1. Introduction

In the last decades global policy decisions have been orienting toward sustainable strategies aiming to: (i) reduce fossil fuel dependency and linked environmental impacts; and (ii) generate new economy. The issue of sustainable consumption is complex and requires composite mix of different implementation policy instruments to address the different involved stakeholders [

1,

2]. Accordingly, the European Union (EU) policy encourages research activities and policies in order to reach: (i) the reduction of overconsumption pattern driven by lifestyle [

2,

3,

4,

5,

6]; and (ii) cleaner production chains, strengthened by the EU Action Plan on Sustainable Consumption and Production and Sustainable Industrial Policy [

7]. Specifically, as it relates to the latter key point, i.e., “the sustainable products”, the EU has recognized the bio-based sector as a priority area with high potential for: Sustainable economy (lower dependency on fossil fuels), future growth, re-industrialization and societal challenges [

8]. Industrial sectors are increasingly involved in developing environmentally-friendly supply chains from renewable feedstocks, through substitution and energetic implementation of traditional petroleum-based routes still dominating our overall standard of living [

9,

10,

11,

12,

13]. To this end, the bio-based materials, entirely or partlyproduced from biological feedstocks, such as food crops, wood, grass and agricultural by-products, may represent a significant and growing market with an extensive range of products. In this context, the scientific research plays a pivotal role in improving technical processes, but, above all, the proper knowledge in evaluating the sustainability of the complex system, represented by the bio-refinery.

The 1,4-Butanediol (BDO) is an organic compound commonly used as a solvent in the industrial cleaners and in the annual manufacture of over 2.5 million tons of valuable polymers [

10]. It represents a key chemical building block used to make several products, such as polybutylene terephthalate (PBT), spandex (lycra, elastane), and polyurethanes (e.g., car bumpers). It was first commercially produced in 1930, through the reaction of formaldehyde with acetylene and subsequent stages of hydrogenation (Reppe chemistry). Nowadays, in the petrochemical industry, BDO can be produced also in different ways from maleic anhydride, propylene oxide and butadiene [

10,

14]; however the Reppe process still accounts for about 42% of global production [

14].

The bio-based BDO manufacture process is not performed worldwide on large scale yet. It can either take place via hydrogenation of succinic acid [

15,

16] or direct fermentation of sugars through experimental metabolic engineered bacterial platform [

10,

12]. The latter one represents an emerging technology, which is claimed as an effective advantageous alternative over the succinic acid route, with a lower risk of market fragmentation and competition, thanks to the use of more abundant feedstock [

14]. Several EU and worldwide companies are currently developing and up-scaling bio-based BDO production, also through direct fermentation of vegetal biomass sugars [

10,

12,

14], on the basis of the generally claimed less energy and emission intensive pattern in comparison to petroleum-based counterparts.

The actual pertinence of the innovative bio-based technologies, framed on feedstock different than fossil oil, needs multi-criteria studies since it causes radical environmental, industrial and social changes. Regarding the environmental impacts of such a new bio-based chemical products, the life cycle assessment (LCA) represents an effective analytical tool [

13,

17,

18]. All the direct and indirect environmental impacts associated with the product, process or activity are included in the assessment. This one encompasses the extraction and processing of raw materials, manufacturing and assembly processes, product distribution, use, maintenance, recycling and disposal [

19,

20]. Previous publications have outlined the effect of green chemistry on several aspects of a product’s life-cycle, using the LCA approach to assess the trade-offs in switching between supply chemicals or processes [

16,

18,

21,

22,

23,

24]. On one hand, bio-based building blocks appeared to entail relevant benefits in terms of non-renewable fossil energy saving and global warming mitigation potential [

11,

16,

18,

25,

26,

27]. On the other hand, contrasting findings arose while investigating the whole environmental performance of bio-based polymers [

18,

28,

29].

Considering the innovative nature of bio-based BDO, there is still a lack of comprehensive analyses about the environmental profile of its production chain. Specifically, no published studies quantitatively assessed the effect of the production of BDO via direct fermentation of renewable sugars from lignocellulosic feedstock. In this regard, the present study aims to assess the environmental load of bio-based BDO, in order to evaluate potential improvements and benefits compared to the fossil counterpart. The inventory was based on experimental primary data (inherent the fermentation and purification steps) completed by secondary data for upstream lignocellulosic feedstock pre-treatment/hydrolysis and regional agronomic supply chains, assuming the energetic valorization of unconverted solids through combustion in a combined heat and power cogeneration system (CHP) located inside the biorefinery plant.

2. Materials and Methods

The methodological framework used in this paper was the LCA as defined by ISO standards and ILCD Handbook guidelines [

19,

20,

30,

31]. This internationally accepted method provides quantitative, confirmable, and manageable process models to evaluate production processes analyze options for innovation and improve understanding of the investigated systems [

32]. An LCA analysis includes four primary stages: (1) definition of the goal and scope (including the selected functional unit and investigated system boundaries); (2) inventory analysis, where input and output flows are quantified along the investigated supply chain; (3) impact analysis, to determine the potential environment loads; and (4) interpretation of results, which include the implementation of optimization procedures in order to reduce impacts of the investigated product or process.

2.1. Goal and Scope

An attributionalcradle-to-factory gate LCAwas applied to a hypothetical local biorefinery scenario in Campania Region (Southern Italy) for the production of bio-based BDO via direct fermentation of sugars from wheat straw feedstock.

