Energy Recovery from Wastewater Treatment Plants in the United States: A Case Study of the Energy-Water Nexus

Abstract

:1. Introduction

2. Background

2.1. Anaerobic Digestion with Biogas Utilization

2.2. Biosolids Incineration with Electricity Generation

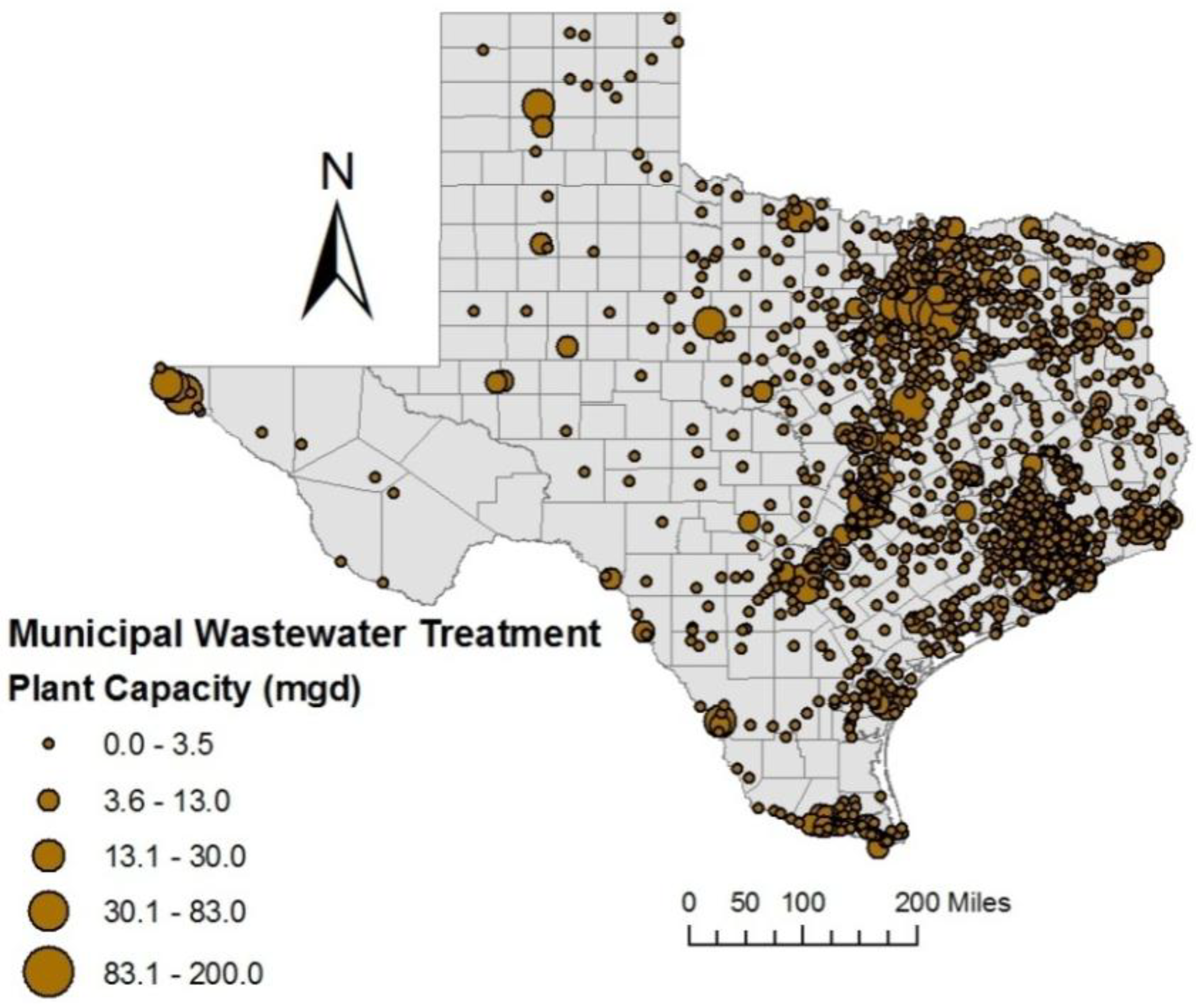

3. United States and Texas as Case Studies

4. Data and Assumptions

- EPA Clean Watershed Needs Survey (CWNS) [20]—This EPA database contains data describing wastewater treatment facilities, including treatment flow capacity and unit operations used during treatment.

