An Integrated Multi-Attribute Model for Evaluation of Sustainable Mobile Phone

Abstract

:1. Introduction

2. Review of the Literature and Contribution

2.1. The Studies on Importance of Mobile Phone Selection Factors According to Customer’s Attitude

- In order to extract metals for these devices, miners in isolated areas perform life-threatening work, often stimulating armed conflicts in countries like the Democratic Republic of the Congo (DRC) and destroying the land;

- Damage to the health of workers in electronic factories that are exposed to hazardous chemicals without their knowledge;

- Increasing device complexity means greater amounts of energy is required to produce each phone which in turns increases demand for coal and other forms of dirty energy in China and other parts of Asia;

- Insufficient product take-back and reuse of materials further contribute to a rapidly growing e-waste stream.

2.2. History of Decision-Making Tools in Application of Mobile Phone Selection

3. Materials and Methods

3.1. DEMATEL Method

3.2. Analytical Hierarchy Process

3.3. Best Worst Method

4. Case Definition, Model Implementation, and Results

4.1. Case of Mobile Phone Sustainable Factors Evaluation

4.2. Results and Discussion

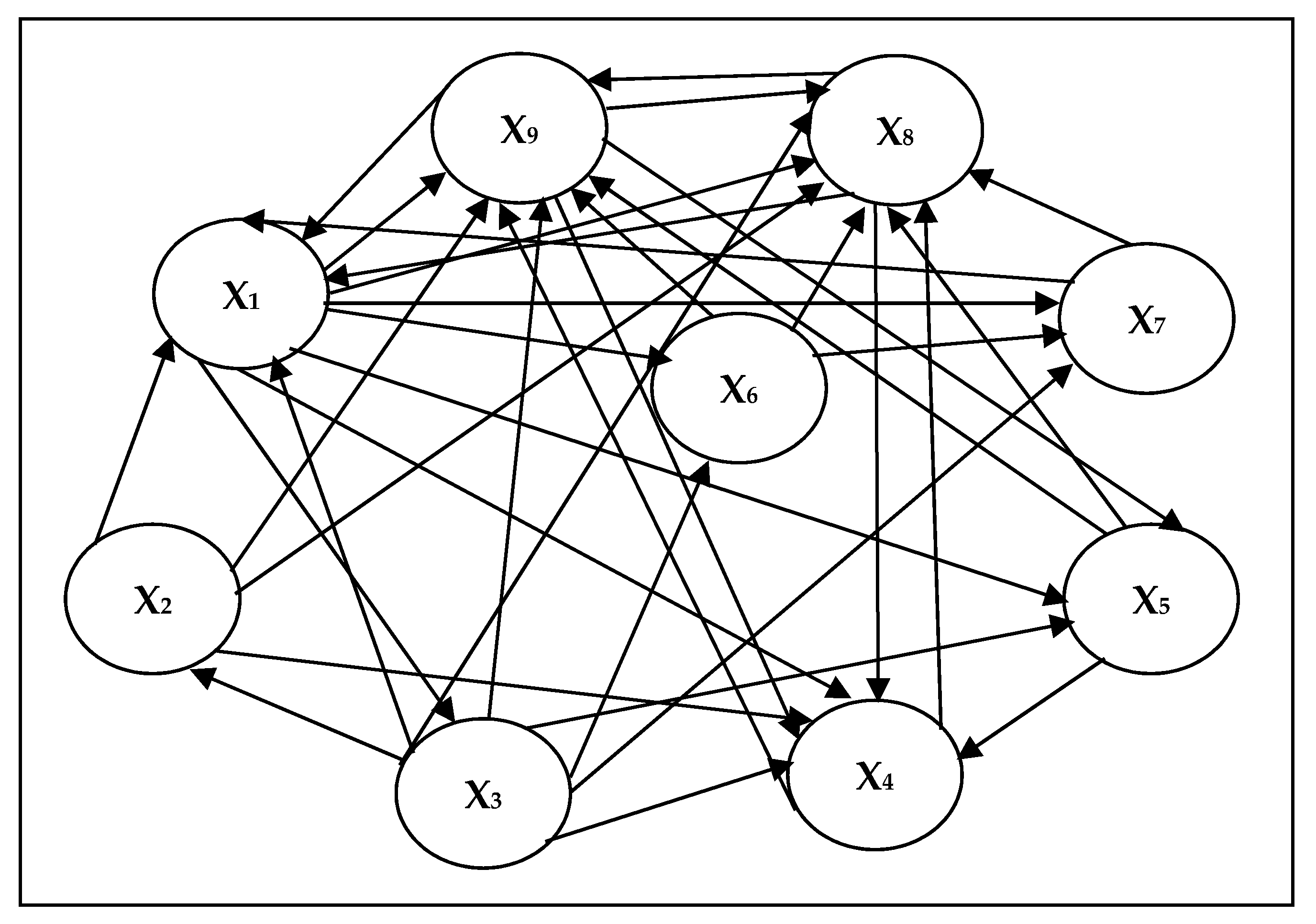

4.2.1. DEMATEL Implementation

4.2.2. Implementation of AHP

4.2.3. Implementation of the Best-Worst Method

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Indicator | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 |

