1. Introduction

Forest tenure reform is anchored on the premise that the government’s legal recognition of the property rights of local communities over forest lands will eventually contribute to poverty alleviation and effective forest conservation. While there has been a significant leap in the number of forests under community management at the global scale [

1], there seems to be a disconnect between forest tenure reform and achieving its objectives on the ground. In the process of implementing reform, what some communities have received are “bundles of responsibilities” instead of “bundles of rights” [

2]. In this case, the use rights of communities and smallholders over the natural resources that they manage, particularly timber, are overshadowed by numerous government requirements. This renders their livelihood at risk. However, unless there are other viable opportunities, timber harvesting would remain a significant source of income among forest communities and smallholders [

3].

Despite the initial gains achieved by forest tenure reform through community forestry, stringent government policies are hampering its continued success [

4]. These policies are meant to protect the existing forest cover and sustain the flow of goods and services obtained from the forest. Likewise, they intend to reduce unfair competition in the timber market from timber coming from illegal sources. The results, however, ran contrary to the envisioned aims, as policies become barriers that constrict the growth of community and smallholder forestry [

5].

Recent studies have pointed to overregulation of timber harvesting as a major institutional obstacle that prevents the flow of benefits to local communities from forest tenure reform in community forestry [

6,

7]. Similarly, smallholder forestry regulations in harvesting trees, even in private lands, restrict the ability of farmers to earn decent income from timber [

8,

9].

Legal compliance presents a major challenge in the development of community-based timber enterprises (CBTEs) where regulations are often beyond the technical and financial capacity of the communities and smallholders [

3,

10]. This creates hesitation on the part of the communities and smallholders to dutifully abide by these rules on account of their existing capabilities [

11], not to mention the other obligations required of them such as forest rehabilitation and development, which also entails costs on their part [

5].

Timber regulations involve transaction costs that are burdensome to both communities and smallholders, as well as to millers and furniture makers who are part of the timber value chain [

12]. More often than not, when the cost is rather restrictive, communities and smallholders are tempted to find “creative” means to circumvent the rules [

13].

A significant body of literature tackles the effects of policies and regulations on timber harvesting activities of communities (see, for instance, [

1,

14,

15]), but no attempt was made yet to examine the interaction of policies and actors on the ground using the timber value chain as an analytical framework. This paper therefore explores the effects of regulations on how timber operations are organized on the ground and how the actors involved in timber harvesting adjust to externalities presented by restrictive policies, being one of the identified gaps in the literature [

3,

16]. Using the case of CBTE and smallholder forestry in the Philippines, the paper illustrates how overregulation and lack of administrative support hamper the potential of community and smallholder tree farming in reducing poverty and addressing sustainable wood supply. Overregulation happens when the government imposes policies that are highly cumbersome and requires costly processes to obtain various permits that tend to discriminate against communities and smallholders, without the necessary support system. It has produced a high transaction cost for communities and smallholders by way of informal barriers such as bestowing bribes that could otherwise be used for other potentially rewarding and beneficial activities.

This paper is organized in six sections. Following this introduction,

Section 2 presents a background on Philippine community and smallholder forestry and their potential to better address the existing forestry problems in the country.

Section 3 describes how value chain analysis can be used to capture the intricate interaction of social actors and policies on the ground.

Section 4 presents the data collection methods used in the research before moving to the results of the study in

Section 5.

Section 6 discusses some themes that emerged from the two case studies and provides the conclusion distilled from the study. A list of acronyms is listed in

Table 1 for ease of reference.

2. Community and Smallholder Forestry: The Philippine Context

Forest tenure reform in the Philippines has achieved important gains in terms of giving secure rights to communities to manage their natural resources. This was facilitated by the passage of Executive Order (EO) 263 in 1995 which adopted community-based forest management (CBFM) as the national strategy to ensure sustainable forest management and social justice in the country’s forest lands. The EO recognizes the capacity of upland communities to manage and develop forest resources in a sustainable manner, including the harvesting of timber for commercial purposes [

5] through the issuance of a 25-year land tenure instrument renewable for another 25 years. Utting [

17] and Pulhin et al. [

14] regarded this as a radical and progressive community forestry policy and one of the exemplary models in Southeast Asia.

About six million hectares (or 38%) of the total 15.8-million-hectare Philippines forestlands are now in the hands of bonafide people’s organizations (POs) representing upland communities who depend on forest resources for survival. This also includes areas formerly under industrial forestry, otherwise known as the Timber License Agreement (TLA), which provides part of the annual wood demand of the country through CBTEs [

5].

The majority of the areas under CBFM are within the second-growth production forests containing an average volume of 145 m

3 per hectare, equivalent to a gross national volume of approximately 217.5 million m

3. This presents a lot of potential for poverty reduction. At a market value of not less than US$60 per m

3, these forests constitute a natural resource asset worth more than US$13 billion [

18].

With this, timber harvesting by communities in the second-growth forests has the potential to deliver a 375% increase in the rural family income, from an income base of US$2.00 per day [

18] (There is no reliable secondary data in the literature on the annual growth rate of these forests because of the highly variable biophysical condition of the country, but it was assumed that the growth rate is above the harvesting rate). In addition, at least 60,000 full-time jobs could be created if communities are given rights to harvest and sell 500,000 m

3 of timber per year. This is equivalent to half of the employment generated during the height of timber extraction [

19].

