A Comprehensive Approach in Assessing the Performance of an Automobile Closed-Loop Supply Chain

Abstract

:1. Introduction

2. Literature Review

2.1. Closed-Loop Supply Chain Management

2.2. Benefits of CLSCM for the Automotive Industry

2.3. Performance Measurement for CLSC

2.4. The Previous Related Studies on GSCM and Its Critical Performance Areas

| Authors | Beamon [11] | Tsoulfas & Pappis [37] | Hervani et al. [14] | Zhu et al. [67] | Van Hoek [17] | Rao [27] | Rao & Holt [68] | McIntyre et al. [16] | |

|---|---|---|---|---|---|---|---|---|---|

| Generic Measures | |||||||||

| Sustainability cost | √ | √ | √ | √ | x | x | x | x | |

| Customer commitment | x | x | x | √ | x | x | x | x | |

| Product features | √ | √ | √ | √ | √ | √ | √ | √ | |

| Process optimization for waste reduction | √ | √ | √ | x | √ | √ | √ | √ | |

| Management initiatives | √ | √ | √ | √ | √ | √ | √ | x | |

| Environmental social concerns | x | √ | √ | x | x | x | √ | x | |

| Supplier initiatives | x | x | x | √ | √ | √ | √ | x | |

| Recycling | √ | √ | √ | √ | √ | √ | √ | √ | |

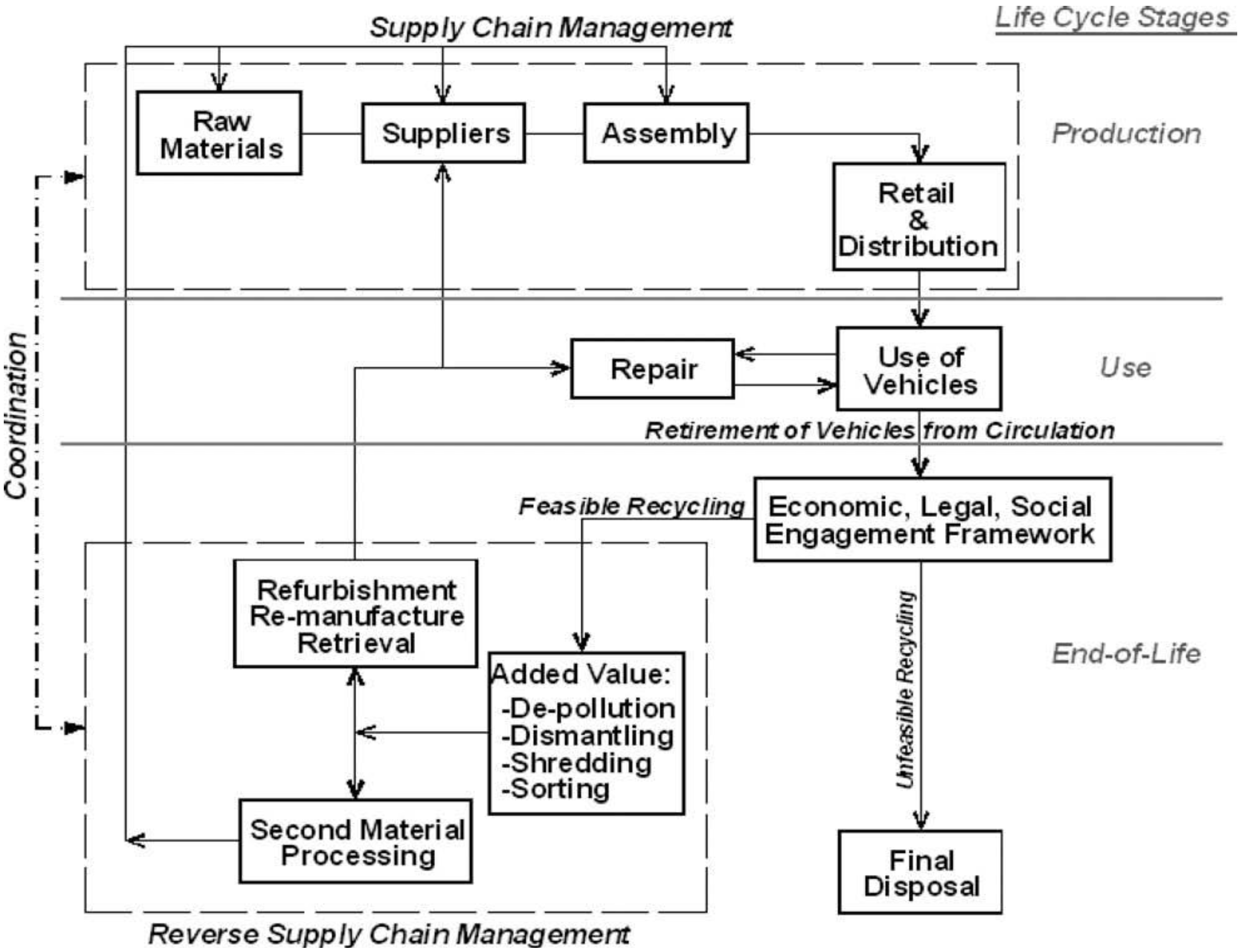

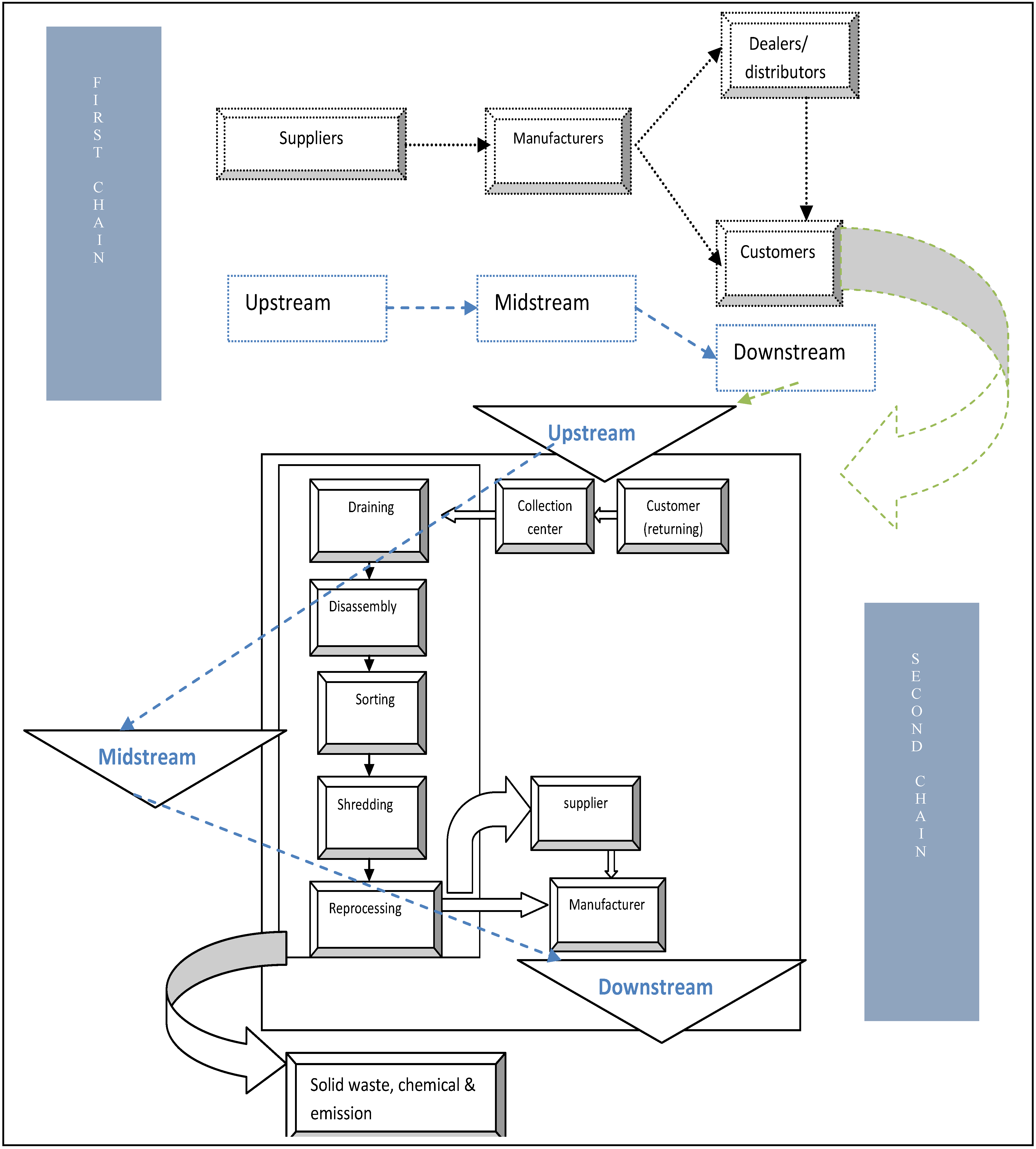

3. The Automobile Supply Chain

Operation of the Automobile CLSC

4. Two-in-One Model for Automobile CLSC Performance Evaluation

4.1. The Forward Chain

4.2. The Reverse Chain

5. Critical Performance Areas

6. Critical Performance Areas for an Automobile CLSC

| Forward chain | Reverse chain | |

|---|---|---|

| Key performance areas | Greening cost | Returning and recycling cost |

| Traditional supply chain cost | ||

| Management commitment | ||

| Product characteristics | Material features | |

| Level of process management | ||

| Customer perspective | Customer involvement | |

