Towards Life Cycle Sustainability Assessment of Alternative Passenger Vehicles

Abstract

:1. Introduction

1.1. Life Cycle Assessment

1.2. Input-Output Based LCA

1.3. The State-of-the-Art: Life Cycle Sustainability Assessment

1.4. Research Objectives Against the Background of the State-of-the-Art

2. Methods

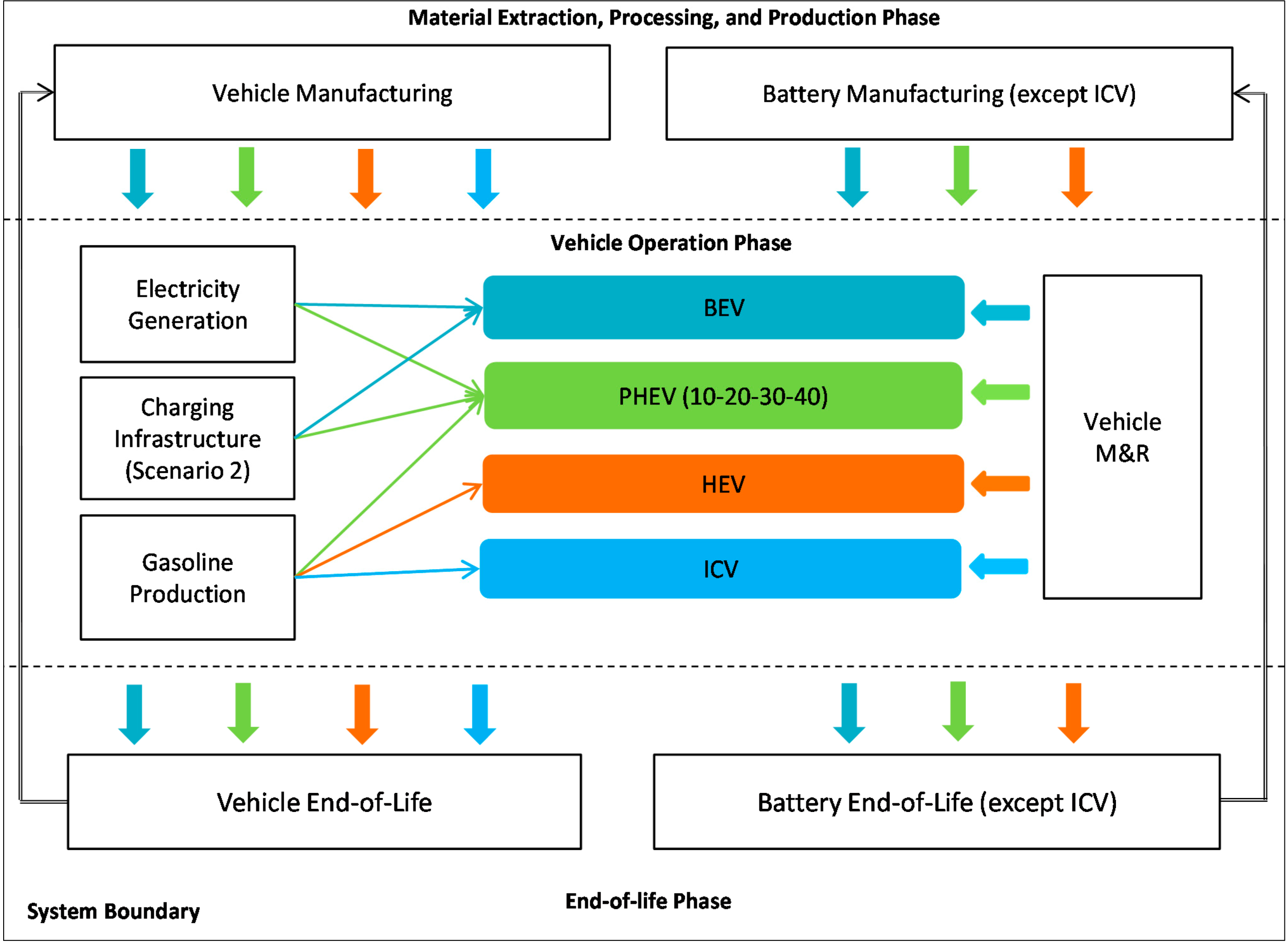

2.1. Scope of the Analysis

2.2. The TBL-LCA Model and Sustainability Indicators

| Bottom Lines | TBL Indicator | Unit | Description |

|---|---|---|---|

| Environmental | Global Warming Potential (GWP) | gCO2-eqv. | The total GHG emissions based on IPPC’s values for GWP100. |

| Water Withdrawal | lt | The total amount of water withdrawals of each sector. | |

| Energy Consumption | MJ | The total energy consumption of industries. | |

| Hazardous Waste Generation | st | The amount of hazardous waste (EPA’s RCRA) generated by U.S. sectors | |

| Particulate Matter Formation Potential (PMFP) | gPM10-eqv. | The total criteria air pollutant emissions based on ReCiPe CFs. | |

| Fishery | gha | The estimated primary production required to support the fish caught. | |

| Grazing | gha | The amount of livestock feed available in a country with the amount of feed required for the livestock produced. | |

| Forestry | gha | The amount of lumber, pulp, timber products, and fuel wood consumed by each U.S. sector. | |

| Cropland | gha | The most bio-productive of all the land use types and includes areas used to produce food and fiber for human consumption. | |

| CO2 uptake land | gha | The amount of forestland required to sequester GHG emitted by sectors. | |

| Import (foreign purchase) | $ | The monetary value of products and services purchased from foreign countries to produce domestic commodities. | |

| Gross Operating Surplus (business profit) | $ | The available capital of corporations, which allows them to pay taxes, to repay their creditors, and to finance their investments. | |

| Gross Domestic Product (GDP) | $ | Economic value added by the U.S. sectors. | |

| Air emission cost | $ | Economic costs of externality damages due to releases of CO, nitrogen oxides (NOx), particulate matter (PM), SO2, volatile organic compounds (VOCs), and GHGs. | |

| Employment | emp-h | The full-time equivalent employment hours for each U.S. sector. | |

| Government Tax | $ | Taxes collected from production and imports, government revenues. | |

| Injuries | #worker | The number of non-fatal injuries associated with the U.S. sectors. | |

| Income | $ | The compensation of employees, wages, and salaries. | |

| Human Health | DALY | The number of years lost due to disability, illness, or early death. |

- ❖

- Income, in other words compensation of employees, is chosen as a positive social indicator since it contributes to the social welfare of households. This indicator represents the compensation of employees, including wages and salaries [15,67]. The total income generated by each sector is obtained from the input-output accounts published by the U.S. Bureau of Economic Analysis [56]. Using the World Input-Output Database supported by the European Commission under the th research programme, the total income is presented in terms of three skill groups such as low-skilled, medium skilled and high-skilled [68]. The WIOD database used the 1997 International Standard Classification of Education classification to define low, medium, and high skilled labors which are defined in Table 2.

| WIOD Skill-Type | ISCED Level | ISCED Level Description |

|---|---|---|

| Low | 1 | Primary education or first stage of basic education |

| Low | 2 | Lower secondary or second stage of basic education |

| Medium | 3 | (Upper) secondary education |

| Medium | 4 | Post-secondary non-tertiary education |

| High | 5 | First stage of tertiary education |

| High | 6 | Second stage of tertiary education |

- ❖

- ❖

- A work-related injury represents the negative social indicator and is the total number of non-fatal injuries at each of 426 sector of U.S economy. The data including the number of total work place injuries are obtained from the U.S. Bureau of Labor Statistics to analyze the contributions of the each sector to work-related non-fatal injuries [28,65].

