The results initiate in

Section 3.1,

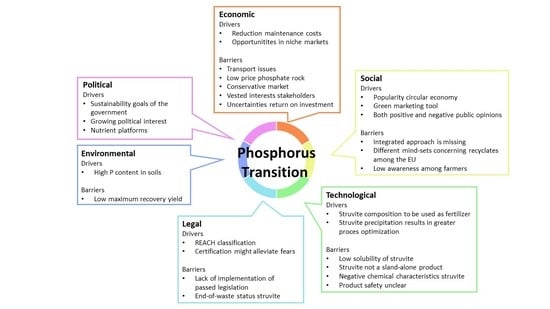

Section 3.2,

Section 3.3,

Section 3.4,

Section 3.5 and

Section 3.6 with an overview of the existing literature and regulations on each PESTLE topic, following an overview of statements made by the respondents on each topic of several main stakeholders (the first study). The results of the second study concerning the Dutch water boards are discussed in

Section 3.7, which includes the barriers and opportunities of the two recovery products, struvite and sewage sludge ash, according to the Dutch water boards.

3.1. Political Aspects

There are various policy documents on P recovery, both at the Dutch national and European level [

15,

16]. Inclusion of phosphate rock on the European critical raw materials list demonstrates the interest of Europe’s governing bodies. As of 2015, the incorporation of an article for recovered phosphate into the Dutch “fertilization law” indicates a political desire to support these developments at the Dutch national level too [

15]. Moreover, the presence of various inter-organizational platforms focusing on nutrient recycling can be seen as a stimulating factor. The most important of which includes the European Sustainable Phosphorus Platform (ESPP) on the European level and the Dutch Nutrient Platform (NWP) on national level. In practice, these platforms serve as a hub for information exchange, and they facilitate communication between all cross-sectoral stakeholders. This Dutch platform, along with the ESPP, have promoted several soft legislative tools and research initiatives within the Dutch sector calling for a collaborative research environment across various stakeholder groups involved in P management in Europe. Examples of this include The Dutch Phosphate Value Chain Agreement facilitated by The ESPP in 2011, which called for a commitment to creating a sustainable market for secondary recycled phosphates over the course of two years in The Netherlands. The agreement was signed by twenty industrial companies, knowledge institutions, government authorities, and NGOs [

16].

Concerns about dependence of countries outside the European Union on phosphate ore, and thus fertilizers for food production, have increased the interest for alternatives [

4]. In fact, in 2011, the EU’s import dependency for phosphate rock reached roughly 92% [

17]. Currently, around 74% of global reserves are located in Morocco [

18]. In terms of production, The United States, China, Morocco, and Russia produce 75% of the world’s annual phosphate rock with the highest being China totaling 138,000 tonnes [

18]. This market concentration thereby produces volatility and certain political and economic risks, as well as international security risks. This is for instance illustrated during the Arab Spring, where a stable supply from Tunisia, Jordan, and Syria was no longer guaranteed [

17]. The phosphate market can be characterized as oligopolistic with monopolistic tendencies due to the limited number of countries acting as supplier but also the limited amount of companies in this sector [

17].

Political Aspects: Interview Results

The public sector has developed an increased interest for sustainability. This has been expressed through keywords during the interviews such as “circular economy”, “recycling” and “sustainability goals” (see

Table 2). Three out of eight of the interviewees emphasized the positive effect of the Dutch Nutrient Platform on the developments at political and legislative level. Six out of eight interviewees indicate that the government and companies can play a critical role in accelerating the implementation of struvite recovery. They mentioned that the government can use tools to accelerate struvite implementation via initiatives such as green deals or via the SER, an advisory board for the Dutch government on the social and economic policy.

Intentions have also been converted into concrete actions. The Netherlands adopted new regulations regarding P recovery in 2015. The implementation process of these laws was experienced by the interviewees as a long, lethargic process (see

Table 2). Besides changes in the political involvement on a national level, developments on international level have been indicated by the interviewees as well. There is an increasing political interest in the sustainable use of phosphate on a European level. Interviewees indicate that the incorporation of phosphate rock in the EU critical materials list has placed this subject on the political agenda and therefore this step can be seen as a vital aspect in this respect.

