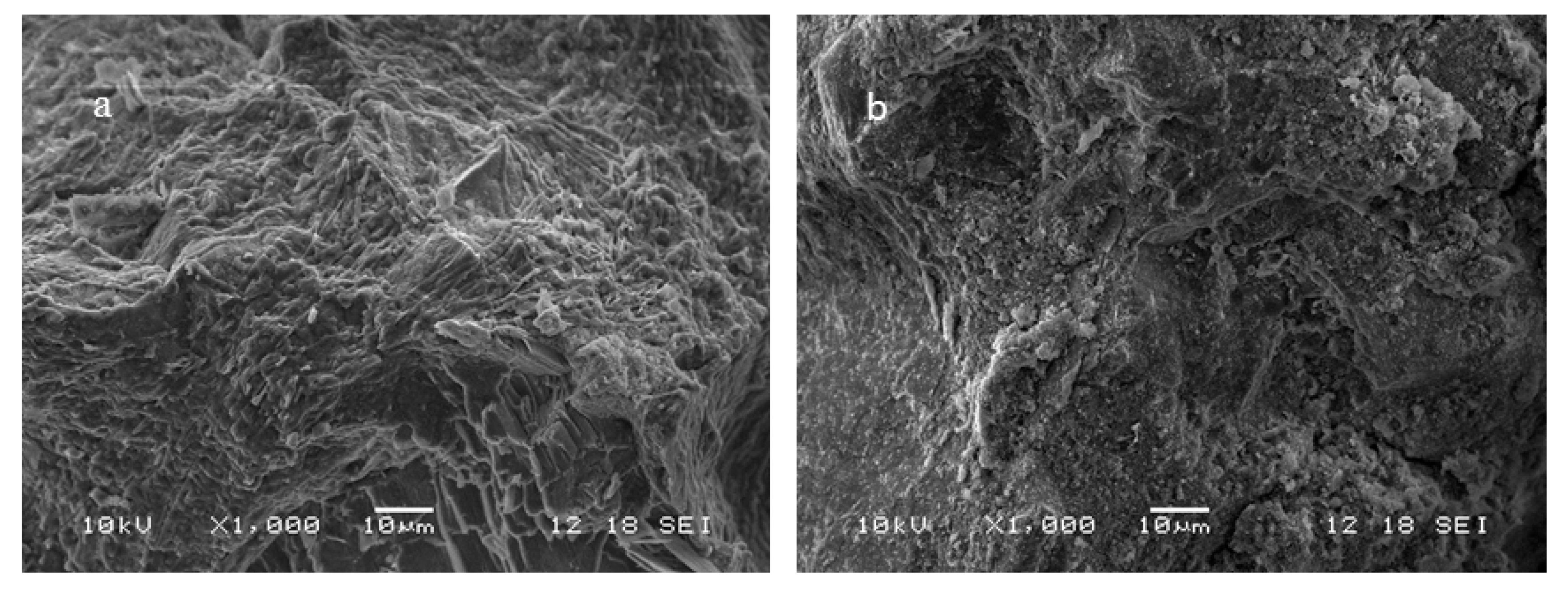

Scanning electron microscopy (SEM) investigations were conducted on a Jeol, mod. 5500 coupled to a EDS probe iXRF system using backscattered electron (BSE) and secondary electron (SE) imaging was used to study the specimens, which were collected from pieces obtained after the biaxial flexural strength test. The fresh fractured pieces were gold coated to ensure conditions of viability for analytical purposes.

