Coal Mine Rock Burst and Coal and Gas Outburst Perception Alarm Method Based on Visible Light Imagery

Abstract

:1. Introduction

2. Disaster Characteristics and Perception Methods

2.1. External Characteristics of Disasters

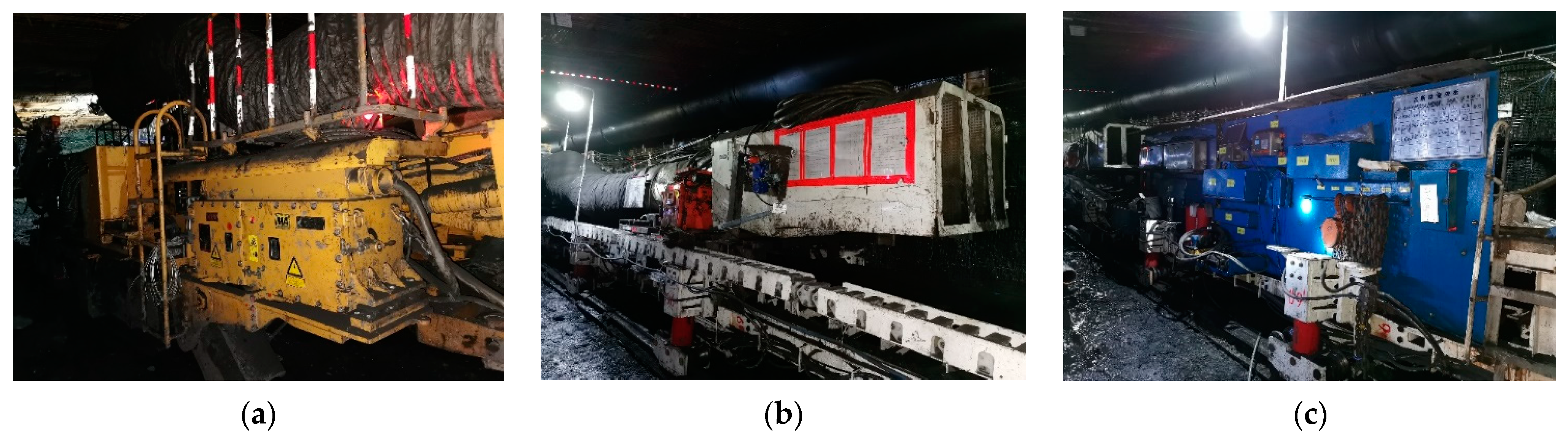

2.2. Video Image Perception Method

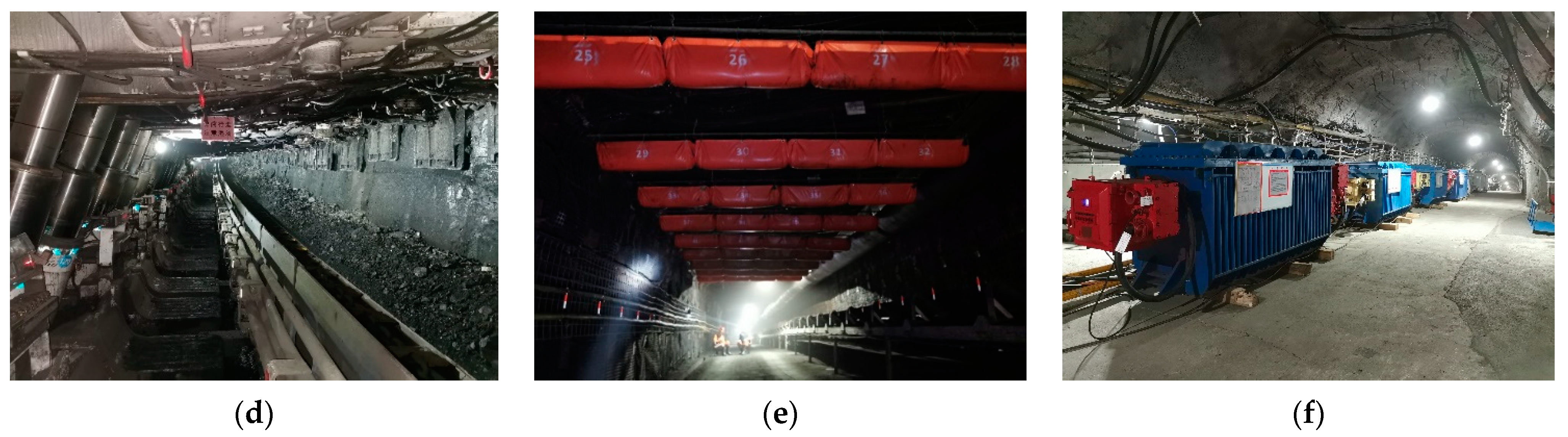

- (1)

