Enhancing Sustainability of Cotton Production Systems in West Africa: A Summary of Empirical Evidence from Burkina Faso

Abstract

: Africa has been hesitant to adopt agricultural biotechnology, lagging behind global trends over the past decade. One exception is Burkina Faso, a West African country that commercially released 125,000 ha of Bt cotton in 2009. Bt cotton may serve as a working example of how African countries can enhance sustainability using modern, science-driven technology to increase production levels while reducing input use and energy consumption. This paper reports the potential impact that Bt cotton can have on sustainability in Burkina Faso's cotton sector based by summarizing empirical evidence from previously published studies. Based on the summary of published data collected from six years of field trials and producer surveys, Bt cotton increased cotton yields by an average of 21.3% and raised income by $106.14 per ha. Using an energy balance model, the introduction of Bt cotton would also result in a 6.6% saving in energy use. The significant increase in productivity and economic returns could be the catalyst for Burkina Faso, and other African countries, to emerge from the decade or so of stagnation and regain their competitive stance in world cotton markets while providing environmental and social benefits.1. Introduction

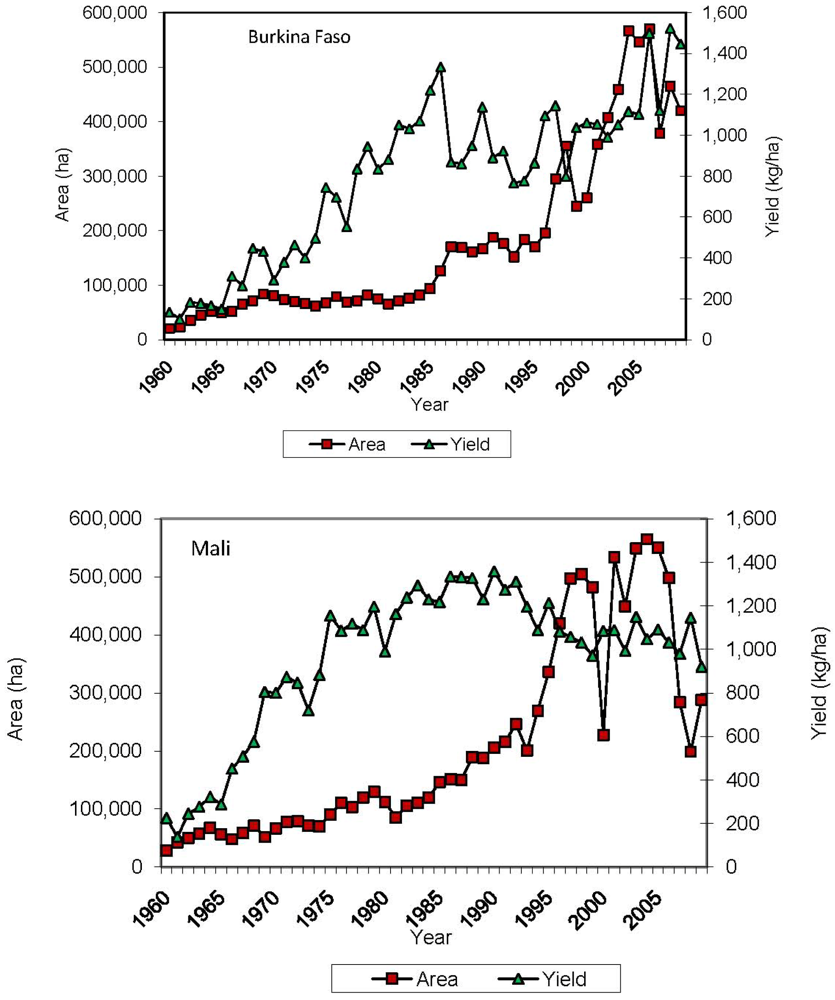

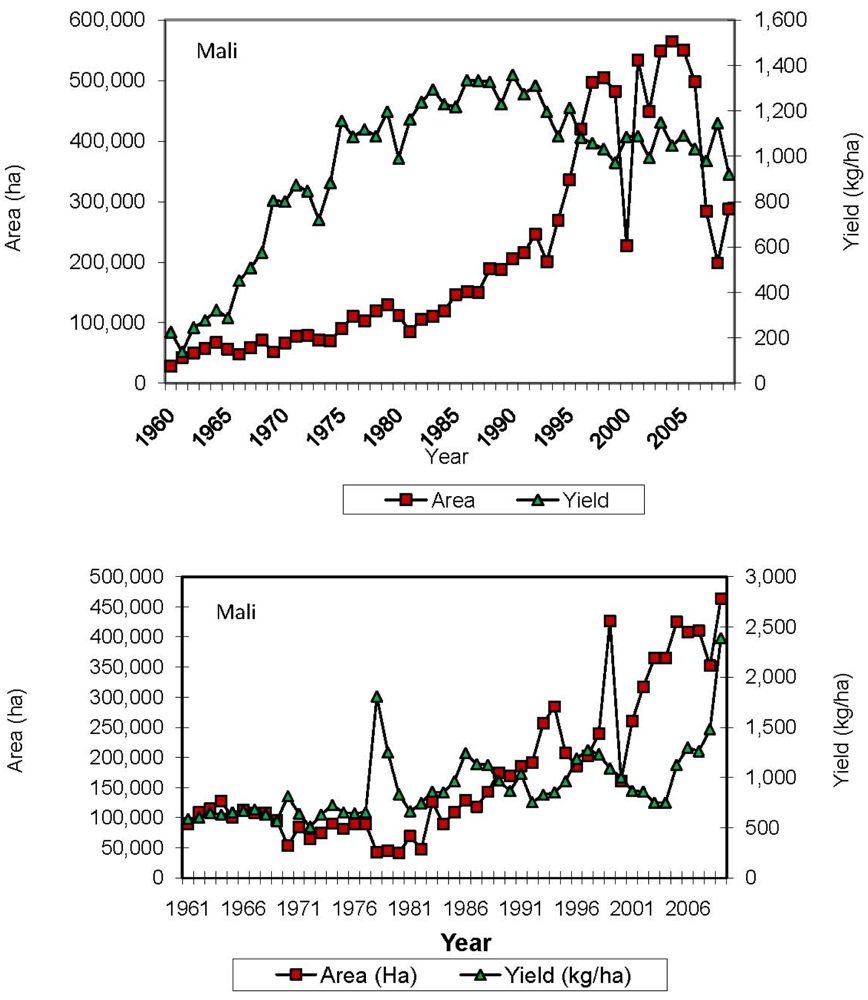

Cotton has been produced in West Africa since the French colonial period [1]. During its formative years following independence in the early 1960s, the West African cotton sector was able to substantially increase production by rapidly introducing new agricultural technology [2-4]. With greater productive capacity, cotton yields increased steadily for over two decades beginning in the early 1960s [1,5-7]. The early success of cotton production in West Africa is typified by Mali and Burkina Faso (Figure 1). Cotton yields in both countries increased from an average of roughly 200 kg ha−1 in 1963 to highs of 1400 kg ha−1 in the middle part of the 1980s [8]. During this period of technological change, development in the West African cotton sector was achieved primarily through crop intensification, rather than the traditional approach used by African farmers whereby production is increased by land-extensive means. The cotton development efforts of the Compagnie Française pour le Développement des Fibres Textiles (CFDT) and Centre de cooperation Internationale en Recherche Agronomique pour de Développement (CIRAD), beginning in the early 1960s, promoted the use of modern inputs such as chemical fertilizers, insecticides, herbicides, and improved cotton seeds [9].

The economic importance of cotton has also increased substantially, generating significant farm income, rural employment, and export revenues for cotton producing countries [10]. Cotton quickly became the region's “white gold”, one of the leading sources of export earnings and a major source of employment in rural areas where livelihoods center about cotton, accounting for 60% of household income [3,10,11]. In Burkina Faso, over 2.2 million Burkinabé derive their income from producing, ginning, weaving, or transporting cotton [8,12,13]. Public services such as schools, roads, public heath, and a variety of agricultural extension services have traditionally been provided by cotton revenues. Cotton has been responsible for alleviating poverty in many of the cotton producing areas [1]. Export earnings from selling cotton on the world market are the primary source of hard currency in these countries and are a vital catalyst to national economic development, with cotton's share of Gross Domestic Product (GDP) reaching up to 10% among the cotton four (C4) countries (Burkina Faso, Mali, Chad, and Benin) [14].

West Africa is now the second leading exporter of cotton in the world, trailing only the U.S. in world market share [8]. West Africa accounts for only a small portion of world cotton production, typically about 5%, but is an increasingly important player in the world market. Exporting nearly all of its cotton production, West Africa produces cotton fiber of relatively high quality, and retains low production costs through its reliance on manual production techniques and the low opportunity cost of household labor [15]. Higher transportation costs in reaching open-sea ports, however, diminish some of West Africa's cost advantages in the land locked C4 countries [14]. Led by the big four countries of Burkina, Mali, Benin, and Cote D'Ivoire, West Africa's share of world cotton exports rose from 2.4 to 9.4% over the past 20 years [16].

