2.1. Sustainability Measures

Muthu et al. [

14] defined a model to quantify the environmental impact made by various textile fibers and also to position them in terms of ecological sustainability. Paju et al. [

15] introduced and illustrated the application of a VSM-based assessment, termed Sustainable Manufacturing Mapping (SMM). SMM takes chosen sustainability indicators into consideration and is based on VSM, Life Cycle Assessment (LCA), and Discrete Event Simulation (DES).

In order to find out whether and how sustainable development indicators (SDI) are applied, Palme and Tillman implemented a series of field studies and performed a literature survey concerning the actual use of SDIs in Swedish organizations [

16]. The main conclusion was that SDIs are frequently used in reporting but not in planning and decision making, and hence may not contribute substantially to sustainable development. One of the main aspects related to sustainability is related to air quality. Two of the main used indexes in terms of Particulate Matter are PM10 and PM2.5 that can be defined as follows [

17]:

PM10: inhalable particles, with diameters that are smaller than 10 µm.

PM2.5: fine inhalable particles, with smaller than 2.5 µm in diameter.

The assessment of the state of air quality is normally made in accordance with the limits established by international and governmental organisms. Those assessments are based on the analysis of the data collected by the in-site monitoring stations. Most of the air quality monitoring throughout Chile is oriented towards PM10 particles. More recently, the PM2.5 standard begins to be used, seeking to use a better indicator of the air quality status. However, if we consider the mining industry, the subjacent processes register a higher contribution of coarse particulate matter [

18].

The triple bottom line (TBL) has become a very useful concept to measure sustainability according to three main attributes, namely, environment, economy, and society. Those attributes have been identified as core pillars of sustainability. Several works have used the TBL concept as an attempt to measure the sustainability of different kinds of organizations, processes, and products. Mahmood et al. [

19] established a relationship among the traditional OEE factors (availability, productivity, and quality) and sustainability (through the use of the TPL concept). The authors concluded that the OEE measure can be translated into manufacturing sustainability, which means that every improvement detected in the OEE metric will have an indirect and positive impact on TBL dimensions. Pires et al. [

20] proposed a model supported by the TBL concept to determine and prioritize a set of attributes that lead to better maintenance performances. The authors proposed the use of Analytical Hierarchical Process (AHP) in order to determine the degree of influence that each TBL factor has into the OEE factors. Other works have pointed to analyze sustainability in logistics and supply chains structures [

21,

22]. Another paper that deals with sustainability in supply chains was reported by De Soete [

23]. In that work, the author suggests mechanisms to embed sustainability attribute into business operational management systems, such as Material Requirement Planning (MRP), Manufacturing Execution Systems (MES), and Enterprise Resource Planning (ERPs) software.

2.2. Overall Efficiency Metrics

One of the most used and accepted indicators of efficiency is the Overall Equipment Effectiveness (OEE). Proposed by Nakajima as a way to evaluate the progress of TPM implementation initiatives, this indicator allows for the tracking of efficiency behaviour. Also, OEE is a tool to calculate efficiency at the equipment level and to measure the productivity of the equipment in relation to its maximum capacity, which is assumed to be constant over the period considered. According to Nakajima [

1], the OEE can be calculated through the product of Availability Efficiency (

Aeff), production performance (

Peff), and quality efficiency (

Qeff).

The mining industry in general lagged behind other industry sectors in adopting OEE as a good measure of performance. Some papers have been reported in the literature addressing the adaptations and utilizations of the OEE in mining operations [

24,

25,

26,

27,

28,

29]. Emery [

26] described the application of the Total Productive Management (TPM) technique and the use of OEE in coal mining operations. Elevli and Elevli [

29] tried to identify causes of time losses for shovel and truck operations. They grouped those losses into three categories, i.e., availability, performance, and quality losses. One of the most important modifications is the one that addresses the quality rate factor. According to Paraszczak [

25], a more pertinent factor for mining equipment is the production efficiency. As in mining production systems, the production process is a quasi-uniform flow of bulk product, and the performance is the degree of operating relative to the nominal production rate or speed. The quality understood as the grade of the ore is substituted by other parameters that describe the net value of the product flow or production speed. Based on that idea, Samanta and Banerjee [

27] proposed an adaptation of the OEE as a function of availability (A), production efficiency (P), and utilization (U) for mining equipment. Dhillon [