- Color cameras with fill lights are arranged at multiple points on or near the roof of the coal mining face, the top of the support of the mining face, and the roof of the roadway or near the roof, etc., to collect color video images in the monitoring area in real time, and methane sensors arranged at multiple points are used to monitor the environmental methane concentration in the monitoring area [30,35];

- (2)

- Against the background of equipment with distinct color differences from the disaster-thrown coal rocks, monitor and identify whether the color video images have a black area change;

- (3)

- When the color cameras detect a significant increase in the black area at the end, middle, and entrance of the driving roadway; the mining face; the entrance and middle of the air inlet roadway; the entrance and middle of the air return roadway; the main transportation roadway; or the auxiliary transportation roadway, indicating the color characteristics at the time of disaster occurrence, then the average brightness of the color video image is monitored and recognized. Otherwise, whether there is a black area change in the color video image is continually monitored and identified where applicable;

- (4)

- If the average brightness is less than the set brightness threshold, it indicates no abnormal brightness, and the interference of gas and coal dust explosion is eliminated [30,34]; thus, the object movement speed that causes a significant increase in the black area is identified. Otherwise, the color video image is continuously monitored to identify whether the black area changes;

- (5)

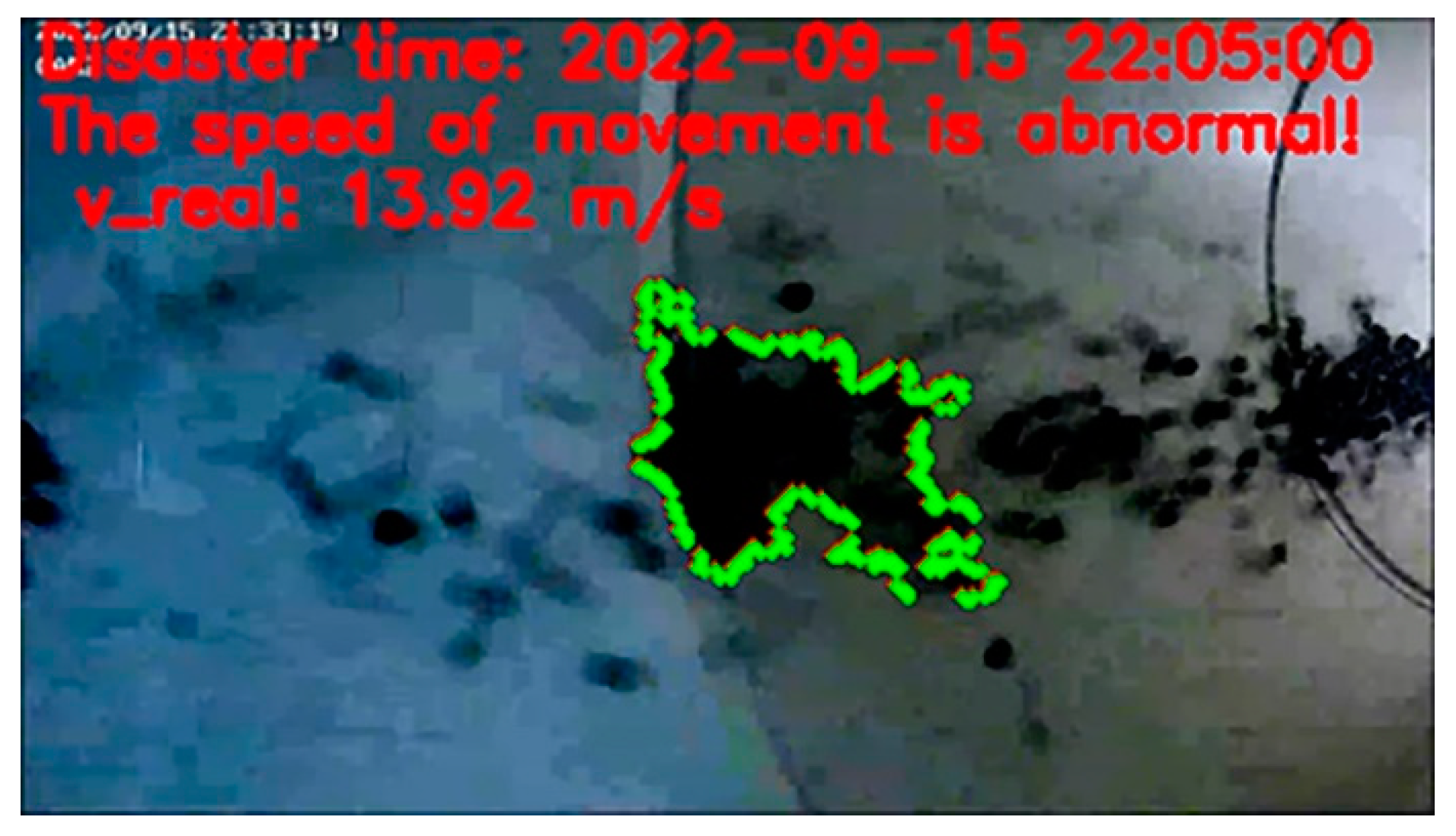

- If the movement velocity is greater than the set velocity threshold (V > 13 m/s), it indicates that there is a velocity characteristic of coal rocks thrown due to the disaster. Therefore, monitoring and identifying the environmental methane concentration in the monitoring area is performed. Otherwise, the color video image is continuously monitored to identify whether the black area changes;

- (6)

- The methane sensors monitor whether the methane concentration in the monitoring area increases rapidly or reaches the alarm value. When multiple different locations, such as the mining face, air inlet tunnel, air return tunnel, and total air return tunnel, detect a significant increase or reach the alarm value, the alarm will be issued for a coal and gas outburst, and vice versa, where the alarm will be issued for a rock burst;

- (7)

- If the emergency response is activated after the alarm of coal and gas outbursts, then the alarm is canceled and there is continued monitoring and identification as to whether there is a black area change in the color video image. Otherwise, the disaster alarm is continued and the emergency response is activated; if the emergency response is activated after the alarm of rock burst, then the alarm is canceled and there is continued monitoring and identification as to whether there is a black area change in the color video image. Otherwise, the disaster alarm is maintained and the emergency response is activated.

