3.1. Results of the Bending Test

Each test sample met grade quality index (GQI) requirements, under which the difference between the observed GQI of the samples and the assumed GQI of the grade must be 5% or less of the total range of possible GQI [

20]. An observed GQI for each test sample can be calculated for all specimens that did not fail in clear wood [

17,

20]. The difference between the observed GQI of the samples and the assumed GQI of the grade was less than 5%. Thus, the observed GQI of test data could be used to represent the grades of the samples.

Table 2 shows the mean value, standard deviation, and coefficient of variation (COV) of the final MOR

15 for each size of lumber. Results indicated that the MOR

15 is correlated to the size. The MOR

15 values showed highly significant (

p < 0.05,

F-test ANOVA) differences between different sizes of dimension lumber, except pairs 2 × 3

vs. 2 × 4 of grade No. 3, and 2 × 4

vs. 2 × 6 of grade No. 3 (

Table 3). For the same grade of lumber, the bigger the size, the smaller the MOR

15. For instance, the mean value of MOR

15 of grade SS for 2 × 3 was 72.1 MPa, 1.11, 1.30 times that of 2 × 4, and 2 × 6, respectively. Similar results were obtained in previous studies [

4,

28].

Table 3.

One-way analysis of variance (ANOVA) test results of MOR15 for different lumber sizes.

Table 3.

One-way analysis of variance (ANOVA) test results of MOR15 for different lumber sizes.