- ❖

- Human health is selected as an end-point social indicator which is originally developed by Harvard University and adopted by the World Health Organization. Impact to human health is presented as disability-adjusted life year (DALY) which is the number of years lost due to disability, illness, or early death as a result of environmental impacts [71]. The human health impacts are quantified in accordance with the characterization factors (CFs) provided ReCiPe which is a well-known Life Cycle Impact Assessment (LCIA) methodology [72]. In this study, DALY is determined by the impacts of particulate matter formation (PMF), photochemical oxidant formation (POF), and global warming potential (GWP), which are three common environmental mid-point indicators. Considering that the value choices influence the analysis of human health damages in LCA, there are different way of quantifying these impacts based on the value choices, which are egalitarian, hierarchist, and individualist [73,74,75]. The quantified human health impacts are based on hierarchist perspective since it is more suitable for macro-level impact assessment than other value choices [74,76].

- ❖

- Air emission cost is presented as life cycle emission cost of alternative vehicle technologies, which includes the location-specific externality damages for releases of CO, nitrogen oxides (NOx), particulate matter (PM), SO2, volatile organic compounds (VOCs), and GHGs. The location-specific emission costs data is obtained from a comprehensive study conducted by Michalek et al. [77], in which the air pollution costs associated with environmental impact, mortality, and morbidity is included. GHG cost estimates includes net agricultural productivity, human health, property damages from increased flood risk, and the value of ecosystem services due to climate change [77,78]. These costs are based on National Resource Council (NRC) study, literature survey and estimates from the US Interagency Working Group on Social Cost of Carbon. In this study, we used, $9.66 per metric tons of CO2-eqv., which is 23% of the medium-level global damage value of Climate change, recommended by the Interagency Working Group [79].

- ❖

- Taxes are chosen as a positive sustainability indicator since collected taxes will be used for supporting the nation’s prosperity through investments on health and education systems, transportation, highways, and other civil infrastructures [60,80]. Taxes are also referred to as government revenue, which accounts for the taxes on production and imports. The data source for taxes generated by each sector is the U.S. input–output tables [56].

- ❖

- Profit, in other words gross operating surplus (GOS), is the residual for industries after subtracting total intermediate inputs, compensation of employees, and taxes from total industry output [62]. Profit is considered as a positive economic indicator since it represents the capital available to sectors, which allow them to pay taxes and to finance their investments.

- ❖

- Gross Domestic Product (GDP) is used as another macro-level economic indicator. GDP typically represents the market value of goods and services produced within the country in a given period of time. GDP is a positive economic indicator that monitors the health of a nation’s economy and includes compensation of employees, gross operating surplus, and net taxes on production and imports [64]. This positive economic indicator is the direct and indirect contribution of one sector to GDP.

- ❖

- Imports, in other words foreign purchases, represent the value of goods and services purchased from foreign countries to produce domestic commodities by industries [67]. This economic indicator accounts for the direct and indirect contributions of one sector to foreign purchases. The import value of each sector is obtained from the U.S. input–output tables [56].

2.3. Life Cycle Inventory

| LCA Phases | NAICS Sector ID | NAICS Sector Name | Process Description | |

|---|---|---|---|---|

| Manufacturing Phase | 335912 | Primary Battery Manufacturing | Li-ion battery manufacturing for vehicles | |

| 336111 | Automobile manufacturing | Manufacturing of passenger vehicles | ||

| Operation phase | Driving related activities | 221100 | Electric power generation, transmission, and distribution | |

| 324110 | Petroleum refineries | Gasoline production and supply for vehicles | ||

| 811100 | Automotive repair and maintenance, except car washes | Vehicle repair and maintenance | ||

| Solar Charging station const. | 334413 | Semiconductor and related device manufacturing | Manufacturing of solar modules and installed system | |

| 327320 | Ready-mix concrete manufacturing | Concrete manufacturing | ||

| 331110 | Iron and steel mills | Steel Manufacturing | ||

| 321212 | Veneer and plywood manufacturing | Medium density fibreboard manufacturing | ||

| 32551 | Paint and coating manufacturing | Paint and coating manufacturing | ||

| 230101 | Other Nonresidential (layer 1) | Construction of the charging station (layer 1 only) | ||

| End-of-Life phase | 331110 | Iron and steel mills | Savings from recycled steel extracted from vehicles and batteries | |

| 33131A | Alumina refining and primary aluminum production | Savings from recycled aluminum extracted from vehicles and batteries | ||

| 331420 | Copper Rolling, Drawing, Extruding, and Alloying | Savings from recycled copper extracted from vehicles and batteries | ||

| 327211 | Flat glass manufacturing | Savings from recycled glass extracted from vehicles | ||

| 325211 | Plastics material and resin manufacturing | Savings from recycled plastic extracted from vehicles | ||

| 325212 | Rubber and plastics hose and belting manufacturing | Savings from recycled rubber extracted from vehicles | ||

| 339910 | Jewelry and Silverware Manufacturing | Savings from recycled platinum extracted from vehicles | ||

| TBL Indicators | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Econ. | Social | Environmental | |||||||||||||||

| LCA Phases | NAICS Sector IDs | Foreign Purchase (M$) | Business Profit (M$) | Employment-hr | Income (M$) | Government Tax (M$) | Injuries (# worker) | Fishery (gha) | ,Grazing (gha) | Forestry (gha) | Cropland (gha) | Carbon Fossil Fuel (gha) | Carbon Electricity (gha) | GHG Total (t) | Total Energy (TJ) | Water (kgal) | Haz. Waste (st) |

| Man. Ph. | 335912 | 0.296 | 0.533 | 23,357 | 0.429 | 0.031 | 0.552 | 0.098 | 0.102 | 3.17 | 3.98 | 97.67 | 41.73 | 540.40 | 8.44 | 6682 | 364,000 |

| 336111 | 0.969 | 0.370 | 28,422 | 0.564 | 0.043 | 0.847 | 0.173 | 2.762 | 3.73 | 9.86 | 100.51 | 42.15 | 547.56 | 8.48 | 8313 | 416,000 | |

| Operation phase | 221100 | 0.099 | 0.488 | 16,125 | 0.364 | 0.143 | 0.290 | 0.273 | 0.174 | 1.34 | 3.88 | 1853.92 | 13.08 | 8243.87 | 98.22 | 219,474 | 125,000 |

| 324110 | 0.853 | 0.545 | 16,099 | 0.345 | 0.100 | 0.329 | 0.153 | 0.126 | 1.73 | 4.67 | 492.07 | 57.46 | 2776.52 | 31.57 | 8546 | 4,120,000 | |

| 811100 | 0.101 | 0.314 | 37,423 | 0.594 | 0.076 | 0.865 | 0.187 | 0.411 | 1.59 | 3.52 | 61.90 | 34.16 | 312.32 | 4.74 | 5184 | 172,000 | |

| 334413 | 0.445 | 0.433 | 23,202 | 0.519 | 0.039 | 0.486 | 0.135 | 0.126 | 2.05 | 3.47 | 93.33 | 54.59 | 579.07 | 7.36 | 7751 | 1,080,000 | |

| 327320 | 0.106 | 0.373 | 32,622 | 0.576 | 0.044 | 1.036 | 0.189 | 0.152 | 1.91 | 7.71 | 638.17 | 68.34 | 2715.16 | 23.39 | 16,526 | 373,000 | |

| 331110 | 0.445 | 0.306 | 32,844 | 0.627 | 0.058 | 1.014 | 0.215 | 0.245 | 2.87 | 6.14 | 546.56 | 123.69 | 3669.30 | 51.02 | 20,233 | 1,450,000 | |

| 321212 | 0.363 | 0.319 | 39,062 | 0.596 | 0.082 | 1.357 | 0.185 | 1.074 | 498.95 | 29.74 | 145.85 | 68.18 | 747.68 | 16.69 | 17,770 | 183,000 | |

| 32551 | 0.234 | 0.383 | 27,653 | 0.563 | 0.044 | 0.639 | 0.204 | 0.228 | 3.61 | 33.42 | 195.35 | 56.83 | 1041.96 | 16.18 | 138,965 | 2,080,000 | |