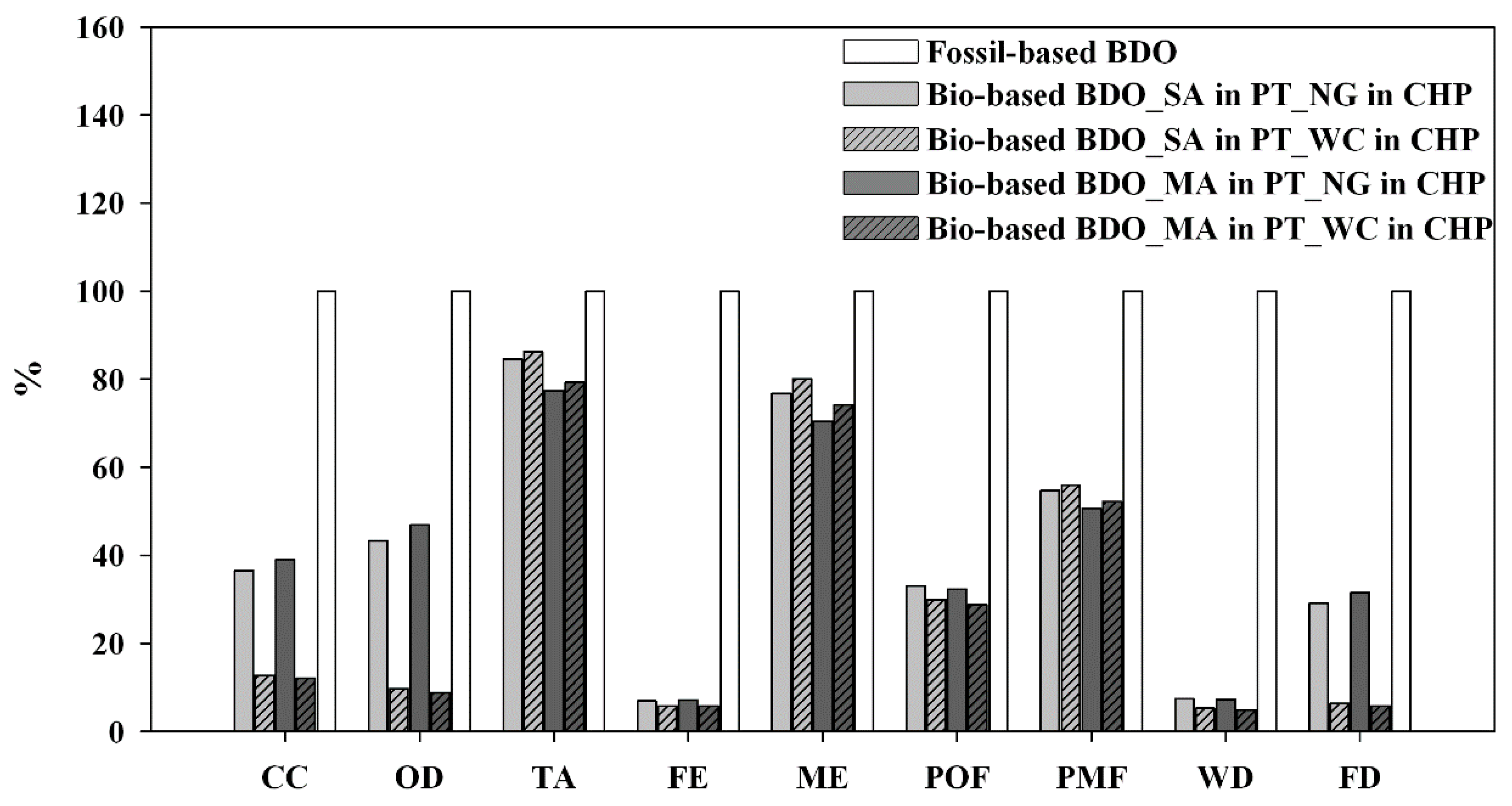

The aim of the study was to: (i) assess the environmental load of bio-based BDO, quantifying the resources use and emissions along the production chain; (ii) evaluate opportunities for improvements of the bio-product supply chain; and (iii) compare the environmental performance of bio-based BDO with fossil-based counterpart, in order to ascertain the potential environmental benefits of this foreseen eco-friendly bio-polymer.