| Grade | Significance |

|---|

| 2 × 3 vs. 2 × 4 | 2 × 3 vs. 2 × 6 | 2 × 4 vs. 2 × 6 |

|---|

| SS | ** | *** | *** |

| No. 1 | *** | - | - |

| No. 2 | ** | ** | 0.320 |

| No. 3 | 0.300 | - | - |

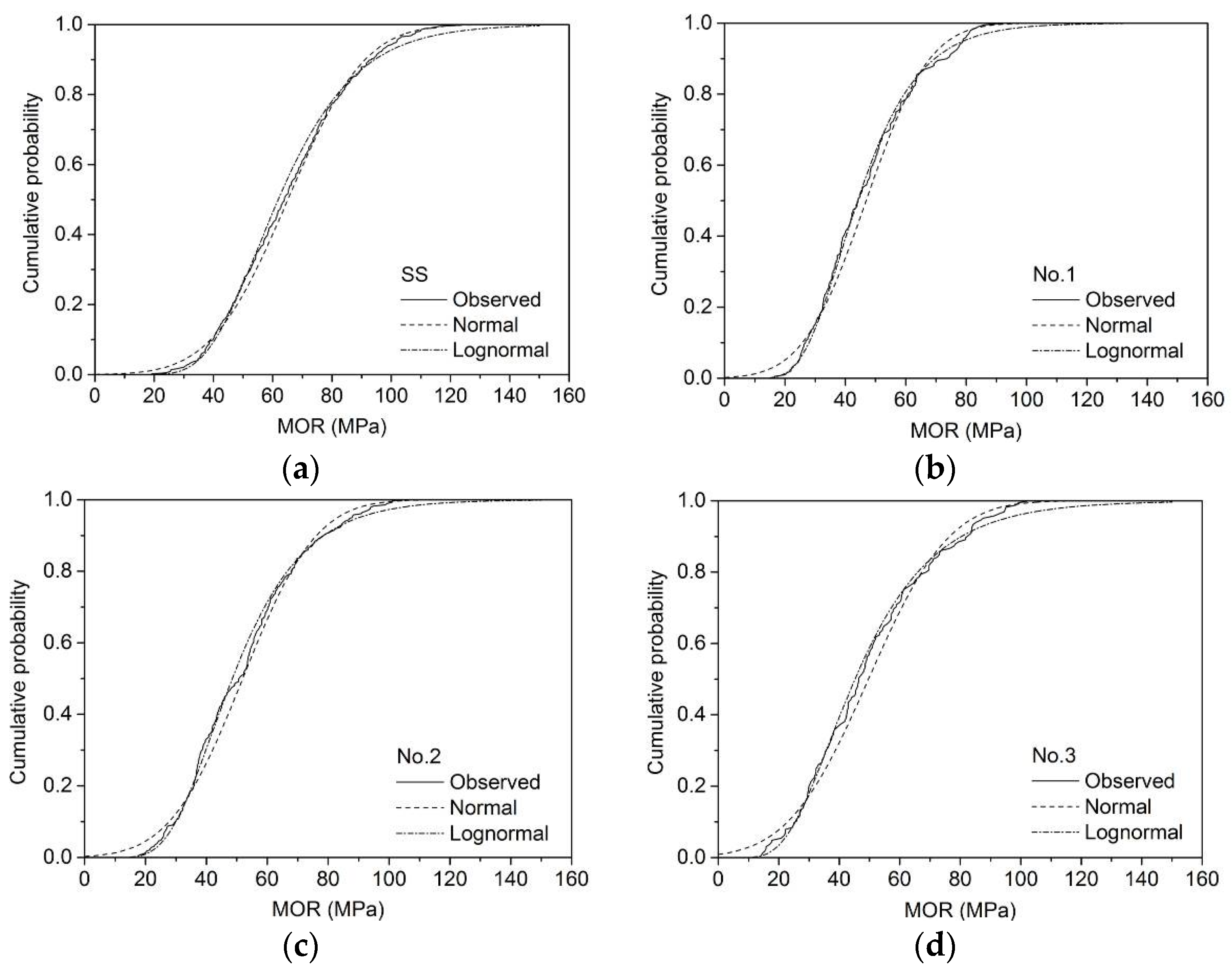

3.2. Probability Distribution

The cumulative probability distributions of MOR

15 for different sizes are presented in

Figure 1,

Figure 2 and

Figure 3. The unknown parameters μ and σ were calculated according to Equations (4)–(8). For example, the estimated μ and σ of MOR

15 of SS grade for 2 × 4 larch lumber were 65.1 and 20.3 MPa, while logarithmic MOR

15 values were 4.12 and 0.328 MPa, respectively (

Table 4).

Figure 1.

Normal and lognormal fit of MOR15 for 2 × 3 lumber: (a) SS; (b) No. 1; (c) No. 2; (d) No. 3.

Figure 1.

Normal and lognormal fit of MOR15 for 2 × 3 lumber: (a) SS; (b) No. 1; (c) No. 2; (d) No. 3.