| 230101 | 0.000 | 0.082 | 20,919 | 0.443 | 0.005 | 0.603 | 0.000 | 0.000 | 0.00 | 8.29 | 48.00 | 7.69 | 200.00 | 3.16 | 216 | 0 | |

| End-of-Life phase | 331110 | 0.445 | 0.306 | 32,844 | 0.627 | 0.058 | 1.014 | 0.215 | 0.245 | 2.87 | 6.14 | 546.56 | 123.69 | 3669.30 | 51.02 | 20,233 | 1,450,000 |

| 33131A | 0.676 | 0.349 | 31,203 | 0.574 | 0.063 | 0.916 | 0.233 | 0.301 | 3.06 | 4.76 | 510.62 | 298.61 | 3303.36 | 48.06 | 37,142 | 233,000 | |

| 331420 | 0.583 | 0.331 | 32,034 | 0.606 | 0.056 | 0.997 | 0.241 | 0.274 | 3.30 | 6.68 | 217.08 | 84.17 | 964.65 | 15.97 | 12,935 | 334,000 | |

| 327211 | 0.236 | 0.423 | 30,176 | 0.528 | 0.041 | 0.992 | 0.164 | 0.140 | 5.44 | 5.71 | 443.78 | 105.47 | 2044.36 | 37.30 | 16,690 | 320,000 | |

| 325211 | 0.431 | 0.384 | 25,825 | 0.537 | 0.066 | 0.510 | 0.247 | 0.277 | 3.02 | 55.21 | 435.45 | 94.45 | 2398.31 | 40.33 | 24,632 | 5,610,000 | |

| 325212 | 0.445 | 0.321 | 34,988 | 0.619 | 0.039 | 1.055 | 0.197 | 0.251 | 9.56 | 28.24 | 167.28 | 63.45 | 864.33 | 14.29 | 15,336 | 1,090,000 | |

| 339910 | 2.368 | 0.308 | 36,677 | 0.620 | 0.047 | 0.984 | 0.198 | 0.150 | 2.29 | 3.38 | 115.59 | 46.68 | 738.35 | 8.78 | 8045 | 240,000 | |

2.3.1. Vehicle and Battery Manufacturing

| Vehicle Type | Battery Weights (lb) | Battery Energy Outputs (kwh) | Cost Per Energy Output ($2002/kwh) |

