1. Introduction

During the last three decades, an important shift has been carried out from traditional alloys and minerals to plastics. The shift was primarily due to easy processing, less cost and the compatibility of plastic material compared to the traditional ones. The importance is also extended to include production of biocompatible materials [

1]. Plastic materials are currently used in piping, packaging, automobiles and, most importantly, in the medical field. Recently, plastics are found to be very competitive materials in the field of injection molding where the last process for industrial manufacturing is taking place. Injection molding provides the ultimate route for dealing with a polymer or blends of copolymers. Briefly, engineering polymer includes vast and broad arrays of types of polymers, additives, properties and production processing conditions. Injection molding is a process through which materials are injected into a mold with or without a host material. The injection process depends on a variety of variables, such as filling time, packing pressure, packing time, cooling time, mold temperature, injection pressure and cooling rates.

Injection is an old technology; however, it has undergone great development in the last 60 years. Injection molding is commonly a very stable process; however, it could undergo some drawbacks, such as discontinuity and internal interaction of several variables, which might demolish the product’s good qualities. Injection molding requires appropriate parameters, which, in turn, could dramatically change the physical and mechanical properties of the product. Maximizing the injection molding parameters is another important step that can be performed via several techniques, such as the design of experiment (DOE) by Taguchi. The optimizing process is used to set the injection molding parameters in order to reduce the number of experiments and to ensure the best quality [

2].

Injection is a very complex process [

3] due to the difficulty of controlling many factors, which include the type of the plastics, additives, temperature, pressure and the cooling/heating rate. Consequently, the designing engineers found a powerful procedure to overcome most of these difficulties by using computer-aided engineer (CAE) software. By using CAE, a trial injection is made followed by a continually reiterating design throughout the simulation process. As the need for a variety of plastics with specific properties as a common practice, the software has undergone a series of improvements [

4]. Setting injection parameters depends partially on previous knowledge about the polymer and deterministically on the concept of trial and error. However, in this regard, rheology could add very important basic and fundamental knowledge about the parameters that strongly influence the injection process of plastic parts. Molten polymers are generally non-Newtonian fluids whose characterizations are very crucial in the final setting of the parameters. It is very important to note that polymer additives have a very strong influence on the rheological behavior of the molten polymer [

5]. Additives are used to enhance the physical and mechanical properties of the produced polymers, such as resistance to scratches and altering the surface visual characteristics [

6]. The tensile, thermal and wettability properties, of the nanocomposites were studied as a function of halloysite nanotubes (HNTs) content and found that it is strongly dependent on both the nature of the polymer and the HNT functionalization [

6]. The process of additives to the polymers is growing very quickly, and most of the production relies on certain experimental procedures, rather than on the simulation process [

7]. Previous research on injection molding has covered aspects that range from the effect of the parameters, the influence of additives, the cost and others. Rahman et al. [

8] suggested that the hollow frame for windows was better for a lower cost than the solid frame. The injection could be performed at high pressure; however, this factor is necessary, but it could be considered as a drawback. Injection molding and the subsequent parameters and their appropriate levels are commonly used to control the properties of the injected materials, such as thermoplastic polyurethane (TPU) and nanotubes. TPU is a unique polymeric material with special physio-chemical properties, and its versatility provides the possibility for various applications [

8]. Finnigan et al. [

9] was the first report in the literature of the preparation of layered silicate-TPU nanocomposites. Since then, a significant number of papers has been published regarding the processing, characterization and fabrication of TPU nanocomposites for high performance and multifunctions [

10]. However, most of these nanocomposites have nanoclays [

11,

12,

13,

14] and carbon nanotubes (CNTs) as fillers [

15,

16,

17].