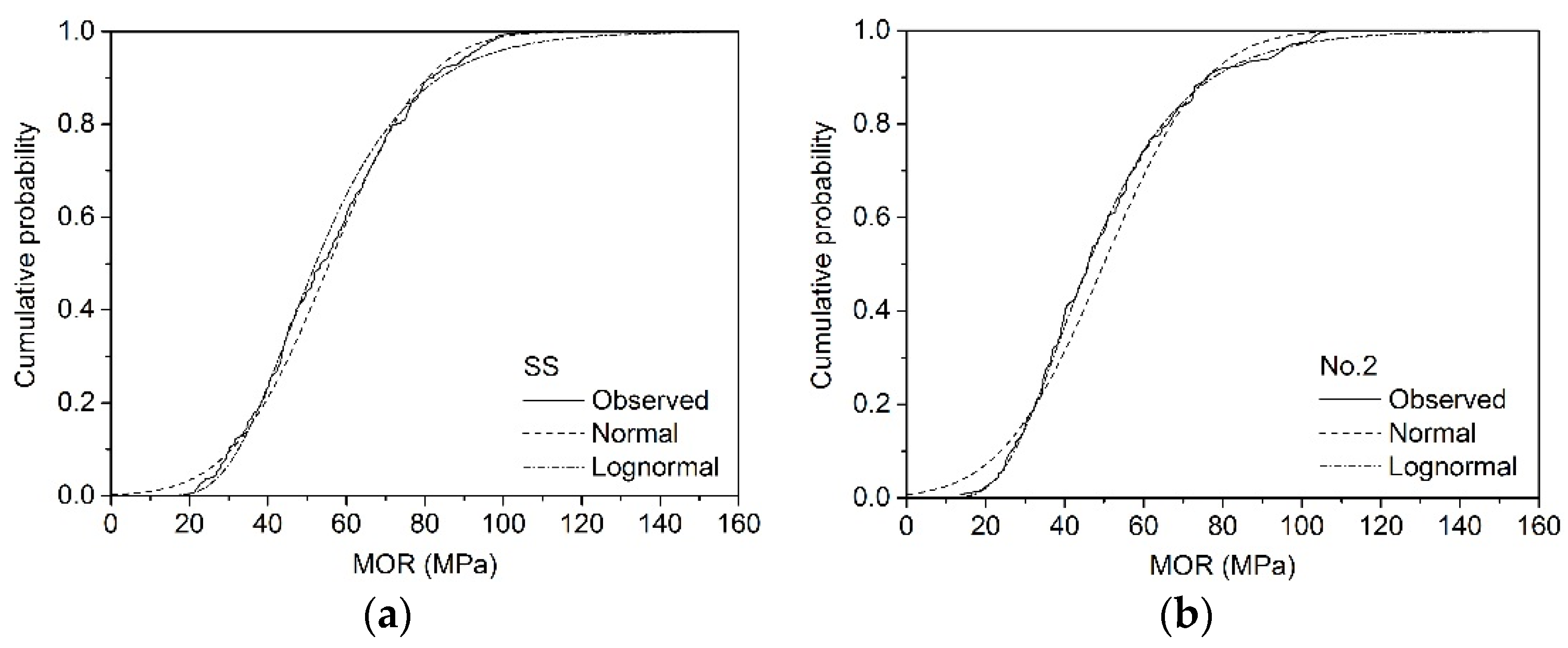

Figure 2.

Normal and lognormal fit of MOR15 for 2 × 4 lumber: (a) SS; (b) No. 1; (c) No. 2; (d) No. 3.

Figure 2.

Normal and lognormal fit of MOR15 for 2 × 4 lumber: (a) SS; (b) No. 1; (c) No. 2; (d) No. 3.

Figure 3.

Normal and lognormal fit of MOR15 for 2 × 6 lumber: (a) SS; (b) No. 2.

Figure 3.

Normal and lognormal fit of MOR15 for 2 × 6 lumber: (a) SS; (b) No. 2.

Table 4.

Calculation table of , and chi-square χ2 of MOR15 of SS grade larch 2 × 4 lumber.

Table 4.

Calculation table of , and chi-square χ2 of MOR15 of SS grade larch 2 × 4 lumber.

| Interval | Interval Center | Observed Numbers (ni) | Probability () | Predicted Numbers () |

|---|

| Normal | Lognormal | Normal | Lognormal |

|---|

| [15, 20] | 17.5 | 1 | 0.0180 | 0.0003 | 7.7215 | 0.1228 |

| [20, 25] | 22.5 | 2 | 0.0235 | 0.0026 | 10.0771 | 1.1236 |

| [25, 30] | 27.5 | 5 | 0.0298 | 0.0109 | 12.7685 | 4.6816 |

| [30, 35] | 32.5 | 11 | 0.0366 | 0.0277 | 15.7082 | 11.9015 |

| [35, 40] | 37.5 | 25 | 0.0437 | 0.0508 | 18.7624 | 21.8053 |

| [40, 45] | 42.5 | 31 | 0.0507 | 0.0743 | 21.7583 | 31.8568 |

| [45, 50] | 47.5 | 38 | 0.0571 | 0.0923 | 24.4986 | 39.5891 |

| [50, 55] | 52.5 | 37 | 0.0624 | 0.1018 | 26.7815 | 43.6884 |

| [55, 60] | 57.5 | 35 | 0.0663 | 0.1028 | 28.4253 | 44.1028 |

