An Improved Scheduling Approach for Minimizing Total Energy Consumption and Makespan in a Flexible Job Shop Environment

Abstract

1. Introduction

2. Literature Review

3. Energy-Efficient Flexible Job Shop Scheduling Model

3.1. Energy-Efficient Mechanism

3.2. Problem Statement and Model Hypothesis

- (1)

- Jobs are mutually independent and there is no priority difference for them.

- (2)

- Each machine cannot process more than one job at a time, and job pre-emption or cancellation is forbidden once processing starts.

- (3)

- Each job contains sequential operations, and each operation can only be executed on one machine in actual production. When an operation of a job, not the terminal operation, ends, such a job is immediately transported to the machine arranged for its next operation, i.e., without regard for batch transportation.

- (4)

- Transportation time varies with the different machines selected for pre- and post-operation of a job, and it is only related to transportation distance. In particular, transportation time is considered as zero under the condition that a machine processes two adjacent operations of a job.

- (5)

- Input buffer of each machine is unlimited. The initial position of each job is the machine executing its first operation, and the ending position is the machine performing its last operation, i.e., transportation is not needed for the first and the last operations of each job.

- (6)

- The processing time of an operation is composed of machining time and auxiliary time (e.g., clamping, inspection and cleaning times).

- (7)

- Each operation on the selected NC machine is executed according to the fixed NC programs.

- (8)

- All jobs are simultaneously available at time zero, and breakdown is not considered.

- (9)

- Total production EC is evaluated with makespan as time boundary.

- (10)

- The energy-efficient mechanism is adopted, and the warm-up operation is neglected.

3.3. Mathematical Model

4. Model Solution Based on Non-Dominated Sorting Genetic Algorithm-II(NSGA-II)

4.1. Encoding Scheme

4.2. Decoding Scheme

| Step 1 | Acquire the values of Xijk and by Constraint (10) and the encoding schema. |

| Step 2 | Analyze the genes successively, and determine the value of Sij. For the gene (i, k) representing Oij, ASij is non-negative, and based on Constraints (14) and (15), , k, q:, . Check the operations performed on machine k that have already been analyzed and obtain all idle ranges [IT_S, IT_E]. Then, check each idle interval [IT_S, IT_E] successively, if max{ASij, IT_S} + TPijk ≤ IT_E, Sij = IT_S and the value of related should be changed according to new order; otherwise, check next idle range. When Oij cannot be inserted into any idle range, Sij will take the maximum of ASij and the end time of the immediate predecessor of Oij on machine k according to Constraint (12) along with (13). |

| Step 3 | Determine the value of Cij. According to Constraint (11), Cij = Sij + TPijk. If the genetic analysis is not finished, turn to Step 2. |

| Step 4 | Combined with the obtained values of decision variables, Tmakespan can be determined by Formula (2) and Etotal can be calculated by Formulae (3) and (4), (6)–(8). |