3. Specific Implementation of the Image Perception Method

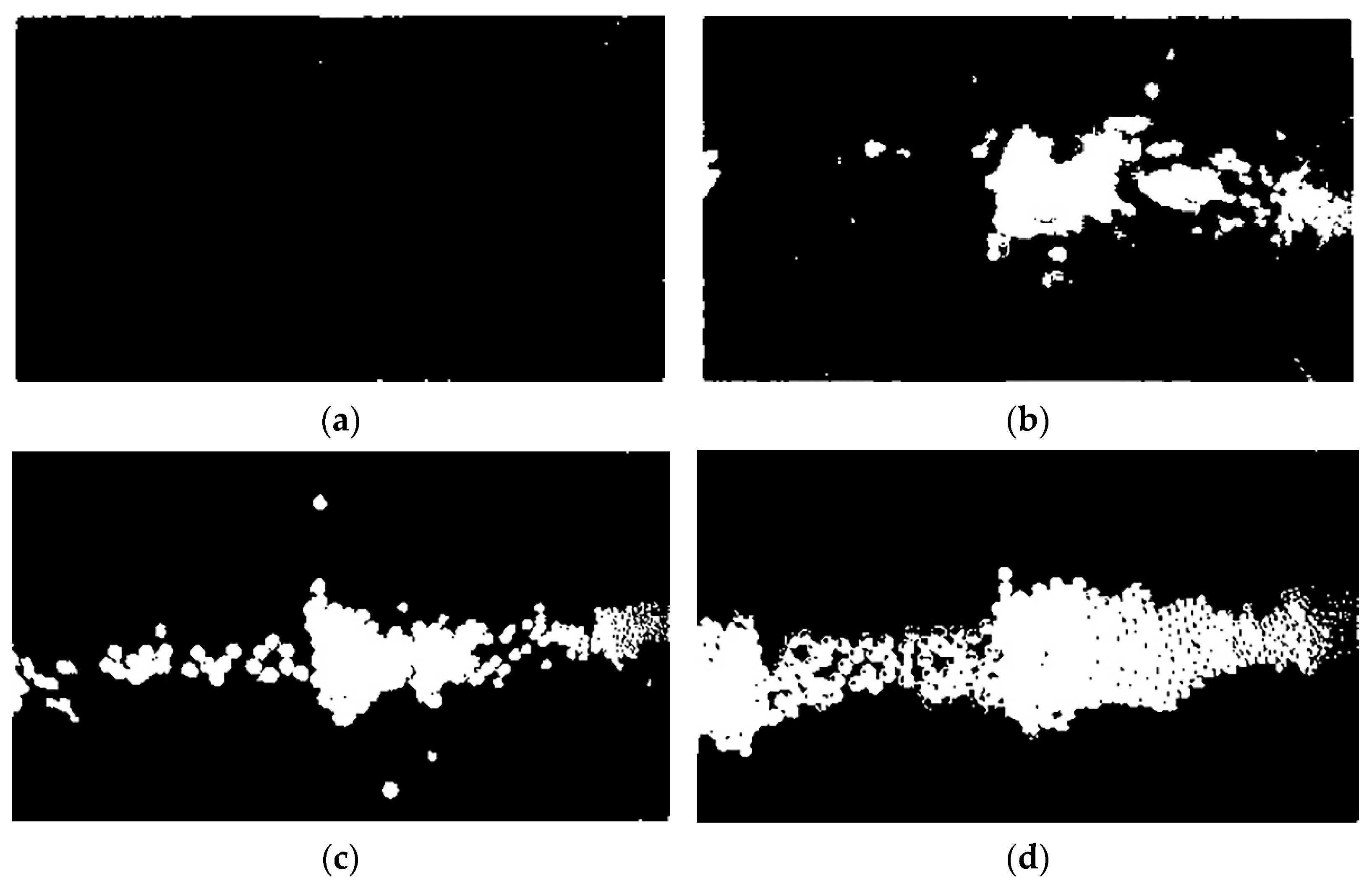

3.1. Color Change Feature Recognition

3.2. Average Brightness Feature Recognition

3.3. Moving Speed Feature Recognition

3.4. Comprehensive Disaster Recognition Alarm

4. Simulation Experiment and Analysis of Results

4.1. General Idea of Simulation Experiment

4.2. Selection of Camera Type

4.3. Selection of Simulated Alleyway Dimensions

4.4. Field Conditions of the Simulated Experiment

4.5. Analysis of Simulation Experiment Results

5. Conclusions

- (1)

- A coal mine rock burst and coal and gas outburst perception alarm method based on visible light imagery is proposed. Using the coal mine underground equipment, which has an obvious color difference from disaster-thrown coal rock, as the background, we used the large increase in the amount of black area in the color video image to capture the disaster-thrown coal rock, an average brightness that is less than the set brightness threshold to exclude the interference of gas and coal dust explosion, and the speed threshold to exclude the interference of the movement of objects in normal working conditions; moreover, the methane concentration of multiple areas must be obviously increased or reach the alarm value to further distinguish between the rock burst and coal and gas outburst;

- (2)