| Supplier commitment | ||

| Responsiveness | Recycling efficiency | |

| Quality | ||

| Flexibility of production systems | Flexibility of recycling processes | |

| Environmental social concerns | ||

| Product development time | Material recovery time | |

| Flexibility of delivery | ||

| Innovativeness | ||

7. Discussions and Implications

8. Conclusions and Recommendations

References

- Clift, R. Metrics for supply chain sustainability. J. Clean Technol. Environ. Policy 2004, 5, 240–247. [Google Scholar]

- Koplin, J.; Seuring, S.; Mesterharm, M. Incorporating sustainability into supply management in the automotive industry: the case of the Volkswagen AG. J. Clean Prod. 2007, 15, 1053–1062. [Google Scholar] [CrossRef]

- Matos, S.; Hall, J. Integrating sustainable development in the supply chain: the case of life cycle assessment in oil, gas and agricultural biotechnology. J. Oper. Manage. 2007, 25, 1083–1102. [Google Scholar] [CrossRef]

- Kemp, R. Technology and the transition to environmental sustainability. Futures 1994, 26, 1023–1046. [Google Scholar] [CrossRef]

- World Commission on Environmental and Development (WCED). Our Common Future; Oxford University Press: New York, NY, USA, 1987. [Google Scholar]

- Beamon, B.M. Environmental and sustainability ethics in supply chain management. Sci. Eng. Ethics 2005, 11, 221–234. [Google Scholar] [CrossRef]

- Seuring, S.; Muller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Linton, J.D.; Klassen, R.; Jaraman, V. Sustainable supply chains: an introduction. J. Oper. Manage. 2007, 25, 1075–1082. [Google Scholar] [CrossRef]

- Schultmann, F.; Zumkeller, M.; Rentz, O. Modeling reverse logistic tasks within closed-loop supply chains: an example from the automotive industry. Eur. J. Oper. Res. 2006, 171, 1033–1050. [Google Scholar] [CrossRef]

