On the Possibility of Using Recycled Mixed Aggregates and GICC Thermal Plant Wastes in Non-Structural Concrete Elements

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation and Curing

2.2. Aggregates

2.3. Methods

3. Results and Discussion

3.1. Compressive Strength

3.2. Density

3.3. Capillary Water Absorption

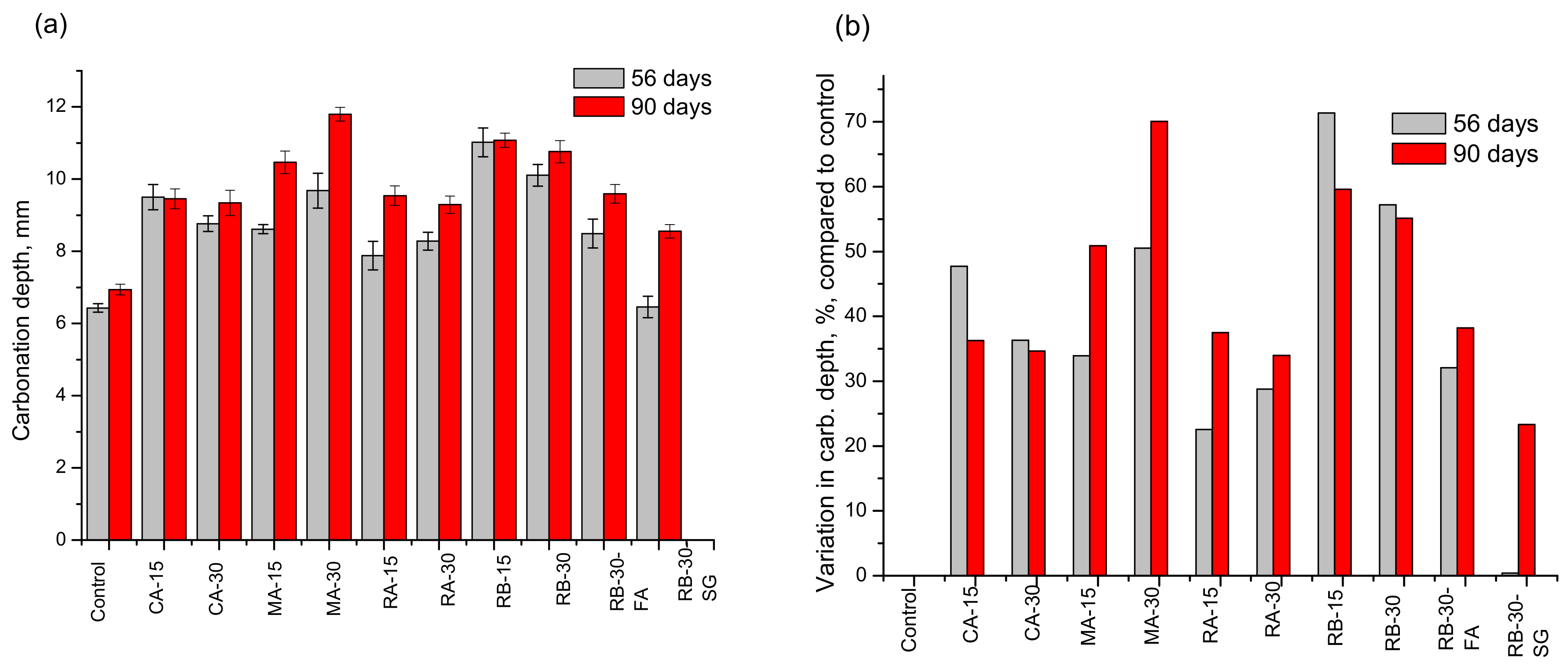

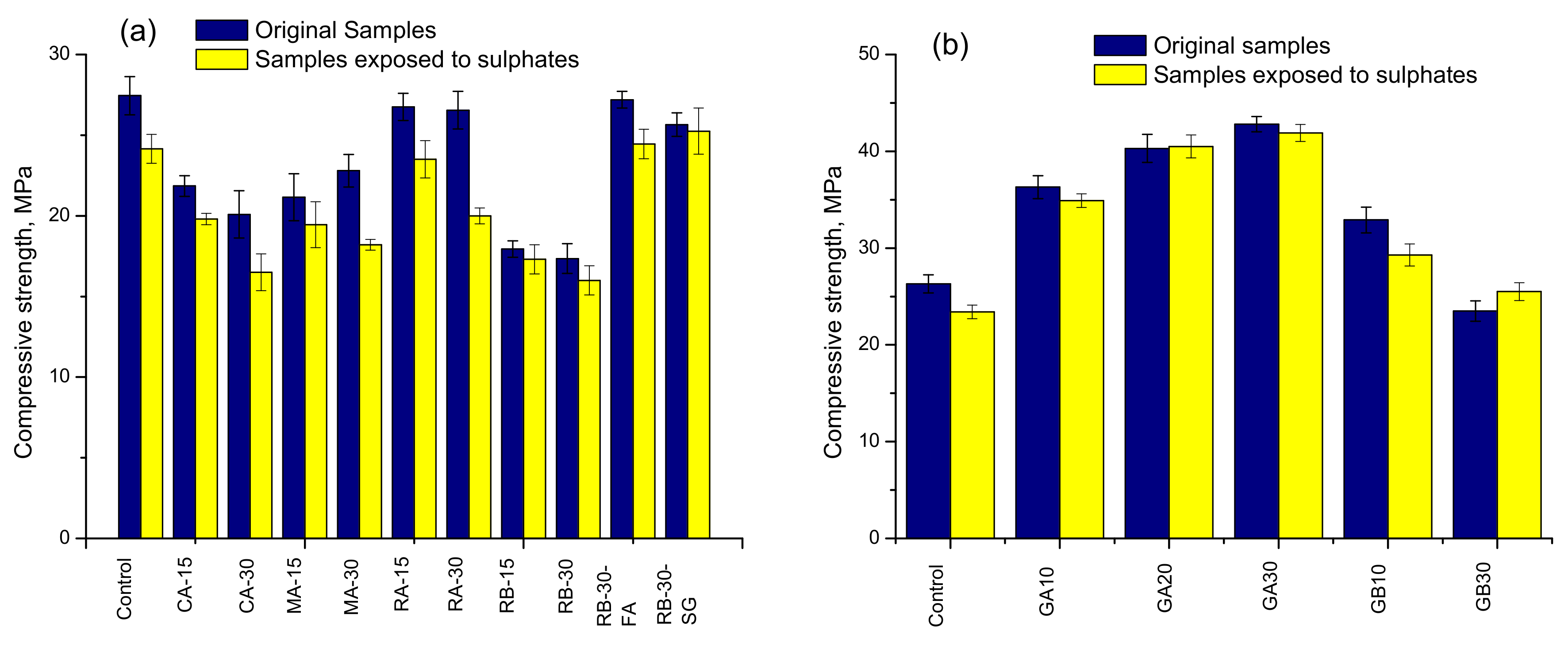

3.4. Resistance to Carbonation

3.5. Resistance to Chloride Ingress

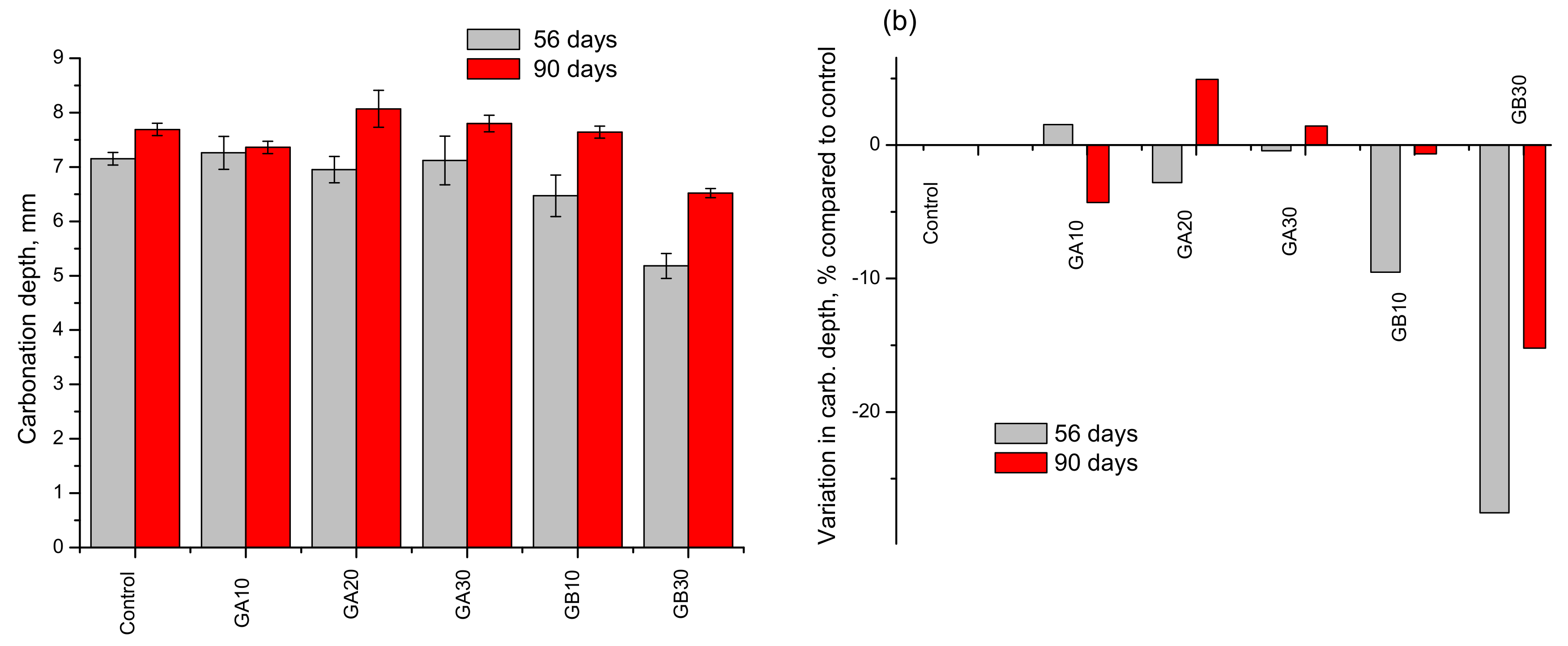

3.6. Resistance to Shulphate Attack

4. Conclusions

- The use of C&DW as recycled aggregate in concrete implies a loss of compressive strength. This loss is mainly due to the nature and composition of C&DW. The worst results were shown by mixed recycled aggregate Type B (RB) that contained floating particles and asphalt particles. However, the use of the fly ash and the fine fraction (Ø < 0.063 mm) of the slag, which were obtained from the GICC thermal power plant, improved substantially the mechanical properties of the concretes prepared with this recycled aggregate, providing better long-term properties than the concrete with 100% natural aggregates.

