Rapeseed and Raspberry Seed Cakes as Inexpensive Raw Materials in the Production of Activated Carbon by Physical Activation: Effect of Activation Conditions on Textural and Phenol Adsorption Characteristics

Abstract

:1. Introduction

2. Material and Methods

2.1. Raw Material

2.2. AC Production

2.3. AC Characterization

2.4. Phenol Adsorption Study

2.4.1. Batch Phenol Adsorption

2.4.2. Effect of the Initial pH of the Phenol Solution

2.4.3. Adsorption Isotherm Models

2.4.4. Kinetic Study

3. Results and Discussion

3.1. AC Production

3.2. AC Characterization

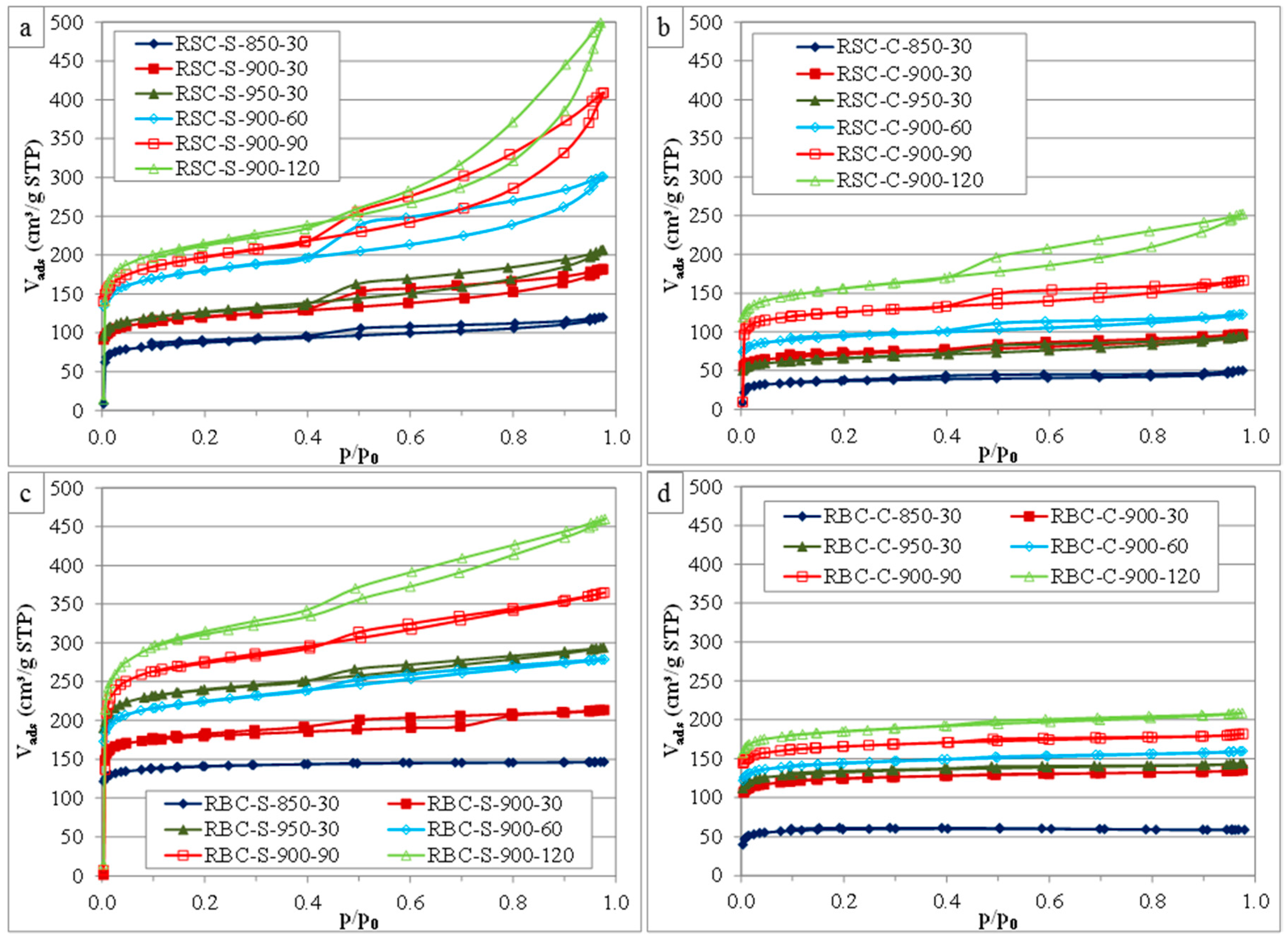

3.2.1. Nitrogen Adsorption Isotherms and Pore Size Distributions

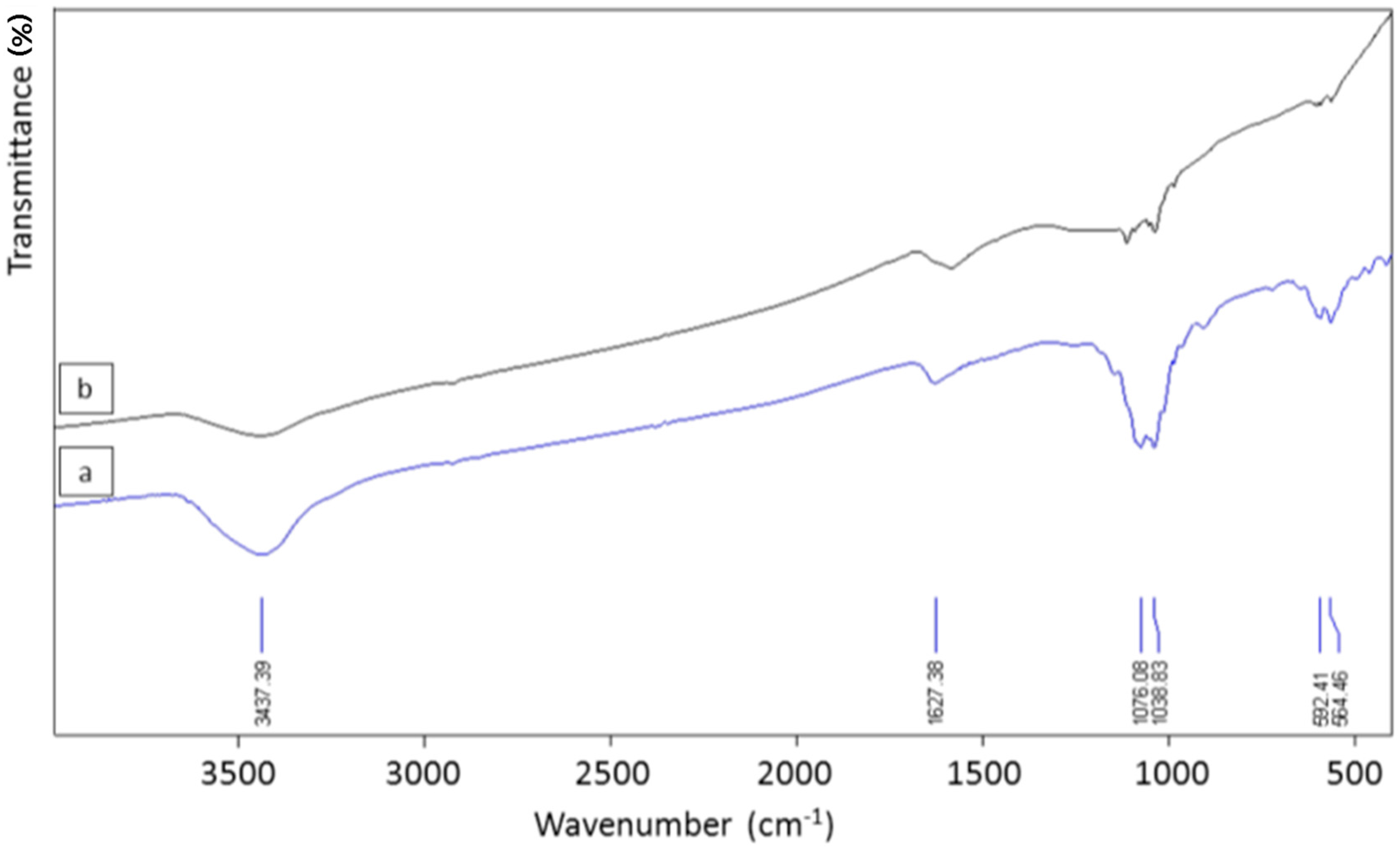

3.2.2. FTIR Analysis

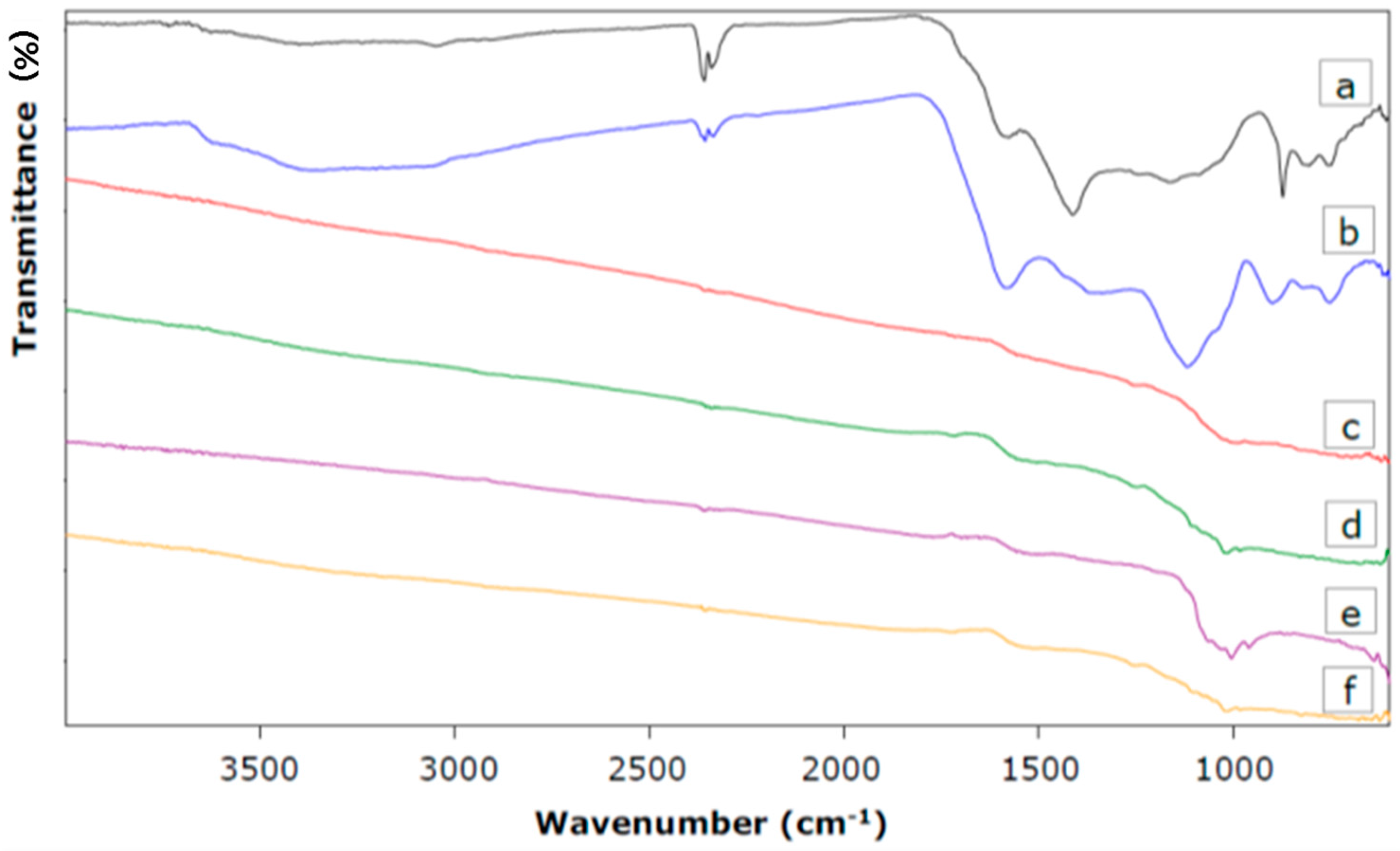

3.2.3. ATR-FTIR Functional Groups Characterization

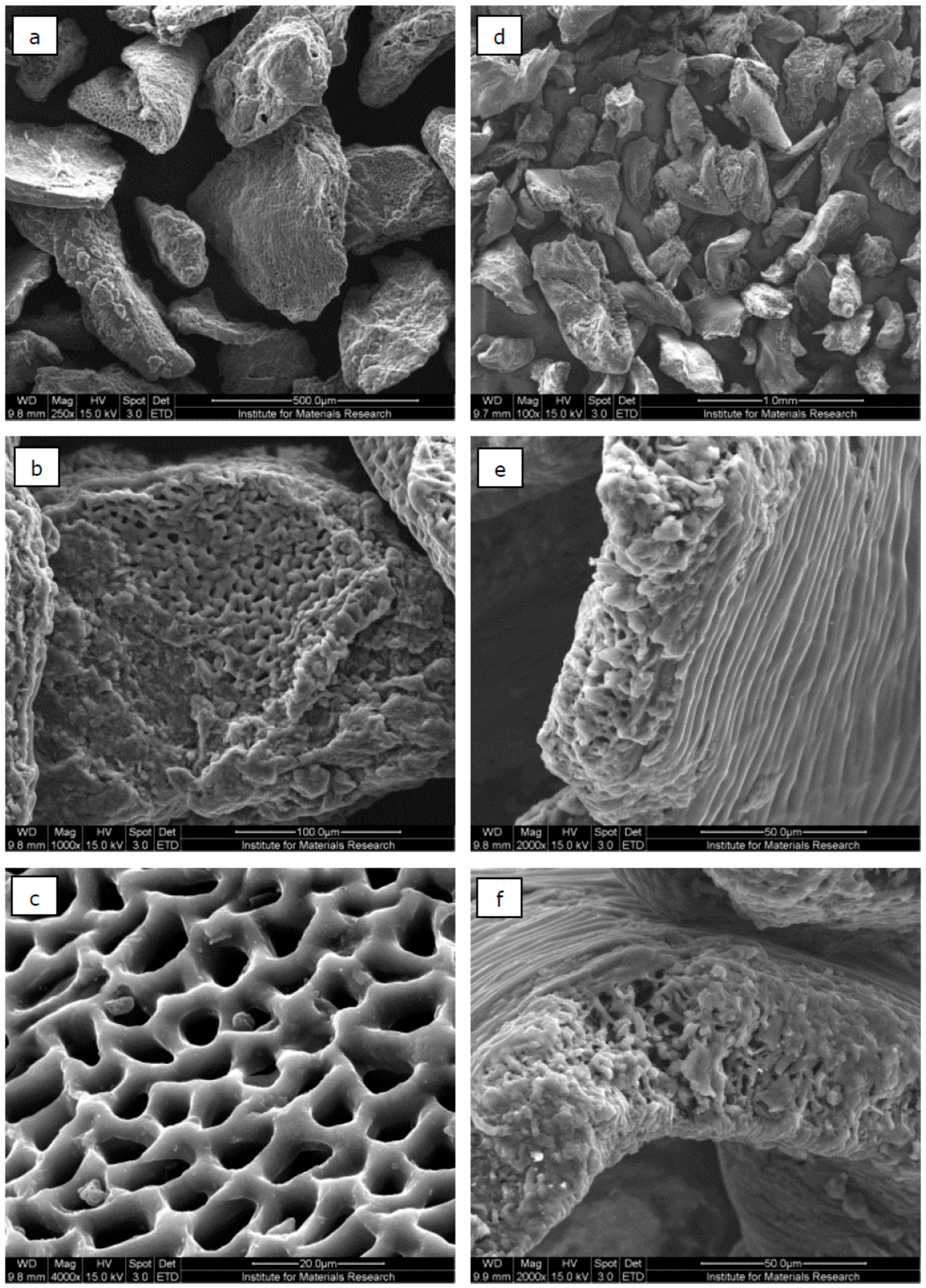

3.2.4. Surface Morphology of Activated Carbons

3.3. Phenol Adsorption Study

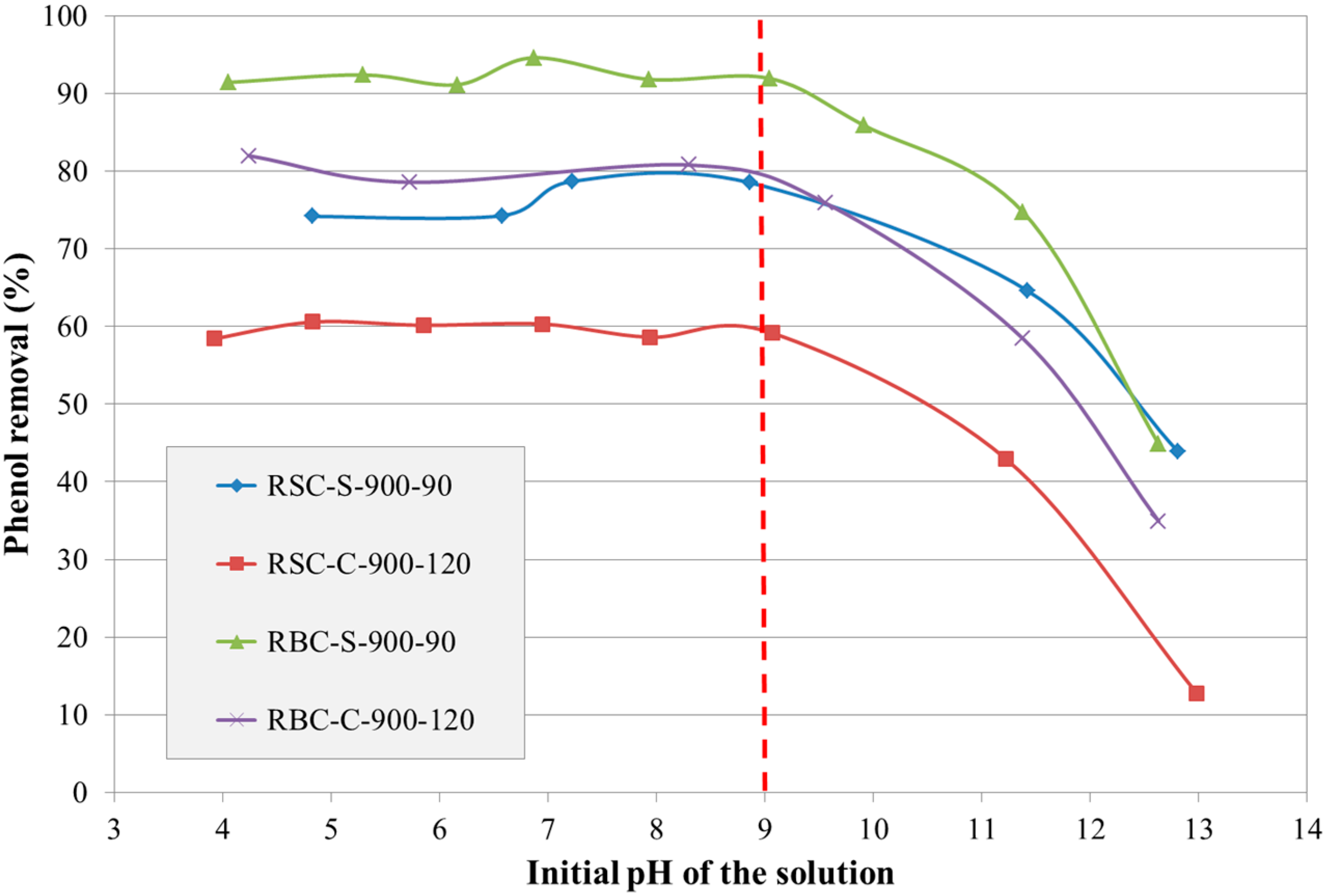

