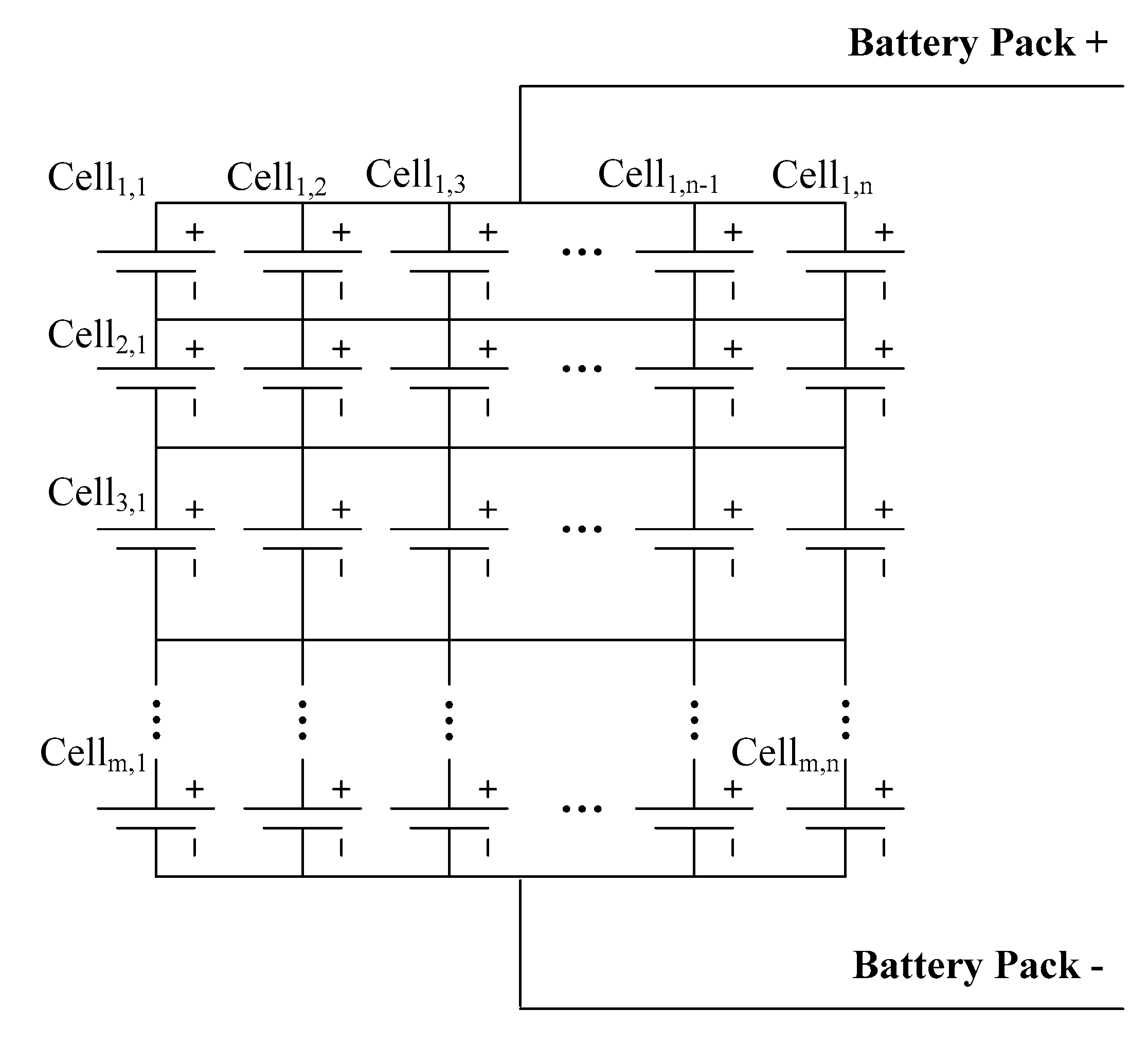

In this chapter, the proposed battery pack model is used in Monte-Carlo experiments to evaluate battery packs with different numbers of parallel. For each configuration, hundreds of battery packs are simulated and the conclusion based on these results will thus not be influenced by possible coincidences of a limited number of samples.

This paper only intends to find out the influence of paralleling more NCR18650PF cells instead of trying to find the optimal cell size and the corresponding parallel number for a given battery pack capacity. Therefore, it should be noted that all the cells generated in this paper have the same nominal capacity and that the battery packs with different parallel numbers thus have different capacities.