The optimization process is an essential process in industry and research in order to characterize the best use of the parameters and to avoid an unnecessarily excessive number of experiments. In this regard, Dr. Genichi Taguchi introduced a technique to address these two points for better outcomes of what are commonly known as responses [

2,

18,

19]. The Taguchi method is a combination of mathematical and statistical techniques, where both the control parameters and their relevant responses are mixed to exercise the optimization process [

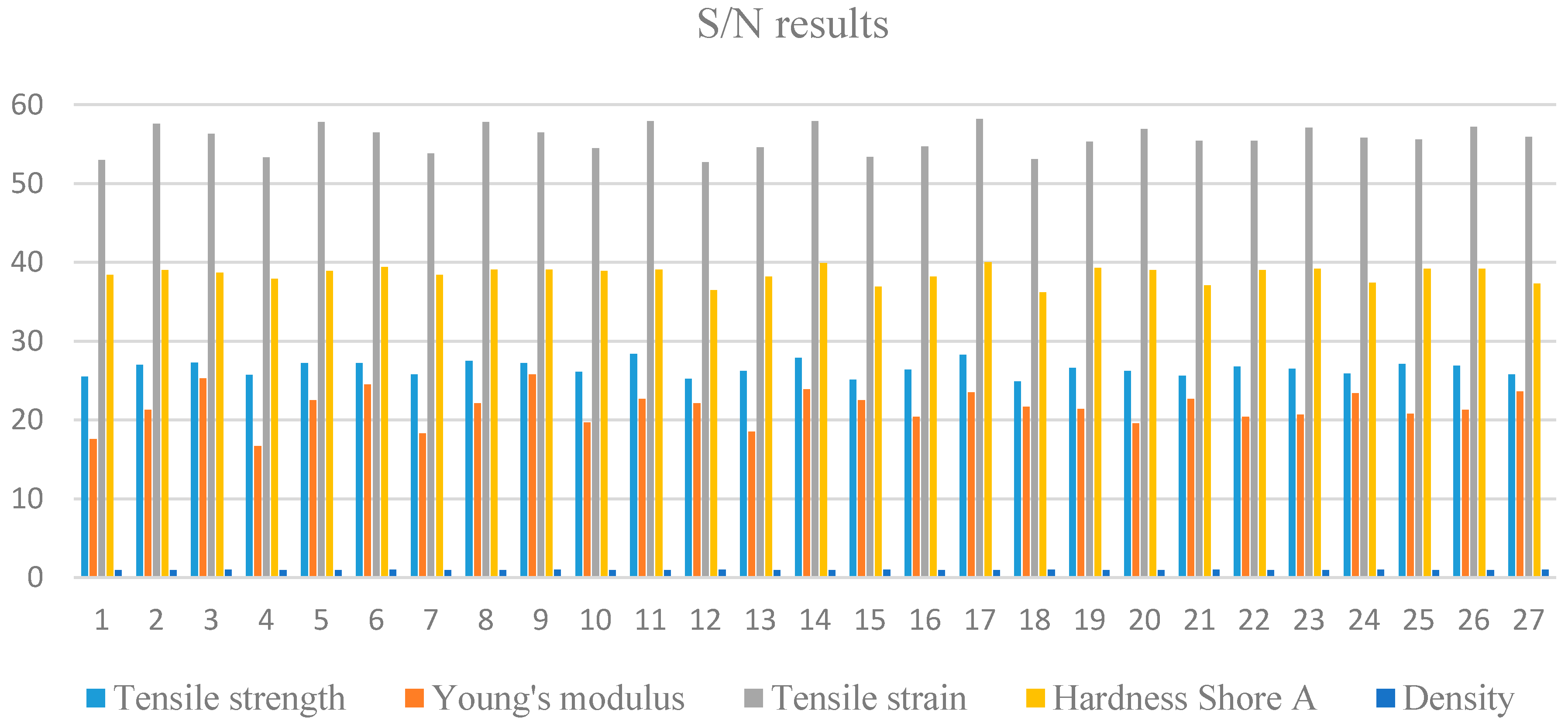

20]. Orthogonal arrays and signal-to-noise (S/N or SNR) ratios are the major tools used in the Taguchi method and emphasize the consideration of quality in product and process design [