- Well, P.; Seitz, M. Business models and closed-loop supply chains: a typology. Suppl. Chain Manag. 2006, 10, 249–251. [Google Scholar]

- Beamon, B.M. Designing the green supply chain. Logist. Info. Manage. 1999, 12, 332–342. [Google Scholar] [CrossRef]

- Green, K.; Morton, B.; New, S. Green purchasing and supply policies: do they improve companies’ environmental performance? Suppl. Chain Manag. 1998, 3, 89–95. [Google Scholar]

- Handfield, R.B.; Nichols, E.L. Introduction to Supply Chain Management; Prentice Hall, Upper Saddle River: New Jersey, NJ, USA, 1999. [Google Scholar]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance measurement for green supply chain management. Benchmark.: Int. J. 2005, 12, 330–353. [Google Scholar] [CrossRef]

- Noci, G. Designing green vendor rating system for the assessment of a supplier’s environmental performance. Eur. J. Purch. Suppl. Manage. 1997, 3, 103–114. [Google Scholar] [CrossRef]

- McIntyre, K.; Smith, H.; Henham, A.; Pretlove, J. Environmental performance indicators for integrated supply chains: the case of Xerox Ltd. Suppl. Chain Manage. 1998, 3, 149–156. [Google Scholar] [CrossRef]

- Van Hoek, R.I. From reversed logistics to green supply chains. Suppl. Chain Manage. 1999, 4, 129–134. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarki, J.; Lai, K. Green supply chain management implications for closing the loop. Transp. Res. Part E 2008, 44, 1–18. [Google Scholar] [CrossRef]

- Trowbridge, P. A case study of green supply chain management at advanced micro devices. In Greening the Supply Chain; Sarki, J., Ed.; Springer-Verlag: London, UK, 2006; pp. 307–322. [Google Scholar]

