Freckle Defect Formation near the Casting Interfaces of Directionally Solidified Superalloys

Abstract

:1. Introduction

2. Materials and Methods

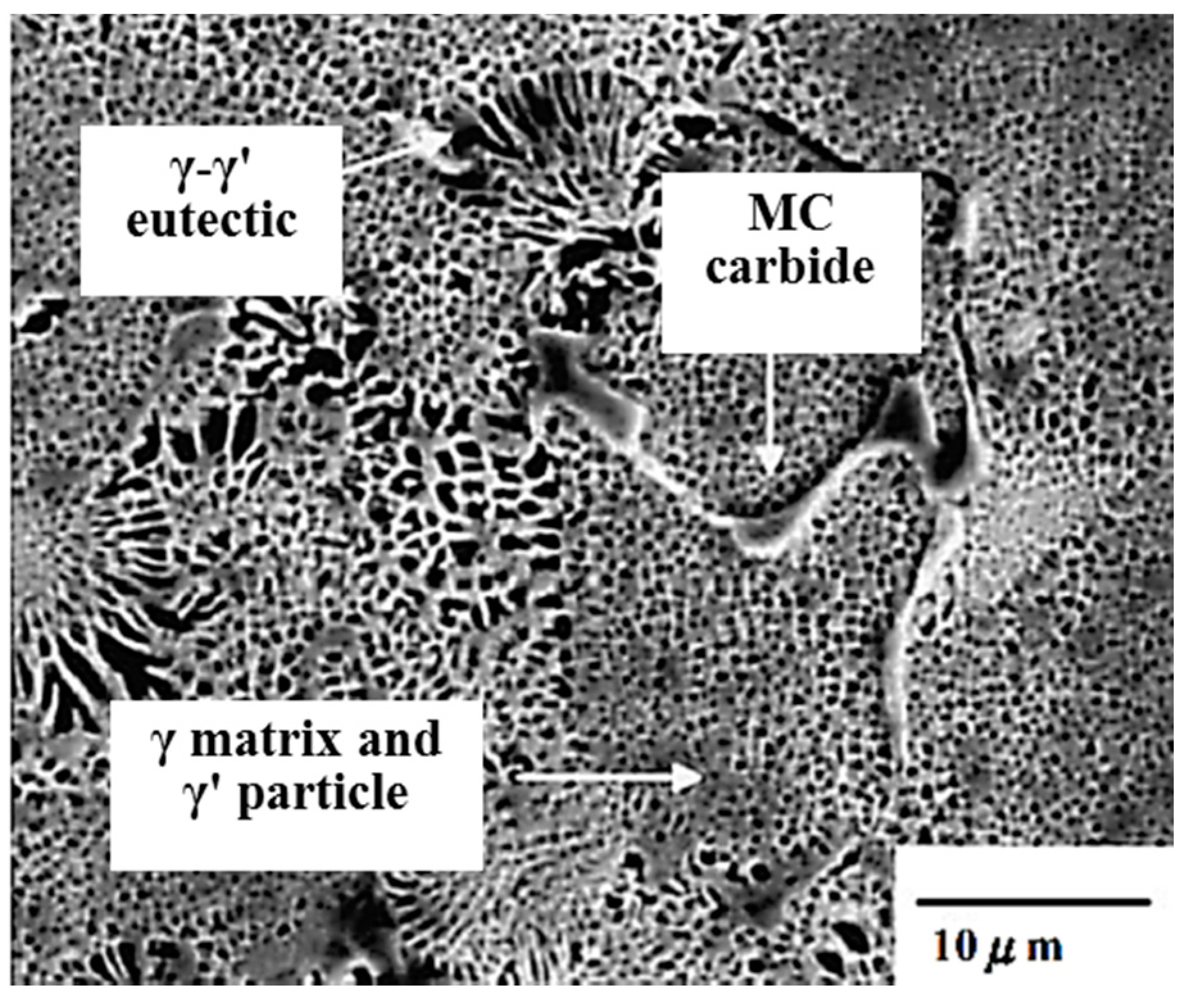

2.1. Selection of Superalloys

2.2. Specimen Design

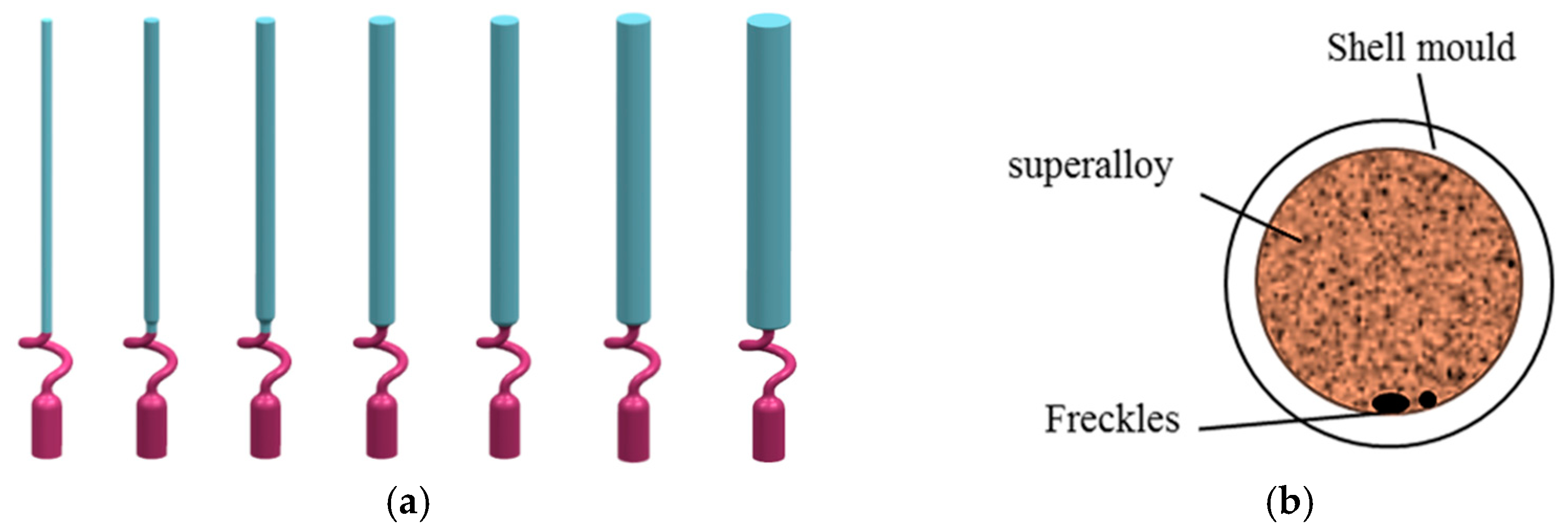