4. Discussion and Conclusions

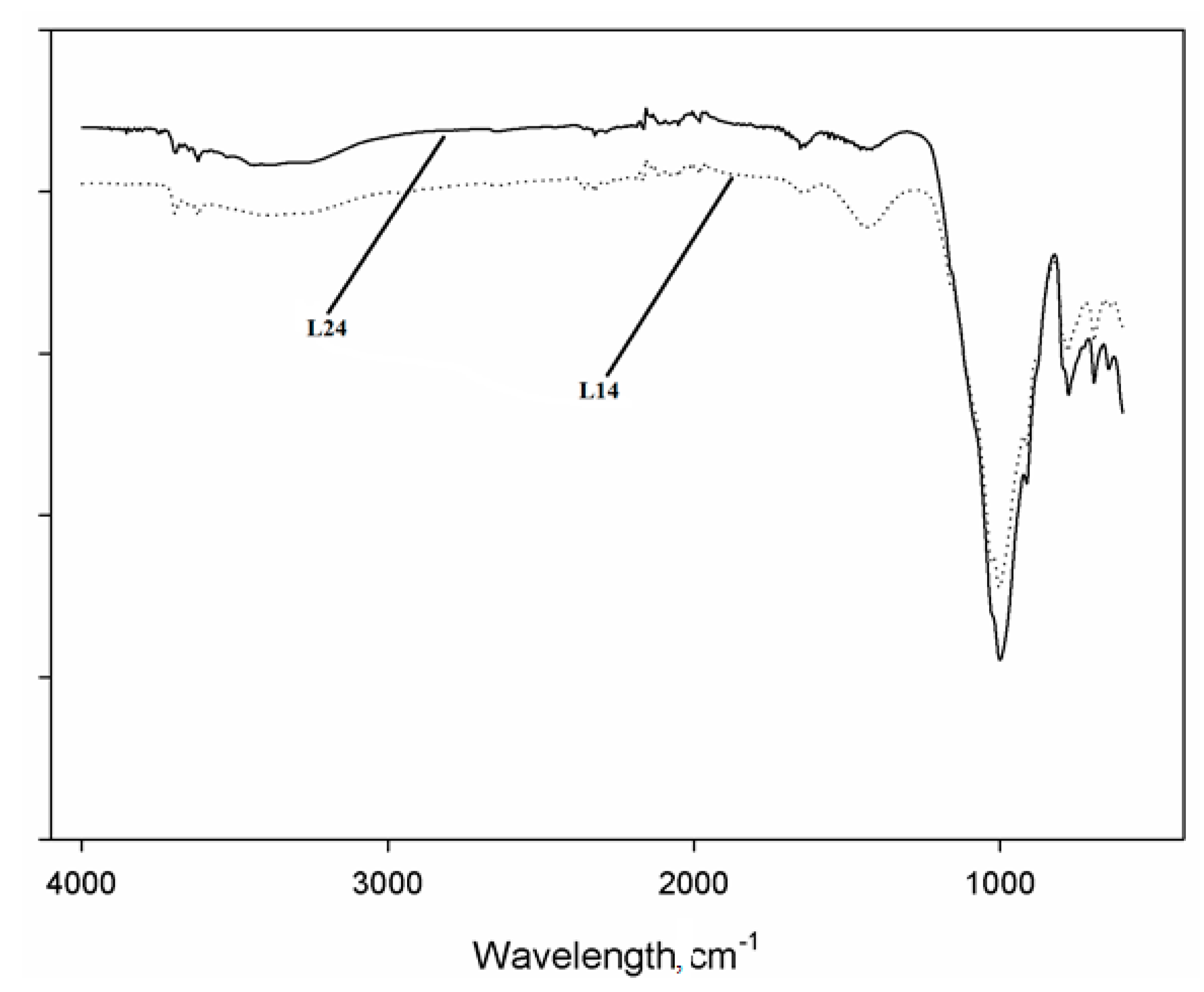

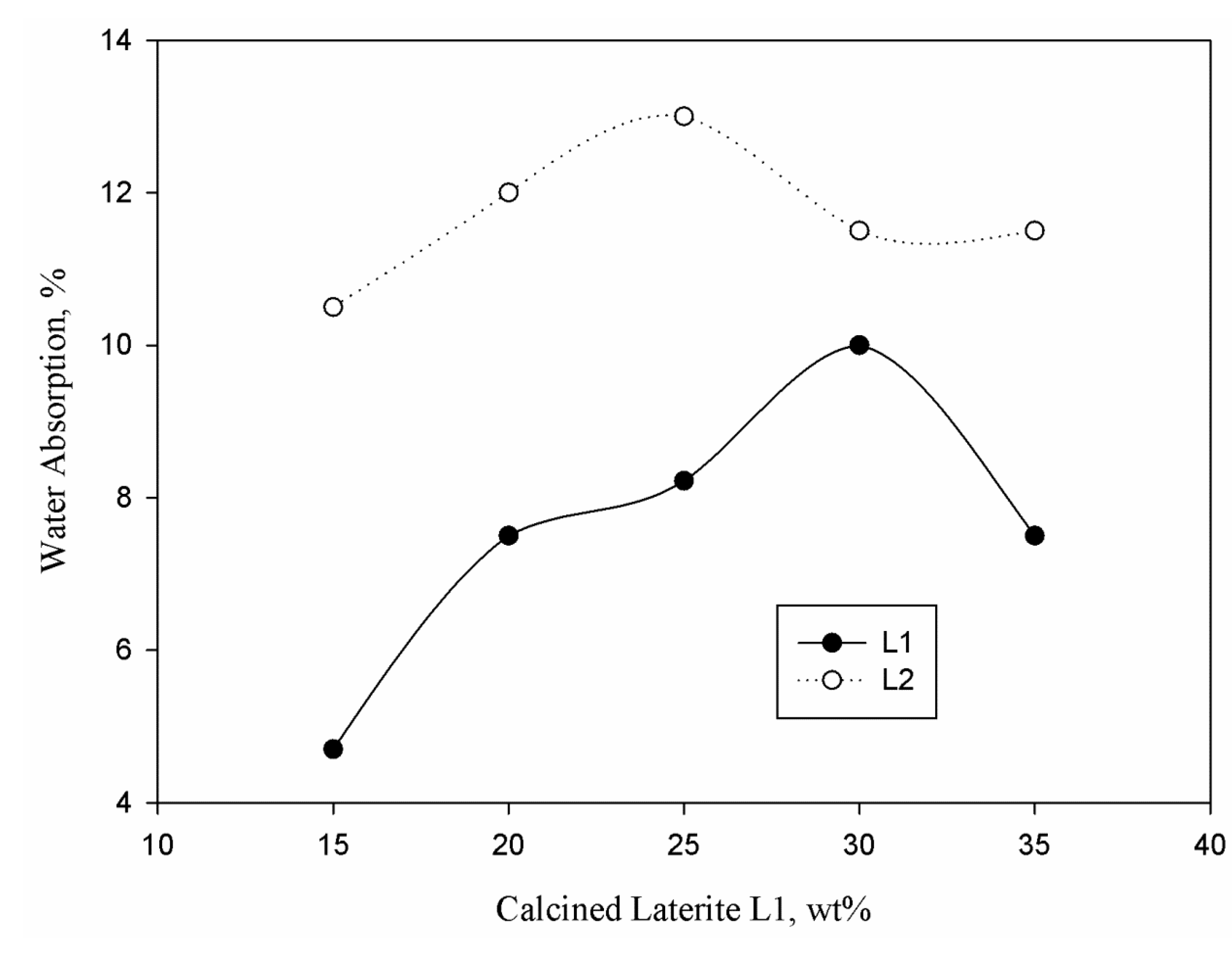

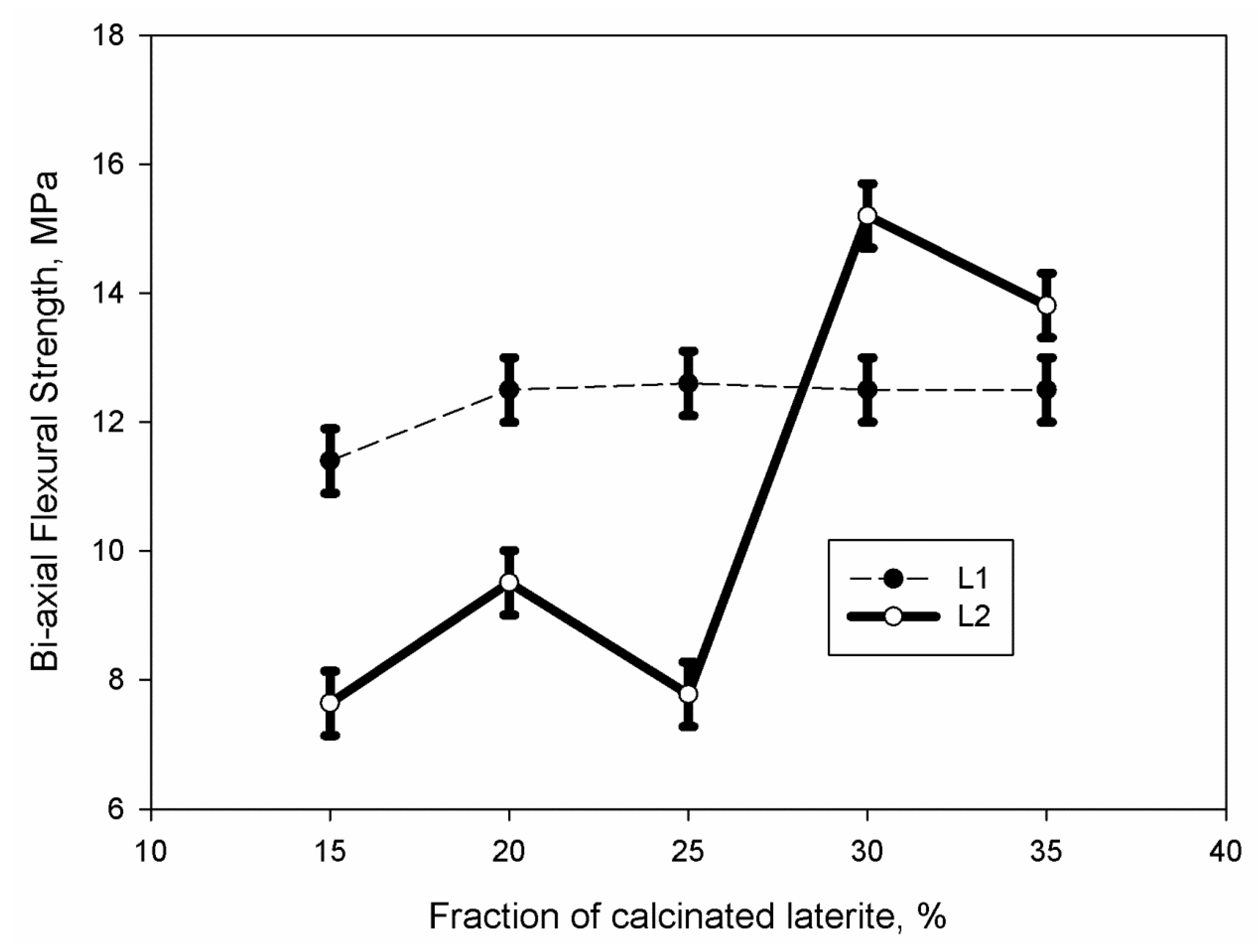

The characterization of laterite-based geopolymer composites revealed the effectiveness of sodium aluminium silicates, H-N-A-S, (

Figure 1), and sodalite as the principal binder phase formed. The final products presented a good stability in water, low water absorption and mechanical properties comparable to that of conventional concretes. The cumulative pore volume presented by the two series (0.138 mL/g for L

14 and 0.127 mL/g for L

24) were found similar to that of hardened cement paste and lower with respect to bricks from fired clayey materials. The microstructure of the products showed compact structure with fracture surfaces evidencing the cross linking between phases and particles with texture similar to that of high compact composites.

The products of the geopolymerization of laterites showed stability in water already after 14 days and good stability after 90 days indicating the effective transformation and induration of the matrices. This stability varies with the content of calcined laterite and the degree of iron accumulation of the laterite used: the higher the calcined laterite in the formulation (35 wt%), the shorter the period of time needed for stability in water. It should be mentioned that the kinetics of geopolymerization of laterites are slow, surely due to the fact that the disorder in the laterite samples (L1 and L2) is not at the level of metakaolin, fly ash, volcanic ash, etc. Nevertheless, the disorder of the structure of aluminosilicate is significant for their dissolution into high alkaline media and, for this reason, even though the kinetic of dissolution and polycondensation is slow, the prerequisites exist and the presence of soluble silica help the polycondensation conduce to the formation of geopolymeric phases. Reducing the curing time by improving the dissolution kinetic could be as significant a contribution to enhance the process and provide the opportunity for it to be competitive in the manufacturing process.