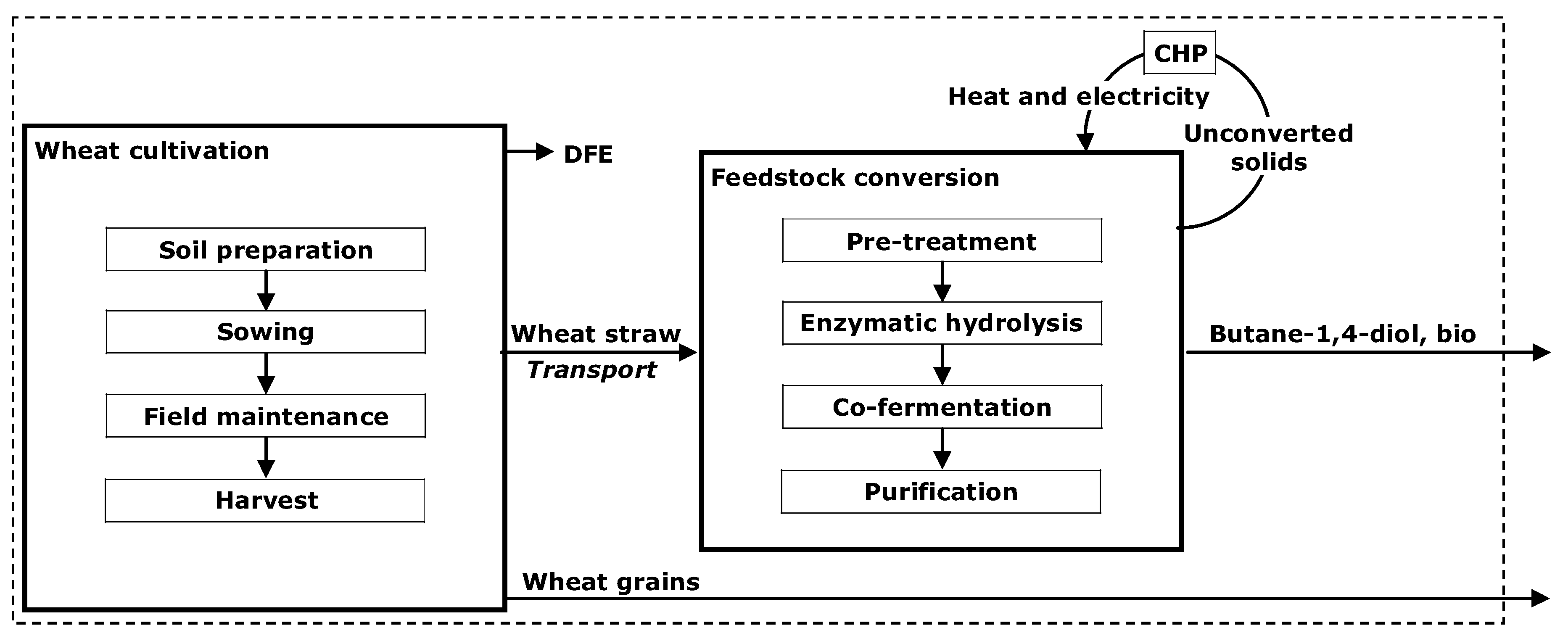

To this end, according to the LCA procedures, data were collected considering the different production stages inside the “cradle-to-factory gate” system boundary (

Figure 1).

The primary data about the bio-based BDO production via direct fermentation of sugars were gathered within the framework of the “EnerbioChem” project (fermentation and purification stages). Differently, a review of pertinent technical and scientific literature was carried out to: (i) check the local availability of wheat straw feedstock; (ii) identify the common agronomic practices for wheat cultivation in the context of Campania Region; and (iii) retrieve material and energetic input for the industrial recovery of fermentable sugars from lignocellulosic feedstock (pre-treatment and enzymatic hydrolysis) and the energetic valorization of unconverted solids inside the designed biorefinery system (electricity and heat production through combustion in a cogeneration plant).

Collected data were analyzed according to ISO standards [

19,

20], by means of SimaPro 8.0.3 software [

33] coupled with the ReCiPe (v.1.10, 2013) [

34] midpoint hierarchic impact assessment method.

For the wheat cultivation, the study included the co-production of wheat grains (sold to the market) and wheat straw (used into the investigated hypothetical regional bio-refinery chain) (see

Section 2.2.1 for more details). For this reason, as suggested by ISO standards [

19,

20] and ILCD [

30,

31], the impacts of wheat cultivation were allocated on economic basis between the two co-products, on the basis of 10-years averaged prices for grains and straws of durum and common wheat (statistics downloaded from regional chamber of commerce [

35,

36]): 85% to grains and 15% to straw. The raw materials, energy use, manufacturing processes, transport, distribution, use and the final disposal of auxiliary inputs within and between each production stages were considered. Otherwise, the study did not encompass: (i) the use phase (BDO can be used in multiple products, each one consumed at different rates) and (ii) the disposal phase (the environmental impacts of bio-polymer disposal have not yet been studied extensively and there is a lack of adequate data on emissions, energy use and inherent degradation) [

18]. In this regard, the biogenic C incorporated within the bio-based BDO molecule was considered as carbon-neutral. Otherwise, no CO

2 uptake was included in the present analysis, since the long term storage of biogenic C inside bio-based compounds is highly affected by the final use and durability of the target biopolymers.

In order to address advantages or disadvantages of the investigated bio-based BDO production chain and allow suitable comparison with other bio-based or fossil-based products, the functional unit (FU) was set as 1 kg of bio-based BDO.

An uncertainty analysis and a sensitivity check were also carried out to assess how the final outcome of the study might be affected by assumptions on foreground input/output data and by alternative biomass feedstock/residues processing routes.

2.2. Life Cycle Inventory (LCI)

As far as the fossil-based BDO was concerned, inventory data were retrieved from the EcoInvent database v. 2.0 [

37]: record “butane-1,4-diol, at plant”.

As regards the bio-based BDO, the inventory analysis (detailed in

Section 2.2.1 and

Section 2.2.2) quantified flows input (using mass and energy balances) and output (products and pollutant emissions released to air, water and soil) for all the processing steps included in the system boundary (

Figure 1).

