Assessing the Potential of Onboard LiDAR-Based Application to Detect the Quality of Tree Stems in Cut-to-Length (CTL) Harvesting Operations

Abstract

:1. Introduction

1.1. Study Background and Aims

- (1)

- How to construct and test the functioning of the process for the tree stem identification based on Point Clouds? This means we want to correctly estimate the number of tree stems and their defects based on the data from the 3D module.

- (2)

- What are the main challenges and advantages when detecting tree stems and their defects with MLS mounted on the harvester in real-time?

1.2. Literature Review on the State of the Art in Forest Operations

2. Materials and Methods

2.1. Mobile LiDAR Technology Used

2.1.1. LiDAR Functioning

2.1.2. Scanning Resolution

- With a 45° vertical field of view, the LiDAR’s laser beams may not cover the entire tree at a certain distance, though they are likely to hit the tree if it is positioned further away.

- A 90° vertical field of view ensures that the laser beams encompass the whole tree at the specified distance.

- From a top perspective, the likelihood of the tree being entirely covered by the laser beams increases as the distance to the tree decreases.

2.2. The Defects of Tree Stems

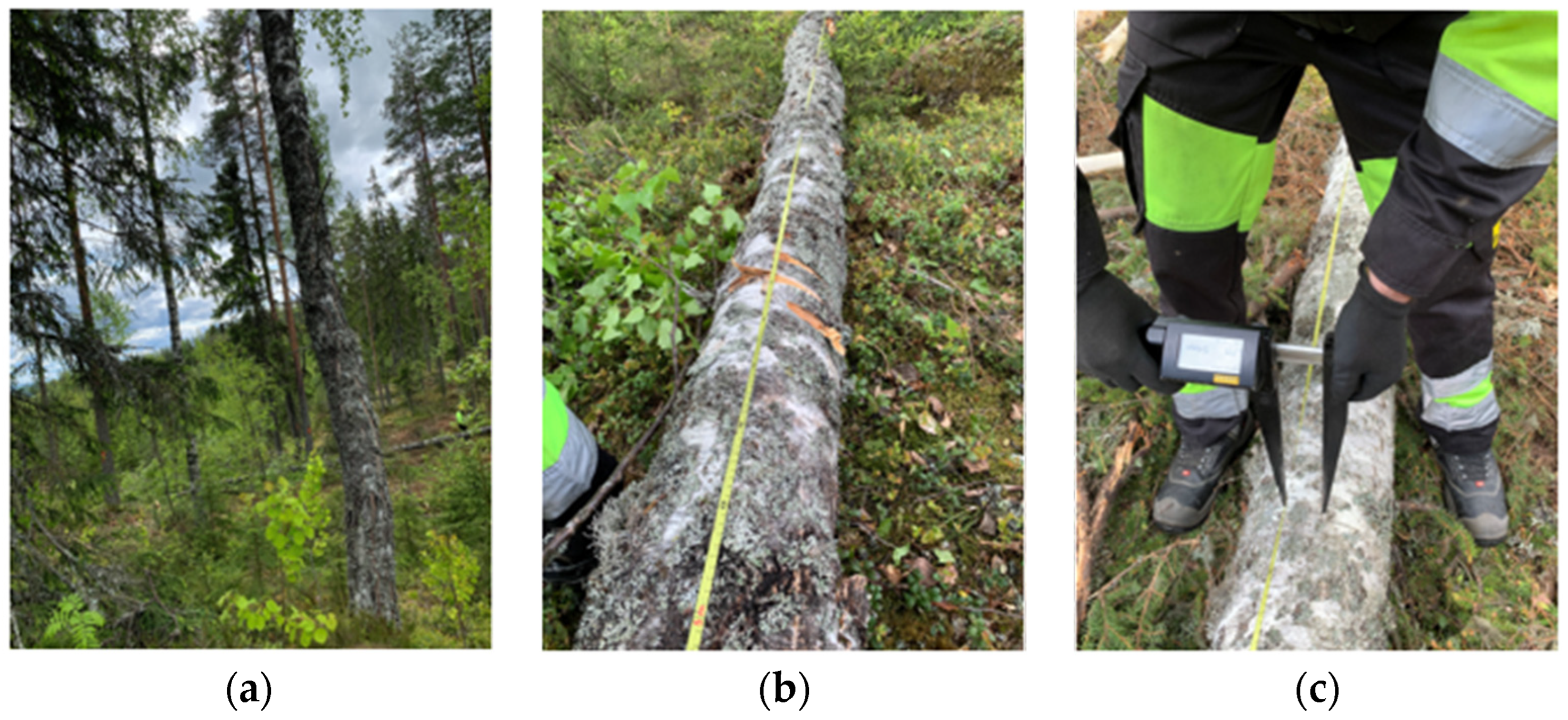

2.3. Data Collection

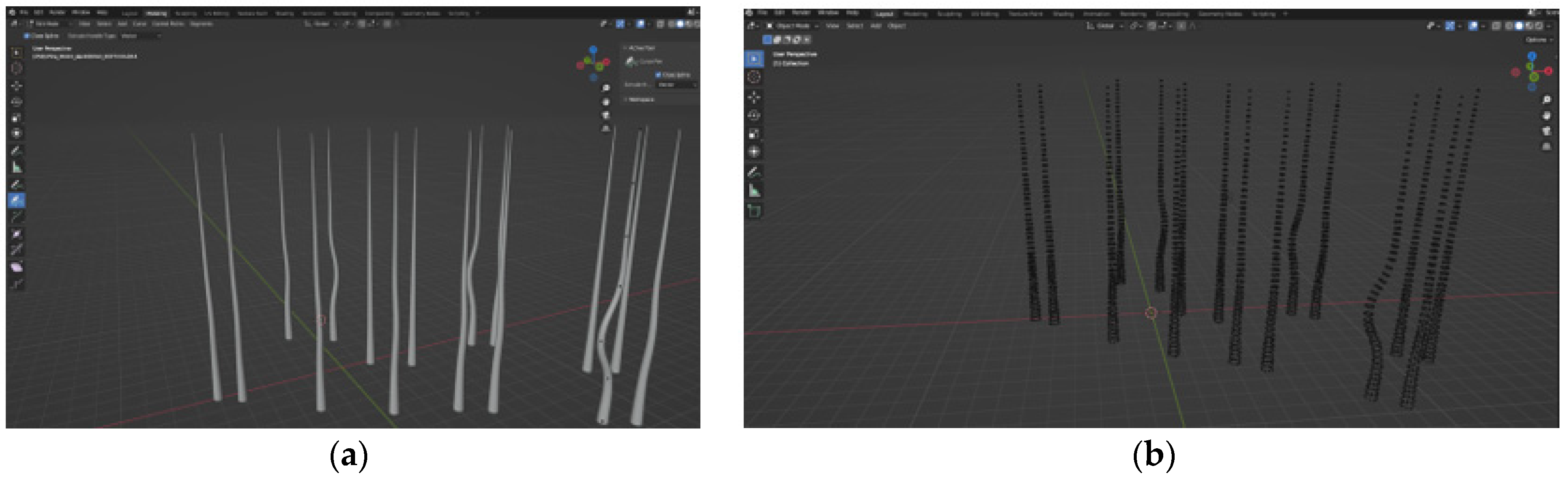

2.3.1. Synthetic Data

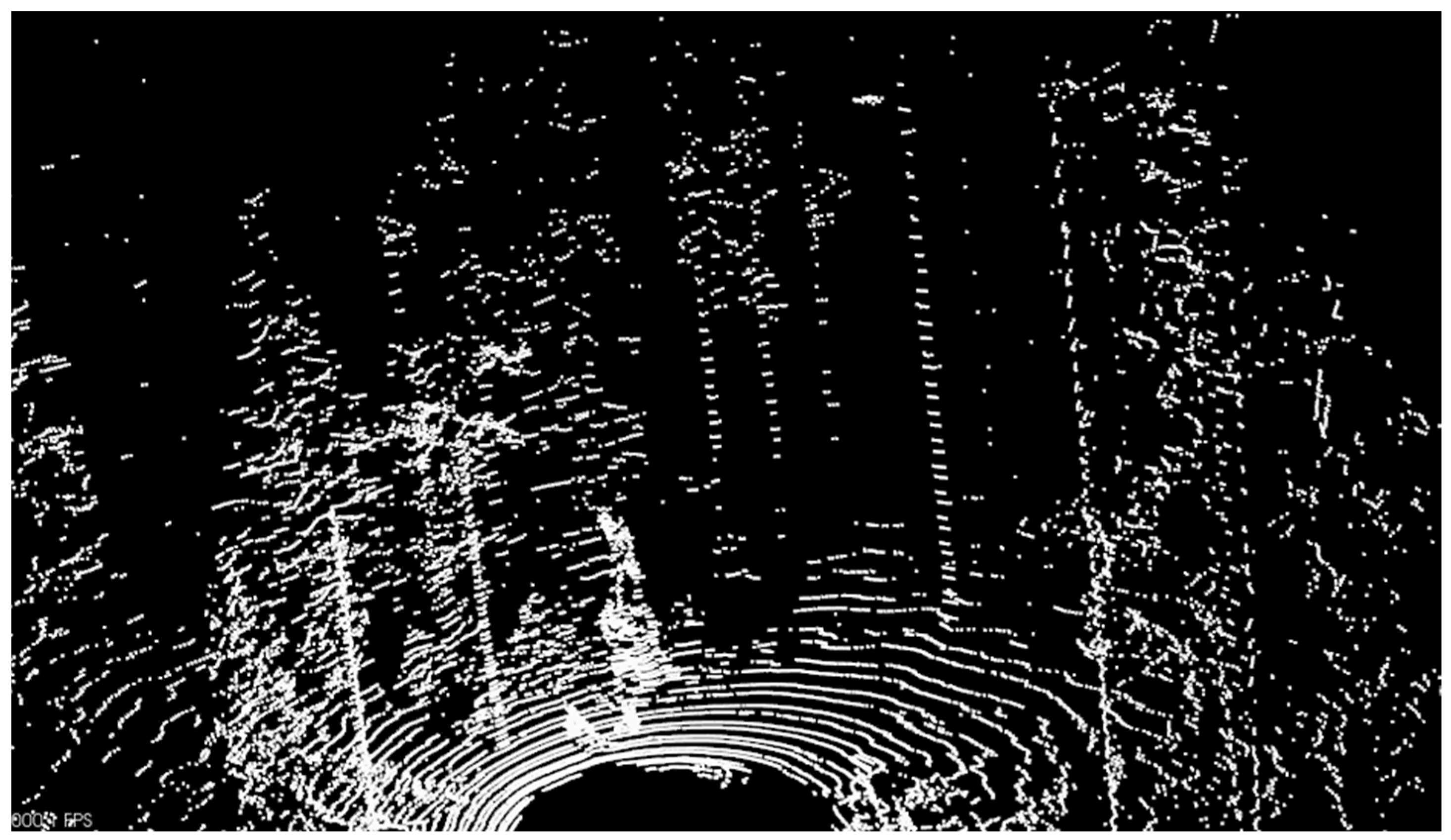

2.3.2. Real-World Data Collection (Point Cloud)

2.4. Data Analysis

2.4.1. Tools Used

2.4.2. Point Cloud Processing

- Input: A cloud of points where each point has a position in 3D space.

- Distance Threshold: The algorithm requires a predefined distance threshold, which determines how close points should be to each other to be considered part of the same cluster.

- Clustering: The algorithm proceeds to group points that are within the distance threshold of each other. Each group of points closer than the threshold to each other forms a cluster.

- Output: The output is a set of clusters, where each cluster is a group of points that are close to each other based on the Euclidean distance.

- Load Point Cloud: Utilizes the PCL’s PCDReader class to initiate the loading of point cloud data.

- Remove Outliers: This phase is dedicated to purging any points that contain “Not-a-Number” (NaN) values from the point cloud to ensure data integrity.

- Clustering: At this juncture, individual tree stems are discerned and segregated from the collective point cloud data set.

- Divide into Sections: Here, the point cloud cluster of each tree stem is segmented into predefined height intervals. It involves calculating the minimum and maximum heights within the cluster, delineating sections for varying height ranges, and allocating points to these sections based on their vertical position.

- Get Center line: This process establishes the center line by pinpointing the central point at both the base and apex sections of the point cloud cluster, effectively marking the core axis of the stem.

