Parameter Identification and State Estimation of Lithium-Ion Batteries for Electric Vehicles with Vibration and Temperature Dynamics

Abstract

:1. Introduction

2. Lithium-Ion Battery

2.1. Modelling

2.2. Problem Statement

3. Parameter Identification

4. Effects of Vibration and Temperature on Battery State

4.1. Vibration

4.2. Temperature

4.3. SOC Estimation

4.4. SOH Estimation

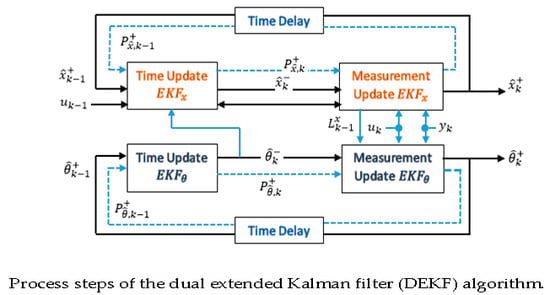

4.5. State Estimation Based on Double Extended Kalman Filter

5. Experimental Test System

5.1. Experimental Set-Up

5.2. Experimental Procedures

5.3. Results and Discussion

5.4. Future Application of DEKF to Address the Challenges of Battery State Estimation

- -

- Non-uniform power delivered by the battery as it depends on the current state of the battery;

- -

- Intensive computational efforts;

- -

- Difficulty in model parameterization, since parameters requires to be adjusted, and they are difficult to measure them;

- -

- Poor robustness and relatively low accuracy;

- -

- The problem of potential over-fitting;

- -

- The problem of sensitivity of optimization methods in terms of quality and quantity of data, etc.

5.5. Future Research Directions and Discussions

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AKF | Adaptive Kalman filter |

| AEKF | Adaptive extended Kalman filter |

| BTS | Battery testing system |

| BMS | Battery management system |

| CCCV | Constant current constant voltage |

| DOD | Depth-of-discharge |

| DEKF | Dual-extended Kalman filter |

| ECM | Equivalent circuit voltage |

| EOL | End of life |

| EVs | Electric vehicles |

| EKF | Extended Kalman filter |

| HPPC | Hybrid pulse power characterization |

| KF | Kalman filter |

| LIB | Lithium-ion battery |

| MATLAB | MATrix LABoratory |

| OCV | Open-circuit voltage |

| RC | Resistance-capacitance |

| RLS | Recursive least square |

| SOC | State-of-charge |

| SOH | State-of-health |

| SOE | State-of-energy |

| SOF | State-of-function |

| SOP | State-of-power |

| SOT | State-of-temperature |

| SOS | State-of-safety |

| SOV | State-of-vibration |

| UKF | Unscented Kalman filter |

| VEHs | Vibration al energy harvesters |

References

- Misyris, G.S.; Doukas, D.I.; Papadopoulos, T.A.; Labridis, D.P.; Agelidis, V.G. State-of-Charge Estimation for Li-Ion Batteries: A More Accurate Hybrid Approach. IEEE Trans. Energy Convers. 2018, 34, 109–119. [Google Scholar] [CrossRef] [Green Version]

- Leng, F.; Tan, C.M.; Pecht, M. Effect of Temperature on the Aging rate of Li Ion Battery Operating above Room Temperature. Sci. Rep. 2015, 5, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Omariba, Z.; Zhang, L.; Sun, D. Review on Health Management System for Lithium-Ion Batteries of Electric Vehicles. Electronics 2018, 7, 72. [Google Scholar] [CrossRef] [Green Version]

- Baek, D.; Chen, Y.K.; Bocca, A.; Bottaccilli, L.; Di Cataldo, S.; Gatteschi, V.; Pagliari, D.J.; Patti, E.; Urgese, G.; Chang, N.; et al. Battery-Aware operation range estimation for terrestrial and aerial electric vehicles. IEEE Trans. Veh. Technol. 2019, 68, 5471–5482. [Google Scholar] [CrossRef]

- Baek, D.; Chen, Y.; Bocca, A.; di Cataldo, S.; Chang, N. Estimation of the residual energy in battery electric vehicles. In Proceedings of the 2019 AEIT International Conference of Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE), Torino, Italy, 2–4 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Zhang, L.; Mu, Z.; Gao, X. Coupling Analysis and Performance Study of Commercial 18650 Lithium-Ion Batteries under Conditions of Temperature and Vibration. Energies 2018, 11, 2856. [Google Scholar] [CrossRef] [Green Version]

- Hooper, J.M.; Marco, J.; Chouchelamane, G.H.; Lyness, C.; Taylor, J. Vibration durability testing of Nickel Cobalt Aluminum Oxide (NCA) lithium-ion 18,650 battery cells. Energies 2016, 9, 281. [Google Scholar] [CrossRef] [Green Version]