Together with CBTEs, smallholder forestry can address the wood requirement of the country. Smallholder forestry involves the management of areas that are relatively small, from less than a hectare to around five hectares or more, which focuses on multiple use management, such as a combination of agriculture, agroforestry or tree plantation. CBTE is considered an aggregation of smallholders, formed into an organization, to manage public lands for multiple benefits and products, such as timber [

20].

Smallholder farmers can plant forest trees in their private lands which later can be harvested to provide income. The history of smallholder forestry can be traced back to the tree farming contract program of the Paper Industries Corporation of the Philippines (PICOP) in the 1970s. Under this program,

Paraserianthes falcataria were planted in individual lots and, upon maturity, bought by the company to augment its wood supply for the production of pulpwood. The assured market encouraged farmers to raise pulpwood in their private lots [

21]. This has expanded to include other species such as

Gmelina arborea and to a lesser extent,

Acacia sp. and

Eucalyptus deglupta which were promoted as “million-peso trees”. The program became a profitable enterprise and an alternative to costly reforestation programs of the government [

22] until it reached market saturation that eventually resulted in a price decline [

23]. A study by Santos-Martin and others [

24] indicated that this can still be reversed if the government would provide an enabling environment in the form of market access and tax exemption for harvesting native species planted by smallholders.

3. Analytical Framework: Timber Value Chain

According to Kaplinsky [

25], a value chain is a “range of activities required to bring a product or service to final consumption”. It has become a fertile ground for interdisciplinary inquiry in understanding the complex social interaction between and among actors in a chain and can be used in wide range of contexts [

26,

27]. In much literature, value chain analysis is often used in the context of agricultural production to understand how actors include themselves in the economic processes [

28], but it is often criticized for focusing more on the structural elements of production and less on the policy and social interaction [

29]. This paper addresses this critique using the case of the timber value chain.

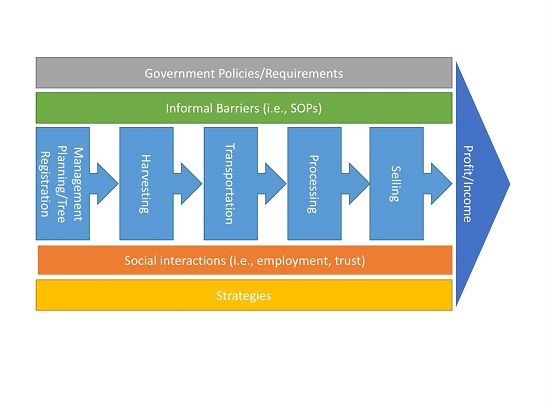

Unlike agricultural products, timber harvesting is not as simple as felling trees. It encompasses various interconnected activities to provide wood products to the market. This is represented by a value chain that includes every effort to produce and deliver a final product or service, from the supplier to customers [

30]. A particular characteristic of a value chain is that entities are connected through the transaction of goods and services [

31]. In the case of timber, the value chain is comprised of links or segments that are being performed by different actors and governed by both a formal and informal set of rules or regulations.

Relationships along the timber value chain play a crucial role in achieving the CBTEs’ and smallholders’ goal, while uncertainties negatively affect their overall performance. Uncertainties may be in the form of political, economic, social and environmental factors that smallholders have to deal with. Thus, smallholders have to adjust or implement new strategies to adapt to uncertainties [

32]. Sometimes this involves employing tactics that are beyond normal or legal, as smallholders are tempted to circumvent restrictive rules to protect their primary source of income.

Another important element in the value chain is trust between actors in a particular link or segment. Trust reduces the transaction cost for opportunistic behavior and facilitates smooth business operation [

33]. Without trust, uncertainties run high and eventually negate any positive impact of CBTEs or smallholder forestry. Trust also builds partnership and relationship qualities that forms the basis for developing needed capacities towards a successful business enterprise [

34]. With this, social interactions among actors have been identified as important to functioning value chains [

35]. Here, we used value chain analysis in weaving together the impact of restrictive policies on the relationships among various actors in the timber value chain (refer to

Figure 1).