|---|---|---|---|---|---|---|---|---|---|

| X1 | 0 | 2 | 3.33 | 3.89 | 2.67 | 4 | 3.67 | 4 | 1 |

| X2 | 4 | 0 | 3 | 3.33 | 0 | 0 | 0 | 1 | 3.67 |

| X3 | 3 | 2 | 0 | 4 | 4 | 3 | 3 | 4 | 4 |

| X4 | 2 | 1 | 2 | 0 | 1 | 0 | 0 | 3.67 | 4 |

| X5 | 2 | 3.33 | 1.89 | 3 | 0 | 0 | 0 | 4 | 1 |

| X6 | 4 | 0 | 2.67 | 3 | 0 | 0 | 4 | 4 | 2.67 |

| X7 | 3 | 0 | 2.67 | 0 | 0 | 3 | 0 | 3 | 2 |

| X8 | 1.83 | 1 | 2 | 1.9 | 2 | 2 | 2 | 0 | 3.89 |

| X9 | 4 | 1.83 | 1 | 3.23 | 3.89 | 0 | 0 | 3.67 | 0 |

| Indicator | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 |

|---|---|---|---|---|---|---|---|---|---|

| X1 | 0 | 0.0732 | 0.1218 | 0.1423 | 0.0977 | 0.1463 | 0.1342 | 0.1463 | 0.0366 |

| X2 | 0.1463 | 0 | 0.1097 | 0.1218 | 0 | 0 | 0 | 0.0366 | 0.1342 |

| X3 | 0.1097 | 0.0732 | 0 | 0.1463 | 0.1463 | 0.1097 | 0.1097 | 0.1463 | 0.1463 |

| X4 | 0.0732 | 0.0366 | 0.0732 | 0 | 0.0366 | 0 | 0 | 0.1342 | 0.1463 |

| X5 | 0.0732 | 0.1218 | 0.0691 | 0.1097 | 0 | 0 | 0 | 0.1463 | 0.0366 |

| X6 | 0 | 0 | 0 | 0 | 0 | 0 | 0.146 | 0.146 | 0.098 |

| X7 | 0.11 | 0 | 0.098 | 0 | 0 | 0.11 | 0 | 0.11 | 0.073 |

| X8 | 0.07 | 0.037 | 0.073 | 0.0690 | 0.0730 | 0.073 | 0.073 | 0 | 0.142 |

| X9 | 0.146 | 0.067 | 0.037 | 0.1180 | 0.1420 | 0 | 0 | 0.134 | 0 |

| Indicator | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 | D |

|---|---|---|---|---|---|---|---|---|---|---|

| X1 | 0.2514 | 0.1945 | 0.315 | 0.371 | 0.2550 | 0.2796 | 0.2752 | 0.4335 | 0.2907 | 2.666 |

| X2 | 0.2998 | 0.0938 | 0.2339 | 0.2863 | 0.1327 | 0.0978 | 0.0978 | 0.2399 | 0.2896 | 1.772 |

| X3 | 0.37 | 0.2128 | 0.2165 | 0.3977 | 0.3188 | 0.2489 | 0.253 | 0.4575 | 0.3978 | 2.873 |

| X4 | 0.2149 | 0.1193 | 0.1821 | 0.1514 | 0.1515 | 0.0823 | 0.0827 | 0.298 | 0.281 | 1.563 |

| X5 | 0.2237 | 0.2004 | 0.1925 | 0.2616 | 0.1114 | 0.0865 | 0.0869 | 0.3152 | 0.2018 | 1.68 |

| X6 | 0 | 0 | 0 | 0 | 0 | 0 | 0.271 | 0.394 | 0.304 | 2.291 |

| X7 | 0.26 | 0.081 | 0.219 | 0.161 | 0.1170 | 0.205 | 0 | 0.294 | 0.223 | 1.67 |

| X8 | 0.241 | 0.13 | 0.207 | 0.239 | 0.1940 | 0.165 | 0.168 | 0 | 0.3 | 1.857 |

| X9 | 0.306 | 0.169 | 0.183 | 0.294 | 0.2600 | 0.101 | 0.101 | 0.339 | 0 | 1.932 |

| R | 2.5137 | 1.3105 | 2.0135 | 2.4686 | 1.695 | 1.404 | 1.4457 | 2.985 | 2.466 |

| Indicator | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 | Local Weight (Wj) |

|---|---|---|---|---|---|---|---|---|---|---|