| [60, 65] | 62.5 | 36 | 0.0683 | 0.0970 | 29.2922 | 41.5938 |

| [65, 70] | 67.5 | 41 | 0.0683 | 0.0867 | 29.3073 | 37.2154 |

| [70, 75] | 72.5 | 38 | 0.0664 | 0.0745 | 28.4693 | 31.9526 |

| [75, 80] | 77.5 | 32 | 0.0626 | 0.0619 | 26.8507 | 26.5543 |

| [80, 85] | 82.5 | 22 | 0.0573 | 0.0501 | 24.5873 | 21.5030 |

| [85, 90] | 87.5 | 23 | 0.0510 | 0.0398 | 21.8597 | 17.0551 |

| [90, 95] | 92.5 | 13 | 0.0440 | 0.0310 | 18.8692 | 13.3038 |

| [95, 100] | 97.5 | 14 | 0.0369 | 0.0239 | 15.8139 | 10.2396 |

| [100, 105] | 102.5 | 10 | 0.0300 | 0.0182 | 12.8678 | 7.7969 |

| [105, 110] | 107.5 | 8 | 0.0237 | 0.0137 | 10.1659 | 5.8860 |

| [110, 115] | 112.5 | 3 | 0.0182 | 0.0103 | 7.7976 | 4.4130 |

| [115, 120] | 117.5 | 2 | 0.0135 | 0.0077 | 5.8071 | 3.2907 |

| [120, 125] | 122.5 | 2 | 0.0098 | 0.0057 | 4.1988 | 2.4434 |

| Sum | - | N = 429 | - | - | 402.388 | 422.120 |

Both the χ

2 (Equation (9)) and K-S (Equation (10)) test values of different sizes of larch lumber are shown in

Table 5. Results indicated that the lognormal distribution fitted the bending test data much better than the normal distribution for all sizes except the SS grade of 2 × 3, SS grade of 2 × 4, and No. 2 grade of 2 × 4. Findings presented by Dahlen

et al. [

29] similarly showed that the lognormal distribution model provides a better fit for Douglas fir and Southern pine 2 × 4 lumber.