3.3.1. Effect of the Initial pH of the Phenol Solution

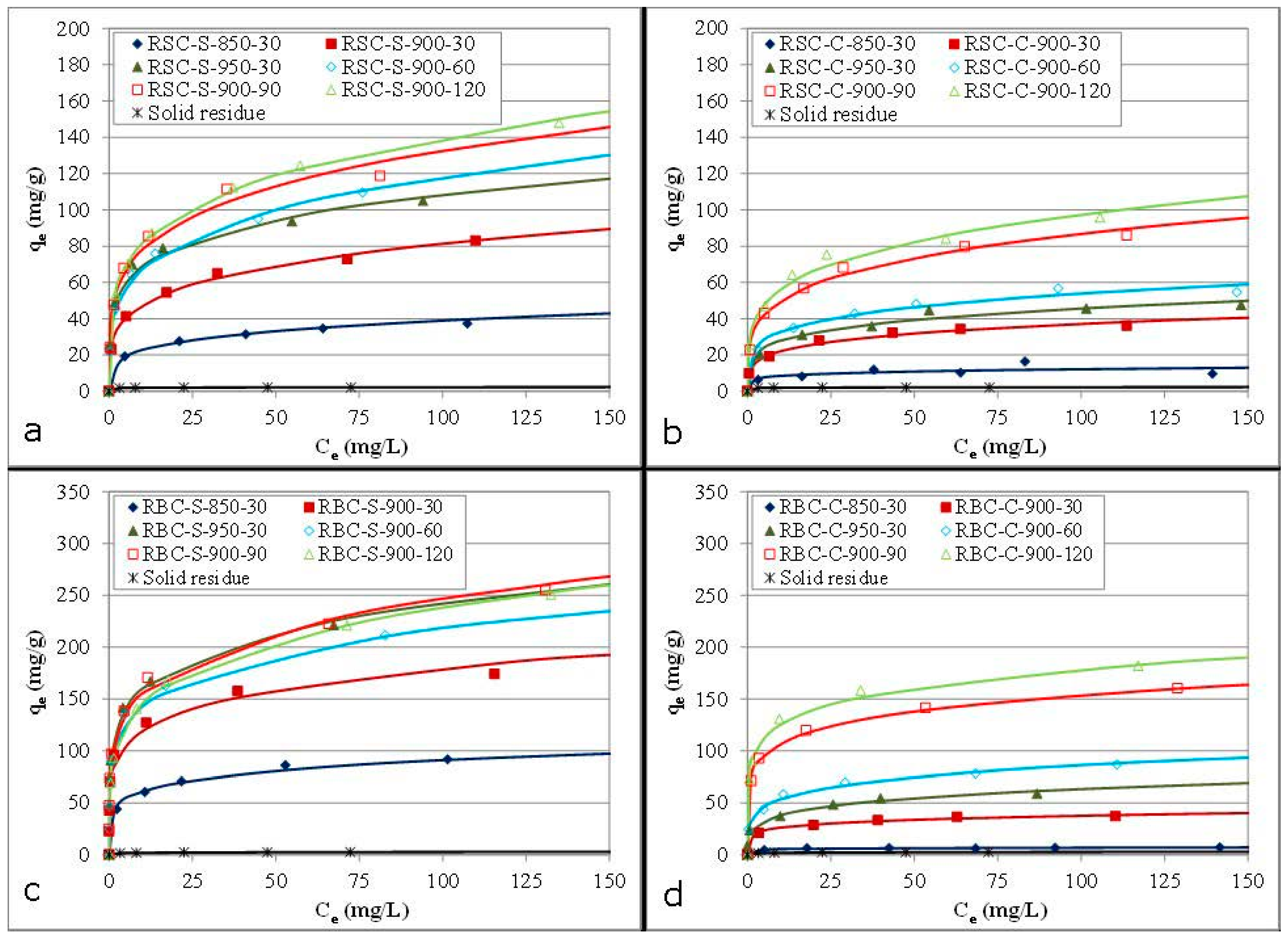

3.3.2. Phenol Adsorption Isotherms

3.3.3. Adsorption Models of Freundlich and Langmuir

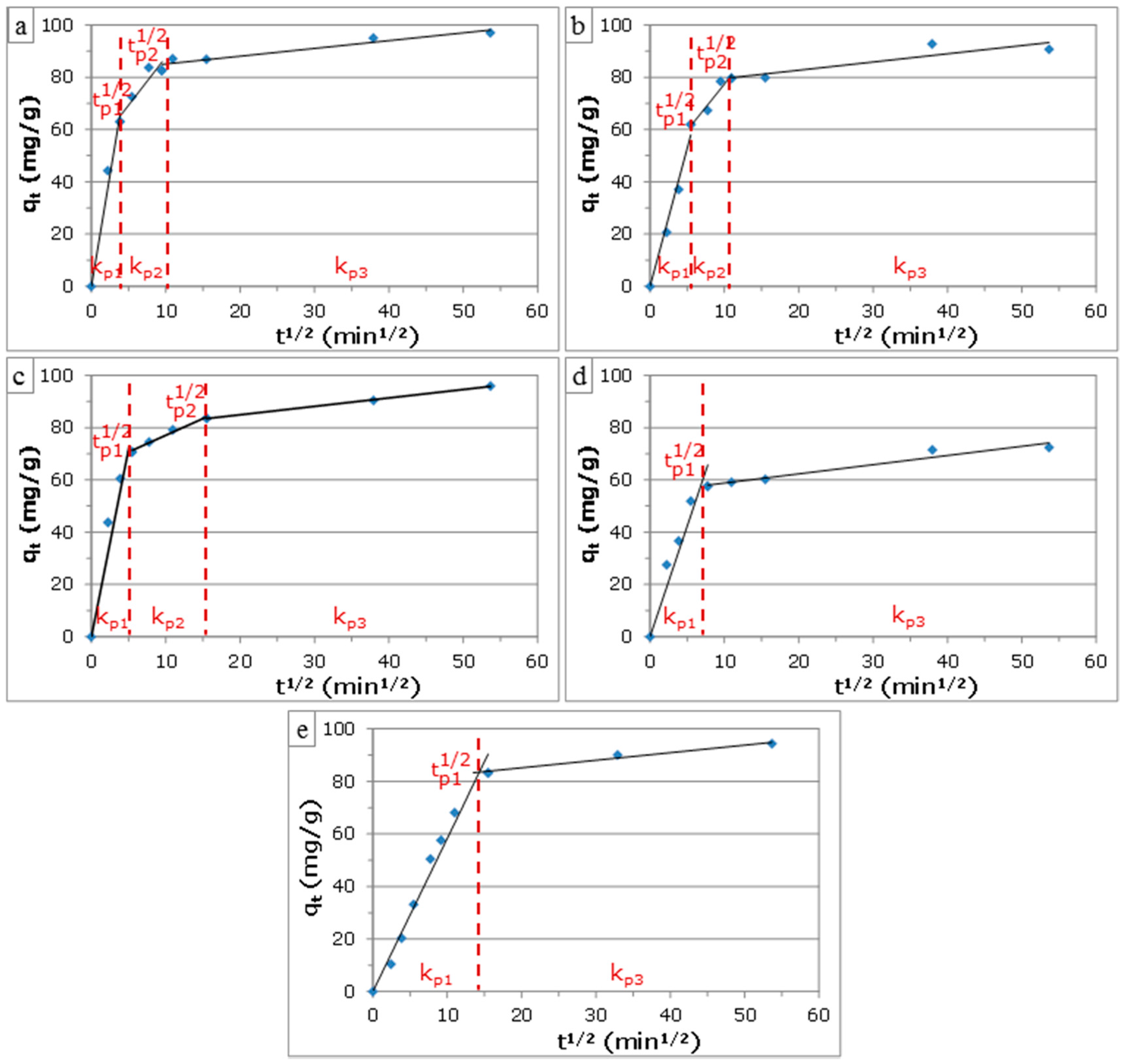

3.3.4. Kinetic Study

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Stavropoulos, G.G.; Zabaniotou, A.A. Production and characterization of activated carbons from olive-seed waste residue. Microporous Mesoporous Mater. 2005, 82, 79–85. [Google Scholar] [CrossRef]

- Román, S.; González, J.F.; González-García, C.M.; Zamora, F. Control of pore development during CO2 and steam activation of olive stones. Fuel Process. Technol. 2008, 89, 715–720. [Google Scholar] [CrossRef]

- Ioannidou, O.; Zabaniotou, A. Agricultural residues as precursors for activated carbon production—A review. Renew. Sustain. Energy Rev. 2007, 11, 1966–2005. [Google Scholar] [CrossRef]

- Gonzalez, J.F.; Roman, S.; Gonzalez-Garcia, C.M.; Nabais, J.M.V.; Ortiz, A.L. Porosity Development in Activated Carbons Prepared from Walnut Shells by Carbon Dioxide or Steam Activation. Ind. Eng. Chem. Res. 2009, 48, 7474–7481. [Google Scholar] [CrossRef]