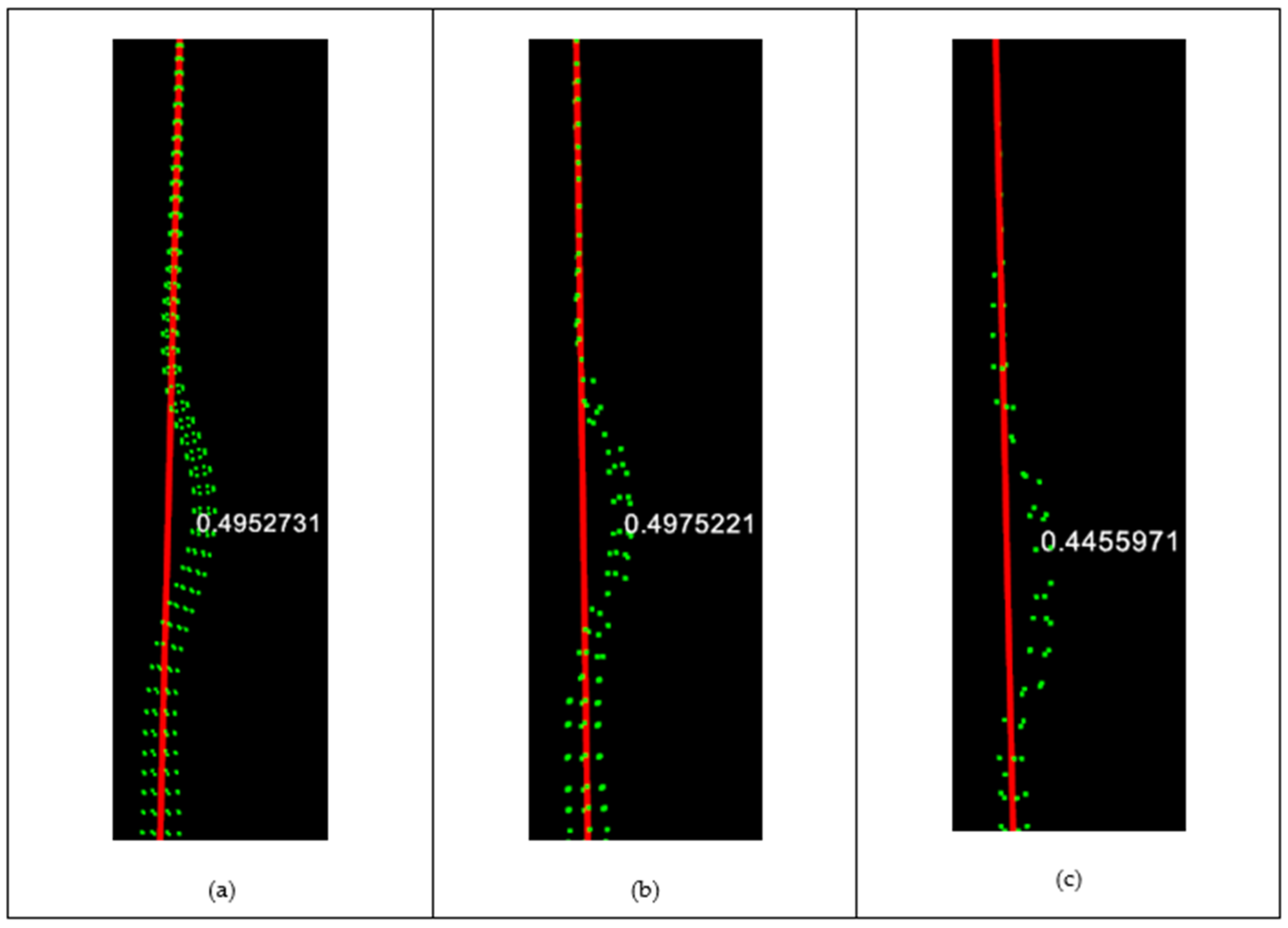

- Calculate the Curve: Employs vector calculus to ascertain the minimal distance between any selected point and a three-dimensional line, or center line, which is charted between two distinct points.