The assumed

F0(

x) can be considered a good fit for the

F(

x) obtained by the static bending test when the critical value, which is dependent on probability levels, is greater than the test value [

21]. At a probability level of 0.05, the χ

2 test results showed that normal distribution fitting did not provide accurate results for most sizes, the exceptions being grade No. 1 of 2 × 3 and No. 3 of 2 × 4 larch lumber. Conversely, lognormal distribution fit the data well for grade SS of 2 × 4 (19.8 < 30.1), No. 1 of 2 × 3 (14.3 < 26.3) and 2 × 4 (17.6 < 22.4), No. 2 of 2 × 6 (11.3 < 27.6), and No. 3 of 2 × 3 (22.1 < 32.7) and 2 × 4 (14.8 < 26.3). When the probability level increased to 0.01, the lognormal distribution provided good fitting results for all sizes apart from SS of 2 × 3 and No. 2 of 2 × 4 (

Table 5). The K-S test results showed that both the normal and lognormal distribution can provide a good fit at probability levels of 0.05 and 0.01. In this paper, lognormal distribution was thus selected for the following reliability analysis.

Table 5.

χ2-values for bending strength adjusted to 15% moisture content (MOR15) for Chinese larch.

Table 5.

χ2-values for bending strength adjusted to 15% moisture content (MOR15) for Chinese larch.

| Grade | Size | χ2 | = 0.05 | = 0.01 | Dmax | Da = 0.05 | Da = 0.01 |

|---|

| Normal | Lognormal | Normal | Lognormal |

|---|

| SS | 2 × 3 | 33.08 | 45.29 | 32.67 | 38.93 | 0.066 | 0.087 | 0.094 | 0.113 |

| 2 × 4 | 57.77 | 19.79 | 30.14 | 36.19 | 0.045 | 0.048 | 0.066 | 0.079 |

| 2 × 6 | 29.67 | 29.15 | 27.59 | 33.41 | 0.068 | 0.057 | 0.086 | 0.102 |

| No. 1 | 2 × 3 | 19.11 | 14.28 | 26.30 | 32.00 | 0.073 | 0.067 | 0.130 | 0.156 |

| 2 × 4 | 33.51 | 17.62 | 22.36 | 27.69 | 0.078 | 0.037 | 0.096 | 0.115 |

| No. 2 | 2 × 3 | 35.53 | 30.57 | 28.87 | 34.81 | 0.074 | 0.064 | 0.085 | 0.102 |

| 2 × 4 | 39.45 | 89.28 | 25.00 | 30.58 | 0.075 | 0.070 | 0.081 | 0.097 |

| 2 × 6 | 34.32 | 11.30 | 27.59 | 33.41 | 0.091 | 0.033 | 0.117 | 0.141 |

| No. 3 | 2 × 3 | 35.40 | 22.05 | 32.67 | 38.93 | 0.066 | 0.054 | 0.081 | 0.097 |

| 2 × 4 | 23.98 | 14.84 | 26.30 | 32.00 | 0.073 | 0.058 | 0.117 | 0.141 |

3.3. Reliability Analysis

Table 6 shows the characteristic values of MOR

15 (

fk) calculated by Equation (11). The

fk value generally decreased alongside the reduction in strength of size. For instance, the

fk for grade SS of 2 × 3 was 38.2 MPa, 0.061, 0.345 times higher than those of 2 × 4 and 2 × 6, respectively. The γ

R values were determined according to the reliability analysis described below.

Table 6.

Characteristic values of MOR15.

Table 6.

Characteristic values of MOR15.

| Grade | SS | No. 1 | No. 2 | No. 3 |

|---|

| Size | 2 × 3 | 2 × 4 | 2 × 6 | 2 × 3 | 2 × 4 | 2 × 3 | 2 × 4 | 2 × 6 | 2 × 3 | 2 × 4 |

| fk (MPa) | 38.2 | 36.0 | 28.4 | 27.8 | 24.5 | 28.4 | 26.1 | 23.5 | 22.9 | 21.6 |

According to the authors’ previous research [

13,

14], random variables of bending resistance (

R) are also distributed lognormally. The calculated mean value and COV of

R for larch lumber are shown in

Table 7 based on statistical theory.