- Wigmans, T. Industrial aspects of production and use of activated carbons. Carbon 1989, 27, 13–22. [Google Scholar] [CrossRef]

- Izquierdo, M.T.; de Yuso, A.M.; Rubio, B.; Pino, M.R. Conversion of almond shell to activated carbons: Methodical study of the chemical activation based on an experimental design and relationship with their characteristics. Biomass Bioenergy 2011, 35, 1235–1244. [Google Scholar] [CrossRef]

- Singh, K.P.; Malik, A.; Sinha, S.; Ojha, P. Liquid-phase adsorption of phenols using activated carbons derived from agricultural waste material. J. Hazard. Mater. 2008, 150, 626–641. [Google Scholar] [CrossRef] [PubMed]

- Dias, J.M.; Alvim-Ferraz, M.C.M.; Almeida, M.F.; Rivera-Utrilla, J.; Sanchez-Polo, M. Waste materials for activated carbon preparation and its use in aqueous-phase treatment: A review. J. Environ. Manag. 2007, 85, 833–846. [Google Scholar] [CrossRef] [PubMed]

- Stavropoulos, G.G.; Zabaniotou, A.A. Minimizing activated carbons production cost. Fuel Process. Technol. 2009, 90, 952–957. [Google Scholar] [CrossRef]

- Smets, K.; Adriaensens, P.; Reggers, G.; Schreurs, S.; Carleer, R.; Yperman, J. Flash pyrolysis of rapeseed cake: Influence of temperature on the yield and the characteristics of the pyrolysis liquid. J. Anal. Appl. Pyrolysis 2011, 90, 118–125. [Google Scholar] [CrossRef]

- Smets, K.; Roukaerts, A.; Czech, J.; Reggers, G.; Schreurs, S.; Carleer, R.; Yperman, J. Slow catalytic pyrolysis of rapeseed cake: Product yield and characterization of the pyrolysis liquid. Biomass Bioenergy 2013, 57, 180–190. [Google Scholar] [CrossRef]

- Smets, K.; Schreurs, S.; Carleer, R.; Yperman, J. Valorization of raspberry seed cake by flash and slow pyrolysis: Product yield and characterization of the liquid and solid fraction. J. Anal. Appl. Pyrolysis 2014, 107, 289–297. [Google Scholar] [CrossRef]

- Jia, Q.; Lua, A.C. Effects of pyrolysis conditions on the physical characteristics of oil-palm-shell activated carbons used in aqueous phase phenol adsorption. J. Anal. Appl. Pyrolysis 2008, 83, 175–179. [Google Scholar] [CrossRef]

- Özkaya, B. Adsorption and desorption of phenol on activated carbon and a comparison of isotherm models. J. Hazard. Mater. 2006, 129, 158–163. [Google Scholar] [CrossRef] [PubMed]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Determination of the Specific Surface Area of Solids by Gas Adsorption—BET Method; Second Edition of ISO 9277; ISO: Geneva, Switzerland, 2010.

- Dubinin, M.M. The potential theory of adsorption of gases and vapors for adsorbents with energetically nonuniform surfaces. Chem. Rev. 1960, 60, 235–241. [Google Scholar] [CrossRef]

- Stoeckli, F.; Centeno, T.A. On the characterization of microporous carbons by immersion calorimetry alone. Carbon 1997, 35, 1097–1100. [Google Scholar] [CrossRef]

- ASTM D1783. Standard Test Method for Phenolic Compounds in Water. In Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2004.