3.2. Economic Aspects

There are distinct market fluxes and geopolitical tensions that place direct pressure on the global phosphate market. China imposed a 135% export tariff on phosphate rock in 2008, placing direct pressure as the biggest supplier on the global phosphate market. Due to an increased demand, uncertainty of available reserves of mineral P and the export tariff of China, the price of P spiked eightfold from

$50 per tonne to

$400 per tonne in 2008 [

19]. After this price peak, the price stabilized around

$100 per tonne, twice as much as before the peak. The trend of large P producing countries becoming net importers resulted in less competition on the supply side, and more on the demand side, which in turn influenced the price of mineral P. This was significant for the EU, since the EU heavily relies on import of mineral P.

The low market price of phosphate ore can be seen as an economic constraining factor for the development of a struvite value chain [

12]. A struvite-based product has to be as efficient, affordable, and predictable in releasing nutrients as existing materials to compete with the established, efficient and relatively cheap starting material phosphate rock [

20]. Nonetheless, the market opportunities should still be pursued to keep technological developments going and attract investors [

12]. Schipper mentioned that even though P recovery might not currently be economically viable, efforts should be made now to ensure that technologies are ready when scarcity of phosphate rocks starts to play a role [

20]. Schipper and Schoumans et al. state that some form of government intervention in the market place will be necessary to create a P recovery market [

20,

21].

Controlled struvite precipitation can be used as a means to reduce maintenance costs at wastewater treatment plants that use a biological treatment technique [

11]. While there are significant costs associated with the chemicals used for struvite precipitation, there are also savings to be considered. This is due to the prevention of incrustations, the reduced chemical demand and the reduced sludge quantity, which results in lower disposal costs. Reported investment costs differ substantially. In general, costs for phosphorus recovery and the return on investment period are highly dependent on the type of technology utilized and size of the plant [

22]. Several studies report a return of investment of six years for facilities with capacities of 265 and 3711 m

3/day, respectively [

23,

24].

Schipper states that upholding the wishes of the market is often overlooked by researchers [

20]. This finding is underlined by Kabbe et al., stating that researchers have reinvented the wheel multiple times, and technological efforts are overly complex and the user is not always sufficiently involved in the research process [

12]. This indicates that there is a knowledge gap concerning the market applications of struvite.

Economic Aspects: Interview Results

The main driver to recover struvite out of wastewater is the reduction of maintenance costs for the water boards (see

Table 3). The reduction of expenditure on chemicals has been the driving factor behind implementing the EBPR technology, a biological wastewater treatment technology, but a disadvantage of EBPR is the increased clogging of pipes, which results in high maintenance costs. Without this operational cost benefit, there is currently no foundation for struvite recovery in The Netherlands.

Struvite as a stand-alone product is seen as not particularly viable by the interviewees from the fertilizer industry. Struvite might serve as a viable solution in niche markets as small, amateur farmers or grassland, but interviewees are skeptical regarding introducing struvite as a product in the fertilizer industry. They agree that the fertilizer industry is a traditional sector and not looking for a new product, while the currently used products have been working efficiently for decades and the price of phosphate rock is low.

Interviewees indicated that one of the main barriers of struvite recycling as fertilizers are the differences in vested interests between the stakeholders. The fertilizer market can be characterized as conservative, rigid, and hard to change. As an interviewee working at a fertilizer company mentioned: “10 years ago they wanted a particular product and in another 10 years they will still want the same product”. The competition from established industry is too high to get things off the ground without any additional incentives. The main incentive of water boards is not producing a well-fitted product for the current existing fertilizer industry, rather it involves reducing the maintenance costs via precipitating a product out of their waste water. It will require the collective effort of different consortia to promote the reuse of struvite.

A driver for the use of P recovery products for fertilizer companies and the implementation for water boards is the sustainable label. As a quote of one of the interviewees clearly shows: “We can stick a green sticker on it and it will sell like crazy”. Phosphate scarcity and environmental effects are known problems within the industry but there is no need or incentive for industry to act.

