Thermo-Mechanical Characterization of Friction Stir Spot Welded AA7050 Sheets by Means of Experimental and FEM Analyses

Abstract

:1. Introduction

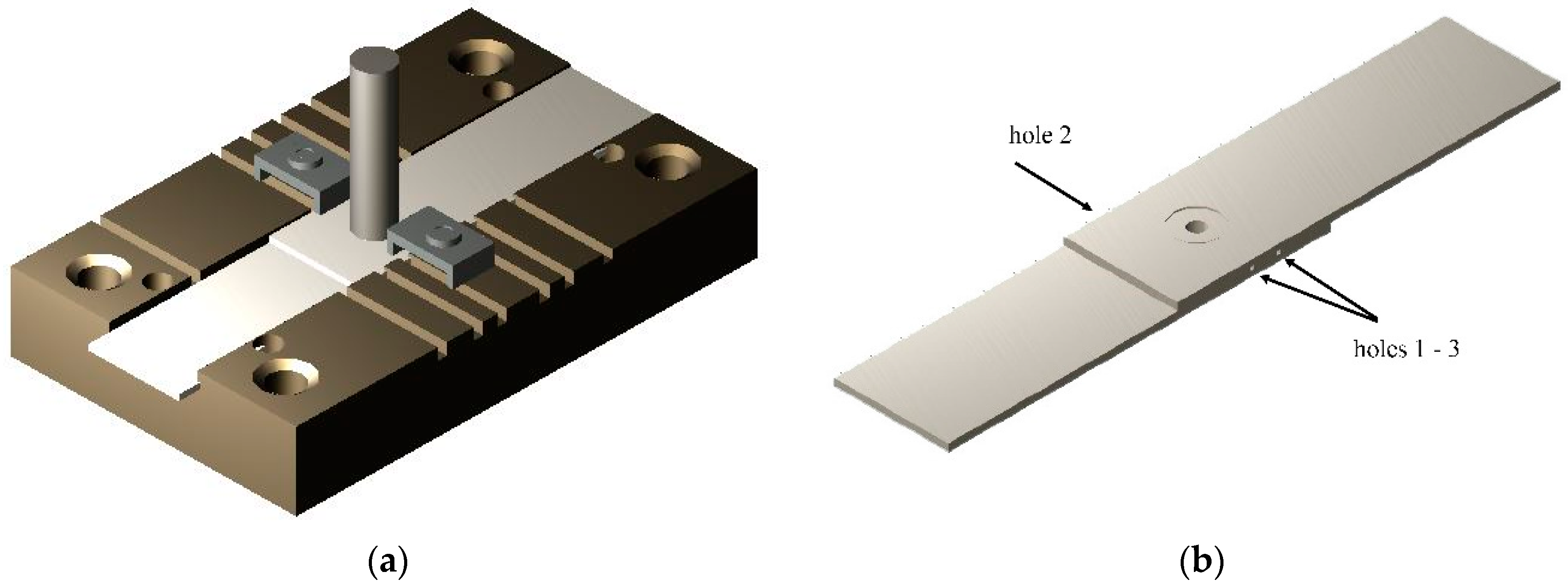

2. Experimental Procedure

3. Analysis of the Results

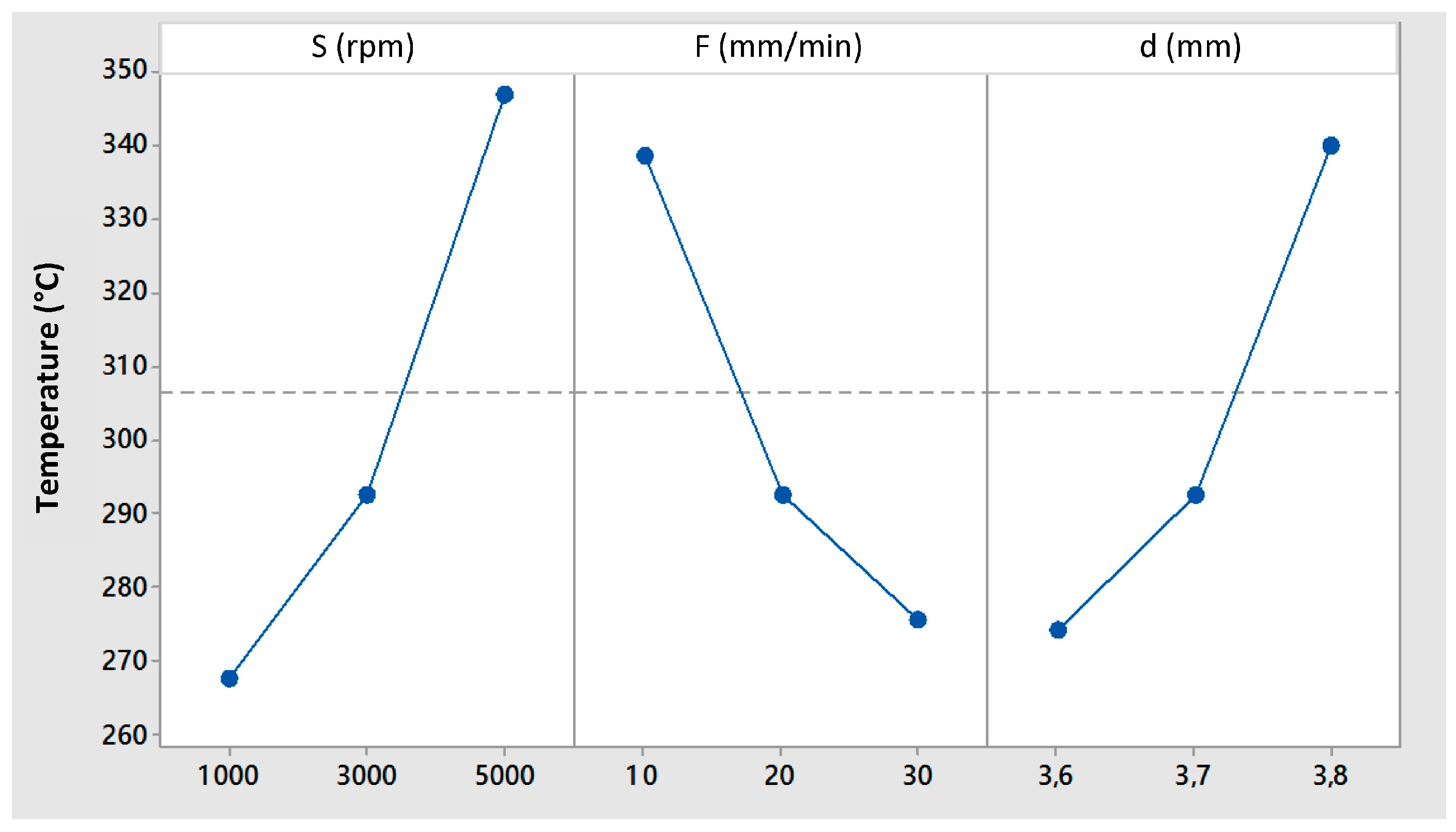

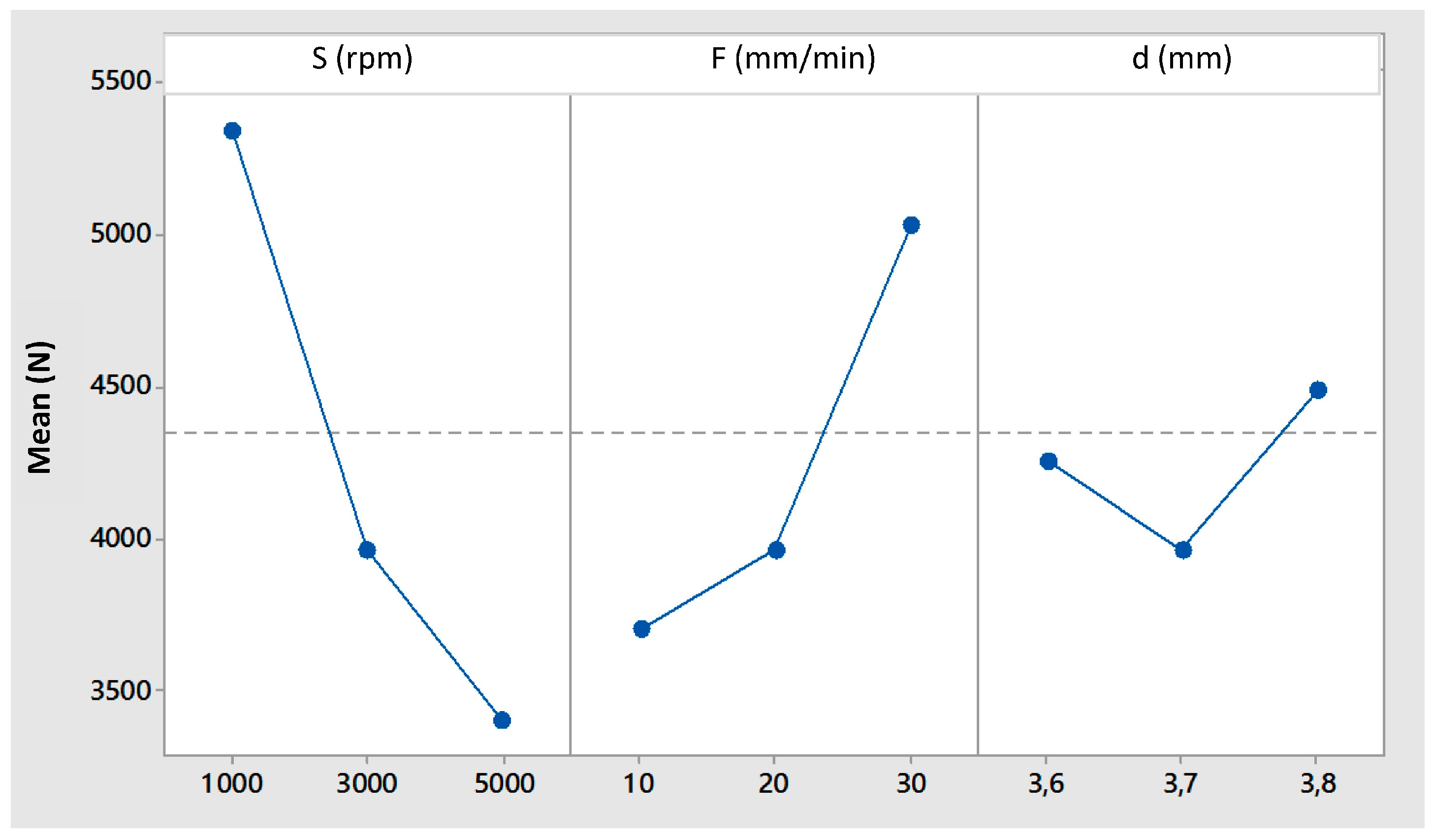

3.1. Welding Forces and Temperature

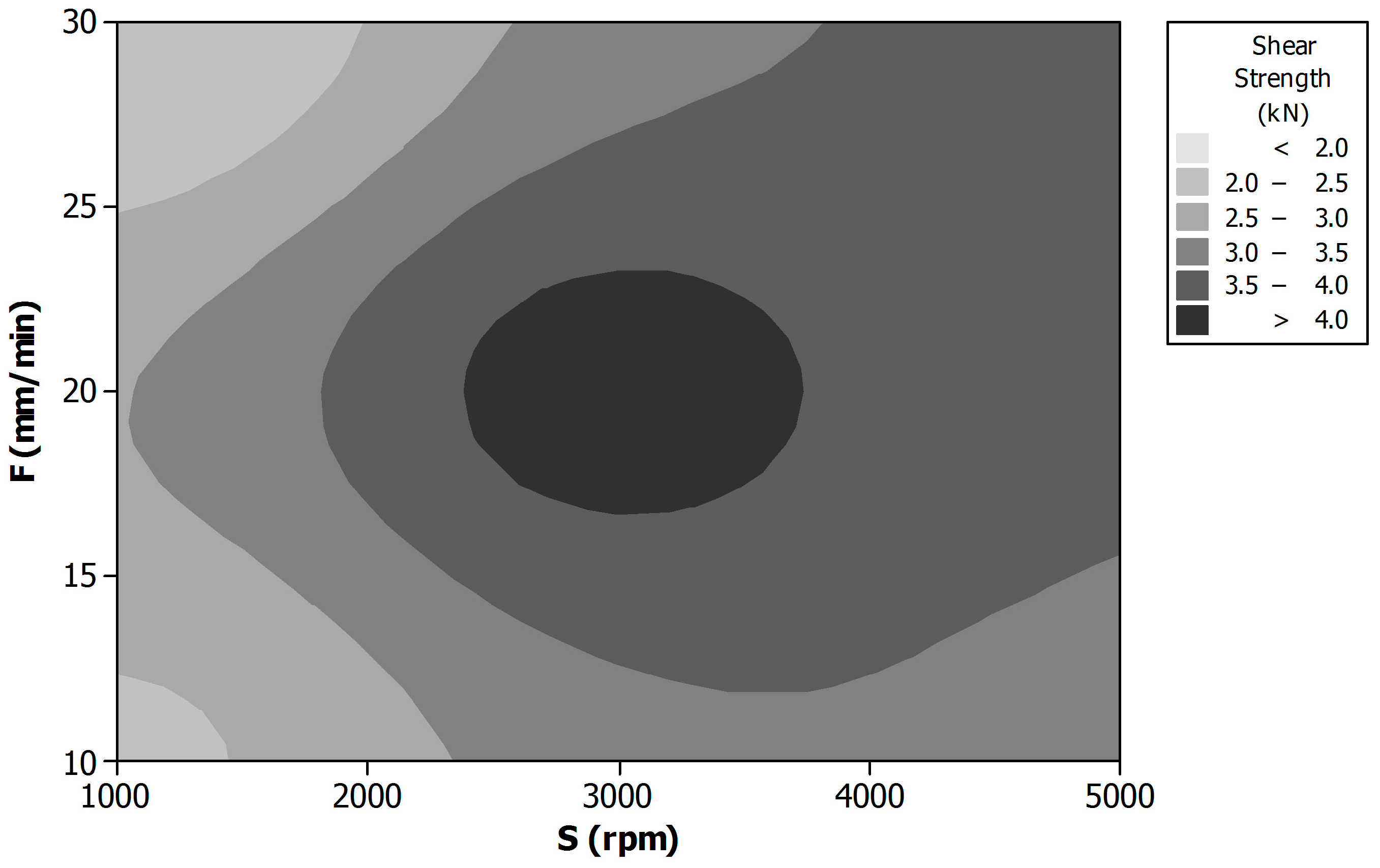

3.2. Shear Test

4. Simulation of the FSSW Process

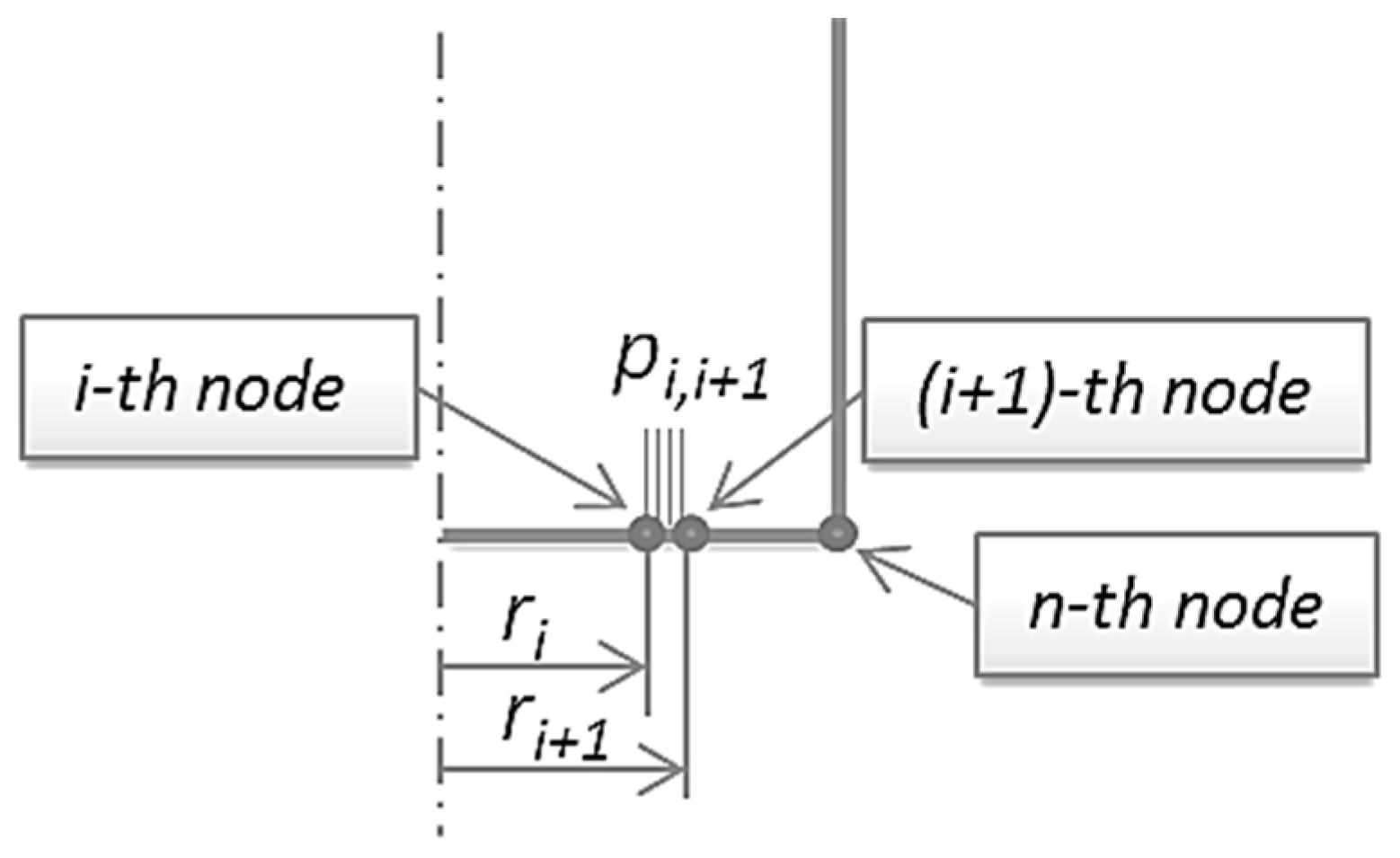

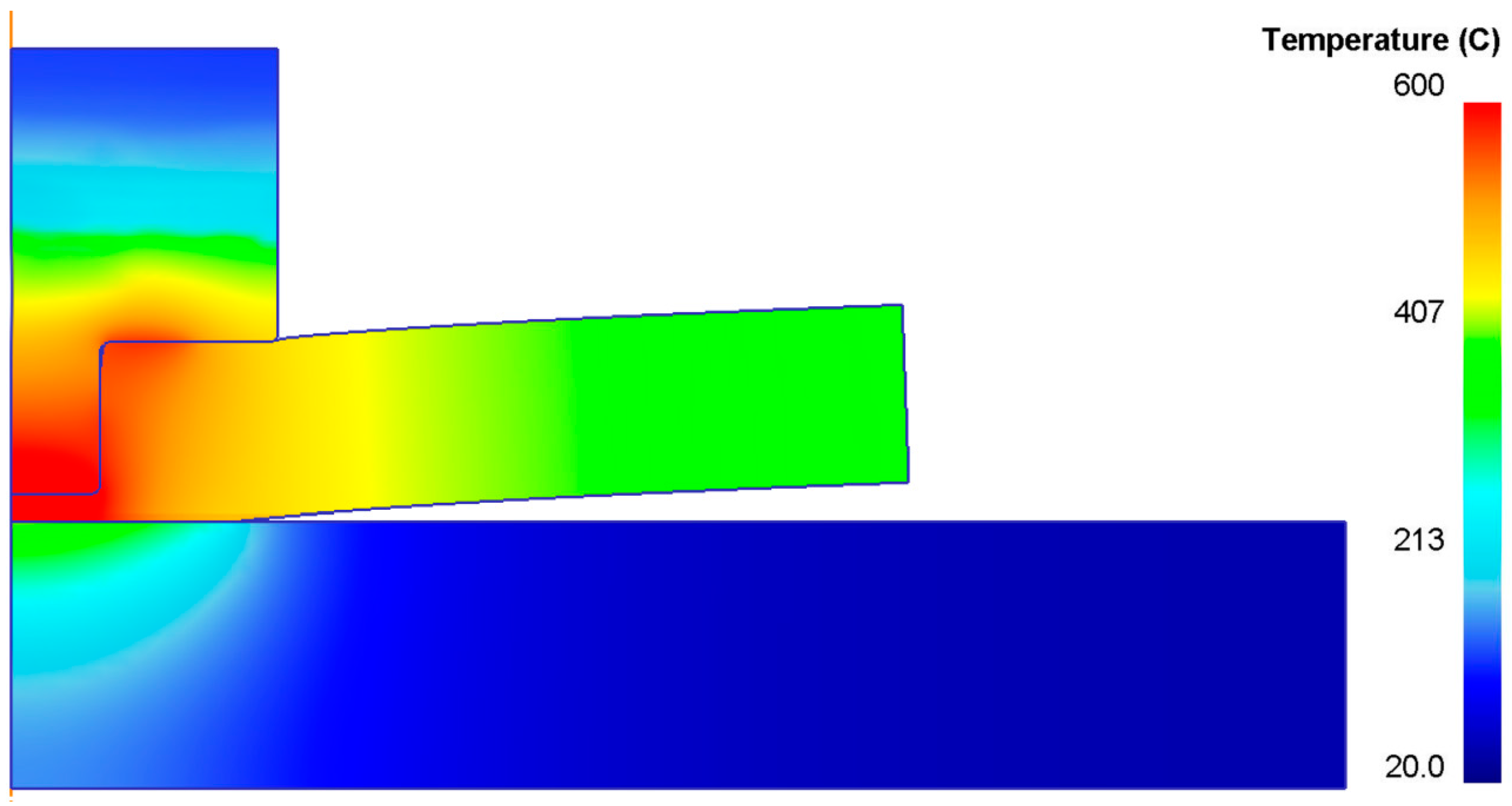

4.1. FEM Model

