4.1. Rice Field Area and Occurrence of Domestic Animals

The results indicate that the majority of Cambodian households cultivate rice and most of these households are smallholders.

Table 4 presents the mean and median values of rice field area per household in different villages. The mean rice field area per household was 1.30 ha, while the median value was 0.50 ha and the largest recorded 71.0 ha. In 90% of households, the area usable for rice cultivation was smaller than 3.0 ha, while one third of all households and, in particular, urban households did not own or rent rice fields. The median areas are consistently below the mean areas, showing that households are mainly smallholders in all village classes except for urban villages (UG) where field areas are smallest. The rice production area was largest in the unelectrified agricultural areas, in particular in lowland agricultural areas with seasonal floods (LOF). However, in fishing villages (RAF) the mean rice field area per household was even smaller than in urban areas.

Table 4.

Cultivable rice field area (ha) per household.

Table 4.

Cultivable rice field area (ha) per household.

| Village class | Grid connection | Mean (ha) | Median (ha) |

|---|

| Lowland agricultural (LOA) | No | 1.35 | 0.75 |

| Lowland agricultural flood (LOF) | No | 2.11 | 1.00 |

| Riverside agricultural/fishing (RAF) | No | 0.40 | 0.30 |

| Upland agricultural (UPA) | No | 0.95 | 1.00 |

| Lowland agricultural on national highway (LOG) | Yes | 1.25 | 0.34 |

| Phnom Penh / province urban (UG) | Yes | 0.71 | 0.00 |

| National total | | 1.29 | 0.50 |

Straw and husk constitute the rice residues suitable for energy uses. As Cambodians usually use rice straw as animal fodder, it is not considered available for energy purposes [

22]. Rice husks have alternative local energy uses as well, such as in rice husk cook stoves, furnaces for heating the air in rice dryers and brick kilns [

5,

23]. While the availability of rice husk has not been evaluated in this study, potential for using it as an additional substrate in biomethanation has been assumed. The quantity of rice husk is presented along with other biogas substrates in

Table 7.

Table 5 presents the mean and median count of domestic animals in unelectrified rural and electrified rural and urban Cambodian households. Cattle, including cows and water buffalo were most common in rural upland areas (UPA) in addition to other unelectrified rural areas, while only households in rural electrified villages (LOG) were likely to own at least one pig. Poultry, referring mostly to chicken and duck, were the most numerous of domestic animals. From the national median, a household was more likely to own poultry rather than cattle or pigs, while in urban areas (UG), animal husbandry was infrequent. Per household, the largest numbers of cattle, pigs and poultry reported were 16, 52 and 1020 respectively. These figures seem plausible when compared to data reported by FAO in 2008, which gives 9.26 fowl, 1.63 cows or buffalo, and 0.96 pigs per household of 5 persons [

16,

18].

Table 5.

Mean and median count of domestic animals per household.

Table 5.

Mean and median count of domestic animals per household.

| Village class | | Cattle | Pigs | Poultry |

|---|

| LOA | Mean | 1.94 | 0.85 | 11.39 |

| | Median | 2.00 | 0.00 | 5.00 |

| LOF | Mean | 2.13 | 0.90 | 12.02 |

| | Median | 2.00 | 0.00 | 6.00 |

| RAF | Mean | 1.45 | 0.62 | 9.79 |

| | Median | 1.00 | 0.00 | 10.00 |

| UPA | Mean | 3.89 | 0.49 | 4.27 |

| | Median | 3.00 | 0.00 | 3.00 |

| LOG | Mean | 1.07 | 1.19 | 7.35 |

| | Median | 0.00 | 0.00 | 3.00 |

| UG | Mean | 0.30 | 0.25 | 5.25 |

| | Median | 0.00 | 0.00 | 0.00 |

| National total | Mean | 1.46 | 0.72 | 9.05 |

| | Median | 0.00 | 0.00 | 3.00 |

4.2. Residential Consumption of Renewable Energy Sources

Cambodian households use various types of renewable energy sources available in their environments, as shown in

Table 6. The survey found that firewood is used in 86% of all households and in rural villages without electricity grid, the figure is 98%, which is in line with the Population Census of 2008 and the findings of San

et al. [

16,

24]. In the urban areas, however, the survey found a larger charcoal consumption than the Census, which neither specifies consumption of plant residues as a cooking fuel [

16]. The survey found that only in the urban areas (UG) is the consumption of charcoal more common than the consumption of firewood. Plant residues are the second most widely used residential bioenergy source, used by 74% of all households. In urban areas, plant residues are the dominant bioenergy source, consumed by a greater share of households (92%) than charcoal (71%) and firewood (58%). The dominance of plant residues, in urban areas in particular, may signify limited access to firewood and limited cash income to purchase commercial fuels, including charcoal. Conversely, consumption of animal dung for energy is not as widespread in Cambodia as it is in, for example, India. Animal dung is used for energy primarily in rural areas without grid electricity. Utilization of biogas as well as solar panels is virtually non-existent. There are a number of biogas development programs in Cambodia, e.g., the National Biodigester Programme [

13]. However, the livelihood survey did not identify any of these.