2.2.1. Solid Specimens

2.2.2. Multi-Interface Specimens

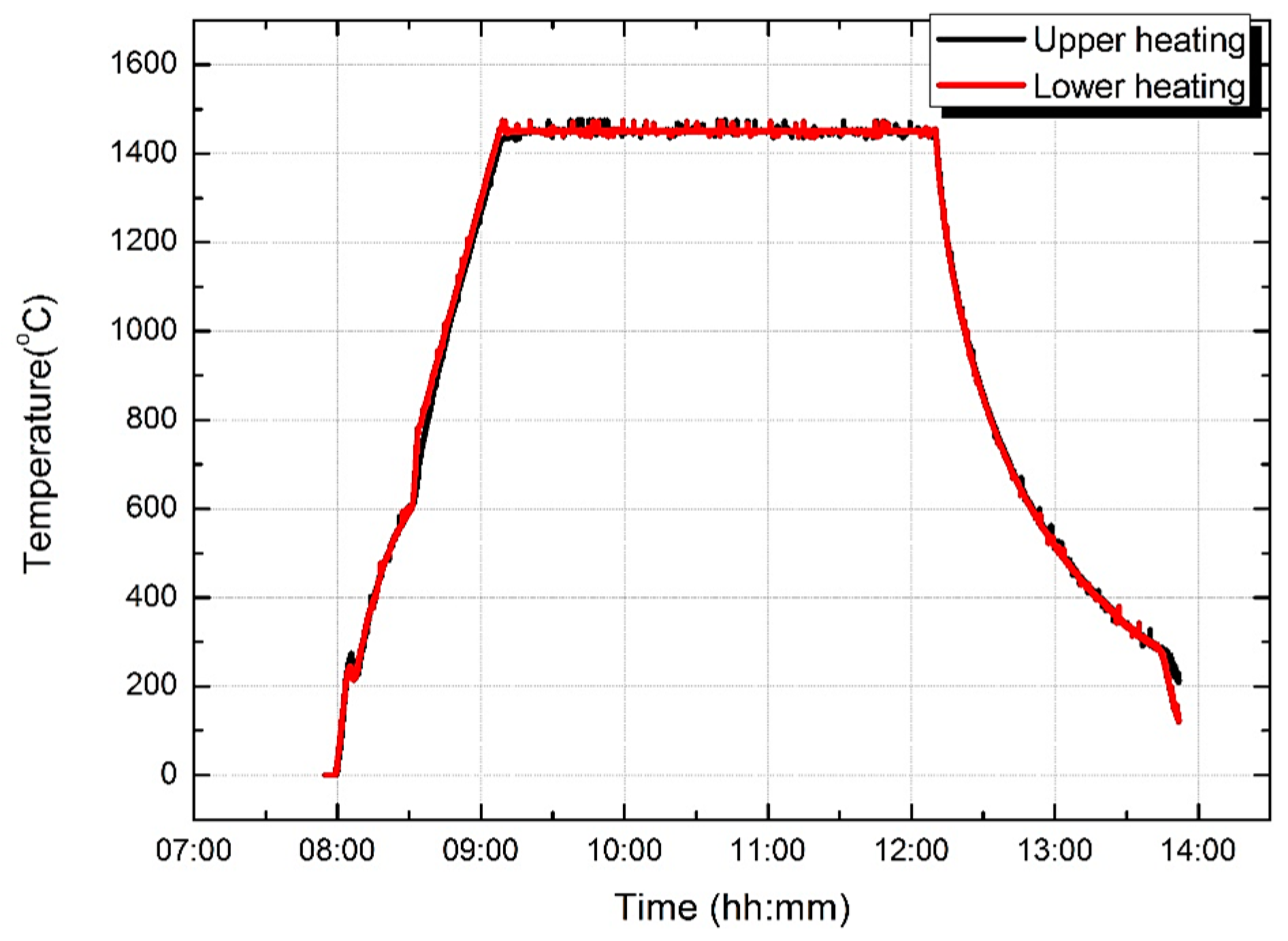

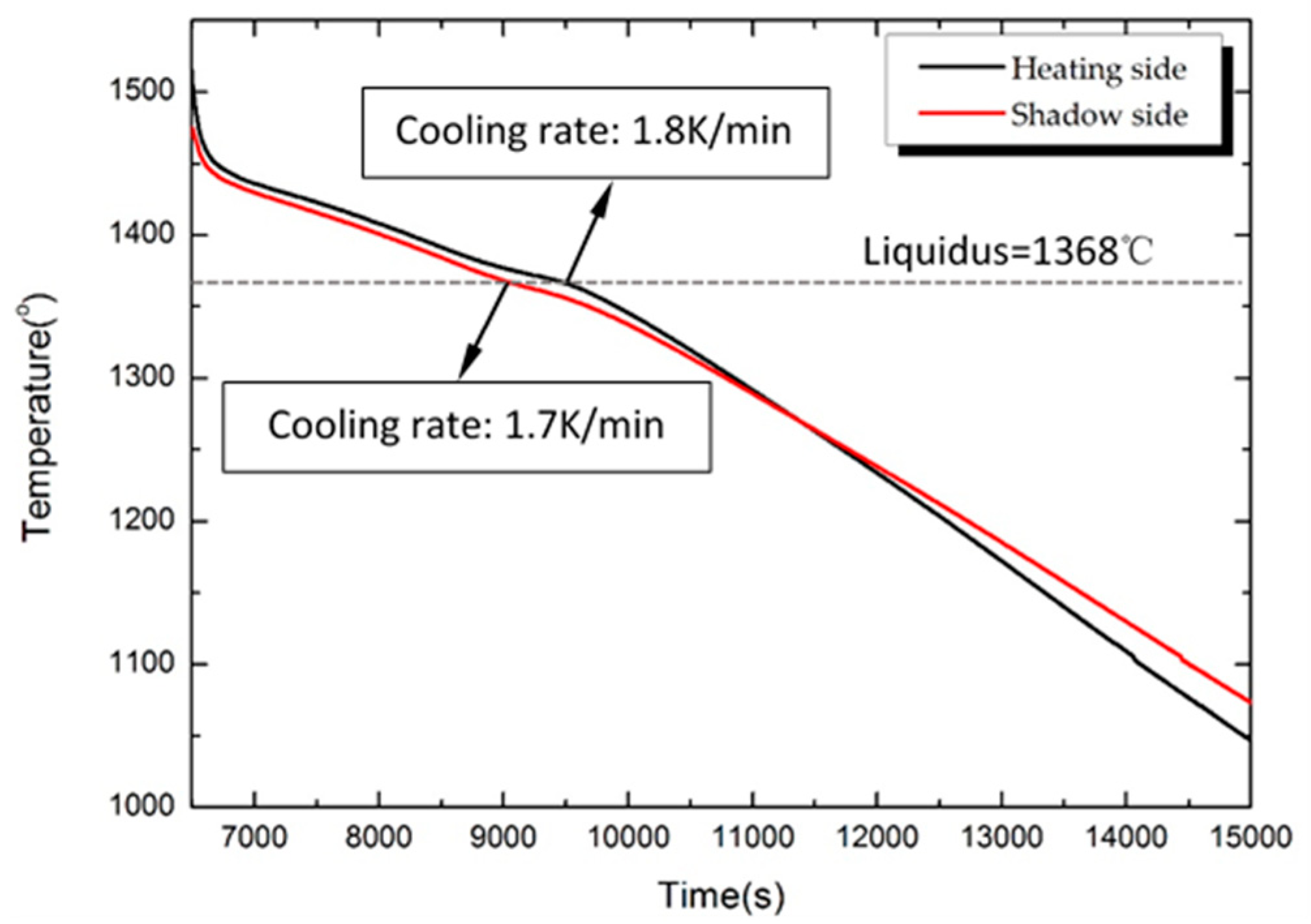

2.3. Procedure of Directional Solidification

2.4. Metallographic and Composition Analysis

3. Results

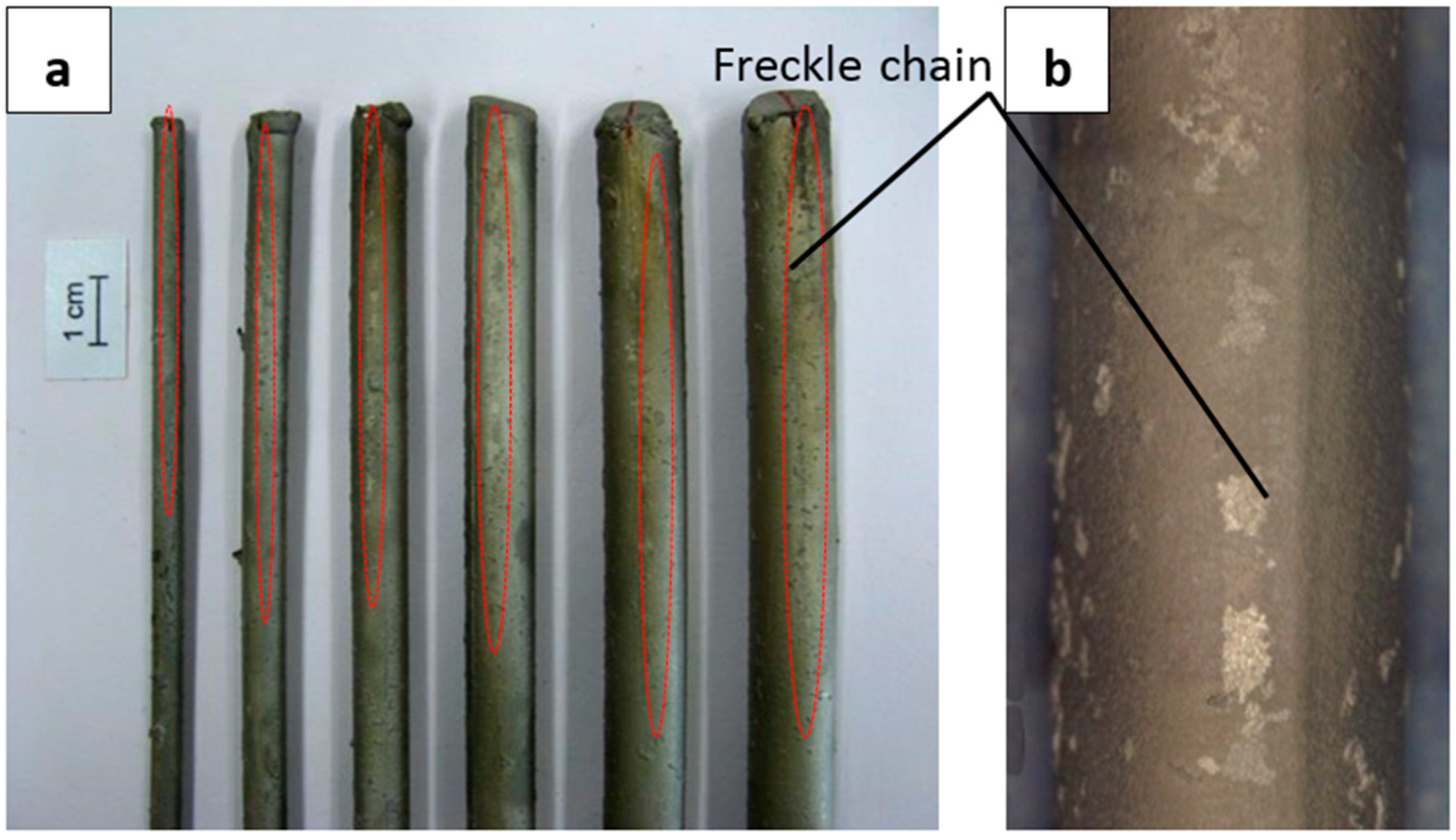