4.3. Initial Population

4.4. Non-Dominated Sorting

4.5. Crowding Distance Sorting

4.6. Genetic Operators

5. Experiments

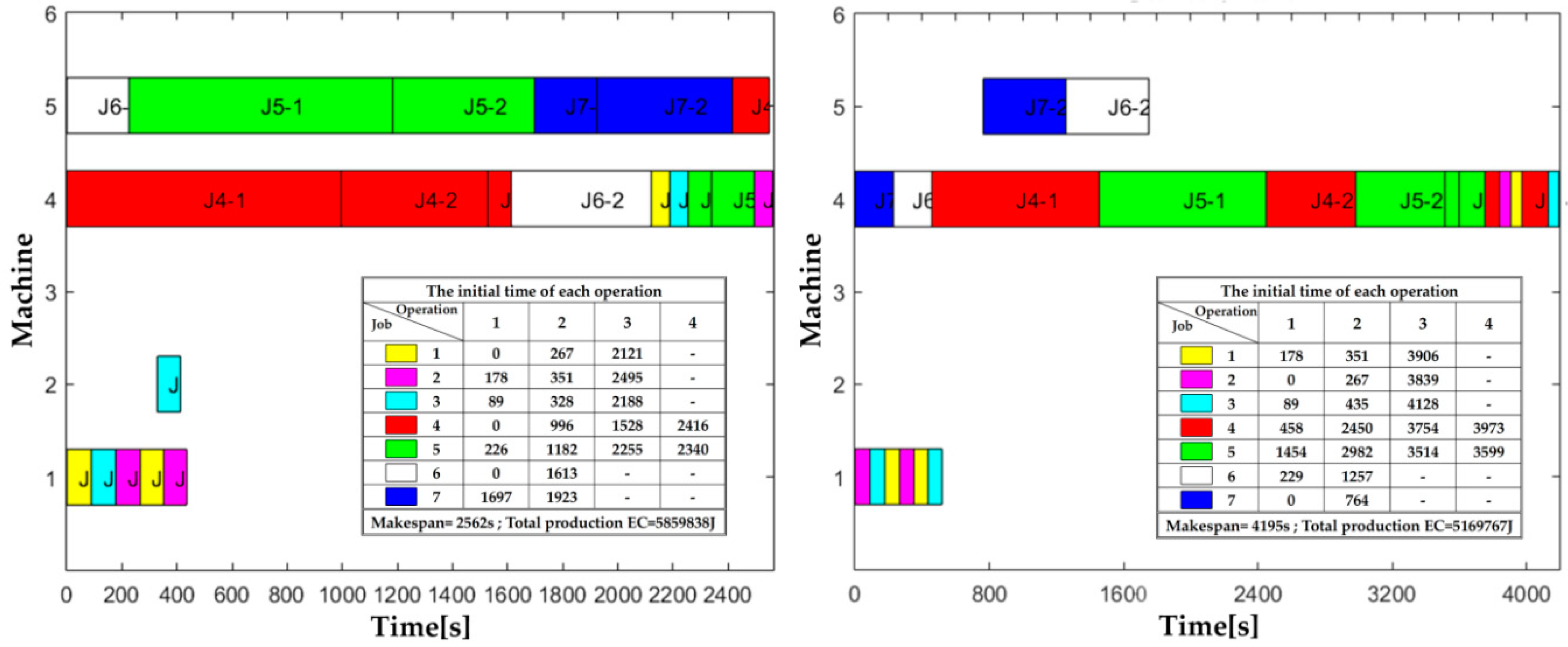

5.1. Experiment 1

5.2. Experiment 2

5.3. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| ACO | Ant Colony Optimization |

| ASij | The allowable earliest starting time of Oij |

| Cij | The completion time of Oij |

| The completion time of Oij which is the lth operation performed on machine k [s] | |

| The Setup operation energy consumption of machine k [J] | |

| EC | Energy consumption |

| EFJSS | Energy-efficient flexible job shop scheduling |

| EIk | The total idle energy consumption of machine k [J] |

| The EC of idle period after the lth operation performed on machine k [J] | |

| EJSS | Energy-efficient job shop scheduling |

| EMk | The total processing energy consumption of machine k [J] |

| ES | Energy-efficient scheduling |

| ESetup | The Setup operation EC for a machine [J] |

| Etotal | The total energy consumption of machines related with all jobs [J] |

| FSS | Flow shop scheduling |

| FFSS | Flexible flow shop scheduling |

| FJSS | Flexible job shop scheduling |

| GA | Genetic algorithm |

| H | An arbitrary large positive number |

| i, i′, i* | Indices of jobs |

| Ji | The number of operations to be performed for job i |

| JSS | Job shop scheduling |

| k, q | Indices of machines |

| l, j, j′, j* | Indices of operations |

| m | The number of machines |

| MEijk | The processing energy consumption of Oij performed on machine k [J] |

| MGA | Modified genetic algorithm |

| MOP | Multi-objective optimization problem |

| MS | Machining system |

| n | The number of jobs |

| NC | Numerical control |

| Nk | The set of operations that can be processed on machine k |

| NSGA-II | Non-dominated sorting genetic algorithm-II |

| Oij | The jth operation of job i |

| PMS | Parallel machine scheduling |

| PSO | The power of Therblig Standby Operation (SO) [W] |

| The Therblig-SO power of machine k [W] | |

| PSO | Particle swarm optimization |

| Rk | The actual number of operations performed on machine k |

| SA | Simulated annealing |

| The starting time of Oij which is the lth operation performed on machine k [s] | |