21]. Because of these considerations, application of the Taguchi method, the S/N and the analysis of variance (ANOVA) seem to be a more practical approaches to the statistical DOE than other methods, which appear to be more complicated [

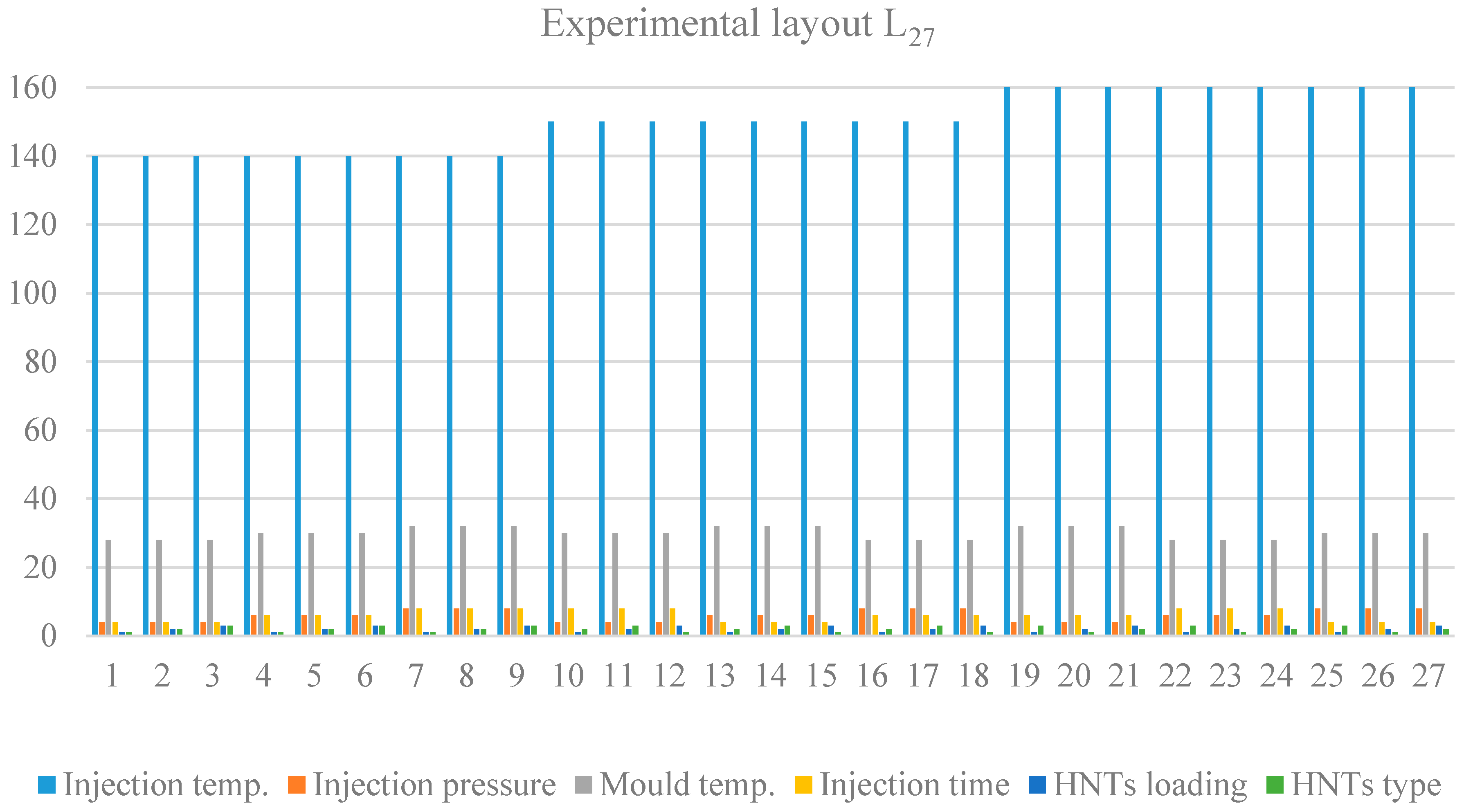

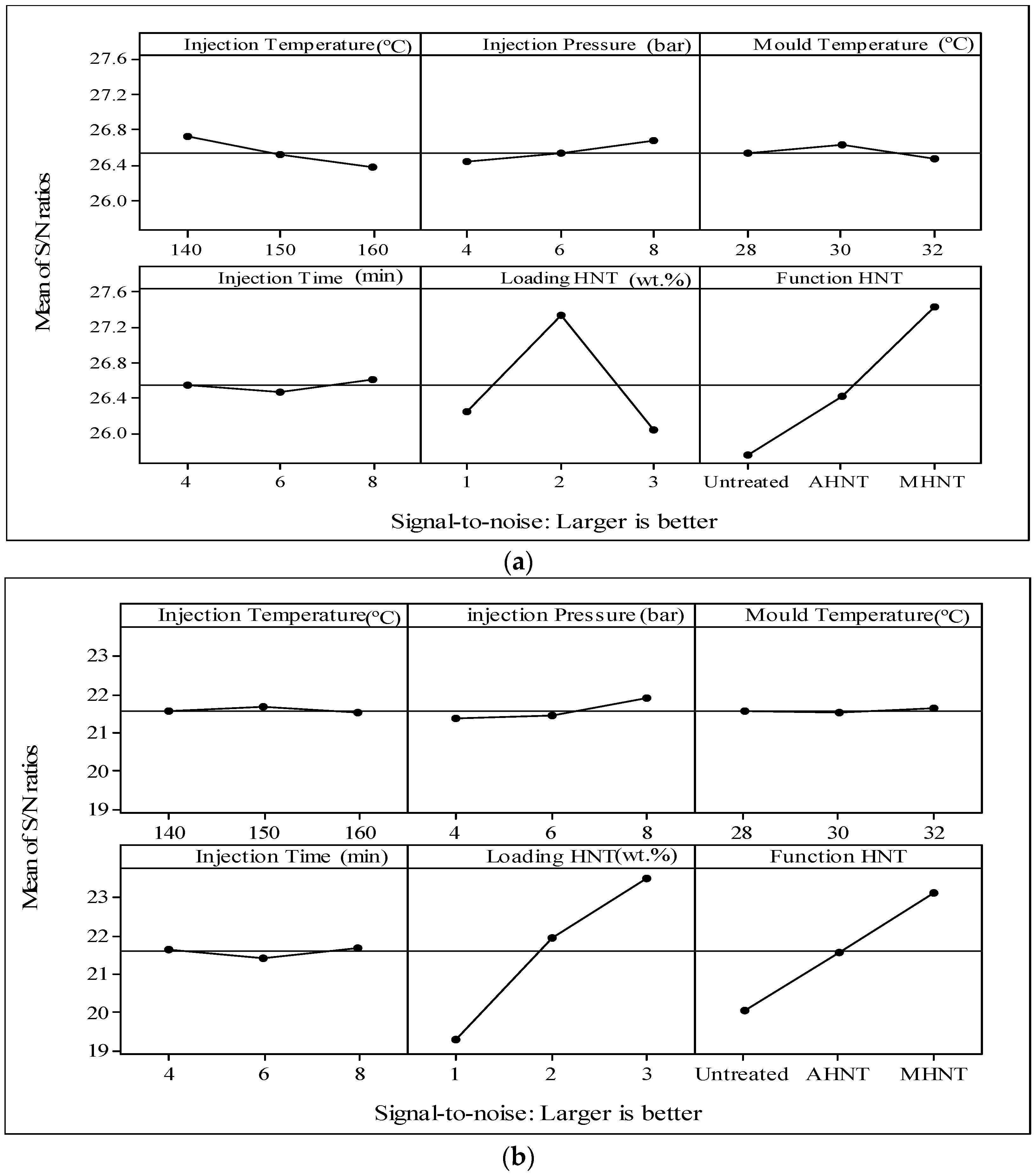

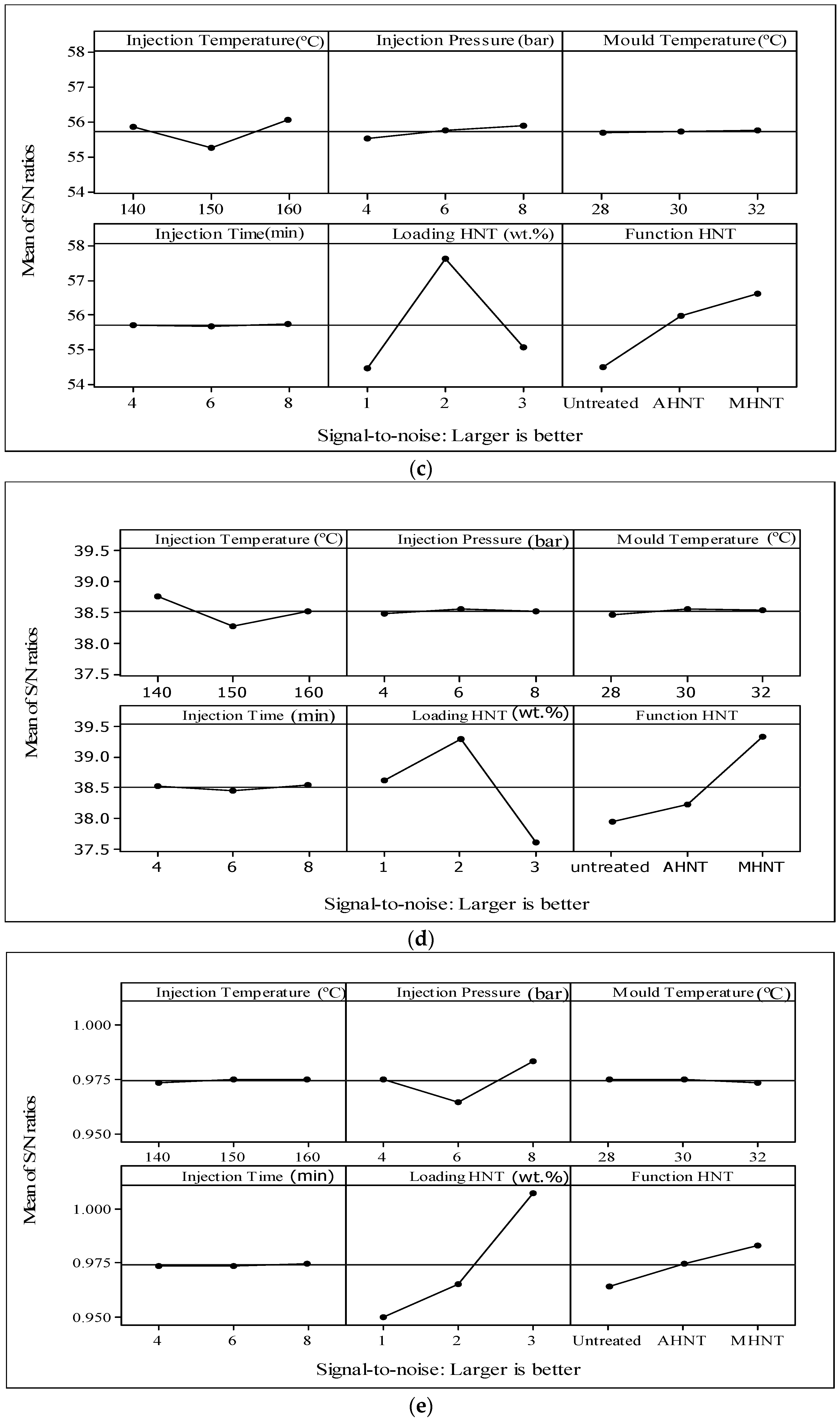

22]. The Taguchi method was developed by systematically allocating factors and levels to suitable orthogonal arrays, then performing an analysis of the S/N and ANOVA to determine the optimal combination of parameters, to validate the results and identify the significant parameters that affect the quality [