The initial success and achievements of the 1960s and 1970s waned, however, as the sector matured and cotton technology generated increasingly marginal returns [1,2]. Cotton yields peaked in the late 1980s throughout most of West Africa, and over the past few years cotton yields have begun a gradual decline in Mali and Burkina Faso (Figure 1). The causes of the yield stagnation in West Africa can be explained by several factors, including agronomic constraints from pest damage and poor soil fertility management, but yields have also been negatively impacted by lack of varietal development, outdated and improper technology packages, the expansion of cotton production into marginal areas where yields are inherently lower, and climate change [17]. Beginning in the mid-1980s, when the downward trend in yields became first evident, the national cotton companies responded by pushing back the agricultural frontier, expanding into marginal production areas (Figure 1). While the land expansion strategy increased aggregate production in the short-run, average yields continued to stagnate and even fall into the 1990s and through to the present (Figure 1). Moreover, the expanded use of marginal lands has increased environmental concerns since the newly introduced lands are typically located in environmentally sensitive areas where exposed soils are prone to erosion and degradation.

The downward trend in cotton yields poses a serious threat to the sustainability of cotton production in West Africa [14]. Although sustainability has many definitions, the United Nations (UN) definition of sustainability as “meeting the needs of the present without compromising the ability of future generations to meet their own needs” has been generally accepted in the development community [4,18,19]. In 2005, the UN's definition of sustainability was broadened by the World Summit to encompass what is now considered the three main “pillars” of sustainable development: social responsibility, environmental protection, and economic sustainability [20]. This implies that West African cotton sectors will need to identify new approaches to restore productivity and profitability in a manner that avoids environmentally risky policies such as land expansion, or other policies that would endanger the social welfare of cotton producers.

Carrying forward the economic success of the past few decades will be a particular challenge. Over the past decade, nearly all of the national cotton companies in West Africa have experienced a financial crisis, requiring government and donor assistance to remain solvent [8]. Three of the larger producers in the region, Mali, Benin, and Cote D'Ivoire, became temporarily insolvent in 2000 when cotton prices went into a temporary free fall. Since then prices have recovered, but credible concerns are growing among all major stakeholders (producers, policy makers, and donors) that West African cotton producing countries could lose part, if not all, of their cotton sector. Production costs have also eroded farm-gate profitability. Labor costs have been increasing as rural-urban migration patterns have bid-up wage rates, and rising energy costs have increased fertilizer and other purchased input costs [14].

In order to enhance sustainability, West Africa will need to consider new technology options to reverse yield stagnation [21,22]. Other cotton producing countries, notably the U.S. and Brazil, have faced similar productivity challenges. The U.S. experienced yield stagnation that spanned a similar two decade period from the mid 1960s through 1980s. Beginning in the early '80s, the U.S. cotton sector experienced a period of rapid productivity growth that remains on-going. The U.S. yield gains have been made possible by several factors, including expansion into the western part of the U.S. where the development of irrigated cotton generated substantial increases in cotton yields. Increased productivity was also achieved through higher fertilizer input levels, enhanced varietal research and improved seed quality, farm support programs, boll weevil eradication, and most recently the introduction of Bt cotton [8]. The U.S. experience provides West Africa with a working model of not only how stagnation can be overcome, but also provides a rather grim warning. Many parts of the U.S. were never able to fully recover from the yield stagnation. In Oklahoma, for example, where cotton acreage once totaled over one million acres, cotton production has dwindled to less than 120,000 acres.

Brazil's yield stagnation began in 1960 and lasted to the end of the 1980s, during which time cotton yields leveled off at an average of 500 kg per ha [8]. Through a concerted effort by government and cotton stakeholders to increase investments in research and development, similar to the U.S., Brazil's cotton yields have increased steadily since the 1990s. Brazil's cotton yields have surpassed those in the U.S. by 50% and are nearly three times higher than in West Africa.

The widening yield gap between West African producers and global competititors such as the U.S. and Brazil is an on-going threat to the sustainability of cotton production in West Africa [8]. While Africa's yields have been stagnant for over two decades, both the U.S. and Brazil found ways to increase productivity when they became mired in stagnation. Much of the cotton yield increase in the U.S. and Brazil was achieved by introducing new technology. One of the major technological changes has been the introduction of Bt cotton. Introduced in 1996, Bt cotton varieites have been genetically modifed to produce Cry proteins, the active ingredient in Bacillius thurengiensis (Bt) that are toxic to one of coton's primary pests, the American bollworm [23].

An attractive feature of Bt cotton for West Africa is that it can increase productivity in the near- to short-term, unlike varietal and pest eradication programs that require long-term investment horizons. Africa's overall use of agricultural biotechnology, however, still lags far behind adoption rates seen throughout the world. Although Africa produces 20% of the world's cotton, it accounted for less than 1% of the world's area of Bt cotton, which in less than 15 years has spread to 10 million ha in 9 countries [24]. Concerns over the boundaries of science and environmental risks have been loudly voiced by special-interest groups. Presumably, special interest groups have successfully influenced African governments to remain cautious towards biotechnology [25-27]. Regulatory and institutional constraints, influenced to some degree by opposition groups, have delayed the introduction of bioengineered crops in Africa while commercial release and adoption of biotech crops has proceeded on most other continents, including smallholder producers [28]. Of the 10.3 million farmers growing biotech crops in 2006, close to 90% were small resource-poor farmers from developing countries [24]. Nearly all of the Bt cotton grown by smallholder producers were from either China or India, which had 6.8 and 2.3 million producers, respectively. While Africa has been hesitant towards biotechnology, and critics have often cast biotechnology as anti-environment (Greenpeace, OXFAM, GRAIN, Global Justice Ecology Project), biotechnology can assist in sustainability. Biotechnology can increase productivity in the near-run with higher yields, and by reducing pesticide use biotechnology can enhance sustainability in other areas as well, including energy savings, water savings, and improved human health [29].

Insects have traditionally been a threat to sustaining cotton production over the long-term on nearly all continents. Continuous cotton production accelerates the build-up of pests, which can cause substantial production losses on cotton fields. In the U.S., bollworm and boll weevil problems were a principal cause of the yield stagnation and threatened cotton production for many decades. Bt cotton has greatly reduced the economic losses from bollworms, as did the boll weevil eradication program of the 1990s. In Africa, however, the long-term build-up of pest pressure from growing cotton remains one of the most significant and economically important problems facing West African cotton producers. In West Africa, conventional approaches to control pets through chemical sprays have grown increasingly ineffective as pest populations have developed resistance. In a typical year, for example, the Burkina Faso cotton sector spends over $60 million for chemically based pest control products, yet a recent study in Burkina Faso found significant pest damage on fields that were protected using a standard regimen of six seasonal sprays [30,31]. Cotton yield losses due to pest damage averaged 24% in the study, and in extreme cases reached as high as 70%.

Frustrated by conventional pest control methods, Burkina Faso's national cotton company, Société Burkinabé des Fibres Textiles (SOFITEX), began a partnership with Monsanto in 2001 to introduce Bt cotton on a commercial basis. Since forming that partnership, Burkina Faso has emerged as the most progressive country in the West Africa region towards biotechnology. After several years of field testing, monitoring, and developing biosafety protocols, in 2008 Burkina Faso became only the second SSA country to commercially release Bt cotton. Adoption has proceeded quickly in Burkina Faso, from an initial release of 12,000 ha in 2008 to slightly over 125,000 ha in 2009. Last year, in 2010, an estimated 400,000 ha of Bt cotton was planted in Burkina Faso.

The purpose of this paper is to assess how biotechnology can enhance the sustainability of cotton production in West Africa. Empirical evidence from Burkina Faso's decade of experience with Bt cotton is summarized to project biotechnology's impact on cotton sustainability, including economic, social, and environmental indicators. While some of the empirical evidence has been published in previous research findings, this paper is the first to assess how biotechnology can enhance cotton sustainability in the West Africa setting. The paper is outlined as follows. Following a background section on Bt cotton and the West African cotton sector, a description of Burkina Faso's decade of experience with Bt cotton, including the legal frameworks and business models that were developed, is presented. The empirical evidence of Bt cotton's performance is then presented and discussed. The paper ends with conclusions.

2. Background

2.1. Study Area

Cotton production in Burkina Faso occurs primarily in the Sudanian and Sudano-Guinean agro-ecological zones, similar to the pattern of cotton production in neighboring Mali (Figure 2). The Sudanian cotton zone was the traditional base of cotton production in the region where it was concentrated during the French colonial period, but over the past three decades it has spread into the Sudano-Guinean zone to the south (Bassett 2001) [1]. Both of those agro-ecological zones are able to support rain-fed cotton production, with average annual rainfall of 600–800 millimeters (mm) in the Sudanian zone and average annual rainfall of 800–1100 millimeters in the Sudano-Guinean zone. Virtually all of the cotton produced in Burkina Faso is grown by smallholder farmers (OECD 2006) [6]. In Burkina Faso, the average cotton producer farms about 3.8 ha of cotton (Baquedano et al. 2010) [8]. Cotton is produced in a three year rotation with cotton grown in the first year, followed by successive years of a cereal crop such as maize, sorghum, or millet.