24] proposed that OEE is a function of availability, utilization, and production index as the following equation:

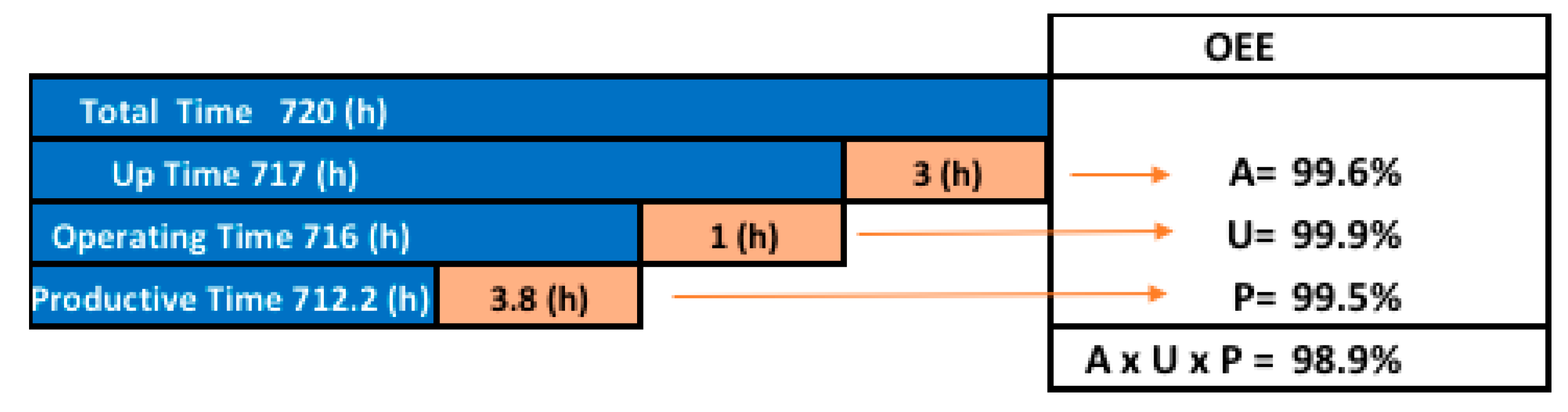

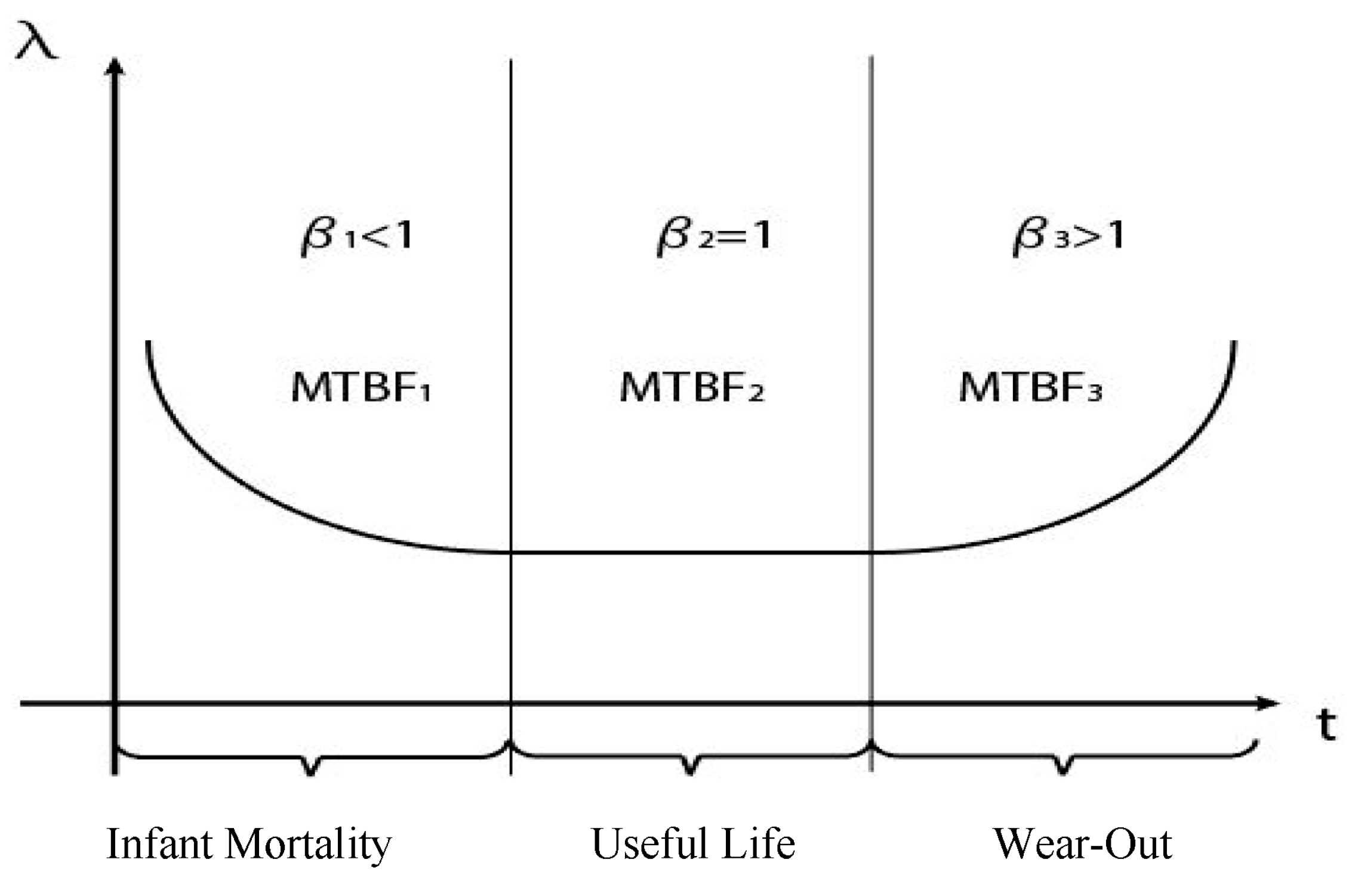

These terms may be better understood by observing the

Figure 2.

There is clear evidence that OEE applications in industry vary from one to another. Although the basis for the measurement is derived from the OEE proposed by Nakajima [

1], its use has been adapted to serve specific industrial sectors. Because of that, the term OEE has been modified for other different terms: for example, overall factory effectiveness (OFE) [

7], overall plant effectiveness (OPE) [

8], overall throughput effectiveness (OTE) [

4], production equipment effectiveness (PEE) [

6], overall asset effectiveness (OAE) [

8], and total equipment effectiveness performance (TEEP) [

9]. Nevertheless, despite its wide use and success, OEE does not provide a global vision at the production system level, nor lessen the impact of specific equipment on overall performance.

So far, few articles have attempted to integrate aspects related to sustainability and the factors of availability, productivity, and quality considered in the conventional OEE. Aguado et al. [

30] presented a model for evaluating improvements in terms of efficiency and sustainability. This model was applied successfully in an actual production system. However, according to their own authors, the results are not related to the OEE and do not differentiate the improvements obtained due to increases in sustainability in each workstation of the manufacturing process.

More recently, Domingo and Aguado [

13] proposed the Overall Environmental Equipment Effectiveness (OEEE); however, this index presents the same limitations as the original OEE, that is, considering efficiency at the equipment level does not allow for evaluation at the production system level.

This proposal is based on the work carried out by Domingo and Aguado [

13]. They proposed a novel indicator, OEEE, that incorporates the well-known factors of traditional OEE (Availability, Productivity, and Quality), as well as the environmental factor. However, it is worth noting that OEEE is about measuring excellence in individual equipment and its impact on the overall system. However, this is done without taking into consideration the relationships among different machines and processes.