- The results of using both the fine and coarse fractions of the slag generated in the GICC thermal power plant as recycled aggregate exhibit excellent behaviour, especially the fine fraction, possibly due to the high percentage of fines (Ø < 0.063 mm). This finding indicates that the slag seems to react with either water or cement hydration products.

- The density of concrete decreases with the use of C&DW as recycled aggregates but it does not change much when slag is used as recycled aggregate, except for the case of 30% replacement of coarse aggregates by slag. The use of the wastes generated in the GICC thermal power plant together with C&DW gives very good density results, which are in agreement with the results of mechanical strength.

- The capillary water absorption of concrete decreases when slag from GICC thermal power plant is used, either as an addition to the cement or as recycled aggregate, probably due to the reactivity of this substance and the refinement of the pore network.

- The resistance to carbonation does not improve when using C&DW as recycled aggregates, not even with additions. In the case of using slag as the coarse fraction of the aggregates, the carbonation depth could be slightly reduced, possibly due to the more refined pore network. The resistance to chloride ingress improves substantially when using the wastes from GICC thermal power plant, either as an addition or as recycled aggregates. The resistance to sulphates is not clearly influenced by the use of any type of recycled aggregate. The influence of the additions to cement is more than that of the type of aggregate.

- It can be stated that under the studied conditions it is possible to use both types of recycled aggregate in a safe way from the mechanical behaviour and durability points of view. It is possible to combine C&DW (even in the worst-case) with the wastes from GICC thermal power plant obtaining materials that can be used without any problem, thus contributing to the sustainability of the construction industry.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Parliament. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain directives. Off. J. Eur. Union 2008, 51, 312–330. [Google Scholar]

- European Comission. Service Contract on Management of Construction and Demolition Waste—Sr1 Final; IEEP; 2008 Arcadis; BIO Intelligence Service: Paris, France, 2008.

- Mália, M.; de Brito, J.; Pinheiro, M.D.; Bravo, M. Construction and demolition waste indicators. Waste Manag. Res. 2013, 31, 241–255. [Google Scholar] [CrossRef] [PubMed]

- Comissión Permanente del Hormigón. Comission for Instrucción de hormigón Estructural EHE-08 (Structural Concrete Instruction, EHE-08); Spanish Ministry of Public Works: Madrid, Spain, 2008.