In West Africa, cotton production is more advanced compared to cereal and other subsistence crops, but still modest by developed country standards [6]. Cotton is one of the few crops grown intensively in West Africa, a region primarily characterized by low-input, extensive farming. Cotton utilizes more inputs in its production than any other crop grown in the region, including rice and maize. Table 1 compares input use between an average U.S. and Burkina Faso cotton producer. On average, U.S. cotton farmers incur significantly higher production costs than Burkina Faso farmers (Table 1). As a result, Burkina Faso cotton producers spend about 73% less per hectare on their variable production costs (Table 1). Three items stand out in the comparison of variable costs: fertilizers, insecticides, and labor, which account for $752 of the $820 per hectare difference in US and Burkina Faso variable production costs. US cotton farmers also spend considerably more on fixed costs, about $119 per hectare, than Burkina Faso cotton farmers, although an advantage of the US farms is their larger size which enables them to their spread fixed costs over more acreage. The fixed costs (tractors, combines, plowing implements, etc.) on U.S. farms often approach $1,000,000 in total value, but the costs are spread over farms that average 504 ha in size and equipment that can be reasonably maintained for fifteen to twenty years [6]. By comparison, West African farmers have smaller fixed costs, but are only able to spread their fixed costs over small land holdings of two to four acres and use equipment (animal draft teams) that last only 3 to 5 years. Most of the West African fixed costs are tied-up in animal draft equipment, costing anything from $250 to $350 for a fully equipped pair of animal traction spread over smaller land holdings that correspond to fixed cost of $32 per ha (Table 1).

The higher returns obtained by U.S. producers' results only from the higher cotton prices that US cotton farmers receive according to the comparison shown in Table 1. Burkinabé cotton producers maintain a competitive advantage in production costs. Average cotton production costs in Burkina Faso are $0.30 per kg, which are 43.3% lower than in the U.S. where production costs average $0.46 per kg (Table 1). Although production costs are lower in Burkina Faso, yield stagnation and declining productivity continue to erode their competitive advantage, particularly during energy shocks when the cost of purchased inputs increase.

2.2. Historical Context

Cotton has played a historically important role in West African life [1,32]. Prior to the French colonial period, circa 1900, cotton (Gossypium arboretum) was introduced into West Africa from either India or East Africa. Cotton was initially grown in association with food crops where it never held a dominant role in farming. During this time, cotton was produced as a perennial crop rather than on an annual basis as it is today [33]. Yields were low during this period, rarely reaching 150 kg per ha of raw cotton [32]. Despite the low productivity, cotton was used to manufacture clothes, where it was ginned, spun, and woven into fabric by local means. Cotton was also an important source of barter with Saharan traders to the north, where cotton was exchanged for either rock salt, or to the south, where cotton was traded for kola.

During the French colonial period, cotton was produced under a top-down technocratic system where the smallholder cotton producer was poorly treated [1,32,34]. French efforts to increase cotton production in West Africa were motivated by a desire to obtain a reliable and low cost supply of cotton for their domestic textile industry, which was crippled in 1902 by a supply crisis on world markets [32]. Soon after the French established the Association Cotonière Coloniale (ACC) to promote cotton production in the French Sudanese colonies. In 1949, the notion of the ACC was transformed into the Compagnie Française pour le Développement des Fibres Textiles (CFDT), which lasted until the end of the colonial period in the early 1960s. For the most part, the development of cotton was a failure during the French Colonial period, due to the harsh treatment of the smallholder producer, the failure to modernize traditional production systems, and the poor commercial infrastructure [1,5]. The abuses of the ACC peaked in the 1920s when cotton producers were nearly enslaved by the French system. Monitors were sent into villages, compelling West African producers to meet production quotas by coercion and direct force. Producers failing to meet quotas were at times executed [1]. French colonial efforts to grow the cotton industry in West Africa failed, perhaps because the smallholder producer was not fully appreciated as a significant stakeholder [1].

A major co-benefit from the development of the cotton sector has been the simultaneous increase in maize and livestock production as illustrated in Figure 3 [1,2,6]. Maize and cotton are usually found in the same cropping system since they demand similar levels of rainfall and soil nutrients [35]. In the formative years of the cotton sector, however, maize acreage declined by about 50% between 1961 and 1983 as cotton temporarily replaced maize acreage (Figure 3). Beginning in 1983 the complementary relationship between cotton and maize developed, as producers adopted improved maize technology and took advantage of the residual fertilizer benefits from the cotton-maize rotation and the availability of organic fertilizers from livestock (Sanders et al. 1996) [2]. In several ways maize has benefited producers nearly as much as cotton. Maize arrives earlier than traditional cereals, such as sorghum and millet, which has helped shorten the hungry period prior to harvest (soudure) and reduce price volatility during the hungry period.

Animal traction was first introduced in West Africa in the late 1920s and early 1930s during the colonial period, but met with only limited success. Following independence in the early 1960s, the adoption of animal traction increased rapidly because of improved technology, better animal husbandry, and more favorable economic conditions. By 1990, Mali had over 300,000 draft animals working on farmers' fields and in Burkina Faso there were 100,000 working draft animals. Currently, 90% of Mali's cotton producers farm with animal traction and in Burkina about 70% of producers are equipped with animal traction [9].

2.3. Institutional Structure

Beginning with the French colonial period, the West African cotton sector has been vertically owned and operated by a combination of French foreign investors and African governments, comprising a quasi-parastatal organization [5,7,11,32,36]. Burkina Faso is typical example of a C4 cotton sector. Since independence, the Burkina Faso cotton sector had been owned and operated by SOFITEX, a government parastatal, in joint cooperation with a privately owned French company, CFDT. Until recently SOFITEX-CFDT had complete control and ownership of the cotton sector. This was a “one-stop” cotton farming system in which SOFITEX provided all of the production inputs, on credit, but maintained exclusive rights to purchase the seed cotton from the farmers [32]. For cotton producers the vertically integrated system has been both good and bad. Cotton producers have benefited from the input supply chain, which provides them with modern inputs (seeds, fertilizers, insecticides, and animal draft power), credit, and a guaranteed pricing system that shields them from risk [6]. The benefits were often eroded, however, by the monopsony control of SOFITEX, which left the cotton producer with only a meager share of the world cotton price [5,9,36].

In 2002 the Burkina Faso government partially divested itself of the cotton sector. Under the new institutional arrangement the cotton sector is now jointly owned by the Burkina Faso government (35%), Dagris (35%), and the union of Burkina Faso cotton producers (30%) [37]. Three cotton companies now operate in Burkina Faso, SOFITEX, Faso Coton, and Societe Cotoniere de Gourma (SOCOMA), with each company operating in a different region of the country. Although each company maintains the same type of “one-stop” cotton farming system, cotton prices are now negotiated among the principal stakeholders within the cotton sector. Since 1999 Burkinabé producers have had an influencing voice in determining cotton price levels through the Union Nationale des Producteurs de Cotton du Burkina Faso (UNPCB), and own a 30% share of the ginning sector [6,9]. All three companies purchase cotton at the same price and follow a pan-territorial pricing scheme.

3. Pest Damage and Bt Cotton

Crop damage caused by insect pests has become a major issue confronting the West Africa cotton sector, which has been a contributing factor to the stagnation and recent cotton yield declines in the region [38,39]. In Sub-Saharan Africa, high temperatures that persist throughout the year enable multiple pest generations per year, fostering heavier pest densities [40]. Pests compete directly with the farmer for yields, reduce his profits, and make it harder for a grower to put food on the table and maintain a solvent household economy. The larva of Helicoverpa armigera (Order: Lepidoptera; Family: Noctuidae), or the cotton bollworm, is the main cotton pest in Burkina Faso and throughout West Africa [41]. On unprotected fields, Burkina Faso researchers claim that insect pests can damage up to 90% of the cotton crop (Traoré et al., 1998) [42]. In severe infestations, pests leave so little behind that the most cost-effective alternative is often for farmers to abandon their fields [42]. Associated losses from pests are even more problematic in smallholder production because food security can be jeopardized, particularly since rural households value food at higher prices than markets would indicate [43]. Moreover the insect pest problem is expected to worsen over the long-term throughout the West Africa region. All of the major global climate change models forecast higher temperatures that will potentially promote higher pest populations within the region [44,45].

Over the past 10 years, H. armigera control measures have not been successful [46]. Conventional pest control measures have been losing effect as pest populations have developed resistance to pyrethroid insecticides, the major agents used in Burkina Faso from 1985 through 2000 [46-48]. Nevertheless, Burkina Faso farmers have continued to use conventional insecticides intensively, especially as cotton production has expanded into more marginal agricultural lands along the frontier where pest populations are often greatest [49]. In addition to becoming increasingly ineffective and costly, conventional pest control has also become more hazardous as the use of more broadly toxic endosulfans has increased since 2000 throughout many parts of West Africa, including Burkina Faso, due to pyrethroid resistance [10].

