Some Issues of Shrinkage-Reducing Admixtures Application in Alkali-Activated Slag Systems

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Drying Shrinkage Tests

2.3. Mechanical Strength Testing

2.4. Isothermal Calorimetry

2.5. Mercury Intrusion Porosimetry

2.6. Scanning Electron Microscopy

3. Results and Discussion

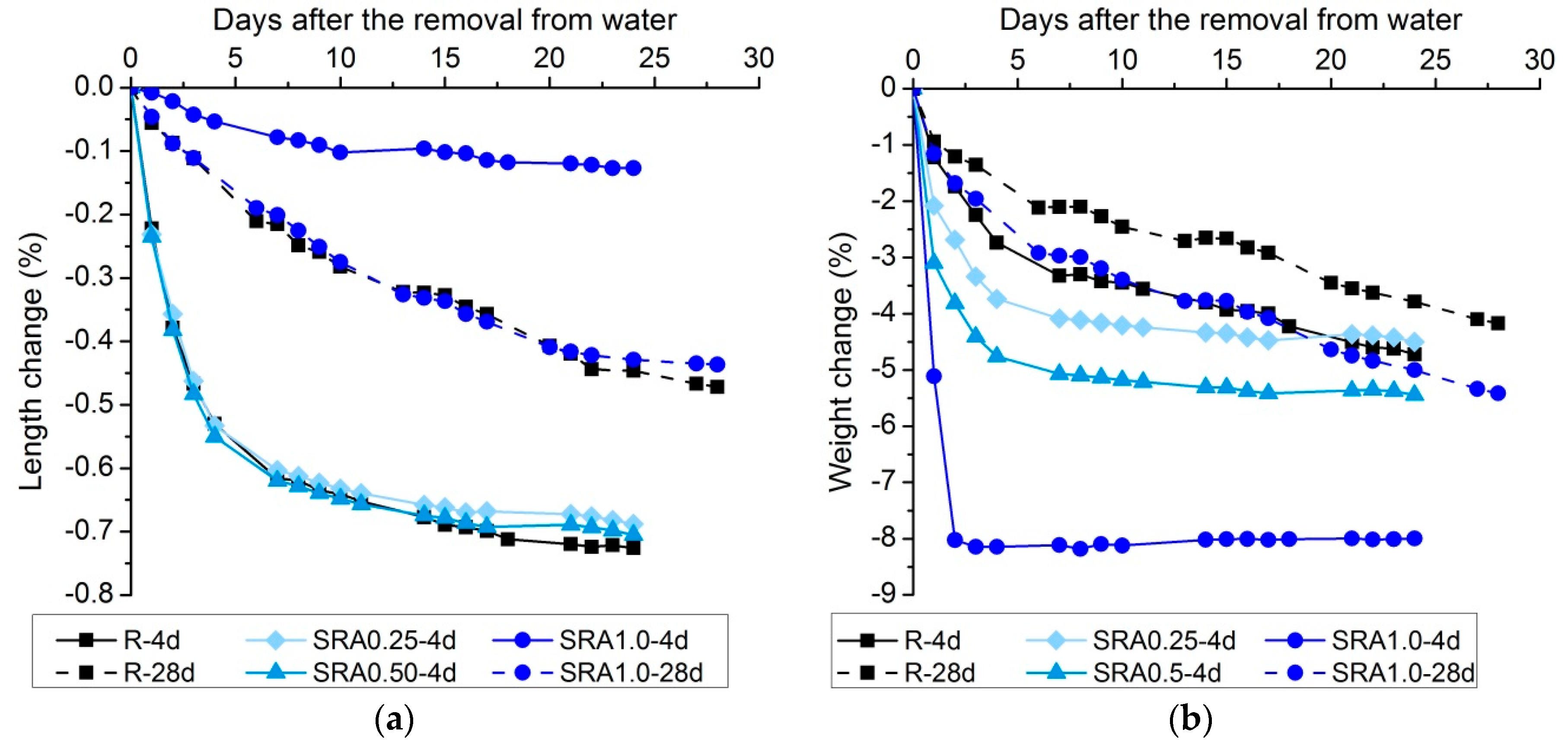

3.1. Drying Shrinkage and Weight Loss