4. Methods

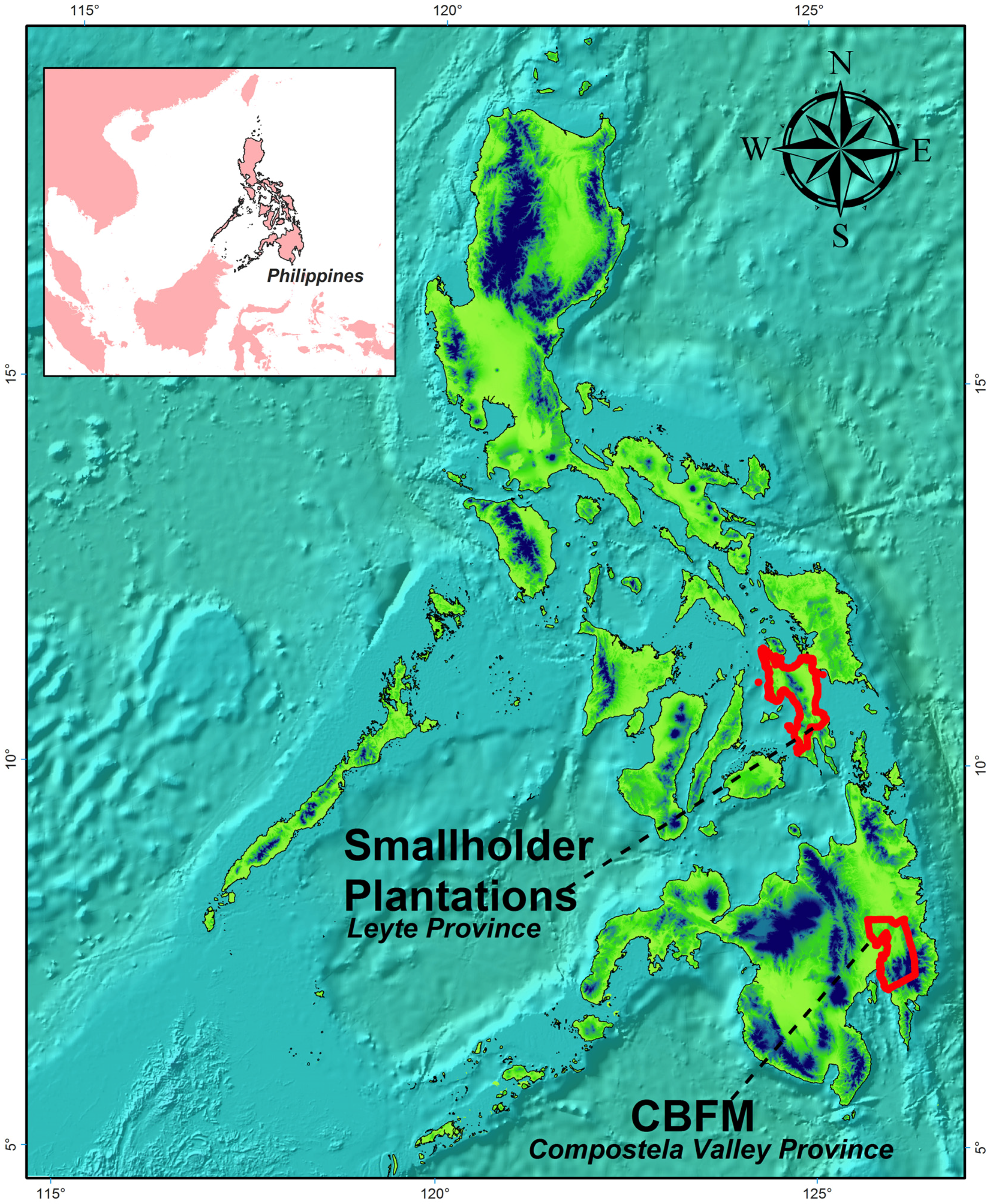

We selected two sites for the study. One fully exemplifies a mature CBTE as represented in Ngan, Panansalan, Pagsabangan Forest Resources Development Cooperative (NPPFRDC), a CBFM community in Mindanao. The other presents the case of smallholder forestry in Southern Leyte in the Visayas.

Figure 2 shows the location of the study sites.

NPPFRDC is the second largest CBFM site in Compostela Valley Province in the Southern Philippines covering an aggregate area of 14,800 ha. It is one of the 40 POs operating as a CBTE in Region XI covering a total area of around 58,000 ha. The cooperative prides itself as being one of the advanced POs in the Philippines in terms of management and enterprise skills, being the first SMARTWOOD-certified wood producer in the country. It has been an active player in the logging industry in Mindanao, producing prime logs in the region which supplied the market in Metro Manila. Since 1996, the cooperative was able to remit more than US$186,000 to government coffers in the form of forest charges and actively participated in protecting the remaining forest in the province together with the Department of Environment and Natural Resources (DENR), the government agency overseeing the management of forests and forestlands in the country [

5].

Leyte, on the other hand, belongs to the provinces with numerous smallholder tree farmers, which included Regions II and XIII. Smallholder farmers in the province have landholdings that range from 0.25 to 3 ha. Smallholder tree farming has somewhat been extensively investigated in the province, as conducted by researchers from the Visayas State University (VSU). These studies have looked into tree plantation establishment, tree harvesting and marketing. The studies of Bugayong [

36] and Mangaoang et al. [

37] revealed that there still exists a wide disparity between the demand and supply of wood in Leyte as well as in Region VIII, which motivates the farmers to plant trees in their private lots. The harvested trees are used for furniture-making and house construction within the province. Smallholder forests can be found in seven municipalities in Leyte Province, namely, Inopacan, Hindang, Hilongos, Bato, Matalom, Baybay, and Albuera.

This study was conducted using a three-stage research approach. First, a comprehensive review of policies on timber harvesting was performed. The majority of government policies on forest management are readily available online and these are supplemented by the written works of known authors, field practitioners and researchers. Since there are numerous policy issuances on timber harvesting, this study limited its analysis to those that currently affect timber harvesting of both the communities and smallholders. The themes presented in the paper were therefore pre-identified, representing the different segments of the timber supply chain as the analytical framework of the study.

Second, the results of the policy and literature review were then complemented by key informant interviews in the two sites. Key informants were selected based on their knowledge or roles in the timber value chain. These include PO leaders and smallholders who are familiar with the timber harvesting process, DENR personnel who implement government policies, buyers of lumber, and furniture makers. A set of guide questions specifically developed for each link in the timber value chain was prepared to ensure complete and contextual validity of data generated.