In a typical year, Burkinabé farmers spend roughly $60 million on protecting their fields from bollworms and other insects using conventional spray based approaches [10,30]. Recommended sprayings, about six per season, will protect only about 11% of the cotton yield from insect pests; about 23% of the cotton yield will still be lost. As many as ten sprayings can be required. Farmers in this region face potential losses between 20 to 65% of their cotton yield to pests and insects [11,50]. Burkina Faso cotton yield losses often surpass 30% on fields treated with recommended insecticide applications. In global terms, about 15% of world cotton production is lost to insects every year [51].

Secondary pest problems from piercing and sucking insects are also growing in importance. The most common sucking pests are the jassids (Empoasca facialis) and aphids (Aphis spp). Cotton producers typically spray twice a year for the piercing and sucking insects, and wait until boll formation has occurred to control them. The spraying methods currently used by farmers (typically back-pack sprayers) often present significant health hazards [52-54].

In addition to the effects of poor pest management, cotton yields have also been negatively influenced by soil depletion [10]. Studies indicate a declining nutrient balance (NPK) through southern Mali and report on the inadequacy of producers to provide their fields with adequate levels of organic fertilizers [11]. Although this paper focuses primarily on how Bt cotton can enhance sustainability through higher productivity, the West Africa cotton sector will need to address other aspects of sustainability as well in the future.

4. Commercialization of Bollgard II in Burkina Faso

With opportunities to increase cotton yields using conventional approaches dwindling, Bt cotton offers an alternative approach to raising cotton yields through improved pest management that cuts farmers costs while exhibiting benign effects on environment [55]. A brief description of Bt cotton is in order; specifically Bollgard II (BG II) will be explained since its commercial introduction into Burkina Faso is presented here as a case study. Genetic engineering techniques were used to insert genes into cotton that encode and promote the production, within the plant, of proteins toxic to certain caterpillar pests of cotton [56]. In Bollgard II, these proteins, Cry1Ac and Cry2Ab, are encoded by genes originating from the common soil bacterium Bacillus thuringiensis (Bt). These Cry proteins are both highly effective in killing certain lepidopteran larvae (caterpillars) [23]. Once ingested, the Cry proteins bind to specific molecular receptors on the lining of the caterpillar's gut, create holes in the gut, and quickly cause death [57]. Individual Bt Cry proteins are highly specific to certain caterpillars and do not target other insects [57,58], unlike conventional pesticides, many of which kill across a wide spectrum of both targeted and non-targeted (sometimes beneficial) insects.

Formulations of microbial Bt fermentation products, containing Cry proteins, have been used for more than 60 years as natural insecticides in spraying programs in agriculture and forestry pest control [59]. While these Bt formulations can be quite effective under certain conditions, the products have never been widely adopted in crops such as cotton because they have short half-lives in the field (the Cry proteins are degraded by UV light); many insect larvae may escape control by these products if spray coverage is not optimal; and they are relatively expensive due to their method of production (fermentation). Interestingly, these Bt fermentation formulations are regularly used as “natural” insecticides in the smaller market of organic cotton [60,61].

4.1. The Burkina Faso Story

It was the growing discontent with conventional pest control methods that prompted Burkina Faso's initial interest in Bt cotton. By 2000, crop damage caused by insect pests had become a major issue confronting the Burkina Faso cotton sector, contributing significantly to the stagnation and decline in cotton yields [38,39]. Stakeholders in the Burkina Faso cotton sector began to explore new pest control options to increase productivity, improve the competitiveness of Burkina Faso cotton growers on international markets, and reduce the environmental and health consequences of chemical sprays. International donors (USAID) and regional organizations such as the Economic Community of West African States (ECOWAS) were successful in making Burkina Faso cotton stakeholders (cotton companies and producers) and national research institutes (INERA) aware of the benefits of Bt cotton at conferences and workshops, fueling interest in the technology.

In May of 2000, the first biotechnology meeting took place in Ouagadougou, Burkina Faso, where the cotton growers union (UNPCB) and Cotton Companies of Burkina (APROCOB) were briefed on experiences from other parts of the world describing the benefits of Bt cotton. Shortly after the May 2000 meeting, UNPCB and APROCOB united under the umbrella organization AICB (Cotton Inter-Professional Association) to fund and support research activities in Bt cotton as part of an effort to identify a sustainable alternative to the use of conventional pesticides, and to increase cotton productivity. The May 2000 meeting also led to a request on behalf of the cotton sector stakeholders to meet with Monsanto. The first official meeting took place early in 2003 in Sacramento, CA, which led to the establishment of regulated Bt cotton field trials in Burkina Faso.

A presidential decree granted approval for conducting the confined field trials under the proviso that the work be overseen by a group of government and scientific experts. A Biosafety Committee was established that included representatives from the Ministries of Environment, Agriculture, Research and Higher Education, along with several other key scientific advisors. This committee set the standards for the 2003 trials and created a more formal set of biosafety standards in time to govern confined trials in 2004 and later. Approval for the second year of confined field trials was granted in April of 2004 by the GoBF through the Ministry of the Environment; these trials began in May of that same year and were reapproved for 2005.

The Ministry of Environment (MOE) was tasked as the primary legal authority in the commercialization process, and was given charge of developing a regulatory infrastructure, consistent with the new Biosafety laws, to govern testing, development, and subsequent environmental release. The National Biosafety Agency, within the MOE, was established by 2006, and became the competent authority establishing standards for submitted regulatory dossiers and granting approval for field testing and the eventual commercialization of Bt cotton. The Professional Association of Cotton Companies of Burkina (APROCOB) and the national cotton producer cooperative association, or growers union, (UNPCB) also played key roles in the commercialization process, providing technical and managerial assistance as needed.

Burkina Faso's national agricultural research center, INERA, conducted the three years of field trials from 2003 to 2005 as part of an umbrella research agreement with Monsanto. The initial tests were conducted under confined conditions and designed to evaluate efficacy and environmental effects, including pollen-mediated gene flow, and effects on non-target arthropods, including bees. Tests were conducted on two INERA research stations in opposite ends of the country (Farako-Bâ located close to Bobo-Dioulasso in the west and Kouaré located close to Fada N'Gourma in the east). This research evaluated the effectiveness of Bollgard® II within the climate and insect conditions specific to Burkina Faso [62,63]. In 2006, the National Biosafety Agency approved an additional confined field trial outside of the INERA research farm environment; this Bollgard II (BG II) field trial was located on a seed-treatment farm in Boni located about 120 km from Bobo-Dioulasso. The Boni trial represented the first test of Bollgard II technology in the two local germplasm varieties, STAM 59 and STAM 103.

In July 2007 Bt cotton achieved another important milestone when the National Biosafety Agency gave its approval to conduct more numerous larger trials much closer to the real operating conditions of cotton growers. That year also marked the first year of large scale testing of BG II in the local germplasm varieties. In collaboration with the cotton companies and the cotton growers union, INERA conducted field trials of these two local varietal versions of Bollgard II on 20 testing sites within the cotton growing zones under the control of the three major cotton companies SOFITEX, SOCOMA, and Faso Coton. In June of 2008 the National Biosafety Agency authorized the commercial planting of BG II in Burkina Faso. This was a significant accomplishment for Burkina Faso, marking the first commercial use of Bt cotton in the country and only the third commercial release of a bioengineered crop in Africa. Due to limits on seed supply, a modest 15,000 ha of Bollgard II was planted in 2008. A much larger area was planted in 2009, 125,000 ha, when seed supply was substantially increased.

5. Enhancing Sustainability with Bt Cotton

In this section, the decade of empirical evidence from Burkina Faso is summarized, highlighting how sustainability can be enhanced through the diffusion of Bt cotton. The findings fall along a rather diverse set of criteria, including impacts of Bt cotton on insecticide use, yield, cotton income, energy use, and the environment.

5.1. Reduced Insecticide Use and Labor

Bollgard II cotton is expected to reduce pesticide use in cotton production by two-thirds, from an average of six sprays under current practices down to two (Table 2). The field trials and on-farm monitoring have found that the Cry 1Ac and Cry2Ab proteins, produced by the Bt gene within the plant's DNA, provide more effective pest control than the four chemical sprays used by conventional cotton in controlling Lepidoptera (Table 2). The effectiveness of Bollgard II was initially tested in the 2003–2005 field trials where it was compared to conventionally treated cotton [63]. Bollgard II cotton was not sprayed early in season for Lepidoptera so that the effectiveness of the Bt gene could be isolated as the control factor in the experiment, although it did receive two late season sprays for secondary pests. Without early season sprays, Bollgard II cotton was protected against Lepidoptera damage only by the presence of the Bt gene and the Cry 1Ac and Cry2Ab proteins it produces. Overall, the six years of field trials and on-farm monitoring found that Bollgard II controlled at least 92% of the attacking Lepidoptera without spraying four times for Lepidoptera (Table 2). In 3 years of confined field tests on INERA experiment stations, Bollgard II cotton had a significantly higher control efficacy on lepidopteron pests than conventional cotton, with a control rate of 88.0% compared to conventional cotton's rate of 22.4%. Pest control efficacy was also tested in the two years of on-farm trials in 2006 and 2007. Bollgard II control efficacy was even higher in the on-farm trials, with control rates of 98% in each year (Table 2). In 2009, the producer surveys did not monitor pest population densities, but greater pest control is implied by the higher yields that were generated by Bollgard II (see next section).

