Incineration of Pre-Treated Municipal Solid Waste (MSW) for Energy Co-Generation in a Non-Densely Populated Area

Abstract

:Symbols

| c | constant pressure specific heat | β | pressure ratio | f | gases |

| h | Enthalpy | ε | efficiency | fa | flying ashes |

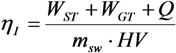

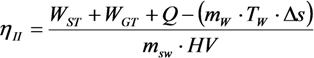

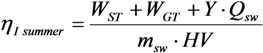

| HV | heating value | ηI | first-principle yield | g | gas |

| k | adiabatic law exponent | ηII | second-principle yield | g-g | gas-gas heat exchanger |

| m | mass flow | η | total efficiency | GT | gas turbine |

| n | air index | χ | coefficient | g-w | gas-water heat exchanger |

| P | Pressure | τ | environmental temperature | sg | slag |

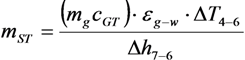

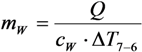

| Q | co-generated thermal power | Δ | finite difference | st | steam |

| s | Entropy | ST | steam turbine | ||

| T | Temperature | Subscripts | sw | solid waste | |

| W | electrical power | ae | air in excess | w | water |

| Y | Yield | at | theoretical air | 0, 1, 2, 3, 4, 5, 6, 7, 8, 9 calculation section | |