| Sij | The starting time of Oij |

| SMS | Single machine scheduling |

| SOP | Single-objective optimization problem |

| TB | The break-event duration for a machine |

| Tidle | The idle time between operations for a machine |

| The Setup operation time of machine k [J] | |

| Tmakespan | The total completion time of all jobs |

| TPijk | The processing time of Oij on machine k [s] |

| TRTkq | The transportation time from machine q to machine k |

| TSetup | The Setup operation time of a machine |

| Xijk | Integer decision variable with value 1 if Oij is processed on machine k, and 0 otherwise |

| Integer decision variable with value 1 if Oij precedes when they are both processed on machine k, and 0 otherwise. |

References

- Energy Statistics Division of National Bureau of Statistics. China Energy Statistical Yearbook 2014; China Statistics Press: Beijing, China, 2015. [Google Scholar]

- Energy Information Administration (EIA). International Energy Outlook 2016. 2016. Available online: http://www.eia.gov/forecasts/ieo/pdf/0484(2016).pdf (accessed on 9 May 2018).

- Hassan Khattak, S.; Oates, M.; Greenough, R. Towards Improved Energy and Resource Management in Manufacturing. Energies 2018, 11, 1006. [Google Scholar] [CrossRef]

- Pusavec, F.; Kramar, D.; Krajnik, P.; Kopac, J. Transitioning to sustainable production-part II: Evaluation of sustainable machining technologies. J. Clean. Prod. 2010, 18, 1211–1221. [Google Scholar] [CrossRef]

- Peng, T.; Xu, X. Energy-efficient machining systems: A critical review. Int. J. Adv. Manuf. Technol. 2014, 72, 1389–1406. [Google Scholar] [CrossRef]

- Dahmus, J.B.; Gutowski, T.G. An environmental analysis of machining. In Proceedings of the 2004 ASME International Mechanical Engineering Congress and Exposition, Anaheim, CA, USA, 13–19 November 2004; pp. 643–652. [Google Scholar]

- Gutowski, T.; Murphy, C.; Allen, D.; Bauer, D.; Bras, B.; Piwonka, T.; Sheng, P.; Sutherland, J.; Thurston, D.; Wolff, E. Environmentally benign manufacturing: Observations from Japan, Europe and the United States. J. Clean. Prod. 2005, 13, 1–17. [Google Scholar] [CrossRef]

- Blazewicz, J.; Ecker, K.H.; Pesch, E.; Schmidt, G.; Weglarz, J. Handbook on Scheduling: From Theory to Applications; Springer: Berlin, Germany, 2007. [Google Scholar]

- Zhang, Q.; Manier, H.; Manier, M.A. A genetic algorithm with tabu search procedure for flexible job shop scheduling with transportation constraints and bounded processing times. Comput. Oper. Res. 2012, 39, 1713–1723. [Google Scholar] [CrossRef]

- Zhao, N.; Li, K.; Tian, Q.; Du, Y. Fast optimization approach of flexible job shop scheduling with transport time consideration. Comput. Integr. Manuf. Syst. 2015, 21, 724–732. (In Chinese) [Google Scholar]

- He, Y.; Li, Y.; Wu, T.; Sutherland, J.W. An energy-responsive optimization method for machine tool selection and operation sequence in flexible machining job shops. J. Clean. Prod. 2015, 87, 245–254. [Google Scholar] [CrossRef]

- Mouzon, G.; Yildirim, M.B.; Twomey, J. Operational methods for minimization of energy consumption of manufacturing equipment. Int. J. Prod. Res. 2007, 45, 4247–4271. [Google Scholar] [CrossRef]

- Liu, C.; Yang, J.; Lian, J.; Li, W.; Evans, S.; Yin, Y. Sustainable performance oriented operational decision-making of single machine systems with deterministic product arrival time. J. Clean. Prod. 2014, 85, 318–330. [Google Scholar] [CrossRef]

- Shrouf, F.; Ordieres-Meré, J.; García-Sánchez, A.; Ortega-Mier, M. Optimizing the production scheduling of a single machine to minimize total energy consumption costs. J. Clean. Prod. 2014, 67, 197–207. [Google Scholar] [CrossRef]