Agricultural plant residues are used for energy purposes in 26% of the households, while in rural villages without grid the rate was 35%. The highest incidence of energy-use of plant residues was observed in Pursat (61%) and Kampot (54%) provinces. Five percent of the households surveyed used livestock dung for energy purposes, while in rural villages without grid electricity the rate was 7%. The occurrence of energy-use of dung was highest in Svay Rieng (19%) and Battambang (16%) provinces.

Table 6.

Number of households in survey consuming each type of renewable energy.

Table 6.

Number of households in survey consuming each type of renewable energy.

| Village class | Sample size | Fire-wood | Char-coal | Plant residues | Animal dung | Biogas | Solar panel |

|---|

| LOA | 406 | 395 | 35 | 250 | 40 | 0 | 0 |

| LOF | 276 | 275 | 29 | 192 | 10 | 0 | 1 |

| RAF | 29 | 29 | 5 | 25 | 1 | 0 | 0 |

| UPA | 37 | 37 | 7 | 22 | 0 | 0 | 0 |

| LOG | 162 | 147 | 83 | 115 | 5 | 1 | 0 |

| UG | 351 | 202 | 248 | 324 | 3 | 0 | 0 |

| National total | 1261 | 1085 | 407 | 928 | 59 | 1 | 1 |

4.3. Occurrence of Biomasses Suitable for Biomethanation and Biogas Potential

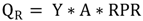

Table 7 shows the daily residential production of biomasses usable for biogas production. Nationally and in all village types, rice husk is the most abundant agricultural by-product, while cow and buffalo dung is the most abundant feces material available for biomethanation. Cows and buffalo were not recorded separately, so it is not possible to calculate the dung mass based on actual species. As the mass of cow dung is the smaller of these two, the biomass and the methanation potential theoretically available have been calculated using cow dung as the reference. The term cattle dung refers here to the dung of both species.

Table 7.

Daily mean production of biogas substrates per household as dry matter [kg].

Table 7.

Daily mean production of biogas substrates per household as dry matter [kg].

| Village class | Cattle dung | Pig manure | Poultry manure | Rice husk |

|---|

| LOA | 2.42 | 0.05 | 0.12 | 2.10 |

| LOF | 2.67 | 0.05 | 0.13 | 3.29 |

| RAF | 1.81 | 0.03 | 0.10 | 0.62 |

| UPA | 1.82 | 0.04 | 0.10 | 1.47 |

| LOG | 1.33 | 0.06 | 0.08 | 1.95 |

| UG | 0.37 | 0.01 | 0.06 | 1.11 |

| National total | 1.46 | 0.72 | 9.05 | 1.29 |

The rice yield per hectare increased by 34% in Cambodia from 2000 to 2009 [

18]. However, for this study, focusing on rural areas, the mean yield for the years 2000–2009, 2,335 kg/ha is used to represent the rice yield of smallholder households, which is unlikely to have increased as rapidly.

Rice husk consist of lignin, cellulose and hemicellulose [

25]. Lignocellulose-containing biomasses are difficult to ferment in a biogas plant and require pretreatment [

10]. Methods for pretreatment of lignocellulosic materials are classified into physical, physico-chemical, chemical and biological pretreatments [

9,

26]. For rural conditions in particular, the cost and technical requirements of the pretreatment are significant considerations. A precomposting procedure, where the plant waste material is bedded in pits and sprinkled with lime water and biogas slurry, could be the most appropriate one for rural conditions [

9].

The portion of rice husk in substrate mixtures proposed varies from 13 to 19% in rural unelectrified villages. In cases where it is high (in particular in UPA areas), it is due to the amount of cow dung available after mixing it with other substrates in a favorable ratio. There may be also other plant residues and kitchen wastes available for biomethanation. These, however, were not specified in the survey and therefore, not included in the calculation.