1. Introduction

2. Materials and Methods

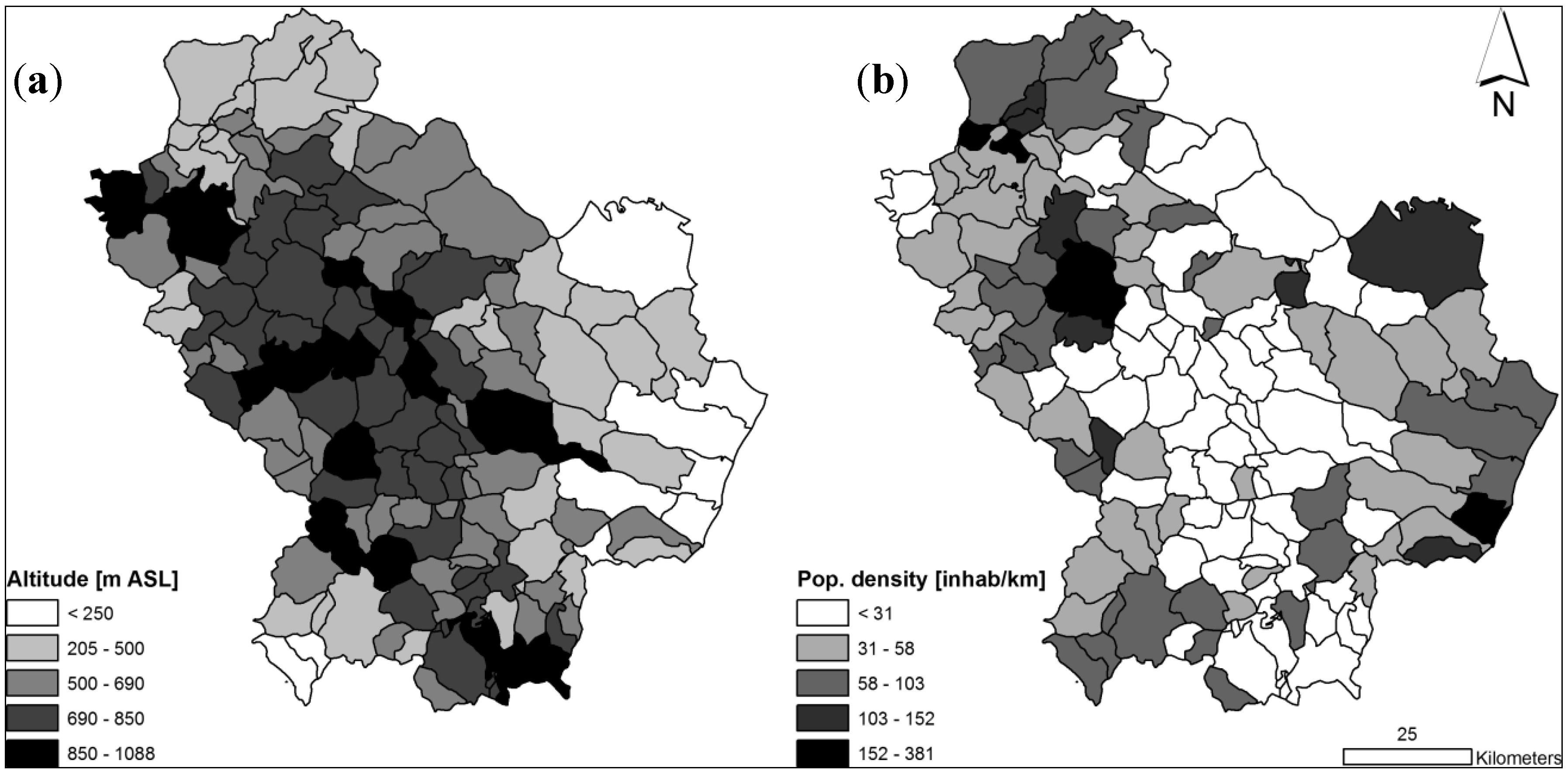

2.1. Investigated Area

2.2. Characteristics of Waste Production

2.3. Environmental Effects Assessment

| Treatment | GHGs emissions | ||

|---|---|---|---|

| Unit | Value | ||

| Biostabilization | without energy recovery | kg CH4eq kg−1 biodegradable VSS | 2.5 |

| with energy recovery | 1.5 | ||

| Incineration plant | 50% of biodegradable fraction removal | kg CH4eq kg−1 VSS | 1.5 |

| Landfilling (50% of biogas capture) | without energy recovery | kg CH4eq kg−1 biodegradable VSS | 10.5 |