- Vargas, A.M.M.; Cazetta, A.L.; Kunita, M.H.; Silva, T.L.; Almeida, V.C. Adsorption of methylene blue on activated carbon produced from flamboyant pods (Delonix regia): Study of adsorption isotherms and kinetic models. Chem. Eng. J. 2011, 168, 722–730. [Google Scholar] [CrossRef]

- Langmuir, I. The constitution and fundamental properties of solids and liquids. Part I: Solids. J. Am. Chem. Soc. 1916, 38, 2221–2295. [Google Scholar] [CrossRef]

- Freundlich, H.M.F. Over the adsorption in solution. J. Phys. Chem. 1906, 57, 385–470. [Google Scholar]

- Tan, I.A.W.; Ahmad, A.L.; Hameed, B.H. Adsorption isotherms, kinetics, thermodynamics and desorption studies of 2,4,6-trichlorophenol on oil palm empty fruit bunch-based activated carbon. J. Hazard. Mater. 2009, 164, 473–482. [Google Scholar] [CrossRef] [PubMed]

- Salame, I.I.; Bandosz, T.J. Role of surface chemistry in adsorption of phenol on activated carbons. J. Colloid Interface Sci. 2003, 264, 307–312. [Google Scholar] [CrossRef]

- Lagergren, S. Zur theorie der sogenannten adsorption gelöster stoffe. K. Sven. Vetenskapsakademiens Handl. 1898, 24, 1–39. [Google Scholar]

- Blanchard, G.; Maunaye, M.; Martin, G. Removal of heavy metals from water by means of natural zeolites. Water Res. 1984, 18, 1501–1507. [Google Scholar] [CrossRef]

- Bacaoui, A.; Yaacoubi, A.; Dahbi, A.; Bennouna, C.; Luu, R.P.T.; Maldonado-Hodar, F.J.; Rivera-Utrilla, J.; Moreno-Castilla, C. Optimization of conditions for the preparation of activated carbons from olive-waste cakes. Carbon 2001, 39, 425–432. [Google Scholar] [CrossRef]

- Marsh, H.; Rodríguez-Reinoso, F. Activated carbon. In Elsevier Science and Technology Books; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemieniewska, T. Reporting physisorption data for gas solid systems with special reference to the determination of surface-area and porosity (recommendations 1984). Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Carrasco-Marín, F.; Domingo-Garcia, M.; Fernandez-Morales, I.; López-Garzón, F.J. Dynamic adsorption of methyl iodide on activated carbons. Carbon 1991, 29, 629–634. [Google Scholar] [CrossRef]

- Haghseresht, F.; Nouri, S.; Lu, G.Q.M. Effects of carbon surface chemistry and solution pH on the adsorption of binary aromatic solutes. Carbon 2003, 41, 881–892. [Google Scholar] [CrossRef]

- Hameed, B.H.; Rahman, A.A. Removal of phenol from aqueous solutions by adsorption onto activated carbon prepared from biomass material. J. Hazard. Mater. 2008, 160, 576–581. [Google Scholar] [CrossRef] [PubMed]

- El-Sheikh, A.H.; Newman, A.P.; Said, A.J.; Alzawahreh, A.M.; Abu-Helal, M.M. Improving the adsorption efficiency of phenolic compounds into olive wood biosorbents by pre-washing with organic solvents: Equilibrium, kinetic and thermodynamic aspects. J. Environ. Manag. 2013, 118, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Weber, W.J.; Morris, J.C. Advances in water pollution research: Removal of biologically resistant pollutant from waste water by adsorption. In Proceedings of the International Conference on Water Pollution Symposium; Pergamon Press: Oxford, UK, 1962; Volume 2, pp. 231–266. [Google Scholar]

- McKay, G.; Otterburn, M.S.; Sweeney, A.G. The removal of colour from effluent using various adsorbents—III. Silica: Rate processes. Water Res. 1980, 14, 15–20. [Google Scholar] [CrossRef]

- Lorenc-Grabowska, E.; Gryglewicz, G. Adsorption characteristics of Congo Red on coal-based mesoporous activated carbon. Dyes Pigments 2007, 74, 34–40. [Google Scholar] [CrossRef]

- Wu, F.-C.; Tseng, R.-L.; Juang, R.-S. Initial behavior of intraparticle diffusion model used in the description of adsorption kinetics. Chem. Eng. J. 2009, 153, 1–8. [Google Scholar] [CrossRef]

- Aravindhan, R.; Rao, J.R.; Nair, B.U. Application of a chemically modified green macro alga as a biosorbent for phenol removal. J. Environ. Manag. 2009, 90, 1877–1883. [Google Scholar] [CrossRef] [PubMed]

| Sample Code | Burn-off a (wt %) | Ash Content b (wt %) | Total AC Yield (wt %) | ||

|---|---|---|---|---|---|

| Before HCl Washing | After HCl Washing | Before HCl Washing | After HCl Washing | ||

| RSC-S-850-30 | 26.3 | 28.6 | 17.0 | 20.1 | 17.8 |

| RSC-S-900-30 | 35.1 | 28.4 | 13.4 | 17.7 | 15.0 |

| RSC-S-950-30 | 36.5 | 30.4 | 12.8 | 17.3 | 14.2 |

| RSC-S-900-60 | 43.9 | 33.9 | 7.1 | 15.3 | 11.2 |

| RSC-S-900-90 | 59.2 | 45.4 | 14.6 | 11.1 | 7.7 |

| RSC-S-900-120 | 69.6 | 57.7 | 21.3 | 8.3 | 5.3 |

| RSC-C-850-30 | 23.2 | 25.4 | 18.7 | 21.0 | 19.6 |

| RSC-C-900-30 | 23.1 | 26.5 | 18.6 | 21.0 | 19.3 |

| RSC-C-950-30 | 34.1 | 27.6 | 18.2 | 18.0 | 16.3 |

| RSC-C-900-60 | 30.4 | 27.7 | 13.7 | 19.0 | 16.3 |

| RSC-C-900-90 | 41.3 | 31.5 | 12.2 | 16.0 | 12.9 |

| RSC-C-900-120 | 49.6 | 37.0 | 17.8 | 13.8 | 11.2 |

| RBC-S-850-30 | 21.7 | 7.5 | – | 27.3 | – |

| RBC-S-900-30 | 35.0 | 6.2 | – | 22.7 | – |

| RBC-S-950-30 | 49.4 | 8.2 | – | 17.7 | – |

| RBC-S-900-60 | 46.6 | 6.3 | – | 18.6 | – |

| RBC-S-900-90 | 55.8 | 8.3 | – | 15.4 | – |

| RBC-S-900-120 | 63.4 | 13.0 | – | 12.8 | – |

| RBC-C-850-30 | 16.2 | 5.7 | – | 29.3 | – |

| RBC-C-900-30 | 19.3 | 6.7 | – | 28.2 | – |

| RBC-C-950-30 | 22.0 | 5.8 | – | 27.2 | – |

| RBC-C-900-60 | 22.7 | 5.9 | – | 27.0 | – |

| RBC-C-900-90 | 27.0 | 8.0 | – | 25.5 | – |

| RBC-C-900-120 | 31.2 | 10.0 | – | 24.0 | – |

| Sample | SBET (m2/g) | Vt (cm3/g) | Vme (cm3/g) | VDR (cm3/g) | VDR/Vt | L0 (nm) |