| X1 | 0.281 | 0.166 | 0.371 | 0.17 | 0.253 | 0.311 | 0.294 | 0.15 | 0.227 | 0.247 |

| X2 | 0.031 | 0.018 | 0.046 | 0.004 | 0.014 | 0.021 | 0.012 | 0.008 | 0.014 | 0.019 |

| X3 | 0.14 | 0.074 | 0.185 | 0.198 | 0.379 | 0.207 | 0.176 | 0.150 | 0.171 | 0.187 |

| X4 | 0.047 | 0.148 | 0.026 | 0.028 | 0.018 | 0.021 | 0.029 | 0.019 | 0.019 | 0.039 |

| X5 | 0.14 | 0.168 | 0.062 | 0.203 | 0.126 | 0.207 | 0.176 | 0.225 | 0.114 | 0.158 |

| X6 | 0.094 | 0.092 | 0.093 | 0.142 | 0.063 | 0.104 | 0.117 | 0.299 | 0.114 | 0.124 |

| X7 | 0.056 | 0.092 | 0.062 | 0.057 | 0.042 | 0.052 | 0.059 | 0.037 | 0.171 | 0.07 |

| X8 | 0.14 | 0.166 | 0.093 | 0.113 | 0.042 | 0.026 | 0.117 | 0.075 | 0.114 | 0.099 |

| X9 | 0.07 | 0.074 | 0.062 | 0.085 | 0.063 | 0.052 | 0.02 | 0.037 | 0.057 | 0.058 |

| (A) × (Wj) | (A) × (Wj)/Wi | CI | RI | CR | ||

|---|---|---|---|---|---|---|

| 2.491 | 10.087 | 10.120 | 0 | 0.140 | 1.460 | 0.090 |

| 0.179 | 9.579 | |||||

| 1.963 | 10.51 | |||||

| 0.383 | 9.704 | |||||

| 1.664 | 10.543 | |||||

| 1.319 | 10.618 | |||||

| 0.691 | 9.909 | |||||

| 0.98 | 9.948 | |||||

| 0.588 | 10.189 |

References

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Tavana, M.; Yazdani, M.; Di Caprio, D. An application of an integrated ANP–QFD framework for sustainable supplier selection. Int. J. Logist. Res. Appl. 2017, 20, 254–275. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. An analysis of metrics used to measure performance in green and sustainable supply chains. J. Clean. Prod. 2015, 86, 360–377. [Google Scholar] [CrossRef]

- Tajbakhsh, A.; Hassini, E. Performance measurement of sustainable supply chains: A review and research questions. Int. J. Product. Perform. Manag. 2015, 64, 744–783. [Google Scholar] [CrossRef]

- Coskun, S.; Ozgur, L.; Polat, O.; Gungor, A. A model proposal for green supply chain network design based on consumer segmentation. J. Clean. Prod. 2016, 110, 149–157. [Google Scholar] [CrossRef]

- Bask, A.; Halme, M.; Kuula, M. Capturing the sustainability features that most affect consumer evaluations case: Mobile phones. Supply Chain Forum Int. J. 2018, 19, 311–330. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, Y.; Yeh, C.H.; Liu, Y.; Zhou, D. City sustainability evaluation using multi-criteria decision making with objective weights of interdependent criteria. J. Clean. Prod. 2016, 131, 491–499. [Google Scholar] [CrossRef]