| with energy recovery | 9.5 | ||

2.4. Modeling

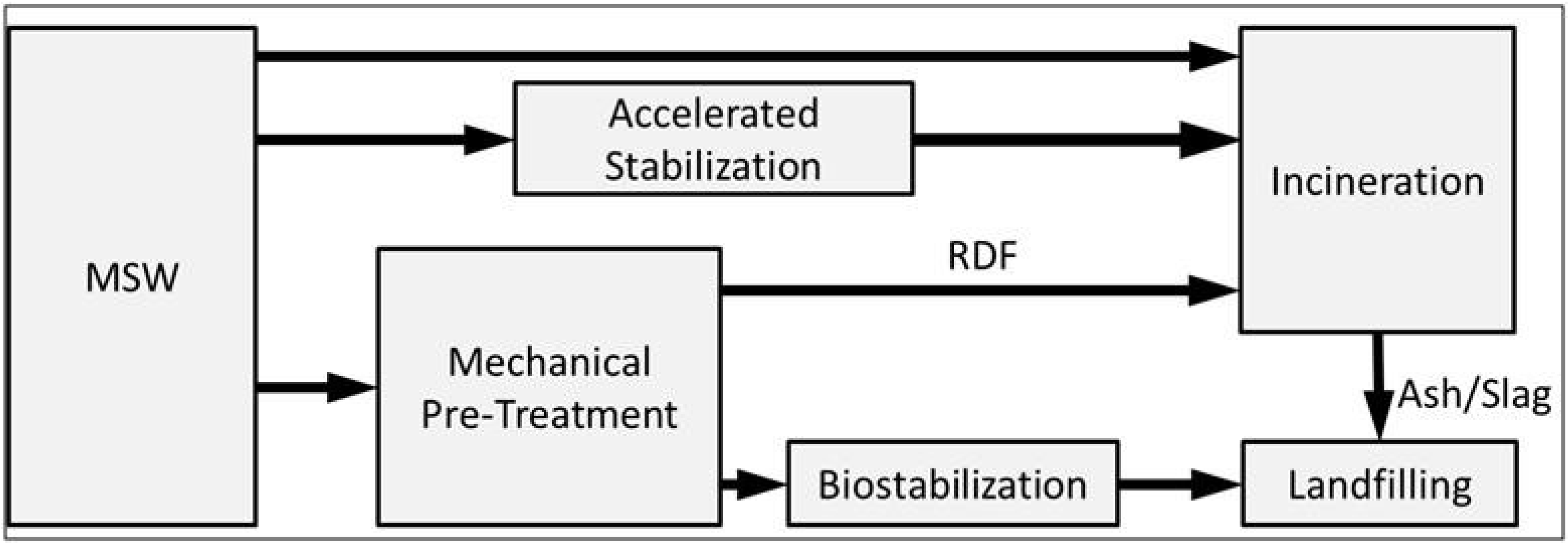

2.4.1. Process and Model Description

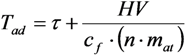

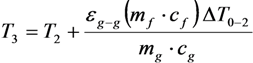

2.4.2. Data and Assumptions

- intended to produce power and low temperature heat for feeding a heating network;

- situated in a strategic area that can be reached from every town through the ordinary communication routes;

- provided with a landfill in order to reduce the transportation of residual waste (e.g., ash, slag).

| Parameter | Unit | Value | ||

|---|---|---|---|---|

| Coefficients | theoretical combustion air (mat/msw) | - | 4.300 | |

| air index (n) | - | 2.300 | ||

| Production rates | slag (χsg) | kg kg−1 | 0.055 | |

| flying ash (χfa) | kg kg−1 | 0.188 | ||

| Specific heats | gases | kJ kg−1 K−1 | 1.260 | |

| gas entering the turbine | kJ kg−1 K−1 | 1.009 | ||

| gas leaving the turbine | kJ kg−1 K−1 | 1.165 | ||

| steam entering the turbine | kJ kg−1 K−1 | 1.091 | ||

| Yield | heat exchanger | gas-gas (εg-g) | - | 0.950 |

| gas-water (εg-w) | - | 0.700 | ||

| Turbine | gas-fed | - | 0.730 | |

| steam-fed | - | 0.730 | ||

| refrigerating machine (Y) | - | 0.800 | ||

3. Results and Discussion

3.1. Waste Production and Energy Potential Evolution

| MSW fraction | Raw MSW | Sieve cut-off [mm] | ||||

|---|---|---|---|---|---|---|

| 40 | 60 | 80 | 100 | 120 | ||

| Organic | 34.3 | 70.3 | 39.6 | 24.3 | 13.3 | 6.4 |

| Paper | 20.5 | 96.1 | 83.5 | 77.7 | 69.1 | 59.4 |

| Plastic and rubber | 11.4 | 93.5 | 83.2 | 81.3 | 73.9 | 63.4 |

| Wood, textile and leather | 5.4 | 85.3 | 70.3 | 63.7 | 61.9 | 59.8 |

| Glass and inert matter | 6.6 | 89.7 | 67.1 | 50.3 | 32.4 | 15.8 |

| Metals | 3.0 | 88.3 | 82.9 | 73.3 | 57.9 | 49.3 |

| Under-sieved (20 mm) | 18.8 | - | - | - | - | - |

| Total | 100.0 | 67.6 | 50.9 | 42.5 | 34.4 | 27.4 |

| MSW fraction | Raw MSW | Sieve cut-off [mm] | |||||

|---|---|---|---|---|---|---|---|

| 20 | 40 | 60 | 80 | 100 | 120 | ||

| Organic | 1,004.0 | 1,236.6 | 1,043.4 | 781.1 | 574.1 | 388.4 | 234.8 |

| Paper | 2,576.0 | 3,172.9 | 3,659.7 | 4,225.7 | 4,709.7 | 5,177.5 | 5,591.8 |

| Plastic and rubber | 2,378.2 | 2,929.2 | 3,287.3 | 3,887.2 | 4,549.6 | 5,112.0 | 5,510.1 |

| Wood, textile and leather | 840.2 | 1,034.9 | 1,059.6 | 1,160.4 | 1,259.4 | 1,512.9 | 1,836.2 |

| Glass and inert matter | - | - | - | - | - | - | - |

| Metals | - | - | - | - | - | - | - |

| Under-sieved | 5,651.1 | 1,063.1 | - | - | - | - | - |

| Total | 6,861.4 | 8,373.6 | 9,050.0 | 10,054.4 | 11,092.8 | 12,190.8 | 13,172.9 |