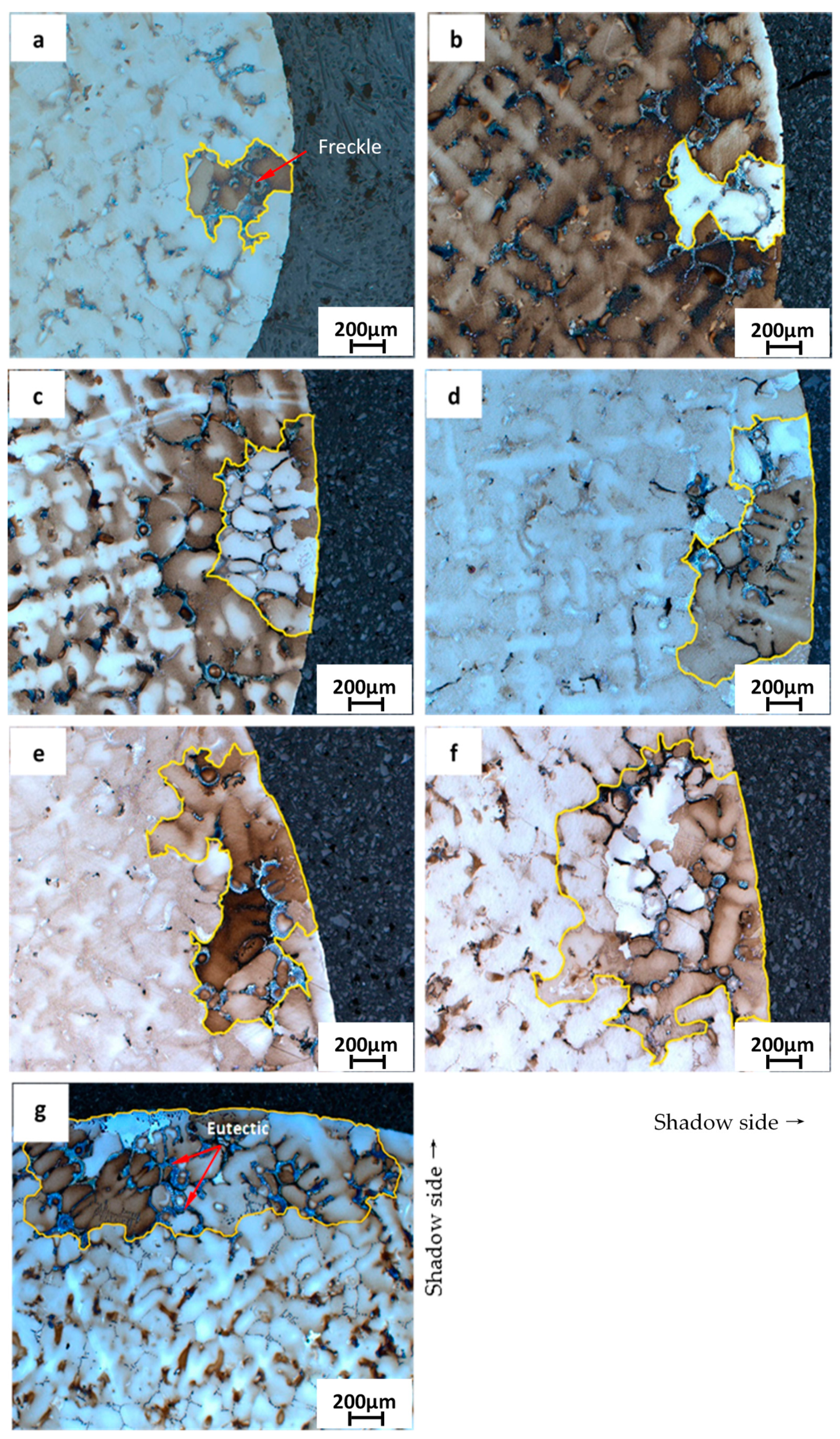

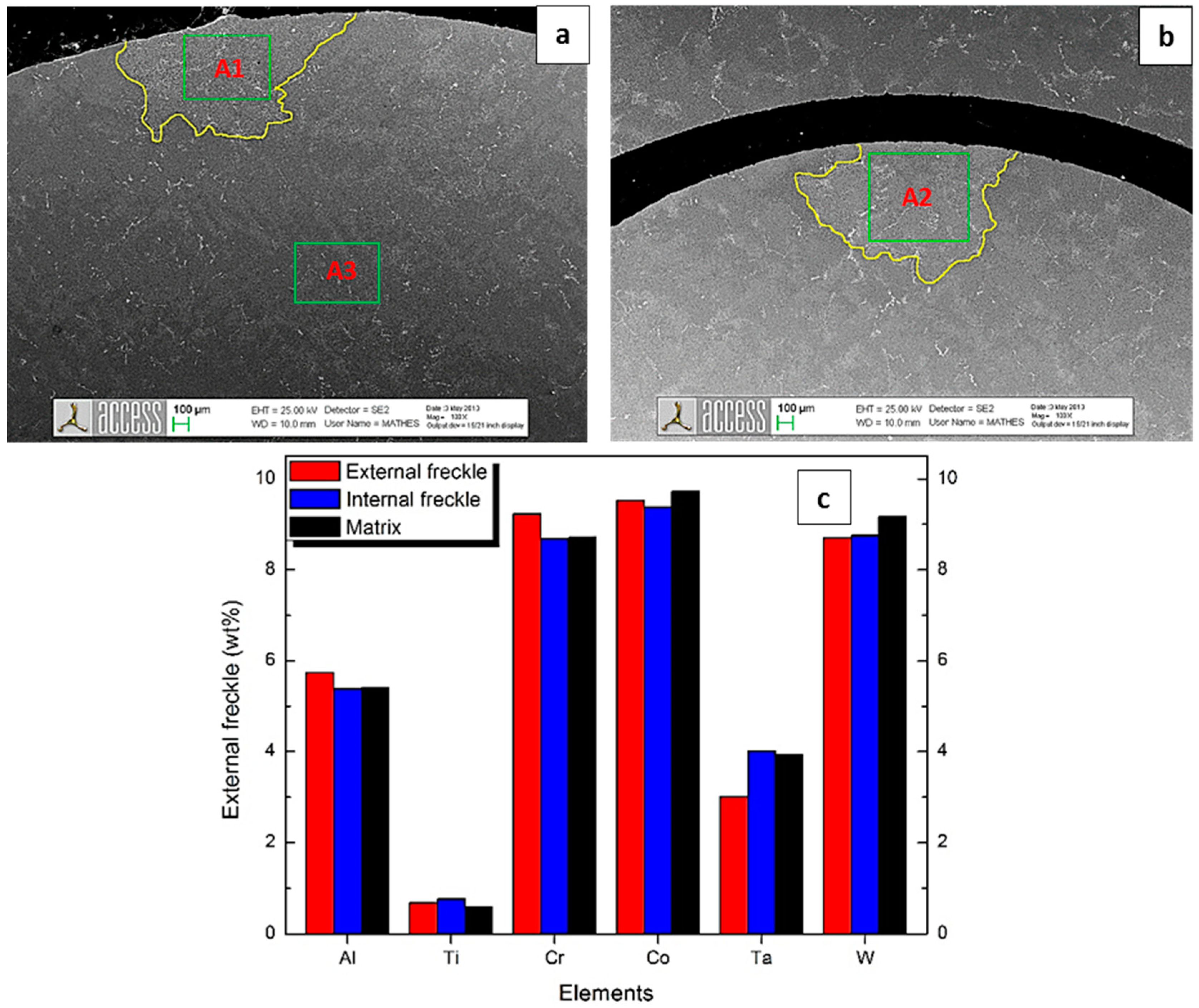

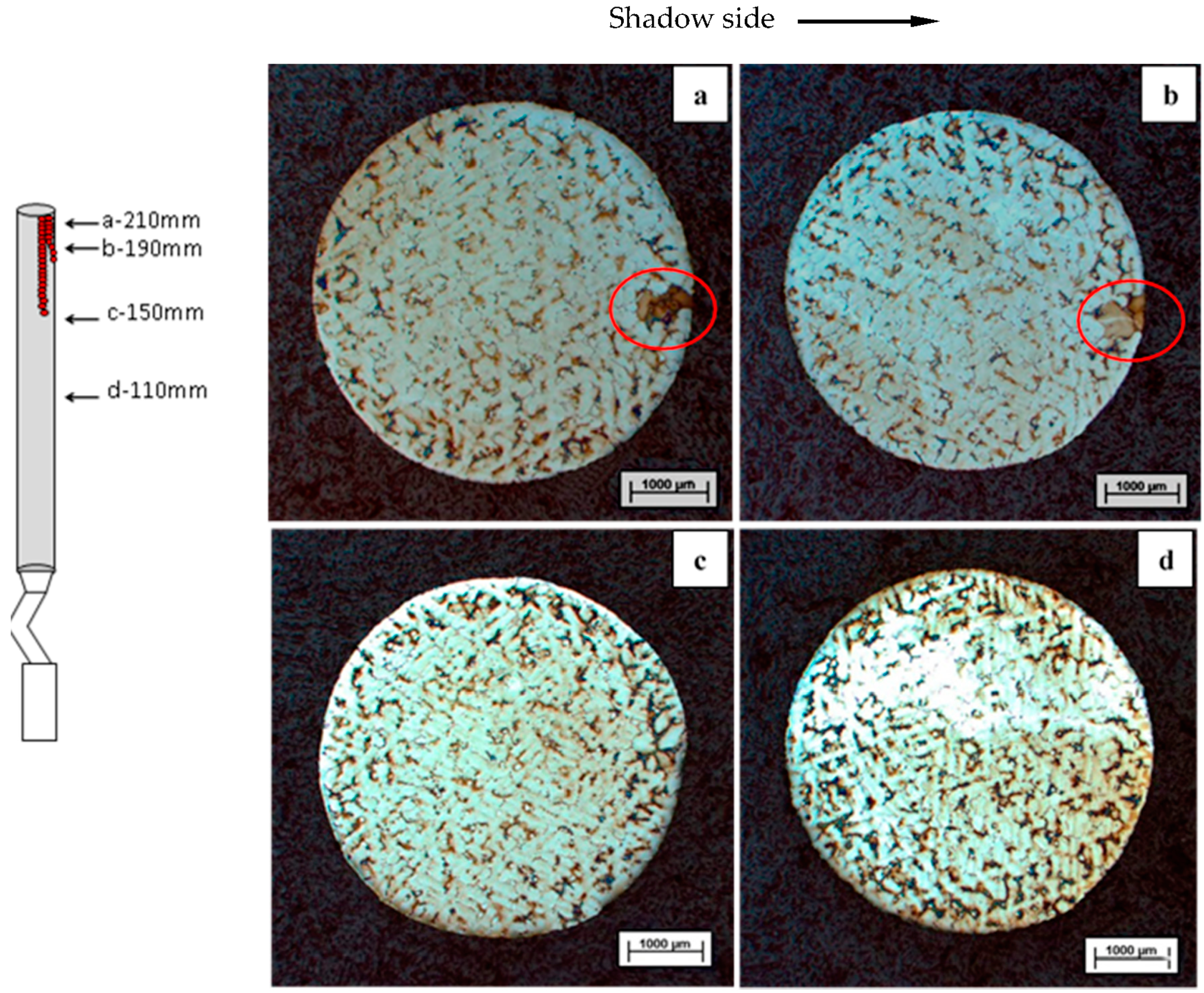

3.1. Freckle Occurrence on the External Surface

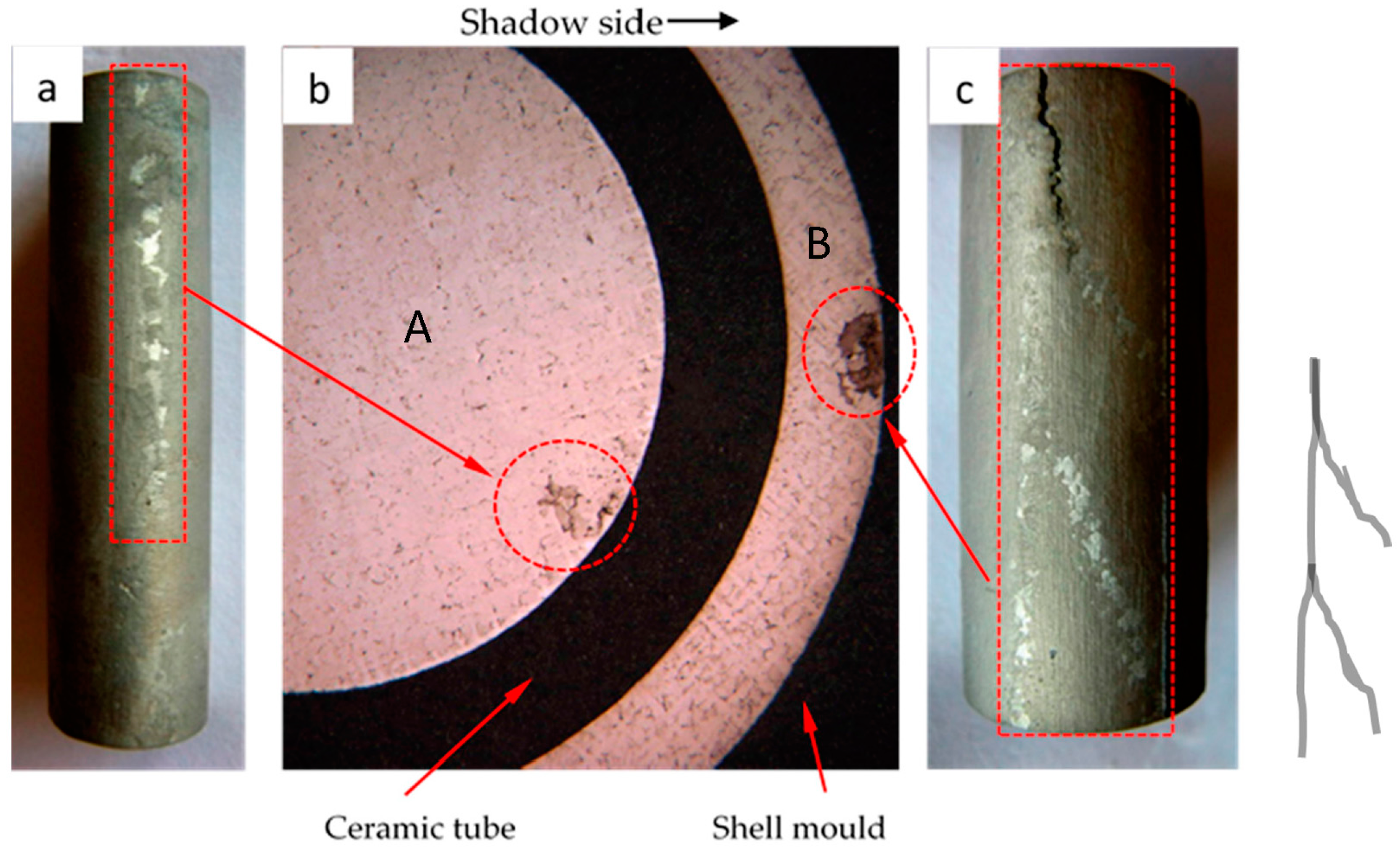

3.2. Freckle Occurrence on Multi-Interfaces

4. Discussion

