The Microwave-Assisted Green Synthesis of TiC Powders

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Synthesis

2.3. Characterization

3. Results and Discussion

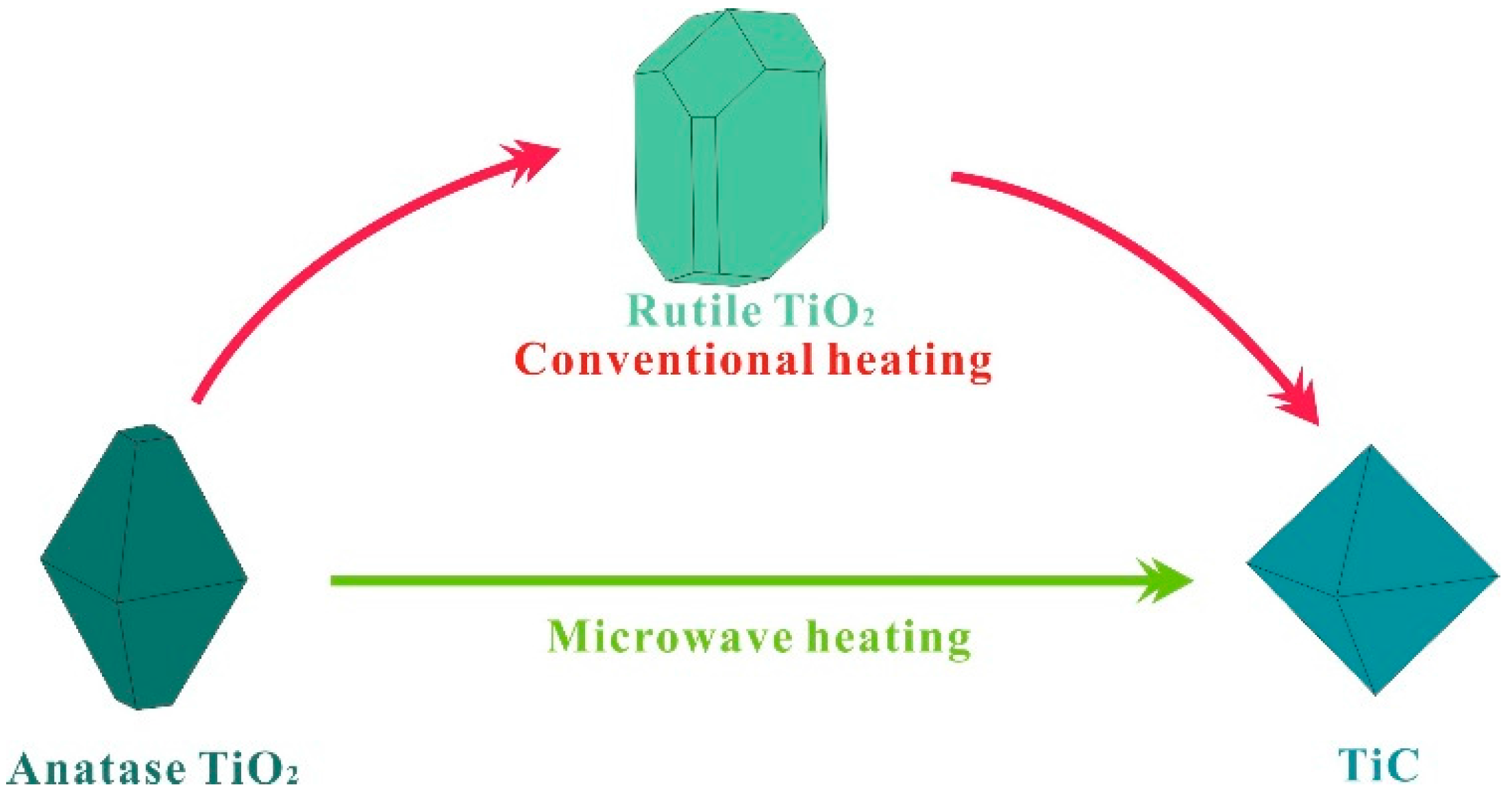

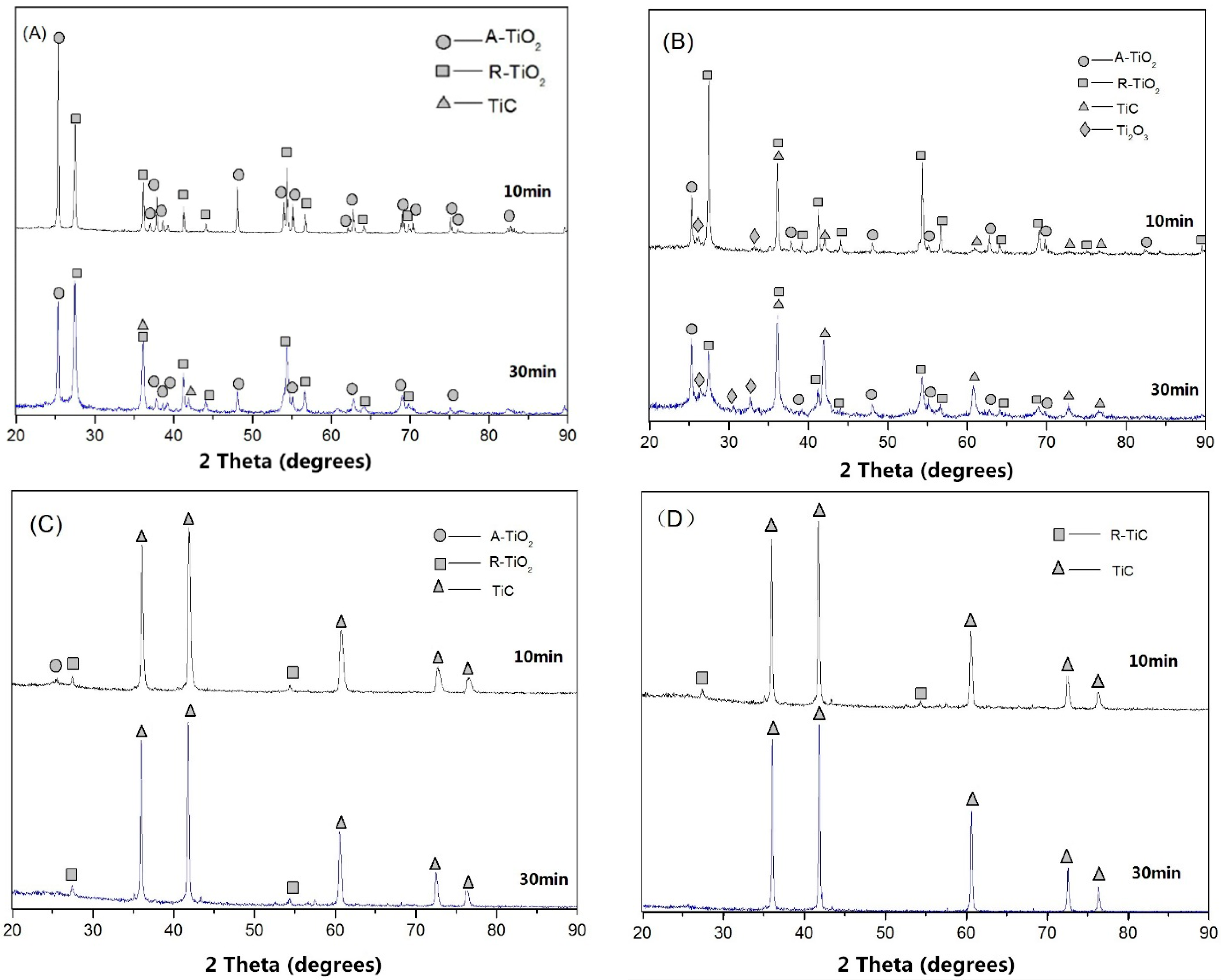

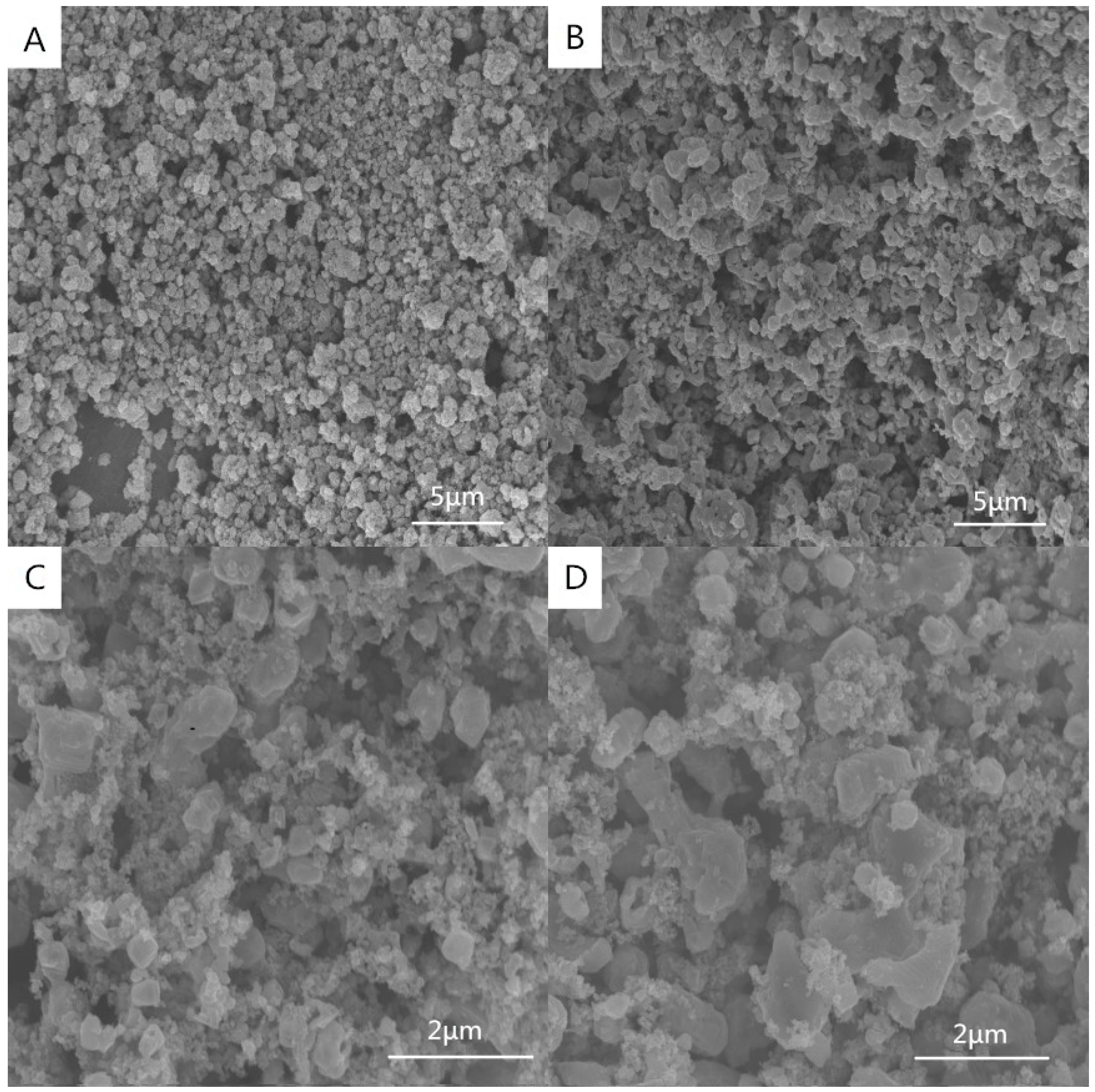

3.1. Effect of Temperature and Reaction Time

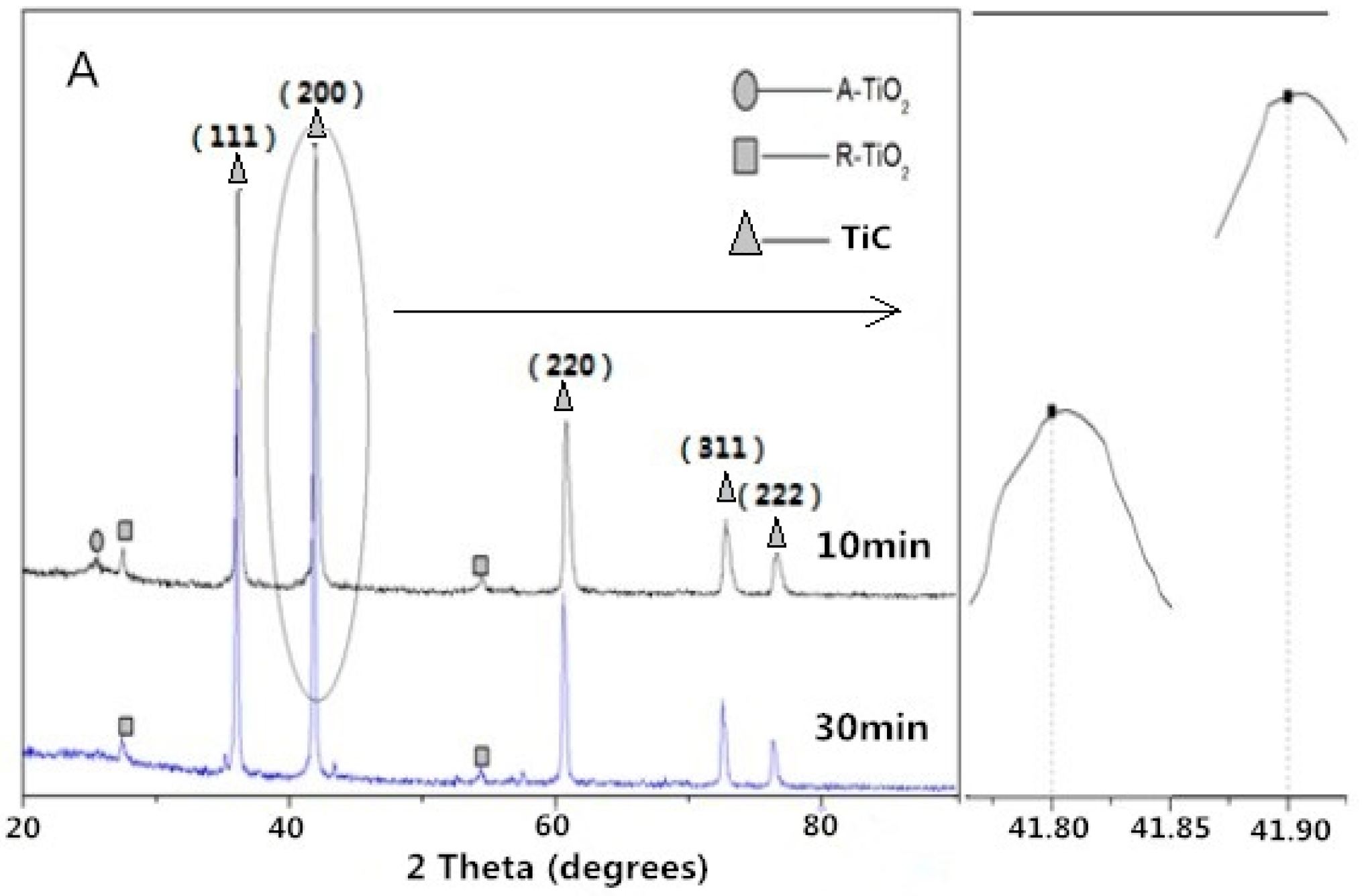

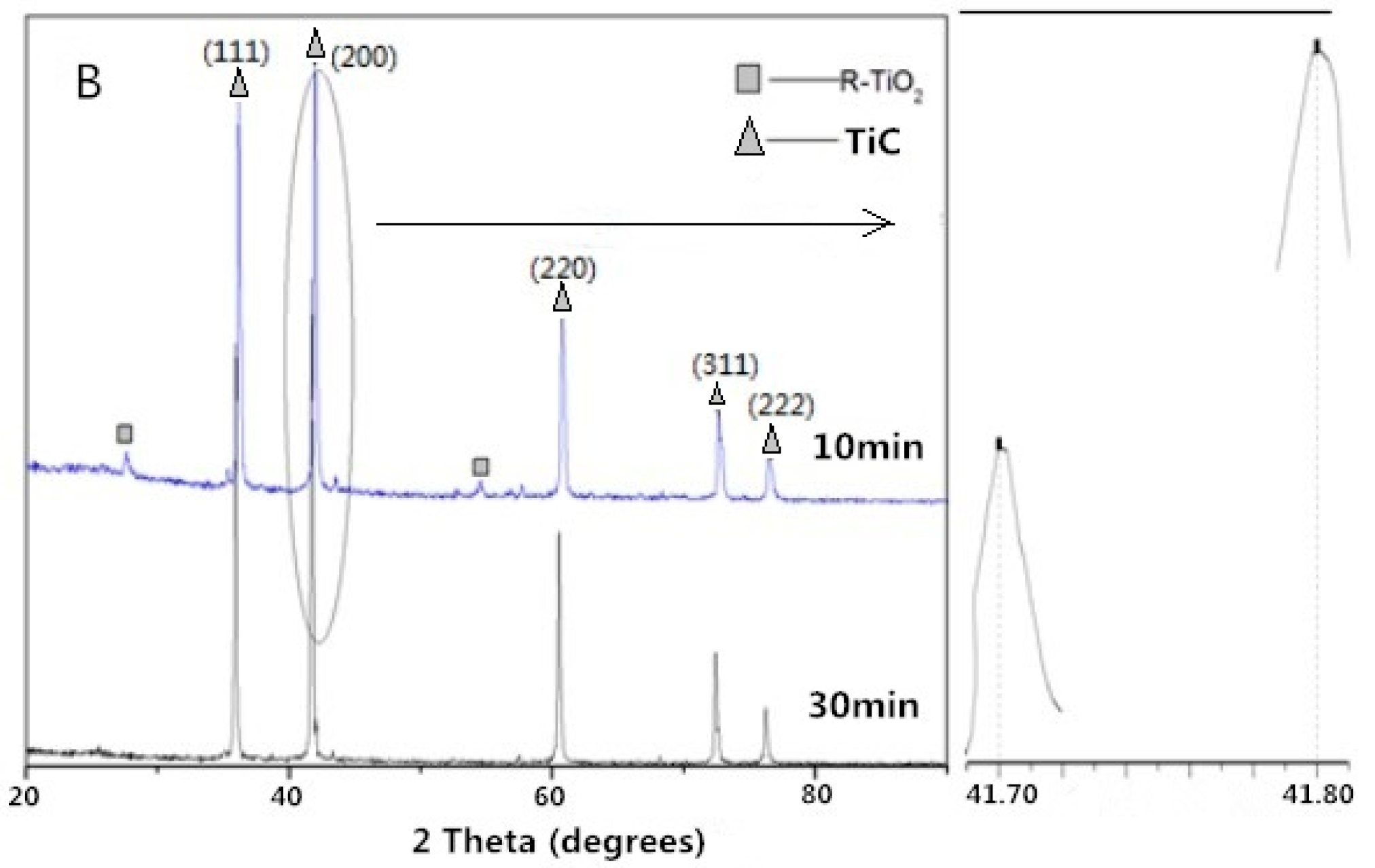