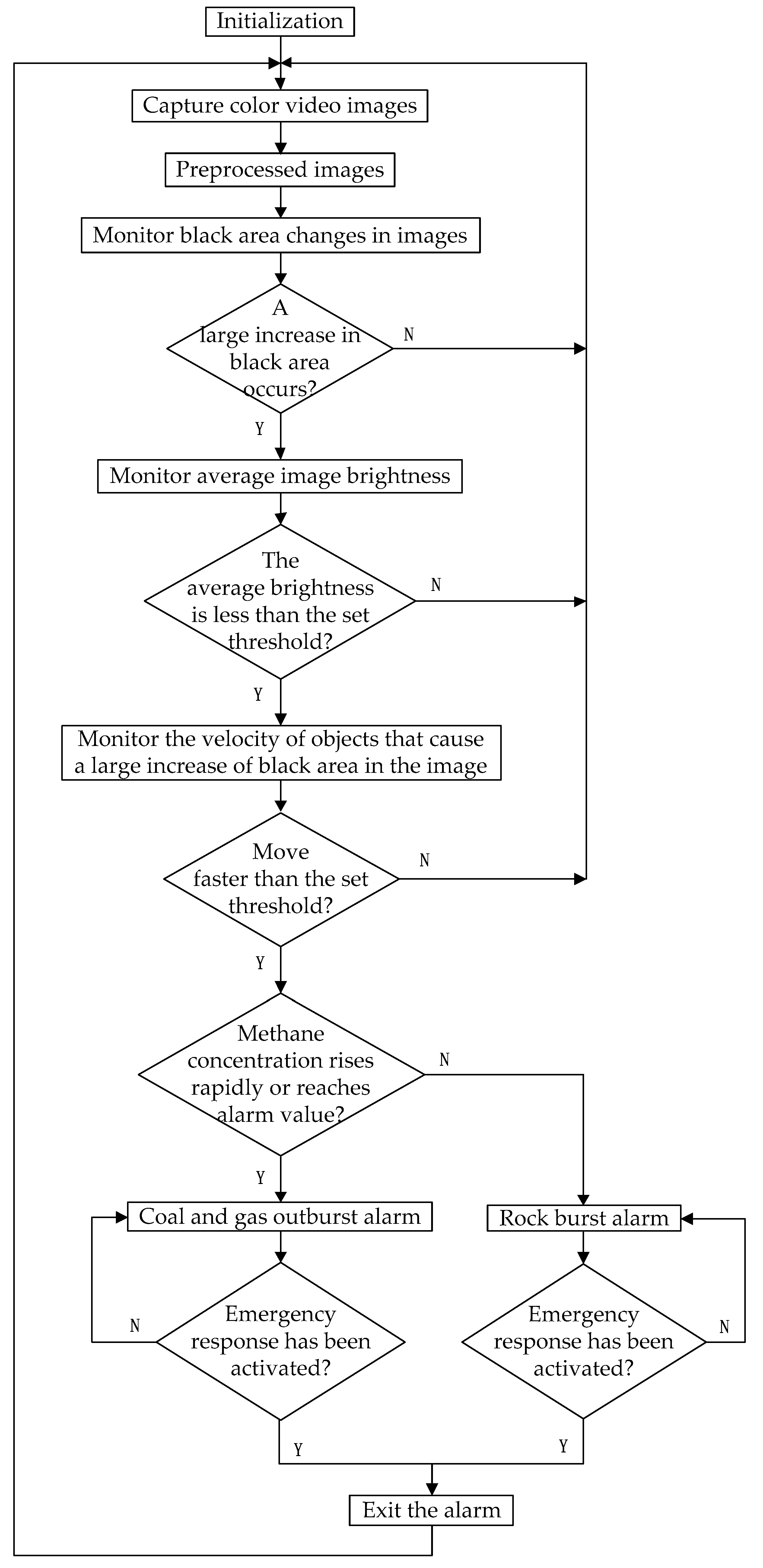

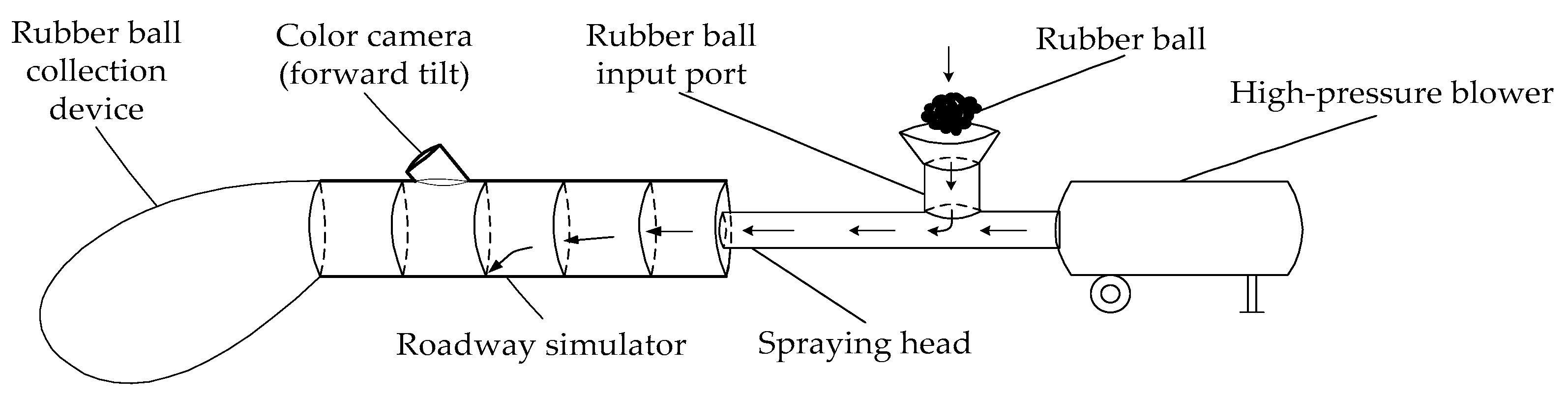

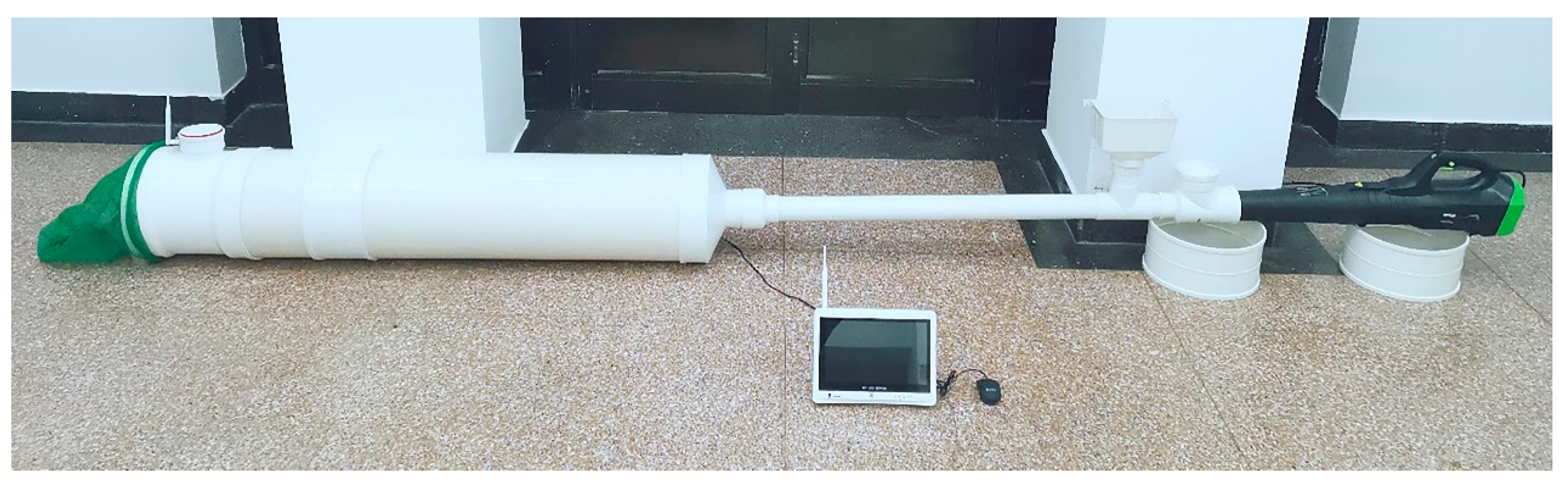

- A set of experimental devices for simulating the color, brightness, and speed characteristics of rock bursts and coal and gas outbursts were designed: a Φ315 mm white PVC pipe was used to simulate the circular roadway and background equipment. An axial flow high-pressure blower was used as the power device, and Φ10 mm rubber balls of similar color and specific gravity were used to replace the broken coal rocks thrown during the disaster to simulate the abnormal characteristics of speed and color caused by a large number of coal rocks thrown during a disaster. Additionally, by building a wireless cascade monitoring system, a hemispherical color camera with 2.8 mm focal length, 30 FPS, and 110° field of view was used to complete the monitoring and color video image acquisition of the simulated disaster process. The device provided a good simulation of disaster characteristics, simplified the complexity of disaster simulation experiments, and ensured experimental safety;