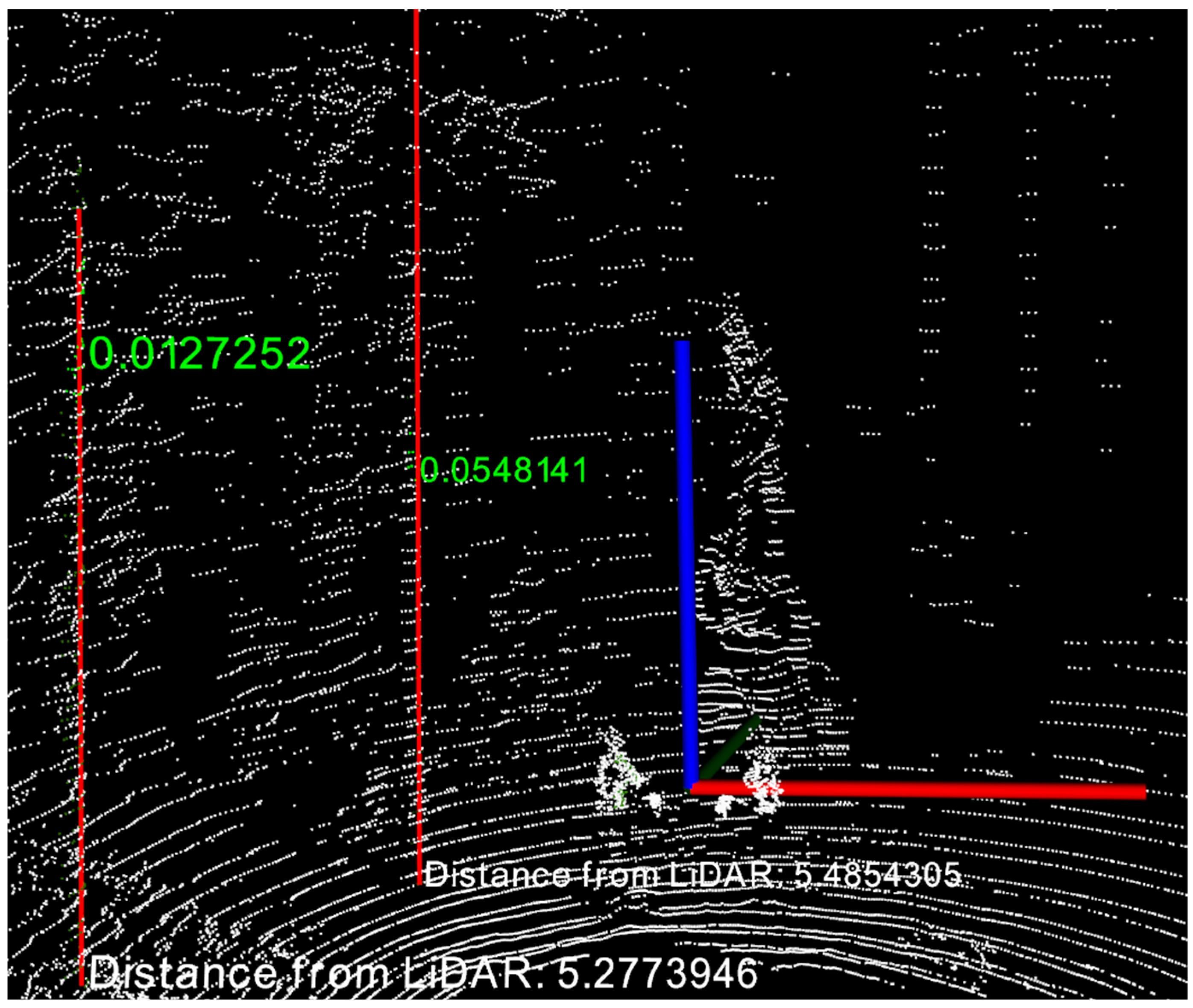

- Visualize: This step involves the graphical representation of the tree stem alongside the maximum distance value from its center line, providing a visual assessment of the stem’s deviation or curvature.

- Alignment: Alignment for the point cloud using the orientation of the LiDAR. The point cloud is orientated upright, the trees are pointing in Z direction, and the ground is in the X and Y plane.

- Segmentation: In the initial phase of segmentation using a 2D grid approach, the point cloud is segmented into grid cells based on their XY coordinates, forming an XY grid. The process of ground point removal involves eliminating the lowest points in each grid cell. Here, the ‘lowest’ refers to selecting the minimum Z value within a grid cell and establishing an offset above this value. Points falling below this threshold (minimum Z value plus offset) are classified as ground points and removed. Following the ground removal, the remaining points in each cell are evaluated. If a cell contains only a few points post-ground removal, it indicates the absence of a tree stem. Conversely, cells with insufficient point counts, determined by a predefined threshold, are identified as containing branch points. Cells meeting or exceeding this point count threshold are then classified as tree stems. This method effectively differentiates between tree stems and branches based on the density of points within each grid cell.

- Fit a cylinder: Estimating the point normal and setting up the model type to a cylinder and the SAC_RANSAC as a method type for each cluster. The cylinder inliers and the coefficients are obtained. Following the grid approach, the focus shifts to isolating the tree points once the ground points and branch points have been excluded. Clustering of the tree or vegetation points is then undertaken. Clustering serves to divide the trees into distinct point clouds for further processing.

2.4.3. Determining the Accuracy

3. Results

3.1. Detecting Tree Stems from Point Clouds

3.2. Detecting Defective Tree Stems from Synthetic Point Clouds

3.3. Detecting Defective Tree Stems from the Real-World Point Clouds

4. Discussion

- Reduced environmental impact: By providing accurate and detailed data on tree characteristics and forest inventory, MLS technology enables more precise planning and management of harvesting activities. This can minimize unnecessary tree removal, reduce habitat disturbance, and decrease the risk of soil erosion and other environmental degradation associated with forest operations.

- Enhanced resource utilization: MLS technology facilitates efficient tree selection and harvesting processes, leading to optimized utilization of timber resources. By accurately identifying trees with defects such as crooks and curves, MLS can help maximize the utilization of merchantable timber while minimizing waste. This contributes to sustainable forestry practices by ensuring the efficient use of available resources.