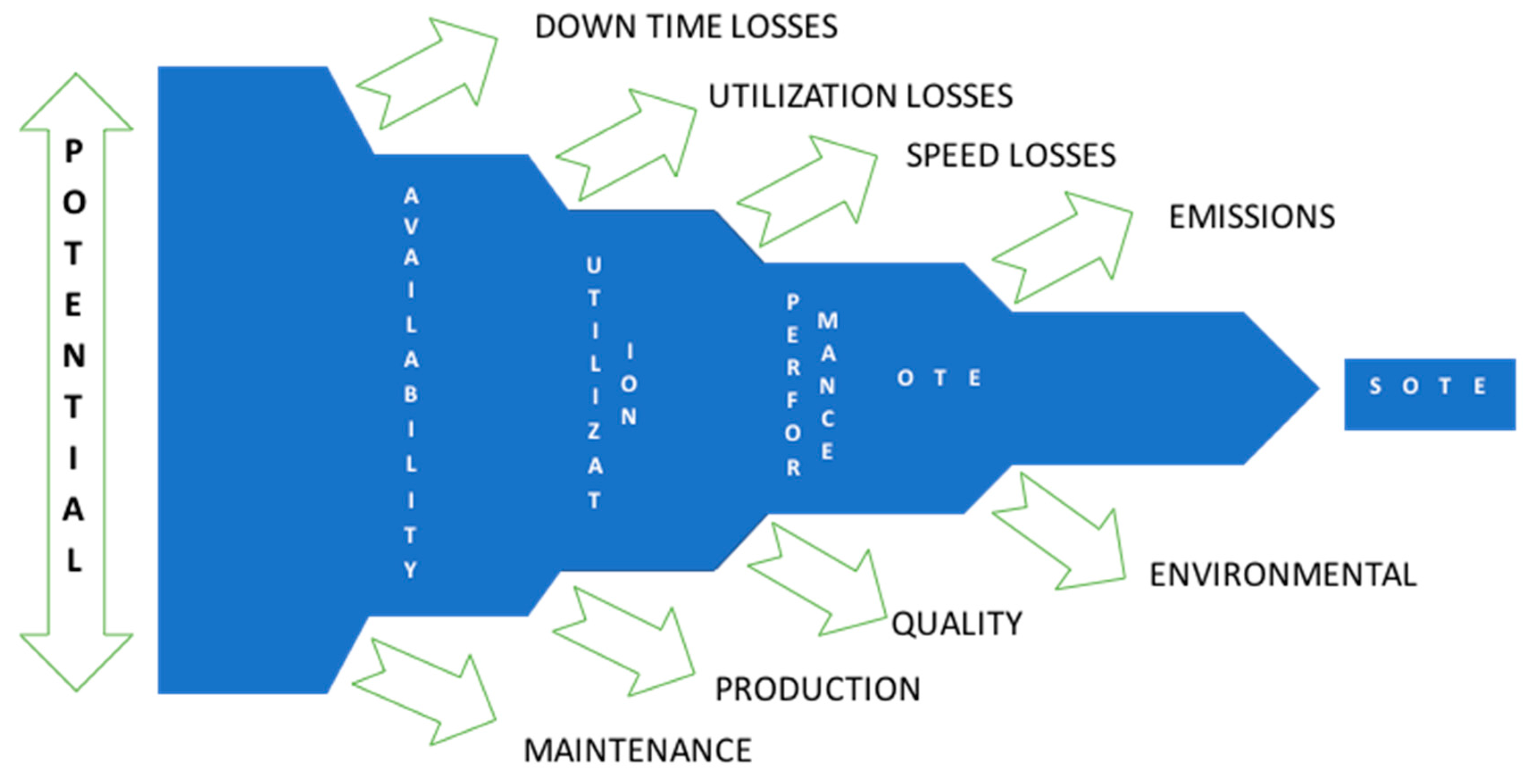

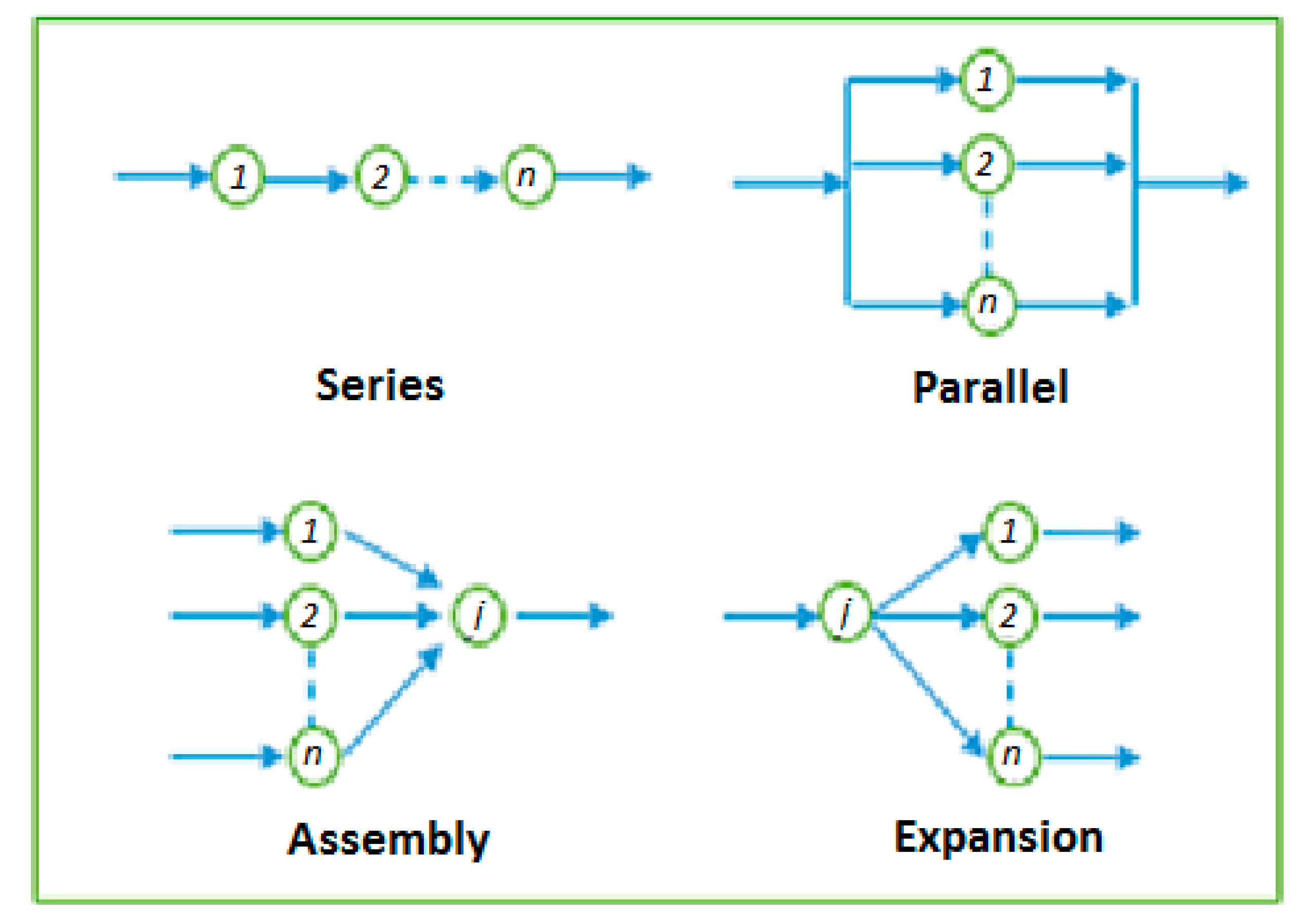

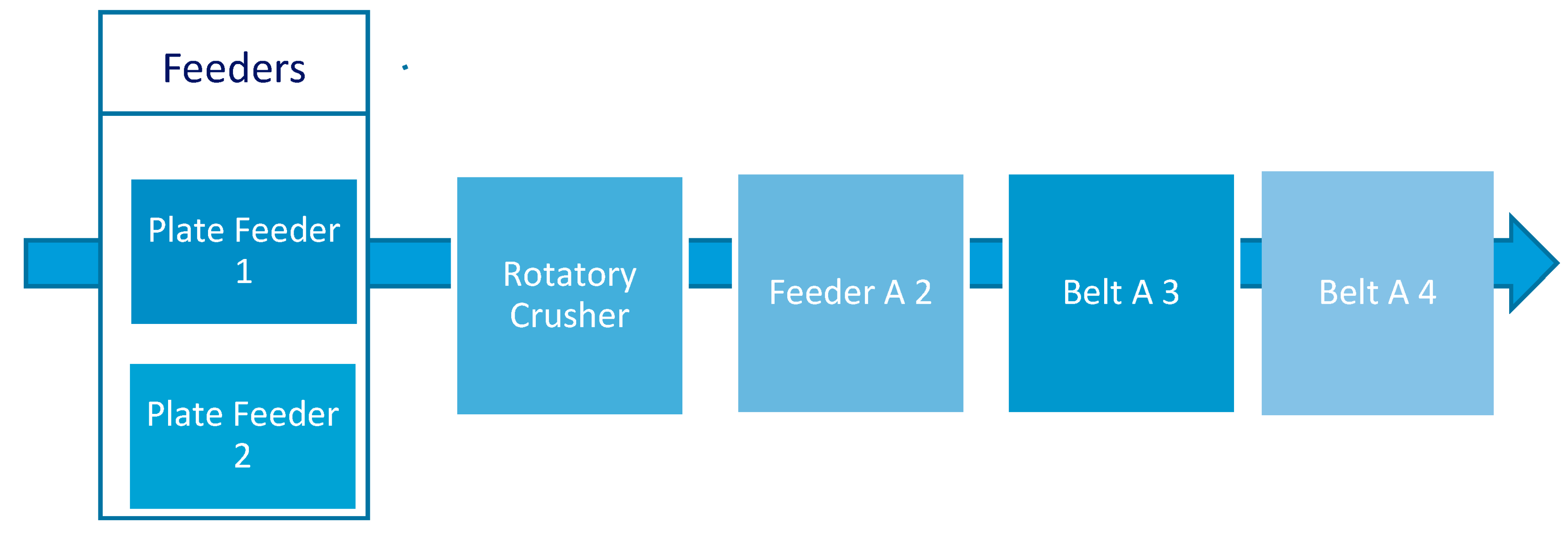