4.1. Statistic Features of Battery Cells

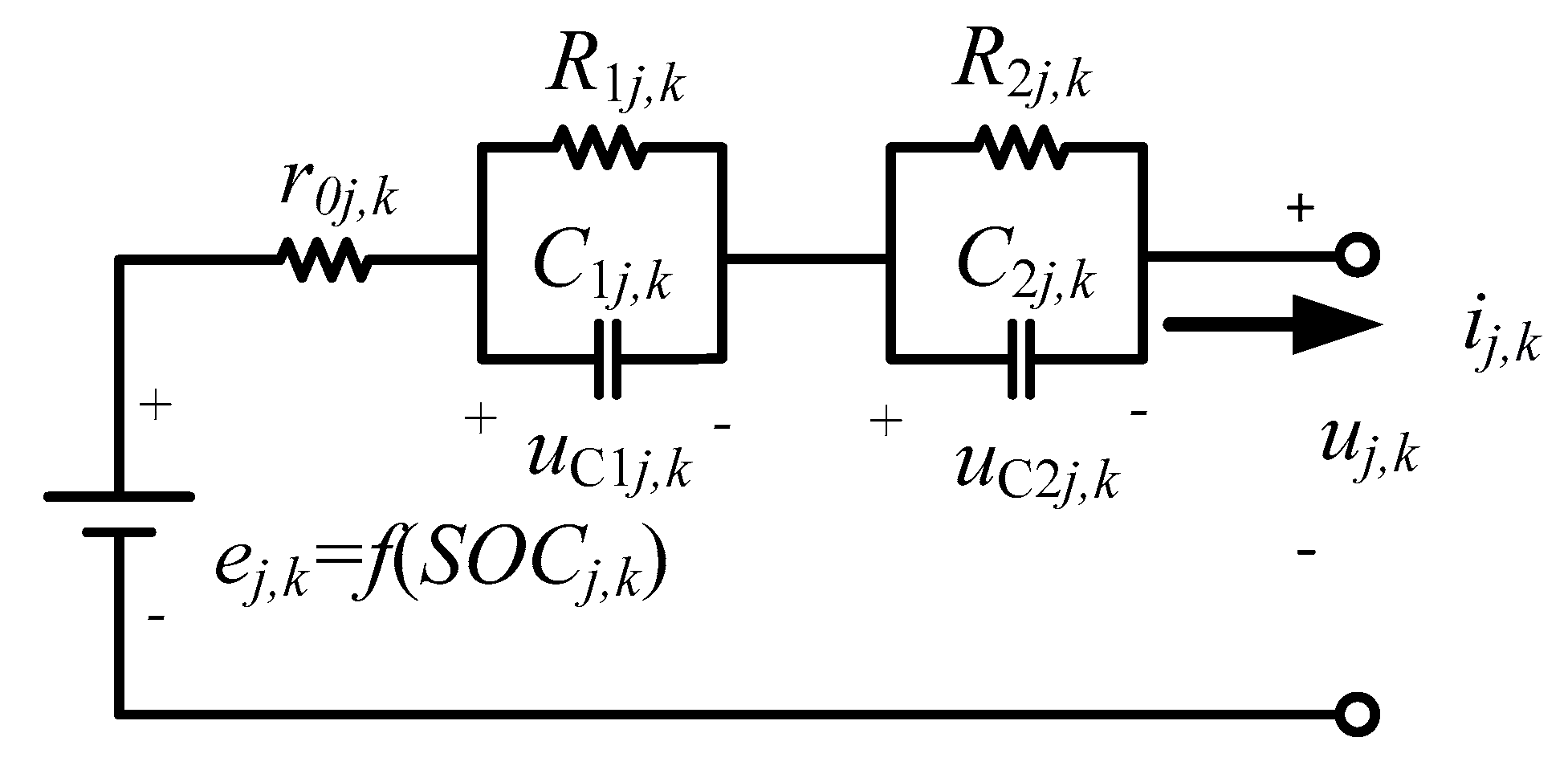

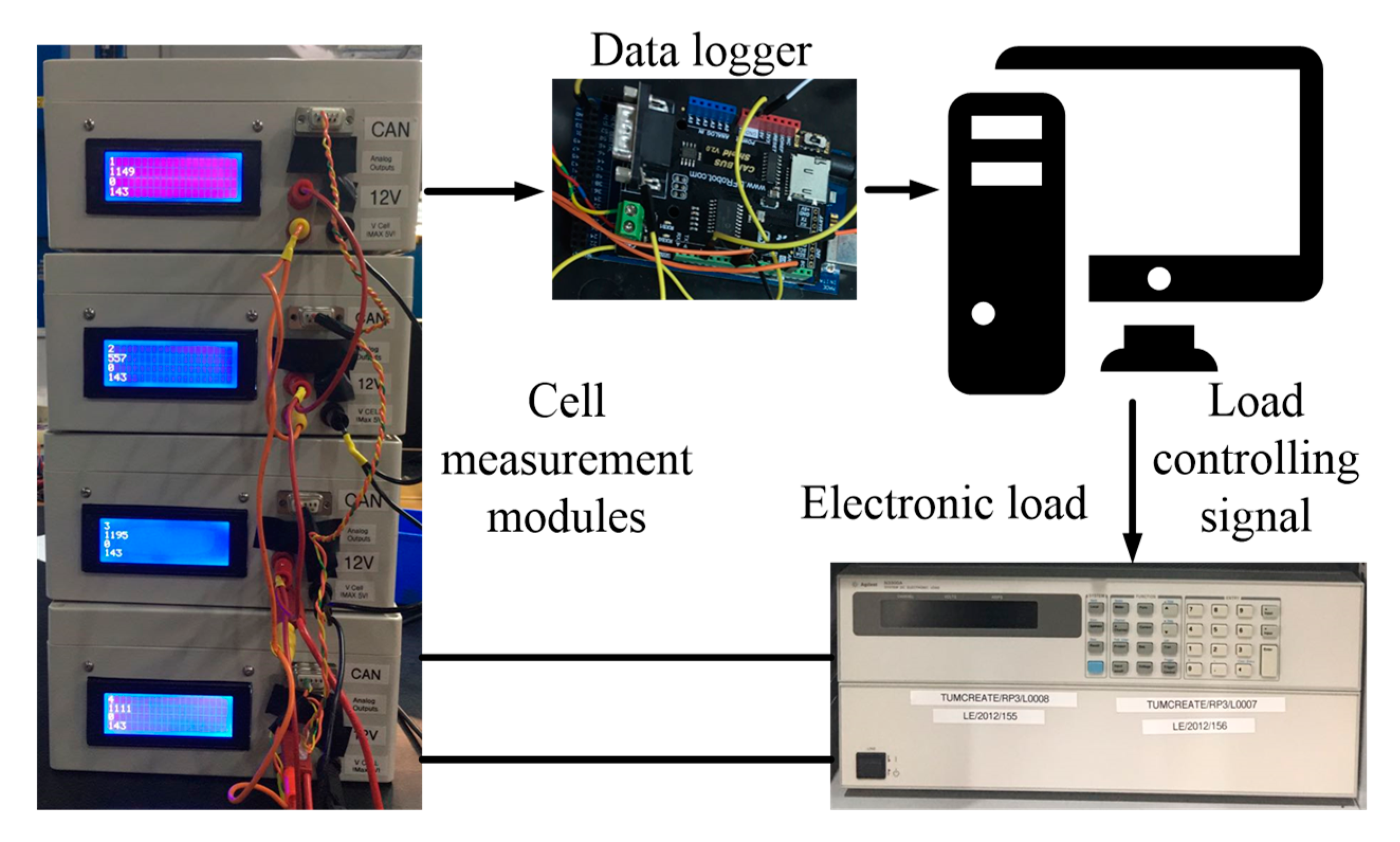

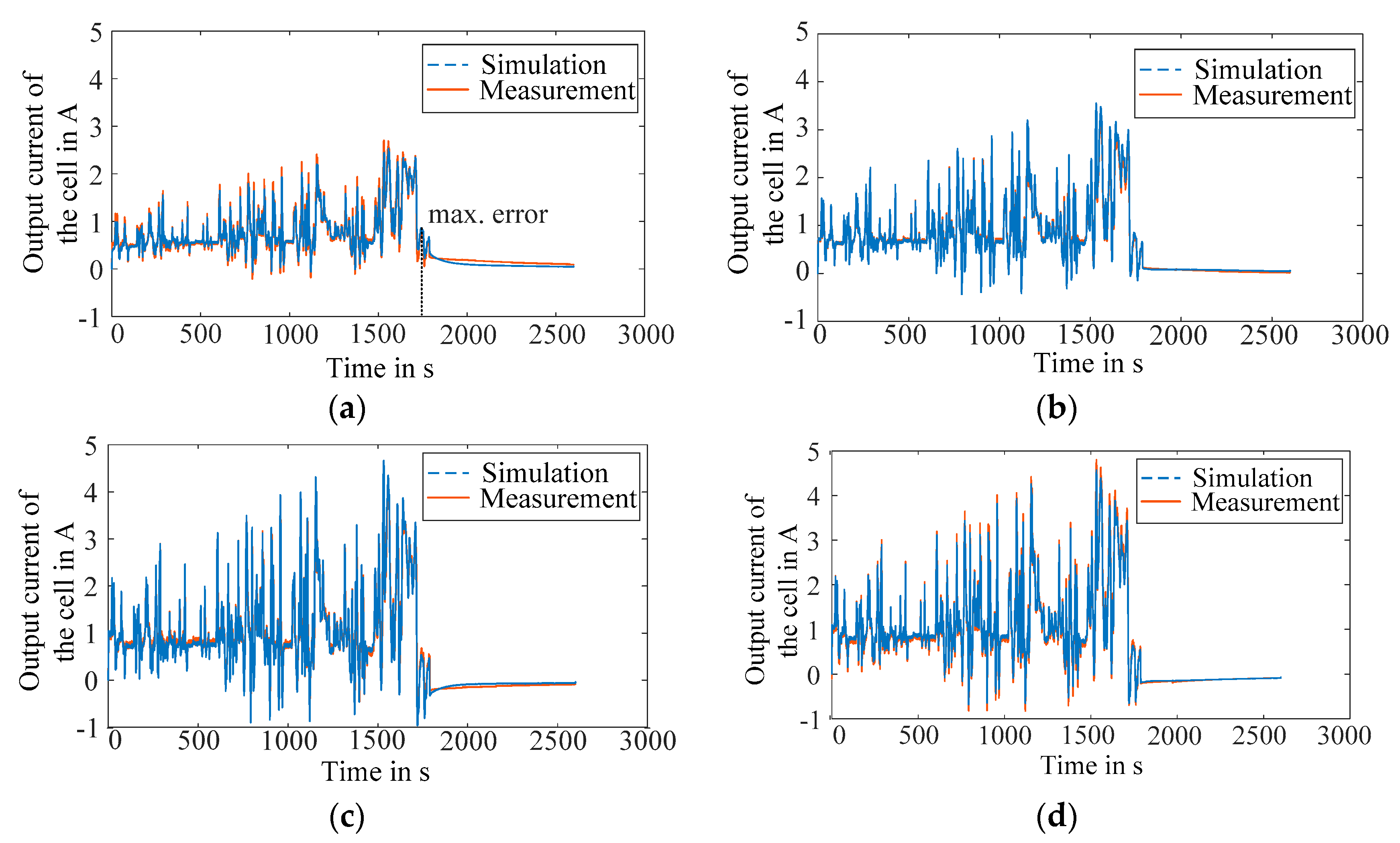

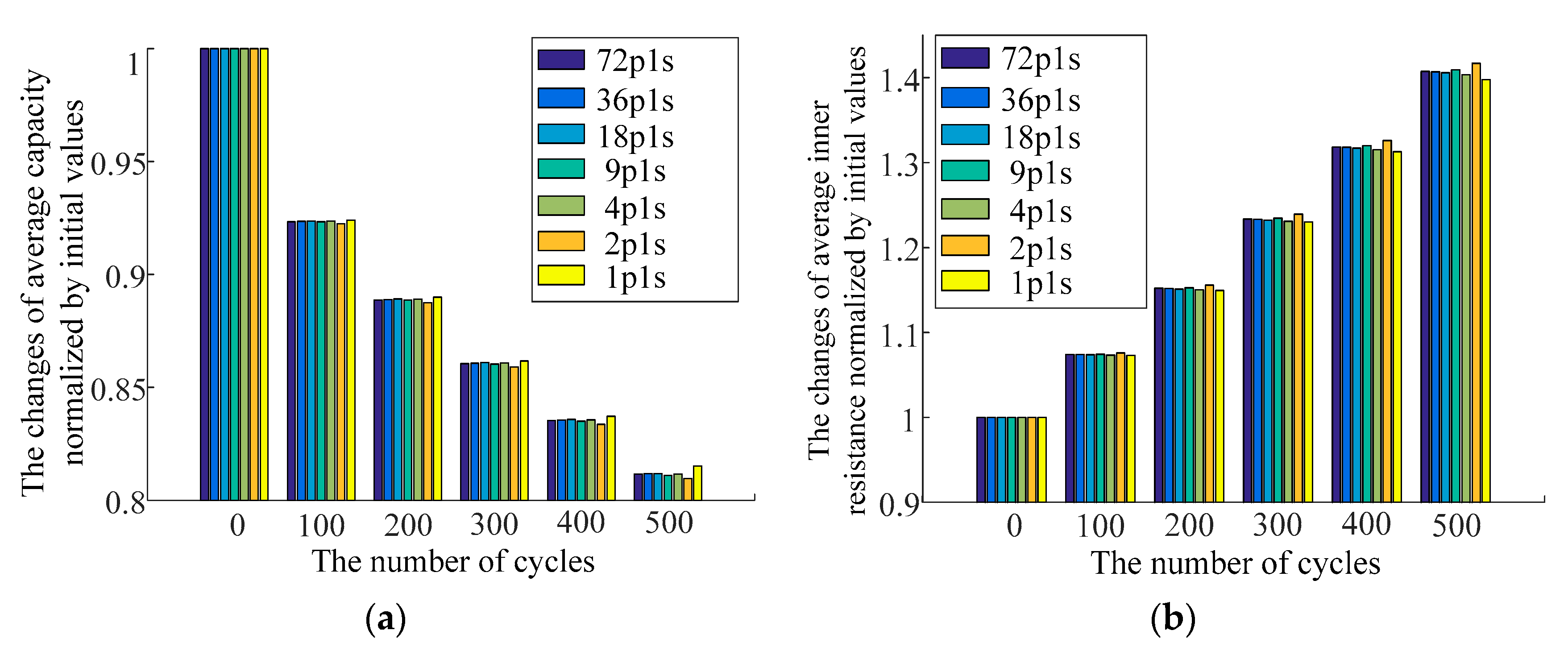

In order to generate the properties of the battery cells, i.e., the inner resistance (R0j,k), capacity (Qj,k), polarization resistors (R1j,k, R2j,k) and polarization capacitors (C1j,k, C2j,k) in the Monte-Carlo experiments, the statistic features and the distributions of the parameters are analysed based on the measured data of 50 Panasonic NCR18650PF cells.

The distribution of the cell capacity is studied first. The frequency histogram of the capacity is in

Figure 7a. The Kolmogorov-Smirnov test (KS-test) shows the probability of the null hypothesis that the capacity data complies with a normal distribution is 66%. As this probability cannot directly decide if the null hypothesis should be accepted, the skewness of the data is also calculated. The skewness 0.1941 and the histogram show that the data has a clear skew on the right side. Therefore, this paper proposes to use the skew normal distribution instead of the normal distribution to generate the capacity of cells [

1]. The choice can be reasonable, because the cell capacity must not be lower than the nominal value in the datasheet, which could result in a tendency in the production to make the distribution of the cell capacity skew to the right side.

Secondly, the distribution of the inner resistance is discussed. The histogram is in

Figure 7b, which resembles the normal distribution better than that of the cell capacity. The skewness of the inner resistance data is 0.11. Therefore, although the probability of the null hypothesis is 51% in the Kolmogorov-Smirnov test, the normal distribution is still adopted for the inner resistance due to the lower skewness and the histogram.