- Poon, C.S.; Chan, D. Paving blocks made with recycled concrete aggregate and crushed clay brick. Constr. Build. Mater. 2006, 20, 569–577. [Google Scholar] [CrossRef]

- Mas, B.; Cladera, A.; del Olmo, T.; Pitarch, F. Influence of the amount of mixed recycled aggregates on the properties of concrete for non-structural use. Constr. Build. Mater. 2012, 27, 612–622. [Google Scholar] [CrossRef]

- Rodríguez, C.; Parra, C.; Casado, G.; Miñano, I.; Albaladejo, F.; Benito, F.; Sánchez, I. The incorporation of construction and demolition wastes as recycled mixed aggregates in non-structural concrete precast pieces. J. Clean. Prod. 2016, 127, 152–161. [Google Scholar] [CrossRef]

- Martín-Morales, M.; Zamorano, M.; Ruiz-Moyano, A.; Valverde-Espinosa, I. Characterization of recycled aggregates construction and demolition waste for concrete production following the Spanish Structural Concrete Code EHE-08. Constr. Build. Mater. 2011, 25, 742–748. [Google Scholar] [CrossRef]

- Lovato, P.S.; Possan, E.; Molin, D.C.C.D.; Masuero, Â.B.; Ribeiro, J.L.D. Modeling of mechanical properties and durability of recycled aggregate concretes. Constr. Build. Mater. 2012, 26, 437–447. [Google Scholar] [CrossRef]

- Rodríguez, C.; Miñano, I.; Aguilar, M.Á.; Ortega, J.M.; Parra, C.; Sánchez, I. Properties of concrete paving blocks and hollow tiles with recycled aggregate from construction and demolition wastes. Materials 2017, 10, 1374. [Google Scholar] [CrossRef] [PubMed]

- Bijen, J. Benefits of slag and fly ash. Constr. Build. Mater. 1996, 10, 309–314. [Google Scholar] [CrossRef]

- Sánchez, I.; López, M.P.; Climent, M.A. Effect of fly ash on chloride transport through concrete: Study by impedance spectroscopy. In 12th International Congress on the Chemistry of Cement; Beaudoin, J.J., Makar, J.M., Raki, L., Eds.; National Research Council of Canada: Montreal, QC, Canada, 2007. [Google Scholar]

- Ortega, J.M.; Sanchez, I.; Anton, C.; de Vera, G.; Climent, M.A. Influence of environment on durability of fly ash cement mortars. ACI Mater. J. Mater. J. 2012, 109, 647–656. [Google Scholar]

- Ortega, J.M.; Tremiño, R.M.; Sánchez, I.; Climent, M.Á. Effects of environment in the microstructure and properties of sustainable mortars with fly ash and slag after a 5-year exposure period. Sustainability 2018, 10. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V.; Peris-Mora, E.; Ordóñez, L.M. Studies on crystalline rice husk ashes and the activation of their pozzolanic properties. Waste Manag. Ser. 2000, 1, 493–503. [Google Scholar] [CrossRef]

- Baeza, F.; Payá, J.; Galao, O.; Saval, J.M.; Garcés, P. Blending of industrial waste from different sources as partial substitution of Portland cement in pastes and mortars. Constr. Build. Mater. 2014, 66, 645–653. [Google Scholar] [CrossRef]

- Goverment of Spain. Aplicación de la Ley 1/2005. Análisis global y sectorial. Año 2017; Spanish Ministry of Ecology: Madrid, Spain, 2017.

- Lobato Gago, I. Economía Circular; Spanish Ministry of Ecology: Madrid, Spain, 2017; p. 7202. ISSN 978848326.

- Oruji, S.; Brake, N.A.; Nalluri, L.; Guduru, R.K. Strength activity and microstructure of blended ultra-fine coal bottom ash-cement mortar. Constr. Build. Mater. 2017, 153, 317–326. [Google Scholar] [CrossRef]

- Pera, J.; Coutaz, L.; Ambroise, J.; Chababbet, M. Use of incinerator bottom ash in concrete. Cem. Concr. Res. 1997, 27, 1–5. [Google Scholar] [CrossRef]

- Pan, J.R.; Huang, C.; Kuo, J.-J.; Lin, S.-H. Recycling MSWI bottom and fly ash as raw materials for Portland cement. Waste Manag. 2008, 28, 1113–1118. [Google Scholar] [CrossRef] [PubMed]

- Bertolini, L.; Carsana, M.; Cassago, D.; Quadrio Curzio, A.; Collepardi, M. MSWI ashes as mineral additions in concrete. Cem. Concr. Res. 2004, 34, 1899–1906. [Google Scholar] [CrossRef]

- Hashemi, S.S.G.; Mahmud, H.B.; Djobo, J.N.Y.; Tan, C.G.; Ang, B.C.; Ranjbar, N. Microstructural characterization and mechanical properties of bottom ash mortar. J. Clean. Prod. 2018, 170, 797–804. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Life cycle assessment of concrete made with high volume of recycled concrete aggregates and fly ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Rohman, R.K.; Aji, S. Effect of fly ash on compressive strength of concrete containing recycled coarse aggregate. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018; Volume 2014, p. 020097. [Google Scholar]