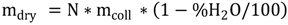

4.4. National Livelihood Survey

Table 8 shows the daily biogas potential per household. Depending on the typical occurrence of substrates for biomethanation in each area, the theoretical biogas yield per day is lowest in urban areas (UG), below national average in rural electrified areas (LOG) and above that in rural unelectrified areas. The specific yield per one kg of raw material varies slightly according to the proportion of substrates produced in different areas. In urban areas, the specific yield is highest but is not sufficient to counteract the low gas production potential. The specific gas yield is fairly consistent for rural areas.

Table 8.

Daily mean biogas potential per household in all areas [Nm3].

Table 8.

Daily mean biogas potential per household in all areas [Nm3].

| Area/ village class | National | Off- Grid | LOG | UG |

|---|

| Gas yield from cattle dung | 0.62 | 0.89 | 0.45 | 0.13 |

| Total gas yield Nm3 | 0.93 | 1.33 | 0.66 | 0.21 |

| Specific yield Nm3/kg TS | 0.42 | 0.41 | 0.42 | 0.44 |

Looking more closely at the unelectrified rural areas,

Table 9 shows the potential for biogas production in the unelectrified village classes. The daily gas yield was highest in upland agricultural villages (UPA), where animal husbandry is more active than in other village types (

Table 5), while the cultivable rice field area was below the national average (

Table 4). The biogas potential in rural villages in lowland (LOA) and occasionally flooded lowland (LOF) was higher than the national average, however in fishing villages by Tonle Sap and Mekong (RAF), the potential was barely up to the national average. The specific biogas yield was consistent for all rural unelectrified areas.

Table 9.

Daily mean biogas potential per household in rural unelectrified areas [Nm3].

Table 9.

Daily mean biogas potential per household in rural unelectrified areas [Nm3].

| Village class | LOA | LOF | RAF | UPA |

|---|

| Gas yield from cattle dung | 0.82 | 0.91 | 0.62 | 1.65 |

| Total gas yield Nm3 | 1.23 | 1.35 | 0.92 | 2.48 |

| Specific yield Nm3/kg TS | 0.41 | 0.41 | 0.41 | 0.41 |

When we look at biogas potential and animal ownership in median households (

Table 5), the situation differs. The national median involves no cattle and no pigs, which also holds for both urban and rural grid-connected villages. Consequently, little raw material would be available for biomethanation.

Table 10, therefore, shows the biogas potential of median households in rural unelectrified villages only. For all unelectrified village classes, the biogas potential based on cattle dung as the main substrate could be calculated. The daily potential was lowest in agricultural-fishing villages (RAF) and highest in upland agricultural villages (UPA). It is sufficient for daily basic energy needs in lowland agricultural areas (LOA, LOF). Again, the specific biogas yield was the same for all unelectrified village types.

Table 10.

Daily median biogas potential per household in rural unelectrified areas [Nm3].

Table 10.

Daily median biogas potential per household in rural unelectrified areas [Nm3].

| Village class | LOA | LOF | RAF | UPA |

|---|

| Gas yield from cattle dung | 0 | 0 | 0 | 1 |

| . | . | . | . |

| 8 | 8 | 4 | 2 |

| 5 | 5 | 3 | 8 |

| Total gas yield Nm3 | 1 | 1 | 0 | 1 |

| . | . | . | . |

| 2 | 2 | 6 | 9 |

| 8 | 8 | 5 | 2 |

| Specific yield Nm3/kg TS | 0 | 0 | 0 | 0 |

| . | . | . | . |

| 4 | 4 | 4 | 4 |

| 1 | 1 | 1 | 1 |

The results suggest that unelectrified upland (UPA) and lowland (LOA, LOF) areas have the best potential for biogas development. This is of particular interest when considering biogas for electricity generation to supply an entire village, where the availability of substrates is an important factor in designing the system. Individual households in other village classes may well produce materials suitable for biomethanation, however the potential for village-scale applications seems small. Substrates not considered include, for example, household waste, human waste or butchery by-products from animal husbandry and fish, as data was not available. However, these results point to areas where more detailed analysis of potential substrates could be conducted. In unelectrified upland villages in particular, biomethanation could be a more suitable local use of rice husk for electricity generation than using it to power other technologies. For example, as an additional substrate to dung, the quantity of rice husk required for biomethanation is low in comparison to direct combustion. Furthermore, the high incidence of plant residues consumed by households (

Table 5) may indicate that rice husk already contributes to residential energy needs. Therefore, the use of rice husk for biomethanation would probably have a less disruptive impact on the existing energy supply structure in rural villages than its use for other modern energy technologies. This may have important implications for the village economy and in particular, to the poorest households.