Because the several years of testing confirmed that Bollgard II could provide more effective pest control without the four early season sprays, the recommended pest management practices extended by the cotton companies to their producers reduced the number of pesticide sprays from six to four in the first year of the 2009 commercial release. The 2009 field surveys monitored the pesticide use of 160 Burkina Faso cotton producers and found further evidence of the effectiveness of Bollgard II cotton in protecting plants, which is discussed in further detail below. The technical merits from reduced insecticide and enhanced pest control establishes a broader stream of benefits including increased cotton income from higher cotton yields and reduced costs, improved health by decreased exposure to pesticides, and promoting more responsible environmental stewardship by reducing energy use and chemical runoffs.

5.2. Increased Cotton Yield

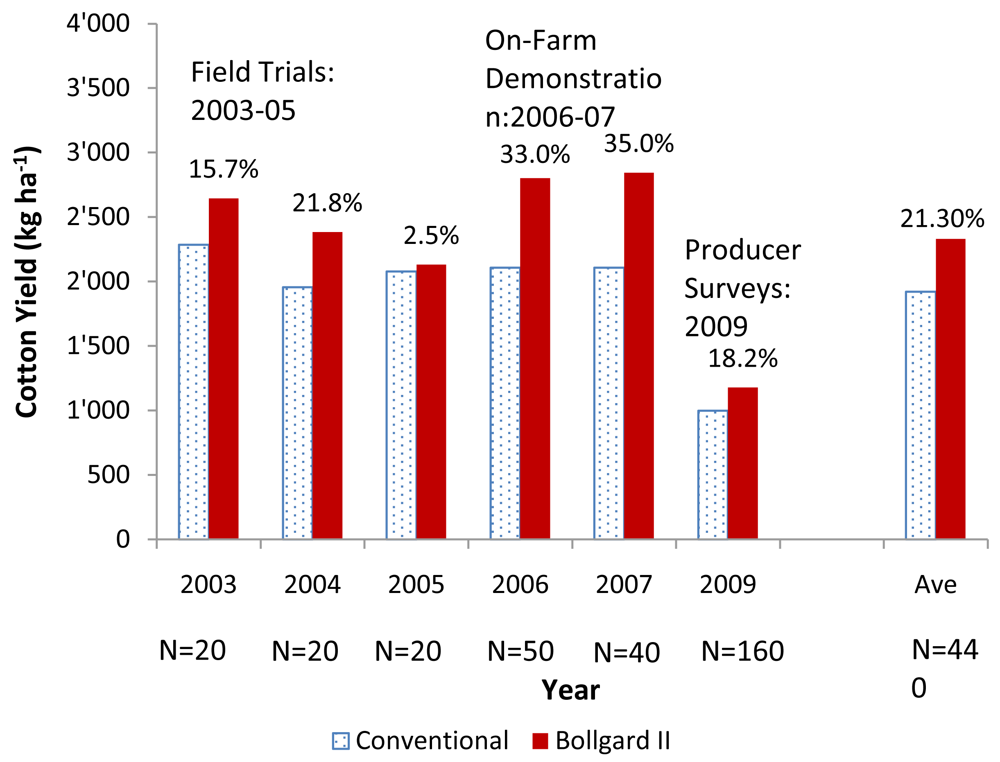

Based on six years of field trials and on-farm monitoring in Burkina Faso, Bollgard II has generated yields that averaged 21.3% higher than yields from conventional cotton (Figure 4). The extremes in Bollgard II yield advantage ranged from a low of 2.5% in 2005 to a high of 35.0% in 2007 (Figure 4). When tested under confined field conditions for three years (2003–2005), Bollgard II generated yields that were 14.7% higher on average than the local cotton varieties. These were important tests since they represented the first testing of Bt cotton under actual conditions in West Africa (Vitale et al. 2008a) [63]. The strong technical performance of Bollgard II over conventional cotton permitted the further testing of Bt cotton under less restrictive conditions. In the following two years, 2006 and 2007, Bollgard II was tested under monitored on-farm conditions at 10 sites throughout Burkina Faso. Results found that Bollgard II obtained higher cotton yields than the three years of field trials conducted in the previous three years, with an average yield of 34% over the two years of on-farm trials (Figure 4).

In 2009, the commercial release of Bollgard II made it possible to assess the yield performance of Bt cotton under actual producer conditions across multiple locations. Based on a survey of 160 Burkina Faso cotton producers, Bollgard II generated cotton yields that were 18.2% higher than conventional cotton. Vitale et al. [64] analyzed whether the Bollgard II yield increase varied across farm size, zone, or the number of sprays applied on fields. Bollgard II yields were significantly different across zones, with the highest cotton yields in the Faso Coton zone, located in the western part of the country, where Bollgard II yields were 36.6% higher than conventional cotton, compared to yield increases of 16.5% and 14.3% in the other two cotton zones [64]. The yield differences are likely explained by differences in pest population pressure that vary significantly across location, including from the field to regional level. There was no significant difference in Bollgard II yield increases, however, across the two farm types in the sample. Large farms (>1.5 ha) had a yield increase of 14.8% when growing Bollgard II and small farms (≤1.5 ha) had statistically similar yield increase (P > 0.05) of 12.4% [64].

The number of pesticide sprays also had a significant effect on Bollgard II yield performance [64]. The 2009 field surveys monitored the pesticide use of 160 Burkina Faso cotton producers and found that a substantial proportion of producers (78%) did not follow the late season spray recommendations and either sprayed only once or did not spray at all. Producers who grew Bollgard II cotton, and sprayed twice for secondary pests, had yields that were on average 14.0% than those who did not spray at all. In the SOFITEX zone, the effect of late season sprays was most significant, where producers who sprayed twice had yields that were 37.0% higher than those not spraying at all. This finding suggests that the yield advantage of Bollgard II could be higher if producers adhered to recommended late season sprayings.

The 18.2% BG II yield advantage found from the 2009 field surveys is consistent with the findings of the prior Burkina Faso field trials conducted from 2003–2007, where yield advantages from BG II averaged 21.6% over the five year period [63]. The results of the 2009 field survey also compare favorably with the findings reported in previous studies that have documented the yield performance of Bt cotton [13]. Among smallholder farmers, two previous studies found similar Bt cotton yield increases in South Africa and China. Ismael et al. (2002) [74] report an average yield increase of 18% from a survey of South African smallholder farmers in and around the Makhitini Flats under agro-ecological conditions that closely coincide with those in Burkina Faso. In China, Huang et al. [65] report a 15% increase in cotton yields when smallholder Chinese cotton adopted Bt cotton. Both the South African and Chinese reported yield increases are similar to the values found in the 2009 producer surveys for the SOFITEX and SOCOMA cotton zones, which had yield increases of 16.5% and 14.3% [64]. Much higher yield increases from adopting Bt cotton have also been reported in the development literature. In India, where results of Bt cotton have been mixed, Qaim [66] reports yield increases of 58% among Indian Bt cotton producers, while Qaim and DeJanvry [67] cite yield increases of up to 42% among smallholder farmers in Argentina who grew Bt cotton. These previously reported higher yields are close to those found for the Faso Coton (36.6%) zone as reported in Vitale et al. [64]. Alternatively, some studies have found significantly lower yield advantages from Bt cotton than the 21.3% yield increase found so far in Burkina Faso. In the U.S., Marra [68] found only a 3–5% increase in U.S. cotton yields, and elsewhere no significant yield increases have been reported including in South Africa [69] and India [70].

The wide variance in Bt cotton is not unexpected since agronomic conditions and other factors that influence agricultural production vary sharply across wide geographical areas. The effectiveness of conventional cotton also plays a critical role in determining the impacts of Bt cotton, as does the level of pest pressure. In Burkina Faso, for instance, pest pressure is greater and existing pest control strategies are less effective than in developed countries, which likely explains why Bt cotton is expected to generate substantial gains in productivity.