- Sunayana, S.; Barai, S.V. Flexural performance and tension-stiffening evaluation of reinforced concrete beam incorporating recycled aggregate and fly ash. Constr. Build. Mater. 2018, 174, 210–223. [Google Scholar] [CrossRef]

- Anastasiou, E.; Georgiadis Filikas, K.; Stefanidou, M. Utilization of fine recycled aggregates in concrete with fly ash and steel slag. Constr. Build. Mater. 2014, 50, 154–161. [Google Scholar] [CrossRef]

- Etxeberria, M.; Gonzalez-Corominas, A.; Pardo, P. Influence of seawater and blast furnace cement employment on recycled aggregate concretes’ properties. Constr. Build. Mater. 2016, 115, 496–505. [Google Scholar] [CrossRef]

- AENOR UNE-EN 12350-2:2009 Ensayos de Hormigón Fresco Parte 2: Ensayo de Asentamiento (Testing Fresh Concrete—Part 2: Slump-Test); AENOR: Madrid, Spain, 2009.

- AENOR UNE-EN 196-1:2005 Métodos de Ensayo de Cementos. Parte 1: Determinación de Resistencias Mecánicas; AENOR: Madrid, Spain, 2005.

- Acosta, A.; Aineto, M.; Iglesias, I.; Romero, M.; Rincón, J.M. Physico-chemical characterization of slag waste coming from GICC thermal power plant. Mater. Lett. 2001, 50, 246–250. [Google Scholar] [CrossRef]

- Rosales, J.; Cabrera, M.; Beltrán, M.G.; López, M.; Agrela, F. Effects of treatments on biomass bottom ash applied to the manufacture of cement mortars. J. Clean. Prod. 2017, 154, 424–435. [Google Scholar] [CrossRef]

- Sanjuan, M.A.; Menendez, E.; Argiz, C. Evaluación de un nuevo constituyente del cemento portland: ceniza de fondo molida. Dyna Ing. E Ind. 2018, 94, 192–196. [Google Scholar] [CrossRef]

- AENOR UNE EN 933-11, Tests for Geometrical Properties of Aggregates–Part 11: Classification Test for the Constituents of Coarse Recycled Aggregate; AENOR: Madrid, Spain, 2009.

- AENOR UNE-EN 12390-3:2009. Ensayos de Hormigón Endurecido. Parte 3: Determinación de la Resistencia a Compresión de Probetas; AENOR: Madrid, Spain, 2009.

- AENOR UNE-EN 12390-7:2001 Ensayos de Hormigón Endurecido Parte 7: Densidad del Hormigón Endurecido (Testing Hardened Concrete–Part 7: Density of Hardened Concrete); AENOR: Madrid, Spain, 2001.

- AENOR UNE 83982:2008 Durabilidad del Hormigón. Métodos de Ensayo. Determinación de la Absorción de Agua por Capilaridad del Hormigón Endurecido; Método Fagerlund; AENOR: Madrid, Spain, 2008.

- AASHTO Resistance of Concrete to Chloride Ion Penetration; American Association of State Highway and Transportation Officials: Washington, WA, USA, 2009; pp. 24–26.

- Pico Cortés, C.M. Propuesta de Concreto con Agregado fino de Escoria de Cubilote como Aporte al Estudio de la Durabilidad y Propiedades Acústicas; Universidad Industrial de Santander: Bucaramanga, Colombia, 2012. [Google Scholar]

- Poon, C.S.; Shui, Z.H.; Lam, L.; Fok, H.; Kou, S.C. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Seara-Paz, S.; González-Fonteboa, B.; Martínez-Abella, F.; González-Taboada, I. Time-dependent behaviour of structural concrete made with recycled coarse aggregates. Creep and shrinkage. Constr. Build. Mater. 2016, 122, 95–109. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; de Rojas, M.I.S.; Frías, M. Influence of mixed recycled aggregate on the physical—mechanical properties of recycled concrete. J. Clean. Prod. 2014, 68, 216–225. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Guzman, A. De Estudio de las propiedades fundamentales de elementos prefabricados de hormigón no estructurales, con incorporación de áridos reciclados en su fracción gruesa y fina. (Study of the Main Properties of Non-Structural Concrete Precast Pieces Prepared with Fine and Coarse recycled aggregates); Final Master Work; Polythechnic University of Madrid: Madrid, Spain, 2010. [Google Scholar]

- Kou, S.; Poon, C.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R. Bonding in cementitious materials with asphalt-coated particles: Part I—The interfacial transition zone. Constr. Build. Mater. 2017, 130, 171–181. [Google Scholar] [CrossRef]