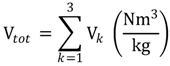

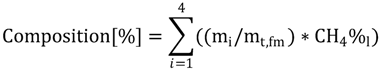

The methane (CH

4) content of biogas was estimated on a mass basis from the share of each substrate in the total dry mass of the feed material, yielding a methane percentage of 63.9–64.4% for the mean households in all village classes, and 63.8–63.9% for the median households in unelectrified rural villages. For biogas, this translates into a lower heating value (LHV) of approximately 22.8–23.0 MJ/Nm

3 for mean households and 22.8 MJ/Nm

3 for median households for all unelectrified villages. The estimate appears reasonable compared to the LHV 23.4 MJ/Nm

3 for biogas from cow dung, containing 65% methane [

9], and to 36 MJ/Nm

3 for 100% CH

4. The data used did not permit the calculation of methane content of the product gas on a volume basis (

Table 2). Further, as the anaerobic digestibility of animal manures is markedly influenced by the animal diet and performance [

27], the data available does not provide further detail in determining the methane production.

4.5. Potential Uses for Biogas

While biogas development is active in Cambodia, only one household, located in a grid-connected rural area, reported using biogas for energy purposes. This indicates substantial room for further biogas development in the country. Typical residential biogas applications are biogas lamps for lighting and biogas stoves for cooking and heating water. According to the National Biodigester Programme Cambodia, one 4-m

3 biodigester producing 0.8–1.6 m

3 biogas per day is sufficient for fueling a biogas stove for 3.5–4 hour, or a biogas lamp for 8–10 hours. One cubic meter of biogas replaces about 5 kg of firewood, based on a woodstove with a 10% efficiency rate [

13]. Considering that a biogas stove is more efficient than a traditional wood stove, about 0.8 m

3 of biogas could suffice for 2 hours of cooking and 4 hours of lighting, sufficient for the basic daily energy needs for an average sized family of five [

9]. As the daily biogas potential in rural areas without grid-connection is 0.9–2.5 m

3, with highest potential in upland agricultural areas (UPA), there seems to be potential for household size biodigesters.

Alternatively, for generating electricity, biogas can be used in both spark ignition and compression ignition engines. In a small system in rural conditions, where the gas supply may vary, a compression ignition engine with dual-fuel operation is more appropriate [

9]. Furthermore, by varying the ratio of biogas and diesel oil, a dual-fuel engine is able to operate regardless of any variation in the methane content of biogas. Vegetable oil or biodiesel can be used instead of mineral diesel oil in a dual-fuel engine [

10].

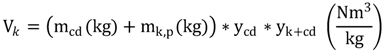

Table 11 shows a comparison between typical rural electricity consumption and the biogas potential found in the study. The annual residential electricity consumption in a rural village for basic lighting and media could be around 60–140 kWh per household [

28], which translates into a daily demand of 160–380 Wh.

Table 11.

Potential for electricity generation from biogas production.

Table 11.

Potential for electricity generation from biogas production.

| Nr of hh | Gas yield; | LOA | LOF | RAF | UPA | Daily electricity |

|---|

| Energy generated | demand kWh |

|---|

| 1 | Biogas yield m3 | 1.2 | 1.4 | 0.9 | 2.5 | |

| Electric energy kWh | 1.8 | 2.0 | 1.3 | 3.6 | 0.16–0.38 |

| 50 | Biogas yield m3 | 62.4 | 68.6 | 46.8 | 124.1 | |

| Electric energy kWh | 89.1 | 98.0 | 66.8 | 177.3 | 8.2–19.2 |

| 100 | Biogas yield m3 | 124.7 | 137.3 | 93.5 | 248.2 | |

| Electric energy kWh | 178.2 | 196.1 | 133.6 | 354.6 | 16.4–38.4 |

For comparison, the survey found that rural grid electricity users (LOG) reported average consumption of about 1 kWh (0.1–6.2 kWh) per day. The variation in income levels essentially explains the differences in electricity consumption. In the LOG village type, households are connected to an already existing electricity grid and tend to have larger electricity consumption than the basic uses (lighting, radio, tv) indicated in table 11, which models typical electricity consumption in a remote rural area. However, while higher-income households in LOG villages owned a wide range of electric appliances, including, e.g., a fan, an electric iron, a computer, or a water pump, some others sufficed to mere electric lighting and the poorest households remained without access to grid electricity.

Table 11 shows the theoretical daily biogas yield and electrical energy available from it for one, fifty and one hundred households. Generating one kWh of electricity with a dual-fuel diesel engine requires about 700 liters of biogas [

9]. The result indicates that in rural unelectrified areas, there is potential for electricity generation that can abundantly supply for the basic residential demand.