- Fang, K.-T.; Lin, B.M.T. Parallel-machine scheduling to minimize tardiness penalty and power cost. Comput. Ind. Eng. 2013, 64, 224–234. [Google Scholar] [CrossRef]

- Wang, Y.-C.; Wang, M.-J.; Lin, S.-C. Selection of cutting conditions for power constrained parallel machine scheduling. Robot. Comput. Integr. Manuf. 2017, 43, 105–110. [Google Scholar] [CrossRef]

- Fang, K.; Uhan, N.; Zhao, F.; Sutherland, J.W. A new approach to scheduling in manufacturing for power consumption and carbon footprint reduction. J. Manuf. Syst. 2011, 30, 234–240. [Google Scholar] [CrossRef]

- Luo, H.; Du, B.; Huang, G.Q.; Chen, H.; Li, X. Hybrid flow shop scheduling considering machine electricity consumption cost. Int. J. Prod. Econ. 2013, 146, 423–439. [Google Scholar] [CrossRef]

- Bruzzone, A.A.G.; Anghinolfi, D.; Paolucci, M.; Tonelli, F. Energy-aware scheduling for improving manufacturing process sustainability: A mathematical model for flexible flow shops. CIRP Ann. Manuf. Technol. 2012, 61, 459–462. [Google Scholar] [CrossRef]

- Dai, M.; Tang, D.; Giret, A.; Salido, M.A.; Li, W.D. Energy-efficient scheduling for a flexible flow shop using an improved genetic-simulated annealing algorithm. Robot. Comput. Integr. Manuf. 2013, 29, 418–429. [Google Scholar] [CrossRef]

- Wu, X.; Shen, X.; Cui, Q. Multi-objective flexible flow shop scheduling problem considering variable processing time due to renewable energy. Sustainability 2018, 10, 841. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, H.; Lohse, N.; Petrovic, S. A multi-objective genetic algorithm for optimisation of energy consumption and shop floor production performance. Int. J. Prod. Econ. 2016, 179, 259–272. [Google Scholar] [CrossRef]

- He, Y.; Liu, B.; Zhang, X.; Gao, H.; Liu, X. A modeling method of task-oriented energy consumption for machining manufacturing system. J. Clean. Prod. 2012, 23, 167–174. [Google Scholar] [CrossRef]

- Zhang, C.; Gu, P.; Jiang, P. Low-carbon scheduling and estimating for a flexible job shop based on carbon footprint and carbon efficiency of multi-job processing. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 328–342. [Google Scholar] [CrossRef]

- Seow, Y.; Rahimifard, S. A framework for modelling energy consumption within manufacturing systems. CIRP J. Manuf. Sci. Technol. 2011, 4, 258–264. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, F.; Wang, X. Multi-objective optimization of machining parameters considering energy consumption. Int. J. Adv. Manuf. Technol. 2014, 71, 1133–1142. [Google Scholar] [CrossRef]

- He, Y.; Liu, F.; Wu, T.; Zhong, F.P.; Peng, B. Analysis and estimation of energy consumption for numerical control machining. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 226, 255–266. [Google Scholar] [CrossRef]

- Jia, S.; Tang, R.; Lv, J. Therblig-based energy demand modeling methodology of machining process to support intelligent manufacturing. J. Intell. Manuf. 2014, 25, 913–931. [Google Scholar] [CrossRef]

- Lv, J.; Tang, R.; Jia, S. Therblig-based energy supply modeling of computer numerical control machine tools. J. Clean. Prod. 2014, 65, 168–177. [Google Scholar] [CrossRef]

- Cruz-Chávez, M.A.; Martínez-Rangel, M.G.; Cruz-Rosales, M.H. Accelerated simulated annealing algorithm applied to the flexible job shop scheduling problem. Int. Trans. Oper. Res. 2017, 24, 1119–1137. [Google Scholar] [CrossRef]

- Nouiri, M.; Bekrar, A.; Jemai, A.; Niar, S.; Ammari, A.C. An effective and distributed particle swarm optimization algorithm for flexible job-shop scheduling problem. J. Intell. Manuf. 2018, 29, 603–615. [Google Scholar] [CrossRef]