Table 7.

Summary of the resistance stress (R) statistics.

Table 7.

Summary of the resistance stress (R) statistics.

| Grade | Size | R (MPa) |

|---|

| Mean Value | SD | COV (%) |

|---|

| SS | 2 × 3 | 48.8 | 17.3 | 35.5 |

| 2 × 4 | 44.1 | 15.3 | 34.8 |

| 2 × 6 | 37.7 | 14.4 | 38.2 |

| No. 1 | 2 × 3 | 38.1 | 15.3 | 40.1 |

| 2 × 4 | 31.7 | 12.2 | 38.3 |

| No. 2 | 2 × 3 | 38.3 | 14.9 | 38.8 |

| 2 × 4 | 35.1 | 13.9 | 39.4 |

| 2 × 6 | 33.8 | 14.7 | 43.6 |

| No. 3 | 2 × 3 | 35.0 | 15.4 | 44.1 |

| 2 × 4 | 33.6 | 15.0 | 44.8 |

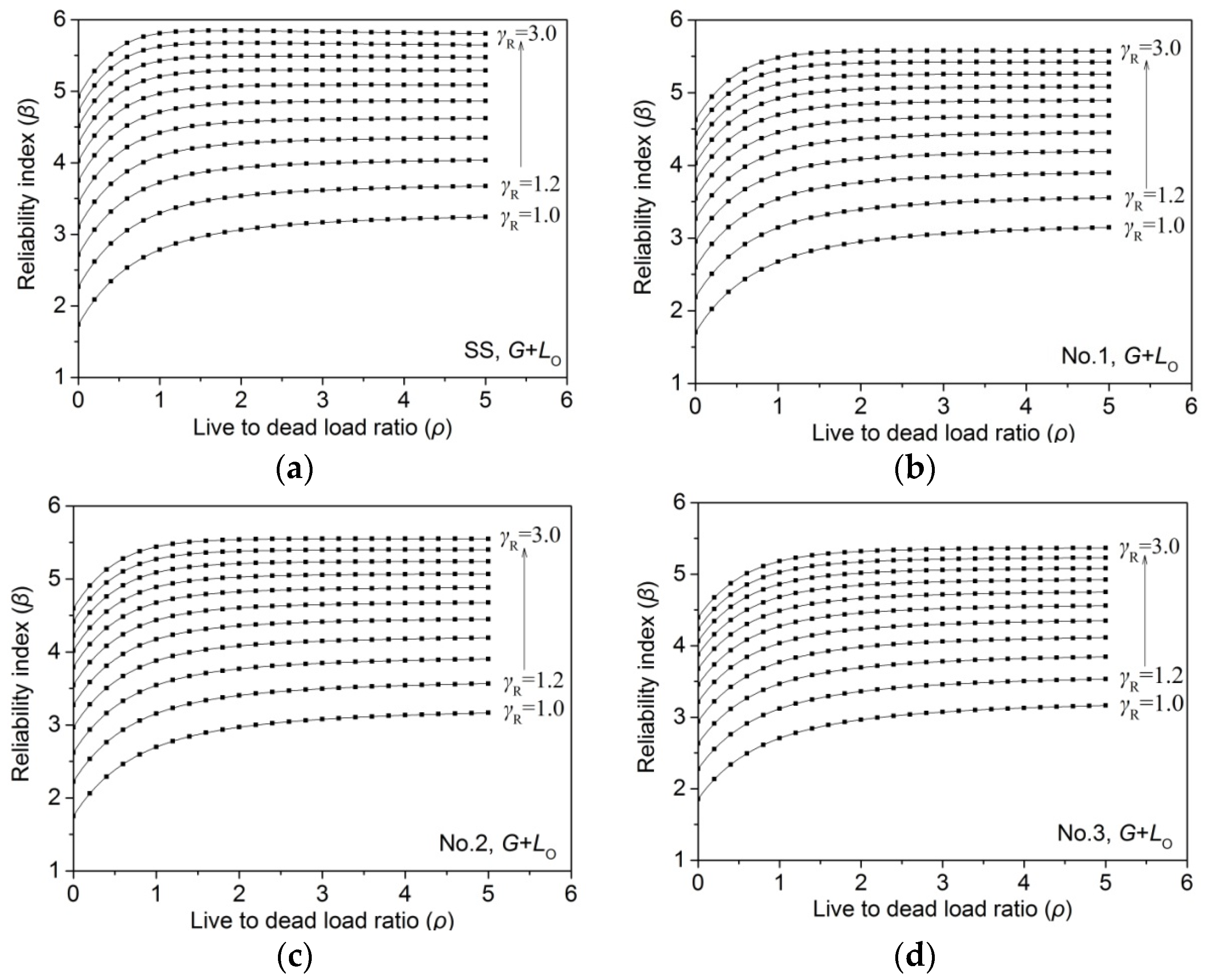

Reliability analysis results indicated that β increased nonlinearly as live-to-dead load ratio (ρ) increased in all the simulation load cases. As an example, the relationship between β and ρ of 2 × 4 larch lumber, under dead load (

G) plus live office load (

LO), are shown in

Figure 4. Several previous studies [

13,

25,

26,

27,

30] achieved a similar result regarding the relationship between ρ and β.

Figure 4.

Relationship between reliability index (β) and live-to-dead load ratio (ρ) for larch 2 × 4 lumber under G + LO: (a) SS; (b) No. 1; (c) No. 2; (d) No. 3.

Figure 4.

Relationship between reliability index (β) and live-to-dead load ratio (ρ) for larch 2 × 4 lumber under G + LO: (a) SS; (b) No. 1; (c) No. 2; (d) No. 3.

The reliability level must meet the target level (β

0 = 3.2) to effectively determine the MOR

15 design value [

24]. In order to evaluate the reliability level, the live-to-dead load ratio (ρ) was specified as 0.25, 0.5, 0.75, 1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5, 2.75, and 3.0 for each load combination (

G +

LO,

G +

LR,

G +

LW, and

G +

LS), respectively, according to the Chinese National Standard [

22], then the average of reliability index was calculated under different load ratios. The relationship between the average reliability index and the partial safety factor is shown in

Figure 5.