|---|---|---|---|

| ICV | 0.0 | 0 | 0 |

| HEV | 41.2 | 28 * | 36.96 * |

| PHEV10 | 119.2 | 4.0 | 201.94 |

| PHEV20 | 208.5 | 7.0 | 201.94 |

| PHEV30 | 387.3 | 13.0 | 201.94 |

| PHEV40 | 536.3 | 18.0 | 201.94 |

| BEV | 821.3 | 38.0 | 201.94 |

2.3.2. Operation Phase

2.3.3. End-of-Life Phase

3. Results

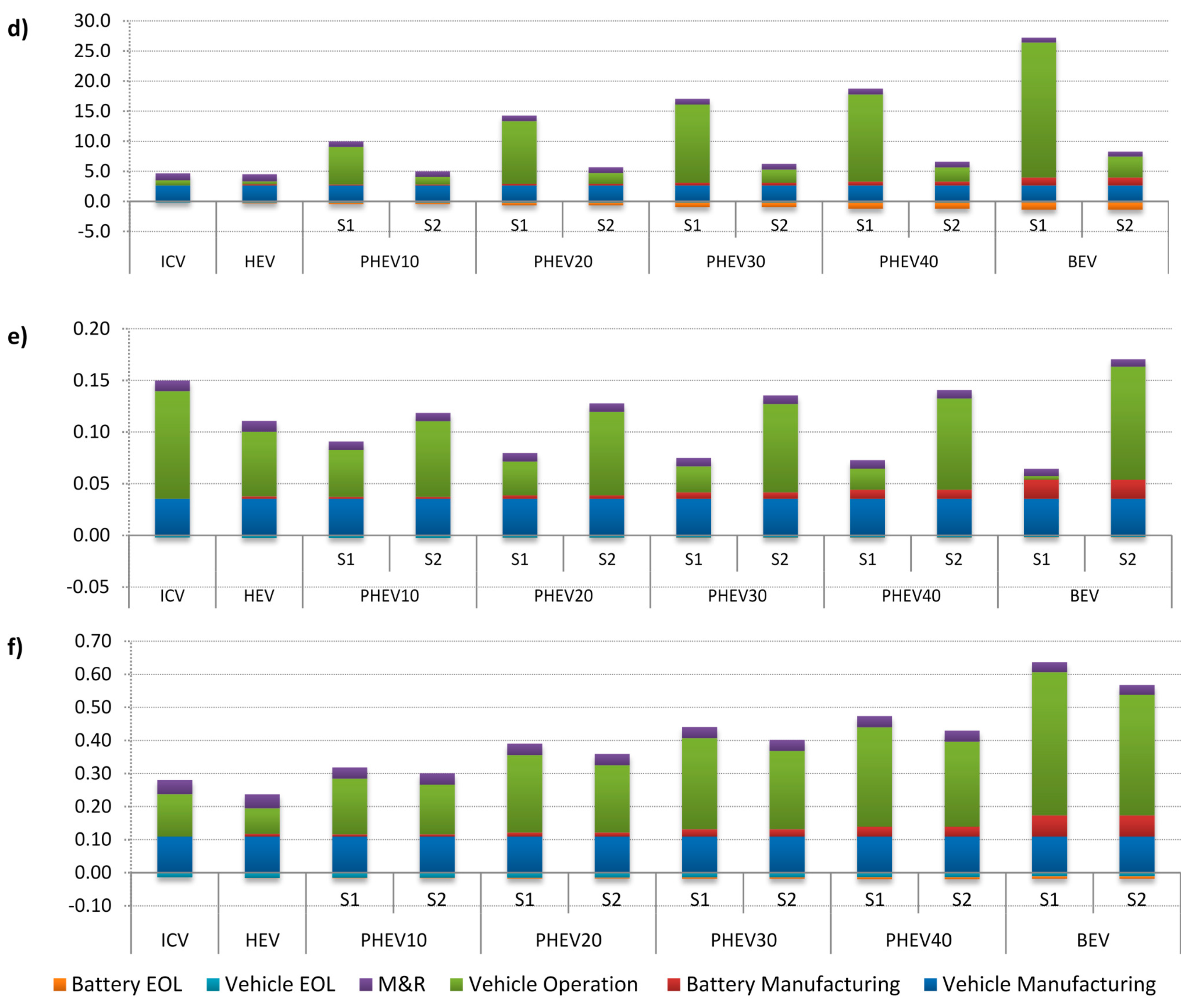

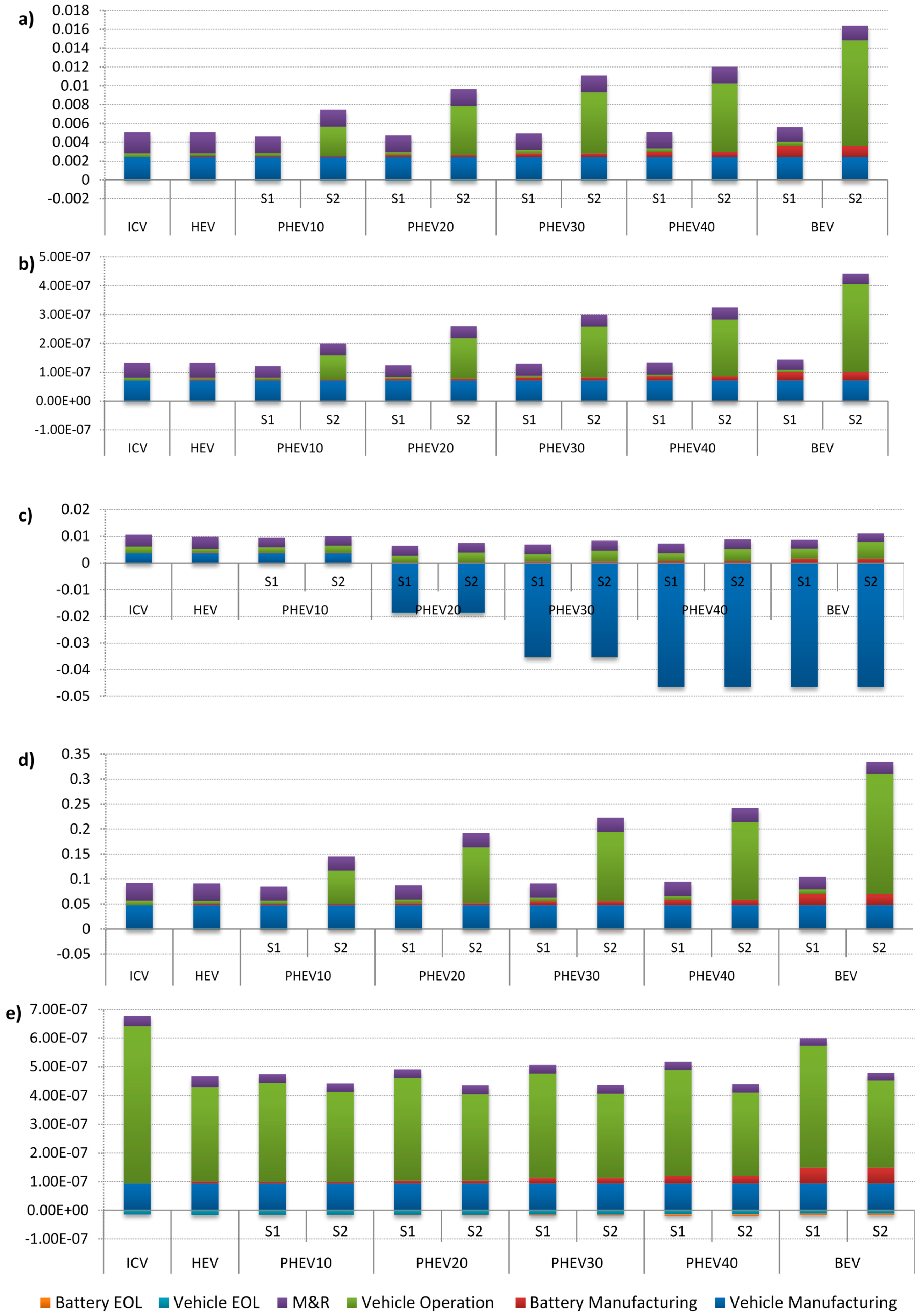

3.1. Environmental Impacts

3.2. Economic Impacts

3.3. Social Impacts

| Income Allocation | High-Skill Compensation | Med-Skill Compensation | Low-Skill Compensation | |

|---|---|---|---|---|

| ICV | 41.1% | 52.3% | 6.6% | |

| HEV | 41.4% | 52.1% | 6.6% | |

| PHEV10 | S1 | 41.3% | 52.3% | 6.5% |

| S2 | 38.7% | 53.7% | 7.6% | |

| PHEV20 | S1 | 41.4% | 52.2% | 6.4% |

| S2 | 37.8% | 54.3% | 7.9% | |

| PHEV30 | S1 | 41.7% | 52.1% | 6.3% |

| S2 | 37.5% | 54.4% | 8.1% | |

| PHEV40 | S1 | 41.9% | 51.9% | 6.2% |

| S2 | 37.5% | 54.5% | 8.1% | |

| BEV | S1 | 42.6% | 51.6% | 5.9% |

| S2 | 37.0% | 54.7% | 8.3% | |

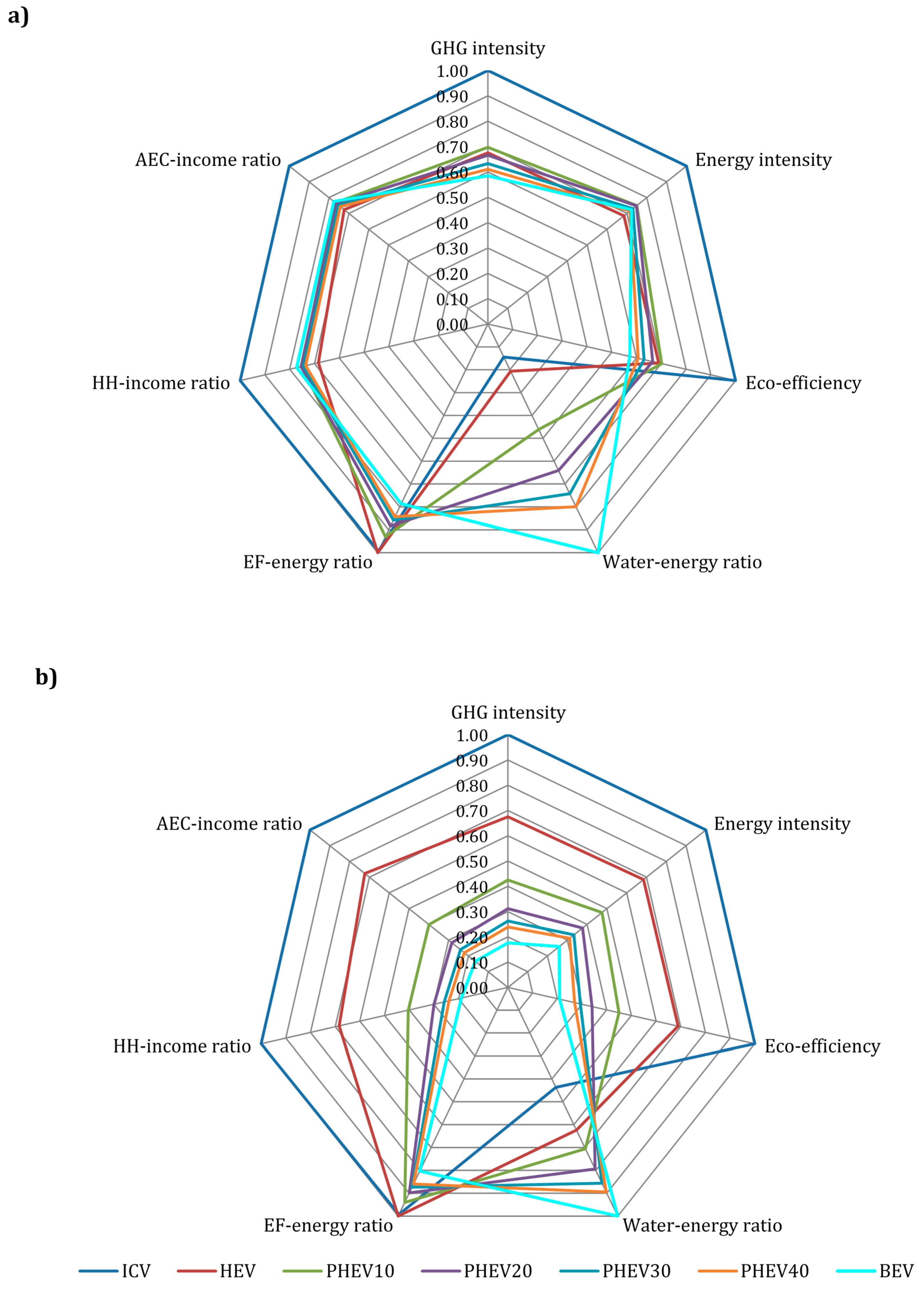

3.4. Comparison of Alternative Vehicle Technologies

- GHG intensity: GHG emissions per $ of contribution to GDP

- Energy intensity: Energy consumption per $ of contribution to GDP

- Eco-efficiency: Ecological land footprint per $ of contribution to GDP

- HH-income ratio: Human health impacts per $ of income generation

- AEC-income ratio: Economic cost of air emission per $ of income generation

- Water-energy ratio: Ratio of water consumption to energy consumption

- EF-energy ratio: Ratio of ecological land footprint to energy consumption

| Vehicle Types | GHG Intensity (gCO2-eqv./$) | Energy Intensity (MJ/$) | Eco-Efficiency (gha/$) | HH-Income Ratio (DALY/$) | AEC-Income Ratio ($/$) | Water-Energy Ratio (gal/MJ) | EF-Energy Ratio (gha/MJ) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | S2 | S1 | S2 | S1 | S2 | S1 | S2 | S1 | S2 | S1 | S2 | S1 | S2 | |

