Advantages and Technological Progress of Hydrogen Fuel Cell Vehicles

1. Background

2. Advantages of Fuel Cell Vehicles

2.1. Strong Power Output

2.2. Safety and Reliability

2.3. Economic Energy Savings

2.3.1. Low Total Cost of Ownership

2.3.2. High Energy-Conversion Efficiency

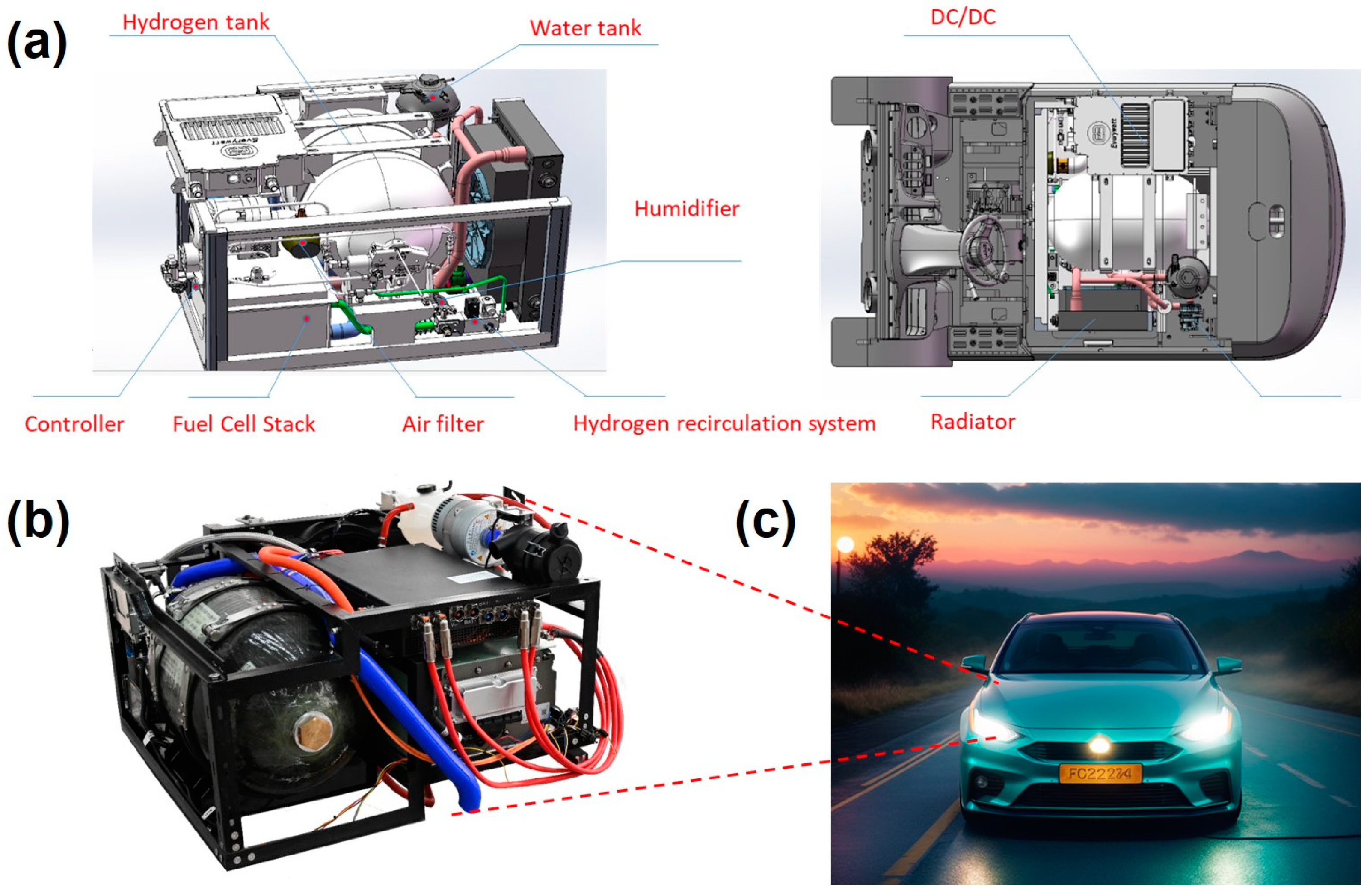

3. Technological Status of Fuel Cell Vehicles

3.1. Technological Status of Fuel Cell Stacks

3.1.1. Proton Exchange Membrane Technology Status

3.1.2. Catalyst Technology Status

3.1.3. Gas Diffusion Layer Technology Status

3.1.4. Bipolar Plate Technology Status

3.2. Compressor Technology Status

3.3. Onboard Hydrogen Storage System Technology Status

Author Contributions

Data Availability Statement

Conflicts of Interest

References

- Mo, T.; Lau, K.T.; Li, Y.; Poon, C.K.; Wu, Y.; Chu, P.K.; Luo, Y. Commercialization of Electric Vehicles in Hong Kong. Energies 2022, 15, 942. [Google Scholar] [CrossRef]

- Mo, T.; Li, Y.; Lau, K.-t.; Poon, C.K.; Wu, Y.; Luo, Y. Trends and Emerging Technologies for the Development of Electric Vehicles. Energies 2022, 15, 6271. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, Y.; Li, B.; Mo, T.; Li, Y.; Feng, S.-P.; Qu, J.; Chu, P.K. Development and application of fuel cells in the automobile industry. J. Energy Storage 2021, 42, 103124. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, Y.; Li, B.; Qu, J.; Feng, S.-P.; Chu, P.K. Optimization and cutting-edge design of fuel-cell hybrid electric vehicles. Int. J. Energy Res. 2021, 45, 18392–18423. [Google Scholar] [CrossRef]

- Tanç, B.; Arat, H.T.; Baltacıoğlu, E.; Aydın, K. Overview of the next quarter century vision of hydrogen fuel cell electric vehicles. Int. J. Hydrogen Energy 2019, 44, 10120–10128. [Google Scholar] [CrossRef]

- Muthukumar, M.; Rengarajan, N.; Velliyangiri, B.; Omprakas, M.A.; Rohit, C.B.; Raja, U.K. The development of fuel cell electric vehicles–A review. Mater. Today Proc. 2021, 45, 1181–1187. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mo, T.; Li, Y.; Luo, Y. Advantages and Technological Progress of Hydrogen Fuel Cell Vehicles. World Electr. Veh. J. 2023, 14, 162. https://doi.org/10.3390/wevj14060162

Mo T, Li Y, Luo Y. Advantages and Technological Progress of Hydrogen Fuel Cell Vehicles. World Electric Vehicle Journal. 2023; 14(6):162. https://doi.org/10.3390/wevj14060162

Chicago/Turabian StyleMo, Tiande, Yu Li, and Yang Luo. 2023. "Advantages and Technological Progress of Hydrogen Fuel Cell Vehicles" World Electric Vehicle Journal 14, no. 6: 162. https://doi.org/10.3390/wevj14060162