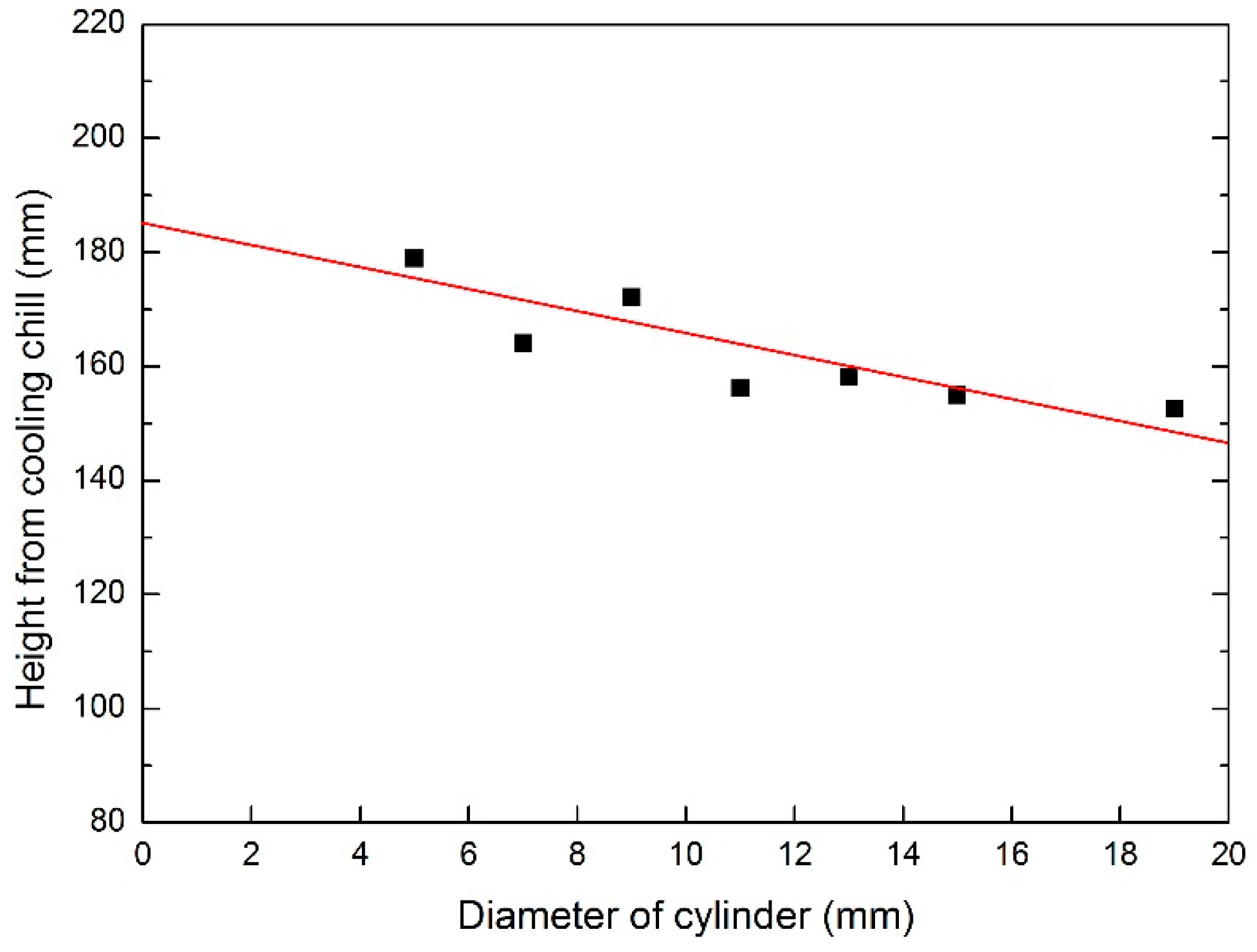

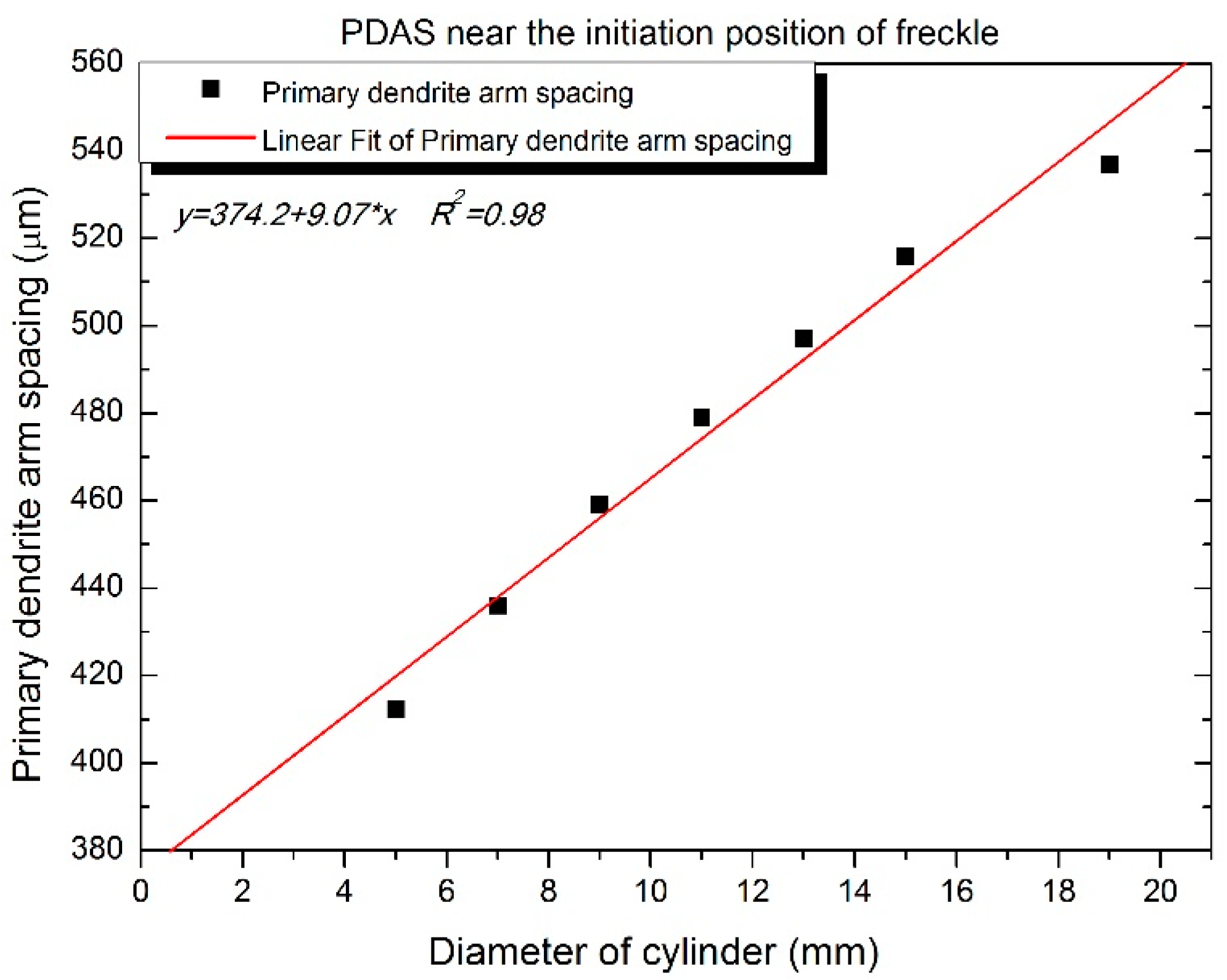

4.1. Influence of Height from Cooling Chill

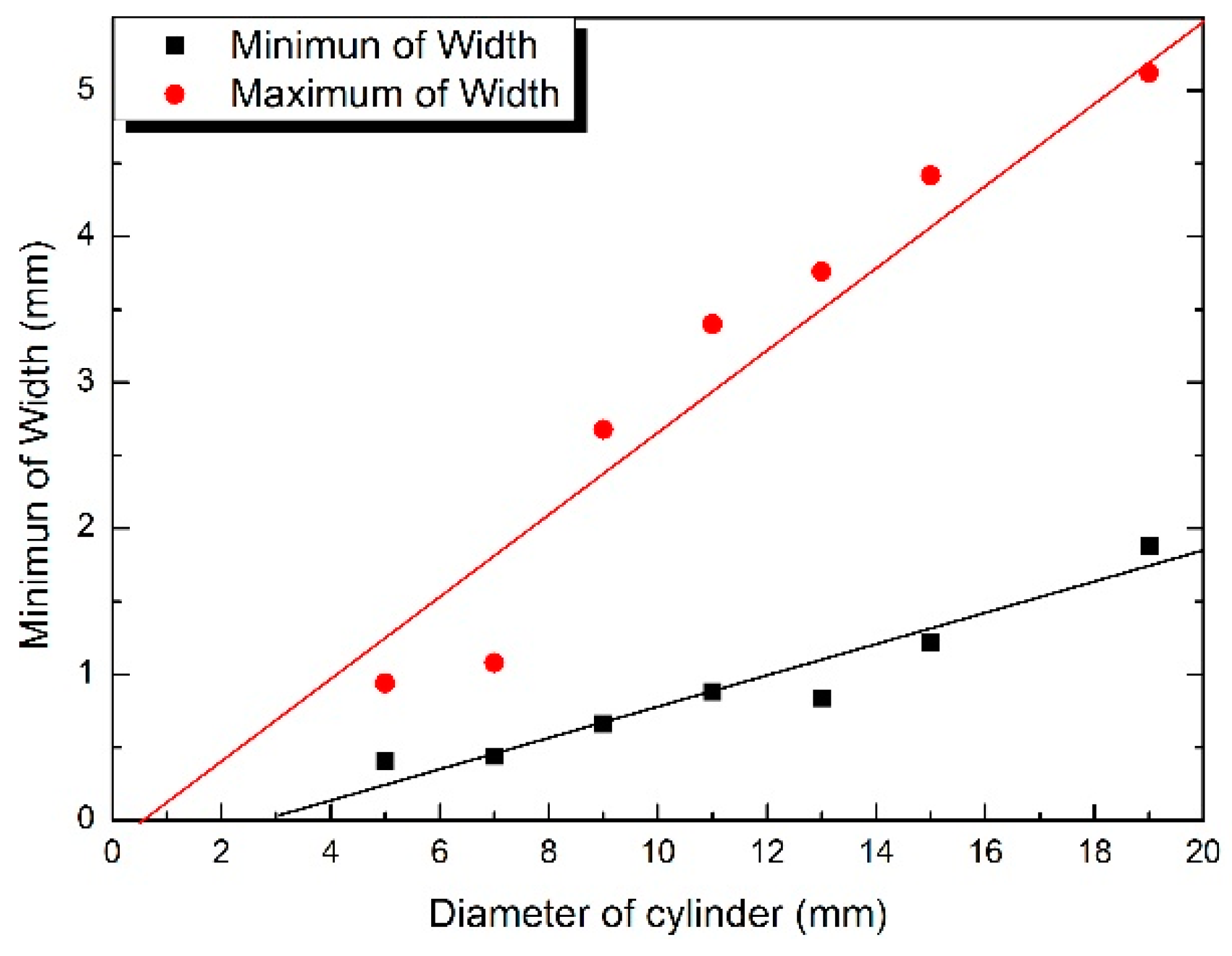

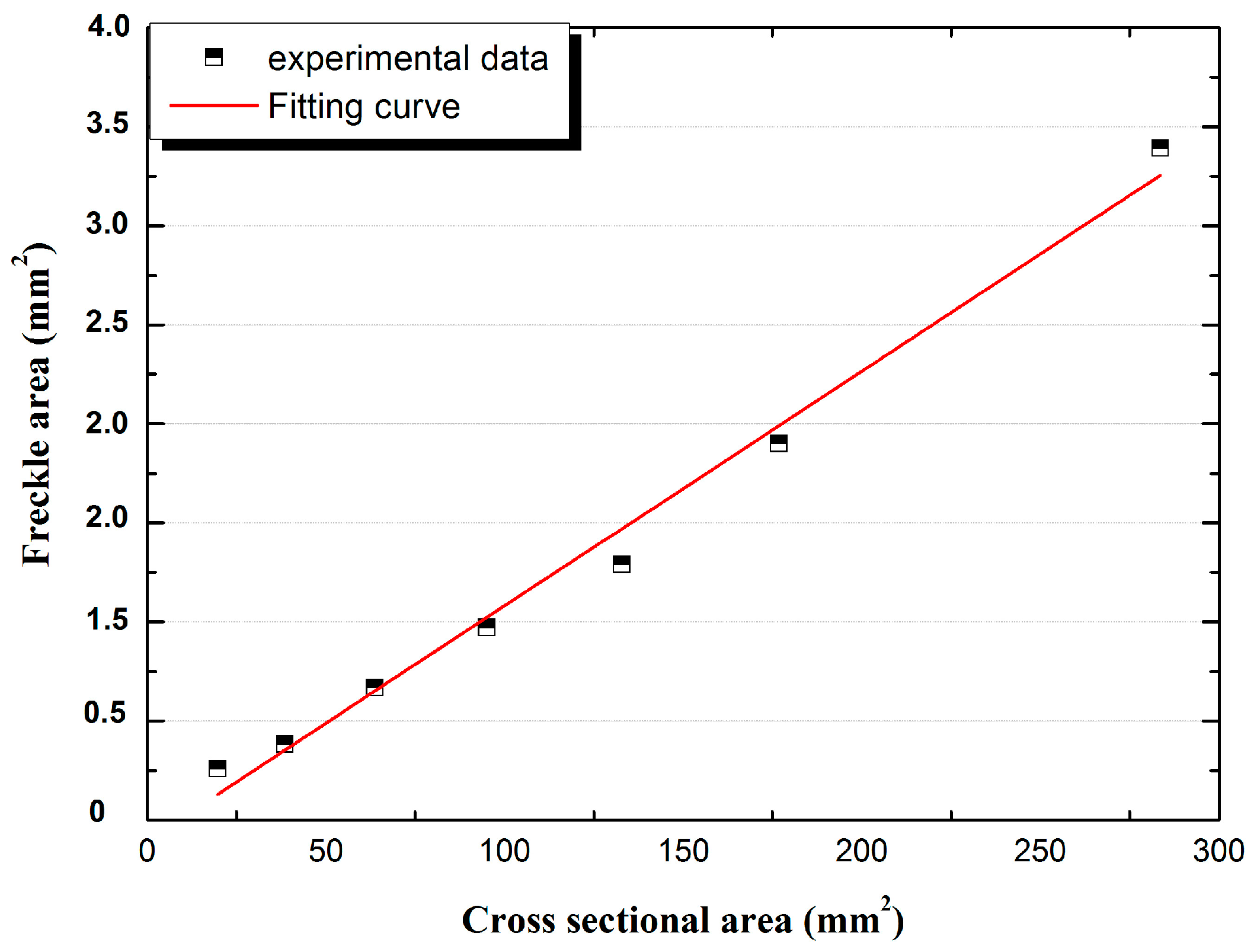

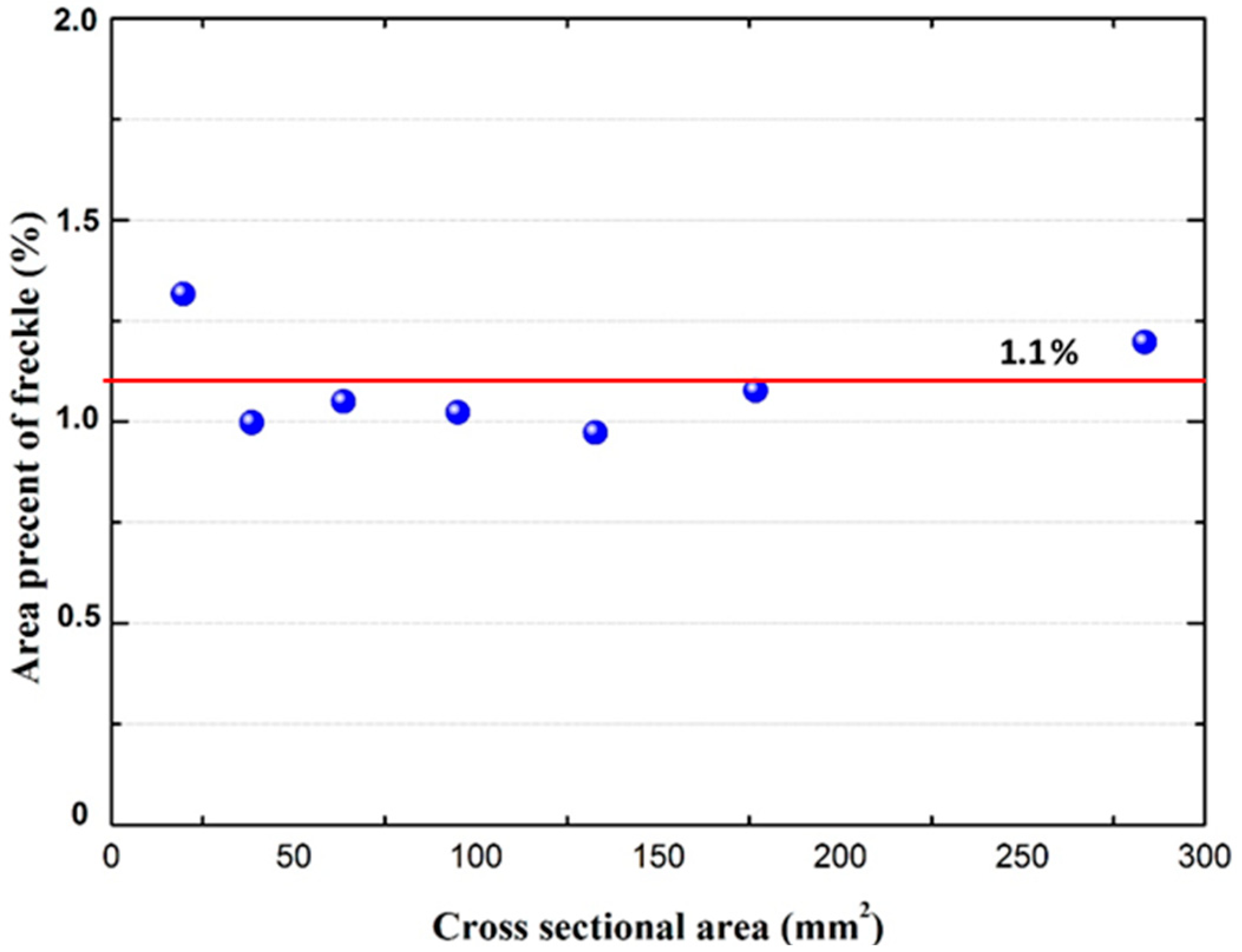

4.2. Influence of Cross Sectional Area