- Yazdani, M.; Zarate, P.; Kazimieras Zavadskas, E.; Turskis, Z. A Combined Compromise Solution (CoCoSo) method for multi-criteria decision-making problems. Manag. Decis. 2018. [Google Scholar] [CrossRef]

- Mulliner, E.; Malys, N.; Maliene, V. Comparative analysis of MCDM methods for the assessment of sustainable housing affordability. Omega 2016, 59, 146–156. [Google Scholar] [CrossRef]

- Behzadian, M.; Otaghsara, S.K.; Yazdani, M.; Ignatius, J. A state-of the-art survey of TOPSIS applications. Expert Syst. Appl. 2012, 39, 13051–13069. [Google Scholar] [CrossRef]

- Kuo, T. A modified TOPSIS with a different ranking index. Eur. J. Oper. Res. 2017, 260, 152–160. [Google Scholar] [CrossRef]

- Sajedi-Hosseini, F.; Choubin, B.; Solaimani, K.; Cerdà, A.; Kavian, A. Spatial prediction of soil erosion susceptibility using a fuzzy analytical network process: Application of the fuzzy decision making trial and evaluation laboratory approach. Land Degrad. Dev. 2018, 29, 3092–3103. [Google Scholar] [CrossRef]

- Statista. 2019. Available online: https://www.statista.com/ (accessed on 24 March 2019).

- Counter Point Research. Available online: https://www.counterpointresearch.com/ (accessed on 4 February 2019).

- Zadok, G.; Puustinen, R. The Green Switch: Designing for Sustainability in Mobile Computing. In Proceedings of the First USENIX Sustainable IT Workshop (Sustain IT 2010), San Jose, CA, USA, 22 February 2010. [Google Scholar]

- Jardim, E. From Smart to Senseless: The Global Impact of 10 Years of Smart Phones; Greenpeace Inc.: Washington, DC, USA, 2017. [Google Scholar]

- Bask, A.; Halme, M.; Kallio, M.; Kuula, M. Consumer preferences for sustainability and their impact on supply chain management: The case of mobile phones. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 380–406. [Google Scholar] [CrossRef]

- Hu, S.K.; Lu, M.T.; Tzeng, G.H. Exploring smart phone improvements based on a hybrid MCDM model. Expert Syst. Appl. 2014, 41, 4401–4413. [Google Scholar] [CrossRef]

- Petruzzellis, L. Mobile phone choice: Technology versus marketing. The brand effect in the Italian market. Eur. J. Mark. 2010, 44, 610–634. [Google Scholar] [CrossRef]

- Roberts, J.A. Profiling levels of Socially Responsible Consumer Behavior: A cluster analytic approach and its implications for Marketing, Journal of Marketing. Theory Pract. 1995, 3, 97. [Google Scholar] [CrossRef]

- Francois-Lecompte, A.; Roberts, J.A. Developing a measure of socially responsible consumption in France. Mark. Manag. J. 2006, 16, 50–66. [Google Scholar]

- Webb, D.; Mohr, L.A.; Harris, K.E. A re-examination of socially responsible consumption and its measurements. J. Bus. Res. 2008, 61, 91–98. [Google Scholar] [CrossRef]

- Perez-Barea, J.J.; Montero-Simo, M.J.; Araque-Padilla, R. Measurement of socially responsible consumption: Lecompte’s Scale Spanish version validation. Int. Rev. Public Non-Profit Mark. 2015, 12, 37–61. [Google Scholar] [CrossRef]

- Srivastava, A.; Majumdar, R.; Tyagi, V.; Choudhary, S.; Choudhary, M. Comparison between Smart phones on the basis of their reliability factors. In Proceedings of the International Conference on Infocom Technologies and Unmanned Systems (Trends and Future Directions) (ICTUS), Dubai, UAE, 18–20 December 2017. [Google Scholar]

- Yildiz, A.; Ergul, E.U. A two-phased multi-criteria decision-making approach for selecting the best smartphone. S. Afr. J. Ind. Eng. 2015, 26, 194–215. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Güleryüz, S. Multi criteria group decision making approach for smart phone selection using intuitionistic fuzzy TOPSIS. Int. J. Comput. Intell. Syst. 2016, 9, 709–725. [Google Scholar] [CrossRef]