|---|---|---|---|---|---|---|

| RSC-S-850-30 | 336 | 0.181 | 0.047 | 0.134 | 0.74 | 1.44 |

| RSC-S-900-30 | 458 | 0.272 | 0.092 | 0.180 | 0.66 | 1.02 |

| RSC-S-950-30 | 483 | 0.309 | 0.118 | 0.191 | 0.62 | 1.04 |

| RSC-S-900-60 | 678 | 0.446 | 0.178 | 0.268 | 0.60 | 1.11 |

| RSC-S-900-90 | 737 | 0.589 | 0.294 | 0.295 | 0.50 | 1.32 |

| RSC-S-900-120 | 804 | 0.720 | 0.392 | 0.328 | 0.46 | 1.94 |

| RSC-C-850-30 | 141 | 0.073 | 0.015 | 0.058 | 0.79 | 2.57 |

| RSC-C-900-30 | 272 | 0.147 | 0.039 | 0.108 | 0.73 | 1.12 |

| RSC-C-950-30 | 250 | 0.142 | 0.043 | 0.099 | 0.69 | 1.01 |

| RSC-C-900-60 | 362 | 0.187 | 0.045 | 0.142 | 0.76 | 0.94 |

| RSC-C-900-90 | 487 | 0.253 | 0.061 | 0.192 | 0.76 | 1.08 |

| RSC-C-900-120 | 591 | 0.379 | 0.145 | 0.234 | 0.62 | 1.09 |

| RBC-S-850-30 | 563 | 0.226 | 0.009 | 0.217 | 0.96 | 0.62 |

| RBC-S-900-30 | 721 | 0.328 | 0.048 | 0.280 | 0.85 | 0.82 |

| RBC-S-950-30 | 941 | 0.451 | 0.081 | 0.370 | 0.82 | 0.98 |

| RBC-S-900-60 | 873 | 0.429 | 0.086 | 0.343 | 0.80 | 0.95 |

| RBC-S-900-90 | 1081 | 0.559 | 0.117 | 0.442 | 0.79 | 2.02 |

| RBC-S-900-120 | 1179 | 0.698 | 0.209 | 0.489 | 0.70 | 2.24 |

| RBC-C-850-30 | 236 | 0.091 | 0.000 | 0.091 | 1.00 | 1.51 |

| RBC-C-900-30 | 492 | 0.208 | 0.018 | 0.190 | 0.92 | 0.69 |

| RBC-C-950-30 | 529 | 0.221 | 0.017 | 0.204 | 0.93 | 0.68 |

| RBC-C-900-60 | 572 | 0.246 | 0.026 | 0.220 | 0.90 | 0.64 |

| RBC-C-900-90 | 660 | 0.279 | 0.025 | 0.254 | 0.91 | 0.63 |

| RBC-C-900-120 | 735 | 0.320 | 0.036 | 0.284 | 0.89 | 0.66 |

| Commercial AC | 1115 | 0.581 | 0.124 | 0.457 | 0.79 | 2.63 |

| Sample | C | H | N | S | O | Ash |

|---|---|---|---|---|---|---|

| RSC-SR | 64.5 | 2.5 | 5.8 | 0.3 | 5.6 | 21.3 |

| RBC-SR | 77.9 | 3.1 | 3.1 | <0.1 | 12.1 | 3.8 |

| RSC-S-850-30 | 68.8 | 1.6 | 3.9 | 1.2 | 7.5 | 17.0 |

| RSC-S-900-30 | 77.0 | 1.3 | 3.5 | 1.0 | 3.8 | 13.4 |

| RSC-S-950-30 | 77.1 | 1.1 | 3.0 | 1.4 | 4.6 | 12.8 |

| RSC-S-900-60 | 82.6 | 1.2 | 3.4 | 0.5 | 5.2 | 7.1 |

| RSC-S-900-90 | 75.8 | 1.1 | 2.7 | 0.6 | 5.2 | 14.6 |

| RSC-S-900-120 | 69.8 | 1.2 | 1.5 | 0.4 | 5.8 | 21.3 |

| RSC-C-850-30 | 69.4 | 1.2 | 4.9 | 1.4 | 4.4 | 18.7 |

| RSC-C-900-30 | 73.9 | 1.2 | 4.6 | 1.5 | 0.2 | 18.6 |

| RSC-C-950-30 | 72.9 | 1.1 | 4.2 | 1.3 | 2.3 | 18.2 |

| RSC-C-900-60 | 73.3 | 1.0 | 4.6 | 0.2 | 7.2 | 13.7 |

| RSC-C-900-90 | 77.1 | 1.1 | 4.7 | 0.3 | 4.6 | 12.2 |

| RSC-C-900-120 | 72.1 | 1.6 | 3.9 | 0.6 | 4.0 | 17.8 |

| RBC-S-850-30 | 89.1 | 1.1 | 2.1 | <0.1 | 0.2 | 7.5 |

| RBC-S-900-30 | 89.1 | 0.9 | 1.5 | <0.1 | 2.4 | 6.2 |

| RBC-S-950-30 | 88.7 | 0.9 | 1.5 | <0.1 | 0.7 | 8.2 |

| RBC-S-900-60 | 88.9 | 0.8 | 1.3 | <0.1 | 2.7 | 6.3 |

| RBC-S-900-90 | 88.7 | 0.9 | 1.3 | <0.1 | 0.9 | 8.3 |

| RBC-S-900-120 | 86.7 | 1.0 | 1.1 | <0.1 | – | 13.0 |

| RBC-C-850-30 | 87.7 | 0.8 | 2.1 | <0.1 | 3.6 | 5.7 |

| RBC-C-900-30 | 89.5 | 0.9 | 2.2 | <0.1 | 0.7 | 6.7 |

| RBC-C-950-30 | 88.9 | 0.8 | 2.2 | <0.1 | 2.3 | 5.8 |

| RBC-C-900-60 | 88.6 | 0.8 | 2.3 | <0.1 | 2.4 | 5.9 |

| RBC-C-900-90 | 88.3 | 0.8 | 2.2 | <0.1 | 0.7 | 8.0 |

| RBC-C-900-120 | 88.6 | 0.8 | 2.2 | <0.1 | – | 10.0 |

| Sample | Freundlich Model | Langmuir Model | ||||

|---|---|---|---|---|---|---|

| KF ((mg/g)(L/mg)1/nF) | 1/nF | R2 | qm (mg/g) | KL (L/mg) | R2 | |

| RSC-S-850-30 | 13 | 0.24 | 0.991 | 41 | 0.13 | 0.944 |

| RSC-S-900-30 | 27 | 0.24 | 0.996 | 78 | 0.23 | 0.944 |

| RSC-S-950-30 | 43 | 0.20 | 0.987 | 96 | 0.60 | 0.952 |

| RSC-S-900-60 | 38 | 0.25 | 0.993 | 104 | 0.30 | 0.955 |

| RSC-S-900-90 | 45 | 0.23 | 0.980 | 116 | 0.39 | 0.966 |