The four polarization parameters in the equivalent circuit,

R1j,k,

C1j,k,

R2j,k and

C2j,k, are more difficult to measure, as there is no equipment specially designed for the automatic measurement of those parameters. Therefore, the polarization parameters of only 10 cells are identified manually to obtain their statistic features. As 10 results cannot show an obvious pattern in the histograms, the statistic indices of the four polarization parameters are calculated to identify their distributions. Results are listed in

Table 2, in which the

p-value of KS-test is the probability that the tested dataset complies with a normal distribution. From the

p-values of the KS-test and the skewness values, it is seen that the

C2j,k quite possibly follows the normal distribution while

R1j,k,

R2j,k and

C1j,k should be generated by skew normal distributions.

Additionally, the interdependence between the six parameters should also be identified. The correlation between every two parameters is tested with the null hypothesis that the tested two parameters are linearly independent. Similar to a covariance matrix, the

p-value (possibilities of the null hypothesis) of each test is listed in the symmetric matrix in

Table 3 and located by the column and the row labelled by the two corresponding parameters. The values on the diagonal are not important, because they correspond to the self-dependence and must be 1. As all the

p-values are lower than 50%, the null hypotheses cannot be declined. The distributions of the parameters can be considered as linearly independent of each other.

Based on the discussions above and the statistic indices, the properties of the cells in Monte-Carlo experiments could be generated by the distributions in Equation (5). r0j,k and C2j,k comply with normal distributions, represented by N in Equation (5), while the other four properties are generated according to the skew normal distributions, represented by SKEWN in Equation (5).

In Equation (5),

μ1,

μ2 and σ

1, σ

2 are respectively the mean values and standard deviations of the two normal distributions.

ω1–

ω4,

α1–

α4 and ε

1–ε

4 are the parameters of the skew normal distributions. In the possibility density function (PDF) of the skew normal distribution,

Φ and

ϕ are respectively the cumulative distribution function (CDF) and the PDF of a standard normal distribution

N(0,1). The values of these parameters are selected to ensure that the distributions have the same mean values, standard deviations and skewness values as those of the measured data. The detailed values and calculation processes are not given in this paper due to the length limit.