- Saket, S.; Purbey, V.; Ray, A. Multi attribute decision making for mobile phone selection. Int. J. Res. Eng. Technol. 2014, 3, 498–501. [Google Scholar]

- Cerit, B.; Küçükyazıcı, G.; Kalem, G. Quality function deployment and its application on a smartphone design. Sci. Comm. 2014, 2, 87. [Google Scholar]

- Akyene, T. Cell phone evaluation base on entropy and TOPSIS. Interdiscip. J. Res. Bus. 2012, 1, 9–15. [Google Scholar]

- Ondrus, J.; Bui, T.; Pigneur, Y.A. Multi-Actor, Multi-Criteria Approach for Technology Selection When Designing Mobile Information Systems. In Mobile Information Systems II; Krogstie, J., Kautz, K., Allen, D., Eds.; Springer: New York, NY, USA, 2010; pp. 271–278. [Google Scholar]

- Chen, Y.F.; Chen, B.C.; Chen, W.Y.; Tsai, C.W.; Lin, W.H. Optimal Strategy for the Smartphone Industry in Taiwan: HTC Case Study. Int. J. Intell. Inf. Technol. 2012, 8, 62–79. [Google Scholar] [CrossRef]

- Asghari, F.; Amidian, A.A.; Muhammadi, J.; Rabiee, H. A fuzzy ELECTRE approach for evaluating mobile payment business models. In Proceedings of the IEEE International Conference on Management of e-Commerce and e-Government, Chengdu, China, 23–24 October 2010; pp. 351–355. [Google Scholar]

- Mahdavi, I.; Fazlollahtabar, H.; Mozaffari, E.; Heidari, M.; Mahdavi-Amiri, N. Data envelopment analysis based comparison of two hybrid multi-criteria decision-making approaches for mobile phone selection: A case study in Iranian telecommunication environment. Int. J. Inf. Decis. Sci. 2008, 1, 194–220. [Google Scholar] [CrossRef]

- Işıklar, G.; Büyüközkan, G. Using a multi-criteria decision making approach to evaluate mobile phone alternatives. Comput. Stand. Interfaces 2007, 29, 265–274. [Google Scholar] [CrossRef]

- Hendrianto, J.; Setyawan, B.; Kusumawardhany, P.A. Sustainability Supply Chain Management On Mobile Phone Features According To Consumer Preferences In Surabaya. In Proceedings of the 12th INSYMA International Annual Symposium on Management, Makassar, South Sulawesi, Indonesia, 13–15 March 2015. [Google Scholar]

- Paiano, A.; Lagioia, G.; Cataldo, A. A critical analysis of the sustainability of mobile phone use. Resour. Conserv. Recycl. 2013, 73, 162–171. [Google Scholar] [CrossRef]

- Bryce, W. Encouraging Sustainable Consumption through product lifetime extension: The case of mobile phones. Int. J. Bus. Soc. Sci. 2012, 3, 17–32. [Google Scholar]

- Wilhelm, W.; Yankov, A.; Magee, P. Mobile phone consumption behavior and the need for sustainability innovations. J. Strateg. Innov. Sustain. 2011, 7, 20–40. [Google Scholar]

- Huang, E.M.; Truong, K.N. Breaking the disposable technology paradigm: Opportunities for sustainable interaction design for mobile phones. In Proceedings of the Conference on Human Factors in Computing Systems, Florence, Italy, 5–10 April 2008. [Google Scholar]

- Zavadskas, E.K.; Turskis, Z.; Kildienė, S. State of art surveys of overviews on MCDM/MADM methods. Technol. Econ. Dev. Econ. 2014, 20, 165–179. [Google Scholar] [CrossRef]

- Rezaei, J. Best-worst multi-criteria decision-making method. Omega 2015, 53, 49–57. [Google Scholar] [CrossRef]

- Keshavarz-Ghorabaee, M.; Amiri, M.; Zavadskas, E.K.; Turskis, Z.; Antucheviciene, J. Simultaneous evaluation of criteria and alternatives (SECA) for multi-criteria decision-making. Informatica 2018, 29, 265–280. [Google Scholar] [CrossRef]

- Aggarwal, A.; Choudhary, C.; Mehrotra, D. Evaluation of smart phones in Indian market using EDAS. Procedia Comput. Sci. 2018, 132, 236–243. [Google Scholar] [CrossRef]

