Experimental Study on Conductivity Anisotropy of Limestone Considering the Bedding Directional Effect in the Whole Process of Uniaxial Compression

Abstract

:1. Introduction

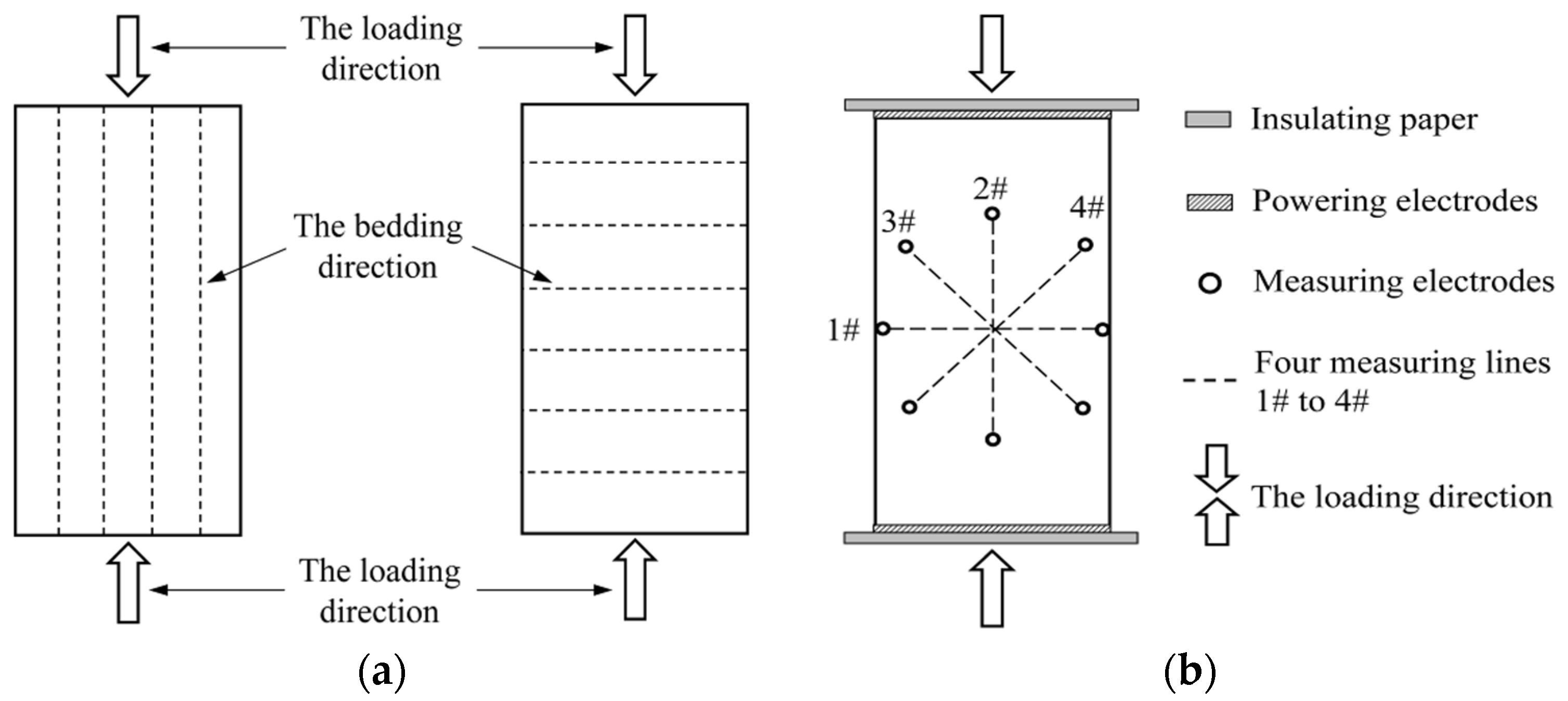

2. Test Device and Method

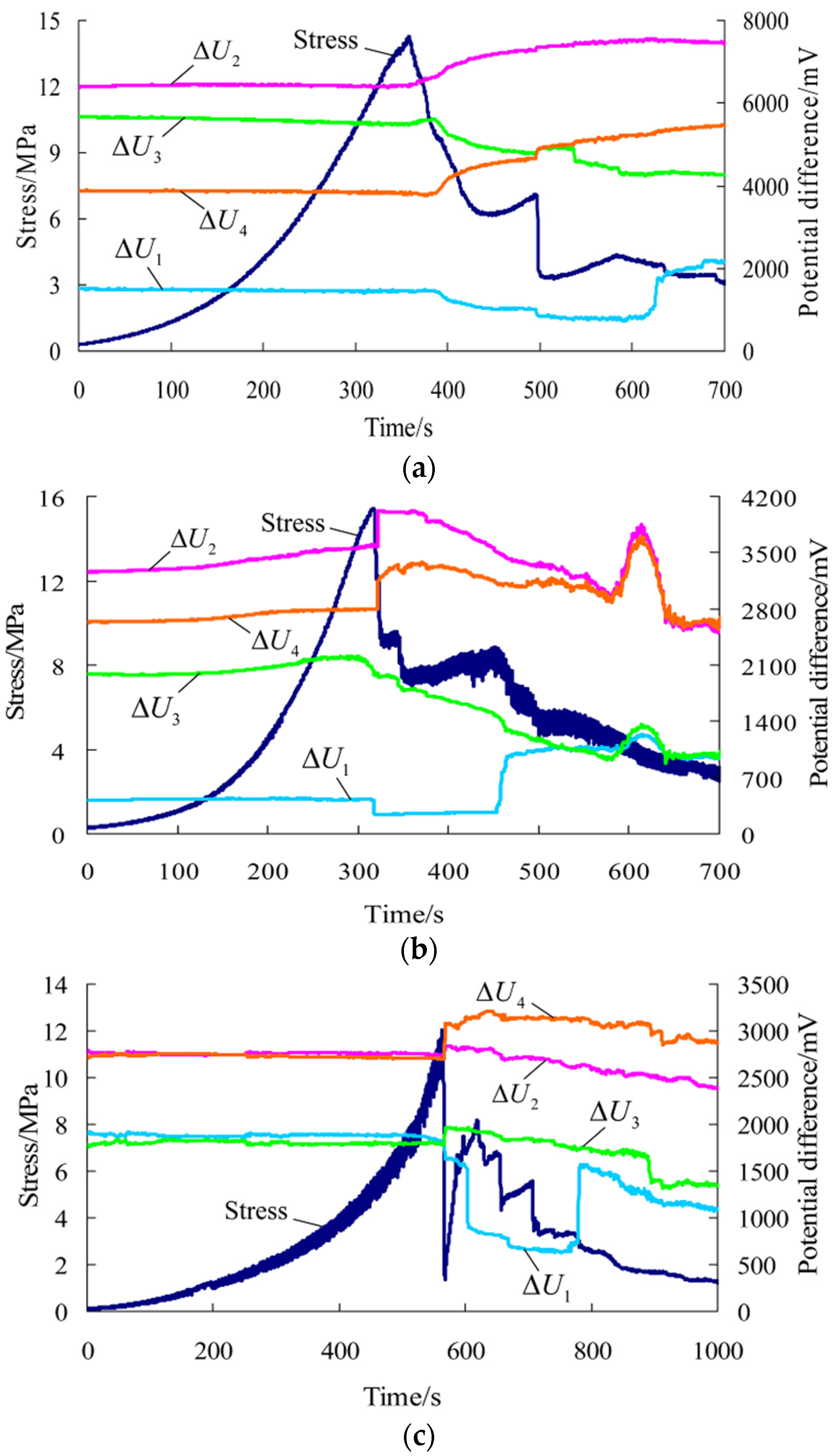

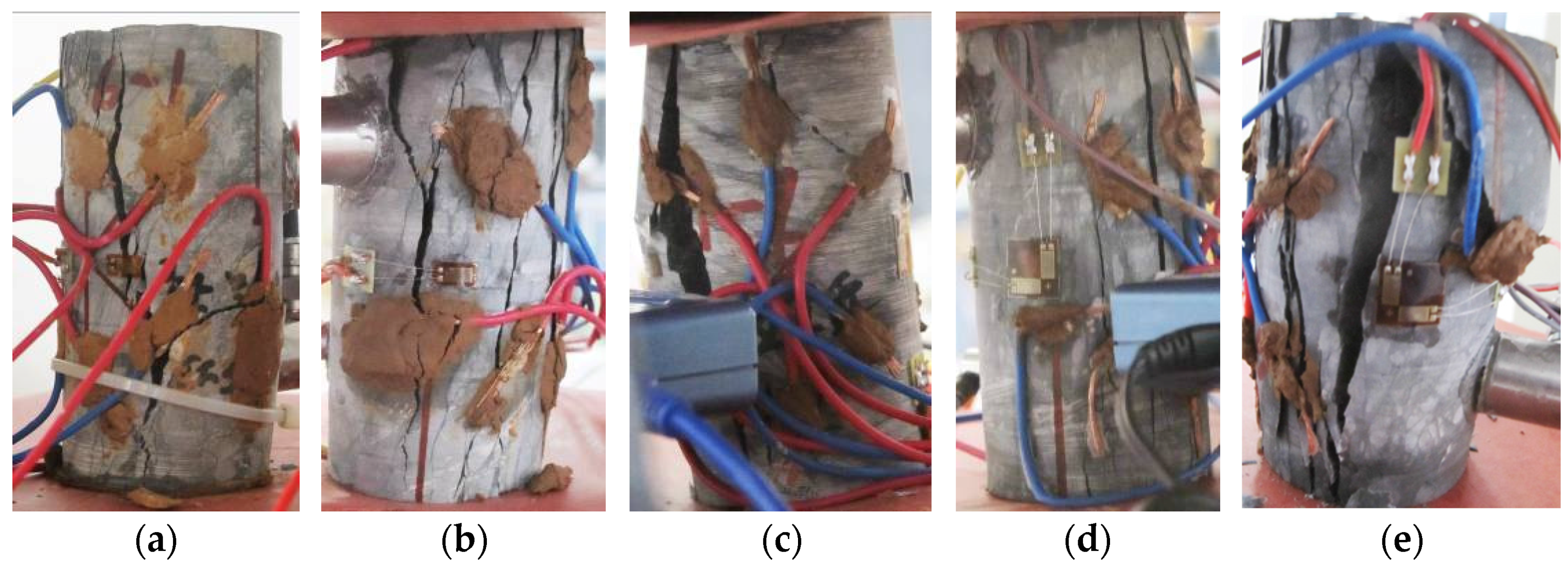

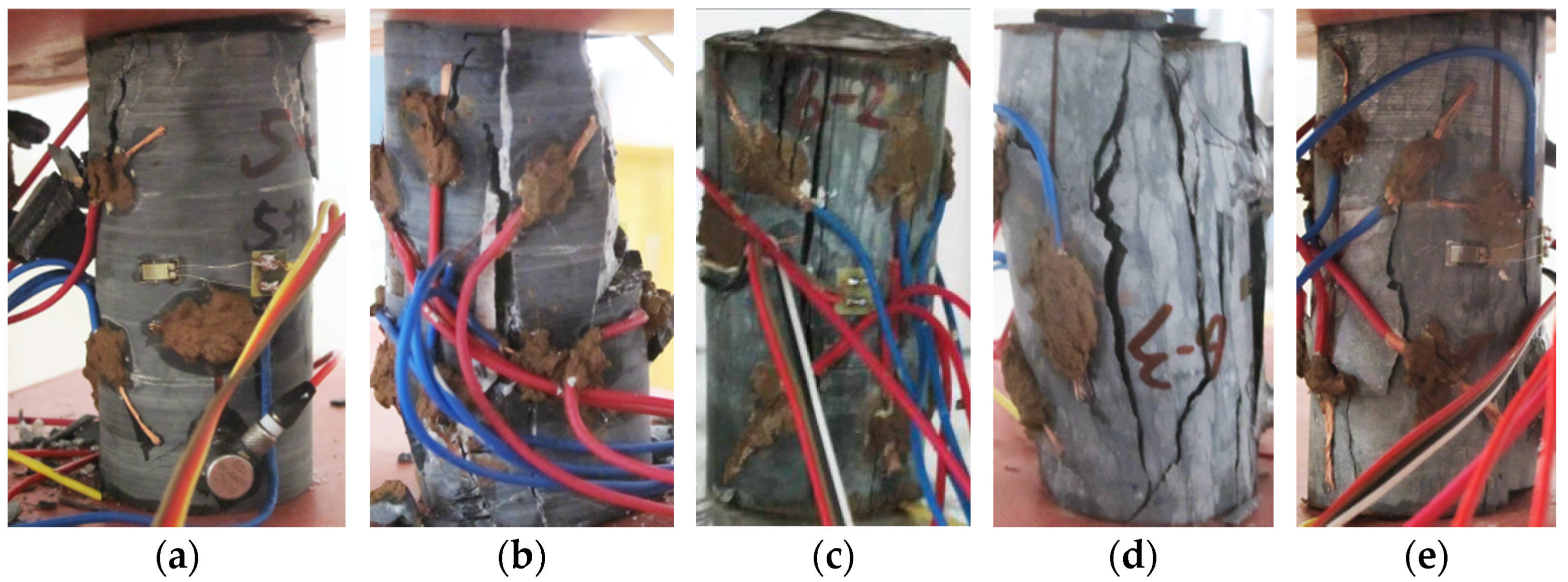

3. Test Results

4. Test Result Analysis