- Hooper, J.M.; Marco, J.; Chouchelamane, G.H.; Chevalier, J.S.; Williams, D. Multi-axis vibration durability testing of lithium ion 18650 NCA cylindrical cells. J. Control Sci. Eng. 2018, 15, 103–123. [Google Scholar] [CrossRef]

- Zhang, L.; Ning, Z.; Peng, H.; Mu, Z.; Sun, C. Effects of Vibration on the Electrical Performance of Lithium-Ion Cells Based on Mathematical Statistics. Appl. Sci. 2017, 7, 802. [Google Scholar] [CrossRef] [Green Version]

- Chiang, C.J.; Yang, J.L.; Cheng, W.C. Temperature and state-of-charge estimation in ultracapacitors based on extended Kalman filter. J. Power Sources 2013, 2234, 234–243. [Google Scholar] [CrossRef]

- Chaoui, H.; Gualous, H. Online parameter and state estimation of lithium-ion batteries under temperature effects. Electr. Power Syst. Res. 2017, 145, 73–82. [Google Scholar] [CrossRef]

- Qu, Z.G.; Jiang, Z.Y.; Wang, Q. Experimental study on pulse self–heating of lithium–ion battery at low temperature. Int. J. Heat Mass Transf. 2019, 135, 696–705. [Google Scholar] [CrossRef]

- Xi, Z.; Dahmardeh, M.; Xia, B.; Fu, Y.; Mi, C. Learning of Battery Model Bias for Effective State of Charge Estimation of Lithium-ion Batteries. IEEE Trans. Veh. Technol. 2019, 68, 8613–8628. [Google Scholar] [CrossRef]

- Arachchige, B.; Perinpanayagam, S.; Jaras, R. Enhanced Prognostic Model for Lithium Ion Batteries Based on Particle Filter State Transition Model Modification. Appl. Sci. 2017, 7, 1172. [Google Scholar] [CrossRef] [Green Version]

- Abada, S.; Marlair, G.; Lecocq, A.; Petit, M.; Sauvant-Moynot, V.; Huet, F. Safety focused modeling of lithium-ion batteries: A review. J. Power Sources 2016, 306, 178–192. [Google Scholar] [CrossRef]

- Zhang, L.; Peng, H.; Ning, Z.; Mu, Z.; Sun, C. Comparative Research on RC Equivalent Circuit Models for Lithium-Ion Batteries of Electric Vehicles. Appl. Sci. 2017, 7, 1002. [Google Scholar] [CrossRef] [Green Version]

- Rivera-Barrera, J.; Muñoz-Galeano, N.; Sarmiento-Maldonado, H. SoC Estimation for Lithium-ion Batteries: Review and Future Challenges. Electronics 2017, 6, 102. [Google Scholar] [CrossRef] [Green Version]

- Ramadan, H.S.; Becherif, M.; Claude, F. Extended kalman filter for accurate state of charge estimation of lithium-based batteries: A comparative analysis. Int. J. Hydrogen Energy 2017, 42, 29033–29046. [Google Scholar] [CrossRef]

- Liu, G.; Xu, C.; Jiang, K.; Wang, K. State of charge and model parameters estimation of liquid metal batteries based on adaptive unscented Kalman filter. Energy Procedia 2019, 158, 4477–4482. [Google Scholar] [CrossRef]

- He, W.; Pecht, M.; Flynn, D.; Dinmohammadi, F. A Physics-Based Electrochemical Model for Lithium-Ion Battery State-of-Charge Estimation Solved by an Optimised Projection-Based Method and Moving-Window Filtering. Energies 2018, 11, 2120. [Google Scholar] [CrossRef] [Green Version]

- Luo, Y.; Kan, Y.; Yin, Y.; Liu, L.; Cui, H.; Wu, F. Study on a High-Accuracy Real-Time Algorithm to Estimate SOC of Multiple Battery Cells Simultaneously. J. Control Sci. Eng. 2017, 2017, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Orcioni, S.; Buccolini, L.; Ricci, A.; Conti, M. Lithium-ion Battery Electrothermal Model, Parameter Estimation, and Simulation Environment. Energies 2017, 10, 375. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Allafi, W.; Dinh, Q.; Ascencio, P.; Marco, J. Online estimation of battery equivalent circuit model parameters and state of charge using decoupled least squares technique. Energy 2018, 142, 678–688. [Google Scholar] [CrossRef]

