Holistic Testing Strategies for Electrified Vehicle Powertrains in Product Development Process

Abstract

:1. Introduction

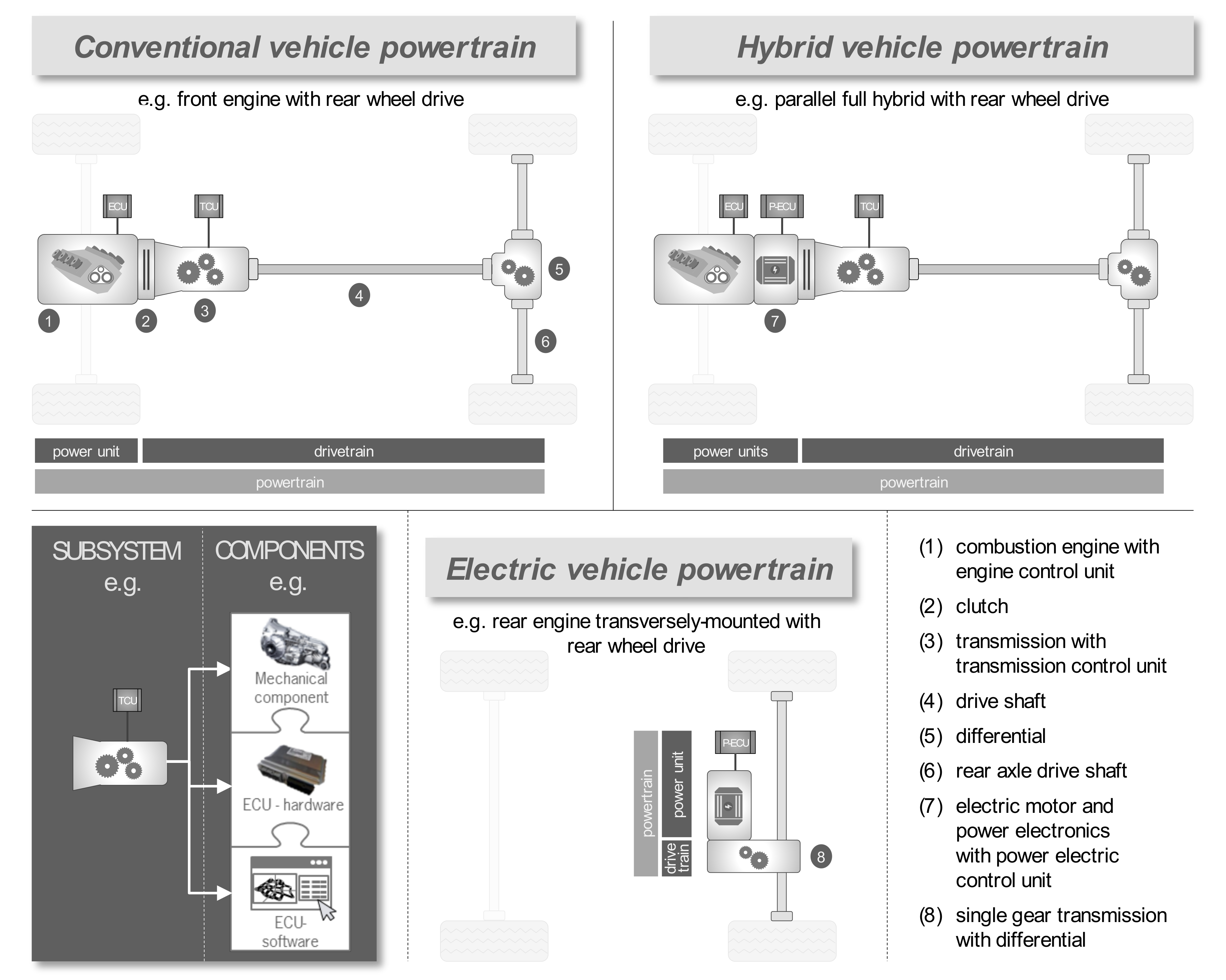

2. Nomenclature

- powertrain: combination of subsystems, which deliver the drive from the power unit up to the wheel flange. The following applies: powertrain = power unit(s) + drivetrain; Therefore, the powertrain and drivetrain are not synonyms.