5.3. Economic Benefits

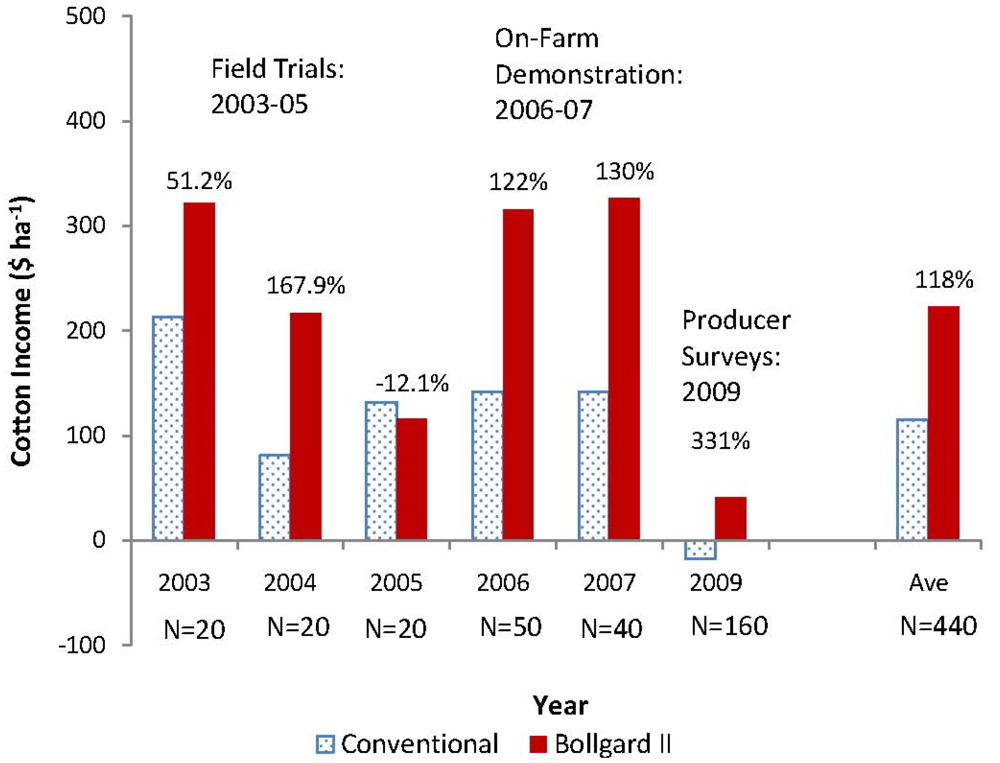

Economic benefits are realized by producers provided that the reduced insecticide applications and higher yields, when combined with labor savings, outweigh any increase in production costs (e.g., higher seed costs). Previous studies have analyzed the potential (ex-ante) economic benefits from adopting Bt cotton in Burkina Faso based on the data compiled from various phases of the six years of field trials [63,71], and a recent study has measured the impacts from the 2009 commercial introduction [64]. In all three studies, Bollgard II cotton was found to generate significantly higher income than conventional cotton. Partial budgeting, a methodology that accounts for changes in production costs, was applied in a study by Vitale et al. [63] to the three years of field trial data from 2003–2005. Based on the higher yields and savings in pesticide costs, higher incomes from growing Bt cotton were reported in the study ranging from $79 to $154 per ha depending on seed costs and year. Figure 5 illustrates the returns for each year of the field trials based on a seed cost of $75, which was closest to the seed cost in 2009. For the $75 per ha seed cost, Bollgard II had a three-year average cotton income of $218 per ha, which was $79 per ha larger than conventional cotton's income of $139 per ha (Figure 5).

The 2009 commercial release of Bollgard II made it possible to measure the impacts of Bollgard II under actual on-farm conditions, including yield performance, production costs, and cotton income. The survey of 160 Burkina Faso producers found that cotton incomes were significantly higher for producers who grew Bollgard II (Figure 5). Compared to conventional cotton, Bollgard II increased cotton income by an average of $61.88 per ha in 2009. Figure 5 highlights how thin profit margins have become for Burkina Faso cotton producers and the difference that introducing new technology can have on economic viability. Among the surveyed producers, only Bollgard II cotton had positive return, generating $39.00 per ha. Conventional cotton, due to recent low prices and stagnating yields, had a negative return of $22.89 per ha. The negative return of $22.89 per ha with conventional cotton reflects valuing the opportunity cost of household labor at $1.67 per day. The negative return does not imply, however, that households growing conventional cotton incurred a financial loss since household labor is not always paid in cash. Rather, the head of the household compensates family members with in-kind gifts (food, clothes, shelter, etc.) for their labor that is likely reduced in years of poor returns. The failure to break-even threatens the sustainability of cotton production if it should persist over the long-term, which in 2009 was clearly enhanced by the introduction of Bollgard II. In 2009, according to the survey Bollgard II's economic impact corresponded to more than a doubling of the income that would have been earned by conventional cotton, a 331% increase in cotton income (Figure 5). For an average household with 3.2 ha of cotton, Bollgard II would increase farm income by $124.79, which would have a substantial impact on household income. The producer surveys found an average household cash income of $655, which increased by an average of 19.1% from the introduction of Bollgard II among surveyed households.

Production costs in the first year of commercial introduction were nearly identical between Bollgard II and conventional cotton (Figure 6). Bollgard II cotton had an average production cost of $377 per ha, which was $3 per ha lower than the production cost of conventional cotton, $380 per ha, but Vitale et al. [64] report that the difference was not statistically significant (P > 0.10). This is an important finding since critics of biotechnology sometimes argue that seed costs for Bt crops are extreme. In the 2009 production year, although Bt seed was significantly more expensive than its conventional counterpart ($60 per ha vs. $9 per ha), the cost was offset by the savings on insecticide input costs of $53 per ha (Figure 6). Hence, Bollgard II is able to recoup its higher seed cost through an equivalent savings in insecticide and conventional seed costs. When the additional yield realized in Bollgard II is considered, the Bt seed cost is a better investment than the purchase of additional insecticide sprays and conventional cotton. Likewise, labor costs also had components that both increased and decreased cotton production costs. Fewer insecticide sprayings reduced labor costs, but the higher yields obtained by growing Bollgard II resulted in higher harvest costs and no significant reduction in labor costs. While labor cost savings are often cited in the biotechnology adoption literature, they have been reported primarily in the developed country context where opportunity cost of operator time and machinery running costs are greater. For instance, in South Africa both Kirsten and Gouse [72] and Shankar and Thirtle [73] report no significant labor cost savings from Bt cotton due to higher harvest costs that offset the effects of reduced labor in pesticide application.

The survey result found that scale (farm size) did not have a significant effect on cotton income. The large farms had a slightly higher income than the small ones, $56 per ha compared to $36 per ha, but the difference in income was not statistically significant (P > 0.10) [64]. Since Bt cotton is by and large scale neutral, the lack of significance of the farm size variable an expected finding, i.e., the increased yields and reduced insecticide costs should benefit both small and large producers in roughly the same manner. Three studies in South Africa support the scale neutrality of Bt cotton where large-scale (mechanized) farms benefitted in the same proportion as smallholder farmers, although they benefitted in different ways [69,74]. Large scale producers benefitted primarily from savings in labor and operating costs (fuel, lube, and repair) since they have high opportunity costs of time and are rely on mechanization to reduce labor, whereas smallholder producers in South Africa benefitted more from higher yields.

The national level impacts of introducing Bt cotton in Burkina Faso have also been estimated [31]. Using an aggregate model of the Burkina Faso cotton sector, economic benefits of $97 million were projected. The aggregate benefits reflect the overall increase in cotton income from all 300,000 Burkina Faso cotton producers, the three national cotton companies (SOFITEX, Faso Coton, and SOCOMA), and the seed company, Monsanto [31]. The study by Vitale et al. [31] also found that the benefits would be more or less equally distributed between producers and the seed company. Even at the highest seed price considered in the analysis, $100 per ha, producers would capture 45% of the economic benefits, slightly more than the seed company's 40% share of the economic benefits, with the remaining 15% in the three cotton companies.

5.4. Energy Savings

Introducing biotechnology in cotton production would also have a positive impact on sustainability by reducing energy use. Table 3 lists the energy use for a typical cotton producer in Burkina Faso on both per ha and a per kg bases. The input use and farm implement requirements were obtained from field surveys of 160 Burkina Faso cotton producers conducted in 2009. The energy use for the crop inputs was obtained from various published sources to provide approximations to energy requirements [75-77].

Among the crop inputs used in Burkina Faso cotton production, only animal traction and inorganic fertilizer use more energy than pesticides (Table 3). Nitrogen fertilizer is the largest energy user in cotton production, requiring 8.10 million Btu ha−1. Animal power has the second highest energy use, 5.16 million Btu ha−1. The animal power use is actually higher than the typical use for a diesel powered tractor (250 HP at 10 acres hr−1), which requires 300,000 Btu hr−1. Animal power is less efficient since it requires energy (feed) even when not in use. The standard pest management practice of six sprays per season applies 3 kg ha−1 of chemicals, which requires 1.11 million Btu ha−1 of energy (Table 3). For an average Burkina Faso cotton producer, Bollgard II would reduce energy use by 1010 Btu kg−1 of cotton produced, a corresponding 6.6% decrease in overall energy use in cotton production (Table 3).

Energy efficiency measures the quantity of energy required to produce a kg of cotton (Table 3). Using the average yield of 950 kg ha−1, it takes 15,837 Btu of energy to produce a kilogram of cotton. Pesticides use 1010 Btu kg−1 of energy (Table 3). Among the other inputs, animal traction uses 4689 Btu kg−1 of cotton followed by inorganic fertilizers that use 7363 Btu kg−1. By using Bt cotton, energy use would be reduced from 15,837 Btu kg−1 to 14,371 Btu kg−1.

The findings of the energy analysis suggest that cotton production will be one of the crops highly prone to energy shocks and rising energy costs that are forecast in the future. Compared to other crops, cotton requires substantially more energy to produce, particularly maize, sorghum, and millet, the primary food crops in the region. Biotechnology will be able to provide some initial energy savings for cotton producers, but the results of the energy analysis also suggests that fertilizer requirements and power requirements for heavy operations such as plowing will also need to be addressed for long-term sustainability.