- Improved operational efficiency: MLS technology enables faster and more accurate data collection compared to traditional manual methods. These efficiency gains in data collection translate to more efficient forest operations overall, reducing the time and resources required for field surveys and inventory assessments. By streamlining operations, MLS can help the forest industries reduce costs and improve productivity, contributing to long-term sustainability.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ponsse Plc. Ponsse Scorpion Harvester. Available online: https://www.ponsse.com/en/web/guest/products/harvesters/product/-/p/scorpion#/ (accessed on 20 February 2024).

- Picchi, G.; Sandak, J.; Grigolato, S.; Panzacchi, P.; Tognetti, R. Smart Harvest Operations and Timber Processing for Improved Forest Management. In Climate-Smart Forestry in Mountain Regions, Managing Forest Ecosystems 40; Tognetti, R., Smith, M., Panzacchi, P., Eds.; Springer: Cham, Switzerland, 2022; pp. 317–359. [Google Scholar] [CrossRef]

- Kärhä, K.; Ovaskainen, H.; Palander, T. Decision-Making Among Harvester Operators in Tree Selection and Need for Advanced Harvester Operator Assistant Systems (AHOASs) on Thinning Sites. In Proceedings of the Joint 43rd Annual Meeting of Council on Forest Engineering (COFE) and the 53rd International Symposium on Forest Mechanization (FORMEC). Forest Engineering Family—Growing Forward Together, Corvallis, OR, USA, 27–30 September 2021; pp. 15–25. [Google Scholar]

- Kärhä, K.; Änäkkälä, J.; Hakonen, O.; Palander, T.; Sorsa, J.A.; Räsänen, T.; Moilanen, T. Analyzing the Antecedents and Consequences of Manual Log Bucking in Mechanized Wood Harvesting. Mech. Mater. Sci. Eng. J. 2017, 12, 1–15. [Google Scholar]

- Kerr, G.; Haufe, J. Thinning Practice A Silvicultural Guide. 2011. Available online: https://www.forestresearch.gov.uk/publications/thinning-practice-a-silvicultural-guide/ (accessed on 20 February 2024).

- Heupel, C.; Wolf, P.; Berns, K. Tree-SLAM: Localization and Mapping in Dense Forest Environments for Autonomous Vehicles. Available online: https://www.researchgate.net/publication/372288298_Tree-SLAM_Localization_and_Mapping_in_Dense_Forest_Environments_for_Autonomous_Vehicles (accessed on 20 February 2024).

- Kärhä, K.; Räsänen, M.; Palander, T. The Profitability of Cross-Cutting Practices in Butt-Rotten Picea abies Final-Felling Stands. Forests 2019, 10, 874. [Google Scholar] [CrossRef]

- Miettinen, M.; Kulovesi, J.; Kalmari, J.; Visala, A. New Measurement Concept for Forest Harvester Head. In Field and Service Robotics; Springer Tracts in Advanced Robotics 62; Howard, A., Iagnemma, K., Kelly, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 35–44. [Google Scholar] [CrossRef]

- Hyyti, H.; Visala, A. Feature Based Modeling and Mapping of Tree Trunks and Natural Terrain Using 3D Laser Scanner Measurement System. IFAC Proc. Vol. 2013, 46, 248–255. [Google Scholar] [CrossRef]

- Li, J.; Thiel, M. Stem and Stand Characterization Using Mobile Terrestrial LiDAR in Plantation and Complex Multi-Cohort Stands; FPInnovations, Technical Report 38. 2018. Available online: https://library.fpinnovations.ca/media/FOP/TR2018N38.PDF (accessed on 20 February 2024).

- Liang, X.; Hyyppä, J.; Kukko, A.; Kaartinen, H.; Jaakkola, A.; Yu, X. The Use of a Mobile Laser Scanning System for Mapping Large Forest Plots. IEEE Geosci. Remote Sens. 2014, 11, 1504–1508. [Google Scholar] [CrossRef]

- Nevalainen, P.; Li, Q.; Melkas, T.; Riekki, K.; Westerlund, T.; Heikkonen, J. Navigation and Mapping in Forest Environment Using Sparse Point Clouds. Remote Sens. 2020, 12, 4088. [Google Scholar] [CrossRef]

- Bienert, A.; Georgi, L.; Kunz, M.; von Oheimb, G.; Maas, H.G. Automatic extraction and measurement of individual trees from mobile laser scanning point clouds of forests. Ann. Bot. 2021, 128, 787–804. [Google Scholar] [CrossRef] [PubMed]