- power unit(s): subsystem(s) of the vehicle powertrain, which generate and provide torque and rotational speed. For example, this can be a combustion engine, including its engine control unit (ECU hardware and software), or an electric motor, including its power electric control unit (P-ECU hardware and software).

- drivetrain: combination of subsystems, which transmit and/or convert torque and rotational speed up to the wheel flange.

- subsystem: is a functioning intrinsic system, which consists of single components.

- component: is a mechanical or mechatronic element. They contribute to the complete functionality of the subsystem. The components of a hybrid vehicle powertrain include the P-ECU (hardware), P-ECU (software) and the power electronics (as the mechatronic component).

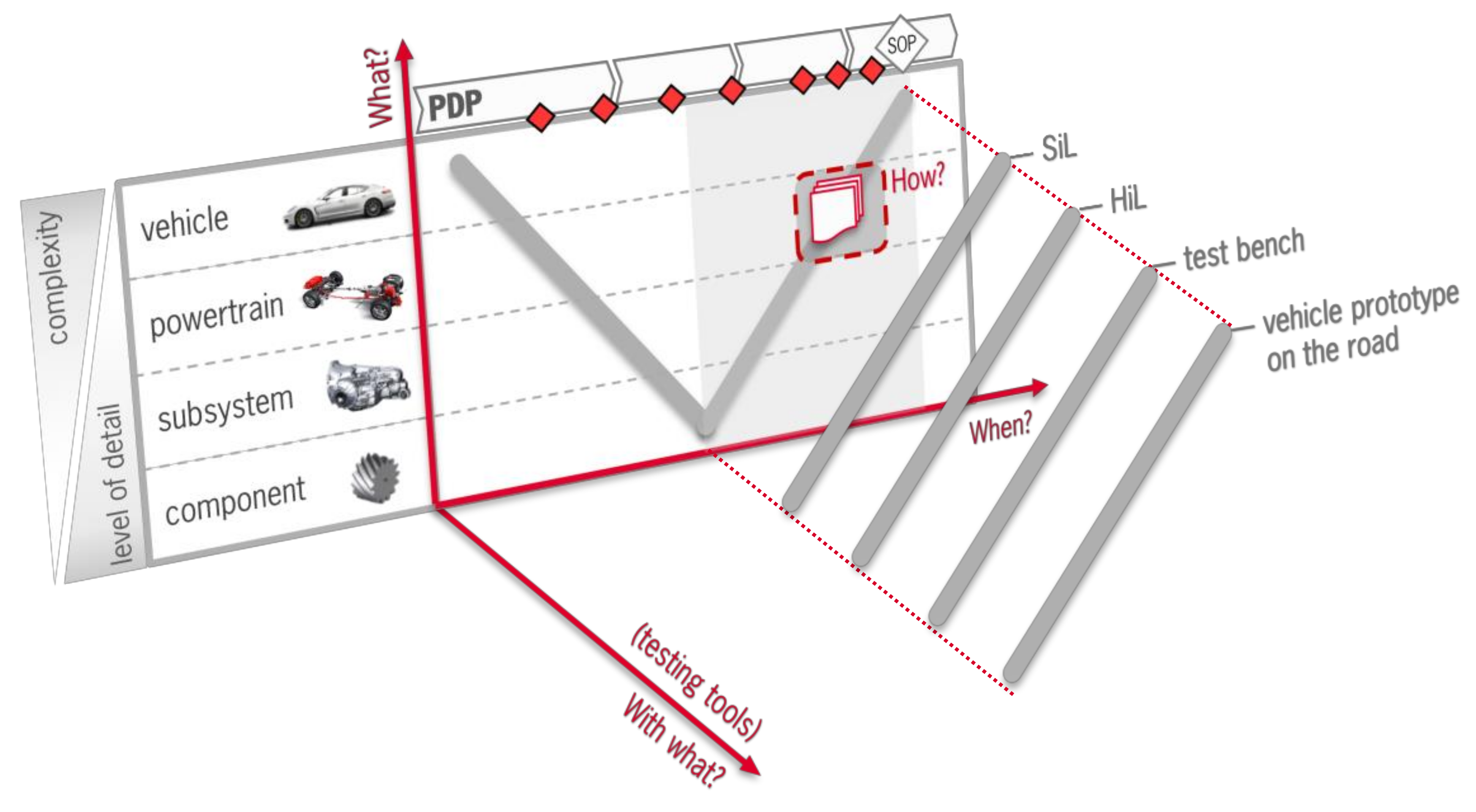

- system levels: For describing the test system level of a test object in a holistic test strategy, four different system levels are established and combined with the v-model:

- ◦

- 1. level: vehicle level

- ◦

- 2. level: powertrain level

- ◦

- 3. level: subsystem level

- ◦

- 4. level: component level

3. Method to Develop a Holistic Test Strategy

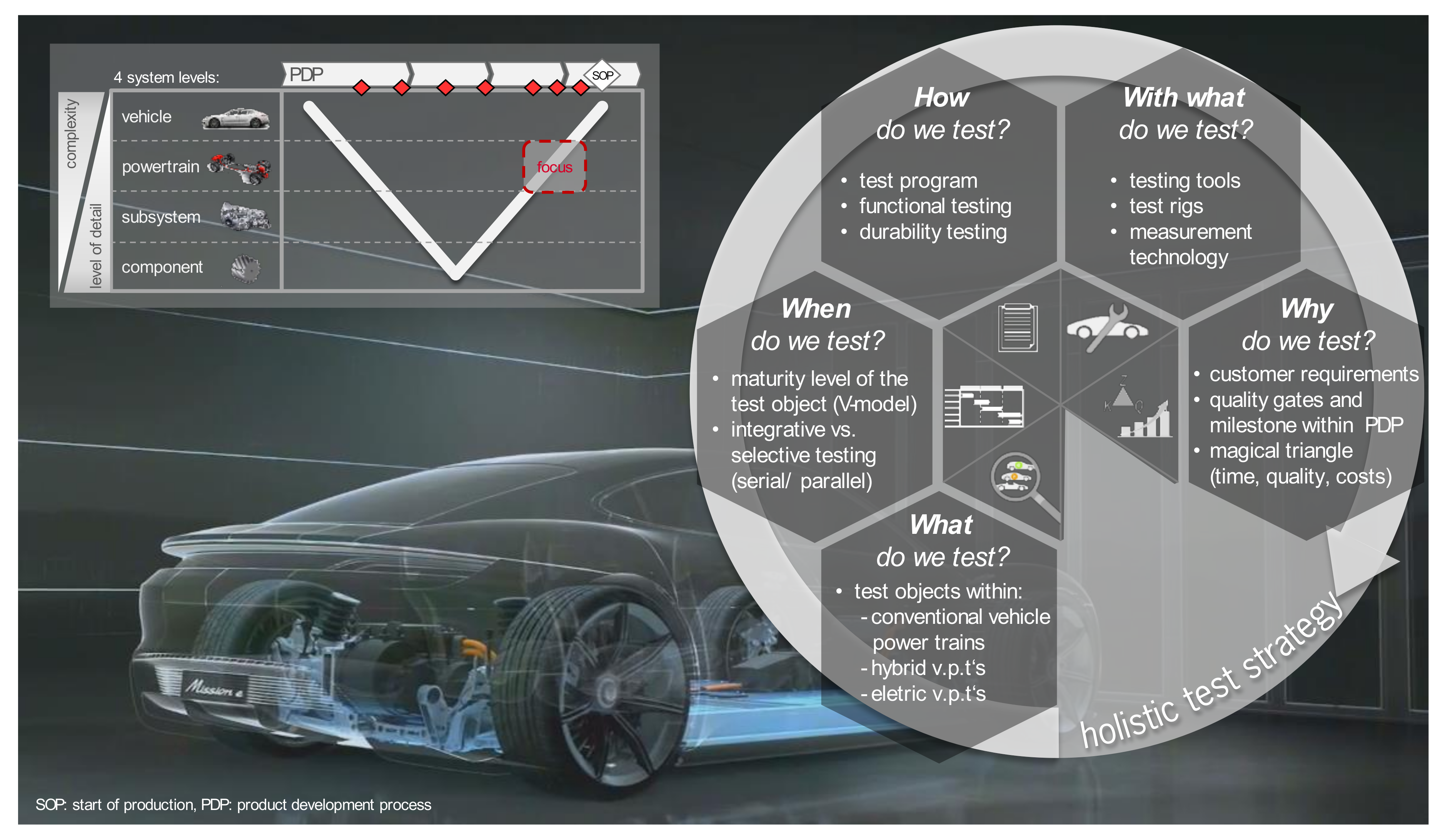

- Step 1: Analyze the test strategy of a conventional vehicle powertrain by answering the five core questions (Figure 2).

- Step 2: Perform a requirement determination by function analysis for either a hybrid or electrical vehicle powertrain topology.

- Step 3: Overlay the test strategies to identify emerged vacancies and dependencies.

- Step 4: Complete the test strategy by filling up the vacancies with testing methods and display it in form of a testing road map.

3.1. Five Core Questions

- What do we test?Within this core question, it is necessary to clarify the extent of consideration of the powertrain with regard to its subsystems and where required, to its components. In the current analysis, the powertrain topologies from Figure 1 are considered. The HV battery, the charging technology and stations are similar to the tires and brake units, which are not covered by the extent of consideration.