- (3)

- The study shows that by identifying the occurrence of simulated disasters, the disaster perception alarm method proposed in this paper can identify the situation where the image color changes significantly, the average brightness of the image is less than the set threshold, and the movement speed of the object that causes the image color to change significantly is greater than the set threshold when a disaster occurs; moreover, the disaster alarm saves the image at the moment when the threshold condition is met. This verifies the feasibility and effectiveness of the perception alarm method of coal mine rock bursts and coal and gas outbursts based on visible light imagery. The method can be adapted well to the underground scenario of coal mines to better meet the demand for the image perception of rock bursts and coal and gas outbursts, which can improve the response speed of disasters and accidents; gain valuable time for self-rescue and rescue after disasters; and reduce the risk of secondary disasters caused by gas asphyxiation and gas and coal dust explosions;

- (4)

- The method proposed in this paper can be applied not only for rock burst and coal and gas outburst disaster alarms in coal mines, but also for rock burst disaster alarms in non-coal mines. Multidimensionally, it can also be used for the early warning of serious secondary disasters such as gas asphyxiation and gas and coal dust explosions due to rock bursts and coal and gas outbursts.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, J. Accident Analysis and Big Data and Internet of Things in Coal Mine. Ind. Mine Autom. 2015, 41, 1–5. [Google Scholar] [CrossRef]

- Sun, J.; Qian, X. Coal Mine Accident and Emergency Rescue Technology and Equipment. Ind. Mine Autom. 2016, 42, 1–5. [Google Scholar] [CrossRef]

- Sun, J. Research on Coal-mine Safe Production Conception. J. China Coal Soc. 2011, 36, 313–316. [Google Scholar] [CrossRef]

- Sun, J. Requirement and Key Technology on Mine Informationalization and Intelligent Technology. Coal Sci. Technol. 2014, 42, 22–25+71. [Google Scholar] [CrossRef]