- Energy for Wastewater Treatment Operations [19,21,22]—Energy use at wastewater treatment plants was estimated based on data from the Electric Power Research Institute (EPRI) regarding wastewater treatment operations and the Texas Commission on Environmental Quality (TCEQ) and the U.S. EPA regarding Texas wastewater treatment plants. See the Appendix for tables of energy consumption for wastewater treatment.

- Energy Recovery from Biogas Utilization [10]—Ranges of energy recovery due to biogas utilization were based on data presented by Burton and EPRI.

5. Methodology

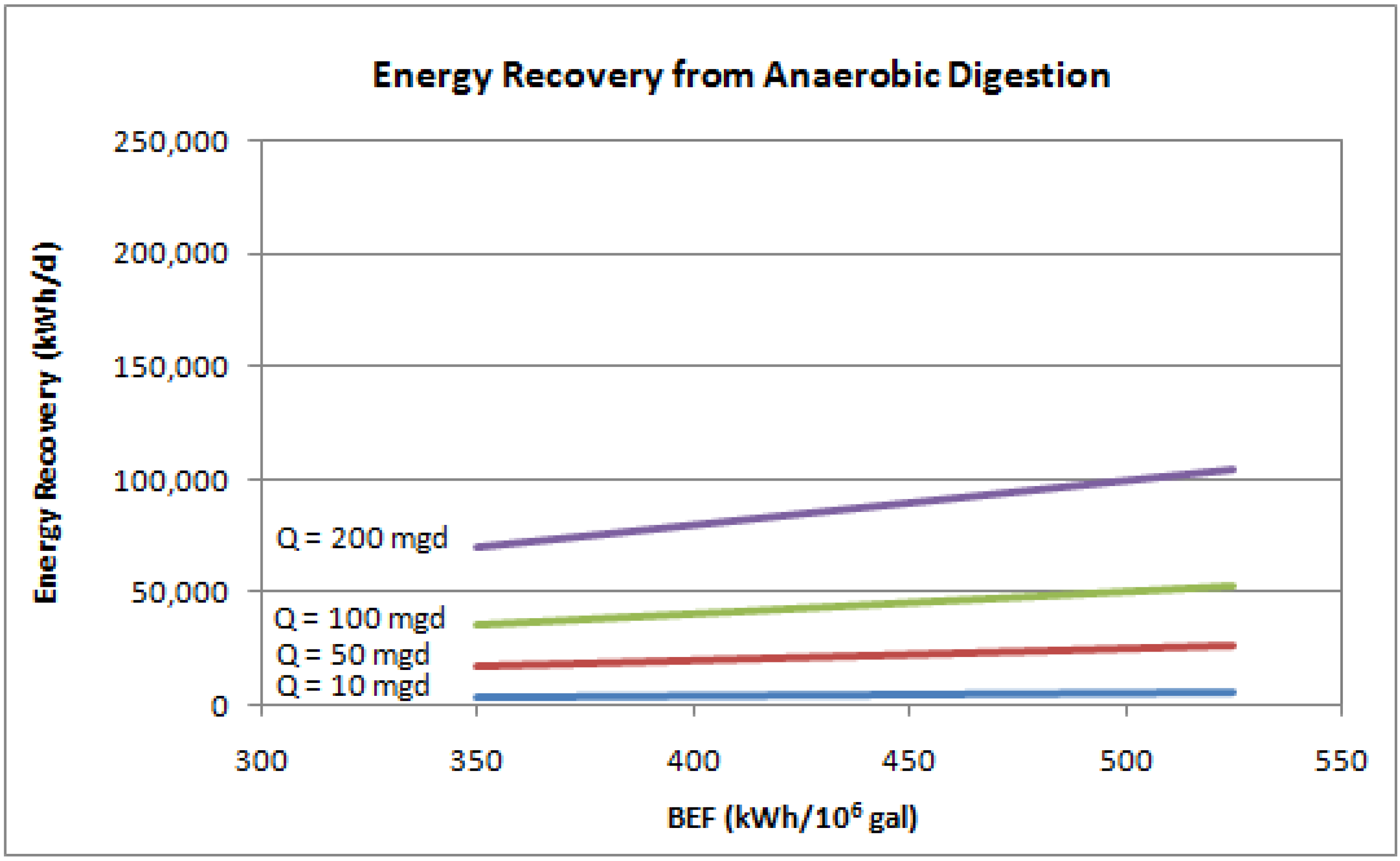

5.1. Anaerobic Digestion with Biogas Utilization

- Case AD-1: Baseline—The baseline energy recovery estimate includes all existing wastewater treatment plants that are already using anaerobic digestion with biogas utilization. For Case AD-1, we assume none of the biogas currently produced from anaerobic digestion is utilized for electricity generation. While some wastewater treatment plants utilize biogas (for digester heating or combined heat and power), most do not and instead flare the biogas. Since the CWNS survey data do not specify how wastewater treatment plants utilize biogas, our assumption provides a reasonable baseline for anaerobic digestion with biogas utilization for electricity generation [24].

- Case AD-2: Utilize existing biogas—This scenario represents energy recovery if all wastewater treatment plants currently using anaerobic digestion utilize the biogas produced, estimated for a range of 350 to 525 kWh/106 gal (0.0925 to 0.139 kWh/m3) [10,14]. Many wastewater treatment plants that utilize anaerobic digestion currently flare off the produced biogas. Case AD-2 reflects the energy recovery possible from utilizing the biogas currently produced instead of disposing by flaring. Only wastewater facilities treating at least 5 mgd (18,900 m3/d) were included in this scenario due to biogas utilization cost-effectiveness, as discussed previously.

- Case AD-3: All wastewater treatment plants utilize biogas—This scenario represents the full potential of anaerobic digestion with biogas utilization, estimated for a range of 350 to 525 kWh/106 gal (0.0925 to 0.139 kWh/m3) [10,14]. In Case AD-3, all wastewater treatment plants treating at least 5 mgd (18,900 m3/d) were modeled as implementing anaerobic digestion with biogas utilization. The minimum of 5 mgd (18,900 m3/d) represents sufficient flow for cost-effective and feasible electricity generation [14].