- Yang, X.; Chen, L.; Xu, X.; Wang, W.; Xu, Q.; Lin, Y.; Zhou, Z. Parameter identification of electrochemical model for vehicular lithium-ion battery based on particle swarm optimization. Energies 2017, 10, 1811. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Lai, Q.; Wang, L.; Lyu, C.; Wang, H. A method for SOC estimation based on simplified mechanistic model for LiFePO4 battery. Energy 2016, 114, 1266–1276. [Google Scholar] [CrossRef]

- Xiong, R.; Cao, J.; Yu, Q.; He, H.; Sun, F. Critical Review on the Battery State of Charge Estimation Methods for Electric Vehicles. IEEE Access 2017, 6, 1832–1843. [Google Scholar] [CrossRef]

- Luo, Q.; He, X.; Jiang, S.; Wang, X. Impact-Based Electromagnetic Energy Harvester with. Energies 2017, 10, 1848. [Google Scholar] [CrossRef] [Green Version]

- Brand, M.J.; Schuster, S.F.; Bach, T.; Fleder, E.; Stelz, M.; Glaser, S.; Muller, J.; Sextl, G.; Jossen, A. Effects of vibrations and shocks on lithium-ion cells. J. Power Sources 2015, 288, 62–69. [Google Scholar] [CrossRef]

- Zhang, M.; Fan, X. Review on State of Charge Estimation Methods for Electric Vehicle Battery. World Electr. Veh. J. 2020, 11, 23. [Google Scholar] [CrossRef] [Green Version]

- Kong, Q.; Ruan, M.; Zi, Y. A health management system for marine cell group. IOP Conf. Ser. Earth Environ. Sci. 2017, 69, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Capron, O.; Jaguemont, J.; Gopalakrishnan, R.; van den Bossche, P.; Omar, N.; van Mierlo, J. Impact of the Temperature in the Evaluation of Battery Performances During Long-Term Cycling—Characterisation and Modelling. Appl. Sci. 2018, 8, 1364. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.-C.M. Development of a New Battery Management System with an Independent Balance Module for Electrical Motorcycles. Energies 2017, 10, 1289. [Google Scholar] [CrossRef] [Green Version]

- Gandoman, F.H.; Ahmadi, A.; Van den Bossche, P.; Van Mierlo, J.; Omar, N.; Nezhad, A.E.; Mavalizadeh, H.; Mayet, C. Status and future perspectives of reliability assessment for electric vehicles. Reliab. Eng. Syst. Saf. 2019, 183, 1–16. [Google Scholar] [CrossRef]

- Daowd, M.; Omar, N.; van den Bossche, P.; van Mierlo, J. Capacitor based battery balancing system. World Electr. Veh. J. 2012, 5, 385–393. [Google Scholar] [CrossRef] [Green Version]

- Andwari, M.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A review of Battery Electric Vehicle technology and readiness levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- Dai, H.; Zhu, L.; Zhu, J.; Wei, X.; Sun, Z. Adaptive Kalman filtering based internal temperature estimation with an equivalent electrical network thermal model for hard-cased batteries. J. Power Sources 2015, 293, 351–365. [Google Scholar] [CrossRef]

- Xing, Y.; He, W.; Pecht, M.; Tsui, K.L. State of charge estimation of lithium-ion batteries using the open-circuit voltage at various ambient temperatures. Appl. Energy 2014, 113, 106–115. [Google Scholar] [CrossRef]

- Yu, T.K.; Tseng, A.; Yen, J.; Fu, T.; Huang, E. Battery cell modeling and online estimation of the state of charge of a lithium-ion battery. J. Chin. Inst. Eng. 2018, 41, 412–418. [Google Scholar]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Xi, Z.; Jing, R.; Yang, X.; Decker, E. State of Charge Estimation of Lithium-Ion Batteries Considering Model Bias and Parameter Uncertainties. In Proceedings of the ASME 2014 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference IDETC/CIE 2014, Buffalo, NY, USA, 17–20 August 2014; pp. 1–7. [Google Scholar]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges and recommendations. Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Perdana, F.A.; Supriyanto, A.; Purwanto, A.; Jamaluddin, A. Study of imbalanced internal resistance on drop voltage of LiFePO 4 battery system connected in parallel. J. Phys. Conf. Ser. 2017, 795, 012036. [Google Scholar] [CrossRef] [Green Version]

- Feng, X.N.; Weng, C.H.; He, X.M.; Han, X.B.; Lu, L.G.; Ren, D.S.; Ouyang, M.G. Online State-of-Health Estimation for Li-ion Battery Using Partial Charging Segment Based on Support Vector Machine. IEEE Trans. Veh. Technol. 2019, 68, 8583–8592. [Google Scholar] [CrossRef]