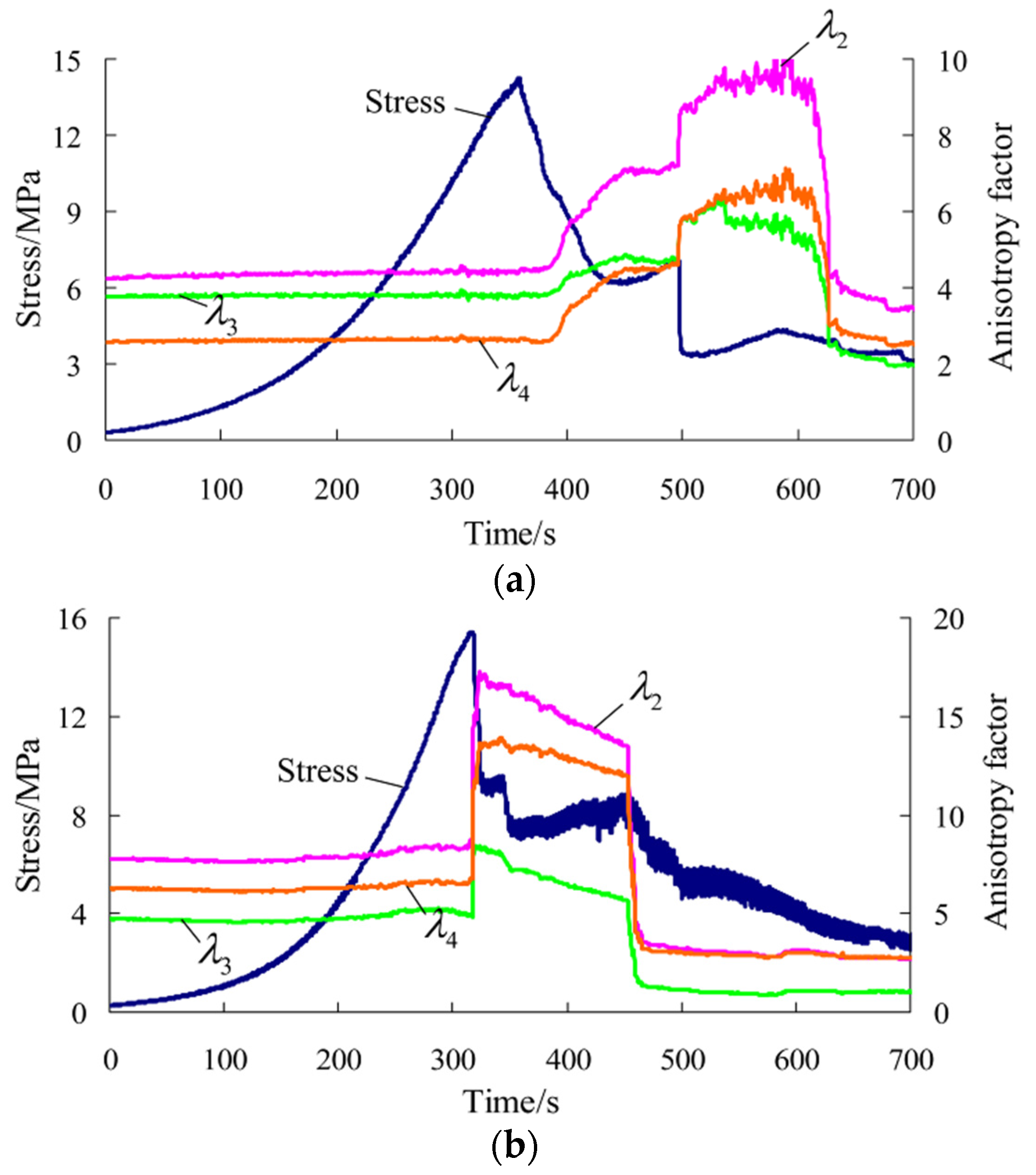

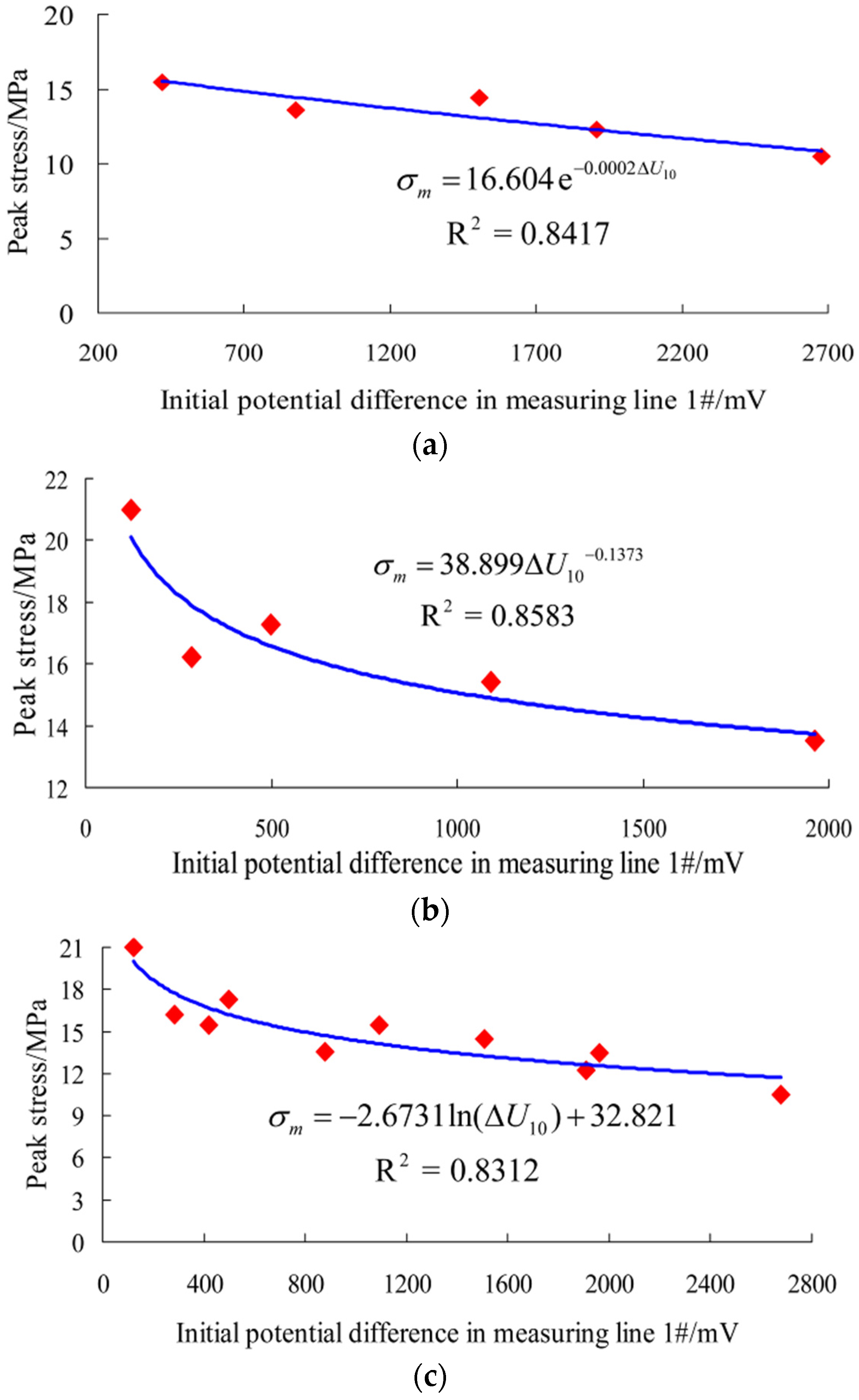

4.1. Analysis on the Conductivity of Rock Samples in Uniaxial Compression

4.2. Analysis of the Anisotropic Change Laws of the Conductivity of Rock Samples in Uniaxial Compression

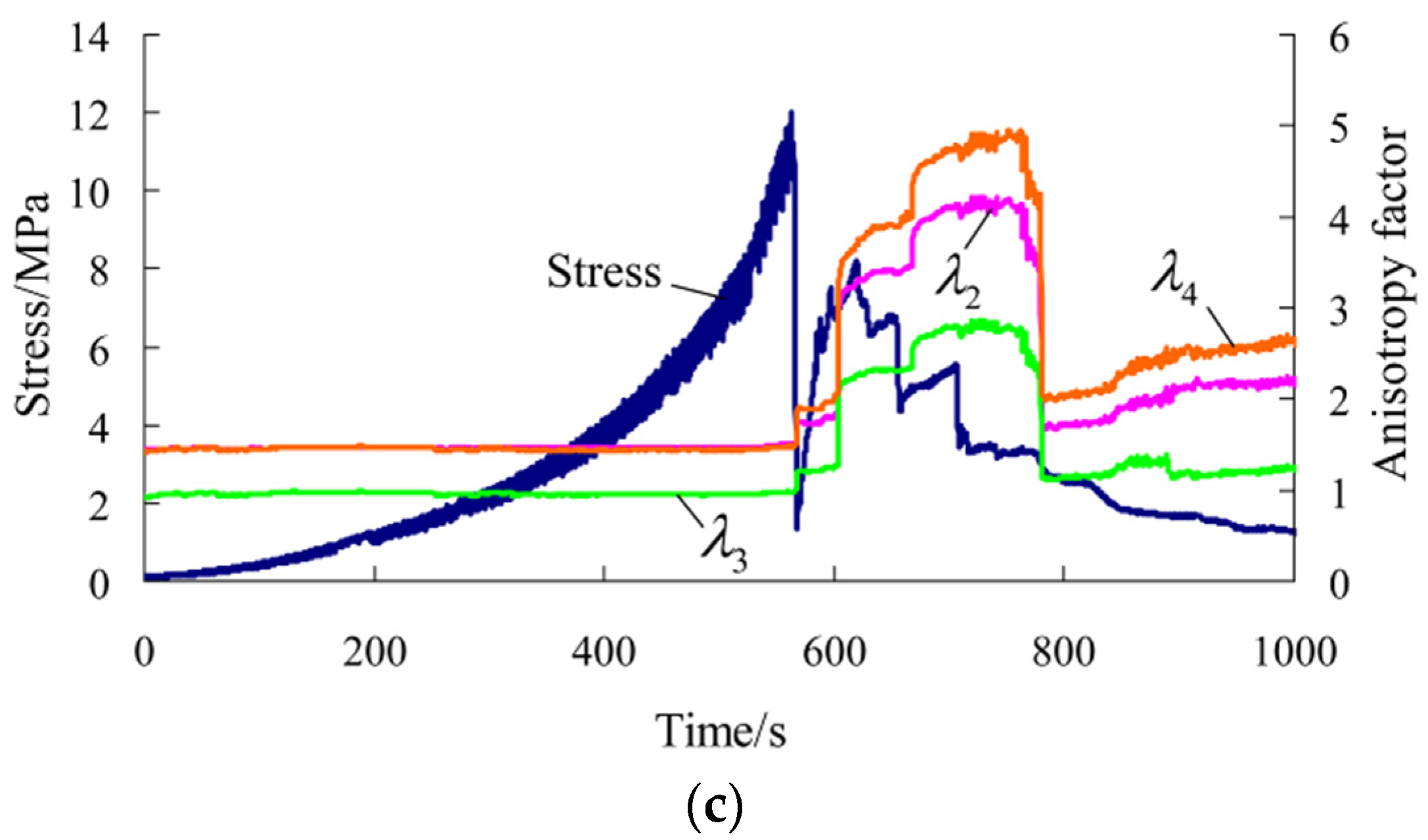

4.3. Relationship between the Initial Potential Difference Normal to the Current Direction and the Uniaxial Compressive Strength