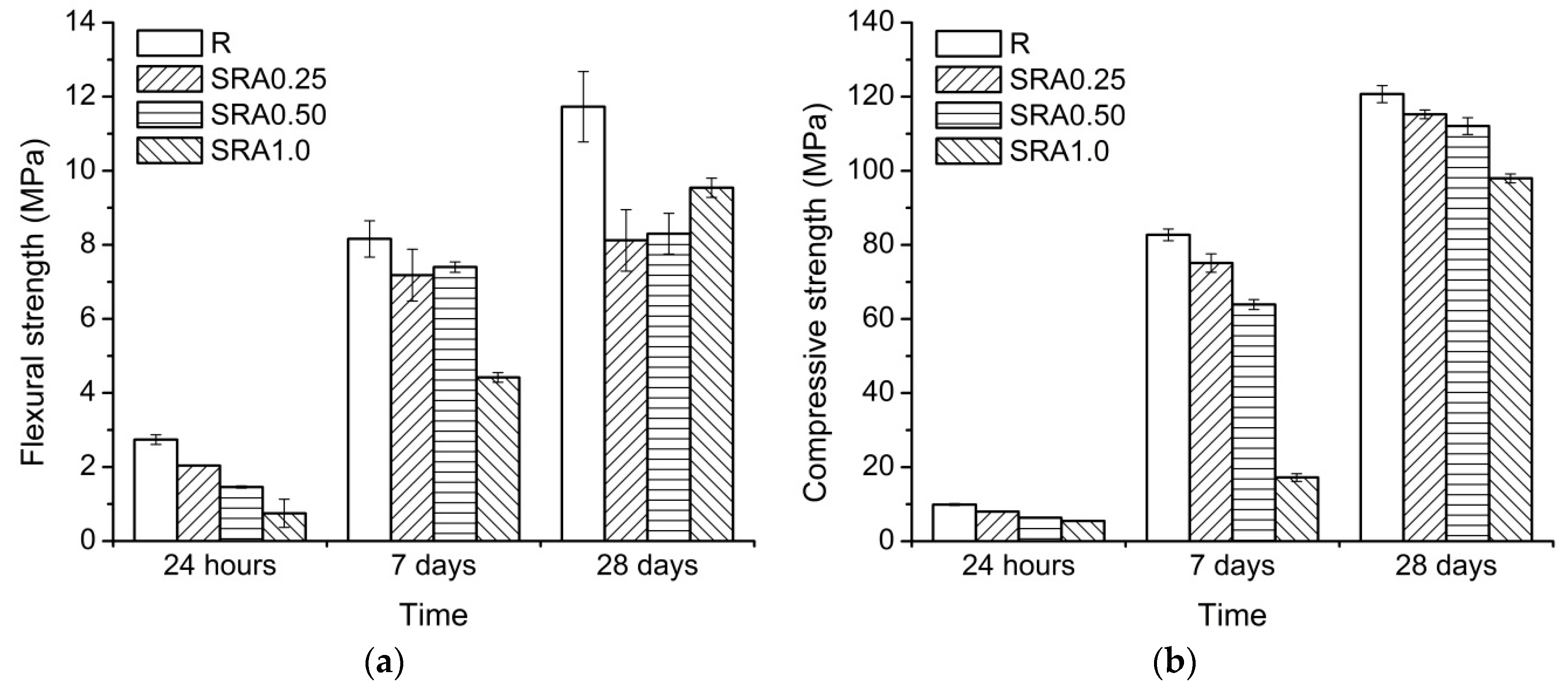

3.2. Flexural and Compressive Strength

3.3. Isothermal Calorimetry

3.4. Mercury Intrusion Porosimetry

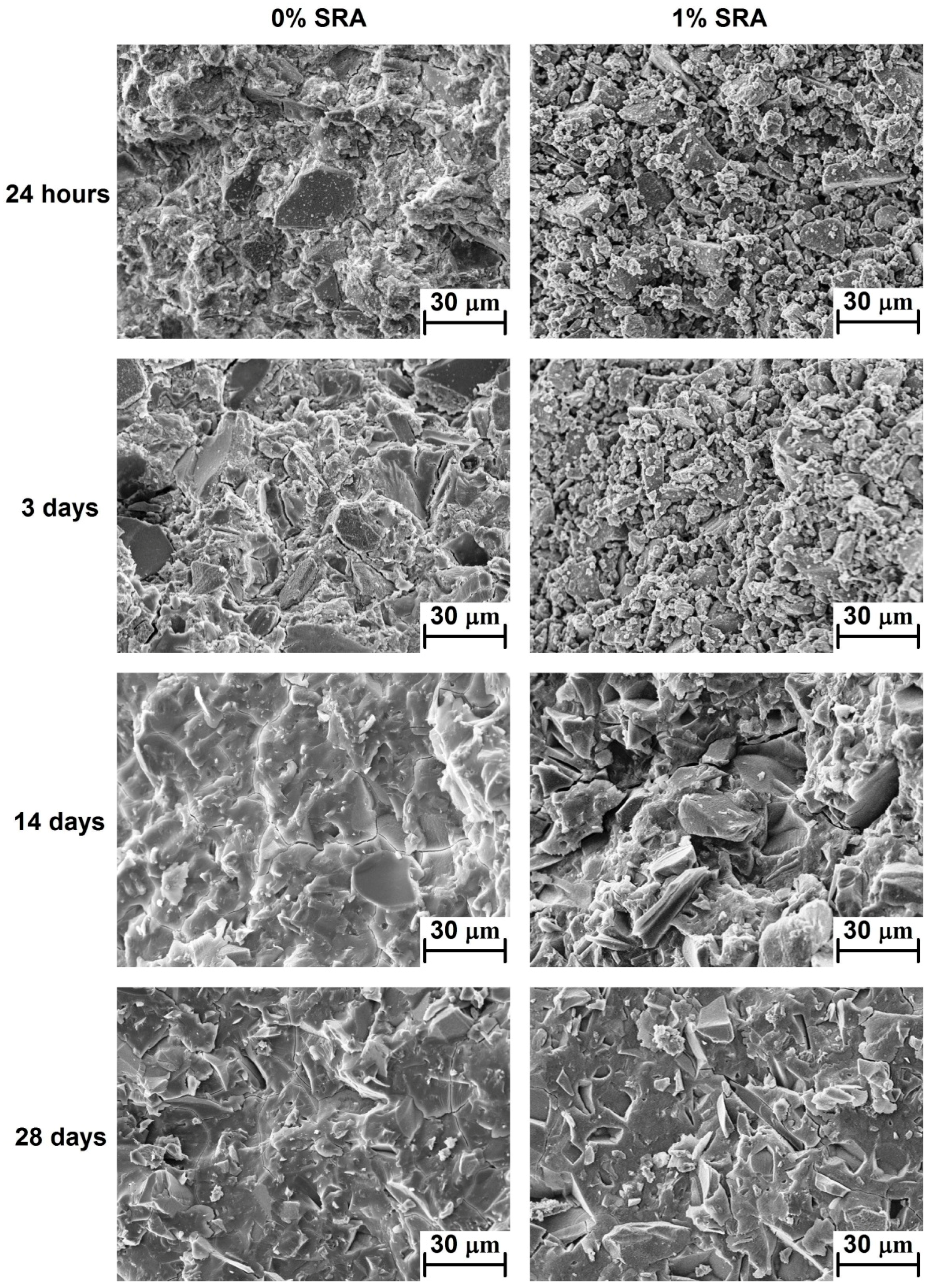

3.5. Scanning Electron Microscopy

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| AAS | Alkali activated slag |

| AABFS/FA | alkali activated blend of BFS and FA |

| BFS | Blast furnace slag |

| C–S–H | Calcium–silicate–hydrate |

| C–A–S–H | Calcium–aluminate–silicate–hydrate |

| FA | Fly ash |

| MIP | Mercury intrusion porosimetry |

| OPC | Ordinary Portland cement |

| SRA | Shrinkage reducing admixture |

| SEM | Scanning electron microscopy |

References

- Aïtcin, P.-C.; Mindess, S. Sustainability of Concrete; Spon Press: New York, NY, USA, 2011. [Google Scholar]