- Morgan, C.J.; Powers, M.; Strimbu, B.M. Estimating Tree Defects with Point Clouds Developed from Active and Passive Sensors. Remote Sens. 2022, 14, 1938. [Google Scholar] [CrossRef]

- Panagiotidis, D.; Surový, P.; Kuželka, K. Accuracy of Structure from Motion models in comparison with terrestrial laser scanner for the analysis of DBH and height influence on error behaviour. J. For. Sci. 2016, 62, 357–365. [Google Scholar] [CrossRef]

- Hyyppä, E.; Kukko, A.; Kaartinen, H.; Yu, X.; Muhojoki, J.; Hakala, T.; Hyyppä, J. Direct and automatic measurements of stem curve and volume using a high-resolution airborne laser scanning system. Sci. Remote Sens. 2022, 5, 100050. [Google Scholar] [CrossRef]

- Yun, T.; Cao, L.; An, F.; Chen, B.; Xue, L.; Li, W.; Pincebourde, S.; Smith, M.J.; Eichhorn, M.P. Simulation of multi-platform LiDAR for assessing total leaf area in tree crowns. Agric. For. Meteorol. 2019, 276–277, 107610. [Google Scholar] [CrossRef]

- Lu, J.; Wang, H.; Qin, S.; Cao, L.; Pu, R.; Li, G.; Sun, J. Estimation of aboveground biomass of Robinia pseudoacacia forest in the Yellow River Delta based on UAV and Backpack LiDAR point clouds. Int. J. App. Earth Obs. 2020, 86, 102014. [Google Scholar] [CrossRef]

- De Paula Pires, R.; Olofsson, K.; Persson, H.J.; Lindberg, E.; Holmgren, J. Individual tree detection and estimation of stem attributes with mobile laser scanning along boreal forest roads. ISPRS J. Photogramm. Remote Sens. 2022, 187, 211–224. [Google Scholar] [CrossRef]

- Kukko, A.; Kaijaluoto, R.; Kaartinen, H.; Lehtola, V.V.; Jaakkola, A.; Hyyppä, J. Graph SLAM correction for single scanner MLS forest data under boreal forest canopy. ISPRS J. Photogramm. Remote Sens. 2017, 132, 199–209. [Google Scholar] [CrossRef]

- Gao, S.; Zhang, Z.; Cao, L. Individual Tree Structural Parameter Extraction and Volume Table Creation Based on Near-Field LiDAR Data: A Case Study in a Subtropical Planted Forest. Sensors 2021, 21, 8162. [Google Scholar] [CrossRef] [PubMed]

- Tatsumi, S.; Yamaguchi, K.; Furuya, N. ForestScanner: A mobile application for measuring and mapping trees with LiDAR-equipped iPhone and iPad. Methods Ecol. Evol. 2023, 14, 1603–1609. [Google Scholar] [CrossRef]

- Metsälehti. Finnmetko 2022: Ponsse toi Laserkeilaimen Hakkuukoneeseensa (Ponsse Introduced a Laser Scanner to Ponsse Scorpion Harvester). Metsälehti Uutinen 2 September 2022. Available online: https://www.metsalehti.fi/uutiset/finnmetko-2022-ponsse-toi-laserkeilaimen-hakkuukoneeseensa/#c79b2cfa (accessed on 20 February 2024).

- Finnish Forest Centre. Metsien Ensiharvennukset Eivät ole Suositusten Mukaisia (First Thinning’s Do Not Comply with Recommendations). Suomen Metsäkeskus, Uutinen 19 December 2022. Available online: https://www.metsakeskus.fi/fi/ajankohtaista/metsien-ensiharvennukset-eivat-ole-suositusten-mukaisia (accessed on 20 February 2024).

- Finnish Forest Centre. Tasaikäisrakenteisten Metsien Korjuujälkitarkastusten Aikasarja (Harvesting Result in Thinnings Reported by the Inventories of Finnish Forest Centre in 2016–2022 in Finland). Available online: https://www.metsakeskus.fi/sites/default/files/document/tiedote-liite-korjuujaljen-tarkastukset.pdf (accessed on 20 February 2024).

- Finnish Forest Industries. Roadmap for the Wood Processing Industry More Biodiverse Forests. 2023. Available online: https://assets-global.website-files.com/5f44f62ce4d302179b465b3a/6524e21683a1c9a3a0d53e85_Metry_Monimuotoisuus_2023_eng_low.pdf (accessed on 20 February 2024).

- Kärhä, K.; Malinen, J.; Hyyppä, J.; Kaartinen, H. Technological Opportunities in Measuring Biodiversity during Harvesting. Finnish Forest Industries, Blog 31 May 2023. Available online: https://www.metsateollisuus.fi/newsroom/technological-opportunities-in-measuringbiodiversity-during-harvesting (accessed on 20 February 2024).