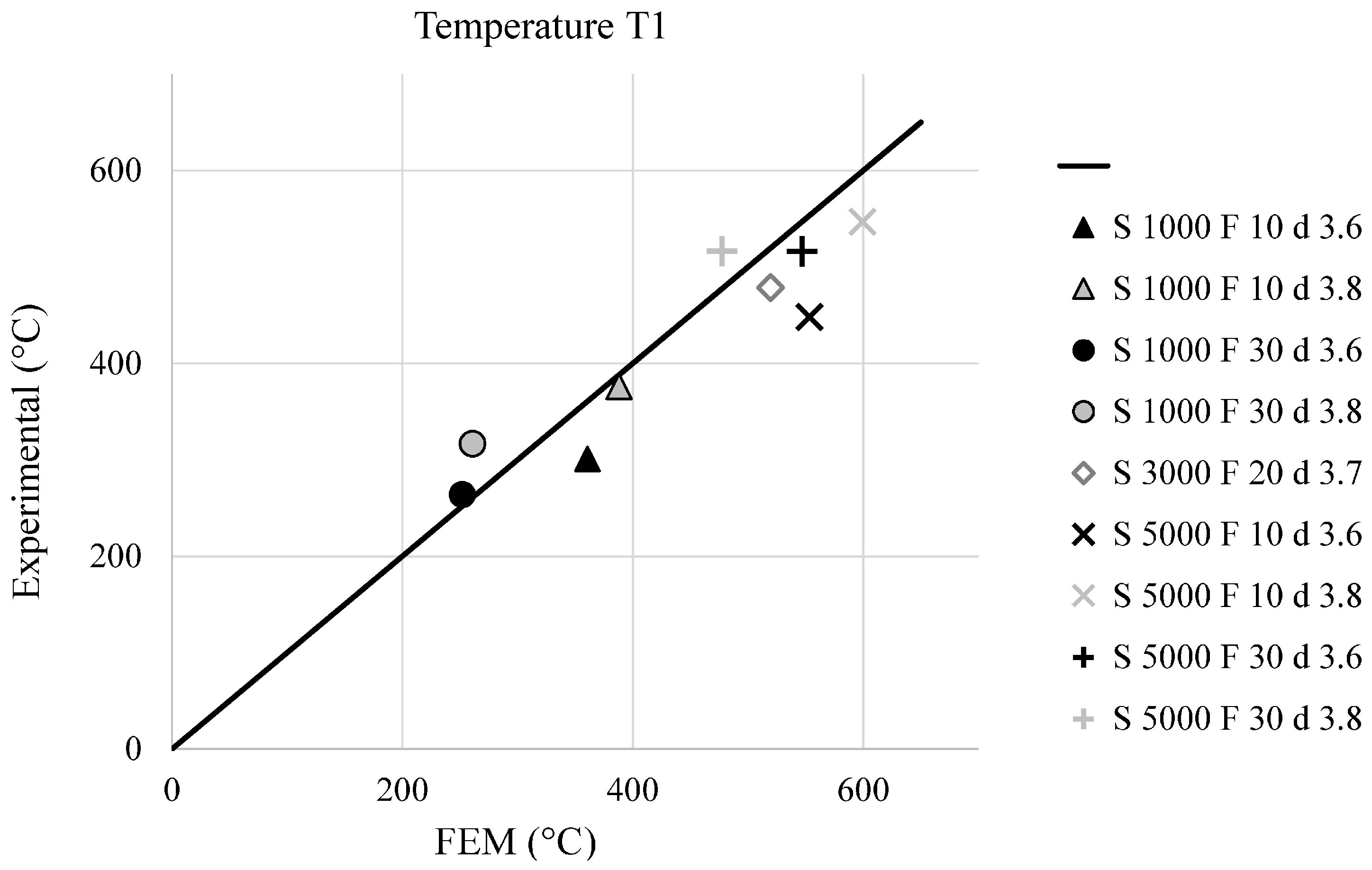

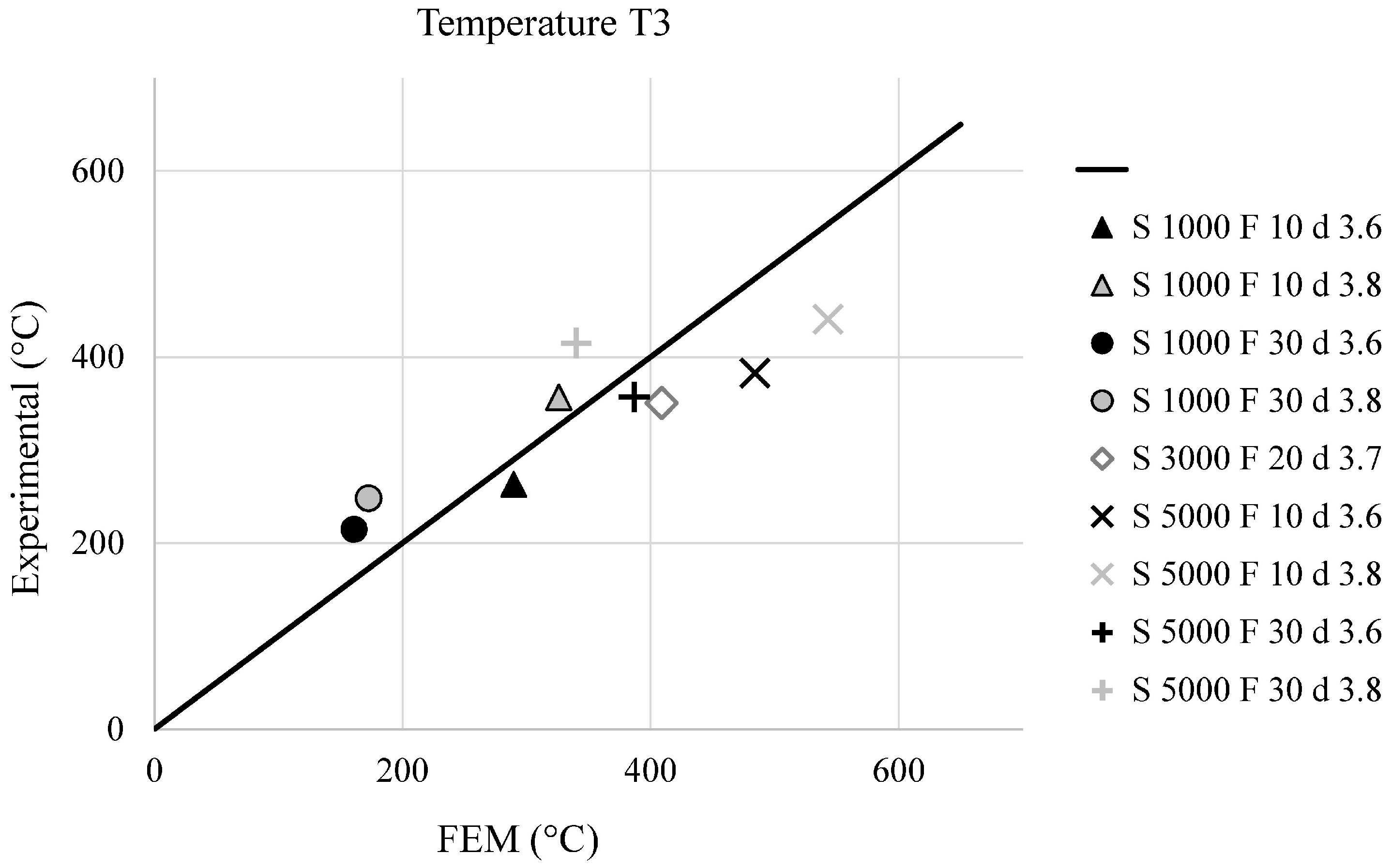

4.2. Model Validation

4.3. Predictive Index of the Joint Resistance

5. Concluding Remarks

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Martinsen, K.; Hu, S.J.; Carlson, B.E. Joining of dissimilar materials. CIRP Ann. Manuf. Technol. 2015, 64, 679–699. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicolas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Friction Stir Butt Welding. International Patent Application No. PCT/GB92/02203, 25 December 1991. [Google Scholar]