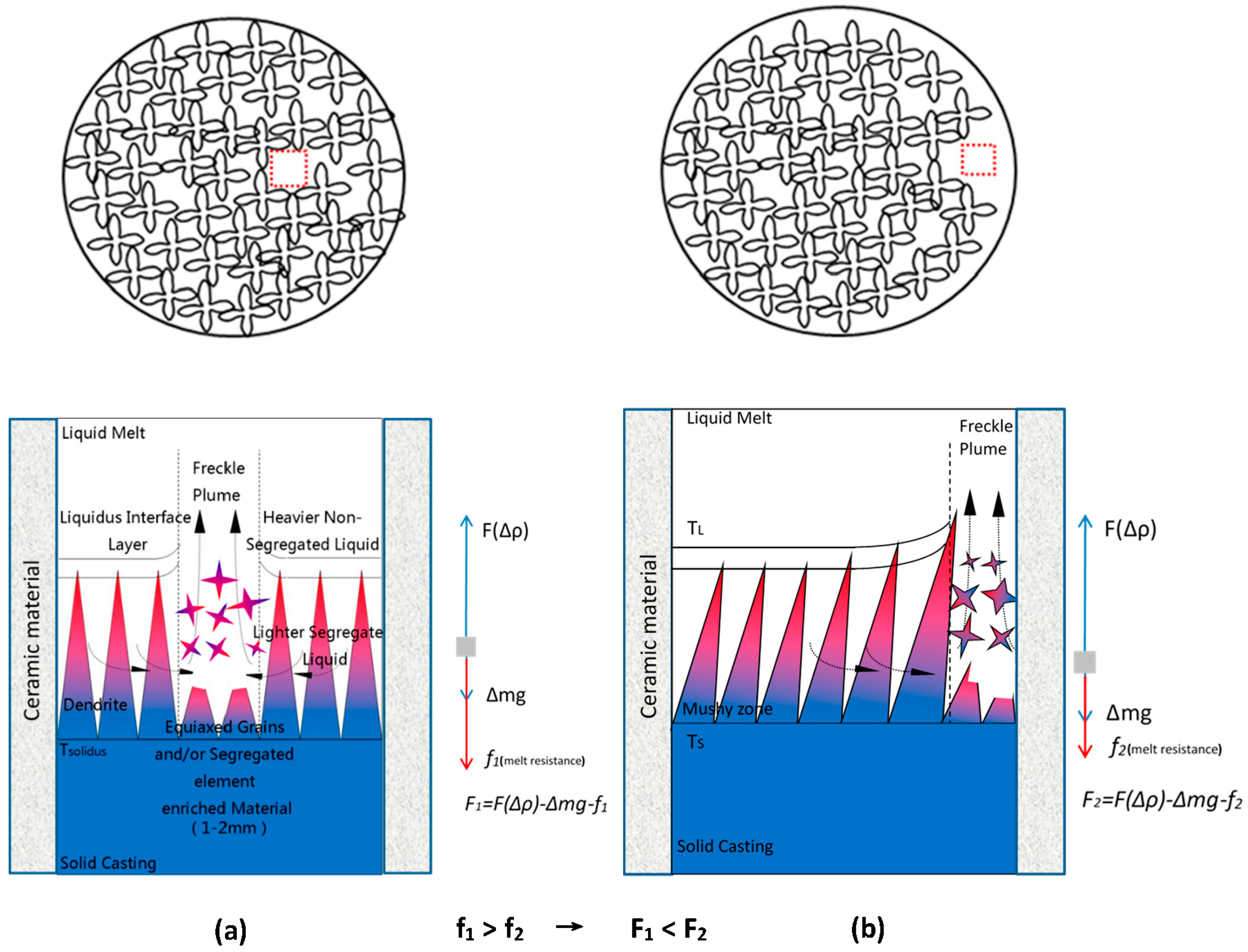

4.3. Interface Effects of Freckle Formation

5. Conclusions

- Freckle defects do not only occur on the external surface of Ni-based superalloys castings, but also on the internal surface, near the interface of superalloys and ceramic materials.

- The height of the initiation position of the freckle chain reduces when the rod diameter increases. Meanwhile, the size of the freckle chain increases when rod diameter increases.

- Freckle area on the rod follows a linear relationship with the cross sectional area. However, there is no significant change of the area percentage of freckles, and the average value is 1.1% of the cross sectional area.

- Freckle defects occur on the large size internal superalloy parts (Diameter of 11 mm and 12 mm), but not on the small sizes (1 to 8 mm).