2.2.1. LignocellulosicFeedstock Cultivation

For this analysis, we considered wheat straw as eligible lignocellulosic feedstock for the BDO supply chain. According to the Italian National Agency for New Technologies, Energy and Sustainable Economic Development [

38], large areas of wheat crops are grown in Campania Region (about 120 kha, i.e., 12% of the total regional agronomic surface), entailing about 210 kton·y

−1 of straw by product. Complying with the regional technical specifications [

39], cereal stubble can be: (i) removed from the field, in case of inoculum of pathogens diseases and/or for on-farm/off-farm use as livestock feed and bedding; or (ii) incorporated in soil through disk harrowing (after cutting). In the latter case, 5–10 kg of additional N fertilizer need to be supplied per ton of incorporated straw, in order to reduce C/N ratio. Following ENEA estimates [

38], about 70% of total produced straw would be used for agronomic and zootechnical purposes, whilst the remaining, about 55 kton·y

−1, might be further valorized inside integrated bio-energy chains. Indeed, in Campania Region stalks are often seen as a waste disposal problem. As far as wheat straw are concerned, farmers are sometimes discouraged to both permitted routes, due to: (i) time and money expensive operations for biomass baling and transport, above all under the off-farm use as output for sale (in case of straw removal); and (ii) delayed establishment of the following crop, additional chopping operations and N additional fertilizer input (in case of straw incorporation in soil). As a result, the burning of cereal stubble, prohibited by the regional regulations [

39], is still a potential relevant cause of brush fire in the regional context [

40].

In this study, only the actual available wheat straw (WS) biomass in Campania Region (not used for agronomic and zootechnical purposes), was considered as potential feedstock for a hypothetical bio-based manufacturing process of BDO.

Table 1 shows the best guess (BG) value (the best estimated value used in this study) and the uncertaintyrange for each agronomic foreground input and output related to wheat cultivation in Campania Region, as retrieved from regional technical specifications [

39], statistics [

38] and pertinent scientific literature [

41,

42,

43,

44,

45,

46,

47,

48,

49,

50,

51]. In detail, specific agronomic input data were collected: from the site preparation until the harvest operation, considering type of agricultural machineries, seeding operations, type and application rate of mineral fertilizers and the other auxiliary chemicals. Afterwards, starting from the EcoInvent (v. 2.0) database [

37], specific records were implemented for all the agricultural practices through the SimaPro software [

33], in compliance with the reviewed pertinent literature and agronomic technical specifications for the analyzed regional context [

38,

39,

40,

41,

42,

43,

44,

45,

46,

47,

48,

49,

50,

51].