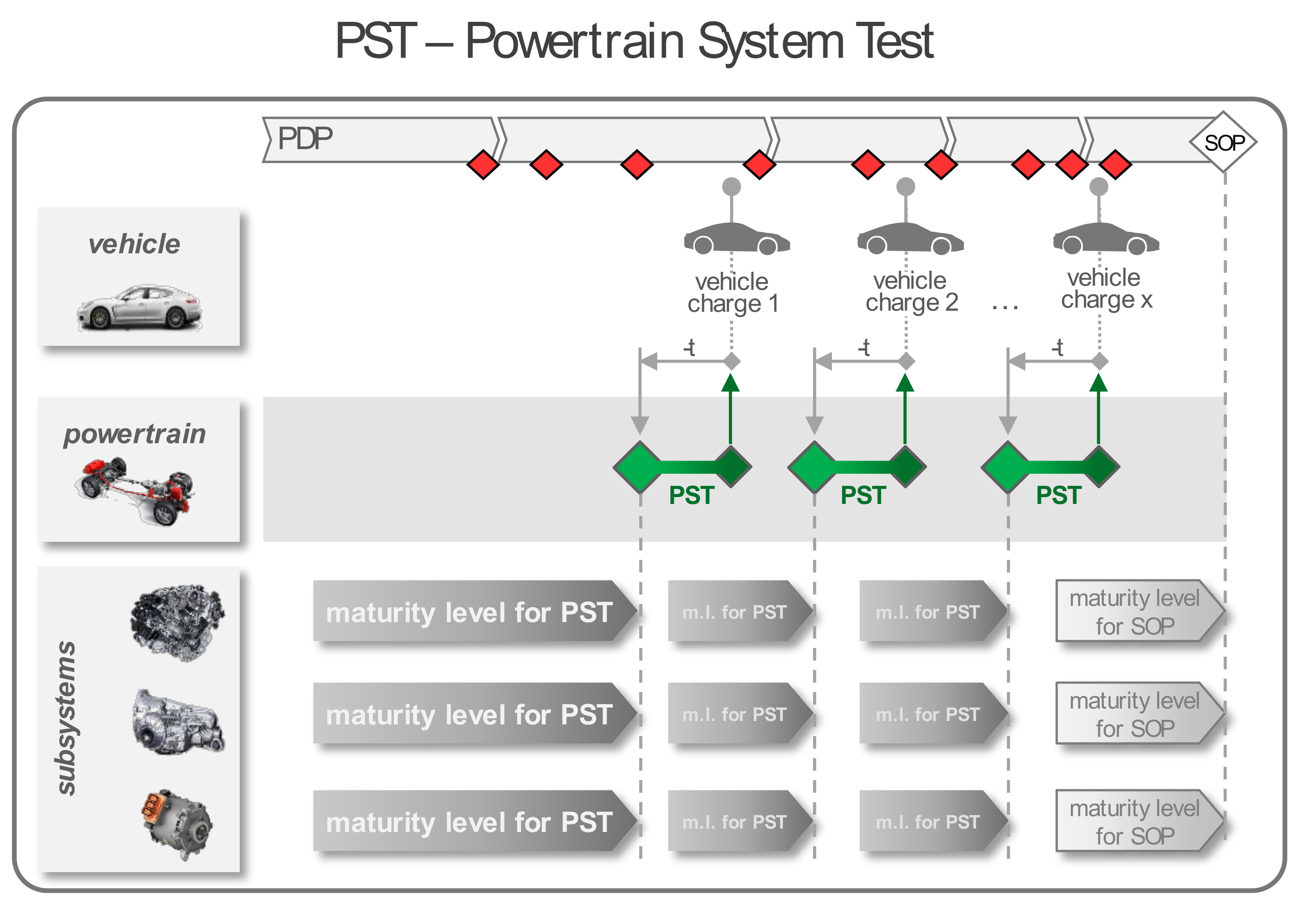

- When do we test?This core question analyzes the maturity levels of the test objects at different times in the product development process. It is important to identify interdependent tests as a qualitative indication so they can be categorized regarding an integrative or selective testing strategy. Therefore, it is linked to the core question “How do we test?”.

- How do we test?Within this core question, the test programs need to be gathered and categorized regarding their testing focus. For example, this includes durability testing, functional testing, misuse testing or testing acoustics or thermodynamics.