- Lebeau, P.; Macharis, C.; Van Mierlo, J. Exploring the choice of battery electric vehicles in city logistics: A conjoint-based choice analysis. Transp. Res. Part E Logist. Transp. Rev. 2016, 91, 245–258. [Google Scholar] [CrossRef]

- Ranjan, R.; Chatterjee, P.; Chakraborty, S. Performance evaluation of Indian Railway zones using DEMATEL and VIKOR methods. Benchmark. Int. J. 2016, 23, 78–95. [Google Scholar] [CrossRef]

- Yazdani, M.; Chatterjee, P.; Zavadskas, E.K.; Zolfani, S.H. Integrated QFD-MCDM framework for green supplier selection. J. Clean. Prod. 2017, 142, 3728–3740. [Google Scholar] [CrossRef]

- Kaur, J.; Sidhu, R.; Awasthi, A.; Chauhan, S.; Goyal, S. A DEMATEL based approach for investigating barriers in green supply chain management in Canadian manufacturing firms. Int. J. Prod. Res. 2018, 56, 312–332. [Google Scholar] [CrossRef]

- Berrittella, M.; Certa, A.; Enea, M.; Zito, P. Analytic hierarchy process for the evaluation of transport policies to reduce climate change impacts. SSRN Electron. J. 2007. [Google Scholar] [CrossRef]

- Wu, H.Y.; Chen, J.K.; Chen, I.S.; Zhuo, H.H. Ranking universities based on performance evaluation by a hybrid MCDM model. Measurement 2012, 45, 856–880. [Google Scholar] [CrossRef]

- Thanki, S.; Govindan, K.; Thakkar, J. An investigation on lean-green implementation practices in Indian SMEs using analytical hierarchy process (AHP) approach. J. Clean. Prod. 2016, 135, 284–298. [Google Scholar] [CrossRef]

- Yazdi, M. An extension of the fuzzy improved risk graph and fuzzy analytical hierarchy process for determination of chemical complex safety integrity levels. Int. J. Occup. Saf. Ergon. 2008, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Wind, Y.; Saaty, T.L. Marketing applications of the analytic hierarchy process. Manag. Sci. 1980, 26, 641–658. [Google Scholar] [CrossRef]

- Van de Kaa, G.; Scholten, D.; Rezaei, J.; Milchram, C. The battle between battery and fuel cell powered electric vehicles: A BWM approach. Energies 2017, 10, 1707. [Google Scholar] [CrossRef]

- Chitsaz, N.; Azarnivand, A. Water scarcity management in arid regions based on an extended multiple criteria technique. Water Resour. Manag. 2017, 31, 233–250. [Google Scholar] [CrossRef]

- Rezaei, J.; Nispeling, T.; Sarkis, J.; Tavasszy, L. A supplier selection life cycle approach integrating traditional and environmental criteria using the best worst method. J. Clean. Prod. 2016, 135, 577–588. [Google Scholar] [CrossRef]

- Rezaei, J.; Wang, J.; Tavasszy, L. Linking supplier development to supplier segmentation using Best Worst Method. Expert Syst. Appl. 2015, 42, 9152–9164. [Google Scholar] [CrossRef]

- Ahmadi, H.B.; Kusi-Sarpong, S.; Rezaei, J. Assessing the social sustainability of supply chains using Best Worst Method. Resour. Conserv. Recycl. 2017, 126, 99–106. [Google Scholar] [CrossRef]

- Gupta, H. Evaluating service quality of airline industry using hybrid best worst method and VIKOR. J. Air Transp. Manag. 2018, 68, 35–47. [Google Scholar] [CrossRef]

- Chen, C.F. Applying the analytical hierarchy process (AHP) approach to convention site selection. J. Travel Res. 2006, 45, 167–174. [Google Scholar] [CrossRef]

| Factors | Indicators | Description |

|---|---|---|

| Sustainable strategy and policy (F1) | X1—A structural sustainable impact-assessment tool is in place | Has a sustainable management system (ISO, EMS, and AA1000), publishes corporate social responsibility report, informs consumers about actions that support sustainable development, participates in global sustainable development initiatives |

| X2—Working conditions follows common ethical principles | Equal pay for equal work and fair remuneration, health and safety at work, increase the commitment of workers and promote dialogue between workers and management, provide managers with the necessary skills to improve both employment practices and health and safety | |