3.2. Modeling

3.2.1. Environmental Effects

3.2.2. Waste Incineration and Energy Recovery

4. Conclusions

Conflicts of Interest

References

- United Nations—U.N. Environment Programme. Developing Integrated Solid Waste Management Plan; Training Manual; International Environmental Technology Centre: Osaka/Shiga, Japan, 2009; Volume 4. [Google Scholar]

- Cossu, R.; Masi, S. Re-thinking incentives and penalties: Economic aspects of waste management in Italy. Waste Manag. 2013, 33, 2541–2547. [Google Scholar] [CrossRef]

- Callegari, A.; Torretta, V.; Capodaglio, A.G. Preliminary trial application of biological desulfonation in pig farms’ anaerobic digesters. Environ. Eng. Manag. 2013, 12, 815–819. [Google Scholar]

- Rada, E.C.; Ragazzi, M.; Torretta, V. Laboratory-scale anaerobic sequencing batch reactor for treatment of stillage from fruit distillation. Water Sci. Technol. 2013, 67, 1068–1074. [Google Scholar] [CrossRef]

- Martinez, S.L.; Torretta, V.; Minguela, J.V.; Siñeriz, F.; Raboni, M.; Copelli, S.; Rada, E.C.; Ragazzi, M. Treatment of slaughterhouse wastewaters using anaerobic filters. Environ. Technol. 2013. [Google Scholar] [CrossRef]

- Torretta, V.; Rada, E.C.; Istrate, I.A.; Ragazzi, M. Poultry manure gasification and its energy yield. UPB-Sci. Bull. Ser. D 2013, 75, 231–238. [Google Scholar]

- Vaccari, M.; Torretta, V.; Collivignarelli, C. Effect of improving environmental sustainability in developing countries by upgrading solid waste management techniques: A case study. Sustainability 2012, 4, 2852–2861. [Google Scholar] [CrossRef]

- Hartmann, H.; Ahring, B.K. Anaerobic digestion of the organic fraction of municipal solid waste: Influence of co-digestion with manure. Water Res. 2005, 39, 1543–1552. [Google Scholar] [CrossRef]

- Chaerul, M.; Tnaka, M. A system dynamics approach for hospital waste management. Waste Manag. 2008, 28, 442–449. [Google Scholar] [CrossRef]

- Birpmar, M.E.; Bilgili, M.S.; Erdoğan, T. Medical waste management in Turkey: A case study of Istanbul. Waste Manag. 2009, 29, 445–448. [Google Scholar] [CrossRef]

- Abdulla, F.; Abu Qdais, H.; Rabi, A. Site investigation on medical waste management practices in northern Jordan. Waste Manag. 2008, 28, 450–458. [Google Scholar] [CrossRef]

- Mancini, G.; Tamma, R.; Viotti, P. Thermal process of fluff: Preliminary tests on a full-scale treatment plant. Waste Manag. 2010, 30, 1670–1682. [Google Scholar] [CrossRef]

- Torretta, V.; Istrate, I.; Rada, E.C.; Ragazzi, M. Management of waste electrical and electronic equipment in two EU countries: A comparison. Waste Manag. 2013, 33, 117–122. [Google Scholar] [CrossRef]

- Di Mauro, C.; Bouchon, S.; Torretta, V. Industrial risk in the Lombardy Region (Italy): What people perceive and what are the gaps to improve the risk communication and the partecipatory processes. Chem. Eng. Trans. 2012, 26, 297–302. [Google Scholar]

- Morris, M.W.; Su, S.K. Social psychological obstacles in environmental conflict resolution. Am. Behav. Sci. 1999, 42, 1322–1349. [Google Scholar] [CrossRef]

- European Council. Directive 91/156/EEC Amending Directive 75/442/EEC on Waste; Official Journal L 078, 26/03/1991 P. 0032 – 0037; EEC: Brussels, Belgium, 1991. [Google Scholar]