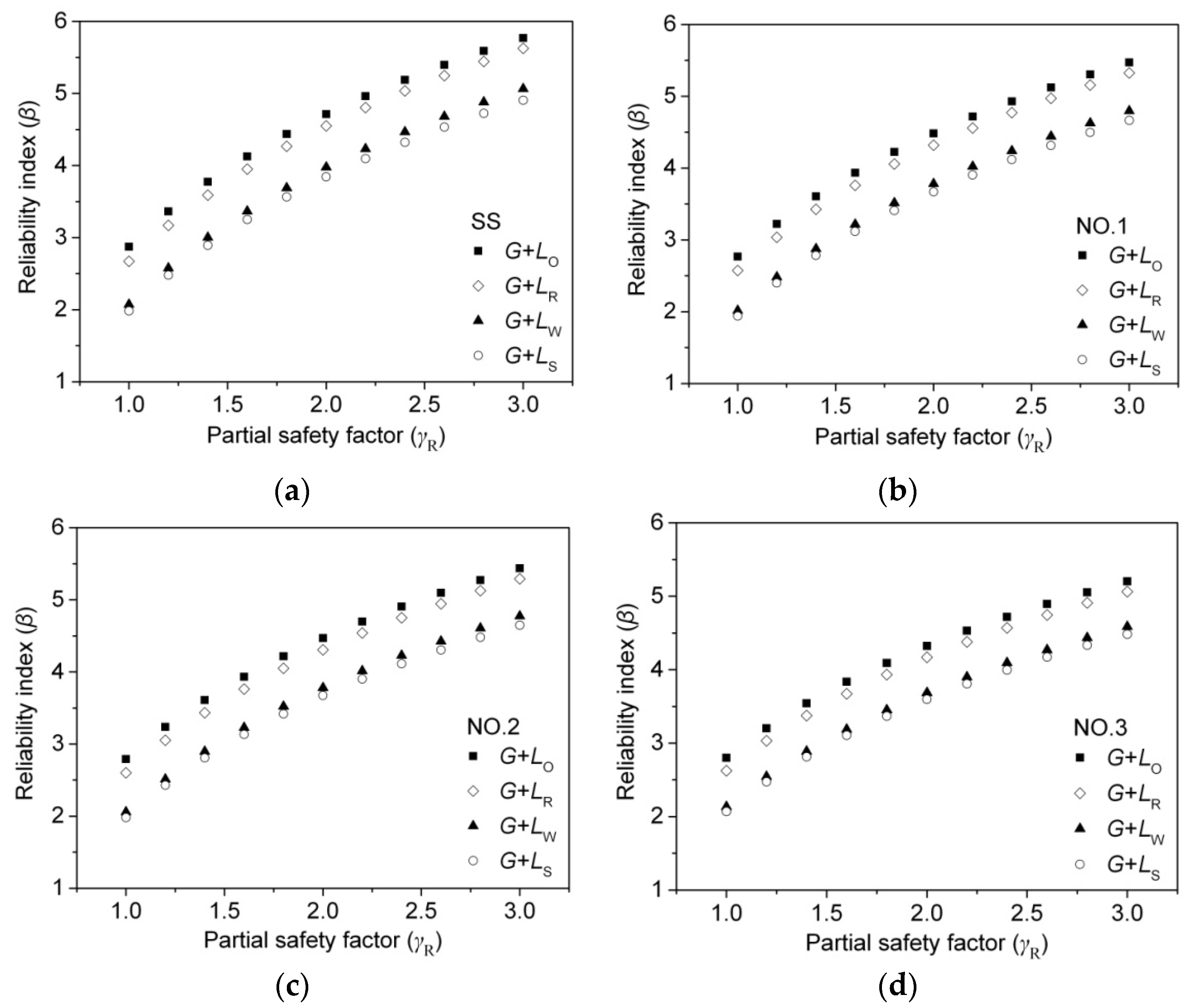

As shown in

Figure 5, β increased nonlinearly with the increase of the partial safety factor (γ

R) in all simulation load cases,

G +

LO,

G +

LR,

G +

LW, and

G +

LS. For the same ratio of live-to-dead load (ρ), the simulated load cases of the maximum and minimum β were

G +

LO and

G +

LS, respectively. This is consistent with the findings of previous researchers [

13,

25,

26,

27]. The partial safety factor (γ

R) of all sizes of larch lumber was obtained, as mentioned above, by taking the average of all simulation load cases. In order to obtain β, the linear, cubic, logarithmic, and inverse models were utilized to predict the relationship between β and γ

R. For example, the predicted result of grade SS of 2 × 4 larch lumber is shown in

Figure 6.

Figure 5.

Relationship between reliability index (β) and partial safety factor (γR) for larch 2 × 4 lumber under G + LO: (a) SS; (b) No. 1; (c) No. 2; (d) No. 3.

Figure 5.

Relationship between reliability index (β) and partial safety factor (γR) for larch 2 × 4 lumber under G + LO: (a) SS; (b) No. 1; (c) No. 2; (d) No. 3.

Figure 6.

Prediction of reliability index (β) by partial safety factor (γR) of grade SS for 2 × 4 lumber.

Figure 6.

Prediction of reliability index (β) by partial safety factor (γR) of grade SS for 2 × 4 lumber.

Fitting results indicated that the linear, cubic, logarithmic, and inverse models precisely predicted β as a function of γ

R for all sizes of larch lumber, though the logarithmic model (which was thus used for the reliability index calculation) fitted the data slightly better than other models.

Table 8 shows all the fitting results for 2 × 4 larch lumber as an example, with standard errors of 0.006, 0.004, 0.004, and 0.002 for grades SS, No. 1, No. 2, and No. 3, respectively.

Table 8.

Fitting results by various models for larch 2 × 4 lumber.

Table 8.

Fitting results by various models for larch 2 × 4 lumber.

| Grade | Model | Calculation Formula | r2 | Std. Error | γR (β = β0 = 3.2) | fd (MPa) |

|---|

| SS | Linear | y = 1.263 + 1.427x | 0.975 | 0.159 | 1.357 | 19.1 |

| Logarithmic | y = 2.411 + 2.674lnx | 1.000 | 0.006 | 1.342 | 19.3 |

| Inverse | y = 6.612 − (4.444/x) | 0.978 | 0.150 | 1.303 | 19.9 |

| Cubic | y = −1.138 + 4.678x − 1.278x2 + 0.146x3 | 1.000 | 0.007 | 1.345 | 19.2 |

| No. 1 | Linear | y = 1.261 + 1.330x | 0.976 | 0.147 | 1.458 | 12.1 |

| Logarithmic | y = 2.332 + 2.492lnx | 1.000 | 0.004 | 1.417 | 12.5 |

| Inverse | y = 6.247 − (4.141/x) | 0.977 | 0.142 | 1.360 | 13.0 |

| Cubic | y = −0.949 + 4.321x − 1.174x2 + 0.134x3 | 1.000 | 0.007 | 1.417 | 12.5 |