4.2. Simulative Evaluations with Monte-Carlo Experiments

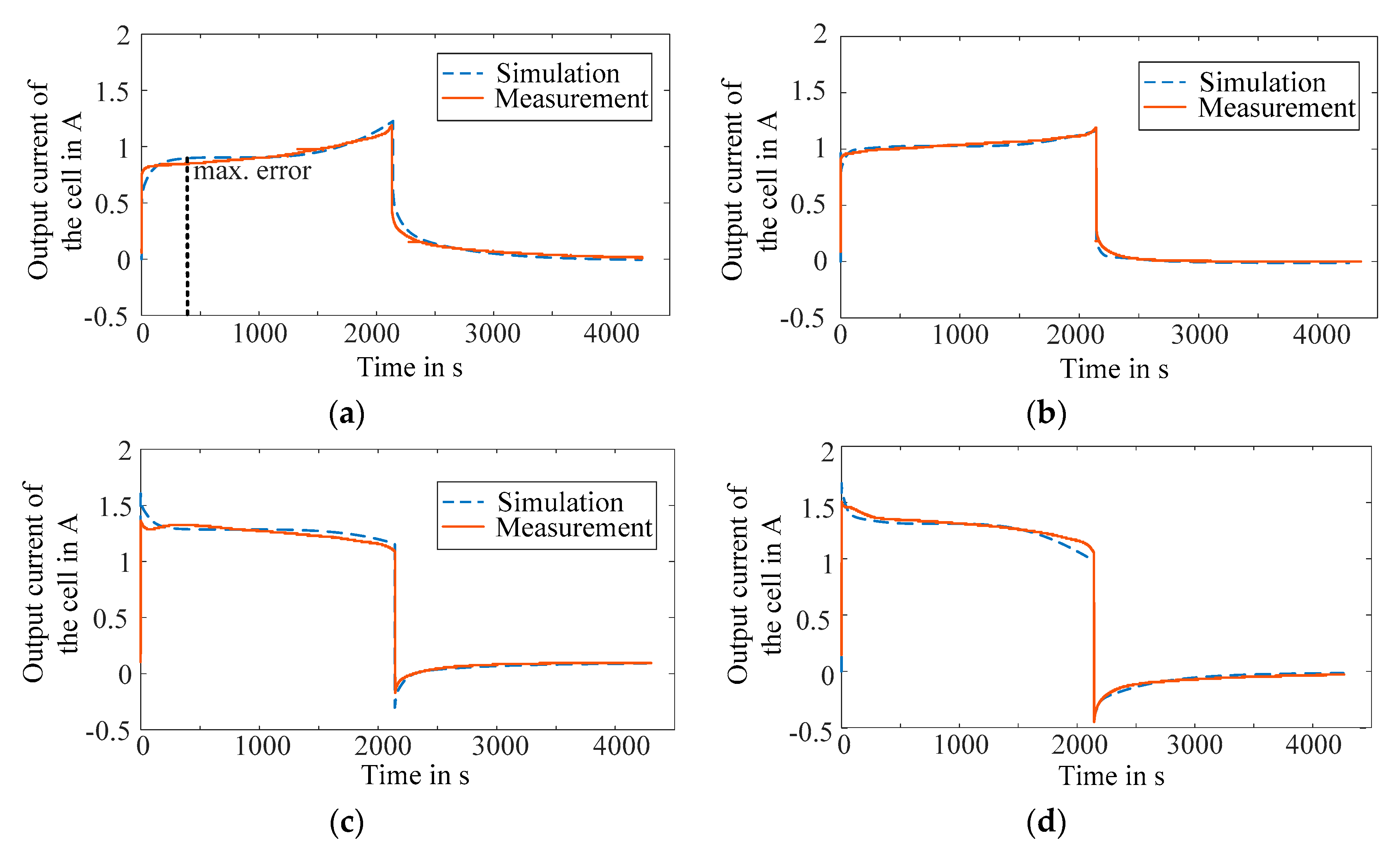

Using the distributions in Equation (5), battery packs composed of randomly generated NCR18650PF cells are simulated to evaluate the influences of the parallel number in terms of efficiency and degradation.

Firstly, battery packs with 36p108s, 18p108s, 9p108s, 4p108s, 2p108s and 1p108s configurations are generated. The parameter of every cell in all tested packs is randomly generated according to the distribution derived in

Section 4.1. In addition, 500 battery packs of each configuration (3000 packs in total) are generated to form enough samples in the Monte-Carlo experiments. The series connection numbers of all the pack configurations are kept constantly 108 to reach the required nominal voltage 400 V, while the parallel number starts at 36, half of the parallel number of the Tesla Model S battery pack, then declines following an equal ratio progression until 1 to make the difference brought by different parallel numbers more noticeable. The parallel number 9 is followed by 4 instead of 4.5, because the parallel number should be integer.

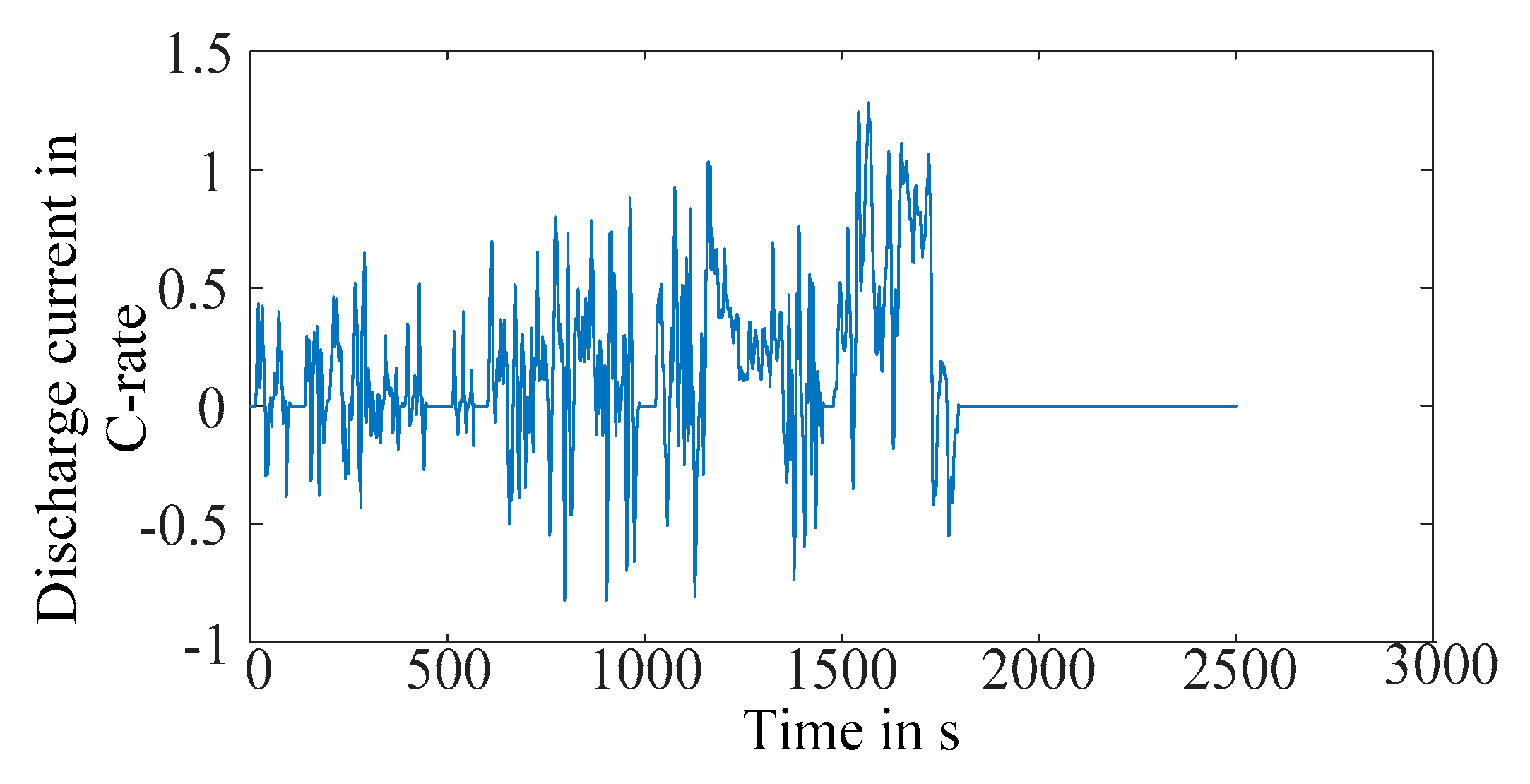

Secondly, to evaluate the efficiency of different configurations, a discharge simulation from 100% to 20% of SOC, repetitive using the C-rate curve in

Figure 5 for 10 times, is performed on every battery of the 3000. The total energy dissipated by the BMS balancing and the total energy loss inside the cells of every battery pack are recorded. To obtain the proportions, the two losses count in the total output, they are then divided by the net output energy of the battery packs. In that way, the losses of different battery packs can be compared. The medians, means, minimums and maximums of the proportions of the two losses over the parallel numbers are plotted in

Figure 8a,b.