Field data collection was done in Leyte and Compostela Valley in January 2012 and February 2012, respectively. The 30–45 minute open-ended interviews were conducted in Filipino. A total of five key informants were interviewed in Leyte and four in Compostela Valley. Tree farms owned by smallholder farmers in Leyte and the communal forests maintained by NPPFRDC were visited to be familiar with the actual situation in the areas. Local DENR offices were likewise visited, as well as checkpoints, furniture shops, police stations and mini-sawmills, to get to know the ideas and perspectives of individuals involved in the transport and processing of timber products.

Data gathered were validated through focus group discussions (FGDs), of which two each were performed in Compostela and Leyte. FGD participants were selected based on their experience and involvement in the supply chain of timber production and in consultation with VSU in Leyte and NPPFRDC officials in Mindanao. The participants in both sites were composed of tree owners, DENR officials, local government unit (LGU) officials, scalers, chainsaw operators, furniture shop owners, sawmill operators, the police and the military.

The two FGDs in Leyte were both held at VSU, and attended by nine and eight participants, respectively. In Compostela, the FGDS were conducted in the office of the NPPFRDC, with 12 and 14 participants for the two sessions. Discussions ran for approximately two hours.

Lastly, a National Experts Workshop was organized in Manila on 22 February 2012 to present the results of the policy analysis and the two case studies. The workshop validated the results of the study and offered recommendations to address the current challenges faced by the CBFM participants, the smallholder tree farmers, and the wood industry sector in general in relation to policies and regulatory barriers that obstruct the growth of timber enterprises in the country. A total of 36 participants from the DENR, the wood industry sector, the group of furniture makers, CBFM POs, smallholders and the academe from Luzon, Visayas and Mindanao were present in the workshop.

5. Results

Although rights to timber harvesting has shifted to CBTEs and smallholders, the present timber value chain retains the old process followed when Timber License Agreements (TLAs) were still prevalent. It still undergoes the following steps: management planning, harvesting, transportation, processing, and selling of lumber. The timber supply chain of smallholder forestry is not much different from the CBTE’s, except for tree registration taking the place of management planning. Each segment has certain rules and procedures that both CBTE and smallholders should comply with.

5.1. Timber Value Chain and Regulations: CBFM

5.1.1. Management Planning

A CBFM site has to undergo rigorous planning activities before the DENR issues any harvesting permit. Specifically, two major documents are needed before any extractive activities can proceed. The first is the Community Resource Management Framework (CRMF) as prescribed by Department Administrative Order (DAO) 96-29 and the Five-Year Work Plan (FWP) under DAO 2004-29.

The CRMF is a “document defining the terms and procedures for access, use, and protection of natural resources, which shall in all cases be consistent with the overall management strategy of the entire watershed area where the CBFM area is located, and shall be formulated by the community with the assistance of its PO and the DENR, LGU and/or private entities”. The CRMF will be in effect for the entire duration of the CBFM Agreement (CBFMA), which is 25 years. The CRMF covers, among other things, the goals and aspirations of the PO in managing the forest, the volume of natural grown trees and planted trees that the PO plans to harvest, the area of degraded forestlands that they want to rehabilitate or reforest and the strategies that they will institute to achieve their long-term goals, including the partnership that they would pursue with other stakeholders. The CRMF is translated into FWP (This is somewhat similar to the Integrated Annual Operation Plan (IAOP) submitted by TLAs) to operationalize its contents into short-term targets.

The FWP details the volume and species of trees that POs are planning to harvest and the amount of forest development work (i.e., reforestation, agroforestry, assisted-natural regeneration, timber stand improvement) that they need to invest per year in the CBFM area. The plan also includes forest protection activities to be implemented in order to minimize if not totally abate illegal activities. The preparation of the CRMF and FWP should both follow a participatory process, and hence, must be presented first to the general membership of the PO for approval and later subjected to review by the LGU and major stakeholders. Completing these documents is arduous, time-consuming, and costly—a task that is further burdened by the so-called “standard operating procedures” or SOPs. It has been a practice in timber harvesting in the country to give grease money, labeled as SOPs, to persons of authority to ensure that operators will be allowed to conduct their activities unhampered.

The FWP costs around US$1888–2360 (US$1.00 is equivalent to PhP 42.37), and its preparation up to submission to the Community Environment and Natural Resources Officer (CENRO) usually takes eight weeks, based on the FGDs (see

Table 2). This amount includes the cost of hiring a professional forester as is required under DAO 2000-29, the cost of barangay consultations, the per diem of DENR personnel and NPPFRDC staff for boundary delineation, timber inventories and tree markings, the cost of public deliberation, and incidental expenses when following up the papers in the Regional Office of the DENR.

NPPFRDC had no choice but to use their savings from previous years to defray the cost for FWP preparation. Some POs with political connections can sometimes secure financial assistance from the LGUs, thus reducing the cost to some degree [

5].

The approval of the plan has a waiting time of eight months to 1.5 years before the PO can proceed with harvesting and forest development activities. While awaiting approval, cooperative members and staff are left with nothing to do due to scarcity of livelihood opportunities in the area. Worse, some opt to work in illegally established sawmills in the municipality or engage in illegal cutting of trees just to make a living.

NPPFRDC’s FWP expired in 2010. Due to the uncertainty in securing approval from the DENR, the PO opted not to undergo the same planning process that could lead to depletion of their savings which, at the time of data gathering, stood at US$8,967. An assessment done by Guiang and Castillo [

19] found that due to similar situations as experienced by NPPFRDC, only 30% of CBFMA holders in the country have approved management plans and work plans.