It is important to indicate that the fired clay technology originated from the availability of plastic and low temperature clayey materials in the part of the world where they are abundantly developed. Unfortunately, in the tropical zone, the plastic clayey materials, particularly those suitable for the low temperature bricks and pipes are not the most available and are even rare in some areas. Iron-rich clays, laterites and lateritic soils are the most abundant raw materials in the tropical regions, with an abundance that allows sustainable exploitation while preserving the environment [

1,

2,

4]. In those laterites, hematite, goethite and ferryhydrates are the main secondary phases indicative of the degree of the iron accumulation and their diffusion into the matrix. The iron accumulation in the clayey matrix conducts to the development of a significant disorder in the structure of kaolinite, the principal clay mineral. Another important impact of the iron accumulation is the increase of the kaolinite interlayer distance from 7.2 up to 11 Å. All these considerations motivated our vision of a sustainable approach of the geopolymerization of laterites. The degree of disorder in the laterites is not to compare with that of the metakaolin therefore, we projected a formulation in which 15–35 wt% of laterite has been thermally treated at 700 °C to enhance the structural disorder with the objectives to promote quick dissolution and polymerization that might act in the matrix as nucleating sites and propagate the dissolution/polycondensation.

Iron accumulation plays a major role in the disorganization of the kaolinite, the principal mineral of laterites, providing the alkaline solution the possibility to complete the dissolution and promote polymerization/polycondensation. However, the reaction kinetic was very slow: instead of being 12–16 h, which is generally consistent with the time it takes for a standard metakaolin-based inorganic polymer cement to complete the transformation of paste to solid matrix, it took more than 72 h for the laterite based inorganic polymer composites to form a strong matrix and more than 60 days to present the maximum strength. With the presence of iron at a significant percentage, the geopolymerization of laterites includes more complex series of reactions as dissolution, diffusion, polymerization and complexation. A temperature slightly higher than that of room temperature is required for the optimization of the reactions. Even though the kinetic of reactions of geopolymerization was not the specific objectives of this work, it was noted that the results described here should be considered for a curing temperature not less than 25 °C and not more than 50 °C. These conditions seem more linked to the iron phase transformations and might be correlated with the conditions described for the induration of laterites where iron plays a significant role [

5,

6,

7,

8,

9]. The incongruent dissolution of the river sand allows the presence of: (1) soluble silica which is important in enhancing the polycondensation and cross linking between phases and particles; and (2) silicates with rough surface particles that can act as a nucleation site or chemical balance for the equilibrium of the structure.

The strength and water permeability of concretes have been improved by adding Fe

2O

3 nanoparticles in the cement up to 4.0 wt%, with the strengthening mechanism related to the capacity of Fe

2O

3 to act as foreign nucleation site as well as nanofillers recovering the pore structure of the specimens and accelerating the C-S-H gel formation [

30,

31]. observed that the amount of iron up to 12–14 wt% found in the volcanic ashes was not detrimental for the reactivity and strength development of geopolymers. However, they noted that major part of this iron was concentrated in the crystalline phases as augite and ferroanforsterite [

32]. The production of geopolymer from red mud with a high amount of iron (>30 wt%) [

29,

31] gives relatively low mechanical properties at an earlier stage of the geopolymerization. Geopolymers with 100% Fe designed by Bell

et al. [

33] 2009; Wagh and Douse, 1991 [

34], do not reach the complete solidification after a year of curing. In the high alkaline solution with the curing temperature considered for the geopolymerization of laterite based polymer composites, oxyhydrates and goethite are able to transform to more stable iron minerals as hematite, or integrate the structure of the geopolymer. In this direction, the chemistry and mineralogy of iron, their particles size and proportion of amorphous are significant in determining the polycondensation and strength of iron-rich aluminosilicates. The difference in mechanical behavior of the two series with calcined L1 < 25 wt% is consistent with the view that the iron interferes with the reactivity and strength development. The extent of geopolymerization and strength development is essentially linked to the stability of the iron phases and their complete integration in the structure of the inorganic polymer composites. The addition of calcined L1 in L2 should not increase only the amorphous fraction ready for polycondensation but re-equilibrate the Si/Al, Al/Fe and even Si/Fe ratio and by the way improve the gel content that acts in cross-linking the particles: the iron content decreases and the H-M-A-S phases increase. The above mentioned help to validate our approach with the objective to maintain under control the key parameters of polycondensation of laterite based inorganic polymers composites. It appeared that mix-design can be applied for the production of stable and highly resistant composites using laterites and lateritic soils through a sustainable cold chemical process.