- Sun, J. New Technologies and New Equipment of Coal Mine Monitoring. Ind. Mine Autom. 2015, 41, 1–5. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhao, Z.; Zhao, T.; Ma, C.; Zhang, K.; Qi, Y. A New Method for Monitoring Coal Stress While Drilling Process: Theoretical and Experimental Study. Energy Sources Part A-Recovery Util. Environ. Eff. 2023, 45, 3980–3993. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, S.; Wang, E.; Zhang, Z.; Wang, Y.; Yang, S. Multi-Index Geophysical Monitoring and Early Warning for Rock burst in Coalmine: A Case Study. Int. J. Environ. Res. Public Health 2023, 20, 392. [Google Scholar] [CrossRef] [PubMed]

- Ji, P.; Shi, S.; Lu, Y.; He, L. Research on Risk Identification of Coal and Gas Outburst Based on PSO-CSA. Math. Probl. Eng. 2023, 2023, 5299986. [Google Scholar] [CrossRef]

- Zhang, E.; Zhou, B.; Yang, L.; Li, C.; Li, P. Experimental study on the microseismic response characteristics of coal and gas outbursts. Process Saf. Environ. Prot. 2023, 172, 1058–1071. [Google Scholar] [CrossRef]

- Wang, A.; Qiu, L.; Liu, Y.; Lou, Q.; Sun, Z.; Wang, W. Study on Synchronous Response Law of Acoustic and Electrical Signals of Outburst Coal Rock under Load and Fracture. Geofluids 2023, 2023, 1253236. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, X.; Wang, X.; Liu, Y.; Xie, H.; Du, P. Acoustic Emission Characteristics of Coal Failure Under Triaxial Loading and Unloading Disturbance. Rock Mech. Rock Eng. 2023, 56, 1043–1061. [Google Scholar] [CrossRef]

- Di, Y.; Wang, E.; Li, Z.; Liu, X.; Li, B. Method for EMR and AE interference signal identification in coal rock mining based on recurrent neural networks. Earth Sci. Inform. 2021, 14, 1521–1536. [Google Scholar] [CrossRef]

- Deng, B.; Nie, B.; Liu, X.; Shi, F. Characteristics of the heterogeneous mechanical response of coal at the nano and micro-scale using instrumented indentation experiments. Chin. J. Theor. Appl. Mech. 2022, 54, 2304–2317. [Google Scholar]

- Chaolin, Z.; Enyuan, W.; Yibo, W.; Zhou, X. Development and application of multi-functional test system for coal and gas outburst simulation. Chin. J. Rock Mech. Eng. 2022, 41, 995–1007. [Google Scholar] [CrossRef]

- Yiyu, L.; Ziye, P.; Binwei, X. Multi-functional physical model testing system of deep coal petrography engineering. J. China Coal Soc. 2020, 45, 272–283. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, J.; Peng, S. Dynamic evolution of gas outburst Multiphysics parameters based on visual data. J. China Univ. Min. Technol. 2020, 49, 1067–1075. [Google Scholar] [CrossRef]

- Yuan, L.; Jiang, Y.; He, X.; Dou, L.; Zhao, X.; Wang, K.; Yu, Q.; Lu, X.; Li, H. Research Progress of Precise Risk Accurate Identification and Monitoring Early Warning on Typical Dynamic Disasters in Coal Mine. J. China Coal Soc. 2018, 43, 306–318. [Google Scholar] [CrossRef]

- Qi, Q.; Li, Y.; Zhao, S.; Zhang, N.; Zheng, W.; Li, H.; Li, H. Seventy Years Development of Coal Mine Rock burst in China: Establishment and Consideration of Theory and Technology System. Coal Sci. Technol. 2019, 47, 1–40. [Google Scholar] [CrossRef]

- Jiang, Y.; Pan, Y.; Jiang, F.; Dou, L.; Ju, Y. State of the Art Review on Mechanism and Prevention of Coal Bumps in China. J. China Coal Soc. 2014, 39, 205–213. [Google Scholar] [CrossRef]

- Wang, J.; Wang, E.; Yang, W.; Li, B.; Li, Z.; Liu, X. Rock Burst Monitoring and Early Warning Under Uncertainty Based on Multi-information Fusion Approach. Measurement 2022, 205, 112188. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, J.; Yu, H.; Pan, Y. Gas Pressure Evolution Characteristics of Deep True Triaxial Coal and Gas Outburst Based on Acoustic Emission Monitoring. Sci. Rep. 2022, 12, 21738. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Dou, L.; Cai, W.; Chen, J.; Kong, Y.; Su, Z.; Li, Z. Signal Characteristics of Coal and Rock Dynamics with Micro-seismic Monitoring Technique. Int. J. Min. Sci. Technol. 2016, 26, 683–690. [Google Scholar] [CrossRef]