23]. This article presents a detailed method for such a calculation that can be used as a reference for researchers/engineers to build an approach using available software, such as Microsoft Office Excel [

2]. In the Taguchi designs, the robustness of the control factors is used to identify the reduction of variability by minimizing the effects of the uncontrolled factors, which are known as the noise factors. The noise is a natural result from all errors encountering the experimental procedure, whether they are originated from mishandling measurements or due to unavoidable electronics devices. The higher value of S/N means the minimum effect of the noise factor. Taguchi’s approach includes two steps of optimization where the S/N signal is used to identify the control factors and secondly to move the mean to target a smaller or no effect of the S/N ratio. Choosing the level of the S/N ratio to a certain level depends on the goal of the experiment. In Minitab, there are four levels of S/N ratios, as explained in

Table 1.

The selection of the control parameters and their applicable levels (minimum two) depends on the physical properties of the mixture components [

24]. The responses are chosen based on the goal of the research under consideration. In this work, the responses are chosen to address the mechanical and the physical properties. The mechanical properties include the tensile strength, Young’s modulus, tensile strain and the hardness (Scale Shore A), while the density is the only physical property investigated. All mechanical properties are well known, and they were discussed in great numbers of research [

25]. However, the hardness was seldom investigated or discussed. The hardness of a material is the resistance of its surface to penetration. The indentation caused by a standard size and shape at the surface of the elastomer is known as hardness. By comparing a small initial force and much larger force, the hardness can be measured. The Shore A scale for measuring hardness is very common global wise [