| X3—Cooperative efforts with a non-profit organization for mutual benefit | Part of the profits obtained with the sale of telephones are delivered for good causes, manufacturer makes donations to good causes | |

| Sustainable product design (F2) | X4—Sustainable material usage and preparedness for recycling | Renewable resources, energy efficient as possible, the origin of the pieces that compose it is traced looking for materials that are good for people and for the planet, recycling and disassembly are taken into account |

| X5—Management of hazardous materials | Imposes more stringent requirements with regard to hazardous materials than regulations demand, uses a third-party certified analytical tool in the product-design phase in reporting this | |

| X6—Extended life-cycle | Design for reliability and robustness, seek for extension of service life by focusing on modularity and ease of repair, possibilities of upgrade, update or modify it according to user’s need, mobile phone compatible in the long term, repair cost lower than replacement costs, repair themselves/easy repairs, offers incentives to keep currents phone | |

| Sustainable sourcing (F3) | X7—Sustainable Package and delivery management | Sustainability should be taken into account in the selection of transportation mode and materials, the product packaging should be as efficient as possible |

| X8—Selecting sustainable suppliers | Purchase of materials from mines that empower vulnerable communities or that have better sustainable performance, has a certified tool in use for evaluating the sustainability of suppliers, trains its suppliers, shares information, audits its suppliers, has clear instructions | |

| Sustainable end-of-life-management-disposal (F4) | X9—Move towards a circular economy with better recycling of electronic devices | Collection of old telephones for reuse and recycling, encourage the disposal of primary, physical material, persuade consumers that refurbished or second-hand mobile are “cool” |

| Author | MCDM Method | Objective |

|---|---|---|

| Isiklar and Büyüközkan, 2006 [34] | AHP, TOPSIS | Evaluate the mobile phone options with respect to the users’ preferences order |

| Mahdavi et al. 2008 [33] | AHP-ENTROPY-TOPSIS | Right selection of phone mobile fitting to the preferences of the users |

| Pigneur, Ondrus and Bui, 2010 [30] | ELECTRE | Assessing the mobile payment market |

| Chen et al. 2012 [31] | AHP | Mobile phone recommendation system for online stores and consumers |

| Akyene, 2012 [29] | Entropy, TOPSIS | Aid customer in selecting which mobile phone to purchase |

| Saket et al. 2014 [27] | QFD | Selection of appropriate mobile to the customers |

| Cerit, Küçükyazici and Kalem, 2014 [28] | QFD | New product development in accordance with customer expectation |

| Hu, Lu and Tzeng, 2014 [18] | DEMATEL-Based ANP, VIKOR | Provide useful information to enterprises regarding how to optimally satisfy customer needs |

| Yildiz and Ergul, 2015 [25] | ANP, GCI | The best smartphone selection for consumers |

| Büyüközkan and Güleryüz, 2016 [26] | IF-TOPSIS | Ranking appropriate mobile phone alternatives for consumers |

| Srivastava et al. 2017 [24] | AHP | Comparison between smartphones on the basis of their reliability factors for consumers |

| Intensity of Importance | Definition |

|---|---|

| 1 | Equally important |

| 3 | Moderately important |

| 5 | Strongly more important |

| 7 | Very strong important |

| 9 | Extremely more important |

| 2,4,6,8 | Intermediate more important |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

|---|---|---|---|---|---|---|---|---|---|

| CI | 0.00 | 0.44 | 1.00 | 1.63 | 2.30 | 3.00 | 3.73 | 4.47 | 5.23 |

| (19) | |||||||||

| Factors with Local Weight (FLW) | Indicator | D + R | D − R | Local Weight of Indicator (ILW) | (FLW) × (ILW) | Normalized Global Weight | Group | Rank |