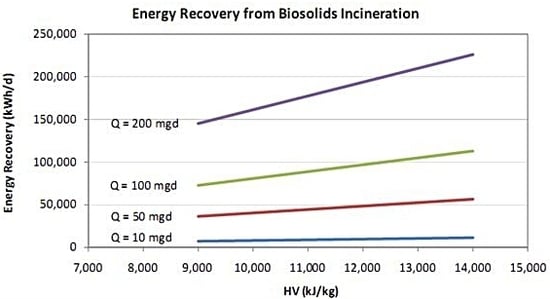

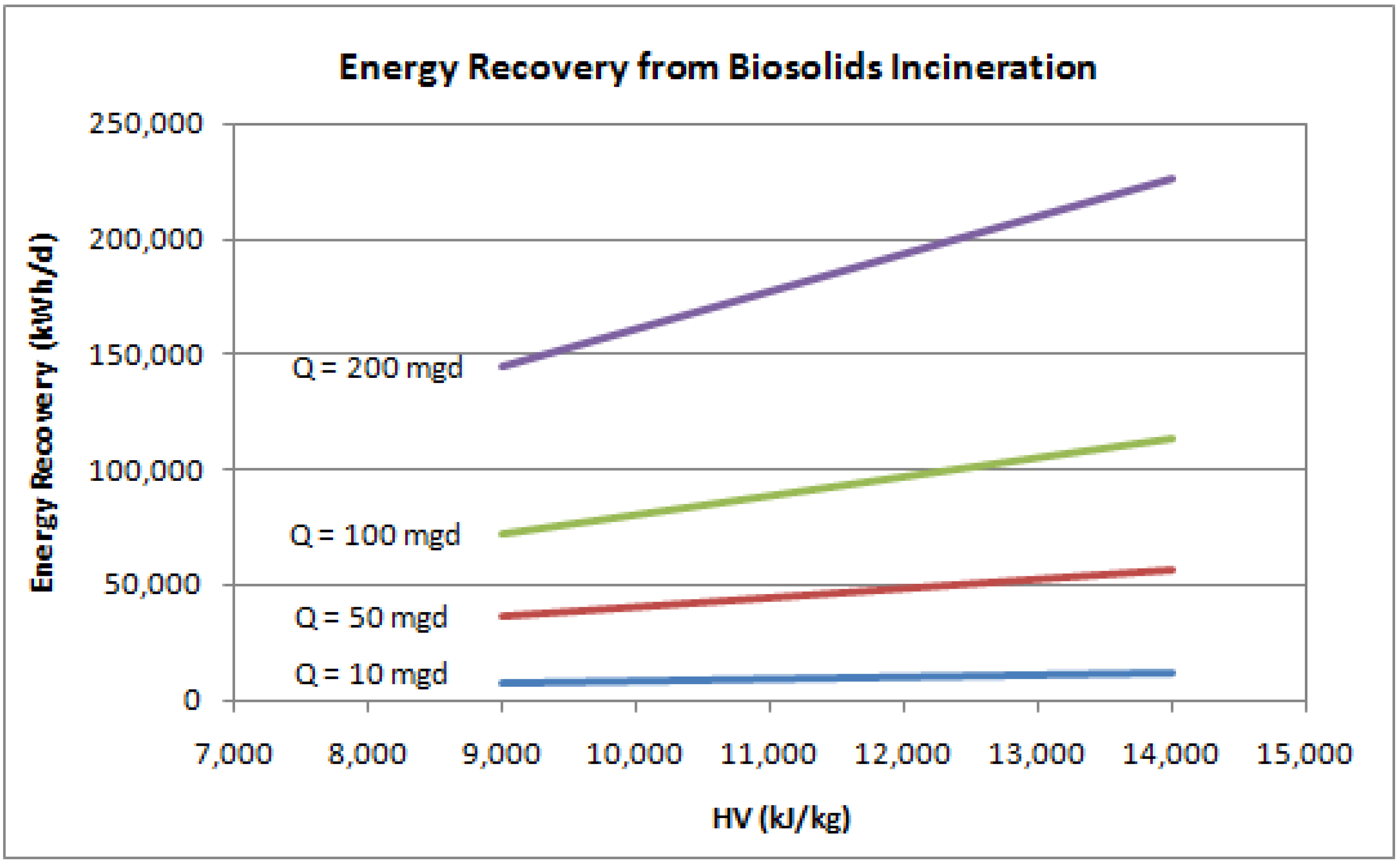

5.2. Biosolids Incineration with Electricity Generation

| Factor | Equation Term | Reported Value | Units | Reference |

|---|---|---|---|---|

| Wastewater dry solids content | 680–1,020 (0.180–0.269) | kg/106 gal (kg/m3) | [9] | |

| Biosolids heating value (Digested biosolids) | † | 9,000–14,000 | kJ/kg | [9] |

| Steam electric heat rate | ‡ | 10,550 | kJ/kWh | [23] |

- Case BI-1: Utilize existing incineration processes—This scenario represents energy recovery if Texas wastewater treatment plants currently using biosolids incineration utilized the heat generated during incineration for a steam electric power plant.

- Case BI-2: All wastewater treatment plants implement incineration processes—This scenario represents the full potential of biosolids incineration with electricity generation. In Case BI-2, all wastewater treatment plants treating at least 5 mgd (18,900 m3/d) were modeled as implementing biosolids incineration with electricity generation. A minimum flow rate of 5 mgd (18,900 m3/d) was selected due to the relatively large amount of biosolids necessary to make incineration with electricity generation feasible without significant dependence on auxiliary fuel.

6. Results