5.5. Discussion and Implications

As an illustration of how Bt cotton could improve yields, the yield increases from the 2009 field surveys were projected over the entire cotton producing area. This projection accounts for the distribution of farm types and reported yields from other cotton producing areas in Burkina Faso. With the introduction of Bt cotton on 80% of the production area- the anticipated level of adoption by 2015-projected aggregate yields increased 22.3% over yields obtained by conventional cotton. This would reverse, at least in part, much of the yield losses that have occurred over the past two decades.

The higher economic returns from introducing Bt cotton in Burkina Faso reported in this paper compares favorably with findings from previous studies in various parts of the world. In South Africa, Ismael et al. [74] report economic returns of 11% and 77% on gross margins among smallholder producers for two successive growing seasons in 1998 and 1999. The higher returns from the adoption of Bt cotton are explained in Ismael et al. [74] as a combination of two factors: higher cotton yields and lower pesticide costs that act to offset increased Bt cotton seed costs, similar to what was found in this study. Bennett et al. [78] in a more recent study also report positive economic returns in South Africa among smallholder producers who adopted Bt cotton.

In a Chinese study that evaluated the economic returns of Bt cotton on Chinese smallholder producers, Huang et al. [79] found, based on the first year of Bt cotton use in 1999, that Bt cotton adopters earned a positive net income, whereas non-adopters had negative net incomes. Results have been mixed in India, but higher economic returns from growing Bt cotton have been reported. The highest economic returns were those reported by Bennett et al. [78] and Morse et al. [80] who based their findings on a large survey of 9,000 India cotton producers. Both studies found higher returns on Bt cotton plots, however results varied significantly from one year to the other and among sub-regions. Significant variation in Bt cotton performance across production zones was also found in the study, and future surveys will need to be conducted to assess Bt cotton performance over time.

5.6. Additional Benefits

The introduction of Bt cotton is expected to provide additional benefits that are likely to emerge over the medium- to long-term once the impacts of Bt cotton have been more firmly established. The large-scale use of Bt crops is likely to result in the suppression of Lepidoptera pest populations that would benefit both Bt and non-Bt cotton producers, including producers of other crops [81-83]. The findings of Hutchinson et al. (2010) indicate that the use of Bt maize has resulted in the suppression of European corn borer, Ostrinia nubilalis (Hübner), the most widespread and economically important pest in the U.S. corn belt. According to the Hutchinson et al. [84] study, European corn borer pest populations in the U.S. corn belt have been reduced by an average of 40.4% since Bt maize was first introduced in 1996. The suppression of European corn borer generated total benefits estimated at $6.9 billion since 1996, with a majority of the benefits, 63%, captured by non-Bt maize producers. While it will take several years before such benefits could be estimated for the introduction of Bt cotton in Burkina Faso, the suppression of H. armigera and other Lepidoptera pest populations controlled by Bt cotton is also likely to take place. In addition to benefitting Bt cotton producers, pest suppression would provide benefits for non-Bt cotton producers, including maize, sorghum, millet, and vegetable crops. Given the potential economic importance of pest suppression, the monitoring of pest suppression and its impact on cotton and food crops should be included in Burkina Faso's future research program.

The commercial use of Bt cotton could provide additional benefits as part of international efforts to maintain tropical and sub-tropical ecosystems for environmental services they provide, including carbon sequestration, recreation, water purification, and biodiversity preservation. Over the past three decades, the expansion of cropland has been greatest in the tropics. A recent study by West et al. [85] emphasizes the poor trade-off that results between crop yield and carbon sequestration when tropical lands are converted into crop production. On average, for every ton of crop yield that is gained by expanding land in the tropics, over 70 tons of carbon is released to the atmosphere that can take decades to recover [85]. Land use decisions, although having the potential for significant global consequences, are nonetheless made locally [85]. While land use is driven by a variety of factors, increasing productivity on existing crop land in response to population and other economic dynamics is considered an important deterrent to land expansion [85,86]. Biotechnology could improve local land use decisions by increasing productivity on already cleared land, reducing producers' incentives to expand land holdings. However, since short-term gains could be captured by clearing new land for cotton production, the introduction of Bt cotton could perhaps result in land expansion. This would particularly be the case in areas along the frontier where Bt cotton could alleviate pest pressure constraints, creating incentives for land clearing. Further research is needed to better understand how producers' land use decisions will be affected once the productivity gains from Bt cotton are realized, including how what types of incentives would be required to prevent socially undesirable land use changes.

6. Managing Bt Cotton Sustainability Over the Long Term

One of the critical challenges to the Burkina Faso cotton sector and its stakeholders will be to sustain the productivity gains of Bt cotton that have been observed in its first few years of commercial use. Sustainability of Bt cotton will be challenged by various technical, economic, and social factors. Managing the sustainability of Bt cotton will require policy direction and leadership by government agencies to maintain and enforce biosafety compliance, on-going research by the agricultural scientists to monitor and assess the performance of Bt cotton, a strong extension network to deliver training and information to producers in a timely manner, maintain communication, and a business environment that encourages competitive pricing.

6.1. Insect Resistance Management

The high efficacy of insect control raises concerns that insect populations could evolve resistance to insecticidal proteins [83,87-91]. Instances of resistance to Bt crops have been previously reported. In Puerto Rico in 2006, Cry1F-resistant fall armyworm, Spodoptera frugiperda (Smith), were discovered [89,92]. Resistance to Cry1Ab corn in the African stem borer Busseola fusca (Full.) was reported by van Rensburg [93] in South Africa. Cry1Ac-resistant populations of pink bollworm, Pectinophora gossypiella (Saunders), were discovered in Gujarat state in India in 2008–2009 [94,95].

Resistance management programs have been implemented in the U.S. and elsewhere to minimize the likelihood of insect resistance to Bt toxins. For the original Cry1Ac-expressing Bollgard, for example, the US EPA required farmers to plant a 5% unsprayed, or 20% sprayed portion of their cotton acres with cotton that did not contain the Bollgard gene. This “refuge” was intended to maintain a population of pest insects that were unexposed to the Cry1Ac toxin, and therefore susceptible. These susceptible individuals would be available to mate with the very rare Bollgard survivor (containing a pair of resistance gene alleles) and thereby dilute these rare resistance alleles in a population, thus maintaining susceptibility to the Cry protein in populations over time and preserving the life of the product in the marketplace [96].

Similar refuge programs have been designed for Bt crops to fit different world geographies. Two common factors associated with the instances of field-derived resistance described above are 1) the Bt crop was expressing a single Bt protein, and 2) likely reduced contribution of refuge for various reasons [89,93,94]. The technology introduced into Burkina Faso has been second-generation Bt cotton, expressing two different Bt proteins (Cry1Ac and Cry2Ab). Both are active against the lepidopteran pests of Burkina Faso and they represent different modes of action [97,98]. Resistance allele frequencies for individual Bt proteins are generally considered rare but are multiplied when specific combinations of Bt resistance alleles are considered, making an individual resistant to more than one Bt protein extremely rare. This creates, in turn, a situation where the amount of refuge required to dilute resistance alleles present in rare survivors is also diminished, rendering products like Bollgard II amenable to smaller, simpler refuge plans. Because of this, the EPA has modified the refuge requirement for Bollgard II to a “natural refuge” for a major portion of the US (EPA 2007). This means that cotton growers planting Bollgard II do not have to plant a 5 or 20% cotton refuge; instead the refuge is provided by the large number of other crops and naturally occurring plants in the environment, besides cotton, that are hosts for the target pests. In Burkina Faso, the refuge plan remains conservative, even for the second generation Bollgard II, and growers are required to plant 20% conventional cotton, which they may spray for worm control. Ongoing research continues to gather data that may be used in the future to move to a smaller refuge requirement. Refuge compliance by growers is monitored by seed company technical personnel in partnership with Monsanto technical representatives and the government cotton research program at INERA.

Monitoring of pest populations for changes in susceptibility to Bt proteins is also an important component of a successful insect resistance management program. In addition to close attention payed to changes in field efficacy of a Bt crop, a common form of monitoring involves the pre-commercial establishment of lab-generated baseline susceptibility data for geographic populations of target pests followed by periodic repetition of these studies after broad commercial adoption of the technology. The point is to discover modest reductions in susceptibility, if they exist, before resistance becomes an economic issue due to crop loss. In Burkina Faso this lab baseline and monitoring program has been established under the leadership of the cotton research program of INERA.

6.2. Gene Outflow

Sustainability will also need to address issues of gene outflow—the inadvertent transfer of genetic material from one species to another—including the possible contamination of conventional plants by bioengineered ones. Gene outflow is a sensitive issue in the African biotechnology debate, with African governments and their citizens placing a high priority on protecting the environment and maintaining biodiversity [99,100]. While of low probability, gene-flow events (spontaneous hybridization) have been associated with Bt crops between both host plant and wild relatives [101], as well as crop-to-crop transgene flow events [102].