| ICV | 2596 | 35.0 | 6.50 × 10−4 | 7.36 × 10−6 | 0.18 | 0.20 | 1.85 × 10−5 | |||||||

| HEV | 1754 | 24.0 | 4.48 × 10−4 | 5.04 × 10−6 | 0.13 | 0.29 | 1.87 × 10−5 | |||||||

| PHEV10 | 1810 | 1103 | 26.3 | 16.7 | 4.56 × 10−4 | 2.92 × 10−4 | 5.53 × 10−6 | 2.97 × 10−6 | 0.14 | 0.07 | 0.65 | 0.33 | 1.74 × 10−5 | 1.75 × 10−5 |

| PHEV20 | 1729 | 809 | 26.2 | 13.2 | 4.32 × 10−4 | 2.21 × 10−4 | 5.55 × 10−6 | 2.20 × 10−6 | 0.14 | 0.05 | 0.91 | 0.37 | 1.65 × 10−5 | 1.68 × 10−5 |

| PHEV30 | 1643 | 681 | 25.6 | 11.7 | 4.10 × 10−4 | 1.91 × 10−4 | 5.48 × 10−6 | 1.90 × 10−6 | 0.13 | 0.04 | 1.05 | 0.40 | 1.60 × 10−5 | 1.63 × 10−5 |

| PHEV40 | 1585 | 620 | 25.1 | 10.9 | 3.94 × 10−4 | 1.76 × 10−4 | 5.42 × 10−6 | 1.76 × 10−6 | 0.13 | 0.04 | 1.13 | 0.42 | 1.57 × 10−5 | 1.60 × 10−5 |

| BEV | 1518 | 457 | 25.3 | 9.1 | 3.72 × 10−4 | 1.36 × 10−4 | 5.68 × 10−6 | 1.39 × 10−6 | 0.14 | 0.03 | 1.41 | 0.47 | 1.47 × 10−5 | 1.50 × 10−5 |

4. Conclusions and Discussions

Acknowledgments

Authors Contributions

Conflicts of Interest

References

- Onat, N.C.; Kucukvar, M.; Tatari, O. Conventional, Hybrid, Plug-in Hybrid or Electric Vehicles? State-based Comparative Carbon and Energy Footprint Analysis in the United States. Appl. Energy 2014, in press. [Google Scholar]

- Samaras, C.; Meisterling, K. Life Cycle Assessment of Greenhouse Gas Emissions from Plug-in Hybrid Vehicles: Implications for Policy. Environ. Sci. Technol. 2008, 42, 3170–3176. [Google Scholar] [CrossRef] [PubMed]

- Kucukvar, M.; Noori, M.; Egilmez, G.; Tatari, O. Stochastic decision modeling for sustainable pavement designs. Int. J. Life Cycle Assess. 2014, 19, 1185–1199. [Google Scholar] [CrossRef]

- Oak Ridge National Lab. Transportation Energy Data book. Available online: http://cta.ornl.gov/data/chapter8.shtml (accessed on 8 July 2013).

- Melaina, M.; Bremson, J. Refueling availability for alternative fuel vehicle markets: Sufficient urban station coverage. Energy Policy 2008, 36, 3233–3241. [Google Scholar] [CrossRef]

- DOT U.S. Department of Transportation Proposes New Minimum Sound Requirements for Hybrid and Electric Vehicles. Available online: http://www.dot.gov/briefing-room/us-department-transportation-proposes-new-minimum-sound-requirements-hybrid-and (accessed on 3 December 2014).

- Executive Office of the President. President Obama’s Climate Action Plan; Executive Office of the President: Washington, DC, USA, 2013; p. 9. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). Mitigation of Climate Change: Contribution of Working Group III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2007; p. 851. [Google Scholar]

- World Business Council for Sustainable Development (WBCSD). Mobility 2030: Meeting the Challenges to Sustainability; WBCSD: Geneva, Switzerland, 2004. [Google Scholar]

- Department of Energy (DOE). One Million Electric Vehicles By 2015; DOE: Washington, DC, USA, 2011. [Google Scholar]

- Department of Energy (DOE). The EV Everywhere Grand Challenge; DOE: Washington, DC, USA, 2013. [Google Scholar]

- Litman, T.A. Sustainable Transportation Indicators: A Recommended Research Program For Developing Sustainable Transportation Indicators and Data. In Proceedings of the Transportation Research Board 88th Annual Meeting, Washington, DC, USA, 11–15 January 2009.

- Hawkins, T.R.; Gausen, O.M.; Strømman, A.H. Environmental impacts of hybrid and electric vehicles—A review. Int. J. Life Cycle Assess. 2012, 17, 997–1014. [Google Scholar] [CrossRef]

- Shepherd, S.P. A review of system dynamics models applied in transportation. Trans. B Trans. Dyn. 2014, 2, 83–105. [Google Scholar]

- Litman, T.; Burwell, D. Issues in sustainable transportation. Int. J. Glob. Environ. Issues 2006, 6, 331–347. [Google Scholar] [CrossRef]

- Forkenbrock, D.; Benshoff, S.; Weisbrod, G. Assessing the Social and Economic Effects of Transportation Projects; Transportation Research Board: Iowa City, IA, USA, 2001. [Google Scholar]

- Offer, G.J.; Howey, D.; Contestabile, M.; Clague, R.; Brandon, N.P. Comparative analysis of battery electric, hydrogen fuel cell and hybrid vehicles in a future sustainable road transport system. Energy Policy 2010, 38, 24–29. [Google Scholar] [CrossRef]

- Stone, S.; Strutt, A.; Hertel, T. Socio-Economic Impact of Regional Transport Infrastructure in the Greater Mekong Subregion. In Infrastructure for Asian Connectivity; Edward Elgar Publishing: Cheltenham, UK, 2012. [Google Scholar]

- The World Bank. Social Analysis in Transportation Projects: Guidelines for Incorporating Social Dimensions into Bank-Supported Projects; The World Bank: Washington, DC, USA, 2006. [Google Scholar]

- Dobranskyte-Niskota, A.; Perujo, A.; Pregl, M. Indicators to Assess Sustainability of Transport Activities; European Comission, Joint Research Centre: Ispra, Italy, 2007. [Google Scholar]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.-P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life cycle assessment part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef] [PubMed]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Suh, S.; Lenzen, M.; Treloar, G.J.; Hondo, H.; Horvath, A.; Huppes, G.; Jolliet, O.; Klann, U.; Krewitt, W.; Moriguchi, Y.; et al. System Boundary Selection in Life-Cycle Inventories Using Hybrid Approaches. Environ. Sci. Technol. 2004, 38, 657–664. [Google Scholar] [CrossRef] [PubMed]

- Deng, L.; Babbitt, C.W.; Williams, E.D. Economic-balance hybrid LCA extended with uncertainty analysis: Case study of a laptop computer. J. Clean. Prod. 2011, 19, 1198–1206. [Google Scholar] [CrossRef]

- Norgate, T.E.; Jahanshahi, S.; Rankin, W.J. Assessing the environmental impact of metal production processes. J. Clean. Prod. 2007, 15, 838–848. [Google Scholar] [CrossRef]

- De Benedetto, L.; Klemeš, J. The Environmental Performance Strategy Map: An integrated LCA approach to support the strategic decision-making process. J. Clean. Prod. 2009, 17, 900–906. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Tatari, O. Scope-based carbon footprint analysis of U.S. residential and commercial buildings: An input–output hybrid life cycle assessment approach. Build. Environ. 2014, 72, 53–62. [Google Scholar] [CrossRef]