Interviewees indicate that the market for fertilizers containing P is not in The Netherlands, due to the surplus of phosphates in the soil, which resulted in strict regulations for fertilizer use. Transport issues could threaten profitability. Feasibility of any value chain will depend on transport costs, both from an environmental and economic perspective.

Other interviewees indicate that entrepreneurs and investors want long-term contracts, but water boards are unable to provide these. This uncertainty on the return on investment is the most important reason long-term investment is currently lacking.

3.3. Social Aspects

The public perception of P recovery is scientifically not well documented due to a lack of research in this area. According to Schipper (2014), the low interest from society for this issue is related to the invisible role P has in the environment and the unattractiveness of sewage treatment [

20]. Acceptance among the farming community and important market players will be decisive for the introduction of a P product that is based on recovered P [

25]. While consumers only represent the end of the phosphorus value chain, they remain important end-user stakeholders who can collectively use their consuming power to contribute to increased phosphorus use efficiency and can move towards a more sustainable phosphorus cycle [

26]. Nevertheless, the majority of food consumers are not aware of issues regarding phosphorus, at least in view of it being an essential finite resource nor its environmental effects [

1].

Social Aspects: Interview Results

The interviewees agree that there is an overall open and enthusiastic mindset about recycling and innovation in The Netherlands. Sustainability is a buzzword, which is utilized by companies and water boards in marketing campaigns on sustainability (see

Table 4). Especially circularity and circular economy are words, which have been mentioned by most of the interviewees in a positive context. The attitude toward recycling is not expected by the interviewees to be equally as receptive. The fertilizer industry is perceived as more conservative. A product that is harvested from waste is not expected to be received with open arms among the public and industry because of hygienic concerns and current views on waste.

Even though the wider public is still hardly aware of phosphorus related issues, there is an increased interest and awareness. As a quote indicates: “If you talked about phosphate recycling 4–5 years ago, nobody had a clue what you were talking about (…), now it is much more of an issue”. Some of the interviewees indicate that the public opinion is negative concerning struvite since it is a product derived from wastewater and they immediately relate this to health issues. Educating society will be necessary to gain product acceptance. Safety may be guaranteed, but the idea that struvite is harvested from waste sources could be problematic. Other interviewees claim the opposite and mention that there is a very positive attitude towards the “green” product struvite, despite its origin.

It is indicated that the users of fertilizers, farmers (not interviewed in this study), are not aware of the effects of the surplus of phosphates. Growing awareness about the phosphate problem could play a helping hand in the use of recycled phosphates. A research conducted by Hasler et al. (2016) shows that the farmers are the most skeptical towards fertilizer eco-innovation of the whole supply chain [

27]. Hasler et al. (2016) concluded that both farmers and suppliers consider legal regulations as a driving force for environmental requirements and eco-innovation [

27]. Further research on the opinion of farmers could shed more light on the opinions of farmers towards the use of struvite or other recovered P products.

3.4. Technological Aspects

Communal waste streams converge at regional WWTPs where water undergoes various treatment steps before it is released to the surface water. These WWTPs are a suitable location to recover P since the high P concentrations and P recovery technologies can often be combined with existing setups. Several types of P removal technologies exist to treat the wastewater and commonly used methods are Bio-P removal or P removal via chemical dosing. The P removal technique Bio-P is commonly used in The Netherlands, but has a negative side effect that it leads to the high release of biologically bound, water soluble P into the aqueous phase of the sludge. At high P concentrations, struvite is unintentionally formed in pipes, pumps and dewatering units of sewage systems and WWTPs, which requires maintenance costs to remove this crystal rock formation. Therefore, the intentional precipitation of struvite before it clogs the pipes reduces the maintenance costs of the pipes. This product, struvite, can afterwards be used as a fertilizer. The P from the P rich sewage sludge can be recovered through either wet chemical treatment via acid or alkali leaching or thermochemical treatment when the P can end up in the sewage sludge ash [

14].