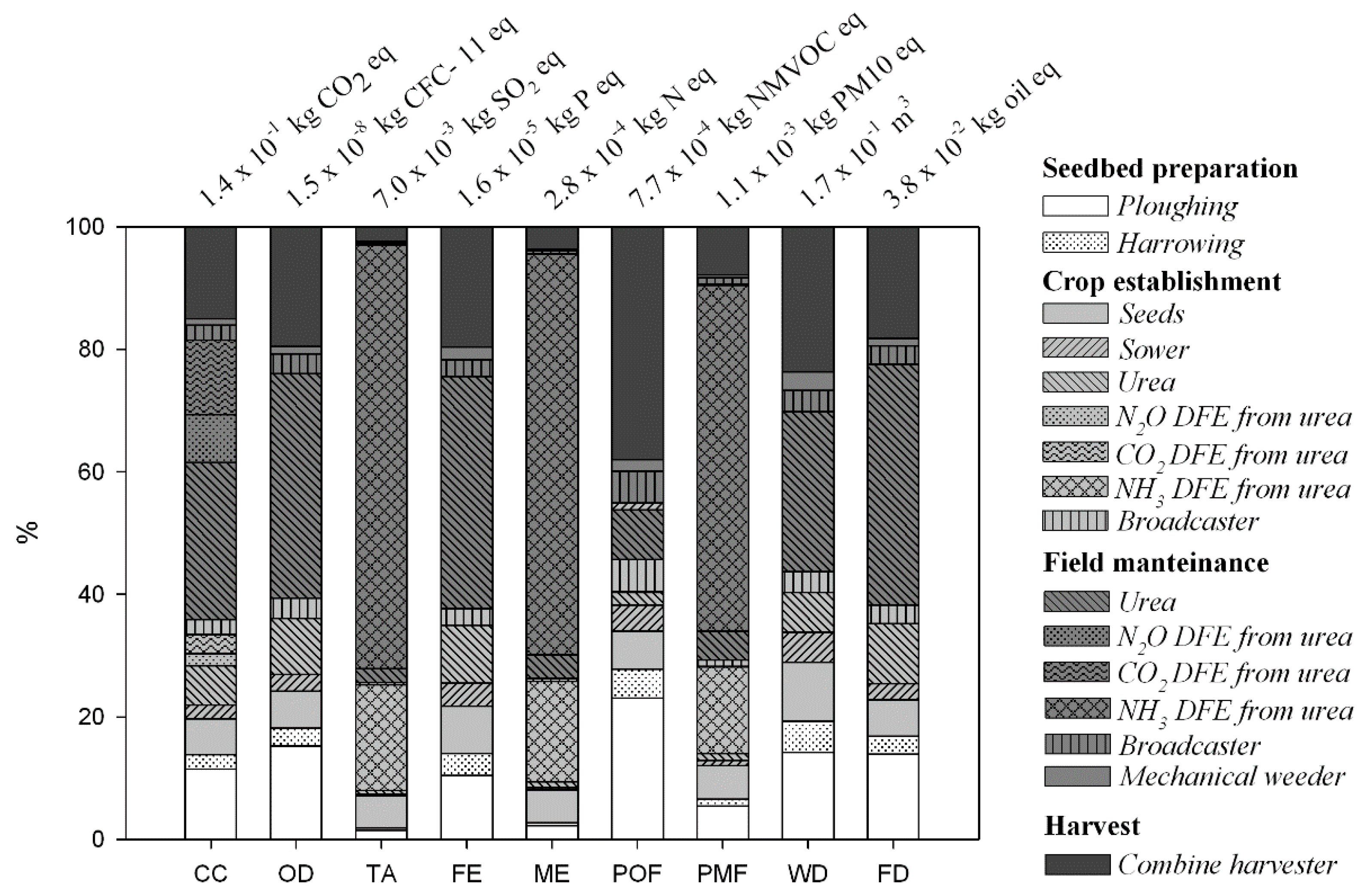

Direct field emissions (DFE) of reactive nitrogen (volatilized ammonia, biogenic dinitrogen monoxides, nitrogen oxides, leached nitrate), carbon dioxide (fossil, from urea molecule decomposition in soil) and P losses (phosphorus/phosphate runoff to surface water and phosphate leaching to ground water, in case of additional P-K synthetic fertilizers) were computed according to EcoInvent guidelines [

47,

48] and IPCC methodology [

48], through the use, when possible, of pedo-climatic and site-crop specific data, relative to wheat cultivation in the Mediterranean context [

46].

The direct biogenic N

2O emissions, following fertilizer application, were calculated over an average estimate of emission factor (EF) for spring-summer Mediterranean crops (0.5%) [

46]. This value is markedly lower than the default EF (percentage of kg N-N

2O per kg N-fertilizer input applied) of 1% considered by IPCC [

48].

2.2.2. Feedstock Conversion in the Industrial Plant

The study assumed a regional short-distance supply scenario of the lignocellulosic feedstock to the biorefinery plant (70 km), (DM 2/03/2010).

The average wheat straw composition was assumed as follow: 37% cellulose, 28% hemicellulose, 20% lignin, 5% ashes, 10% other organics and extractives [

52,

53,

54].

Energy and material inputs for the pre-treatment (dilute acid) and saccharification (enzymatic hydrolysis) were secondary data retrieved from the EcoInvent database v. 2.02 and guidelines [

55] and pertinent scientific literature [

23]. According to Volynets and Dahman [

53] an average 74% recovery efficiency of total sugars after pre-treatment and saccharification was assumed. The preliminary primary data for energy and material (nutrients and chemicals) inputs along the fermentation and purification steps were available inside the framework of the EnerbioChem Project. The BDO product purity is a crucial parameter to meet the current commercial requirements for polymer-based supply chains. High purity BDO was achieved through standard industrial recovery technologies, according to the following steps: cell and salt separation, water evaporation (to be further recycled within the system) and final BDO purification. Inputs and process efficiency at these stages represent sensitive industrial data. For this reason, all the industrial processing data (foreground and background) were disclosed aggregated (

Table 2). The entire outcome of the LCA analysis was referred to an averaged medium scenario of co-fermentation efficiency of cellulose and hemicellulose equal to 80% of the maximum stechiometric bio-based BDO yield. Additionally other two fermentation efficiency scenarios were considered and encompassed inside the study: 100% (best-case) and 70% (worst-case) of the maximum stechiometric yield.

Within the designed bio-refinery system, the recovered C6 and C5 sugars were used for the co-fermentation process, whilst (ii) the lignin residues, the not hydrolyzed holocelluloses and the not fermented sugars were assumed to be recovered as unconverted solids (US) and burned beneficially, in a cogeneration unit system (Combined Heating and Power plant, CHP) for the on-site generation of process heat and electricity (

Figure 1).

Table 2 summarizes the input flows related to the whole feedstock conversion process from wheat straw towards bio-based BDO (data input and output are referred to the selected FU: 1 kg of BDO).

According to the best estimated value (BG) for the unconverted solids characteristics, related to the default averaged medium scenario of co-fermentation efficiency (summarized in

Table 3), the system might be self sufficient as far as the electricity input is concerned; whilst an additional amount of heat (assumed supplied by natural gas burning) would be necessary. Following the EcoInvent guidelines [

55], the input and output pollutant emissions related to the CHP plant were calculated by adapting the record “wood chips, burned in cogen 6400 kWth, emission control” on the basis of dry matter, carbon and energy content of the analyzed unconverted solids.

The effect of the different fermentation efficiencies on the total amount of input process and available unconverted solids to CHP plant (and the system energy balance) was also taken into account. For this reason, the uncertainty ranges of industrial input and output were derived respecting the three different fermentation scenario efficiencies: (i) on a linear basis for material industrial input (water, chemicals and nutrients), according to the different wheat straw biomass input required; and (ii) in compliance with the different modeled US amount and characteristics, for energy balance and pollutant emissions from the CHP (

Table 3).

The background inventory data (i.e., extraction and treatment of raw materials, manufacturing process, transport, distribution, use phase and the final disposal) for machineries and infrastructures were retrieved from the EcoInvent product or process database (v. 2.02) [

37].

2.3. Life Cycle Impact Assessment (LCIA)

LCIA phase assigns qualitative and quantitative environmental effects to all foreground and background data collected during the inventory analysis. Environmental impacts are computed based on the selected functional units.