- Thomas, W.M.; Nichola, E.D.; Needam, J.C.; Murch, M.G.; Templesmith, P.; Dawes, C.J. U.S. Patent Application No. 5460317.P.L, 25 October 1995.

- Kawasaki, T.; Makino, T.; Todori, S.; Takai, H.; Ezumi, M.; Inada, Y. Application of Friction Stir Welding to the Manufacturing of Next Generation A-train Type Rolling Stock. In Proceedings of the 2nd International Symposium on Friction Stir Welding, Gothenburg, Sweden, 27–29 June 2000.

- Ken-ichiro, M.; Niels, B.; Livan, F.; Micari, F.; Tekkaya, A.E. Joining by plastic deformation. CIRP Ann. Manuf. Technol. 2013, 62, 673–694. [Google Scholar]

- Lohwasser, D. Application of Friction Stir Welding for aircraft industry. In Proceedings of the 2nd International Symposium on Friction Stir Welding, Gothenburg, Sweden, 27–29 June 2000.

- Khaled, T. An Outsider Looks at Friction Stir Welding. Fed. Aviat. Adm. 2005, 25, 27–29. [Google Scholar]

- Mishra, R.S.; Ma, Z. Friction Stir Welding and processing Materials Science and Engineering. Reports 2005, 50, 1–78. [Google Scholar]

- Taban, E.; Gould, J.E.; Lippold, J.C. Dissimilar Friction Stir Welding of 6061.T6 Aluminium