- Dhir, R.K.; Hewlett, P.C.; Dyer, T.D. Mechanisms of water retention in cement pastes containing a self-curing agent. Mag. Concr. Res. 1998, 50, 85–90. [Google Scholar] [CrossRef]

- El-Dieb, A.S. Self-curing concrete: Water retention, hydration and moisture transport. Constr. Build. Mater. 2007, 21, 1282–1287. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Lynn, C.J.; Dhir, R.K. Environmental impacts of the use of bottom ashes from municipal solid waste incineration: A review. Resour. Conserv. Recycl. 2019, 140, 23–35. [Google Scholar] [CrossRef]

- Jankovic, K.; Nikolic, D.; Bojovic, D. Concrete paving blocks and flags made with crushed brick as aggregate. Constr. Build. Mater. 2012, 28, 659–663. [Google Scholar] [CrossRef]

- Baroghel-Bouny, V. Water vapour sorption experiments on hardened cementitious materials. Cem. Concr. Res. 2007, 37, 414–437. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Durability related transport properties of OPC and slag cement mortars hardened under different environmental conditions. Constr. Build. Mater. 2012, 27, 176–183. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Influencia de diferentes condiciones de curado en la estructura porosa y en las propiedades a edades tempranas de morteros que contienen ceniza volante y escoria de alto horno. Mater. Constr. 2012, 63, 219–234. [Google Scholar] [CrossRef]

- Vieira, T.; Alves, A.; de Brito, J.; Correia, J.R.; Silva, R.V. Durability-related performance of concrete containing fine recycled aggregates from crushed bricks and sanitary ware. Mater. Des. 2016, 90, 767–776. [Google Scholar] [CrossRef]

- De Oliveira Andrade, J.J.; Possan, E.; Squiavon, J.Z.; Ortolan, T.L.P. Evaluation of mechanical properties and carbonation of mortars produced with construction and demolition waste. Constr. Build. Mater. 2018, 161, 70–83. [Google Scholar] [CrossRef]

- Nadesan, M.S.; Dinakar, P. Influence of type of binder on high-performance sintered fly ash lightweight aggregate concrete. Constr. Build. Mater. 2018, 176, 665–675. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem. Concr. Res. 2000, 30, 291–299. [Google Scholar] [CrossRef]

- Zornoza, E.; Payá, J.; Monzó, J.; Borrachero, M.V.; Garcés, P. The carbonation of OPC mortars partially substituted with spent fluid catalytic catalyst (FC3R) and its influence on their mechanical properties. Constr. Build. Mater. 2009, 23, 1323–1328. [Google Scholar] [CrossRef]

- Etxeberria, M.; Gonzalez-Corominas, A. The assessment of ceramic and mixed recycled aggregates for high strength and low shrinkage concretes. Mater. Struct. Constr. 2018, 51, 1–21. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Durability performance of high-performance concrete made with recycled aggregates, fly ash and densified silica fume. Cem. Concr. Compos. 2018, 93, 63–74. [Google Scholar] [CrossRef]

- Ortega, J.M.; Albaladejo, A.; Pastor, J.L.; Sánchez, I.; Climent, M.A. Influence of using slag cement on the microstructure and durability related properties of cement grouts for micropiles. Constr. Build. Mater. 2013, 38, 84–93. [Google Scholar] [CrossRef]

- ASTM C1012/C1012M-15 Standard Test Method for Length Change of Hydraulic-Cement Mortars Exposed to a Sulfate Solution. ASTM International: West Conshohocken, PA, USA, 2015; Volume 11, pp. 5–9. [CrossRef]

- Li, Y.; Wang, R.; Li, S.; Zhao, Y.; Qin, Y. Resistance of recycled aggregate concrete containing low- and high-volume fly ash against the combined action of freeze–thaw cycles and sulfate attack. Constr. Build. Mater. 2018, 166, 23–34. [Google Scholar] [CrossRef]

| Parameter | Result |

|---|---|

| Composition | |

| Clinker | 84% |

| addition | 15% |

| Physical prescriptions | |

| Initial set | 160 min |

| Final set | 200 min |

| Mechanical prescriptions | |

| 2 days | 24 MPa |

| 28 days | 49 MPa |

| Chemical Prescriptions | |

| Sulphur trioxide | 3.20% |

| Chlorides | 0.06% |

| Composition | Fly Ash | Slag |

|---|---|---|

| Na2O | 0.40 | 0.87 |

| MgO | 0.96 | 1.97 |

| Al2O3 | 29.00 | 19.23 |

| SiO2 | 55.94 | 60.23 |

| SO3 | 0.35 | 0.08 |

| K2O | 3.21 | 1.99 |

| CaO | 2.18 | 5.20 |

| Fe2O3 | 6.39 | 8.76 |

| Others | 1.53 | 1.63 |

| Mixture | Cement | Effective Water | Plasticiser Additive | GICC Fly Ash | GICC Slag | Natural Aggregates 0/4 | Natural Aggregates 5/12 | Natural Aggregates 12/25 | Recycled Aggregate 5/25 | Recycled GICC |