A dual-fuel application could be particularly appropriate in places where the diesel generator and local grid already exist. Replacing imported fuel with local energy sources is central in improving national energy security, in particular for developing countries. In Cambodia, more than 1,000 rural electricity enterprises (REEs) provide electricity through mini-grids powered by diesel generators [

13]. These could benefit from converting diesel-powered generation partly to biogas. The actual electricity demand in each grid would determine the extent to which biogas could be used to replace imported diesel fuel.

Institutionally, a local REE would be in a good position to organize the biodigester and managing substrate collection by buying those from the farmers, as a part of its business. A local REE would already have the benefit of having an established business and customer relationships in the area. Collecting substrates could perhaps be organized in association with collecting payments for electricity. Alternatively, a local community organization could take charge of the biodigester and substrate management and sell the produced biogas to the local REE. Even households that are below the capacity for a household digester could have an opportunity for participation and income from collecting substrates for a community digester system. In either case, the issues of developing a coordinating framework and building trust in the operation within the community would need to be addressed.

The calculation is based on the assumption that half of dung produced would be collectable [

9]. This suggests that the farm animals were kept in a pen or a shelter during night. Rice husk is a by-product from rice milling. It could be collected from rice mill and pretreated while it is stored and waiting to be fed in a digester.

It should be born in mind that these results are indicative,

i.e., that the amount of substrates that are genuinely available for biomethanation case by case are not known based on the survey. Furthermore, the biogas potential presented here is a theoretical, yet conservative estimate. Determining the actual methane yield of the substrate mix found in this study would require field experiments. NBP Cambodia reports that the smallest 4 m

3 Farmer’s Friend biodigester model costs 420 US$ to construct, including all material and work. This digester is roughly sufficient for the basic cooking and lighting needs of an average family of five persons through combustion in biogas lamps and stoves [

13]. For comparison, a small 40Wp Solar home system can power a few light bulbs, a radio, a black and white TV and charge mobile phones. A larger system can also power Color TVs and fans [

29]. The price in April 2011 of solar home system including a solar panel, charge controller, cables, transport and installation, without battery, was 298US$ for a 40Wp and $450 US$ for a 80Wp system [

29].

Household electricity demand with few basic appliances is usually too small for electricity generation by an individual dual-fuel generator. Biogas household users apply it mainly for cooking and lighting. Biogas also brings households many additional benefits that are difficult to monetize.

In addition to energy, one of the main benefits for a household is improved indoor air quality as a result of cooking with a fuel that emits less particulate matter than a traditional wood fire. This directly improves the respiratory health of household’s women and children [

11].

While rural households prefer to use biogas for cooking, farms tend to utilize it for heat, shaft power and electricity generation. In Thailand, gas engines are usually considered as prime candidates for shaft power and electricity generation [

30]. Although it is difficult to get accurate information, in Myanmar a 10-kW SI biogas aggregate costs around 600–800 US$. In Cambodia, conversion of CI diesel engine into dual-fuel operation costs below 100 US$ [

31].

In case of a household or a farm with sufficient biogas potential for generating electricity, the intended electricity consumption, including the types of appliances and machinery need to be considered. Dual-fuel engine for electricity generation allows more flexibility in terms of the electrical power it can supply and electricity demand than a solar PV system. The generator needs capacity to serve peak loads and withstand various types of electrical phenomena that may be caused by the machinery in the system. Neither should it operate on too low load [

32].

According to NBP, 25% of rural Cambodian households own enough domestic animals to produce at least 20 kg of dung per day [

13]. This is required for technical potential to have a 4-m

3 biodigester plant, giving 1.36 m

3 of biogas per day. Hence the biogas potential in rural households is at least 2.87× 10

8 m

3 per year, with energy content of 6.54 PJ per year. The work presented here suggests based on the survey that in rural unelectrified areas, the potential is 25.5 PJ, 3.9 times the minimum estimate, while the mean biogas yield is 1.33 m

3 per day. The difference is explained by the fact that the survey covers the substrate potential of all sizes of households, those below the potential for an individual digester, as well as those with potential for a larger unit. Further, the calculation in this study aimed at combining substrates in such proportions that improve the biogas yield in comparison to the digestion of cow dung as a single substrate. In 2009, the primary energy consumption in Cambodia was 73.3 PJ [

33]. Considering that this study has presented residential biogas potential, and that larger commercial agricultural production units are outside the scope of the survey, the figures show that biogas has nationally significant technical potential in Cambodia.