- Huang, S.; Tseng, K.; Liang, J.; Chang, C.; Pecht, M.G. An Online SOC and SOH Estimation Model for Lithium-Ion Batteries. Energies 2017, 10, 512. [Google Scholar] [CrossRef]

- Wassiliadis, N.; Adermann, J.; Frericks, A.; Pak, M.; Reiter, C.; Lohmann, B.; Lienkamp, M. Revisiting the dual extended Kalman filter for battery state-of-charge and state-of-health estimation: A use-case life cycle analysis. J. Energy Storage 2018, 19, 73–87. [Google Scholar] [CrossRef]

- Zheng, L.; Zhu, J.; Wang, G.; Lu, D.D.C.; He, T. Differential voltage analysis based state of charge estimation methods for lithium-ion batteries using extended Kalman filter and particle filter. Energy 2018, 158, 1028–1037. [Google Scholar] [CrossRef]

- Wang, L.; Lu, D.; Liu, Q.; Liu, L.; Zhao, X. State of charge estimation for LiFePO4 battery via dual extended kalman filter and charging voltage curve. Electrochim. Acta 2019, 296, 1009–1017. [Google Scholar] [CrossRef]

- Fang, L.; Li, J.; Peng, B. Online estimation and error analysis of both SOC and SOH of lithium-ion battery based on DEKF method. Energy Procedia 2019, 158, 3008–3013. [Google Scholar] [CrossRef]

- Shi, Y.; Wen, L.; Pei, S.; Wu, M.; Li, F. Choice for graphene as conductive additive for cathode of lithium-ion batteries. J. Energy Chem. 2019, 30, 19–26. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Jiao, Z.; Zhou, L. Analysis of performance degradation and residual life prediction of batteries for electric vehicles under driving conditions. IEEJ Trans. Electr. Electron. Eng. 2019, 14, 493–498. [Google Scholar] [CrossRef]

- Tremblay, O.; Dessaint, L.A. Experimental Validation of a Battery Dynamic Model for EV Applications. World Electr. Veh. J. 2015, 3, 289–298. [Google Scholar]

- Hu, X.; Feng, F.; Liu, K.; Zhang, L.; Xie, J.; Liu, B. State estimation for advanced battery management: Key challenges and future trends. Renew. Sustain. Energy Rev. 2019, 114, 109334. [Google Scholar] [CrossRef]

| Cell Property | Value |

|---|---|

| Nominal capacity | 2.9 Ah |

| Rated capacity | 2.7 Ah |

| Nominal voltage | 3.6 V |

| Dimensions (D × l) | 18 mm × 65 mm |

| Internal resistance | 35 mΩ |

| Charging Voltage | 4.20 ± 0.03V |

| End of Discharge Voltage | 2.5 V |

| Standard charging current | 1.35 A |

| Charge/discharge efficiency | 80–90% |

| Approximate Weight | 47.0 g |

| Series | Cylindrical cell |

| Property | Value | Property | Value |

|---|---|---|---|

| Maximum acceleration | 20 g | Amplitude Range | 0~5 mm |

| Frequency range (0.1 Hz) | 1~600 Hz | Vibration waveform | Sine wave (half-wave/full-wave) |

| Rated Frequency | 1–600 Hz | Vibration direction | Up and down + left and right + before and after (three axes) |

| Table size | 1000 × 1000 mm | Precision | 0.1 Hz |

| Max. Test Load | 100 kg | Power | 5 Kw |

| Time Rise (s) | Cumulative Time (s) | Relative Current (I) | Relative Voltage (V) |

|---|---|---|---|

| 13 | 13 | 0 | 4.1325 |

| 11 | 24 | −2.9002 | 3.9186 |

| 41 | 65 | 0 | 4.1183 |

| 11 | 76 | 2.1752 | 4.3086 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Omariba, Z.B.; Zhang, L.; Kang, H.; Sun, D. Parameter Identification and State Estimation of Lithium-Ion Batteries for Electric Vehicles with Vibration and Temperature Dynamics. World Electr. Veh. J. 2020, 11, 50. https://doi.org/10.3390/wevj11030050

Omariba ZB, Zhang L, Kang H, Sun D. Parameter Identification and State Estimation of Lithium-Ion Batteries for Electric Vehicles with Vibration and Temperature Dynamics. World Electric Vehicle Journal. 2020; 11(3):50. https://doi.org/10.3390/wevj11030050

Chicago/Turabian StyleOmariba, Zachary Bosire, Lijun Zhang, Hanwen Kang, and Dongbai Sun. 2020. "Parameter Identification and State Estimation of Lithium-Ion Batteries for Electric Vehicles with Vibration and Temperature Dynamics" World Electric Vehicle Journal 11, no. 3: 50. https://doi.org/10.3390/wevj11030050