- Goodland, R. The case that the world has reached limits. In Environmentally Sustainable Economic Development: Building on Brundtland; Goodland, R., Daly, H., El Serafy, S., Eds.; World Bank: Washington, DC, USA, 1991. [Google Scholar]

- Spengler, T.; Stolting, W.; Ploog, M. Recovery planning in closed loop supply chain: an activity analysis based approach. In Supply Chain Management and Reverse Logistics; Dyckhoff, H., Lackes, R., Reese, J., Eds.; Springer-Verlag: Berlin, Germany, 2004; pp. 61–89. [Google Scholar]

- Guide, V.D.R., Jr.; van Wassenhove, L. Closed-loop supply chains. In Quantitative Approaches to Distribution Logistics and Supply Chain Management; Klose, A., Speranza, M.G., van Wassenhove, L., Eds.; Springer: Berlin, Germany, 2002; pp. 47–60. [Google Scholar]

- Fleischmann, M.; Dekker, R.; van der Laan, E.; van Numen, J.; van Wassenhove, L.; Ruwaard, J. Quantitative models for reverse logistics: a review. Eur. J. Oper. Res. 1997, 103, 1–17. [Google Scholar] [CrossRef]

- French, M.L.; LaForge, R.L. Closed-loop supply chains in process industries: an empirical study of producer re-use issues. J. Oper. Manage. 2006, 24, 271–286. [Google Scholar] [CrossRef]

- Guide, V.D.R., Jr.; van Wassenhove, L.N. Closed-Loop Supply Chains; Working Paper 2000/75/TM; INSEAD: Fontainebleau, France, 2000. [Google Scholar]

- Solvang, W.D.; Roman, E.; Deng, Z.; Solvang, B. A framework for holistic greening of value chains. In Knowledge Enterprise: Intelligent Strategies in Product Design, Manufacturing, and Management; Springer: Boston, MA, USA, 2006; Volume 207, pp. 350–355. [Google Scholar]

- Rao, P. Greening of the supply chain: a new initiative in South East Asia. Int. J. Oper. Prod. Manage. 2002, 22, 632–655. [Google Scholar] [CrossRef]

- Dyckhoff, H.; Souren, R.; Keilen, J. The expansion of supply chains to close loop systems: a conceptual framework and the automotive industry’s point of view. In Suppy Chain Management and Reverse Logistics; Dyckhoff, H., Lackes, R., Reese, J., Eds.; Springer-Verlag: Berlin, Germany, 2004; pp. 13–34. [Google Scholar]

- CEC Directive 2000/53/EC of the European Parliament and of the Council of 18 September 2000 on End-of Life Vehicles. Official Journal of the European Union, L Series, 21 October 2000; 34–42.

- von Ahsen, A. Environmental management in automotive supply chains: an empirical analysis. In Greening the Supply Chain; Sarki, J., Ed.; Springer-Verlag: London, UK, 2006; pp. 293–306. [Google Scholar]

- Johnson, P.F. Managing value in reverse logistics systems. Transp. Res. Part E: Logist. Transp. Rev. 1998, 34, 217–227. [Google Scholar]

- Autry, C.W. Formalization of reverse logistics programs: a strategy for managing liberalized returns. Ind. Market. Manage. 2005, 34, 749–757. [Google Scholar] [CrossRef]

- Nunes, K.R.A.; Mahler, C.F.; Valle, R.A. Reverse logistics in the Brazilian construction industry. J. Environ. Manage. 2009, 90, 3717–3720. [Google Scholar] [CrossRef] [PubMed]

- Efendigil, T.; Onut, S.; Kongar, E. A holistic approach for selecting a third-party reverse logistics provider in the presence of vagueness. Comput. Ind. Eng. 2008, 54, 269–287. [Google Scholar] [CrossRef]

- Pun, K.F. Determinants of environmentally responsible operations: a review. Int. J. Quali. Reliab. Manage. 2006, 23, 279–297. [Google Scholar] [CrossRef]

- International Solid Waste Association (ISWA). Position on R1 and D10 Criteria in the EU Waste Framework Directive. 2003. Available online: www.iswa.org (assessed on 1 December 2009).