5.1.2. Harvesting

Once the CBTE has an approved FWP, a Resource Use Permit (RUP) has to be secured in order to proceed with timber harvesting. RUP is a document that serves as a permit to sell logs, lumber and other forest products coming from CBFM areas (DAO 2000-29). The DENR Secretary has the sole authority to approve RUPs; hence, NPPFRDC had no choice but to follow up their papers in Manila. Pursuing this activity is too costly for the PO to bear. This stultifying livelihood environment drives them to secure the support of a financier who is usually a buyer of logs or rely on patronage (or padrino) system, where they seek the help of politicians who will exert pressure to DENR to approve their papers.

When approved, the PO will share half of the annual allowable cut (AAC) with the financier. In the case of the politician, the approved papers of the NPPFRDC will be “recycled” by the former’s supporters who usually cut trees illegally from areas outside the CBFM. To illustrate, if the cooperative has an AAC of 2700 m3 based on their approved RUP, they can only get 1350 m3 in actual volume and the remaining half will be for the financier, which is estimated to cost around US$80,245. This amount represents the cost of the “follow-up” activities, a huge but necessary amount needed to secure the RUP. The political influence of the financier and padrino system shorten the RUP approval process to a period of one to two months compared to the regular waiting time which takes months or even years (Despite the long, tedious and costly process, the PO can only use its RUP for a year reckoned from the end of its last RUP operation. For instance, if the RUP was released in June, the PO is only left with less than six months to operate since more than six months have been used up in just processing the RUP application). If approved, the next step would be to get the Notice to Proceed from the CENRO, signaling that they can now legally harvest trees in the designated cutting areas for the remaining months of a given fiscal year.

The insecure withdrawal right also takes its toll on the annual development targets of the PO. Because the funds for forest development, forest protection and livelihood projects rely on profit from timber harvesting, management activities also suffer (see

Table 3). Originally planned development targets in the CRMF and FWP are not adjusted by the DENR in light of suspensions or delays in the RUP approval, thus putting excessive pressure on the cooperative. In effect, instead of transferring bundles of rights, which is the true essence of CBFMA, what is handed over to the communities are “bundles of responsibilities [

2]”. Without the necessary RUP to continue their timber harvesting activity in 2010 and the issuance of EO 23 on 1 February 2011, declaring a moratorium on the cutting and harvesting of timber in the natural and residual forests, NPPFRDC decided to end their operation in 2011.

The cutting activities will not be done by the NPPFRDC themselves but by local financiers who are either members or non-members of the cooperative. The latter organizes cutting teams, usually from or near the cutting areas. The team is composed of chainsaw operators, scalers, haulers, carabao loggers and truck drivers who will be paid on a pro-rated or per board foot basis (e.g., US$0.23/bdft for the chainsaw operator). Depending on the arrangement and the species, NPPFRDC will pay them US$0.28–0.33/bdft of log delivered to their sawmills or a US$0.17/bdft pick-up price, which includes the share of the New People’s Army or NPA, the armed wing of the communist rebel group noted for extracting "revolutionary tax" from certain productive activities. The harvesting stage is where most of residents within the CBFM area can earn the most as laborers. For instance, a hauler can earn around US$4.70–11.80 per day depending on the volume of round logs that he can carry to the pick-up point.

Aside from the above problems faced by NPPFRDC, their more serious concern is the numerous suspensions and cancelations of timber harvesting rights of CBFM POs. From 1997 to 2011, a total of five cancelations occurred. The logging bans “disallow the extraction of timber from the natural forest”, through cancelation, suspension and non-renewal of timber licenses or logging concessions [

37], and RUPs.

Guiang [

38] reported that the issuance of RUPs is one of the “tension points” of the CBFM, as civil society in general takes an interest in forest management. Timber harvesting in CBFM actually has a noble purpose, which is “borrowing from nature” in order to finance sustainable agroforestry production systems, build community financial assets, and reduce dependency on timber. This principle, however, has been forgotten in implementing CBFM.

5.1.3. Transportation

Transporting timber products is covered by EO 277 which amended Presidential Decree 705. It states that the mere possession of timber or other forest products without legal documents as required under existing forest regulations is considered as illegal logging and therefore a criminal act. Cutting, gathering, collecting, or removing timber or other forest products from any forest land, from alienable and disposable (A and D) public land, or from private land, without any authority or appropriate documents are not allowed.

Logs are deemed illegal if transported without a duly approved Certificate of Timber Origin (CTO). The Certificate of Transport Agreement (CTA) and Certificate of Transshipment (COT) are also required along with the CTO for all logs shipped outside the province or through normal log delivery routes from the cutting area to the wood processing plant or main log storage area of the licensee, or if the conveyance used for transport is not owned by the licensee.

DAO 94-07 outlines the process of securing a CTO. The CTO is usually issued by the CENRO with jurisdiction over the CBTE engaged in logging operations, and subscribed to by a notary public or an LGU executive officer. Before the CTO is issued, the logs must be properly measured and the legitimacy of the source of the logs must be verified and established. Blank forms of CTOs are properly documented and numbered before they are issued to the Timber Management Officers (TMOs). The TMOs see to it that the forms are filled out correctly and completely. Otherwise, any inconsistency and noncompliance with the standards and procedures will make the issuing officer as well as the shipper liable to criminal and administrative charges. Monthly accounting of used and unused CTO forms is regularly performed by requiring the TMOs to submit monthly reports of all used and unused CTO forms to avoid irregularities. Despite this stringent procedure, cases of fake, forged and recycled CTOs are still rampant [

5,

39]. When caught, CBFM POs are usually the scapegoats of illegal loggers in using fake documents.