Struvite is less soluble in water than traditional fertilizers, making it a slow release fertilizer, which means that the nutrients are only gradually available for crops. Several studies have been conducted on the final yields of crops grown using struvite as well as conventional fertilizers. The use of struvite in combination with conventional fertilizers results in high phosphorus efficiency and P uptake during the early and late growth [

28]. To date, there is still a lot of ongoing research on the quality of struvite and the effect on the soil quality.

Technological Aspects: Interview Results

There are diverging viewpoints among the interviewees surrounding the quality of struvite as a fertilizer. There are two opinions about the quality of struvite. Two interviewees indicate that the chemical composition of struvite is favorable, both not working in the fertilizer industry (see

Table 5). The interviewees from the fertilizer industry indicate that struvite is not a complete, final product from a market perspective. The characteristics are poor due to the low solubility and the lack of potassium. They conclude that it must be treated before it has value as a stand-alone fertilizer. Besides this, they indicate that struvite is not compatible with the machinery of the farmers.

The low solubility was a reason for one interviewed fertilizer company to discontinue their research into struvite. Another company uses struvite as an additive starting material besides phosphate rock. The customers want a product highly soluble in water. Struvite applications are limited to its use as a side input in the production of regular fertilizer or in the niche market for specialty fertilizers. This means it can be used in niche markets with other requirements, such as grasslands.

Another technological constraint of struvite is the limited rate of recovery from waste streams. Recovery of P via a struvite precipitation method at full scale generates several thousands of tons of P each year. Production of fertilizer takes place at several hundred thousand tons each year. Therefore, struvite does not have a significant contribution to overall production output. A higher recovery rate can be realized when the sanitary infrastructure changes drastically, i.e. separation of urine without the dilution with rainwater, but this is costly.

Fertilizer companies wish to remain far under the minimum requirements for hazardous compounds. Therefore, the lack of clarity on product safety and characteristics are barriers to use struvite as material.

3.5. Legislative Aspects

Struvite and more specifically the trading of struvite is subject to several national and European regulations. The recovered P from waste streams is seen as a waste product by law. Reuse in production processes will therefore require adherence to additional criteria.

Two main types of legislations are involved in implementing P recovery technologies, regulations on the installation of P recovery technologies and on the recovered P products. A selection of the most important legislations regarding P products will be discussed.

All companies are obligated to require permits for their P recovery installations. Currently, most WWTPs are classified as “waste management” by two directives: the EIA (Environmental Impact Assessment directive) and the IED (Industrial Emissions Directive) which are in place for companies in waste management and recovering/recycling [

25]. Recycling and recovering companies, labeled as waste management, have to follow far stricter rules than fertilizer companies using phosphate rock [

25].

To gain a status of “fertilizer producer”, extra permits and new installations are both needed for WWTPs, which costs extra time and money. Registering a new (sustainable) fertilizer type can take up to 7 years, which therefore blocks innovation [

25]. Consequently, WWTPs often choose to sell the recovered P as waste, instead of turning it into fertilizers.

Next to the two directives concerning this classification, there is the Shipment of Waste Regulation. This regulation applies to WWTPs that would like to export their recovered products, which are labeled as waste, such as sewage sludge or struvite, for recycling across borders. This regulation states that a contract should be set up between the person responsible for the shipment of the waste and the receiver of the waste. Moreover, authorities from both the country of origin and waste product destination should authorize the shipment. This process is time-consuming. Meanwhile, importing phosphate rock does not have to undergo similar processes, making it easier to import phosphate rock than P containing waste [

25].

The placement of the recycled materials is divided into two subcategories, namely material type and market segments of recycled materials. Material type legislation looks at whether the designated material is a product or waste. This is examined on a national or regional level via the End-of-Waste (EoW) criteria of the Waste Framework Directive (WFD) [

29]. Consequently, a material can be registered as a product in one country, but as waste in the other, which is an obstacle to trade across borders. Waste and product materials need to conform to different regulations and directives, such as REACH [

30].