In the results, it is observed that as the parallel number increases, the energy consumed by the balancing of BMS decreases. The reason is that the sum of several independent and identical distributions always has a lower relative standard deviation (standard deviation divided by mean value) compared to the original distribution as deduced in Equation (6).

SD means standard deviation while the

E is the expectation function. The first sub equation shows that the standard deviation of the sum value counts for a portion of

σ/

μ in the mean value, while in the second sub equation the deviation of a single variable counts for a portion of

σ/

μ in the mean value, which is

times higher than that of the summed value. In Equation (6)

X1,

X2 …,

XN are not physical variables in the battery model, but just a group of independent normal distributed variables to prove that the deviation of the sum value is much smaller than the deviation of individual variables. Connecting more cells in parallel will lower the capacity difference between different rows of paralleled cells, and thus reduces the proportion of the energy consumed by the balancing of the BMS.

Additionally, an increasing number of paralleled cells is expected to result in a higher loss in the cells, because as the parallel number increases, a cell with the properties significantly different from those of the other cells in parallel is more likely to appear. This cell intensifies the energy exchanges between the cells and thus makes the energy loss inside the cells higher.

The curves of the maximum and minimum values manifest that the distribution of the total in-cell loss tends to converge as the parallel number increases in the Monte-Carlo experiments. Therefore, although the total in-cell loss tends to grow together with the parallel number, this loss is also more unlikely to diverge far from the expectation value.

However, the influence of the parallel number on the efficiency of a battery pack is not significant, as the changes of losses count lower than 0.1% in the net output energy when the parallel number varies. Nonetheless, if the small influences accumulate over a longer time, it is possible that the aging behaviours of the battery packs are different.