- Juenger, M.; Winnefeld, F.; Provis, J.L.; Ideker, J. Advances in alternative cementitious binders. Cem. Concr. Res. 2011, 41, 1232–1243. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J.S.J. Alkali Activated Materials; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; van Deventer, J.S. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Collins, F.; Sanjayan, J. Workability and mechanical properties of alkali activated slag concrete. Cem. Concr. Res. 1999, 29, 455–458. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.; Cheng, Y.-B. Resistance of alkali-activated slag concrete to acid attack. Cem. Concr. Res. 2003, 33, 1607–1611. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.; Cheng, Y.-B. Sulfate attack on alkali-activated slag concrete. Cem. Concr. Res. 2002, 32, 211–216. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; de Gutiérrez, R.M.; Provis, J.L. Performance of alkali-activated slag mortars exposed to acids. J. Sustain. Cem. Based Mater. 2012, 1, 138–151. [Google Scholar] [CrossRef]

- Wang, W.-C.; Wang, H.-Y.; Lo, M.-H. The engineering properties of alkali-activated slag pastes exposed to high temperatures. Constr. Build. Mater. 2014, 68, 409–415. [Google Scholar] [CrossRef]

- Guerrieri, M.; Sanjayan, J.; Collins, F. Residual compressive behavior of alkali-activated concrete exposed to elevated temperatures. Fire Mater. 2009, 33, 51–62. [Google Scholar] [CrossRef]

- Guerrieri, M.; Sanjayan, J.; Collins, F. Residual strength properties of sodium silicate alkali activated slag paste exposed to elevated temperatures. Mater. Struct. 2010, 43, 765–773. [Google Scholar] [CrossRef]

- San Nicolas, R.; Bernal, S.A.; de Gutiérrez, R.M.; van Deventer, J.S.; Provis, J.L. Distinctive microstructural features of aged sodium silicate-activated slag concretes. Cem. Concr. Res. 2014, 65, 41–51. [Google Scholar] [CrossRef]

- Palacios, M.; Puertas, F. Effect of superplasticizer and shrinkage-reducing admixtures on alkali-activated slag pastes and mortars. Cem. Concr. Res. 2005, 35, 1358–1367. [Google Scholar] [CrossRef]

- Kashani, A.; Provis, J.L.; Xu, J.; Kilcullen, A.R.; Qiao, G.G.; van Deventer, J.S. Effect of molecular architecture of polycarboxylate ethers on plasticizing performance in alkali-activated slag paste. J. Mater. Sci. 2014, 49, 2761–2772. [Google Scholar] [CrossRef]

- Palacios, M.; Puertas, F. Effectiveness of mixing time on hardened properties of waterglass-activated slag pastes and mortars. ACI Mater. J. 2011, 108, 73. [Google Scholar]

- Collins, F.; Sanjayan, J. Cracking tendency of alkali-activated slag concrete subjected to restrained shrinkage. Cem. Concr. Res. 2000, 30, 791–798. [Google Scholar] [CrossRef]

- Shi, C.; Krivenko, P.V.; Roy, D. Alkali-Activated Cements and Concretes; Taylor & Francis: London, UK, 2006. [Google Scholar]

- Collins, F.; Sanjayan, J. Effect of pore size distribution on drying shrinking of alkali-activated slag concrete. Cem. Concr. Res. 2000, 30, 1401–1406. [Google Scholar] [CrossRef]

- Krizan, D.; Zivanovic, B. Effects of dosage and modulus of water glass on early hydration of alkali–slag cements. Cem. Concr. Res. 2002, 32, 1181–1188. [Google Scholar] [CrossRef]

- Neto, A.A.M.; Cincotto, M.A.; Repette, W. Drying and autogenous shrinkage of pastes and mortars with activated slag cement. Cem. Concr. Res. 2008, 38, 565–574. [Google Scholar] [CrossRef]

- Lee, N.; Jang, J.; Lee, H. Shrinkage characteristics of alkali-activated fly ash/slag paste and mortar at early ages. Cem. Concr. Compos. 2014, 53, 239–248. [Google Scholar] [CrossRef]

- Scherer, G.W. Drying, shrinkage, and cracking of cementitious materials. Transp. Porous Media 2015, 110, 311–331. [Google Scholar] [CrossRef]

- Aydın, S. A ternary optimisation of mineral additives of alkali activated cement mortars. Constr. Build. Mater. 2013, 43, 131–138. [Google Scholar] [CrossRef]