| RSC-S-900-120 | 47 | 0.24 | 0.999 | 139 | 0.19 | 0.955 |

| RSC-C-850-30 | 6 | 0.16 | 0.765 | 12 | 0.25 | 0.785 |

| RSC-C-900-30 | 13 | 0.23 | 0.989 | 36 | 0.20 | 0.954 |

| RSC-C-950-30 | 17 | 0.22 | 0.982 | 48 | 0.14 | 0.973 |

| RSC-C-900-60 | 20 | 0.22 | 0.985 | 56 | 0.16 | 0.970 |

| RSC-C-900-90 | 28 | 0.24 | 0.991 | 84 | 0.20 | 0.960 |

| RSC-C-900-120 | 32 | 0.24 | 0.986 | 93 | 0.20 | 0.970 |

| RBC-S-850-30 | 40 | 0.18 | 0.994 | 94 | 0.25 | 0.960 |

| RBC-S-900-30 | 79 | 0.18 | 0.978 | 153 | 2.05 | 0.931 |

| RBC-S-950-30 | 103 | 0.18 | 0.995 | 184 | 2.88 | 0.898 |

| RBC-S-900-60 | 91 | 0.19 | 0.985 | 195 | 1.69 | 0.914 |

| RBC-S-900-90 | 96 | 0.21 | 0.988 | 216 | 1.04 | 0.891 |

| RBC-S-900-120 | 88 | 0.22 | 0.999 | 223 | 0.40 | 0.911 |

| RBC-C-850-30 | 4 | 0.11 | 0.980 | 7 | 0.41 | 0.985 |

| RBC-C-900-30 | 18 | 0.16 | 0.996 | 38 | 0.30 | 0.974 |

| RBC-C-950-30 | 23 | 0.22 | 0.990 | 53 | 0.94 | 0.933 |

| RBC-C-900-60 | 33 | 0.21 | 0.993 | 84 | 0.25 | 0.936 |

| RBC-C-900-90 | 75 | 0.16 | 0.998 | 155 | 0.51 | 0.951 |

| RBC-C-900-120 | 88 | 0.15 | 0.994 | 174 | 0.93 | 0.946 |

| RSC-SR | 1.7 | 0.06 | 0.990 | 2.2 | 1.23 | 0.998 |

| RBC-SR | 1.4 | 0.16 | 0.983 | 2.6 | 0.41 | 0.982 |

| Commercial AC | 56 | 0.28 | 0.983 | 159 | 0.33 | 0.953 |

| Sample | PFO Model | PSO Model | ||||

|---|---|---|---|---|---|---|

| qe (mg/g) | k1 (1/min) | R2 | qe (mg/g) | k2 (g/mg·min) | R2 | |

| RSC-S-900-90 | 83 | 0.11 | 0.927 | 88 | 0.0018 | 0.978 |

| RSC-C-900-120 | 64 | 0.064 | 0.930 | 68 | 0.0014 | 0.973 |

| RBC-S-900-90 | 87 | 0.098 | 0.947 | 92 | 0.0017 | 0.989 |

| RBC-C-900-120 | 84 | 0.039 | 0.968 | 91 | 0.00060 | 0.990 |

| Commercial AC | 90 | 0.013 | 0.991 | 97 | 0.00019 | 0.997 |

| Sample | kpi (mg/g·min1/2) | Ci (mg/g) | Corr. Coeff. | t1/2p1 | t1/2p2 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| kp1 | kp2 | kp3 | C1 | C2 | C3 | R21 | R2 | R23 | (min1/2) | (min1/2) | |

| RSC-S-900-90 | 14.38 | 1.28 | 0.32 | 0 | 64.31 | 78.46 | 0.924 | 0.985 | 0.999 | 4.91 | 14.74 |

| RSC-C-900-120 | 8.49 | 0.35 | – | 0 | 55.28 | – | 0.911 | 0.943 | – | 7.79 | – |

| RBC-S-900-90 | 17.14 | 3.68 | 0.30 | 0 | 50.99 | 82.09 | 0.978 | 0.875 | 0.920 | 3.79 | 9.20 |

| RBC-C-900-120 | 10.60 | 3.53 | 0.31 | 0 | 42.10 | 76.42 | 0.980 | 0.935 | 0.807 | 5.95 | 10.66 |

| Commercial AC | 5.83 | 0.29 | – | 0 | 79.32 | – | 0.978 | 0.969 | – | 14.32 | – |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smets, K.; De Jong, M.; Lupul, I.; Gryglewicz, G.; Schreurs, S.; Carleer, R.; Yperman, J. Rapeseed and Raspberry Seed Cakes as Inexpensive Raw Materials in the Production of Activated Carbon by Physical Activation: Effect of Activation Conditions on Textural and Phenol Adsorption Characteristics. Materials 2016, 9, 565. https://doi.org/10.3390/ma9070565

Smets K, De Jong M, Lupul I, Gryglewicz G, Schreurs S, Carleer R, Yperman J. Rapeseed and Raspberry Seed Cakes as Inexpensive Raw Materials in the Production of Activated Carbon by Physical Activation: Effect of Activation Conditions on Textural and Phenol Adsorption Characteristics. Materials. 2016; 9(7):565. https://doi.org/10.3390/ma9070565

Chicago/Turabian StyleSmets, Koen, Mats De Jong, Iwona Lupul, Grazyna Gryglewicz, Sonja Schreurs, Robert Carleer, and Jan Yperman. 2016. "Rapeseed and Raspberry Seed Cakes as Inexpensive Raw Materials in the Production of Activated Carbon by Physical Activation: Effect of Activation Conditions on Textural and Phenol Adsorption Characteristics" Materials 9, no. 7: 565. https://doi.org/10.3390/ma9070565