All chemical substances that are traded in Europe must be approved through the European Chemical Regulation (REACH) legislative framework. This approval for struvite has been obtained in 2015, alleviating an important legislative hurdle. Currently, an important obstacle for reuse of secondary phosphorus-containing products is the lack of an end-of-waste status.

Next to material type, there is legislation on market segments of recycled materials. An important regulation is The Fertilizers Regulation [

31]. This regulation imposes certain requirements on fertilizers. For example, the fertilizer may not be harmful towards the environment or human health. If fertilizers meet all requirements, they can be labeled as EC fertilizers (safe and effective fertilizers on the EU market). This can improve a fertilizer’s marketing position drastically. Unfortunately, it is often the case that gaining this label for a fertilizer can cost half a decade. Moreover, there are criteria in The Fertilizers Regulation on the source of materials used for fertilizers instead of regulations on the final fertilizer product, and a procedure for organic fertilizers is lacking. This creates a barrier for new innovative (phosphorus-friendly) fertilizers. Some countries, such as The Netherlands, pay special attention to recycled fertilizers by changing their national regulation in a favorable way for the use of struvite. However, other countries have more rigid regulations on pollutant concentrations, such as heavy metals which can have a negative effect for struvite due to the difference in composition of struvite compared to traditional fertilizers. This results from the fact that there are no regulations on pollutant concentrations at the European level, again imposing a barrier for the EC fertilizer label. Struvite has been registered as a fertilizer in The Netherlands from 15 December 2014. Conforming to all regulations in all countries is extremely difficult, costly and time-consuming. Kabbe et al. (2015) state that designing supportive legislation for the circular economy should be a priority [

12]. The working group STRUBIAS is trying to make headway with this issue through proposed amendments to The Fertilizer Regulation. The proposed EU fertilizers regulation revision includes to add struvite, biochars, and ash-based recycled nutrient products to the new regulations, which will grant an end-of-waste status to fertilizers using these recovered phosphorus products. Phosphorus taxes for usage in agriculture have already been experimented with in several European countries: The Netherlands, Sweden, Denmark, Austria, Norway, and Finland. The aim of these taxes was largely to decrease phosphorus usage on farms for environmental reasons [

32,

33]. More information on phosphorus taxes can be found in the

Supplementary Materials.

Legislative Aspects: Interview Results

Interviewees indicated that the REACH classification is an important contribution to struvite development (see

Table 6). However, these developments are very recent. The Netherlands has adopted new regulations concerning P recovery in 2015. The implementation of P recovery products in the fertilizer regulation would also be a big step forward. Other improvements at the public policy level would be removing trade barriers between countries. Influencing the water boards through legislation is very difficult because they act as an independent governing body. The EFGF (Energie en grondstoffenfabriek) is a cooperative effort of the water boards in The Netherlands. There are one or two moments in the year when the EFGF meets physically. However, only the water board members participating in the EFGF meet here so the diversity in opinion is not very broad. Most interviewees think that governmental intervention will be necessary to stimulate market formation, as has been the case with bioplastics and green energy.

Using struvite as a raw material in existing processes is possible under the condition that fertilizer quality standards are met. Current legislation is seen as problematic, since struvite cannot legally be transported across national boundaries unless both countries approve it. This is troublesome since firms are not allowed to transport or accept the material. Registration of struvite as a fertilizer or waste product is therefore necessary. However, the end-of-waste label is currently governed under national legislation, it often cannot be transported across borders. For proper waste management, waste needs to be seen as resource and therefore EU-wide EoW criteria are needed.

3.6. Environmental Aspects

Life cycle assessments have shown that struvite based fertilizer has a lower environmental impact than phosphate rock [

34,

35]. Looking at P efficiency, using sewage sludge directly on farmland is the most desirable, since all P is reapplied to farmland. However, from a toxicity perspective, phosphate ore has been found to be more favorable than direct application of sludge due to the medicines and pathogens in sludge [

36]. The lack of heavy metals in struvite makes struvite even more favorable from a toxicity perspective than phosphate ore [

36].