Transporting timber products from the cutting area or sawmill to their destination point presents another window for corruption, especially at checkpoints manned by the DENR, military and Philippine National Police (PNP) personnel, a practice that has survived since the 1970s. It is widely acknowledged that during the time of big TLAs in the country, DENR officials were given “grease money” (Also known, in the present, as standard operating procedures or SOPs) by the TLA holders so that they would not scrutinize their operation, especially in meeting the requirements of the government (i.e., silvicultural practices, reforestation targets). This act later evolved into SOPs by different stakeholders in the community, especially at checkpoints. SOPs range from the simple giving of rice and fish to providing money.

In the case of NPPFRDC, the cost of transporting the round logs substantially increases due to the numerous checkpoints (or what the respondents called “collection points”) in the forest. They said that there are around seven checkpoints within and adjacent to the CBFM site of the NPPFRDC, manned by various agencies such as the DENR, the military, the barangay and municipal LGUs, aside from the “mobile checkpoints” at night which can number from three to five. There is also the so-called “land use fee” reserved for the owner of the land where the logs will pass. Altogether, the SOPs can add up to as high as US$200 per truckload of legally cut logs or US$260 for illegally cut logs. Since NPPFRDC harvests around 30 truckloads of legally cut logs in a day, the total SOPs that they pay amount to US$6000, an amount that could have otherwise been used for other income-generating activities to benefit their poor members.

5.1.4. Processing

Wood processing is usually done by a third party, usually a mini-sawmill, but there are few POs that have the capacity to process their round logs into lumber. Most of these mills, however, have old and inefficient equipment due to the absence of investments, stemming largely from a diminishing wood supply and the uncertainty of policies on wood utilization [

22].

DENR Memorandum Order 96-09 prescribes the guideline governing the issuance of permits to establish and operate mini-sawmills. Mills can be operated by CBFMA holders, IFMA holders and private individuals provided that the raw materials are planted trees coming from private lands and A and D areas; planted trees from forest lands under government plantation development leases/contracts; planted trees managed and developed under the CBFM program(s) of DENR; and naturally grown timber harvested by CBFMA holders authorized by DENR. However, DENR Memorandum Circular (DMC) 2003-14 declares a moratorium on the establishment of a new wood-processing plant. Owners of plantations do not usually process their harvested timber but sell these as logs to sawmill operators, pulpwood manufacturers and furniture makers within the locality and nearby markets.

For NPPFRDC, the natural course of round logs is to be processed into lumber. Most if not all of the trees cut inside the CBFM area are transported to their mini-sawmill where these will be turned into various sizes of lumber for consumers in Davao or Manila. The machinery in the sawmill is actually owned by the Valderama Lumber Company (VALMA) and is being leased to the cooperative though an output or per board foot basis. It is covered by a permit issued to the NPPFRDC as part of its CBFM agreement when there is an approved RUP. The processing stage employs a lot of laborers for sawmill operation and, next to harvesting, it provides the needed income for locals who are skilled in handling sawmill machineries. A sawmill operator can earn around US$118 per month if there is continuous operation with an average daily output of 14,000 bdft/day.

A Certificate of Lumber Origin (CLO) is covered by DAO 2007-31 to transport lumber outside the sawmill accompanied by a Certificate of Verification Clearance (CVC), a Certificate of Transport Agreement (CTA), if the truck is not owned by the buyer, and hatchet markings on the products. “Recycled documents” from legal sources are being bought at US$0.01/bdft, equivalent to the forest charge of one board foot of Lauan, to comply with the above requirements, and can be used for one week even after their expiration date, a common practice in Mindanao to circumvent the policies according to sources. Respondents also counted at least 20 illegally operating sawmills in Compostela using “recycled papers” from legal sources to transport lumber.

5.1.5. Selling

One of the obligations of the government to CBFMA holders is to link them to appropriate markets that will make their timber products more competitive. In reality, however, these POs have to look for a viable market with limited assistance from the government, and compete with wood imports and illegally sourced logs that are usually priced lower than their products [

5].

Respondents declared that NPPFRDC will buy round logs at a pick-up price of US$0.17/bdft for naturally grown trees, sell it at US$0.42/bdft as processed lumber to buyers, and then this will be sold in Davao at US$0.71/bdft and in Manila at US$0.99/bdft. The selling prices already incorporate the SOPs at the checkpoints, the Bureau of Customs, and other incidental expenses such as the food of loaders and driver. To be able to recoup their expenses, respondents recounted that lumber dealers sells a 6/4’’thick lumber for the price of 8/4’’ thick lumber since buyers cannot easily determine the actual size of the lumber they bought.