| Scenario | Applicable Flow mgd (million m3/d) | Calculated Energy Recovery 106 kWh/yr | ||

|---|---|---|---|---|

| United States | Texas | United States | Texas | |

| Case AD-1: Baseline | 4,918 (18.6) | 315 (1.19) | 628–942 | 40.2–60.4 |

| Case AD-2: Utilize existing biogas | 18,184 (68.8) | 1,086 ( 4.11 × 106) | 2,320–3,480 | 139–208 |

| Case AD-3: All wastewater treatment plants utilize biogas | 25,796 (97.6) | 2,401 (9.09) | 3,300–4,940 | 307–460 |

| Case BI-1: Utilize existing incineration processes | Not calculated | 189 (0.715) | Not calculated | 51.9–80.8 |

| Case BI-2: All wastewater treatment plants implement incineration processes | Not calculated | 2,401 (9.09) | Not calculated | 661–1,030 |

7. Policy Implications

8. Conclusions

Nomenclature

| CWNS | Clean Watershed Needs Survey |

| EPA | Environmental Protection Agency |

| EPRI | Electric Power Research Institute |

| mgd | million gallons per day |

| TCEQ | Texas Commission on Environmental Quality |

Acknowledgements

References and Notes

- Stillwell, A.S.; King, C.W.; Webber, M.E.; Duncan, I.J.; Hardberger, A. Energy-Water Nexus in Texas; Environmental Defense Fund, University of Texas at Austin: Austin, TX, USA, 2009. [Google Scholar]

- Energy Conservation in Wastewater Treatment Facilities Manual of Practice; Water Environment Federation: Alexandria, VA, USA, 1997; pp. 1–142.