A steep increase in the use of P rich fertilizer has led to the production of more food but also more waste. Together with deforestation, this has caused displacement of large amounts of P throughout the environment [

37]. Today, 1.9 terragrams (Tg) of P flows into the EU from outside sources each year and 80% of this influx can be attributed to P rock imports to be processed for use as fertilizers, in the food industry and detergents [

1].

Excess amounts of P can be found in water bodies that are sourced from agricultural runoff and the outflow from industrial and municipal wastewater facilities, which subsequently leads to the development of eutrophication. This problem is stimulated by soil erosion, which carries a significant amount of soil-bound phosphorus into surface waters. A 2013 model developed by the EU estimated that roughly 1.3 million km

2 of land was affected by soil erosion in the EU-27 [

4]. Rodriguez-Garcia showed that the environmental benefit with regards to eutrophication is significant when P recovery technologies will be implemented, especially when different technologies are combined at the same location [

38].

Regarding loss, this is exhibited readily throughout different areas of the P supply chain. Kimo van Dijk et al. (2016) examined all categories of loss for the EU, which included consumption, non-food production, food processing, animal production, and crop production [

39]. Out of all sectors, consumption demonstrated the highest level of loss is the waste water sector (32% of the total system losses).

Environmental Aspects: Interviews Results

P recycling could help to correct the large regional differences in P in the soil. In The Netherlands, there is a large surplus of P in the ground, whereas much soil in Eastern Europe has a phosphorus deficiency. This has also been indicated as a driver by two respondents (see

Table 7). This can work as an incentive to export to Eastern Europe. Exporting surplus P could help The Netherlands adhere to European soil guidelines in the future. There are concerns about the efficiency of struvite recovery since a large amount of P is not recovered from the waste streams and remains in the sludge. Other technologies will be necessary to recover the rest.

3.7. Results from Study 2: Drivers and Barriers from the Key Stakeholders’ Point of View, the Dutch Water Boards

This paragraph contains the results of the second study. All the data retrieved in the second study from the questionnaires and gathered during the interviews with the Dutch water boards are visualized in

Table 8 and

Table 9. These responses picture the trends for opportunities and barriers for both struvite recovery and treated sewage sludge ash products, which were the two routes identified by the water boards as the two most promising technologies for P recovery.

The most common response (five responses) for the drivers of struvite recovery are the avoided maintenance costs (see

Table 8). This fits into the economic category of the PESTLE framework (see

Section 3.2). The positive effect on the image of the water board is also mentioned three times, which is part of the social category of the PESTLE analysis. Besides this, several water boards have indicated that they have future plans for onsite P recovery in the form of struvite, which is an indication that the amount of implemented struvite precipitators will increase in the nearby future. The implementation of a struvite precipitator also results in greater process limitations, which has also been mentioned as a key driver by two respondents.

Regarding ash products, the highest number of responses (five) claimed that the largest benefit of engaging in sewage sludge ash treatment for P recovery is that it destroys organic matter and, as a result, lowers the potential risk for contamination of organic pollutants and pathogens, which therefore fits into the environmental and technological category of PESTLE. Three respondents also indicated that they are optimistic about the potential for the production of recovered products with the new EcoPhos and SNB/HVC partnership that will start in 2018.

In contrast to these drivers, a reported barrier for struvite recovery was the relatively high investment costs with a low certainty for return on investment (

Table 9). Besides this, the end-of-waste status of struvite has been mentioned as a barrier for the trade of struvite across borders, which is a legal aspect. Moreover, two water boards indicated that it is not favorable for them to implement struvite recovery technologies, since the population equivalent of their wastewater treatment plants is too small and therefore economically not feasible to implement a struvite precipitator. Another driver which has been mentioned was that Dutch water boards are often publicly owned and funded entities. This gives conflicts as soon as they start to produce commercial products as struvite. Therefore, the products are often sold by another company, aquaminerals.

A reported barrier for struvite and total P recovery mentioned was that water boards that already have an incineration partnership with SNB/HVC and as a result are affiliated with EcoPhos, have little motivation to use on-site P recovery technologies since they are part of a bigger more centralized scheme for P recovery.