5.2. Timber Value Chain and Regulations: Smallholder Forestry

5.2.1. Tree Registration

Requirements at the first stage of the value chain for smallholders’ plantations are not very strict, particularly those in private lands. There is no need to formulate a management plan; instead, planted trees intended for commercial harvest in the future have to be registered. As prescribed by DMC 99-20 and DMC 97-07 smallholders have to provide the following: (a) a letter of application/intent; (b) a certified photocopy of either an original land title, a transfer certificate of title, a certificate of land ownership award or a tax declaration of untitled A and D lands; (c) a certification of tree plantation ownership from the Barangay Chairman or Chief Executive of the Municipality/City; (d) a picture of the tree plantation; and (e) a sketched map and plantation records. Although these documents are relatively easy to prepare, information regarding tree registration does not usually get to the farmers [

40].

A perceived problem in tree registration is the need to undertake a boundary survey of the property to be registered. This entails charges for hiring a surveyor and transportation costs for the DENR personnel who would inspect and validate the survey. Currently, many do not register their trees with DENR for a number of reasons, including the expense of registration [

41].

The inspection will establish the date and number of individual trees per species planted. Once approved, the CENRO will issue a Certificate of Tree Plantation Ownership (CTPO) which is needed prior to harvesting as mandated by DMC 99-20. Based on DMC 97-09, there are several benefits from tree registration: (a) it will help make harvesting and transport of timber easier; (b) it is easy to secure documents/clearances to harvest and transport timber products from the plantation; (c) there is exemption from any forest charges and other environmental fees; and (d) there is better access to potential buyers through DENR database information. It takes an average of three days to secure a tree registration in the Philippines [

42].

Tree registration can be done any time and costs around US$7.08–11.80, covering legal fees such as barangay and municipal certification and the issuance of the CTPO from the CENRO, regardless of the number of trees to be cut. The only external cost that the owner has to shoulder is the inspection of the area to be done by CENRO personnel, which is estimated at around US$23.60–70.80 to “cover” their gasoline and food expenses (see

Table 4). The CTPO can be secured in three days to a week, depending on how fast the survey on the ground is.

Tree farmers in smallholder plantations are often caught in tricky situations as their plantations were established on the basis of individual preference and not on technical forestry practices usually specified in management plans. Hence, when you visit a smallholder in Leyte, chances are that it does not observe proper spacing and lacks appropriate silvicultural practices, leading to poor wood quality.

5.2.2. Harvesting

Approval of timber harvesting by smallholders is governed by DMC 97-09 and DMC 99-20, which necessitates private tree plantations to be registered first with the DENR. The problem here lies in the lack of information about the existing market and the prevailing market price of Gmelina and Mahogany, two species preferred by smallholders in Leyte. As a case in point, typical buyers or traders would buy a whole plantation for a price that is grossly disadvantageous to the plantation owner. In one of the interviews conducted, an 87-year-old farmer confided that he sold his one-hectare, 10-year-old Gmelina plantation, with around 500 trees, for only US$1,062 or US$2.12 per tree. He said that the buyer shouldered all the expenses to secure the CTPO and the cost of cutting, unaware that he lost a significant amount of revenue as his plantation can easily make around US$5,664 assuming that each tree can produce 80 bdft of lumber at US$0.14 per bdft. On top of this, the buyer will also pay for US$0.02/bdft SOP to the DENR, which is quite high in comparison to the SOPs in the CBFM area.

Less the cost of registration fees and permits, which is calculated at around US$130, the cost of cutting and hauling of around US$1000 and the cost of SOPs which is estimated at around US$800, the farmer should have earned US$3734 as compared to the price that the buyers paid him at US$1062. An estimated amount of US$2672 was foregone by the farmer which is around 2.5 times higher than the actual amount he received. This amount could have significantly add up to his income from farming to support the needs of his family.

5.2.3. Transportation

Transporting logs from tree plantations is easier, as compared to that of CBTE’s. Under DMC 99-20, the original copy of the duly accomplished Self-Monitoring Form (SMF) from the CENRO, manifesting the timber or forest products to be transported, is needed for the transportation of logs from the cutting area to the destination points such as sawmills. This must be duly verified through a Certificate of Verification issued by the CENRO. A certified photocopy of the CTPO will also be checked and, in the event that the person transporting the timber is not the owner himself, the transporter must have a special power of attorney to transport the product. This is not much of a problem as there is only one checkpoint in Baybay, Leyte. Of course, illegal loggers avoid this route and they often transport logs at night or use the river for conveyance.

5.2.4. Processing

Establishing a sawmill requires a log supply contract from a legal source, a wood processing permit and a lumber dealer permit from the DENR if the owner plans to sell it. However, since securing a wood processing permit from the regional office of the DENR costs around US$1416, including SOPs and other incidental expenses, most of the “re-saw mills” in Leyte only have business permits from the LGUs which can be technically construed as illegal operation.

5.2.5. Selling

Wood processors in Leyte will buy round logs of introduced species at US$0.14/bdft and sell it at around US$0.61/bdft. The pricing for furniture made from Gmelina and Mahogany depends on the finished product and can range from US$118–236. Buyers of lumber in Leyte go directly to the sawmill, unlike in Manila where buyers have to visit a hardware store or a lumber dealer. It is also required for these purchases to be issued official receipts for taxation purposes, but some unscrupulous businesses do not comply with this regulation to hide their income.

6. Discussion and Conclusions

This paper addressed the dearth of information in the literature on the effect of regulations in timber harvesting operations and how concerned actors adjust to policies that are beyond their technical and financial capacities. The Philippines provides a relevant case for this analysis, and this was performed by exploring how policies and actors in CBFM and smallholder forestry interact using the value chain analysis as a framework.