- Westerhoff, P.; Yoon, Y.; Snyder, S.; Wert, E. Fate of Endocrine-Disruptor, Pharmaceutical, and Personal Care Product Chemicals during Simulated Drinking Water Treatment Processes. Environ. Sci. Technol. 2005, 39, 6649–6663. [Google Scholar] [CrossRef] [PubMed]

- Zwiener, C.; Frimmel, F.H. Oxidative Treatment of Pharmaceuticals in Water. Water Res. 2000, 34, 1881–1885. [Google Scholar] [CrossRef]

- Means, E.G. Water and Wastewater Industry Energy Efficiency: A Research Roadmap; Water Research Foundation: Denver, CO, USA, 2004; p. 28. Available online: http://www.waterresearchfoundation.org/research/topicsandprojects/execSum/2923.aspx (accessed on 9 October 2009).

- Hoppock, D.C.; Webber, M.E. Energy Needs and Opportunities at POTWs in the United States. In Proceedings of the American Society of Mechanical Engineers (ASME) 2nd International Conference on Energy Sustainability, Jacksonville, FL, USA, 10–14 August 2008.

- California’s Water-Energy Relationship; CEC-700-2005-011-SF; California Energy Commission: Sacramento, CA, USA, 2005. Available online: http://www.energy.ca.gov/2005publications/CEC-700-2005-011/CEC-700-2005-011-SF.PDF (accessed on 8 October 2009).

- Primer for Municipal Wastewater Treatment Systems; Office of Wastewater Management, Environmental Protection Agency: Washington, DC, USA, 2004. Available online: http://www.epa.gov/npdes/pubs/primer.pdf (accessed on 8 October 2009).

- Metcalf & Eddy, Inc. Wastewater Engineering: Treatment and Reuse, 4th ed.; McGraw Hill: Boston, MA, USA, 2003; pp. 1345–1446. [Google Scholar]

- Burton, F.L. Water and Wastewater Industries: Characteristics and Energy Management Opportunities; Burton Environmental Engineering, Electric Power Research Institute Community Environmental Center: Los Altos, CA, USA, 1996. [Google Scholar]

- Ekama, G.A.; Sotemann, S.W.; Wentzel, M.C. Biodegradability of activated sludge organics under anaerobic conditions. Water Res. 2007, 41, 244–252. [Google Scholar] [CrossRef] [PubMed]

- Rosso, D.; Stenstrom, M.K. The carbon-sequestration potential of municipal wastewater treatment. Chemosphere 2008, 70, 1468–1475. [Google Scholar] [CrossRef] [PubMed]

- Stoica, A.; Sandberg, M.; Holby, O. Energy use and recovery strategies within wastewater treatment and sludge handling at pulp and paper mills. Bioresource Technol. 2009, 100, 3497–3505. [Google Scholar] [CrossRef]

- Opportunities for and Benefits of Combined Heat and Power at Wastewater Treatment Facilities; Eastern Research Group and Energy and Environmental Analysis, U.S. Environmental Protection Agency: Washington, DC, USA, 2007; p. ii–10. Available online: http://www.epa.gov/CHP/documents/wwtf_opportunities.pdf (accessed on 8 October 2009).

- Biosolids Recycling: Beneficial Technology for a Better Environment; Environmental Protection Agency: Washington, DC, USA, 1984. Available online: http://www.epa.gov/owm/mtb/biosolids/bio1-3.pdf (accessed on 15 October 2009).

- Sewage Sludge. Available online: http://ec.europa.eu/environment/waste/sludge/index.htm (accessed on 19 March 2010).

- Biosolids Technology Fact Sheet: Use of Incineration for Biosolids Management; Environmental Protection Agency: Washington, DC, USA, 2003. Available online: http://www.epa.gov/owm/mtb/incineration_biosolids.pdf (accessed on 15 October 2009).

- WaterWorld Briefs: Black & Veatch addresses nexus of energy, water at Hartford wastewater treatment plant. Available online: http://www.waterworld.com/index/display/article-display/2255210937/articles/water-utility-management/volume-2/Issue_3/Departments/briefs.html (accessed on 2 October 2009).