and AISI 1018 Steel: Properties and Microstructural Characterization. Mater. Des. 2010, 31, 2305–2311. [Google Scholar] [CrossRef]

- Uzun, H.; Dalle Donne, C.; Argognotto, A.; Ghidini, T.; Gambaro, C. Friction Stir Welding of Dissimilar Al 6013.T4 to X5CrNi18-10 Stainless Steel. Mater. Des. 2005, 26, 41–46. [Google Scholar] [CrossRef]

- Watanabe, T.; Takayama, H.; Yanagisawa, A. Joining of Aluminium Alloy to Steel by Friction Stir Welding. J. Mater. Proc. Technol. 2006, 178, 342–349. [Google Scholar] [CrossRef]

- Kellenberger, O.; Silvanus, J.; Voller, G.; Zah, M.F. Potential of Robotic Friction Stir Welding Using the Example of Aeronautics. Weld. Cut. 2007, 6, 348–351. [Google Scholar]

- Zaeh, M.F.; Voellner, G. Three-Dimensional Friction Stir Welding Using a High Payload Industrial Robot. Prod. Eng. 2010, 4, 127–133. [Google Scholar] [CrossRef]

- Yuana, W.; Mishraa, R.S.; Webba, S.; Chenb, Y.L.; Carlsonb, B.; Herlingc, D.R.; Grantc, G.J. Effect of tool design and process parameters on properties of Al alloy 6016 friction stir spot welds. J. Mater. Proc. Technol. 2011, 211, 972–977. [Google Scholar] [CrossRef]