- Sun, J. Alarm methods of coal and gas outburst. Ind. Mine Autom. 2014, 40, 1–5. [Google Scholar] [CrossRef]

- Sun, J.; Yu, X. Research on Alarm Method of Coal Mine Extraordinary Accidents Based on Sound Recognition. Ind. Mine Autom. 2021, 47, 1–5+44. [Google Scholar] [CrossRef]

- Sun, J.; Yu, X.; Wang, Y.; Li, X. Research on Perception Method of Coal Mine Gas and Coal Dust Explosion Based on Explosion Sound Recognition. Ind. Mine Autom. 2023, 49, 1–114. [Google Scholar] [CrossRef]

- Sun, J.; Yu, X.; Wang, Y. Recognition Method of Coal Mine Gas and Coal Dust Explosion Based on Sound Spectrogram and SVM. Coal Sci. Technol. 2023, 51, 366–376. [Google Scholar] [CrossRef]

- Sun, J.; Yu, X. Sound Recognition Method of Coal Mine Gas and Coal Dust Explosion Based on CEEMD Component Sample Entropy and SVM Classification. J. Min. Saf. Eng. 2022, 39, 1061–1070. [Google Scholar] [CrossRef]

- Sun, J.; Yu, X. Recognition Method of Coal Mine Gas and Coal Dust Explosion Based on Sound Characteristics. J. China Univ. Min. Technol. 2022, 51, 1096–1105. [Google Scholar] [CrossRef]

- Sun, J.; Cheng, J. Study on the Perception and Alarm Method of Coal Mine Rock Burst and Coal and Gas Outburst. Ind. Mine Autom. 2022, 48, 1–6. [Google Scholar] [CrossRef]

- Sun, J.; Cheng, J.; Wang, Y. Coal Mine Rock Burst and Coal and Gas Outburst Perception Alarm Method Based on Color Image. Ind. Mine Autom. 2022, 48, 1–5. [Google Scholar] [CrossRef]

- Nie, B.; Ma, Y.; Meng, J.; Hu, S. Middle Scale Simulation System of Coal and Gas Outburst. Chin. J. Rock Mech. Eng. 2018, 37, 1218–1225. [Google Scholar] [CrossRef]

- Yuan, R.; Li, H. Development and Application of Simulation Test Apparatus for Gassy Coal Dynamic Failure. J. China Coal Soc. 2013, 38, 117–123. [Google Scholar] [CrossRef]

- State Administration of Work Safety. Coal Mine Safety Regulations; Coal Industry Press: Beijing, China, 2022.

- Zhang, Y.; Wang, D.; Zhu, H. Coal Mine Explosion, Fire and Its Prevention Technology; China University of Mining and Technology Press: Xuzhou, China, 2007. [Google Scholar]

- AQ1029-2019; Specification for the Use and Management of Coal Mine Safety Monitoring Systems and Detection Instruments. Emergency Management Press: Beijing, China, 2019.

- Wang, X.; Han, J.; Xiang, H.; Wang, B.; Wang, G.; Shi, H.; Chen, L.; Wang, Q. A Lightweight Traffic Lights Detection and Recognition Method for Mobile Platform. Drones 2023, 7, 293. [Google Scholar] [CrossRef]

- Ma, H.; Liu, Z.; Jiang, K.; Jiang, B.; Feng, H.; Hu, S. A Novel ST-ViBe Algorithm for Satellite Fog Detection at Dawn and Dusk. Remote Sens. 2023, 15, 2331. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, J.; Liu, Y.; Li, X. Coal Mine Rock Burst and Coal and Gas Outburst Perception Alarm Method Based on Visible Light Imagery. Sustainability 2023, 15, 13419. https://doi.org/10.3390/su151813419

Cheng J, Liu Y, Li X. Coal Mine Rock Burst and Coal and Gas Outburst Perception Alarm Method Based on Visible Light Imagery. Sustainability. 2023; 15(18):13419. https://doi.org/10.3390/su151813419

Chicago/Turabian StyleCheng, Jijie, Yi Liu, and Xiaowei Li. 2023. "Coal Mine Rock Burst and Coal and Gas Outburst Perception Alarm Method Based on Visible Light Imagery" Sustainability 15, no. 18: 13419. https://doi.org/10.3390/su151813419