- Goldstein, R.; Smith, W. Water & Sustainability (Volume 4): U.S. Electricity Consumption for Water Supply & Treatment—The Next Half Century; Electric Power Research Institute: Palo Alto, CA, USA, 2002. Available online: http://mydocs.epri.com/docs/public/000000000001006787.pdf (accessed on 8 October 2009).

- 2004 Clean Watershed Needs Survey Database. Available online: http://epa.gov/cwns (accessed on 24 January 2009).

- TCEQ Site Layers. Available online: http://www.tceq.state.tx.us/gis/sites.html (accessed on 13 June 2008).

- EPA Envirofacts Data Warehouse. Available online: http://www.epa.gov/enviro/ (accessed on 18 November 2008).

- Masters, G.M. Renewable and Efficient Electric Power Systems; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- EPA CWNS 2004 Data. Available online: http://www.epa.gov/cwns/2004data.htm (accessed on 10 September 2009).

- Lang, M.; Forste, J.; Goldstein, N.; Johnston, T.; Brandt, R. National Manual of Good Practice for Biosolids; National Biosolids Partnership: Alexandria, VA, USA, 2005. [Google Scholar]

- Energy Audit Manual for Water/Wastewater Facilities; Electric Power Research Institute: Palo Alto, CA, USA, 1994.

Appendix

| Item | Electricity used, kWh/day1 (except where noted) | |||||

|---|---|---|---|---|---|---|

| 1-mgd2 plant | 5-mgd plant | 10-mgd plant | 20-mgd plant | 50-mgd plant | 100-mgd plant | |

| Wastewater pumping | 171 | 716 | 1,402 | 2,559 | 6,030 | 11,818 |

| Screens | 2 | 2 | 2 | 3 | 6 | 11 |

| Aerated grit removal | 49 | 87 | 134 | 250 | 600 | 1,200 |

| Primary clarifiers | 15 | 78 | 155 | 310 | 776 | 1,551 |

| Trickling filters3 | 352 | 1,319 | 2,528 | 4,686 | 11,551 | 22,826 |

| Secondary clarifiers | 15 | 78 | 155 | 310 | 776 | 1,551 |

| Gravity thickening | 6 | 15 | 25 | 37 | 75 | 138 |

| Dissolved air floatation | na4 | na | 1,805 | 2,918 | 6,257 | 11,819 |

| Aerobic digestion | 1,000 | 1,200 | na | na | na | na |

| Anaerobic digestion | na | na | 1,100 | 2,100 | 5,000 | 11,000 |

| Belt filter press | na | 192 | 384 | 579 | 1,164 | 2,139 |

| Chlorination | 1 | 5 | 27 | 53 | 133 | 266 |

| Lighting and buildings | 200 | 400 | 800 | 1,200 | 2,000 | 3,000 |

| Totals | 1,811 | 4,892 | 8,517 | 15,005 | 34,368 | 67,319 |

| Unit electricity use, kWh/mil gal5 | 1,811 | 978 | 852 | 750 | 687 | 673 |

| Energy recovery (from biogas combustion) | na | na | 2,800 | 5,600 | 14,000 | 28,000 |

| Net consumption6 | 1,811 | 4,892 | 5,717 | 9,405 | 20,368 | 39,319 |

| Unit net electricity use kWh/mil gal | 1,811 | 978 | 572 | 470 | 407 | 393 |

| Biogas kWh/d per mgd | - | - | 280 | 280 | 280 | 280 |

- To convert from kWh/day to W, multiply by 41.67

- To convert from mgd to m3/s, multiply by 4.38 × 10–2

- Includes energy use required to recirculation pumping

- Not Applicable for this size treatment plant

- To convert from kWh/(million gal) to J/m3, multiply by 951.1

- Total unit energy use less energy recovered from biogas

| Item | Electricity used, kWh/day1 (except where noted) | |||||

|---|---|---|---|---|---|---|

| 1-mgd2 plant | 5-mgd plant | 10-mgd plant | 20-mgd plant | 50-mgd plant | 100-mgd plant | |