5. Discussion and Conclusions

5.1. Discussion

5.2. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pan, P.Z.; Feng, X.T.; Shen, L.F.; Yang, J.B.; Zhou, H. Study of anisotropic creep behavior of fracture granite. Chin. J. Rock Mech. Eng. 2011, 30, 36–44. [Google Scholar]

- Gao, C.Y.; Xu, J.; Li, Z.H.; Deng, J.H. Experimental study of anisotropically mechanical characteristics of sandy slate in Xuefeng mountain tunnel. Rock Soil Mech. 2011, 32, 1360–1364. [Google Scholar]

- Liu, K.D.; Liu, Q.S.; Zhu, Y.G.; Liu, B. Experimental study of coal considering directivity effect of bedding plane under brazilian splitting and uniaxial compression. Chin. J. Rock Mech. Eng. 2013, 32, 308–316. [Google Scholar]

- Teisseyre, K. Anisotropy of electric resistivity related to crack processes before fracturing. Acta Geophys. Pol. 1989, 37, 185–192. [Google Scholar]

- Abousrafa, E.M.; Somerville, J.M.; Hamilton, S.A.; Olden, P.W.H. A laboratory measurement technique for axial and radial resistivity at ambient or reservoir stress state conditions. J. Pet. Sci. Eng. 2013, 102, 57–65. [Google Scholar] [CrossRef]

- Samouëlian, A.; Richard, G.; Cousin, I.; Guerin, R.; Bruand, A.; Tabbagh, A. Three-dimensional crack monitoring by electrical resistivity measurement. Eur. J. Soil Sci. 2004, 55, 751–762. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Q.Y.; Hang, Y.Y.; Liu, H.L.; Dai, S.H.; Xu, J.P. The anisotropic properties of rock resistivity during saturation and desaturation processes revealed by electrical resistivity tomography. Chin. J. Geophys. 2009, 52, 281–288. [Google Scholar]