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bradley, E.F. Source Book on Materials for Elevated-Temperature Applications; American Society for Metals: Metals Park, OH, USA, 1969; pp. 275–298. [Google Scholar]

- Sabol, G.P.; Stickler, R. Microstructure of nickel-based superalloys. Phys. Status Solidi B 1969, 35, 11–52. [Google Scholar] [CrossRef]

- Jena, A.K.; Chaturvedi, M.C. The role of alloying elements in the design of nickel-base superalloys. J. Mater. Sci. 1984, 19, 3121–3139. [Google Scholar] [CrossRef]

- Bradley, E.F. Superalloys: A Technical Guide; ASM International: Metals Park, OH, USA, 1988. [Google Scholar]

- Kotval, P.S. The microstructure of superalloys. Metallography 1969, 1, 251–285. [Google Scholar] [CrossRef]

- Sims, C.T. Superalloys: Genesis and Character. In Superalloys II; Sims, C.T., Stoloff, N.S., Hagel, W.C., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 1987; pp. 3–21. [Google Scholar]

- Gao, S.; Liu, L.; Hu, X.; Ge, B.; Zhang, J.; Fu, H. Review of Freckle Defects under Directional Solidification of Nickel-based Superalloys. J. Mater. Sci. Eng. 2010, 28, 145–151. [Google Scholar]

- Ronan, K. A statistical analysis of variations in hot tear performance and microporosity formation versus composition in investment cast FSX-414. In Superalloys 2008; The Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 2008; pp. 157–166. [Google Scholar]

- Yang, X.L.; Dong, H.B.; Wang, W.; Lee, P.D. Microscale simulation of stray grain formation in investment cast turbine blades. Mater. Sci. Eng. A 2004, 386, 129–139. [Google Scholar] [CrossRef]

- Auburtin, P.B.L. Determination of the Influence of Growth Front Angle on Freckle Formation in Superalloys. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 1998. [Google Scholar]

- Auburtin, P.; Wang, T.; Cockcroft, S.L.; Mitchell, A. Freckle formation and freckle criterion in superalloy castings. Metall. Mater. Trans. B 2000, 31, 801–811. [Google Scholar] [CrossRef]

- Fecht, H.-J.; Wunderlich, R.K.; Garandet, J.; Hayashi, M.; Mills, K.C.; Passerone, A.; Quested, P.N.; Ricci, E.; Schmidt-hohagen, F.; Seetharaman, S. Thermophysical properties of in738Lc, Mm247Lc and Cmsx-4 in the liquid and high temperature solid phase. Superalloys 2005, 467–476. [Google Scholar]

- Harris, K.; Erickson, G.L.; Schwer, R.E. MAR M 247 derivations—CM 247 LC DS alloy CMSX single crystal alloys properties & performance. In Superalloys 1984; The Minerals, Metals and Materials Society: Pittsburgh, PA, USA, 1904; pp. 221–230. [Google Scholar]

- Huang, H.E.; Koo, C.H. Effect of zirconium on microstructure and mechanical properties of cast fine-grain CM 247 LC superalloy. Mater. Trans. 2004, 45, 554–561. [Google Scholar] [CrossRef]

- Hong, J.; Ma, D.; Wang, J.; Wang, F.; Dong, A.; Sun, B.; Bührig-Polaczek, A. Geometrical effect of freckle formation on directionally solidified superalloy CM247 LC components. J. Alloys Compd. 2015, 648, 1076–1082. [Google Scholar] [CrossRef]

- Hellawell, A.; Sarazin, J.R.; Steube, R.S. Channel convection in partly solidified systems. Philos. Trans. R. Soc. B Biol. Sci. 1993, 345, 507–544. [Google Scholar] [CrossRef]

- Pollock, T.; Tin, S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure and properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Brewster, G.; Dong, H.B.B.; Green, N.R.R.; D’Souza, N. Surface segregation during directional solidification of Ni-base superalloys. Metall. Mater. Trans. B 2008, 39, 87–93. [Google Scholar] [CrossRef]

- Brewster, G.; D’Souza, N.; Ryder, K.S.; Simmonds, S.; Dong, H.B. Mechanism for formation of surface scale during directional solidification of Ni-base superalloys. Metall. Mater. Trans. A 2012, 43, 1288–1302. [Google Scholar] [CrossRef]

- McDonald, R.J.; Hunt, J.D. Fluid motion through partially solid regions of a casting and its importance in understanding a type segregation. Trans. Metall. Soc. AIME 1969, 245, 1993–1997. [Google Scholar]

- Valdés, J.; King, P.; Liu, X. On the formulation of a freckling criterion for Ni-based superalloy vacuum arc remelting ingots. Metall. Mater. Trans. A 2010, 41, 2408–2416. [Google Scholar] [CrossRef]

- Yu, K.O.; Domingue, J.A.; Maurer, G.E.; Flanders, H.D. Macrosegregation in ESR and VAR processes. JOM 1986, 38, 46–50. [Google Scholar] [CrossRef]

- Yu, K.O.; Domingue, J.A. Control of Solidification Structure in VAR and ESR Processed Alloy 718 Ingots. In Proceedings of the International Symposium on the Metallurgy and Applications of Superalloy 718, Pittsburgh, PA, USA, 12–14 June 1989.

- Helms, A.D.; Adasczik, C.B.; Jackman, L.A. Extending the Size Limits of Cast/Wrought Superalloy Ingots. In Superalloys 1996; The Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 1996; pp. 427–433. [Google Scholar]

- Yang, W.; Chang, K.-M.; Chen, W.; Mannan, S.; DeBarbadillo, J. Freckle criteria for the upward directional solidification of alloys. Metall. Mater. Trans. A 2001, 32, 397–406. [Google Scholar] [CrossRef]

- Yang, W.H.; de Barbadillo, J.J.; Morita, K.; Suzuki, T.; Chen, W.; Chang, K.-M. A freckle criterion for the solidification of superalloys with a tilted solidification front. JOM 2004, 56, 56–61. [Google Scholar] [CrossRef]

- Poirier, D.R. Permeability for flow of interdendritic liquid in columnar-dendritic alloys. Metall. Trans. B 1987, 18, 245–255. [Google Scholar] [CrossRef]

- Bhat, M.S.; Poirier, D.R.; Heinrich, J.C. Permeability for cross flow through columnar-dendritic alloys. Metall. Mater. Trans. B 1995, 26, 1049–1056. [Google Scholar] [CrossRef]

- Bhat, M.S.; Poirier, D.R.; Heinrich, J.C. A permeability length scale for cross flow through model structures. Energy 1995, 26, 1091–1092. [Google Scholar] [CrossRef]

| Alloy | Cr | Co | Mo | W | Ta | Al | Ti | Hf | B | C | Zr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CM247 LC | 8.1 | 9.2 | 0.5 | 9.5 | 3.2 | 5.6 | 0.7 | 1.4 | 0.015 | 0.07 | 0.015 | Bal. |

| Specimen No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Diameter (mm) | 5 | 7 | 9 | 11 | 13 | 15 | 19 |

| Cross Sectional area (mm2) | 20 | 39 | 64 | 95 | 133 | 177 | 283 |

| Specimen No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| External diameter (mm) | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 |

| Internal diameter (mm) | 1 | 2 | 4 | 5 | 6 | 8 | 11 | 12 |

| Internal cross sectional area (mm2) | 0.8 | 3 | 13 | 20 | 28 | 50 | 95 | 113 |

| Specimen No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| External diameter (mm) | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 |

| Freckle? | YES | YES | YES | YES | YES | YES | YES | YES |

| Internal diameter (mm) | 1 | 2 | 4 | 5 | 6 | 8 | 11 | 12 |

| Freckle? | NO | NO | NO | NO | NO | NO | YES | YES |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, J.; Ma, D.; Wang, J.; Wang, F.; Sun, B.; Dong, A.; Li, F.; Bührig-Polaczek, A. Freckle Defect Formation near the Casting Interfaces of Directionally Solidified Superalloys. Materials 2016, 9, 929. https://doi.org/10.3390/ma9110929

Hong J, Ma D, Wang J, Wang F, Sun B, Dong A, Li F, Bührig-Polaczek A. Freckle Defect Formation near the Casting Interfaces of Directionally Solidified Superalloys. Materials. 2016; 9(11):929. https://doi.org/10.3390/ma9110929

Chicago/Turabian StyleHong, Jianping, Dexin Ma, Jun Wang, Fu Wang, Baode Sun, Anping Dong, Fei Li, and Andreas Bührig-Polaczek. 2016. "Freckle Defect Formation near the Casting Interfaces of Directionally Solidified Superalloys" Materials 9, no. 11: 929. https://doi.org/10.3390/ma9110929