| Wastewater pumping | 171 | 716 | 1,402 | 2,559 | 6,030 | 11,818 |

| Screens | 2 | 2 | 2 | 3 | 6 | 11 |

| Aerated grit removal | 49 | 87 | 134 | 250 | 600 | 1,200 |

| Primary clarifiers | 15 | 78 | 155 | 310 | 776 | 1,551 |

| Aeration (diffused air) | 532 | 2,660 | 5,320 | 10,640 | 26,600 | 53,200 |

| Return sludge pumping | 45 | 213 | 423 | 724 | 1,627 | 3,131 |

| Secondary clarifiers | 15 | 78 | 155 | 310 | 776 | 1,551 |

| Gravity thickening | 6 | 15 | 25 | 37 | 75 | 138 |

| Dissolved air floatation | na3 | na | 1,805 | 2,918 | 6,257 | 11,819 |

| Aerobic digestion | 1,200 | 2,400 | na | na | na | na |

| Anaerobic digestion | na | na | 1,400 | 2,700 | 6,500 | 13,000 |

| Belt filter press | na | 192 | 384 | 579 | 1,164 | 2,139 |

| Chlorination | 1 | 5 | 27 | 53 | 133 | 266 |

| Lighting and buildings | 200 | 400 | 800 | 1,200 | 2,000 | 3,000 |

| Totals | 2,236 | 6,846 | 12,032 | 22,283 | 52,544 | 102,824 |

| Unit electricity use, kWh/mil gal4 | 2,236 | 1,369 | 1,203 | 1,114 | 1,051 | 1,028 |

| Energy recovery (from biogas combustion) | na | na | 3,500 | 7,000 | 17,500 | 35,000 |

| Net consumption5 | 2,236 | 6,779 | 8,532 | 15,283 | 35,044 | 67,824 |

| Unit Net electricity use kWh/mil gal | 2,236 | 1,356 | 853 | 764 | 701 | 678 |

| Biogas kWh/d per mgd | 350 | 350 | 350 | 350 | ||

- To convert from kWh/day to W, multiply by 41.67

- To convert from mgd to m3/s, multiply by 4.38 × 10–2

- Not Applicable for this size treatment plant

- To convert from kWh/(million gal) to J/m3, multiply by 951.1

- Total unit energy use less energy recovered from biogas

| Item | Electricity used, kWh/day1 (except where noted) | |||||

|---|---|---|---|---|---|---|

| 1-mgd2 plant | 5-mgd plant | 10-mgd plant | 20-mgd plant | 50-mgd plant | 100-mgd plant | |

| Wastewater pumping | 171 | 716 | 1,402 | 2,559 | 6,030 | 11,818 |

| Screens | 2 | 2 | 2 | 3 | 6 | 11 |

| Aerated grit removal | 49 | 87 | 134 | 250 | 600 | 1,200 |

| Primary clarifiers | 15 | 78 | 155 | 310 | 776 | 1,551 |

| Aeration (diffused air) | 532 | 2,660 | 5,320 | 10,640 | 26,600 | 53,200 |

| Return sludge pumping | 45 | 213 | 423 | 724 | 1,627 | 3,131 |

| Secondary clarifiers | 15 | 78 | 155 | 310 | 776 | 1,551 |

| Chemical addition | 80 | 290 | 552 | 954 | 2,187 | 4,159 |

| Filter feed pumping | 143 | 445 | 822 | 1,645 | 3,440 | 6,712 |

| Filtration | 137 | 247 | 385 | 709 | 1,679 | 3,295 |

| Gravity thickening | 6 | 15 | 25 | 37 | 75 | 138 |

| Dissolved air floatation | na3 | na | 2,022 | 3,268 | 7,008 | 13,273 |

| Aerobic digestion | 1,200 | 2,400 | na | na | na | na |

| Anaerobic digestion | na | na | 1,400 | 2,700 | 6,500 | 13,000 |

| Belt filter press | na | 228 | 457 | 689 | 1,385 | 2,545 |

| Chlorination | 1 | 5 | 27 | 53 | 133 | 266 |

| Lighting and buildings | 200 | 400 | 800 | 1,200 | 2,000 | 3,000 |

| Totals | 2,596 | 7,864 | 14,081 | 26,051 | 60,822 | 118,814 |

| Unit electricity use, kWh/mil gal4 | 2,596 | 1,573 | 1,408 | 1,303 | 1,216 | 1,188 |

| Energy recovery (from biogas combustion) | na | na | 3,500 | 7000 | 17,500 | 35,000 |