|---|---|---|---|---|---|---|---|---|

| F1 (0.25) | X1 | 5.1797 | 0.1524 | 0.1410 | 0.0353 | 0.1414 | Cause | 1 |

| X2 | 3.0821 | 0.4612 | 0.0840 | 0.0210 | 0.0841 | Cause | 9 | |

| X3 | 4.8867 | 0.8596 | 0.1330 | 0.0333 | 0.1334 | Cause | 2 | |

| F2 (0.245) | X4 | 4.0320 | −0.9052 | 0.1100 | 0.0269 | 0.1079 | Effect | 5 |

| X5 | 3.3757 | −0.0156 | 0.0920 | 0.0225 | 0.0903 | Effect | 7 | |

| X6 | 3.6954 | 0.8862 | 0.1010 | 0.0247 | 0.0989 | Cause | 6 | |

| F3 (0.275) | X7 | 3.1153 | 0.2239 | 0.0850 | 0.0221 | 0.0884 | Cause | 8 |

| X8 | 4.8423 | −1.1276 | 0.1320 | 0.0343 | 0.1375 | Effect | 3 | |

| F4 (0.245) | X9 | 4.3979 | −0.5348 | 0.1200 | 0.0294 | 0.1177 | Effect | 4 |

| Indicator | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 |

|---|---|---|---|---|---|---|---|---|---|

| X1 | 1 | 9 | 2 | 6 | 2 | 3 | 5 | 2 | 4 |

| X2 | 1/9 | 1 | 1/4 | 1/8 | 1/9 | 1/5 | 1/5 | 1/9 | 1/4 |

| X3 | 1/2 | 4 | 1 | 7 | 3 | 2 | 3 | 2 | 3 |

| X4 | 1/6 | 8 | 1/7 | 1 | 1/7 | 1/5 | 1/2 | 1/4 | 1/3 |

| X5 | 1/2 | 9 | 1/3 | 7 | 1 | 2 | 3 | 3 | 2 |

| X6 | 1/3 | 5 | 1/2 | 5 | 1/2 | 1 | 2 | 4 | 2 |

| X7 | 1/5 | 5 | 1/3 | 2 | 1/3 | 1/2 | 1 | 0,5 | 3 |

| X8 | 1/2 | 9 | 1/2 | 4 | 1/3 | 1/4 | 2 | 1 | 2 |

| X9 | 1/4 | 4 | 1/3 | 3 | 1/2 | 1/2 | 1/3 | 1/2 | 1 |

| Sum | 3.5611 | 54.091 | 5.3929 | 35.268 | 7.9167 | 9.65 | 17.033 | 13.361 | 17.583 |

| Factors with Local Weight (FLW) | Sub-Factor | (FLW) × (Wj) | Global Weight | Ranking |

|---|---|---|---|---|

| F1 (0.3319) | X1 | 0.08196 | 0.24694 | 1 |

| X2 | 0.00621 | 0.01872 | 9 | |

| X3 | 0.06199 | 0.18677 | 2 | |

| F2 (0.1949) | X4 | 0.01309 | 0.03944 | 8 |

| X5 | 0.05239 | 0.15787 | 3 | |

| X6 | 0.04122 | 0.12421 | 4 | |

| F3 (0.29) | X7 | 0.02315 | 0.06975 | 6 |

| X8 | 0.03271 | 0.09855 | 5 | |

| F4 (0.1832) | X9 | 0.01917 | 0.05776 | 7 |

| Best to Others | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 |

| X1 | 1 | 9 | 2 | 6 | 2 | 3 | 5 | 2 | 4 |

| Others to the Worst | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 |

| X2 | 1/9 | 1 | 1/4 | 1/8 | 1/9 | 1/5 | 1/5 | 1/9 | 1/4 |

| Weights | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 |

|---|---|---|---|---|---|---|---|---|---|

| 0.231 | 0.027 | 0.152 | 0.051 | 0.152 | 0.101 | 0.061 | 0.152 | 0.076 | |

| (CR) | 0.0719 | ||||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yazdani, M.; Chatterjee, P.; Montero-Simo, M.J.; Araque-Padilla, R.A. An Integrated Multi-Attribute Model for Evaluation of Sustainable Mobile Phone. Sustainability 2019, 11, 3704. https://doi.org/10.3390/su11133704

Yazdani M, Chatterjee P, Montero-Simo MJ, Araque-Padilla RA. An Integrated Multi-Attribute Model for Evaluation of Sustainable Mobile Phone. Sustainability. 2019; 11(13):3704. https://doi.org/10.3390/su11133704

Chicago/Turabian StyleYazdani, Morteza, Prasenjit Chatterjee, Maria Jose Montero-Simo, and Rafael A. Araque-Padilla. 2019. "An Integrated Multi-Attribute Model for Evaluation of Sustainable Mobile Phone" Sustainability 11, no. 13: 3704. https://doi.org/10.3390/su11133704