Most countries legislate the isolation of Bt crops at prescribed minimum distances from conventional non-Bt fields in order to manage risks of gene outflow [103-105]. This regulatory regime is based on the assumption that separation distances are sufficient to reduce the probability of gene outflow events within an acceptable minimum level [104,106]. There is a wide variation in what constitutes such a minimum distance. Many countries have taken a highly precautionary approach to isolation, requiring threshold levels of cross contamination to be quite low, and separation distances to be relatively large. The European Union, for example, requires levels less than 0.9% and Australia and New Zealand require levels of 1%. Other countries, however, have accepted more modest levels of risk. Japan requires threshold levels of 5% and in the U.S. no minimum distance is mandated [107].

In smallholder farming, the cost of establishing an adequate buffer zone can be substantial [107]. Field geometry is an important determinant of establishment costs. Fields that are widely spaced, e.g., where land is abundant, are likely to have an adequate distance between them without the need for a buffer zone. However, in land scarce areas where fields are narrowly spaced, the distance between fields can be within the minimum allowed separation distance. When this occurs, producers will be required to reduce the area of the Bt crop so that the exterior of the field can be used as a buffer zone. A recent study projects that the cost of establishing buffer zones in Kenya would be a limiting factor to the adoption of Bt maize due to high population pressure and the short distances (<50 m on average) between maize fields [107]. According to Tumusiime et al. [107], risk also plays an important role in buffer zone establishment costs. If Kenya were to adopt highly risk averse biosafety standards based on European Precautionary Principle, adoption would be reduced by as much as 80% compared to the more modest standards used in the U.S.

In Burkina Faso, pollen-mediated gene flow studies were conducted over three years by cotton researchers at INERA (Denys Sanfo, INERA, unpublished data) to establish proper isolation distances for the production of Bt and conventional seed. Their research, consistent with cotton studies done elsewhere [108-110], determined that pollen-mediated gene flow decreased rapidly as a function of distance and was nil past 25 m. In situations where a high level of genetic purity may be desired (seed production nurseries), or where the presence of transgenes is unwanted (fields designated as organic), it was recommended that an isolation distance from a transgenic cotton source of at least 25 m be maintained. Depending upon the desired level of genetic isolation in seed production, the common practices of insecticide treatments to reduce the activity of pollinating insects, and/or the close cultivation of alternate crops as pollen traps near transgenic plots could be utilized. Under standard Burkina Faso commercial cotton production practices, however, where seedcotton is to be harvested and ginned, and the seed crushed for oil/meal, there was no perceived need for the genetic isolation of transgenic cotton from conventional cotton.

6.3. Market Power and Social Responsibility

An important dimension of sustainable cotton production is social responsibility. Cotton in particular has a long legacy of enabling socially and morally inept institutions, including slavery [1]. Purveyors of capital have in the past been able to extract economic rents from cotton production, resulting in skewed income distributions that leave rural households mired in cycles of poverty that can persist for generations. Bioengineered crops have been scrutinized given their potential for exerting market power. Innovative technology such as bioengineered crops typically has no competition in the short- to medium-term, establishing the potential for monopoly pricing in seed markets.

Empirical studies conducted over the past decade have found mixed evidence of market power within the Bt maize and Bt cotton seed industries. In the U.S., Oehmke and Wolf [111] investigated market power in Bt cotton seed markets and found that Monsanto had priced its seed optimally, without any evidence of market power. They explain that the heterogeneity in producer valuation makes it difficult for a seed company to exert market power. Qaim and DeJanvry [67] studied the adoption of Bt cotton in Argentina that took place during the 2003 growing season and concluded that market power exerted by seed companies was a significant deterrent to Bt cotton adoption.

India's experience with Bt cotton has been well publicized over the past few years, with reports of both gains and losses. While the price of Bt cotton seed have in some years been four times larger than conventional cotton seed, prompting public outcry and government restrictions on Bt cotton seed prices, a handful of empirical studies have found that Indian cotton producers have on average gained significantly from adopting Bt cotton [66,112-114]. The most dramatic outcomes have been reported in Anhdra Pradesh, where Bt cotton has been vilified due to the significant losses experienced by producers who adopted it [115]. The price of Bt cotton seed was cited as a cause for suicides that reportedly occurred among Bt cotton producers in Andhra Pradesh when Bt cotton was first introduced, but many other factors contributed to the losses [115]. In China, where competition has existed between Monsanto's Bt cotton and varieties developed by the Chinese government, [116] find no evidence of monopoly pricing, with producers receiving nearly 91% of the benefits generated by Bt cotton.

While the legislation of commerce will be different for each country, the enforcement of laws will require empirical evidence. On-going socio-economic monitoring will be required to assess the distribution of benefits from introducing Bt cotton. Monitoring will be particularly important in countries such as Burkina Faso that are expected to privatize their cotton sector over the next few years to make transparent the distribution of benefits from Bt cotton.

7. Conclusions

Cotton is one of the more difficult crops to sustain over the long-term. In various parts of the world, including the U.S. and Brazil, cotton has gone through periods of yield stagnation caused by a variety of factors, including pests, soil degradation, and poor institutional structures. In extreme cases, cotton production has been permanently lost due to the inability of producers to sustain productivity over extended periods of time. The history of the U.S. Southern Plains, where cotton production went from boom to bust in a mere twenty years (1920–1940), is a reminder of the potential fragility of cotton.

West African countries are currently challenged with similar issues as yields have remained stagnant since the mid 1980s. Burkina Faso is beginning to provide empirical evidence that biotechnology can enhance prospects for long-term sustainability by increasing productivity and reducing pesticide input use. Based on the accumulated evidence to date, the success that Bt cotton has had in raising cotton yields in other parts of the world (U.S., Australia, China) is expected to be replicated in Burkina Faso. Once the risk of pest pressure is reduced, the improved plant protection will provide added incentives for producers to invest in other crop technologies to address other agronomic constraints such as soil nutrient depletion, moisture stress, weeds, etc. Hence, policy makers and planners will need to develop complementary technologies built around Bt cotton to generate maximum returns from Bt cotton over the long-term. This will require field testing and extension services to deliver the new technology packages to the producers.

Long-term sustainability will also need to address the challenges West Africa faces to remain competitive in world cotton markets. Although West Africa has some of the lowest cotton production costs in the world, its competitive advantage has been substantially reduced by U.S. cotton subsidies that have depressed world cotton prices over the past decade. The C4 countries, along with Brazil, have actively challenged U.S. cotton subsidies. Even though the World Trade Organization (WTO) ruled that certain U.S. subsidies were in violation of WTO regulations in 2004, it is unclear whether the WTO will be able to force the U.S. to eliminate all of its cotton over the long-term. West Africa will need to continue seeking multilateral assistance with countries like Brazil so that agricultural subsidies and other unfair trading practices are included in upcoming WTO negotiations.

The introduction of Bt cotton in Burkina Faso is a watershed event in African agriculture. If Bt cotton is successfully introduced in Burkina Faso, its success is expected to be a gateway to the future introduction and development of other biotech crops in Africa. Burkina Faso will have demonstrated to other African countries that it is possible to developing the scientific, legal, and business infrastructures to introduce genetically modified (GM) crops in developing countries. While capacity may be lacking initially, through proper planning, management, and partnership with the private sector, Burkina Faso is demonstrating that African countries can successfully introduce GM crops such as Bt cotton. African countries won't be able to do this on their own. International donors and the private sector will need to also partner to make the initial investments, including in the creation of biosafety protocols, testing and evaluation of biotechnology products under local conditions, marketing channels, and institutional reform.

Other countries in the region are much more likely to adopt Bt cotton if it continues to have a positive impact in Burkina Faso. In particular, this would include the other C4 countries (Mali, Chad, and Benin) that share similar agro-ecological zones, farming systems, and cotton industry structures with Burkina Faso. Regional networks such as ECOWAS should facilitate cooperation the countries to share the costs of establishing biosafety protocols and other legal mandates to reduce costs and accelerate the introduction process.

Other GM crops such as Roundup Ready Bt cotton and Bt maize may also be introduced to increase agricultural productivity and raise farm incomes while reducing energy use. In the long-term, biotechnology is expected to address additional constraints and crops. The WEMA (Water Efficient Maize for Africa) project, for instance, is a partnership of several African governments, AATF, CIMMYT, and Monsanto, with funding from the Bill & Melinda Gates and Howard G. Buffett foundations. As its name implies, its goal is to eventually provide small growers with maize varieties that utilize water more efficiently.

Domestic marketing conditions will need to be improved within the region. West African producers have historically received some of the lowest share of world cotton price compared to producers from various parts of the world. External factors also can affect the adoption and returns from Bt cotton. One of the distinguishing features of the Burkina Faso cotton industry is the vertical integration in the input and output supply chains. While international donors have pushed for liberalization and the shift from parastatal to private ownership to improve efficiency, the vertical control of the Burkina Faso cotton industry by the cotton companies appears to make it better suited to introduce Bt cotton than a privately owned sector.

The role of the private sector cannot be ignored or undermined. As illustrated by the Burkina Faso example, Africa's ability to generate sustainable agricultural systems is likely to include a greater role of the private sector than in the past. Clearly the relationship between the smallholder producer and the private sector needs to be equitable, and not falling into trappings of neo- or post colonialism. Burkina Faso is taking shape as a working example of how a business model can be successfully implemented in a parastatal industry comprised of an atomistic network of over 300,000 smallholder producers.