| Net consumption5 | 2,596 | 7,964 | 10,581 | 19,051 | 43,322 | 83,814 |

| Unit net electricity use kWh/mil gal | 2,596 | 1,573 | 1,058 | 953 | 866 | 838 |

| Biogas kWh/d per mgd | 350 | 350 | 350 | 350 | ||

- To convert from kWh/day to W, multiply by 41.67

- To convert from mgd to m3/s, multiply by 4.38 × 10–2

- Not Applicable for this size treatment plant

- To convert from kWh/(million gal) to J/m3, multiply by 951.1

- Total unit energy use less energy recovered from biogas

| Item | Electricity used, kWh/day1 (except where noted) | |||||

|---|---|---|---|---|---|---|

| 1-mgd2 plant | 5-mgd plant | 10-mgd plant | 20-mgd plant | 50-mgd plant | 100-mgd plant | |

| Wastewater pumping | 171 | 716 | 1,402 | 2,559 | 6,030 | 11,818 |

| Screens | 2 | 2 | 2 | 3 | 6 | 11 |

| Aerated grit removal | 49 | 87 | 134 | 250 | 600 | 1,200 |

| Primary clarifiers | 15 | 78 | 155 | 310 | 776 | 1,551 |

| Aeration (diffused air) | 532 | 2,660 | 5,320 | 10,640 | 26,600 | 53,200 |

| Biological nitrification | 346 | 1,724 | 3,446 | 6,818 | 16,936 | 33,800 |

| Return sludge pumping | 54 | 256 | 508 | 869 | 1,952 | 3,757 |

| Secondary clarifiers | 15 | 78 | 155 | 310 | 776 | 1,551 |

| Chemical addition | 80 | 290 | 552 | 954 | 2,187 | 4,159 |

| Filter feed pumping | 143 | 445 | 822 | 1,645 | 3,440 | 6,712 |

| Filtration | 137 | 247 | 385 | 709 | 1,679 | 3,295 |

| Gravity thickening | 6 | 15 | 25 | 37 | 75 | 138 |

| Dissolved air floatation | na3 | na | 2,022 | 3,268 | 7,008 | 13,273 |

| Aerobic digestion | 1,200 | 2,400 | na | na | na | na |

| Anaerobic digestion | na | na | 1,700 | 3,200 | 7,800 | 15,600 |

| Belt filter press | na | 228 | 457 | 689 | 1,385 | 2,545 |

| Chlorination | 1 | 5 | 27 | 53 | 133 | 266 |

| Lighting and buildings | 200 | 400 | 800 | 1,200 | 2,000 | 3,000 |

| Totals | 2,951 | 9,631 | 17,912 | 33,514 | 79,383 | 155,540 |

| Unit electricity use, kWh/mil gal4 | 2,951 | 1,926 | 1,791 | 1,676 | 1,588 | 1,558 |

| Energy recovery (from biogas combustion) | na | na | 3,500 | 7,000 | 17,500 | 35,000 |

| Net consumption5 | 2,951 | 9,631 | 14,412 | 26,514 | 61,883 | 120,540 |

| Unit net electricity use kWh/mil gal | 2,951 | 1,926 | 1,441 | 1,326 | 1,238 | 1,208 |

| Biogas kWh/d per mgd | - | - | 350 | 350 | 350 | 350 |

- To convert from kWh/day to W, multiply by 41.67

- To convert from mgd to m3/s, multiply by 4.38 × 10–2

- Not Applicable for this size treatment plant

- To convert from kWh/(million gal) to J/m3, multiply by 951.1

- Total unit energy use less energy recovered from biogas

© 2010 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Stillwell, A.S.; Hoppock, D.C.; Webber, M.E. Energy Recovery from Wastewater Treatment Plants in the United States: A Case Study of the Energy-Water Nexus. Sustainability 2010, 2, 945-962. https://doi.org/10.3390/su2040945

Stillwell AS, Hoppock DC, Webber ME. Energy Recovery from Wastewater Treatment Plants in the United States: A Case Study of the Energy-Water Nexus. Sustainability. 2010; 2(4):945-962. https://doi.org/10.3390/su2040945

Chicago/Turabian StyleStillwell, Ashlynn S., David C. Hoppock, and Michael E. Webber. 2010. "Energy Recovery from Wastewater Treatment Plants in the United States: A Case Study of the Energy-Water Nexus" Sustainability 2, no. 4: 945-962. https://doi.org/10.3390/su2040945