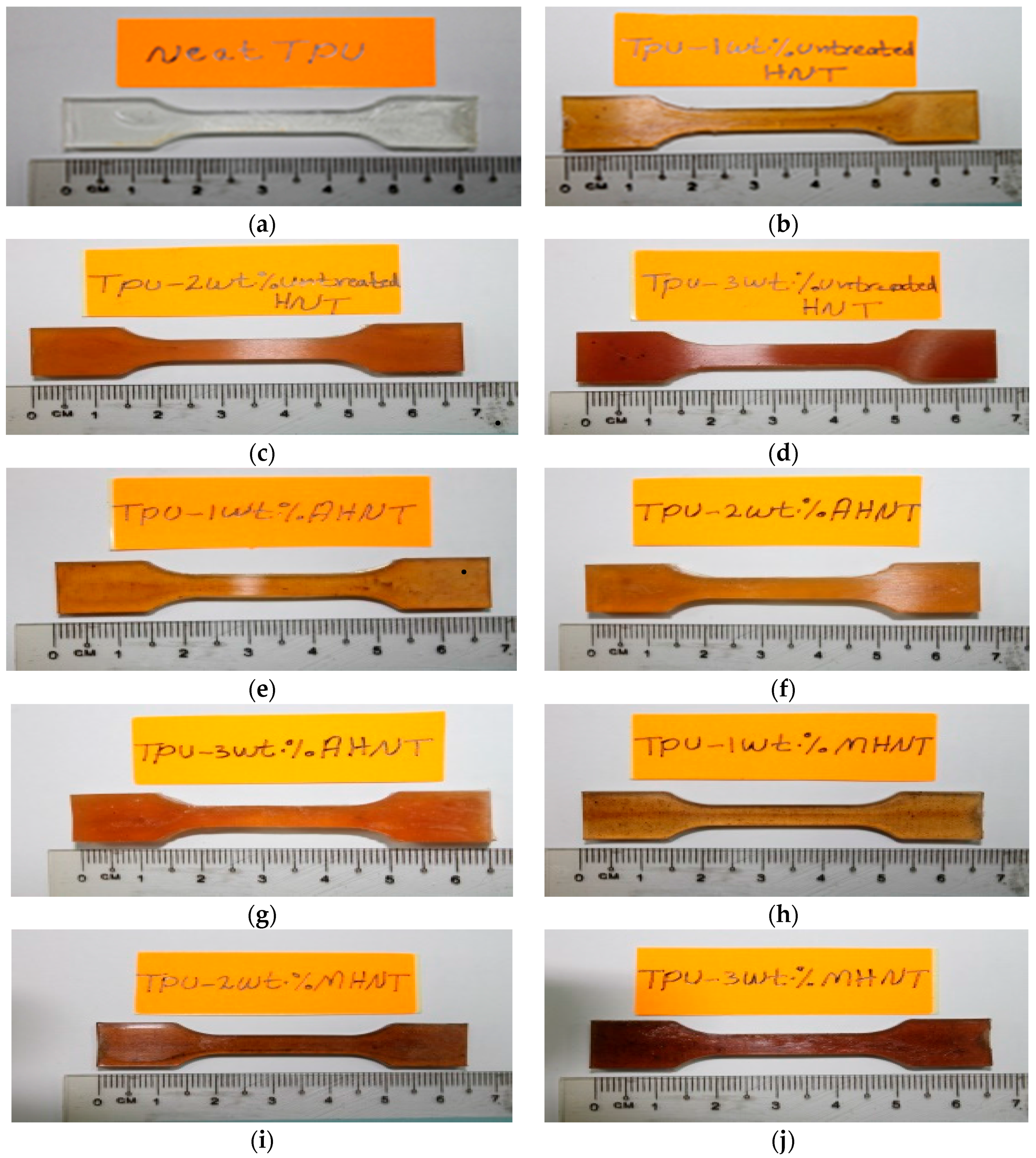

26]. The aim of this work is to optimize the injection molding parameters for halloysite nanotubes-thermoplastic polyurethane (HNTs-TPU) nanocomposites through the Taguchi method. The use of HNT in this study as a nano-filler could be attributed to the HNTs’ tabular microstructure nature, high thermal resistance, unique crystallization behavior and the credibility of improving the mechanical properties of TPU based on previous studies [