- Tsoulfas, G.T.; Pappis, C.P. A model for supply chains environmental performance analysis and decision making. J. Clean. Prod. 2008, 16, 1647–1657. [Google Scholar] [CrossRef]

- Beamon, B.M. Sustainability and the future of supply chain management. Oper. Supp. Chain Manage. 2008, 1, 4–18. [Google Scholar]

- Ostlin, J.; Sundin, E.; Bjorkman, M. Importance of closed-loop supply chain relationships for product remanufacturing. Int. J. Prod. Econ. 2008, 115, 336–348. [Google Scholar] [CrossRef]

- Bhagwat, M.; Sharma, M.K. Performance measurement of supply chain management: a balanced scorecard approach. Comput. Ind. Eng. 2007, 53, 43–62. [Google Scholar] [CrossRef]

- Neely, A.; Gregory, M.; Platts, K. Performance measurement system design: a literature review and research agenda. Int. J. Oper. Prod. Manage. 2005, 25, 1228–1263. [Google Scholar]

- Srivastava, S.K. Green supply chain management: a state-of-the-art literature review. Int. J. Manage. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Kannan, G.; Sasikumar, P.; Devika, K. A genetic algorithm approach for solving a closed loop supply chain model: a case of a battery recycling. Appl. Math. Model. 2010, 34, 655–670. [Google Scholar] [CrossRef]

- Yang, G.; Wang, Z.; Li, X. The optimization of the closed-loop supply chain network. Transp. Res. Part E: Logist. Transp. Rev. 2009, 45, 16–28. [Google Scholar]

- Amaro, A.C.S.; Barbosa-Povoa, A.P.D.F. Optimal planning of closed loop supply chain: a discrete versus a continuous time formulation. Comput. Aided Chem. Eng. 2007, 24, 673–678. [Google Scholar]

- Hammond, D.; Beullens, P. Closed-loop supply chain network equilibrium under legislation. Eur. J. Oper. Res. 2007, 183, 895–908. [Google Scholar] [CrossRef]

- Vlachos, D.; Georgiadis, P.; Iakovou, E. A system dynamics model for dynamic capacity planning of remanufacturing in closed-loop supply chain. Comput. Oper. Res. 2007, 34, 367–394. [Google Scholar] [CrossRef]

- Amaro, A.C.S.; Barbosa-Póvoa, A.P.F.D. The effect of uncertainty on the optimal closed-loop supply chain planning under different partnership structure. Comput. Chem. Eng. 2009, 33, 2144–2158. [Google Scholar] [CrossRef]

- Flapper, S.D. Introduction to feature cluster on closed-loop supply chains. Eur. J. Oper. Res. 2008, 191, 1205–1217. [Google Scholar] [CrossRef]

- Salema, M.I.G.; Barbosa-Povoa, A.P.; Novais, A.Q. Simaultaneous design and planning of supply chains with reverse flows: a generic modeling framework. Eur. J. Oper. Res. 2010, 203, 336–349. [Google Scholar] [CrossRef]

- Guide, V.D.R., Jr.; Jayaraman, V.; Linton, J.D. Building contingency planning for closed-loop supply chains with product recovery. J. Oper. Manage. 2003, 1, 259–279. [Google Scholar] [CrossRef]

- Chung, S.L.; Wee, H.M.; Yang, P.C. Optimal policy for a closed-loop supply chain inventory system with remanufacturing. Math. Comput. Mod. 2008, 48, 867–881. [Google Scholar] [CrossRef]

- Kumar, S.; Malegeant, P. Strategic alliance in a closed-loop supply chain, a case of manufacturer and eco-nonprofit organization. Technovation 2006, 26, 1127–1135. [Google Scholar] [CrossRef]

- Shepherd, C.; Gunter, H. Measuring supply chain performance: current research and future directions. Int. J. Prod. Perform. Manage. 2006, 55, 242–258. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Patel, C.; Tirtiroglu, E. Performance measures and metrics in a supply chain. Int. J. Oper. Prod. Manage. 2001, 21, 71–87. [Google Scholar] [CrossRef]

- Beamon, B.M. Measuring supply chain performance. Int. J. Oper. Prod. Manage. 1999, 19, 275–292. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Qi, H.J. An innovative performance measurement method for supply chain management. Suppl. Chain Manage. 2003, 8, 209–223. [Google Scholar] [CrossRef]

- Chan, F.T.S. Performance measurement in a supply chain. Int. J. Adv. Manuf. Technol. 2003, 21, 534–548. [Google Scholar] [CrossRef]

- Schonsleben, P. Integral Logistics Management: Planning and Control of Comprehensive Supply Chains; St Lucie Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Hieber, R. Supply Chain Management: A Collaborative Performance Measurement Approach; VDF: Zurich, Switzerland, 2002. [Google Scholar]