Our findings yielded no doubt that timber harvesting in both cases provides income to upland communities and smallholders, although at a much reduced amount due to high transaction costs along the value chain. Even those who are outside the realm of community forestry, such as the middlemen and the government personnel manning the checkpoints, are benefiting from the opportunities, albeit illegally, along the timber supply chain. The wide distribution of income benefits is also particularly manifested during harvest operations with various groups positioned at certain value chain segments (such as, cutters, haulers, saw millers, wood processors) positively making earnings.

For smallholder forestry, full benefits from timber harvesting are not realized due to the uneven playing field between the sellers and buyers in the absence of available information on timber prices. This result in buyers or middlemen having the upper hand during price negotiation. Informal timber markets tend to depress the prices of timber, usually at the expense of smallholders [

16]. Aside from these, smallholders felt that they are being taken advantage of by DENR personnel, especially during tree inspection, by shouldering the personal expenses of the latter. The same can also be said between the wood processors and the DENR when it comes to getting their sawmill permits, with bloated charges due to SOPs.

Given the above realities, strict government regulation on timber harvesting must be complemented with adequate support for POs and smallholders in terms of technical assistance (i.e., silvicultural practices) and dissemination of market information (i.e., prevailing market price) that would help them decide when to harvest their planted trees (i.e., maximization of profit). The same information can be used in dealing with buyers or middlemen to level the business playing field.

Both cases presented, that as much as possible, communities and smallholders follow government regulations in harvesting timber. It is only when their resources have dried up or when they do not have enough capital that they resort to bending these rules to achieve their objectives. In particular, when there is a bottleneck in following the policies and procedures, the CBTEs resort to shortchanging the process and give in to the opportunistic demands of the people in positions, such as giving SOPs at checkpoints during the transport of timber from the cutting area to the intended destination, the recycling of transportation papers, and even bestowing part of their AACs to politicians just to make sure that their RUPs are approved in a short period. As policies and regulations become unfavorable, transaction costs evidently increase [

12]. Overregulation, in this case, provides a breeding ground for opportunistic and corrupt practices by those in power. This is clearly evident during the harvesting of logs and transporting them to their point of destination.

It is likewise of interest to note that the timber value chain does not differ significantly from the old value chains of industrial forestry [

10]. Policies and regulations designed for industrial forestry are retained by the government in dealing with communities and smallholders. This should not have been the case since the objective of industrial forestry is the maximization of profit while that of the timber harvesting activities of the CBTE and smallholders is primarily directed to social, environmental and economic objectives through continued forest protection, rehabilitation efforts and creation of income generating livelihood [

43]. While the TLA concessionaires have the resources and technical capacity to comply with regulations, which are incidentally present at every link in the timber value chain, the CBTEs and the smallholders do not have adequate capacities and financial resources, which makes it difficult for them to satisfy most of these requirements. This is manifested in the too-technical aspect of the management planning or tree registration, which requires hiring of a professional forester or dealing with financiers or middlemen when they need additional capital, as is also happening in other parts of the tropics such as in Ecuador [

3].

When one thinks things could not get worse, the government decided to cancel or delay the issuance of RUPs effectively denying the communities their right to harvest timber, thus tantamount to denying them of the promises of tenurial reform. This affects not only the members of the PO but also the non-members involved in timber operations. The pressure to supply wood to the market therefore shifts to illegal logging, and communities and smallholders also rely on these informal networks to provide their needed income [

3]. As timber harvesting in secondary forest is allowed under CBFM, the sustainability of this strategy comes into question. Timber harvesting in CBFM has a noble purpose of “borrowing from nature” in order to finance sustainable agroforestry production systems, build community financial assets and reduce dependency on timber, but these are challenged by overregulation.

It can be observed from both cases that no attempt on the part of the CBTE and smallholders was made to engage the government in a dialogue to air their concerns. This maybe because the central government is too distantly located from their areas or they do not believe that the government is concerned about their plight. In the past, the Philippines had the National Federation of CBFM POs, but it has long become inactive due to lack of support from the government and the waning interest of the current DENR administration on CBFM. The smallholders, on the other hand, are not yet organized as they are yet to be recognized by the government as a common group of timber producers. Evidently, there is no venue for dialogue where the communities and government can discuss issues and challenges concerning the timber value chain and arrive at mutually agreed- upon actions to address them. This situation will continue to hamper the achievement of the goal of forest tenure reform.

In conclusion, it can be deduced without a doubt that timber harvesting provides additional income to the actors involved in the timber value chain, proof that community and smallholder forestry has kept its promise of providing benefits to rural communities and households. Unfortunately, overregulation as a result of restrictive policies and informal barriers such as the practice of giving bribes to persons-in-charge threatens to supersede these benefits. When government policies or procedures are perceived as too tight, these provide entry points for corruption along the timber value chain. Nothing in our findings suggests that providing stringent policies can prevent illegal activities. In fact, the reverse is expected when the government restricts timber harvesting in community-managed areas since people will find ways to earn something to meet their basic needs. While regulations have a noble purpose of ensuring checks and balances in the timber production chain, which are still necessary, these should be more responsive to the needs of communities and smallholders in order to be more effective [

6].

Tenure security alone could not solve the perennial problem of illegal forest activities without the necessary policy support from the government which should consider the current capacities of communities and smallholders. This support should be reflected at every link of the timber supply chain, creating mutual trust between and among actors involved in the timber harvesting operation.