- Hendrickson, C.; Lave, L.B.; Matthews, H.S. Environmental Life Cycle Assessment of Goods and Services: An Input-Output Approach; Routledge: London, UK, 2006. [Google Scholar]

- Egilmez, G.; Kucukvar, M.; Tatari, O. Sustainability assessment of U.S. manufacturing sectors: An economic input output-based frontier approach. J. Clean. Prod. 2013, 53, 91–102. [Google Scholar] [CrossRef]

- Kucukvar, M.; Tatari, O. Towards a triple bottom-line sustainability assessment of the U.S. construction industry. Int. J. Life Cycle Assess. 2013, 18, 958–972. [Google Scholar] [CrossRef]

- Lenzen, M. Errors in Conventional and Input-Output based Life-Cycle Inventories. J. Ind. Ecol. 2000, 4, 127–148. [Google Scholar] [CrossRef]

- Matthews, H.S.; Hendrickson, C.T.; Weber, C.L. The Importance of Carbon Footprint Estimation Boundaries. Environ. Sci. Technol. 2008, 42, 5839–5842. [Google Scholar] [CrossRef] [PubMed]

- Hertwich, E.G.; Peters, G.P. Carbon Footprint of Nations: A Global, Trade-Linked Analysis. Environ. Sci. Technol. 2009, 43, 6414–6420. [Google Scholar] [CrossRef] [PubMed]

- Onat, N.C.; Kucukvar, M.; Tatari, O. Integrating triple bottom line input–output analysis into life cycle sustainability assessment framework: The case for US buildings. Int. J. Life Cycle Assess. 2014, 19, 1488–1505. [Google Scholar] [CrossRef]

- Kucukvar, M.; Egilmez, G.; Tatari, O. Sustainability assessment of U.S. final consumption and investments: Triple-bottom-line input–output analysis. J. Clean. Prod. 2014, 81, 234–243. [Google Scholar] [CrossRef]

- Sala, S.; Farioli, F.; Zamagni, A. Life cycle sustainability assessment in the context of sustainability science progress (part 2). Int. J. Life Cycle Assess. 2012, 18, 1686–1697. [Google Scholar] [CrossRef]

- Zamagni, A. Life cycle sustainability assessment. Int. J. Life Cycle Assess. 2012, 17, 373–376. [Google Scholar] [CrossRef]

- Ciroth, A.; Finkbeier, M.; Hildenbrand, J.; Klöpffer, W.; UGent, B.M.; Prakash, S.; Sonnemann, G.; Traverso, M.; Ugaya, C.M.L.; Valdivia, S.; et al. Towards a Live Cycle Sustainability Assessment: Making Informed Choices on Products; United Nations Environment Programme (UNEP): Nairobi, Kenya, 2011. [Google Scholar]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life cycle assessment: Past, present, and future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Valdivia, S.; Ugaya, C.; Sonnemann, G.; Hildenbrand, J. Towards a Life Cycle Sustainability Assessment-Making Informed Choices on Products. UNEP/SETAC Life Cycle Initiative. Available online: http://www.unep.org/publications/contents/pub_details_search.asp?ID=6236 (accessed on 12 December 2014).

- United Nations Environment Programme (UNEP). Towards a Life Cycle Sustainability Assessment: Making Informed Choices on Products; UNEP: Nairobi, Kenya, 2011. [Google Scholar]

- Kloepffer, W. Life cycle sustainability assessment of products. Int. J. Life Cycle Assess. 2008, 13, 89–95. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Schau, E.M.; Lehmann, A.; Traverso, M. Towards Life Cycle Sustainability Assessment. Sustainability 2010, 2, 3309–3322. [Google Scholar] [CrossRef]

- Valdivia, S.; Ugaya, C.M.L.; Hildenbrand, J.; Traverso, M.; Mazijn, B.; Sonnemann, G. A UNEP/SETAC approach towards a life cycle sustainability assessment—Our contribution to Rio+20. Int. J. Life Cycle Assess. 2012, 18, 1673–1685. [Google Scholar] [CrossRef]

- Hu, M.; Kleijn, R.; Bozhilova-Kisheva, K.P.; di Maio, F. An approach to LCSA: The case of concrete recycling. Int. J. Life Cycle Assess. 2013, 18, 1793–1803. [Google Scholar] [CrossRef]

- Traverso, M.; Asdrubali, F.; Francia, A.; Finkbeiner, M. Towards life cycle sustainability assessment: An implementation to photovoltaic modules. Int. J. Life Cycle Assess. 2012, 17, 1068–1079. [Google Scholar] [CrossRef]

- Wood, R.; Hertwich, E.G. Economic modelling and indicators in life cycle sustainability assessment. Int. J. Life Cycle Assess. 2012, 18, 1710–1721. [Google Scholar] [CrossRef]

- Nanaki, E.A.; Koroneos, C.J. Comparative economic and environmental analysis of conventional, hybrid and electric vehicles–the case study of Greece. J. Clean. Prod. 2013, 53, 261–266. [Google Scholar] [CrossRef]

- Strecker, B.; Hausmann, A.; Depcik, C. Well to wheels energy and emissions analysis of a recycled 1974 VW Super Beetle converted into a plug-in series hybrid electric vehicle. J. Clean. Prod. 2014, 68, 93–103. [Google Scholar]

- Faria, R.; Moura, P.; Delgado, J.; de Almeida, A.T. A sustainability assessment of electric vehicles as a personal mobility system. Energy Convers. Manag. 2012, 61, 19–30. [Google Scholar] [CrossRef]

- Nordelöf, A.; Messagie, M.; Tillman, A.-M.; Ljunggren Söderman, M.; van Mierlo, J. Environmental impacts of hybrid, plug-in hybrid, and battery electric vehicles—What can we learn from life cycle assessment? Int. J. Life Cycle Assess. 2014, 19, 1866–1890. [Google Scholar] [CrossRef]

- Markel, T. Plug-In HEV Vehicle Design Options and Expectations. In Proceedings of the ZEV Technology Symposium California Air Resources Board, Sacramento, CA, USA, 27 September 2006.

- Leontief, W. Environmental Repercussions and the Economic Structure: An Input-Output Approach. Rev. Econ. Stat. 1970, 52, 262–271. [Google Scholar] [CrossRef]

- Murray, J.; Wood, R. The Sustainability Practitioner’s Guide to Input-Output Analysis; Common Ground Publishing: Champaign, IL, USA, 2010. [Google Scholar]

- Tukker, A.; Poliakov, E.; Heijungs, R.; Hawkins, T.; Neuwahl, F.; Rueda-Cantuche, J.M.; Giljum, S.; Moll, S.; Oosterhaven, J.; Bouwmeester, M. Towards a global multi-regional environmentally extended input–output database. Ecol. Econ. 2009, 68, 1928–1937. [Google Scholar] [CrossRef]

- BEA Benchmark input-output data. Available online: http://www.bea.gov/iTable/iTable.cfm?ReqID=5&step=1#reqid=5&step=100&isuri=1&406=3&403=2&404=7 (accessed on 19 May 2014).

- BEA 2002 Benchmark Input-Output-Item Output Detail. Available online: http://www.bea.gov/industry/xls/2002DetailedItemOutput.xls&ei=nxqHUbT-EIie8QSn74HgCA&usg=AFQjCNEOABYqv8MJKxkgHKmjU54cTqMCxQ&sig2=4eDqdCLk_kuEpu6PgEu9Dg (accessed on 19 May 2013).

- Carnegie Mellon University Green Design Institute Economic Input-Output Life Cycle Assessment (EIO-LCA). Available online: http://www.eiolca.net/index.html (accessed on 9 March 2014).

- OSU—The Ohio State University Eco-LCA software, ecologically based life cycle assessment. Available online: http://resilience.eng.ohio-state.edu/eco-lca/index.htm (accessed on 9 March 2014).