- Paoletti, A.; Lambiase, F.; Di Ilio, A. Optimization of friction stir welding of thermoplastics. Procedia CIRP 2015, 33, 562–567. [Google Scholar] [CrossRef]

- Bilici, M.K. Application of polypropylene. Mater. Des. 2012, 35, 113–119. [Google Scholar] [CrossRef]

- Azarsa, E.; Mostafapour, A. On the feasibility of producing polymer-metal composites via novel variant of friction stir processing. J. Manuf. Proc. 2013, 15, 682–688. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T. On the feasibility of friction spot joining in magnesium/fiber reinforced polymer composite hybrid structures. Mater. Sci. Eng. 2011, A528, 3841–3848. [Google Scholar] [CrossRef]

- Dashatan, S.H.; Azdast, T.; Ahmadi, S.; Bagheri, A. Friction stir spot welding of dissimilar polymethyl methacrylate and acrylonitrile butadiene styrene sheets. Mater. Des. 2013, 45, 135–141. [Google Scholar] [CrossRef]

- Bilici, M.K.; Yükler, A.I. Influence of tool geometry and process parameters on macrostructure and static strength in friction stir spot welded polyethylene sheets. Mater. Des. 2012, 33, 145–152. [Google Scholar] [CrossRef]

- Shi, S.G.; Westgate, S.A. Resistance spot welding of high-strength steel sheet. In Corporate Research Program Report No 767; The Welding Institute (TWI): Cambridge, UK, 2003. [Google Scholar]

- Spinella, D.J.; Brockenbrough, J.R.; Fridy, J.M. Trend in aluminum resistance spot welding for the automotive industry. Weld J. 2005, 84, 34–40. [Google Scholar]

- Suenger, S.; Kreissle, M.; Kahnert, M.; Zaeh, M.F. Influence of Process Temperature on Hardness of Friction Stir Welded High Strength Aluminum Alloys for Aerospace Application. Procedia CIRP 2014, 24, 120–124. [Google Scholar] [CrossRef]

- Kahnert, M.; Mestek, M.; Windisch, M.; Tessier, I.; Okulla, M. Preparation of Friction Stir Welding of Aluminum Alloy AA 2219 for Launcher Applications. In Proceedings of the 9th International Friction Stir Welding Symposium, Huntsville, AL, USA, 15–17 May 2012.

- Klett, A.; Hegels, J.; Bartesh, G.; Glaser, U.; Nold, E.; Rantke, W. Sprinforming of Friction Stir Welded AA 2219 circolar blanks for ARIANE 5 main stage tank bulkheads. DVS Berischte 2004, 229, 90–94. [Google Scholar]

- Hirasawa, S.; Badarinarayan, H.; Okamoto, K.; Tomimura, T.; Kawanami, T. Analysis of effect of tool geometry on plastic flow during friction stir spot welding using particle method. J. Mater. Proc. Technol. 2010, 210, 1455–1463. [Google Scholar] [CrossRef]

- Lorrain, O.; Favier, V.; Zahroumi, H.; Lawrjaniec, D. Understanding the material flow path of friction stir welding process using unthreaded tools. J. Mater. Proc. Technol. 2010, 210, 603–609. [Google Scholar] [CrossRef]

- Hattingh, D.G.; Blignault, C.; Van Niekerk, T.I.; James, M.N. Characterization of the influences of FSW tool geometry on welding forces and weld tensile strength using an instrumented tool. J. Mater. Proc. Technol. 2008, 203, 46–57. [Google Scholar] [CrossRef]

- Zhang, L.; Ji, S.; Luan, G.; Dong, C.; Fu, L. Friction Stir Welding of Al Alloy Thin Plate by Rotational Tool without Pin. J. Mater. Proc. Technol. 2007, 27, 647–652. [Google Scholar] [CrossRef]

- Montag, T.; Wulfsberg, J.P.; Hameister, H.; Marschner, R. Influence of Tool Wear on Quality Criteria for Refill Friction Stir Spot Welding (RFSSW) Process. Procedia CIRP 2014, 24, 108–113. [Google Scholar] [CrossRef]

- Sakano, R.; Murakami, K.; Yamashita, K.; Hyoe, T.; Fuzimoto, M.; Inuzuka, M. Development of spot FSW robot system for automotive body members. In Proceedings of the 3rd International Symposium of Friction Stir Welding, Kobe, Japan, 27–28 September 2001.

- Iwashita, T. Method and Apparatus for Joining. U.S. Patent No. 6601751 B2, 5 August 2003. [Google Scholar]

- Badarinarayan, H.; Shi, Y.; Li, X.; Okamoto, K. Effect of tool geometry on hook formation and static strength of friction stir spot welded aluminum 5754-O sheets. Int. J. Mach. Tools Manuf. 2009, 49, 814–823. [Google Scholar] [CrossRef]

- Jonckheere, C.; De Meester, B.; Cassiers, C.; Delhaye, M.; Simar, A. Fracture and mechanical properties of friction stir spot welds in 6063-T6 aluminum alloy. Int. J. Adv. Manuf. Technol. 2012, 62, 569–575. [Google Scholar] [CrossRef]

- Fanelli, P.; Vivio, F.; Vullo, V. Experimental and numerical characterization of Friction Stir Spot Welded joints. Eng. Fract. Mech. 2012, 81, 17–25. [Google Scholar] [CrossRef]

- Jata, K.V.; Semiatin, S.L. Continuous dynamic recrystallization during friction stir welding of high strength aluminum alloys. Scr. Mater. 2000, 43, 743–749. [Google Scholar] [CrossRef]

- Freeney, T.; Sharma, S.R.; Mishra, R.S. Effect of Welding Parameters on Properties of 5052 Al Friction Stir Spot Welds. SAE Tech. Paper 2006. [Google Scholar] [CrossRef]