- Artz, K.W. Buyer-supplier performance: the role of asset specificity, reciprocal investments and relational exchange. Br. J. Manage. 1999, 10, 113–126. [Google Scholar] [CrossRef]

- Windischer, A.; Grote, G. Success factors for collaborative planning. In Strategy and Organization in Supply Chain; Seuring, S., Muller, M., Goldbach, M., Eds.; Physica: Heidelberg, Germany, 2003; pp. 131–146. [Google Scholar]

- Graham, T.S.; Dougherty, P.J.; Dudley, W.N. The long term strategic impact of purchasing partnerships. Int. J. Purch. Mater. Manage. 1994, 30, 13–18. [Google Scholar]

- Maloni, M.J; Benton, W.C. Supply chain partnerships: opportunities for operations research. Eur. J. Oper. Res. 1997, 101, 419–429. [Google Scholar]

- van der Vorst, J.; Beulens, A. Identifying sources of uncertainty to generate supply chain redesign strategies. Int. J. Phys. Distrib. Logist. Manage. 2001, 32, 409–430. [Google Scholar]

- Vonderembse, M.A.; Uppal, M.; Huang, S.H.; Dismukes, J.P. Designing supply chains: towards theory development. Int. J. Prod. Econ. 2006, 100, 223–238. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Initiatives and outcomes of green supply chain management implementation by Chinese manufacturers. J. Environ. Manage. 2007, 85, 179–189. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manage. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Lettice, F.; Wyatt, C.; Evans, S. Buyer-supplier partnerships during product design and development in the global automotive sector: who invests, in what and when? Int. J. Prod. Econ. 2009, (in press). [Google Scholar]

- Zhu, Q.; Sarkis, J.; Lai, K. Green supply chain management: pressures, practices and performance within the Chinese automobile industry. J. Clean Prod. 2007, 15, 1041–1052. [Google Scholar] [CrossRef]

- Cruz-Rivera, R.; Ertel, J. Reverse logistics network design for the collection of end-of-life vehicles in Mexico. Eur. J. Oper. Res. 2009, 196, 930–939. [Google Scholar] [CrossRef]

- Olugu, E.U.; Wong, K.Y. Supply chain performance evaluation: trends and challenges. Am. J. Eng. Appl. Sci. 2009, 2, 202–211. [Google Scholar] [CrossRef]

- Wong, W.P.; Wong, K.Y. Supply chain performance measurement system using DEA modeling. Ind. Manage. Data Syst. 2007, 107, 361–381. [Google Scholar]

- Anderson, K.; McAdam, R. A critique of benchmarking and performance measurement. Benchmark.: Int. J. 2004, 11, 465–483. [Google Scholar] [CrossRef]

- Mentzer, J.T.; Meyers, M.B.; Stank, T.P. Handbook of Global Supply Chain Management; Sage Publications: Thousand Oaks, CA, USA, 2007; p. 585. [Google Scholar]

- Kaplan, R.S.; Norton, P.D. The balanced scorecard: measures that drives performance. Harv. Bus. Rev. 1992, 70, 71–79. [Google Scholar]

- Vachon, S.; Klassen, R.D. Environmental management and manufacturing performance: the role of collaboration in the supply chain. Int. J. Prod. Econ. 2008, 111, 299–315. [Google Scholar]

© 2010 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Olugu, E.U.; Wong, K.Y.; Shaharoun, A.M. A Comprehensive Approach in Assessing the Performance of an Automobile Closed-Loop Supply Chain. Sustainability 2010, 2, 871-889. https://doi.org/10.3390/su2040871

Olugu EU, Wong KY, Shaharoun AM. A Comprehensive Approach in Assessing the Performance of an Automobile Closed-Loop Supply Chain. Sustainability. 2010; 2(4):871-889. https://doi.org/10.3390/su2040871

Chicago/Turabian StyleOlugu, Ezutah Udoncy, Kuan Yew Wong, and Awaludin Mohamed Shaharoun. 2010. "A Comprehensive Approach in Assessing the Performance of an Automobile Closed-Loop Supply Chain" Sustainability 2, no. 4: 871-889. https://doi.org/10.3390/su2040871

APA StyleOlugu, E. U., Wong, K. Y., & Shaharoun, A. M. (2010). A Comprehensive Approach in Assessing the Performance of an Automobile Closed-Loop Supply Chain. Sustainability, 2(4), 871-889. https://doi.org/10.3390/su2040871