- Foran, B.; Lenzen, M.; Dey, C.; Bilek, M. Integrating sustainable chain management with triple bottom line accounting. Ecol. Econ. 2005, 52, 143–157. [Google Scholar] [CrossRef]

- Wiedmann, T.; Lenzen, M. Unravelling the Impacts of Supply Chains—A New Triple-Bottom-Line Accounting Approach and Software Tool. Manag. Account. Clean. Prod. 2009, 24, 65–90. [Google Scholar]

- Eurostat. Eurostat Manual of Supply, Use and Input–Output Tables; Eurostat: Luxembourg, 2008. [Google Scholar]

- United Nations. UN (1999) Studies in Methods: Handbook of National Accounting; United Nations: New York, NY, USA, 1999. [Google Scholar]

- Miller, R.E.; Blair, P.D. Input–Output Analysis: Foundations and Extensions, 2nd ed.; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- U.S. Bureau of Labor Statistics. Industry Injury and Illness Data; U.S. Bureau of Labor Statistics: Washington, DC, USA, 2002; pp. 2–28. [Google Scholar]

- Global Footprint Network (GFN) National footprint accounts: Ecological footprint and bio-capacity. Available online: http://www.footprintnetwork.org/en/index.php/GFN/page/footprint_for_nations (accessed on 21 June 2014).

- Wiedmann, T.O.; Lenzen, M.; Barrett, J.R. Companies on the Scale: Comparing and benchmarking the sustainability performance of businesses. J. Ind. Ecol. 2009, 13, 361–383. [Google Scholar] [CrossRef]

- Timmer, M.; Erumban, A.; Gouma, R. The world input-output database (WIOD): Contents, sources and methods. Available online: http://www.wiod.org/publications/papers/wiod10.pdf (accessed on 26 November 2014).

- Erumban, A.; Gouma, R.; de Vries, G.; de Vries, K.; Timmer, M. WIOD Socio-Economic Accounts (SEA): Sources and Methods. Available online: http://www.wiod.org/publications/source_docs/SEA_Sources.pdf (accessed on 20 November 2014).

- Stern, J.; Lewis, J. Employment Patterns and Income Growth: An Application of Input-Output Analysis; The World Bank: Washington, DC, USA, 1980. [Google Scholar]

- World Health Organization Health statistics and information systems, Metrics: Disability-Adjusted Life Year (DALY). Available online: http://www.who.int/healthinfo/global_burden_disease/metrics_daly/en/ (accessed on 26 November 2014).

- ReCiPE ReCiPe LCIA Methodology. Available online: http://www.lcia-recipe.net/project-definition (accessed on 26 November 2014).

- De Schryver, A.M.; Brakkee, K.W.; Goedkoop, M.J.; Huijbregts, M.A.J. Characterization Factors for Global Warming in Life Cycle Assessment Based on Damages to Humans and Ecosystems. Environ. Sci. Technol. 2009, 43, 1689–1695. [Google Scholar] [CrossRef] [PubMed]

- De Schryver, A.M.; van Zelm, R.; Humbert, S.; Pfister, S.; McKone, T.E.; Huijbregts, M.A.J. Value Choices in Life Cycle Impact Assessment of Stressors Causing Human Health Damage. J. Ind. Ecol. 2011, 15, 796–815. [Google Scholar] [CrossRef]

- De Schryver, A.; van Zelm, R.; Humbert, S.; McKone, T.E.; Huijbregts, M.A.J. Value choices in human health endpoint modelling. Available online: http://www.lcacenter.org/LCA9/presentations/77.pdf (accessed on 26 November 2014).

- Tukker, A. Risk Analysis, Life Cycle Assessment-The Common Challenge of Dealing with the Precautionary Frame (Based on the Toxicity Controversy in Sweden and the Netherlands). Risk Anal. 2002, 22, 821–832. [Google Scholar] [CrossRef] [PubMed]

- Michalek, J.J.; Chester, M.; Jaramillo, P.; Samaras, C.; Shiau, C.-S.N.; Lave, L.B. Valuation of plug-in vehicle life-cycle air emissions and oil displacement benefits. Proc. Natl. Acad. Sci. USA 2011, 108, 16554–16558. [Google Scholar] [CrossRef] [PubMed]

- Kopp, R.E.; Mignone, B.K. The U.S. Government’s Social Cost of Carbon Estimates after Their First Two Years: Pathways for Improvement. Econ. Open-Access Open-Assess. E-J. 2012, 6, 1–41. [Google Scholar]

- US Interagency Working Group on Social Cost of Carbon. Technical Support Document: Social Cost of Carbon for Regulatory Impact Analysis Under Executive Order 12866; US Interagency Working Group on Social Cost of Carbon: Washington, DC, USA, 2010. [Google Scholar]

- Tatari, O.; Kucukvar, M. Sustainability Assessment of U.S. Construction Sectors: Ecosystems Perspective. J. Constr. Eng. Manag. 2012, 138, 918–922. [Google Scholar] [CrossRef]

- Burnham, A.; Wang, M.; Wu, Y. Development and Applications of GREET 2.7—The Transportation Vehicle-Cycle Model; U.S. Department of Energy: Oak Ridge, TN, USA, 2009. [Google Scholar]

- Marshall, B.M.; Kelly, J.C.; Lee, T.-K.; Keoleian, G.A.; Filipi, Z. Environmental assessment of plug-in hybrid electric vehicles using naturalistic drive cycles and vehicle travel patterns: A Michigan case study. Energy Policy 2013, 58, 358–370. [Google Scholar] [CrossRef]

- Argonne Transportation Technology R&D Center GREET Vehicle cycle model. Available online: https://greet.es.anl.gov/greet_2_series (accessed on 7 August 2014).

- Autonomie Argonne Transportation Technology R&D Center. Available online: http://www.transportation.anl.gov/modeling_simulation/PSAT/autonomie.html (accessed on 8 September 2014).

- Elgowainy, A.; Burnham, A. Well-to-wheels energy use and greenhouse gas emissions of plug-in hybrid electric vehicles. SAE Int. J. Fuels Lubr. 2009, 2, 627–644. [Google Scholar]

- Argonne Transportation Technology R&D Center. Costs of Lithium-Ion Batteries for Vehicles; Argonne Transportation Technology R&D Center: Argonne, IL, USA, 2000. [Google Scholar]

- U.S. DEO Federal Tax Credits for Plug-in Hybrids. Available online: http://www.fueleconomy.gov/feg/taxphevb.shtml (accessed on 7 December 2014).

- Toyota 2014 Toyota Corolla Specifications. Available online: http://www.toyota.com/corolla/#!/Welcome (accessed on 9 January 2014).

- Toyota 2014 Toyota Prius-HEV Specifications. Available online: http://www.toyota.com/prius/features.html#!/weights_capacities/1223/1225/1227/1229 (accessed on 1 September 2014).

- Nissan 2014 Nissan Leaf Specifications. Available online: http://www.nissanusa.com/electric-cars/leaf/versions-specs/ (accessed on 1 September 2014).

- Toyota 2014 Toyota Prius-PHEV Specifications. Available online: http://www.toyota.com/prius-plug-in/features.html#!/mechanical/1235/1237 (accessed on 2 February 2014).

- Chevrolet 2014 Chevrolet Volt Specifications. Available online: http://www.chevrolet.com/volt-electric-car/specs/dimensions.html (accessed on 1 September 2014).

- EPA Gasoline Emission Factor-Calculations and References. Available online: http://www.epa.gov/cleanenergy/energy-resources/refs.html (accessed on 10 November 2013).

- U.S. Environmental Protection Agency Office of Transportation and Air Quality. Fuel Economy Labeling of Motor Vehicles: Revisions to Improve Calculation of Fuel Economy Estimates; U.S. Environmental Protection Agency Office of Transportation and Air Quality: Washington, DC, USA, 2006. [Google Scholar]

- Matthews, H.S.; Hendrickson, C.; Horvath, A. External Costs of Air Emissions from Transportation. J. Infrastruct. Syst. 2001, 7, 13–17. [Google Scholar] [CrossRef]

- The U.S. Department of Transportation. National Household Survey-Summary of Household Travel Trends; The U.S. Department of Transportation: Washington, DC, USA, 2009. [Google Scholar]

- National Household Travel Survey Online Analysis Tools—Table Designer. Available online: http://nhts.ornl.gov/tools.shtml (accessed on 3 July 2014).