In this study the LCIA was performed by means of the LCA software SimaPro 8.0.3 [

33] and one of the most recent and up-to-date LCA methods, Europe ReCiPe H v. 1.10 midpoint method [

34]. The ReCiPe method can be profitably used to assess environmental impacts for a large number of upstream (i.e., referred to depletion of natural resources, such as fossil and water depletion categories) and downstream (i.e., referred to impacts generated on the natural matrices, such as terrestrial, marine or freshwater acidification) impact categories [

34]. The midpoint level was chosen in this study, since it characterizes impacts somewhere in the middle of the environmental cause-effect chain and it is widely recognized as more robust and less uncertain compared with endpoint indicators [

34]. The ReCiPe method provides characterization factors to quantify the contribution of processes to each impact category and normalization factors to allow a comparison across categories [

34]. The normalization step is not mandatory in the ISO 14040-14044 standards [

19,

20], nor it is in the ILCD Handbook [

30]. The main reason is that this step is still very uncertain and based on parameters considered arbitrary. As a consequence, the interpretation phase (result and discussion session) in this study was based on the characterization diagrams and the absolute value of impacts focusing on their breakdown into the different impact sources.

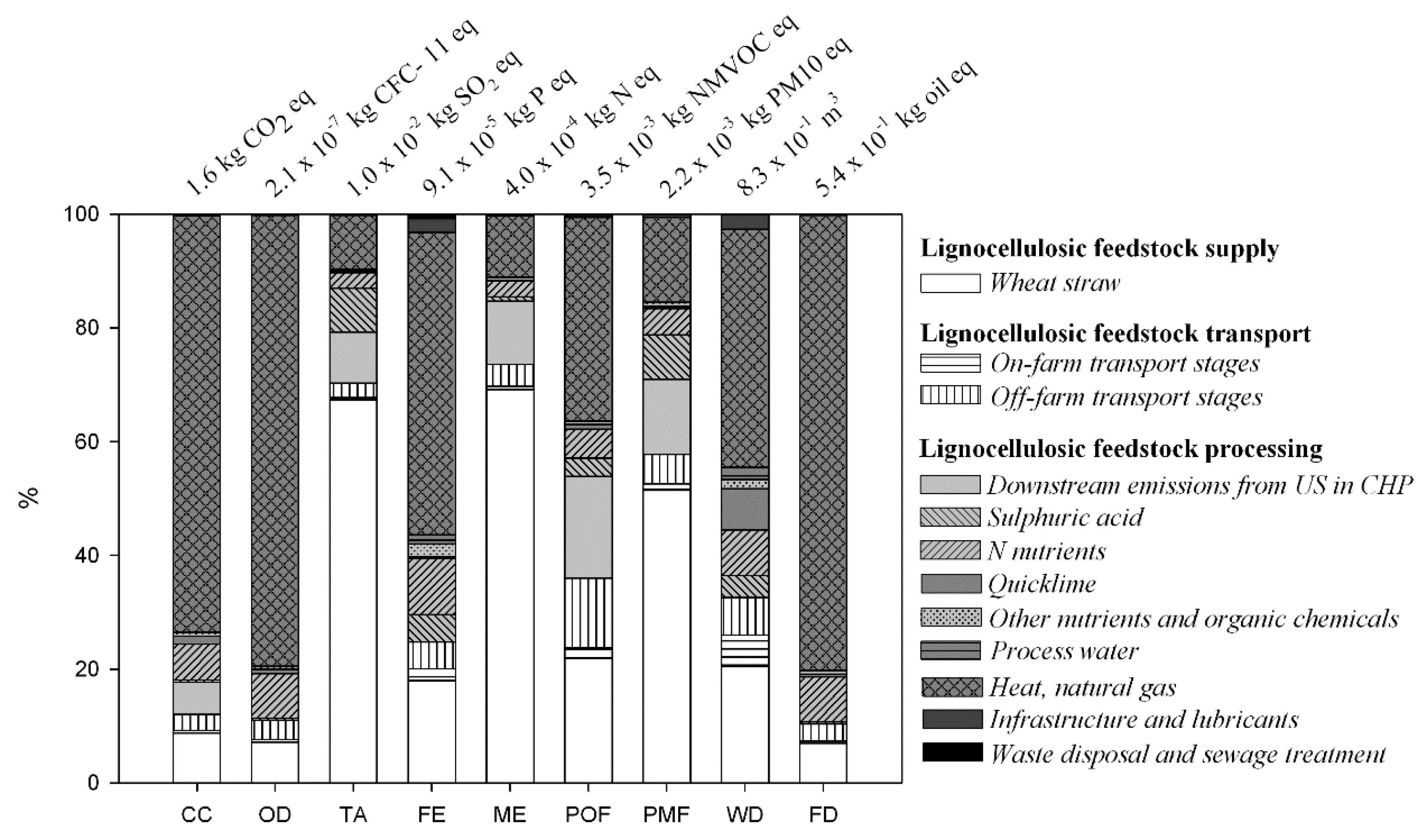

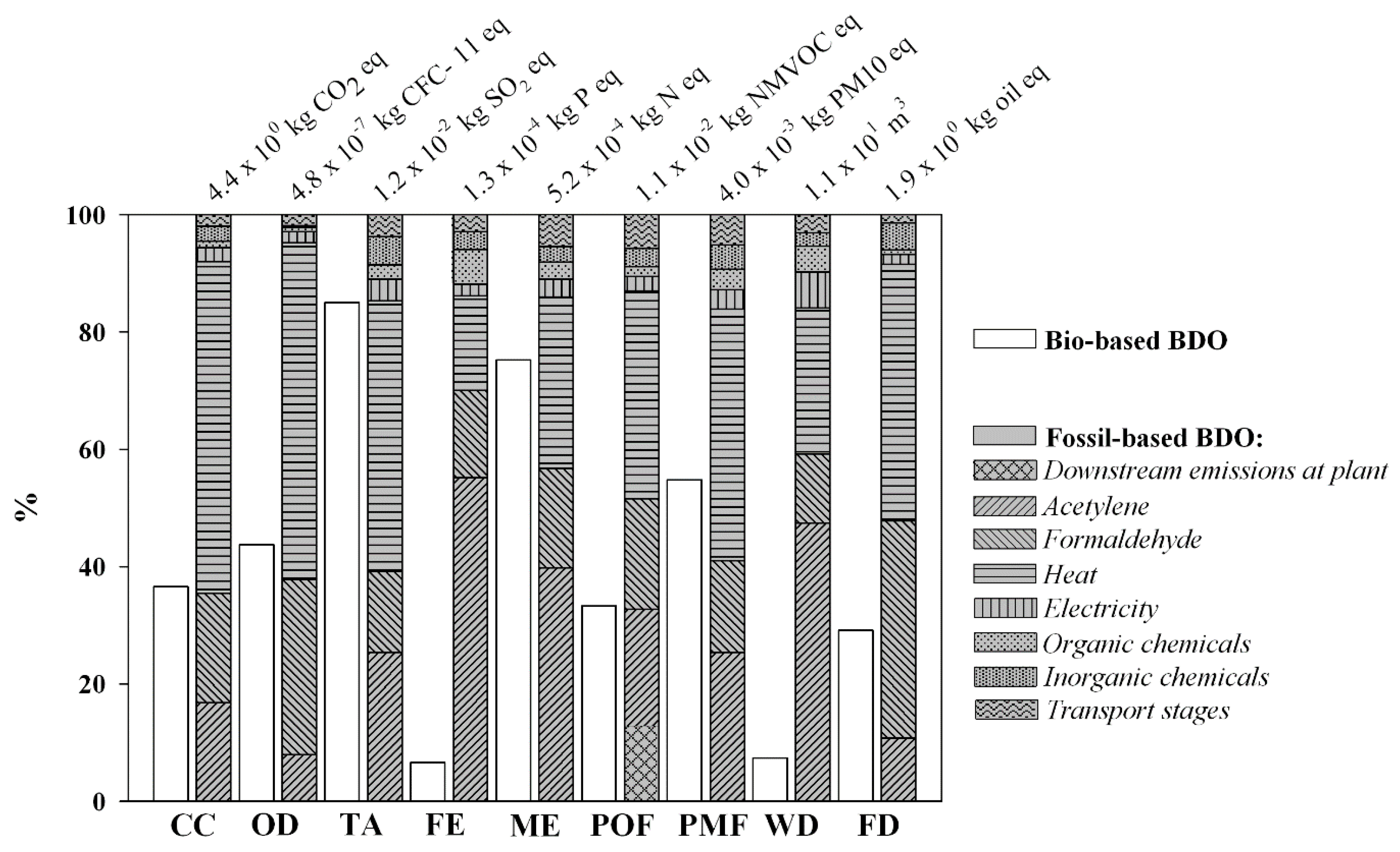