- Tozaki, Y.; Uematsu, Y.; Tokaji, K. Effect of processing parameters on static strength of dissimilar friction stir spot welds between different aluminium alloys. Fatigue Fract. Eng. Mater. 2007, 30, 143–148. [Google Scholar] [CrossRef]

- Arul, S.G.; Miller, S.F.; Kruger, G.H.; Pan, T.Y.; Mallick, P.K.; Shih, A.J. Experimental study of joint performance in spot friction welding of 6111-T4 aluminum alloy. Sci. Technol. Weld Join 2008, 13, 629–637. [Google Scholar] [CrossRef]

- Merzoug, M.; Mazari, M.; Berrahal, L.; Imad, A. Parametric studies of the process of friction spot stir welding of aluminium 6060-T5 alloys. Mater. Des. 2010, 31, 3023–3028. [Google Scholar] [CrossRef]

- Yin, Y.H.; Sun, N.; North, T.H.; Hu, S.S. Hook formation and mechanical properties in AZ31 friction stir spot welds. J. Mater. Proc. Technol. 2010, 210, 2062–2070. [Google Scholar] [CrossRef]

- Bozzi, S.; Helbert-Etter, AL.; Baudin, T.; Klosek, V.; Kerbiguet, J.G.; Criquid, B. Influence of FSSW parameters on fracture mechanisms of 5182 aluminium welds. J. Mater. Proc. Technol. 2010, 210, 1429–1435. [Google Scholar] [CrossRef]

- Roth, A.; Hake, T.; Zaeh, M.F. An analytical approach of modeling friction stir welding. Procedia CIRP 2014, 18, 197–202. [Google Scholar] [CrossRef]

- Khandhar, M.Z.H.; Khan, J.A.; Reynold, A.P. Prediction of temperature distribution and thermal history during friction stir welding: Input torque based model. Sci. Technol. Weld Join 2003, 8, 165–174. [Google Scholar] [CrossRef]

- Ceretti, E.; Fratini, L.; Giardini, C.; La Spisa, D. Numerical modelling of the linear friction welding process. Int. J. Mater. Form. 2010, 3, 1015–1018. [Google Scholar] [CrossRef]

- Esme, U.; Külekci, M.K.; Kazangoglu, Y. The use of artificial neural networks in predicting fatigue life of friction stir welded lap joints of AA 5754. J. Adv. Mater. 2010, 42, 14–21. [Google Scholar]

- Rajamanickam, N.; Balusamy, V.; Madhusudhann, R.G.; Natarajan, K. Effect of process parameters on thermal history and mechanical properties of friction stir welds. Mater. Des. 2009, 30, 2726–2731. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.W. Numerical studies on controlling of process parameters in friction stir welding. J. Mater. Proc. Technol. 2008, 209, 241–270. [Google Scholar] [CrossRef]

- D’Urso, G.; Longo, M.; Giardini, C. Friction Stir Spot Welding (FSSW) of Aluminum sheets: Experimental and Simulative Analysis. Key Eng. Mater. 2013, 549, 477–483. [Google Scholar] [CrossRef]

- Awang, M.; Mucino, V.H.; Feng, Z.; David, S.A. Thermo-mechanical modeling of friction stir spot welding (FSSW) process: Use of an explicit adaptive meshing scheme. SAE Int. 2005, 1, 1251–1256. [Google Scholar]

- Mandal, S.; Rice, J.; Elmustafa, A.A. Experimental and numerical investigation of the plunge stage in friction stir welding. J. Mater. Proc. Technol. 2008, 203, 411–419. [Google Scholar] [CrossRef]

- D’Urso, G.; Giardini, C. FEM model for the thermo-mechanical characterization of friction stir spot welded joint. Int. J. Mater. Form 2015, 9, 149–160. [Google Scholar] [CrossRef]

- Specimen Dimensions and Procedure for Shear Testing Resistance Spot, Seam and Embossed Projection Welds; UNI EN ISO 14273; International Institute of Welding: Sydney, Australia, 2002.

| Al | Cr | Cu | Fe | Mg | Mn | Si | Ti | Zn | Zr |

|---|---|---|---|---|---|---|---|---|---|

| 87.3 | ≤0.04 | 2.0 | ≤0.15 | 1.9 | ≤0.10 | ≤0.12 | ≤0.06 | 5.7 | 0.08 |

| 90.3 | 2.6 | 2.6 | 6.7 | 0.15 |

| Rotational Speed (S) (rpm) | Feed Rate (F) (mm/min) | Plunging Depth (d) (mm) |

|---|---|---|

| 1000–5000 | 10–30 | 3.6–3.8 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Urso, G.; Giardini, C. Thermo-Mechanical Characterization of Friction Stir Spot Welded AA7050 Sheets by Means of Experimental and FEM Analyses. Materials 2016, 9, 689. https://doi.org/10.3390/ma9080689

D’Urso G, Giardini C. Thermo-Mechanical Characterization of Friction Stir Spot Welded AA7050 Sheets by Means of Experimental and FEM Analyses. Materials. 2016; 9(8):689. https://doi.org/10.3390/ma9080689

Chicago/Turabian StyleD’Urso, Gianluca, and Claudio Giardini. 2016. "Thermo-Mechanical Characterization of Friction Stir Spot Welded AA7050 Sheets by Means of Experimental and FEM Analyses" Materials 9, no. 8: 689. https://doi.org/10.3390/ma9080689

APA StyleD’Urso, G., & Giardini, C. (2016). Thermo-Mechanical Characterization of Friction Stir Spot Welded AA7050 Sheets by Means of Experimental and FEM Analyses. Materials, 9(8), 689. https://doi.org/10.3390/ma9080689