- Engholm, A.; Johansson, G.; Persson, A.Å. Life Cycle Assessment: Of Solelia Greentech’s Photovoltaic BasedCharging Station for Electric Vehicles. Available online: http://www.diva-portal.org/smash/get/diva2:626019/FULLTEXT01.pdf (accessed on 9 December 2014).

- Transportation Energy Data book Transportation and the Economy-Car Operating Cost per Mile, 1985–2012. Available online: http://cta.ornl.gov/data/chapter10.shtml (accessed on 19 January 2014).

- Faria, R.; Marques, P.; Moura, P.; Freire, F.; Delgado, J.; de Almeida, A.T. Impact of the electricity mix and use profile in the life-cycle assessment of electric vehicles. Renew. Sustain. Energy Rev. 2013, 24, 271–287. [Google Scholar] [CrossRef]

- Delucchi, M.A.; Lipman, T.E. An analysis of the retail and lifecycle cost of battery-powered electric vehicles. Transp. Res. Part D Transp. Environ. 2001, 6, 371–404. [Google Scholar] [CrossRef]

- Joshi, S. Product Environmental Life-Cycle Assessment Using Input-Output Techniques. J. Ind. Ecol. 1999, 3, 95–120. [Google Scholar] [CrossRef]

- Gaines, L.; Nelson, P. Lithium-ion Batteries: Examining Material Demand and Recycling Issues; Argonne National Laboratory: Argonne, IL, USA, 2010. [Google Scholar]

- Gaines, L.; Sullivan, J.; Burnham, A.; Belharouak, I. Life-Cycle Analysis for Lithium-Ion Battery Production and Recycling. Trans. Res. Record J. Trans. Res. Board 2010. [Google Scholar] [CrossRef]

- Jody, B.J.; Duranceau, C.M.; Daniels, E.J.; Pomykala, A.J. End-of-Life Vehicle Recycling: State of the Art of Resource Recovery from Shredder Residue. Available online: http://www.osti.gov/scitech/biblio/925337 (accessed on 12 December 2014).

- EPA Wastes-Resource Conservation-Common Wastes & Materials. Available online: http://www.epa.gov/epawaste/conserve/materials/auto.htm (accessed on 8 September 2014).

- World Economic Forum Global Agenda Council on Employment. Matching Skills and Labour Market Needs Building Social Partnerships for Better Skills and Better Jobs. Available online: http://www.weforum.org/reports/matching-skills-and-labour-market-needs-building-social-partnerships-better-skills-and-bette (accessed on 12 December 2014).

- Foster-McGregor, N.; Stehrer, R.; de Vries, G.J. Offshoring and the skill structure of labour demand. Rev. World Econ. 2013, 149, 631–662. [Google Scholar] [CrossRef]

- Energy Information Administration (EIA). ternational Energy Outlook 2010; EIA: Washington, DC, USA, 2010. [Google Scholar]

- Cameron, C.; Yelverton, W.; Dodder, R.; West, J. Strategic responses to CO2 emission reduction targets drive shift in US electric sector water use. Energy Strateg. Rev. 2014, 4, 16–27. [Google Scholar] [CrossRef]

- Kenny, J.F.; Barber, N.L.; Hutson, S.S.; Linsey, K.S.; Lovelace, J.K.; Maupin, M.A. Estimated Use of Water in the United States in 2005; U.S. Geological Survey Circular: Reston, VA, USA, 2009. [Google Scholar]

- Kimmell, T.; Veil, J. Impact of Drought on US Steam Electric Power Plant Cooling Water Intakes and Related Water Resource Management Issues; Argonne National Laboratory Environmental Science Division: Argonne, IL, USA, 2009. [Google Scholar]

- Zamuda, C.; Mignone, B.; Bilello, D.; Hallett, K. US Energy Sector Vulnerabilities to Climate Change and Extreme Weather; The U.S. Department of Energy: Washington, DC, USA, 2013. [Google Scholar]

- Harto, C.; Meyers, R.; Williams, E. Life cycle water use of low-carbon transport fuels. Energy Policy 2010, 9, 4933–4944. [Google Scholar] [CrossRef]

- King, C.; Webber, M. Water intensity of transportation. Environ. Sci. Technol. 2008, 42, 7866–7872. [Google Scholar] [CrossRef] [PubMed]

- Pepermans, G.; Driesen, J.; Haeseldonckx, D.; Belmans, R.; D’haeseleer, W. Distributed generation: Definition, benefits and issues. Energy Policy 2005, 33, 787–798. [Google Scholar] [CrossRef]

- Li, X.; Lopes, L.A.C.; Williamson, S.S. On the suitability of plug-in hybrid electric vehicle (PHEV) charging infrastructures based on wind and solar energy. In Proceedings of the 2009 IEEE Power & Energy Society General Meeting, Calgary, AB, Canada, 26–30 July 2009; pp. 1–8.

- The U.S. Energy Information Administration (EIA). Annual Energy Outlook with Projections to 2040; EIA: Washington, DC, USA, 2013. [Google Scholar]

- Andrew, R.M.; Peters, G.P. A Multi-Region Input–Output Table Based On the Global Trade Analysis Project Database (GTAP-MRIO). Econ. Syst. Res. 2013, 25, 99–121. [Google Scholar] [CrossRef]

- Dietzenbacher, E.; Los, B.; Stehrer, R.; Timmer, M.; de Vries, G. The Construction of World Input–Output Tables in the WIOD Project. Econ. Syst. Res. 2013, 25, 71–98. [Google Scholar] [CrossRef]

- Lenzen, M.; Moran, D.; Kanemoto, K.; Geschke, A. Building EORA: A Global Multi-Region Input–Output Database at High Country And Sector Resolution. Econ. Syst. Res. 2013, 25, 20–49. [Google Scholar] [CrossRef]

- Tukker, A.; Dietzenbacher, E. Global Multiregional Input–Output Frameworks: An Introduction and Outlook. Econ. Syst. Res. 2013, 25, 1–19. [Google Scholar] [CrossRef]

- Raykin, L.; MacLean, H.L.; Roorda, M.J. Implications of driving patterns on well-to-wheel performance of plug-in hybrid electric vehicles. Environ. Sci. Technol. 2012, 46, 6363–6370. [Google Scholar] [CrossRef] [PubMed]

- Karabasoglu, O.; Michalek, J. Influence of driving patterns on life cycle cost and emissions of hybrid and plug-in electric vehicle powertrains. Energy Policy 2013, 60, 445–461. [Google Scholar] [CrossRef]

- Onat, N.C.; Egilmez, G.; Tatari, O. Towards greening the U.S. residential building stock: A system dynamics approach. Build. Environ. 2014, 78, 68–80. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onat, N.C.; Kucukvar, M.; Tatari, O. Towards Life Cycle Sustainability Assessment of Alternative Passenger Vehicles. Sustainability 2014, 6, 9305-9342. https://doi.org/10.3390/su6129305

Onat NC, Kucukvar M, Tatari O. Towards Life Cycle Sustainability Assessment of Alternative Passenger Vehicles. Sustainability. 2014; 6(12):9305-9342. https://doi.org/10.3390/su6129305

Chicago/Turabian StyleOnat, Nuri Cihat, Murat Kucukvar, and Omer Tatari. 2014. "Towards Life Cycle Sustainability Assessment of Alternative Passenger Vehicles" Sustainability 6, no. 12: 9305-9342. https://doi.org/10.3390/su6129305

APA StyleOnat, N. C., Kucukvar, M., & Tatari, O. (2014). Towards Life Cycle Sustainability Assessment of Alternative Passenger Vehicles. Sustainability, 6(12), 9305-9342. https://doi.org/10.3390/su6129305