|---|---|---|---|---|---|---|---|---|---|---|

| (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | |

| Control | 200 | 146 | 4.16 | 1254.0 | 286.0 | 660.0 | 0.0 | |||

| C-15 | 200 | 146 | 4.16 | 1254.0 | 243.1 | 561.0 | 141.9 | |||

| C-30 | 200 | 146 | 4.16 | 1254.0 | 200.2 | 462.0 | 283.8 | |||

| M-15 | 200 | 146 | 4.16 | 1254.0 | 243.1 | 561.0 | 141.9 | |||

| M-30 | 200 | 146 | 4.16 | 1254.0 | 200.2 | 462.0 | 283.8 | |||

| RA-15 | 200 | 146 | 4.16 | 1254.0 | 243.1 | 561.0 | 141.9 | |||

| RA-30 | 200 | 146 | 4.16 | 1254.0 | 200.2 | 462.0 | 283.8 | |||

| RB-15 | 200 | 146 | 4.16 | 1254.0 | 243.1 | 561.0 | 141.9 | |||

| RB-30 | 200 | 146 | 4.16 | 1254.0 | 200.2 | 462.0 | 283.8 | |||

| R B-30- FA | 200 | 146 | 4.16 | 27.7 | 1254.0 | 200.2 | 462.0 | 283.8 | ||

| R B-30- S | 200 | 146 | 4.16 | 27.7 | 1254.0 | 200.2 | 462.0 | 283.8 | ||

| Control GICC | 220 | 152 | 3.52 | 1234.1 | 931.0 | |||||

| GA-10 | 220 | 152 | 3.52 | 1110.6 | 931.0 | 123.4 | ||||

| GA-20 | 220 | 152 | 3.52 | 987.2 | 931.0 | 246.8 | ||||

| GA-30 | 220 | 152 | 3.52 | 863.8 | 931.0 | 370.2 | ||||

| G B-10 | 220 | 152 | 3.52 | 1234.1 | 837.9 | 93.1 | ||||

| GB-30 | 220 | 152 | 3.52 | 1234.1 | 651.7 | 279.3 |

| Properties | Aggregate 0/4 mm | Aggregate 5/12 mm |

|---|---|---|

| Water absorption (%) | 0.8 | 0.9 |

| Dry surface density (g/cm3) | 2.69 | 2.71 |

| Resistance to fragmentation | - | 29 |

| Fines value (<0.063 mm) | 14 | 0 |

| Properties | Concrete Aggregate | Masonry Aggregate | Recycled Mixed agg. | Recycled Mixed agg. | GICC Fine | GICC Coarse |