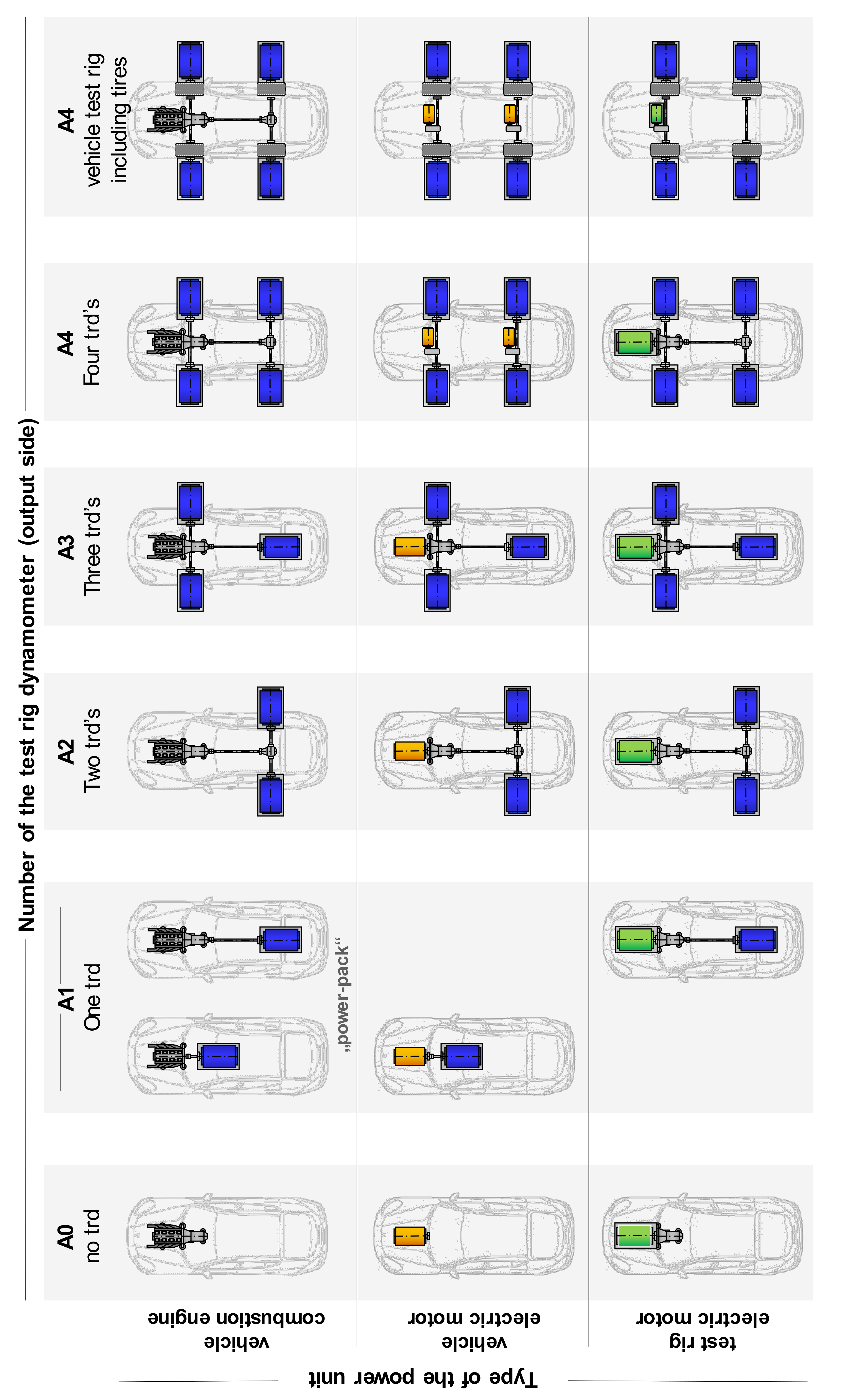

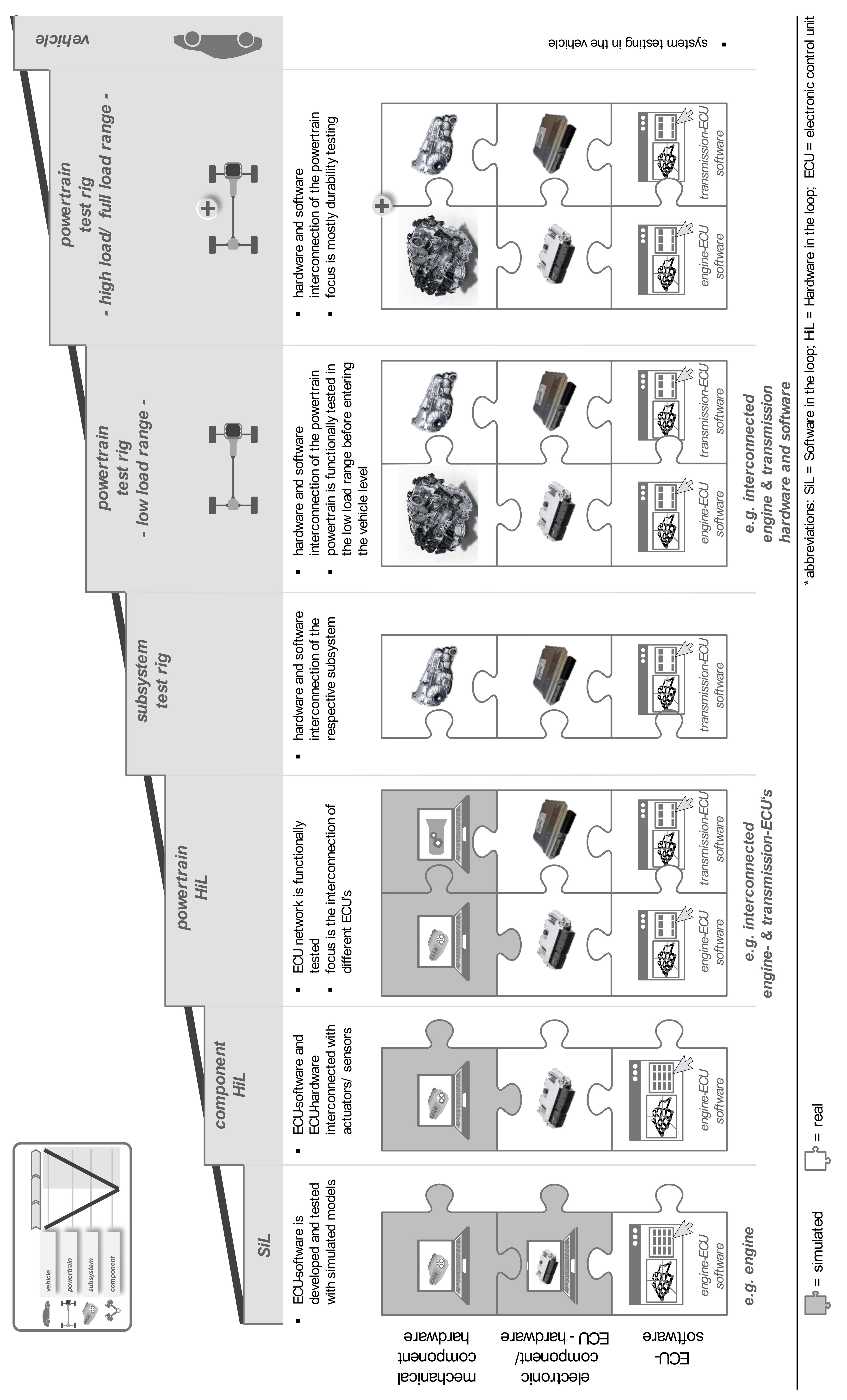

- With what do we test?A large toolbox of testing tools is available for realizing and implementing the test requirements. These include simulation models, test rigs and measurement technologies. As test resources have to follow the trend to be more flexible and not just cover one test application [9], the description of several configurations is quite permissible. For this core question, both analysis and categorization of the toolbox is to be carried out to connect the contents to the other core questions. An example categorization of the test rigs is shown in Figure 3.

- Why do we test?This core question examines the customer requirements, quality gates and milestones within the product development process referring to the magical triangle of time, quality and cost factors. This question is superordinate.

3.2. System Levels in the v-Model

3.3. Maturity Level of the Powertrain

4. Concept of the Powertrain System Test (PST)

- conventional vehicle powertrain: rear wheel drive (two wheel drive) with a front engine, clutch, automatic transmission, drive shaft, differential and rear axle drive shafts

- hybrid vehicle powertrain: rear wheel drive (two wheel drive) with a front engine, clutch, automatic transmission, drive shaft, differential and rear axle drive shafts and an electric motor with power electronics

- electric vehicle powertrain: rear wheel drive (two wheel drive) with a rear engine transversely-mounted with an electric motor (including power electronics) and a single gear transmission with a differential

5. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Burgard, K.; Krohn, C.; Geisler, J. Prüfkonzepte für elektrifizierte Antriebe: Mess- und Prüftechnik Antriebsstrang. ATZextra 2014, 19, 20–25. [Google Scholar]