- Bilek, V.; Parizek, L.; Kalina, L. Effect of the by-pass cement kiln dust and fluidized bed combustion fly ash on properties of fine-grained alkali-activated slag-based composites. Mater. Tehnol. 2015, 49, 549–552. [Google Scholar] [CrossRef]

- Chi, M.; Huang, R. Binding mechanism and properties of alkali-activated fly ash/slag mortars. Constr. Build. Mater. 2013, 40, 291–298. [Google Scholar] [CrossRef]

- Marjanović, N.; Komljenović, M.; Baščarević, Z.; Nikolić, V.; Petrović, R. Physical–mechanical and microstructural properties of alkali-activated fly ash–blast furnace slag blends. Ceram. Int. 2015, 41, 1421–1435. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.; Cheng, Y.-B. Effect of elevated temperature curing on properties of alkali-activated slag concrete. Cem. Concr. Res. 1999, 29, 1619–1625. [Google Scholar] [CrossRef]

- Aydin, S.; Baradan, B. Mechanical and microstructural properties of heat cured alkali-activated slag mortars. Mater. Des. 2012, 35, 374–383. [Google Scholar] [CrossRef]

- Chi, M. Effects of dosage of alkali-activated solution and curing conditions on the properties and durability of alkali-activated slag concrete. Constr. Build. Mater. 2012, 35, 240–245. [Google Scholar] [CrossRef]

- Sakulich, A.; Bentz, D. Mitigation of autogenous shrinkage in alkali activated slag mortars by internal curing. Mater. Struct. 2013, 46, 1355–1367. [Google Scholar] [CrossRef]

- Aydın, S.; Baradan, B. The effect of fiber properties on high performance alkali-activated slag/silica fume mortars. Compos. Part B Eng. 2013, 45, 63–69. [Google Scholar] [CrossRef]

- Alcaide, J.; Alcocel, E.; Puertas, F.; Lapuente, R.; Garcés, P. Carbon fibre-reinforced, alkali-activated slag mortars. Mater. Constr. 2007, 57, 33–48. [Google Scholar]

- Puertas, F.; Gil-Maroto, A.; Palacios, M.; Amat, T. Alkali-activated slag mortars reinforced with ar glassfibre. Performance and properties. Mater. Constr. 2006, 56, 79–90. [Google Scholar]

- Shen, W.G.; Wang, Y.H.; Zhang, T.; Zhou, M.K.; Li, J.S.; Cui, X.Y. Magnesia modification of alkali-activated slag fly ash cement. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2011, 26, 121–125. [Google Scholar] [CrossRef]

- Yuan, X.-H.; Chen, W.; Lu, Z.-A.; Chen, H. Shrinkage compensation of alkali-activated slag concrete and microstructural analysis. Constr. Build. Mater. 2014, 66, 422–428. [Google Scholar] [CrossRef]

- Chang, J.J.; Yeih, W.; Hung, C.C. Effects of gypsum and phosphoric acid on the properties of sodium silicate-based alkali-activated slag pastes. Cem. Concr. Compos. 2005, 27, 85–91. [Google Scholar] [CrossRef]

- Rajabipour, F.; Sant, G.; Weiss, J. Interactions between shrinkage reducing admixtures (sra) and cement paste's pore solution. Cem. Concr. Res. 2008, 38, 606–615. [Google Scholar] [CrossRef]

- Saliba, J.; Roziere, E.; Grondin, F.; Loukili, A. Influence of shrinkage-reducing admixtures on plastic and long-term shrinkage. Cem. Concr. Compos. 2011, 33, 209–217. [Google Scholar] [CrossRef]

- Bian, R.; Jian, S. Synthesis and evaluation of shrinkage-reducing admixture for cementitious materials. Cem. Concr. Res. 2005, 35, 445–448. [Google Scholar]

- Folliard, K.J.; Berke, N.S. Properties of high-performance concrete containing shrinkage-reducing admixture. Cem. Concr. Res. 1997, 27, 1357–1364. [Google Scholar] [CrossRef]

- Sant, G.; Lothenbach, B.; Juilland, P.; Le Saout, G.; Weiss, J.; Scrivener, K. The origin of early age expansions induced in cementitious materials containing shrinkage reducing admixtures. Cem. Concr. Res. 2011, 41, 218–229. [Google Scholar] [CrossRef]