| No. 2 | Linear | y = 1.317 + 1.301x | 0.976 | 0.143 | 1.447 | 13.0 |

| Logarithmic | y = 2.365 + 2.438lnx | 1.000 | 0.004 | 1.408 | 13.4 |

| Inverse | y = 6.193 − (4.050/x) | 0.977 | 0.139 | 1.354 | 13.9 |

| Cubic | y = −0.838 + 4.216x − 1.144x2 + 0.131x3 | 1.000 | 0.007 | 1.411 | 13.3 |

| No. 3 | Linear | y = 1.461 + 1.179x | 0.976 | 0.129 | 1.475 | 10.5 |

| Logarithmic | y = 2.410 + 2.209lnx | 1.000 | 0.002 | 1.429 | 10.9 |

| Inverse | y = 5.879 − (3.669/x) | 0.977 | 0.127 | 1.369 | 11.4 |

| Cubic | y = −0.470 + 3.790x − 1.023x2 + 0.117x3 | 1.000 | 0.006 | 1.432 | 10.9 |

According to the above reliability analysis, plus the requirements for the minimum reliability index (β > β

0 = 3.2) [

22], the suggested design values of MOR

15 and partial safety factors are shown in

Table 9. For instance, the partial safety factors which satisfied the conditions γ

R ≥ 1.34, 1.42, 1.41, and 1.43 for grades SS, No. 1, No. 2, and No. 3 of 2 × 4 larch lumber, respectively, can be considered safe for engineering design; the design values should be set to 19.3, 12.5, 13.4, and 10.9 MPa, as calculated by Equation (12). It is not reasonable, however, that

fd of grade No. 2 was larger than that of grade No. 1 in 2 × 3 and 2 × 4. To ensure conservative estimates and safe design, the

fd for grade No. 1 and No. 2 must have the small design value between them. Thus, the final design values of grade No. 2 in 2 × 3 and 2 × 4, which were 14.2, 13.4 MPa, respectively, were considered the same as that of grade No. 1.

Table 9 indicates that the size of larch lumber had significant impact on the design value of MOR

15. For each grade of lumber, the bigger the size, the smaller the design value of MOR

15. As an example, the design value of grade SS of 2 × 3 was 20.8 MPa, which was 1.08 and 1.40 times that of 2 × 4 and 2 × 6, respectively. It is important to note that, for convenience in practical engineering application, the design value specified in the national standard requires multiplying different adjusting factors by the same reference value for different sizes of the same grade of lumber. The design value of 2 × 3 larch lumber was selected as the reference value.

Table 9.

Design values of MOR15 and partial safety factor γR.

Table 9.

Design values of MOR15 and partial safety factor γR.

| Grade | SS | No. 1 | No. 2 | No. 3 |

|---|

| Size | 2 × 3 | 2 × 4 | 2 × 6 | 2 × 3 | 2 × 4 | 2 × 3 | 2 × 4 | 2 × 6 | 2 × 3 | 2 × 4 |

| fd (MPa) | 20.8 | 19.3 | 14.9 | 14.2 | 12.5 | 14.9 | 13.4 | 11.3 | 11.5 | 10.9 |

| γR | 1.318 | 1.342 | 1.375 | 1.411 | 1.417 | 1.375 | 1.408 | 1.492 | 1.429 | 1.429 |

The adjusting factors of 2 × 4 were 0.925, 0.900, 0.900, and 0.942 for grades SS, No. 1, No. 2 and No. 3, and those of 2 × 6 were 0.713 and 0.762 for grades SS and No. 2, respectively. These results indicate that the adjusting factors were not the same among different grades, though most countries do set the same adjusting factors for different grades in one dimension. To ensure conservative estimates and safe design, it was reasonable to set adjusting factors to 0.900, 0.713 for 2 × 4 and 2 × 6 lumber, as shown in

Figure 7. In the United States Code [

2], adjusting factors are equal to 1.0 if the section height is not more than 90 mm, and grade and adjusting factors are uncorrelated. The adjusting factors of 2 × 4 and 2 × 6 are 1.00 and 0.867 for any tree species—significantly higher than those for larch lumber.

Figure 7.

Adjusting factor of size effect (kZ) for larch lumber.

Figure 7.

Adjusting factor of size effect (kZ) for larch lumber.