- Korhonen, L.; Kärhä, K.; Maltamo, M.; Malinen, J.; Hyyppä, J.; Kaartinen, H.; Toivonen, J.; Packalen, P.; Koivula, M. Kaukokartoitus ja metsäkoneiden sensorit metsien monimuotoisuus indikaattorien seurannassa (Remote sensing and forest machine sensors in the monitoring of forest biodiversity indicators). Manuscript submitted, 2024.

- La Hera, P.M.; Trejo, O.M.; Lindroos, O.; Lideskog, H.; Lindbäck, T.; Latif, S.; Li, S.; Karlberg, M. Exploring the Feasibility of Autonomous Forestry Operations: Results from the First Experimental Unmanned Machine. Authorea 2023. [Google Scholar] [CrossRef]

- Visser, R.; Obi, O.F. Automation and Robotics in Forest Harvesting Operations: Identifying Near-Term Opportunities. Croat. J. For. Eng. 2021, 42, 13–24. [Google Scholar] [CrossRef]

- Sagar, A.; Einola, K.; Ghabcheloo, R. Tree stem geometry quality assist system for cut-to-length harvester operator—Defining needs & solutions. In Proceedings of the 18th Scandinavian International Conference on Fluid Power (SICFP’23), Tampere, Finland, 30 May–1 June 1 2023. [Google Scholar]

- Metsäteho. Opas, Sahapuurunkojen Apteeraus (Guidelines for Bucking Sawlog Stems). 1989. Available online: https://www.metsateho.fi/wp-content/uploads/Opas_sahapuurunkojen-apteeraus-1989.pdf (accessed on 20 February 2024).

- Keinänen, E.; Tahvanainen, V. Puutavaralajien Mitta-ja Laatuvaatimukset (Measuring and Quality Requirements for Timber Assortments). Keski-Suomen Metsäkeskuksen Julkaisu 7/1999. Available online: https://docplayer.fi/6113385-Puutavaralajien-mitta-ja-laatuvaatimukset.html (accessed on 20 February 2024).

- Blender Software. Open Source 3D Creation Suite. Available online: https://www.blender.org/ (accessed on 20 February 2024).

- Jones, M.H. Add-On for Importing and Exporting PCD Files. Available online: https://github.com/MarkHedleyJones/blender-pcd-io (accessed on 20 February 2024).

- Ouster Datasheet. Available online: https://data.ouster.io/downloads/datasheets/datasheet-rev06-v2p5-os0.pdf (accessed on 20 February 2024).

- CloudCompare. Available online: https://www.cloudcompare.org/main.html (accessed on 20 February 2024).

- Point Cloud Library (PCL). Available online: https://pointclouds.org/ (accessed on 20 February 2024).

- Microsoft Visual Studio 2022. Available online: https://visualstudio.microsoft.com/vs/professional/ (accessed on 20 February 2024).

- Liang, X.; Kukko, A.; Balenović, I.; Saarinen, N.; Junttila, S.; Kankare, V.; Holopainen, M.; Mokroš, M.; Surový, P.; Kaartinen, H.; et al. Close-Range Remote Sensing of Forests: The State of the Art, Challenges, and Opportunities for Systems and Data Acquisitions. IEEE Geosci. Remote Sens. Mag. 2022, 10, 32–71. [Google Scholar] [CrossRef]

- Panagiotidis, D.; Abdollahnejad, A. Reliable Estimates of Merchantable Timber Volume from Terrestrial Laser Scanning. Remote Sens. 2021, 13, 3610. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sagar, A.; Kärhä, K.; Einola, K.; Koivusalo, A. Assessing the Potential of Onboard LiDAR-Based Application to Detect the Quality of Tree Stems in Cut-to-Length (CTL) Harvesting Operations. Forests 2024, 15, 818. https://doi.org/10.3390/f15050818

Sagar A, Kärhä K, Einola K, Koivusalo A. Assessing the Potential of Onboard LiDAR-Based Application to Detect the Quality of Tree Stems in Cut-to-Length (CTL) Harvesting Operations. Forests. 2024; 15(5):818. https://doi.org/10.3390/f15050818

Chicago/Turabian StyleSagar, Anwar, Kalle Kärhä, Kalle Einola, and Anssi Koivusalo. 2024. "Assessing the Potential of Onboard LiDAR-Based Application to Detect the Quality of Tree Stems in Cut-to-Length (CTL) Harvesting Operations" Forests 15, no. 5: 818. https://doi.org/10.3390/f15050818