- European Council. Directive 91/689/EEC on Hazardous Waste; Official Journal L 377, 31/12/1991 P. 0020 – 0027; EEC: Brussels, Belgium, 1991. [Google Scholar]

- European Parliament and Council. Directive 94/62/EC on Packaging and Packaging Waste; Official Journal L 365, 31/12/1994, P. 0010–0023; EC: Brussels, Belgium, 1994. [Google Scholar]

- European Parliament and Council. Directive 2000/76/EC on the Incineration of Waste; Official Journal L 332, 28/12/2000, P. 0091; EC: Brussels, Belgium, 2000. [Google Scholar]

- Italian Parliament. Decreto Legislativo 5 febbraio 1997, n. 22 “Attuazione delle direttive 91/156/CEE sui rifiuti, 91/689/CEE sui rifiuti pericolosi e 94/62/CE sugli imballaggi e sui rifiuti di imballaggio”. Available online: http://www.parlamento.it/parlam/leggi/deleghe/97022dl.htm (accessed on 2 May 2013).

- Italian Parliament. Decreto Legislativo 3 aprile 2006, n. 152 “Norme in materia ambientale”. Available online: http://www.camera.it/parlam/leggi/deleghe/06152dl.htm (accessed on 2 May 2013).

- Eriksson, O.; Carlsson, R.M.; Frostell, B.; Björklund, A.; Assefa, G.; Sundquist, J.-O.; Granath, J.; Baky, A.; Thyselius, L. Municipal solid waste management from a systems perspective. J. Clean. Prod. 2005, 13, 241–252. [Google Scholar] [CrossRef]

- Tascione, V.; Raggi, A. Identification and selection of alternative scenarios in LCA studies of integrated waste management systems: A review of main issues and perspectives. Sustainability 2012, 4, 2430–2442. [Google Scholar] [CrossRef]

- Bovea, M.D.; Ibáñez-Forés, V.; Gallardo, A.; Colomer-Mendoza, F.J. Environmental assessment of alternative municipal solid waste management strategies: A Spanish case study. Waste Manag. 2010, 30, 2383–2395. [Google Scholar] [CrossRef]

- De Feo, G.; Malvano, C. The use of LCA in selecting the best MSW management system. Waste Manag. 2009, 29, 1901–1915. [Google Scholar] [CrossRef]

- Iriarte, A.; Gabarrel, X.; Rieradevall, J. LCA of selective waste collection systems in dense urban areas. Waste Manag. 2009, 29, 903–914. [Google Scholar] [CrossRef]

- Emery, A.; Davies, A.; Griffiths, A.; Williams, K. Environmental and economic modelling: A case study of municipal solid waste management scenarios in Wales. Resour. Conserv. Recycl. 2007, 49, 244–263. [Google Scholar] [CrossRef]

- Chang, Y.H.; Chang, N.B. Compatibility analysis of material and energy recovery in a regional solid waste management system. J. Air Waste Manag. Assoc. 2003, 53, 32–40. [Google Scholar] [CrossRef]

- Di Maria, F.; Micale, C. Impact of source segregation intensity of solid waste on fuel consumption and collection costs. Waste Manag. 2013, 33, 2170–2176. [Google Scholar] [CrossRef]

- Nguyen, T.T.T.; Wilson, B.G. Fuel consumption estimation for kerbside municipal solid waste (MSW) collection activities. Waste Manag. Res. 2010, 28, 289–297. [Google Scholar] [CrossRef]

- European Commission. Eurostat Database. Available online: http://epp.eurostat.ec.europa.eu/portal/page/portal/statistics/search_database (accessed on 1 December 2013).

- Tchobanoglous, G.; Kreith, F. Handbook of Solid Waste Management; Mc-Graw-Hill: New York, NY, USA, 2002. [Google Scholar]

- Murphy, J.D.; McKeogh, E. Technical, economic and environmental analysis of energy production from municipal solid waste. Renew. Energy 2004, 29, 1043–1057. [Google Scholar] [CrossRef]

- Rimaitytė, I.; Denafas, G.; Martuzevicius, D.; Kavaliauskas, A. Energy and environmental indicators of municipal solid waste incineration: Toward selection of an optimal waste management system. Pol. J. Environ. Stud. 2010, 19, 989–998. [Google Scholar]

- Italian Institute of Statistics (ISTAT). Maps and Census Data. (in Italian). Available online: http://www.istat.it/it/strumenti/cartografia (accessed on 23 April 2013).