The following impact categories were explored in this work: Climate Change (CC, kg CO2 eq), Ozone Depletion (OD, kg CFC-11 eq), Terrestrial Acidification (TA, kg SO2 eq), Freshwater Eutrophication (FE, kg P eq), Marine Eutrophication (ME, kg N eq), Photochemical Oxidant Formation (POF, kg NMVOC), Particulate Matter Formation (PMF, kg PM10 eq), Water Depletion (WD, m3) and Fossil Depletion (FD, kg oil eq).

The toxicity impact categories were not evaluated, due to the large uncertainty still affecting their computation [

57].

2.4. Interpretation

In this stage, according to goal and scope of this study, the overall findings of inventory analysis and impact assessment are combined and discussed to gain conclusions and recommendations [

19,

20]. This is a systematic technique to check and evaluate information from the results of the LCI and LCIA, and communicate them effectively. Indeed, the interpretation stage is based on the contribution check of the quantified hotspots and identified elements (input, processes and stages) which will have the greatest influence on certain impact category or on the total life cycle impacts.

Results Evaluation

The interpretation includes a critical reflection about the study, through sensitivity check and/or uncertainty analysis related to representativeness of input data and adequacy of methodological choices. In this study, to test the robustness of the LCA results and assess the influence of the key parameters on the evaluated impact categories, both an uncertainty analysis and a sensitivity check were carried out.