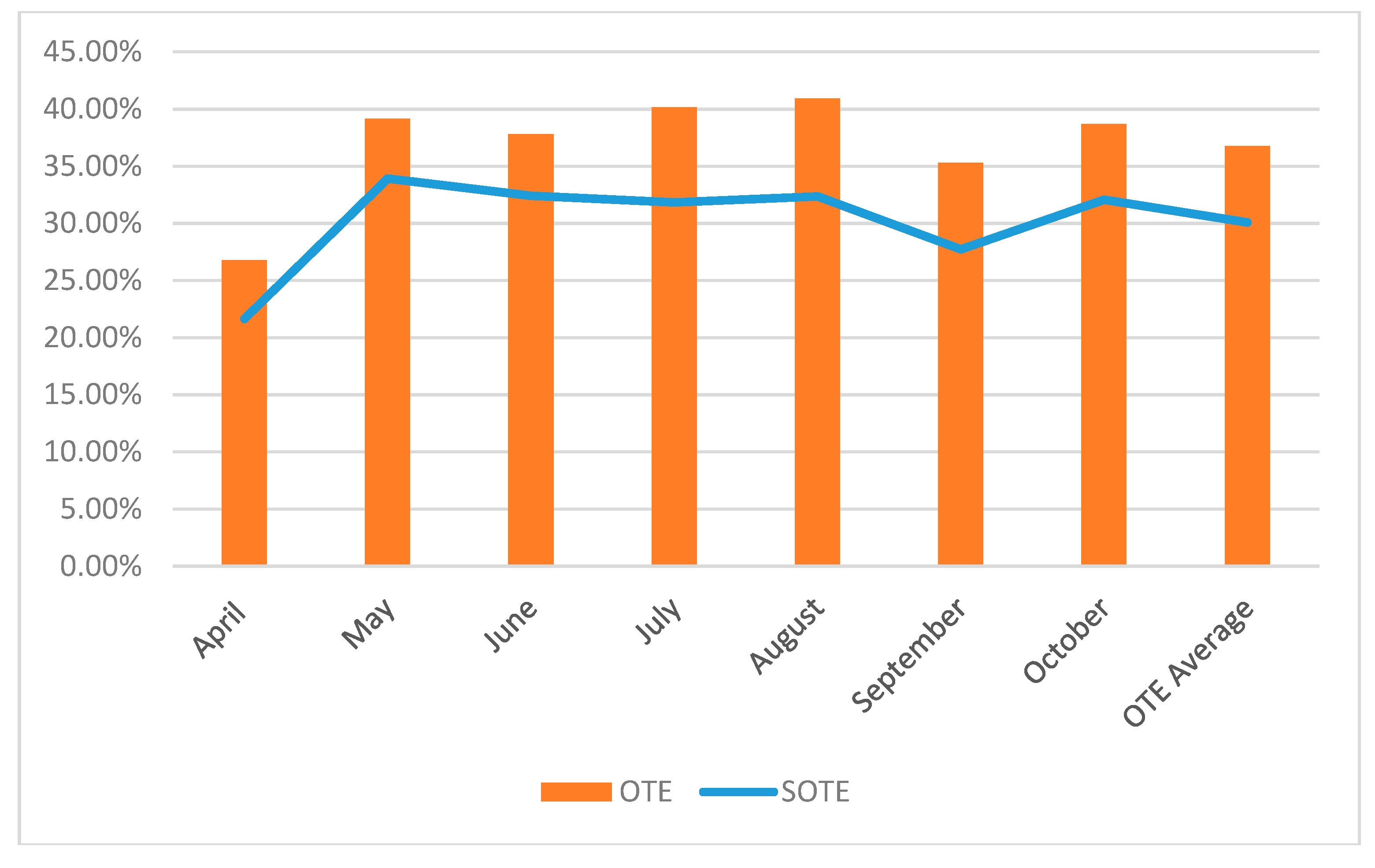

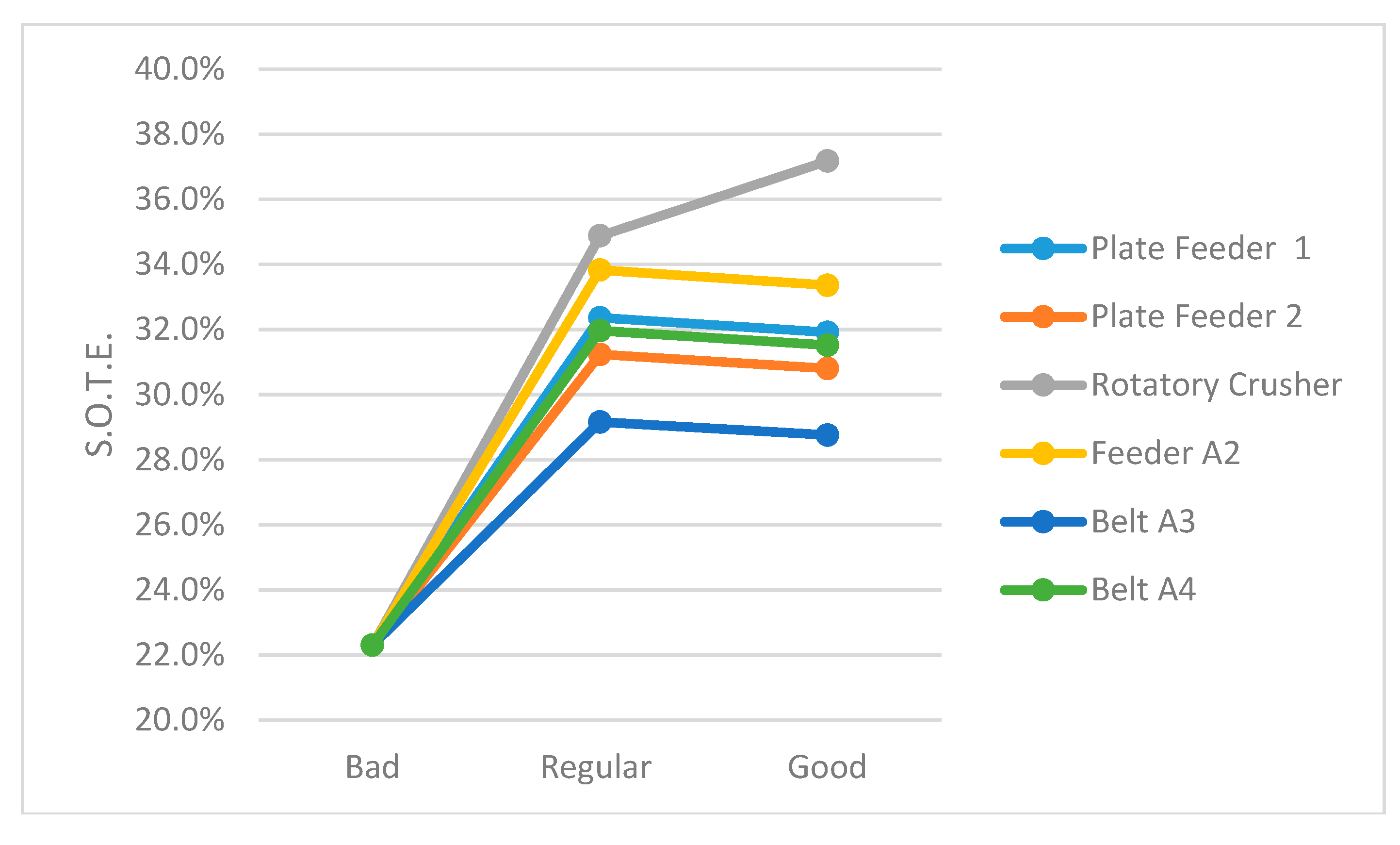

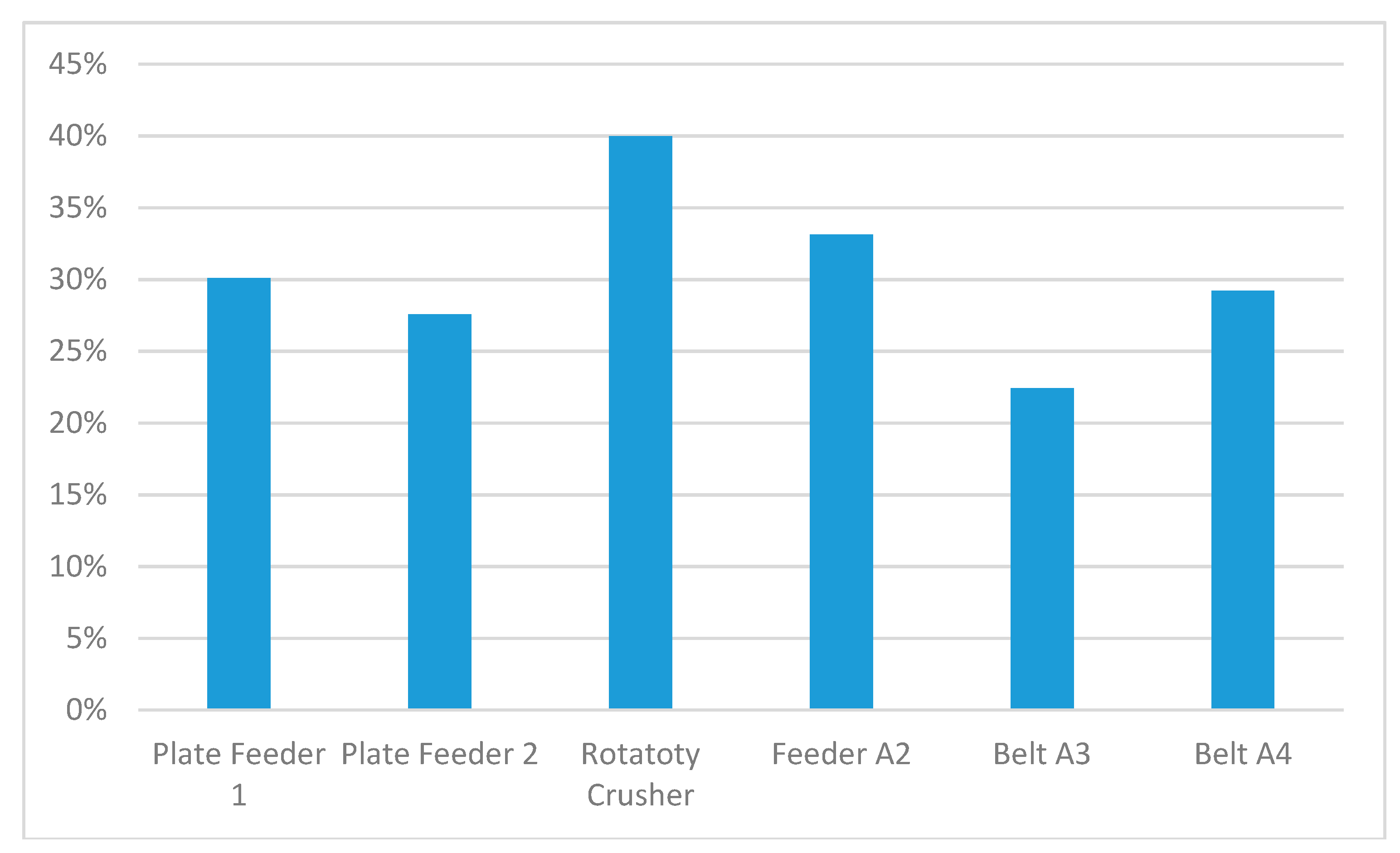

Here, a new metric based on the Overall Throughput Effectiveness (OTE) [

5] is proposed: the Sustainable Overall Throughput Effectiveness (S.O.T.E.). This indicator allows us to determine which equipment, within a production system, causes a greater effect on the Overall Sustainable Throughput. With this indicator, the effects of the individual factors, on the overall results, availability, performance, quality, and sustainability can be traced throughout the production system.