- Institute for the Environmental Protection and Research—ISPRA. Rapporto rifiuti urbani (Municipal Waste Report); ISRRA: Rome, Italy, 2012. [Google Scholar]

- Regione Basilicata. Piano regionale gestione rifiuti, Potenza, Italy. Available online: http://www.regione.basilicata.it/giunta/files/docs/DOCUMENT_FILE_242375.pdf (accessed on 20 April 2013).

- Consonni, S.; Viganò, F. Material and energy recovery in integrated waste management systems: The potential for energy recovery. Waste Manag. 2011, 31, 2074–2084. [Google Scholar] [CrossRef]

- Valkenburg, C.; Gerber, M.A.; Walton, C.W.; Jones, S.B.; Thompson, B.L.; Stevens, D.J. Municipal Solid Waste (MSW) to Liquid Fuels Synthesis, Volume 1: Availability of Feedstock and Technology; U.S. Deptartment of Energy: Washington, DC, USA, 2008. [Google Scholar]

- Cosmi, C.; Cuomo, V.; Macchiato, M.; Mangiamele, L.; Masi, S.; Salvia, M. Waste management modeling by MARKAL model: A case study for Basilicata Region. Environ. Model. Assess. 2000, 5, 19–27. [Google Scholar] [CrossRef]

- Cosmi, C.; Mancini, I.; Mangiamele, L.; Masi, S.; Salvia, M.; Macchiato, M. The management of urban waste at regional scale: The state of the art and its strategic evolution—Case study Basilicata Region (Southern Italy). Fresenius Environ. Bull. 2001, 10, 131–138. [Google Scholar]

- Çengel, Y.A. Introduction to Thermodynamics and Heat Transfer; McGraw-Hill: New York, NY, USA, 2007. [Google Scholar]

- Environmental Protection Agency—Ireland. Municipal Solid Waste—Pre-treatment & Residuals Management; IR-EPA: Wexford, Ireland, 2009. [Google Scholar]

- Sue, D.C.; Chuang, C.C. Engineering design and energy analyses for combustion gas turbine based power generation system. Energy 2004, 29, 1183–1205. [Google Scholar] [CrossRef]

- Roher, A. Comparison of combined heat and power generation plants. ABB Review 1996, 3, 24–32. [Google Scholar]

- Lombardi, F.; Lategano, E.; Cordiner, S.; Torretta, V. Waste incineration in rotary kilns: A new simulation combustion’s tool to support design and technical change. Waste Manag. Res. 2013, 31, 739–750. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Trulli, E.; Torretta, V.; Raboni, M.; Masi, S. Incineration of Pre-Treated Municipal Solid Waste (MSW) for Energy Co-Generation in a Non-Densely Populated Area. Sustainability 2013, 5, 5333-5346. https://doi.org/10.3390/su5125333

Trulli E, Torretta V, Raboni M, Masi S. Incineration of Pre-Treated Municipal Solid Waste (MSW) for Energy Co-Generation in a Non-Densely Populated Area. Sustainability. 2013; 5(12):5333-5346. https://doi.org/10.3390/su5125333

Chicago/Turabian StyleTrulli, Ettore, Vincenzo Torretta, Massimo Raboni, and Salvatore Masi. 2013. "Incineration of Pre-Treated Municipal Solid Waste (MSW) for Energy Co-Generation in a Non-Densely Populated Area" Sustainability 5, no. 12: 5333-5346. https://doi.org/10.3390/su5125333

APA StyleTrulli, E., Torretta, V., Raboni, M., & Masi, S. (2013). Incineration of Pre-Treated Municipal Solid Waste (MSW) for Energy Co-Generation in a Non-Densely Populated Area. Sustainability, 5(12), 5333-5346. https://doi.org/10.3390/su5125333