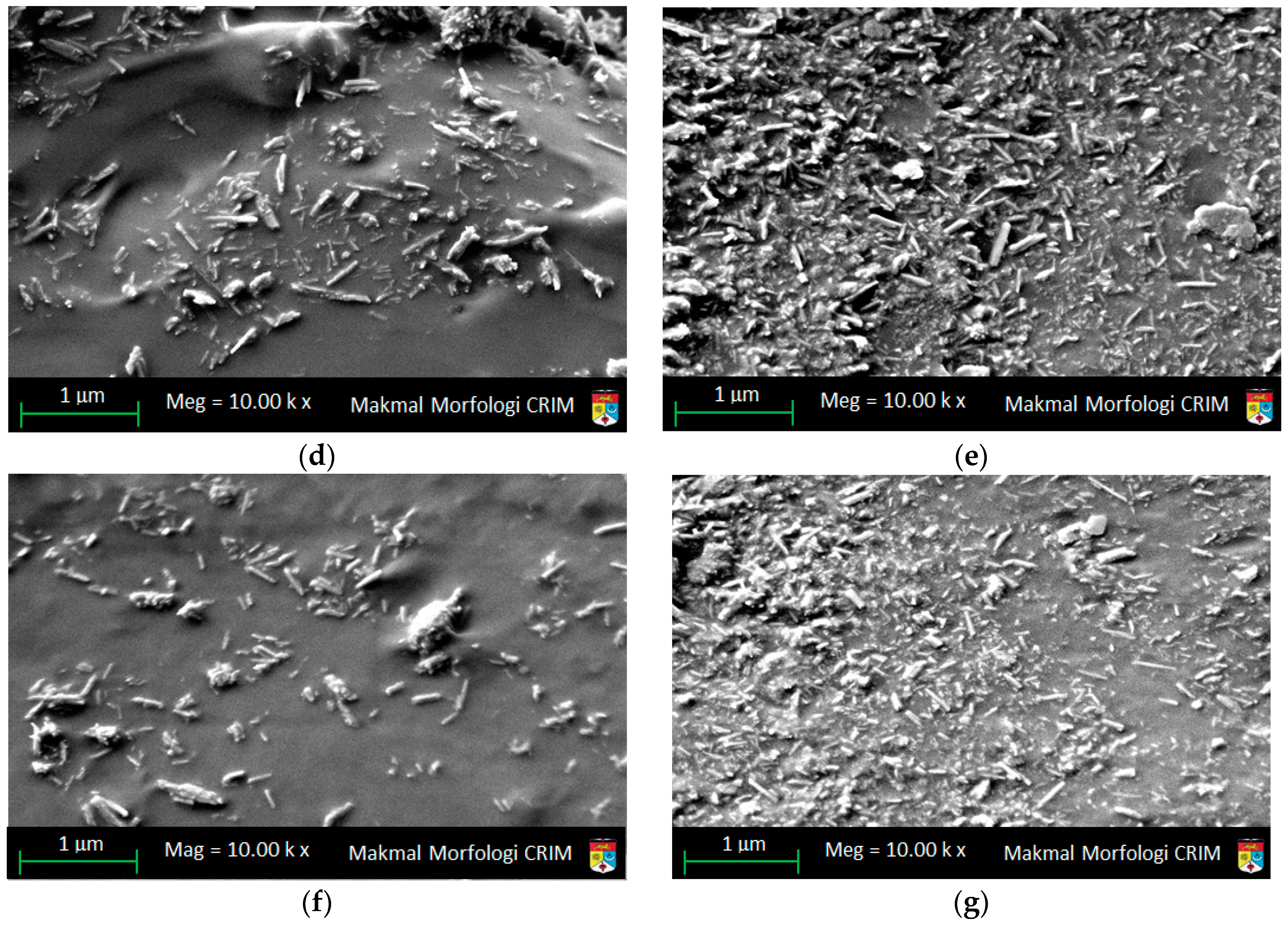

3]. The Taguchi method phase is the most important design one, which serves the objective of determining the optimal injection molding parameters to achieve the optimized parameters for the tensile, compression, hardness and density. The relationship between the control factors (injection temperature, injection pressure, mold temperature, injection time, HNTs loading and HNTs type) and output response factors (tensile, hardness, and density test) is thoroughly identified.

4. Conclusions

Injection molding has been used to finalize products for marketing. Prior to injection, samples have to be prepared according to the optimization process, which is carried out independently. Another stage of optimization is performed prior to the injection process. The molding machine is equipped with sophisticated software; however, selecting parameters for optimization is not a part of the software. In this study, six control parameters (injection temperature, injection pressure, mold temperature, injection time, HNTs loading and HNTs type) were chosen to optimize five responses (tensile strength, Young’s modulus, tensile strain, hardness and density). The optimization does not depend only on the control parameters, but also depends on the level of each parameter. It was found that the control parameters and their suitable levels could be utilized as a guide for determining the qualities and purposes needed from the nanocomposite. The dispersion of HNTs is a very influential and effective approach in enhancing all responses while the levels play another important role for the best production. The other control parameters at certain levels have their own positive influence, which was measured by a combination of analyses, including Taguchi and ANOVA. Next to HNTs loading and HNTs type, it was found that injection the pressure of 8 bar is the most influential parameter, as it appeared four times followed equally well by the injection temperature of Level II (150 °C) and the injection time of Level III (8 min). The results are supported by FESEM, which shows clearly the dispersion of HNTs. All of these features have a direct impact on the quality of the nanocomposites regarding the mechanical and physical properties.