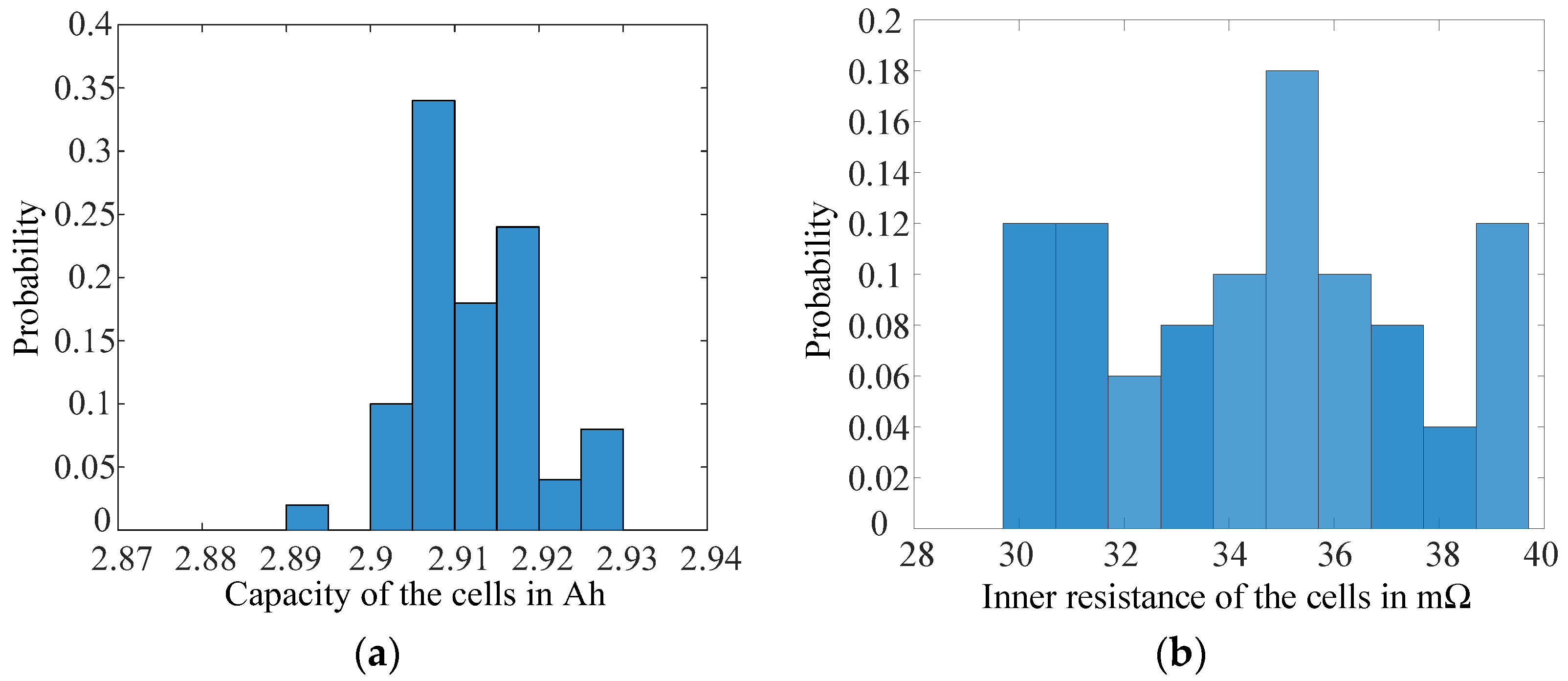

Therefore, as the third step of the Monte Carlo experiment, one battery pack with respectively 72p1s, 36p1s, 18p1s, 9p1s, 4p8s, 2p1s and 1p1s configuration is generated and simulated for 500 discharging cycles (the cycle life of Panasonic NCR18650PF cells) to observe the long term influence of the parallel number. In each cycle of simulation, the load curve in

Figure 5 is repeated for 10 times to discharge the battery pack from 100% SOC to 20% SOC. The degradation model in [

17] is used. Only one pack of each configuration is simulated, because of the long simulation time of the degradation test. In addition, the series connection number of battery packs is reduced to one, because only the cells in parallel can influence each other in terms of degradation and one parallel row is thus already enough to demonstrate the aging behaviours. The simulation time is also in this way further reduced.

The simulation contains no temperature model and the temperature of the cells is set to be constantly 25 °C. Therefore, this simulation implies the assumption that the battery packs have a good cooling system to maintain the constant temperature. The statistic indices of the capacity and the inner resistance of all cells in each battery pack before and after the aging test are listed in

Table 4. The aging curves of the average capacity and the average inner resistance after every 100 cycles are plotted in

Figure 9.

It is observed that the influence of the parallel number is more conspicuous in terms of degradation. In

Table 4 the highest increase of the mean inner resistance is 41.69% in the 2p1s battery pack while the lowest increase is 39.77% in the 1p1s battery pack (single cell). The difference is around 2%.

Moreover, as the parallel number increases, instead of a monotonic trend,

Figure 9a,b shows that the changes of the average inner resistance and the average capacity tend to converge (to respectively around 40.7% and −18.8% in this paper) after 500 cycles of degradation test. The convergence is also supported by the standard deviations: When the parallel number is higher than nine, the post-test standard deviations of the capacity and the inner resistance of cells are significantly lower than those in the 2p1s and 4p1s packs, although the initial deviations of the 2p1s and 4p1s packs can be lower. This means the cell properties do not tend to diverge but to follow a consistent pattern when the parallel number is higher. The battery pack properties will thus also distribute in narrower intervals after the degradation test.

Although only one pack of each configuration is simulated in the aging test, the trend of convergence can still be confirmed by the degradation of the battery pack properties and the cell properties. Therefore, it can be concluded that the degradation behaviour of battery packs with a higher parallel number is more consistent or, in other words, more predictable.

A possible explanation is that the energy exchange caused by the few particularly weak or strong cells is shared by more cells when the parallel number increases. The influence of these few cells on the aging of the battery pack degradation is thus limited.

Another noteworthy phenomenon is that the degradation of the 1p1s battery pack (single cell) is slower than that of the other battery packs as seen in

Figure 9. To verify if this is a coincidence of a single sample, another 15 single cells, i.e., 1p1s battery packs, are simulated. The maximum inner resistance growth and capacity reduction are respectively 40.31% and −19.76%, which are still lower than the corresponding changes of the other battery packs tested in this paper. Therefore, this phenomenon can be confirmed as a general situation. An explanation is that a single cell is not involved in any extra charging or discharging processes and thus has a lower cycle aging.

Based on the results collected in Monte-Carlo experiments, it can be concluded that the parallel number is able to influence the efficiency and the degradation of a battery pack. If the parallel number increases, the BMS balancing loss tends to decrease while the energy loss inside the cells tends to rise. However, when evaluating battery packs composed of homogeneous cells as in this paper, the influence on the efficiency is only marginal. The influence on the degradation is in comparison more conspicuous. If more cells are paralleled in a battery pack, the degradation behaviours of the battery pack tend to be more predictable.

4.3. Discussion

As proved by the Monte-Carlo experiments, the parallel number cannot significantly influence the efficiency of a battery pack. The reason is that the significance is limited by the highly consistent cell properties, as all the distributions of the properties are obtained from the measurement results of high quality cells. If cells with higher variance are used to design a battery pack, the influence on efficiency should be considered.

Secondly, although the degradation simulation shows that the single cell has a slower aging process than that of the paralleled cells, it does not mean reducing the parallel number to one is an optimal choice. On the one hand there are more factors, e.g., the cost and reliability, that need to be considered. On the other hand, the degradation simulation largely depends on the degradation model and the temperature model. The conclusion could be changed if different models are selected to adapt to different scenarios of application.

Nonetheless, although the simulation in this paper does not have a temperature model and the universality of the conclusions could thus be limited, the proposed approach can still be used to further evaluate the configuration of battery packs in other scenarios by implementing more detailed or more specific models, because of the compatibility of the battery pack model.