|---|---|---|---|---|---|---|

| (CA) | (MA) | (RA) | (RB) | (GA) | (GB) | |

| 5/25 mm | 5/25 mm | 5/25 mm | 5/25 mm | 0/4 mm | 4/12 mm | |

| Water absorption | 5.80% | 12.90% | 2.90% | 4.70% | 6.40% | 9.00% |

| Dry surface density (g/cm3) | 2.52 | 2.22 | 2.65 | 2.54 | 2.03 | 1.56 |

| Soluble sulfates | 0.60% | 0.00% | 1.00% | 1.20% | 0.00% | 0.00% |

| Fines value (<0.063 mm) | 0% | 1% | 0% | 0% | 50% | 2% |

| Concrete Agg. | Masonry Agg. | Recycled Mixed Agg. | Recycled Mixed Agg. | |

|---|---|---|---|---|

| (CA) | (MA) | (RMA A) | (RMA B) | |

| Floating particles | - | - | 0.10% | 3.40% |

| Other | 1% | - | 5.80% | 2.40% |

| Concrete | 99% | - | 4.20% | 43.7% |

| Unbound aggregate | - | - | 86.40% | 41.40% |

| Masonry | - | 100% | 3.50% | 6.30% |

| Asphalt | - | - | 0.00% | 6.10% |

| Type | Density, g/cm3 | % Variation |

|---|---|---|

| Control | 2.35 ± 0.20 | 0 |

| CA15 | 2.15 ± 0.05 | −8.5 |

| CA30 | 2.16 ± 0.13 | −8.1 |

| MA15 | 2.26 ± 0.10 | −3.8 |

| MA30 | 2.21 ± 0.19 | −6.0 |

| RA15 | 2.26 ± 0.16 | −3.8 |

| RA30 | 2.30 ± 0.09 | −2.1 |

| RB15 | 2.15 ± 0.19 | −8.5 |

| RB30 | 2.10 ± 0.20 | −10.6 |

| RB30-FA | 2.27 ± 0.17 | −3.4 |

| RB30-SG | 2.28 ± 0.12 | −3.0 |

| Control | 2.32 ± 0.13 | 0 |

| GA 10 | 2.32 ± 0.16 | 0.0 |

| GA20 | 2.33 ± 0.04 | 0.4 |

| GA30 | 2.3 ± 0.15 | −0.9 |

| GB10 | 2.22 ± 0.09 | −4.3 |

| GB30 | 2.02 ± 0.13 | −12.9 |

| Type | K, ×10−2 kg/(m2·s0.5) | % Variation |

|---|---|---|

| Control | 2.64 ± 0.41 | 0.0 |

| C15 | 4.99 ± 0.30 | 88.8 |

| C30 | 5.55 ± 0.36 | 110.1 |

| M15 | 4.19 ± 0.24 | 58.8 |

| M30 | 4.92 ± 0.31 | 86.2 |

| RA15 | 4.74 ± 0.16 | 79.5 |

| RA30 | 5.10 ± 0.41 | 93.0 |

| RB15 | 4.83 ± 0.34 | 83.0 |

| RB30 | 5.08 ± 0.37 | 92.2 |

| RB30-FA | 2.73 ± 0.37 | 3.5 |

| RB30-SG | 2.04 ± 0.45 | −22.6 |

| Control | 2.60 ± 0.15 | 0.0 |

| GA 10 | 1.70 ± 0.17 | −34.6 |

| GA20 | 0.80 ± 0.11 | −69.2 |

| GA30 | 0.70 ± 0.11 | −73.1 |

| GB10 | 1.70 ± 0.09 | −34.6 |

| GB30 | 3.20 ± 0.15 | 23.1 |

| Type | Penetration Depth, mm | % Variation |

|---|---|---|

| Control | 36.4 ± 2.52 | 0.0 |

| CA15 | 52.6 ± 3.84 | 44.5 |

| CA30 | 61.0 ± 1.83 | 67.5 |

| MA15 | 45.9 ± 3.18 | 26.0 |

| MA30 | 69.0 ± 4.00 | 89.6 |

| RA15 | 40.2 ± 0.35 | 10.3 |

| RA30 | 42.8 ± 4.70 | 17.6 |

| RB15 | 44.5 ± 3.73 | 22.3 |

| RB30 | 47.0 ± 4.25 | 29.1 |

| RB30-FA | 26.7 ± 3.18 | −26.6 |

| RB30-SG | 27.3 ± 2.78 | −24.9 |

| Control | 47.32 ± 1.14 | 0.0 |

| GA 10 | 30.46 ± 1.57 | −35.6 |

| GA20 | 26.34 ± 2.01 | −44.3 |

| GA30 | 27.12 ± 2.88 | −42.7 |

| GB10 | 45.52 ± 1.22 | −3.8 |

| GB30 | 36.34 ± 1.77 | −23.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez, C.; Sánchez, I.; Miñano, I.; Benito, F.; Cabeza, M.; Parra, C. On the Possibility of Using Recycled Mixed Aggregates and GICC Thermal Plant Wastes in Non-Structural Concrete Elements. Sustainability 2019, 11, 633. https://doi.org/10.3390/su11030633

Rodríguez C, Sánchez I, Miñano I, Benito F, Cabeza M, Parra C. On the Possibility of Using Recycled Mixed Aggregates and GICC Thermal Plant Wastes in Non-Structural Concrete Elements. Sustainability. 2019; 11(3):633. https://doi.org/10.3390/su11030633

Chicago/Turabian StyleRodríguez, Carlos, Isidro Sánchez, Isabel Miñano, Francisco Benito, Marta Cabeza, and Carlos Parra. 2019. "On the Possibility of Using Recycled Mixed Aggregates and GICC Thermal Plant Wastes in Non-Structural Concrete Elements" Sustainability 11, no. 3: 633. https://doi.org/10.3390/su11030633

APA StyleRodríguez, C., Sánchez, I., Miñano, I., Benito, F., Cabeza, M., & Parra, C. (2019). On the Possibility of Using Recycled Mixed Aggregates and GICC Thermal Plant Wastes in Non-Structural Concrete Elements. Sustainability, 11(3), 633. https://doi.org/10.3390/su11030633