- Zhu, T.; Zhou, J.G.; Hao, J.Q. Resistivity anisotropy and its application to earthquake research. Prog. Geophys. 2009, 24, 871–878. [Google Scholar]

- Wang, J.X.; Zhao, M.J.; Su, C.M. Research review of resistivity variation characteristic under load conditions of rock. J. Chongqing Jiaotong Univ. 2011, 30, 419–423. [Google Scholar]

- Brace, W.F.; Orange, A.S. Electrical resistivity changes in saturated rocks during fracture and frictional sliding. J. Geophys. Res. 1968, 73, 1433–1445. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Lu, Y.Q. Experimental studies on resistivity changes of rock samples under tri-axial pressure. Acta Seismol. Sin. 1983, 5, 440–445. [Google Scholar]

- Chen, D.Y.; Chen, F.; Wang, L.H. Studies on resistivity of rock samples under uniaxial pressure-anisotropy of resistivity. Chin. J. Geophys. 1983, 26, 784–792. [Google Scholar]

- An, J.Z.; Xiu, J.G.; Chen, F.; Chen, D.Y. Anisotropy studies of rock resistivity changes under uniaxial pressure and water replenishment. Earthq. Res. China 1996, 12, 300–306. [Google Scholar]

- Chen, Y.F. The directivity of electrical resistivity under stress rock and its application in earthquake prediction. S. China J. Seismol. 1993, 13, 1–8. [Google Scholar]

- Chen, F.; Xiu, J.G.; An, J.Z.; Liao, C.T.; Chen, D.Y. Detecting rupture precursors and determining the main fracture spread direction of rock with dynamic rock resistivity change anisotropy. Acta Seismol. Sin. 2000, 22, 210–213. [Google Scholar] [CrossRef]

- Chen, F.; Xiu, J.G.; An, J.Z.; Liao, C.T.; Chen, D.Y. Research on dependence of resistivity changing anisotropy on microcracks extending in rock with experiment. Acta Seismol. Sin. 2000, 22, 310–318. [Google Scholar]

- Chen, F.; An, J.Z.; Liao, C.T. Directional characteristic of resistivity changes in rock of original resistivity anisotropy. Chin. J. Geophys. 2003, 46, 271–280. [Google Scholar] [CrossRef]

- Chen, F.; Ma, M.N.; An, J.Z. Relation between directional characteristics of resistivity changes and principal stress. Acta Seismol. Sinica 2013, 35, 84–93. [Google Scholar]

- Deng, T.; Han, W.F.; Bao, H.Z. On the characteristics of wave velocity variations for marbles saturated in water. Chin. J. Rock Mech. Eng. 2000, 19, 762–765. [Google Scholar]

- Deng, T.; Yang, L.D. Characteristics of velocity ratio of p-wave and s-wave for anisotropic rocks. Chin. J. Rock Mech. Eng. 2006, 25, 2023–2029. [Google Scholar]

- Deng, T.; Huang, B.C.; Yang, L.D. Anisotropy comparison of P wave and S wave velocity for compacted rocks. Rock Soil Mech. 2007, 28, 493–498. [Google Scholar]

- Deng, H.F.; Yuan, X.F.; Li, J.L.; He, M.; Luo, Q.; Zhu, M. Experimental research on influence of saturation degree on sandstone longitudinal wave velocity and strength. Chin. J. Rock Mech. Eng. 2013, 32, 1625–1631. [Google Scholar]

- Ulusay, R.; Hudson, J.A. The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006; The ISRM Turkish National Group: Ankara, Turkey, 2007. [Google Scholar]

- Li, S.C.; Xu, X.J.; Liu, Z.Y.; Yang, W.M.; Liu, B.; Zhang, X.; Wang, Z.C.; Nie, L.C.; Li, J.L.; Xu, L. Electrical resistivity and acoustic emission response characteristics and damage evolution of sandstone during whole process of uniaxial compression. Chin. J. Rock Mech. Eng. 2014, 33, 14–23. [Google Scholar] [CrossRef]

- Ji, H.G.; Xiang, P.; Zhang, L.; Han, F.; Yang, Z.J. Experimental study and detection analysis of mechanical properties variability of rock mass in excavation disturbance. Chin. J. Rock Mech. Eng. 2011, 30, 2352–2359. [Google Scholar]

- Zhang, X.P.; Wang, S.J.; Han, G.Y.; Zhang, B. Crack propagation study of rock based on uniaxial compressive test—A case study of schistose rock. Chin. J. Rock Mech. Eng. 2011, 30, 1772–1781. [Google Scholar]