- Carrizosa, E.; Romero-Morales, D. Combining minsum and minmax: A goal programming approach. Oper. Res. 2001, 49, 169–174. [Google Scholar] [CrossRef]

- Wang, X.H.; Wan, C.H.; Sun, C.C.; Xia, R.W. An optimization algorithm for multi-objective optimization problem by using envelope-dual method. Procedia Eng. 2013, 67, 457–466. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Pinedo, M.L. Scheduling: Theory, Algorithms, and Systems; Springer: New York, NY, USA, 2012. [Google Scholar]

- Shao, X.; Li, X.; Gao, L.; Zhang, C. Integration of process planning and scheduling—A modified genetic algorithm-based approach. Comput. Oper. Res. 2009, 36, 2082–2096. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, R.; Peng, T.; Tao, L.; Jia, S. A method for minimizing the energy consumption of machining system: Integration of process planning and scheduling. J. Clean. Prod. 2016, 137, 1647–1662. [Google Scholar] [CrossRef]

- Iredi, S.; Merkle, D.; Middendorf, M. Bi-criterion optimization with multi colony ant algorithms. In Proceedings of the International Conference on Evolutionary Multi-Criterion Optimization, Zurich, Switzerland, 7–9 March 2001; pp. 359–372. [Google Scholar]

- Wang, H.; Jiang, Z.; Wang, Y.; Zhang, H.; Wang, Y. A two-stage optimization method for energy-saving flexible job-shop scheduling based on energy dynamic characterization. J. Clean. Prod. 2018, 188, 575–588. [Google Scholar] [CrossRef]

- Jia, S.; Yuan, Q.; Cai, W.; Li, M.; Li, Z. Energy modeling method of machine-operator system for sustainable machining. Energy Convers. Manag. 2018, 172, 265–276. [Google Scholar] [CrossRef]

| Part | Job | Machine | 1 (CK6136i) | 2 (CK6153i) | 3 (CAK6150Di) | 4 (JTVM6540) | 5 (XHK-714F) | |

|---|---|---|---|---|---|---|---|---|

| Operation | ||||||||

| A | 1–3 | 1 | 89 s, 1.0684 × 105 J | 89 s, 1.2173 × 105 J | 89 s, 1.2599 × 105 J | - | - | |

| 2 | 84 s, 0.8870 × 105 J | 84 s, 1.0206 × 105 J | 84 s, 1.0615 × 105 J | - | - | |||