- Schenk, M.; Klos, W.; Schwämmle, T.; Müller, M.; Bertsche, B. Antriebsstrangerprobung bei der Daimler AG: Moderne Erprobungsmethodik. In Proceedings of the Internationales Symposium für Entwicklungsmethodik, Wiesbaden, Germany, 8–9 November 2011; AVL Deutschland GmbH: Stuttgart, Germany, 2011. [Google Scholar]

- Schyr, C. Modellbasierte Methoden für die Validierungsphase im Produktentwicklungsprozess Mechatronischer Systeme am Beispiel der Antriebsstrangentwicklung. Ph.D. Dissertation, Institut für Produktentwicklung (IPEK), Universität Karlsruhe, Karlsruhe, Germany, 2006. [Google Scholar]

- Düser, T. X-In-The-Loop-ein Durchgängiges Validierungsframework für die Fahrzeugentwicklung am Beispiel von Antriebsstrangfunktionen und Fahrerassistenzsystemen; Institut für Produktentwicklung (IPEK), Universität Karlsruhe: Karlsruhe, Germany, 2010. [Google Scholar]

- Bock, M. Literaturrecherche und Bewertung von Erprobungsstrategien für Hybride und rein Elektrische Fahrzeugantriebe auf Prüfständen. Master’s Thesis, Institut für Verbrennungsmotoren und Kraftfahrwesen (IVK), Universität Stuttgart, Stuttgart, Germany, 9 December 2016. [Google Scholar]

- Ott, M.W.; Bartzsch, M.; Holtkötter, C. Optimierte Entwicklung von alternativen Antriebssystemen. ATZextra 2013, 18, 48–53. [Google Scholar]

- List, H. Zukünftige Antriebsentwicklung: Bewältigung kurzer Entwicklungszeiten und hoher Komplexitäten. In 35th Internationales Wiener Motorensymposium; Lenz, H.P., Ed.; Fortschritt-Berichte VDI Reihe 12, Verkehrstechnik/Fahrzeugtechnik; VDI: Düsseldor, Germany, 2014. [Google Scholar]

- Lindemann, M.; Wolter, T.-M.; Freimann, R.; Fengler, S. Konfiguration von Hybridantriebssträngen mittels Simulation. ATZ Automob. Z. 2009, 111, 332–338. [Google Scholar]

- Guggenmos, J.; Rückert, J.; Thalmair, S.; Stopper, D. Das Prüffeld der Antriebsentwicklung im Wandel. In VPC–Simulation und Test 2015; Springer: Wiesbaden, Germany, 2016; pp. 12–17. [Google Scholar]

- VDI Wissensforum GmbH (Ed.) 6th Fachtagung AUTOREG 2013: Steuerung und Regelung von Fahrzeugen und Motoren mit Fachausstellung; VDI Wissensforum GmbH: Düsseldor, Germany, 2013. [Google Scholar]

- Lindemann, U. Methodische Entwicklung Technischer Produkte: Methoden Flexibel und Situationsgerecht Anwenden; Springer: Berlin, Germany, 2009. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akkaya, F.; Klos, W.; Schwämmle, T.; Haffke, G.; Reuss, H.-C. Holistic Testing Strategies for Electrified Vehicle Powertrains in Product Development Process. World Electr. Veh. J. 2018, 9, 5. https://doi.org/10.3390/wevj9010005

Akkaya F, Klos W, Schwämmle T, Haffke G, Reuss H-C. Holistic Testing Strategies for Electrified Vehicle Powertrains in Product Development Process. World Electric Vehicle Journal. 2018; 9(1):5. https://doi.org/10.3390/wevj9010005

Chicago/Turabian StyleAkkaya, Filiz, Wolfgang Klos, Timm Schwämmle, Gregor Haffke, and Hans-Christian Reuss. 2018. "Holistic Testing Strategies for Electrified Vehicle Powertrains in Product Development Process" World Electric Vehicle Journal 9, no. 1: 5. https://doi.org/10.3390/wevj9010005