- Palacios, M.; Puertas, F. Effect of shrinkage-reducing admixtures on the properties of alkali-activated slag mortars and pastes. Cem. Concr. Res. 2007, 37, 691–702. [Google Scholar] [CrossRef]

- Bilim, C.; Karahan, O.; Atis, C.D.; Ilkentapar, S. Influence of admixtures on the properties of alkali-activated slag mortars subjected to different curing conditions. Mater. Des. 2013, 44, 540–547. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.B. Effect of admixtures on properties of alkali-activated slag concrete. Cem. Concr. Res. 2000, 30, 1367–1374. [Google Scholar] [CrossRef]

- Abell, A.B.; Willis, K.L.; Lange, D.A. Mercury intrusion porosimetry and image analysis of cement-based materials. J. Colloid Interface Sci. 1999, 211, 39–44. [Google Scholar] [CrossRef] [PubMed]

- Eberhardt, A.B. On the Mechanisms of Shrinkage Reducing Admixtures in Self Consolidationg Mortars and Concretes. Ph.D. Thesis, Bauhaus Universität Weimar, Weimar, Germany, 2011. [Google Scholar]

- Aïtcin, P.C.; Flatt, R.J. Science and Technology of Concrete Admixtures; Woodhead Publishing: Sawston, Cambridge, UK, 2015. [Google Scholar]

- Bílek, V., Jr.; Kalina, L.; Koplík, J.; Hajdúchová, M.; Radoslav, N. Effect of combination of fly ash and shrinkage reducing additives on properties of alkali activated slag based mortars. Mater. Tehnol. 2016, in press. [Google Scholar]

- Shi, C.J.; Day, R.L. A calorimetric study of early hydration of alkali-slag cements. Cem. Concr. Res. 1995, 25, 1333–1346. [Google Scholar] [CrossRef]

- Ravikumar, D.; Neithalath, N. Reaction kinetics in sodium silicate powder and liquid activated slag binders evaluated using isothermal calorimetry. Thermochim. Acta 2012, 546, 32–43. [Google Scholar] [CrossRef]

- Diamond, S. Mercury porosimetry-an inappropriate method for the measurement of pore size distributions in cement-based materials. Cem. Concr. Res. 2000, 30, 1517–1525. [Google Scholar] [CrossRef]

- Cook, R.A.; Hover, K.C. Mercury porosimetry of hardened cement pastes. Cem. Concr. Res. 1999, 29, 933–943. [Google Scholar] [CrossRef]

- Bulejko, P.; Bílek, V., Jr. Influence of chemical additives and curing conditions on mechanical properties and carbonation resistance of alkali-activated slag composites. Mater. Tehnol. 2017, in press. [Google Scholar]

| Raw Material | Chemical Composition wt. % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| BFS | SiO2 | Al2O3 | CaO | Na2O | K2O | MgO | SO3 | Fe2O3 | TiO2 | MnO |

| 34.7 | 9.1 | 41.1 | 0.4 | 0.9 | 10.5 | 1.4 | 0.3 | 1.0 | 0.6 | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bílek, V.; Kalina, L.; Novotný, R.; Tkacz, J.; Pařízek, L. Some Issues of Shrinkage-Reducing Admixtures Application in Alkali-Activated Slag Systems. Materials 2016, 9, 462. https://doi.org/10.3390/ma9060462

Bílek V, Kalina L, Novotný R, Tkacz J, Pařízek L. Some Issues of Shrinkage-Reducing Admixtures Application in Alkali-Activated Slag Systems. Materials. 2016; 9(6):462. https://doi.org/10.3390/ma9060462

Chicago/Turabian StyleBílek, Vlastimil, Lukáš Kalina, Radoslav Novotný, Jakub Tkacz, and Ladislav Pařízek. 2016. "Some Issues of Shrinkage-Reducing Admixtures Application in Alkali-Activated Slag Systems" Materials 9, no. 6: 462. https://doi.org/10.3390/ma9060462

APA StyleBílek, V., Kalina, L., Novotný, R., Tkacz, J., & Pařízek, L. (2016). Some Issues of Shrinkage-Reducing Admixtures Application in Alkali-Activated Slag Systems. Materials, 9(6), 462. https://doi.org/10.3390/ma9060462