| 3 | - | - | - | 67 s, 4.7815 × 104 J | 66 s, 4.7912 × 104 J | |||

| B | 4, 5 | 1 | - | - | - | 996 s, 1.0986 × 106 J | 956 s, 1.1109 × 106 J | |

| 2 | - | - | - | 532 s, 5.3333 × 105 J | 525 s, 5.4448 × 105 J | |||

| 3 | - | - | - | 85 s, 5.1481 × 104 J | - | |||

| 4 | - | - | - | 155 s, 1.1115 × 105 J | 133 s, 9.9921 × 104 J | |||

| C | 6, 7 | 1 | - | - | - | 229 s, 2.4488 × 105 J | 226 s, 2.6095 × 105 J | |

| 2 | - | - | - | 508 s, 5.1276 × 105 J | 493 s, 4.8041 × 105 J | |||

| Machine | k | |||

|---|---|---|---|---|

| CK6136i | 1 | 1.9065 × 104 | 60 | 335.7 |

| CK6153i | 2 | 2.7800 × 104 | 75 | 332.1 |

| CAK6150Di | 3 | 2.8400 × 104 | 80 | 414.0 |

| JTVM6540 | 4 | 2.7000 × 104 | 65 | 360.5 |

| XHK-714F | 5 | 2.9700 × 104 | 75 | 371.0 |

| Target Position | CK6136i | CK6153i | CAK6150Di | JTVM6540 | XHK-714F | |

|---|---|---|---|---|---|---|

| Initial Position | ||||||

| CK6136i | 0 | 150 s | 210 s | 465 s | 515 s | |

| CK6153i | 180 s | 0 | 250 s | 450 s | 475 s | |

| CAK6150Di | 220 s | 270 s | 0 | 435 s | 425 s | |

| JTVM6540 | 485 s | 460 s | 500 s | 0 | 535 s | |

| XHK-714F | 530 s | 510 s | 520 s | 505 s | 0 | |

| Operation | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Job | |||||

| 1 | CK6136i | CK6153i | JTVM6540 | - | |

| 2 | CK6153i | CAK6150Di | XHK-714F | - | |

| 3 | CAK6150Di | CK6136i | JTVM6540 | - | |

| 4 | JTVM6540 | XHK-714F | JTVM6540 | JTVM6540 | |

| 5 | XHK-714F | JTVM6540 | JTVM6540 | XHK-714F | |

| 6 | JTVM6540 | XHK-714F | - | - | |

| 7 | XHK-714F | JTVM6540 | - | - | |

| Parameter | Population Size | Evolutional Generation | Crossover Probability | Mutation Probability | Tournament Size |

|---|---|---|---|---|---|

| Value | 50 | 300 | 0.9 | 0.1 | 2 |

| Job | Operation | Machine Tool (min, RMB, kJ) | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | ||

| 1 | 1 | (2.0, 2.04, 720) | (1.0,1.22, 492) | - | - | - | - | - |

| 2 | - | - | (2.0, 2.78, 621) | (2.0, 3.21, 756) | - | - | - | |

| 3 | - | - | - | - | - | (1.5, 1.46, 432) | - | |

| 4 | - | - | - | (1.0, 1.55, 342) | - | - | ||

| 5 | - | - | - | - | - | - | (2.0, 2.08, 636) | |

| 2 | 1 | (2.0, 2.04, 696) | (2.0, 2.44, 960) | - | - | - | - | - |

| 2 | - | - | - | - | (1.0, 1.55, 348) | - | - | |

| 3 | - | - | - | - | - | (1.0, 0.97, 270) | - | |

| 4 | - | - | (2.0, 2.78, 600) | (1.0, 1.61, 426) | - | - | - | |

| 5 | - | - | - | - | - | - | (2.0, 2.08, 576) | |

| 3 | 1 | - | - | - | - | (1.0, 1.55, 324) | - | - |

| 2 | (2.0, 2.04, 744) | (2.0, 2.44, 996) | - | - | - | - | - | |

| 3 | - | - | - | - | - | - | (2.0, 2.08, 540) | |

| 4 | - | - | (2.0, 2.78, 564) | (1.0, 1.61, 432) | - | - | - | |

| 5 | - | - | - | - | - | (1.5, 1.46, 387) | - | |

| 4 | 1 | - | - | (2.0, 2.78, 684) | (1.0, 1.61, 438) | - | - | - |

| 2 | (2.0, 2.04, 732) | (2.0, 2.44, 996) | - | - | - | - | - | |

| 3 | - | - | - | - | (1.0, 1.61, 330) | - | - | |

| 4 | - | - | - | - | - | - | (2.0, 2.08, 600) | |

| 5 | - | - | - | - | - | (1.5, 1.46, 378) | - | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Wu, L.; Peng, T.; Jia, S. An Improved Scheduling Approach for Minimizing Total Energy Consumption and Makespan in a Flexible Job Shop Environment. Sustainability 2019, 11, 179. https://doi.org/10.3390/su11010179

Zhang Z, Wu L, Peng T, Jia S. An Improved Scheduling Approach for Minimizing Total Energy Consumption and Makespan in a Flexible Job Shop Environment. Sustainability. 2019; 11(1):179. https://doi.org/10.3390/su11010179

Chicago/Turabian StyleZhang, Zhongwei, Lihui Wu, Tao Peng, and Shun Jia. 2019. "An Improved Scheduling Approach for Minimizing Total Energy Consumption and Makespan in a Flexible Job Shop Environment" Sustainability 11, no. 1: 179. https://doi.org/10.3390/su11010179

APA StyleZhang, Z., Wu, L., Peng, T., & Jia, S. (2019). An Improved Scheduling Approach for Minimizing Total Energy Consumption and Makespan in a Flexible Job Shop Environment. Sustainability, 11(1), 179. https://doi.org/10.3390/su11010179