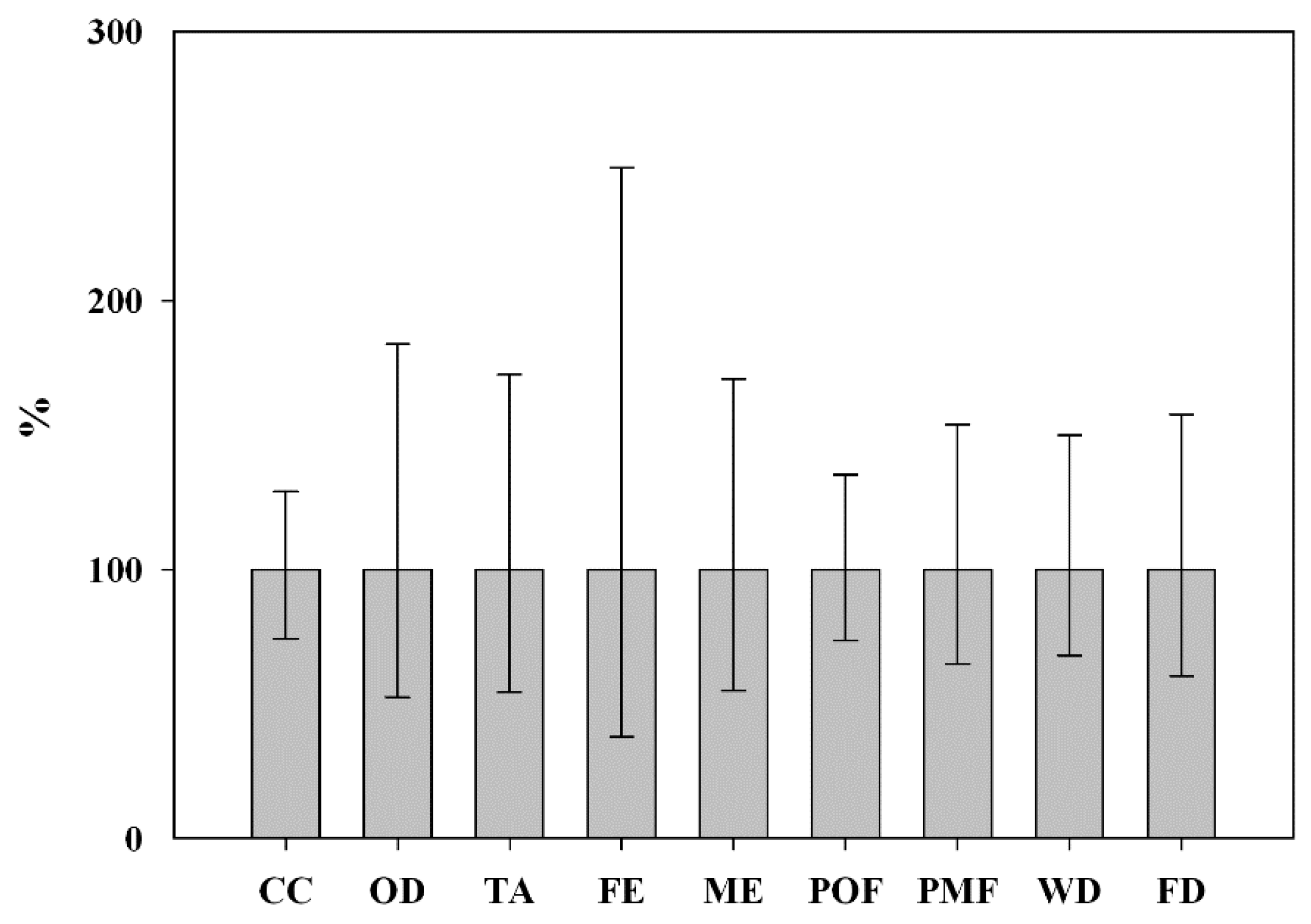

The uncertainty analysis was performed by the Monte Carlo (MC) functional unit within SimaPro 8.0.3 software, in order to propagate the uncertainty linked to foreground input/output of the crop stage (see

Section 2.2.1) and industrial phase (see

Section 2.2.2). For background inputs and emissions of both feedstock cultivation and processing, the probability distributions were retrieved from the EcoInvent v. 2.0 database. The 95% confidence limits were generated by running simulations of 10,000 trials.

On the basis of the main outcomes of the LCA analysis, the sensitivity check was used to evaluate and argue the potential implementation of emerged key steps, through possible alternative routes along the bio-based BDO production chain.

5. Conclusions

This paper represents a first piece in the complex mosaic of studying the feasibility of a territorial biorefinery toward the sustainable principles.

It has dealt the environmental performance of BDO production chain, with main goals (i) individuate the hot spots production stages; and (ii) assess potential benefits compared with fossil counterpart. According to the results achieved in this LCA study, hot spots have been identified in the energy demand of the entire process and in the feedstock production. Our assessment pointed out that the available wheat straw lignocellulosic feedstock in Campania Region (not in competition with current agro-zootechnical use) appeared as a suitable alternative source for eco-friendly bio-based BDO production within a hypothetical local biorefinery scenario.

Several issues need to be further addressed to: (i) constrain the impact of lignocellulosic feedstock cultivation; (ii) implement technical aspects of the industrial bio-based manufacturing process; and (iii) achieve in the future a proper balance between agricultural and industrial use of cereal stalks. As far as the last point is concerned, updated large-scale surveys appear necessary to characterize local straw availability and current destination routes. This in order to assess the viability of straw market as a renewable material, respecting its agronomic use through soil incorporation and its linked benefits in terms of enhancement of soil nutrient and physical properties. Additionally, further topics need to be encompassed inherent to economic aspects such as policy incentives and directives, which were behind the scope of the present work, but can heavily affect commercial farming practices and market dynamics. Indeed, the issue of sustainable is complex and requires robust and integrated scientific studies in order to address accurately policy decisions, stakeholders’ interests and social needs.