- Zhang, G.K.; Li, H.B.; Xia, X.; Li, J.R.; Yu, C.; Liu, J.S. Research on energy and damage evolution of rock under uniaxial compression. Rock Soil Mech. 2015, 36, 94–100. [Google Scholar]

- Lajtai, E.Z. Microscopic fracture processes in a granite. Rock Mech. Rock Eng. 1998, 31, 237–250. [Google Scholar] [CrossRef]

- Diederichs, M.S. The 2003 canadian geotechnical colloquium: Mechanistic interpretation and practical application of damage and spalling prediction criteria for deep tunnelling. Can. Geotech. J. 2007, 44, 1082–1116. [Google Scholar] [CrossRef]

- Brace, W.F.; Paulding, B.W.; Scholz, C.H. Dilatancy in the fracture of crystalline rocks. J. Geophys. Res. 1966, 71, 3939–3953. [Google Scholar] [CrossRef]

- Brady, B.T.; Duvall, W.I.; Horino, F.G. An experimental determination of the true uniaxial stress-strain behavior of brittle rock. Rock Mech. 1973, 5, 107–120. [Google Scholar] [CrossRef]

- Deng, H.F.; Li, J.L.; Deng, C.J.; Wang, L.H.; Lu, T. Analysis of sampling in rock mechanics test and compressive strength prediction methods. Rock Soil Mech. 2011, 32, 3399–3403. [Google Scholar]

| Serial Number | Diameter (D/mm) | Height (H/mm) | Peak Stress (σm/MPa) | Peak Strain (εm/10−3) | Initial Potential Difference in Measuring Line 1# (ΔU10/mV) |

|---|---|---|---|---|---|

| 6-1 | 49.10 | 103.00 | 14.43 | 11.46 | 1506.21 |

| 6-5 | 49.18 | 103.11 | 10.46 | 16.25 | 2677.00 |

| 7-1 | 49.16 | 101.82 | 15.47 | 10.45 | 419.80 |

| 7-2 | 49.22 | 102.90 | 13.60 | 9.80 | 877.00 |

| 7-3 | 49.00 | 102.58 | 12.26 | 18.41 | 1907.95 |

| Average | 49.13 | 102.68 | 13.24 | 13.27 | 1477.59 |

| Variation coefficient | 0.08 | 0.47 | 1.74 | 3.42 | 787.94 |

| Serial Number | Diameter (D/mm) | Height (H/mm) | Peak Stress (σm/MPa) | Peak Strain (εm/10−3) | Initial Potential Difference in Measuring Line 1# (ΔU10/mV) |

|---|---|---|---|---|---|

| 5-1 | 49.28 | 101.70 | 17.26 | 19.75 | 499.45 |

| 5-2 | 49.04 | 101.58 | 16.20 | 28.81 | 285.43 |

| 6-2 | 49.16 | 102.50 | 20.98 | 14.66 | 121.83 |

| 6-3 | 49.21 | 102.22 | 13.50 | 17.34 | 1960.92 |

| 6-4 | 49.00 | 102.34 | 15.42 | 20.09 | 1090.60 |

| Average | 49.14 | 102.07 | 16.67 | 20.13 | 791.65 |

| Variation coefficient | 0.10 | 0.36 | 2.48 | 4.76 | 670.35 |

| Regression Equation Type | Rock Samples Parallel to the Bedding Direction | Rock Samples Normal to the Bedding Direction | All Samples |

|---|---|---|---|

| Linear | 0.8400 | 0.6893 | 0.7400 |

| Logarithm | 0.7397 | 0.8430 | 0.8312 |

| Power | 0.7175 | 0.8583 | 0.8089 |

| Exponent | 0.8417 | 0.7470 | 0.7939 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Liu, B.; Li, S.; Yang, L.; Song, J.; Li, M.; Mei, J. Experimental Study on Conductivity Anisotropy of Limestone Considering the Bedding Directional Effect in the Whole Process of Uniaxial Compression. Materials 2016, 9, 165. https://doi.org/10.3390/ma9030165

Xu X, Liu B, Li S, Yang L, Song J, Li M, Mei J. Experimental Study on Conductivity Anisotropy of Limestone Considering the Bedding Directional Effect in the Whole Process of Uniaxial Compression. Materials. 2016; 9(3):165. https://doi.org/10.3390/ma9030165

Chicago/Turabian StyleXu, Xinji, Bin Liu, Shucai Li, Lei Yang, Jie Song, Ming Li, and Jie Mei. 2016. "Experimental Study on Conductivity Anisotropy of Limestone Considering the Bedding Directional Effect in the Whole Process of Uniaxial Compression" Materials 9, no. 3: 165. https://doi.org/10.3390/ma9030165