3.2. Effect of Carbon Content

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shin, Y.; Li, X.S.; Wang, C.; Coleman, J.R.; Exarhos, G.J. Synthesis of hierarchical titanium carbide from titania-coated cellulose paper. Adv. Mater. 2004, 16, 1212–1215. [Google Scholar] [CrossRef]

- Pierson, H.O. Handbook of Refractory Carbides & Nitrides: Properties, Characteristics, Processing and Apps; William Andrew: Norwich, NY, USA, 1996. [Google Scholar]

- Toth, L. Transition Metal Carbides and Nitrides; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Koc, R. Kinetics and phase evolution during carbothermal synthesis of titanium carbide from ultrafine titania/carbon mixture. J. Mater. Sci. 1998, 33, 1049–1055. [Google Scholar] [CrossRef]

- El-Eskandarany, M.S. Structure and properties of nanocrystalline TiC full-density bulk alloy consolidated from mechanically reacted powders. J. Alloys Compd. 2000, 305, 225–238. [Google Scholar] [CrossRef]

- Ushakov, A.; Karpov, I.; Lepeshev, A.; Krushenko, G. Physicochemical properties of nanomodifiers based on electric arc titanium nitride powder for polymer nanocomposite materials. Tekhnol. Met. 2011, 3, 16–21. [Google Scholar]

- Kappe, C.; Dallinger, D.; Murphree, S. Practical Microwave Synthesis for Organic Chemists: Strategies, Instruments, and Protocols; Wiley VCH Verlag GmbH & Co., KGaA: Weinheim, Germany, 2009. [Google Scholar]

- Choi, Y.; Rhee, S.-W. Effect of aluminium addition on the combustion reaction of titanium and carbon to form TiC. J. Mater. Sci. 1993, 28, 6669–6675. [Google Scholar] [CrossRef]

- Koc, R.; Folmer, J. Carbothermal synthesis of titanium carbide using ultrafine titania powders. J. Mater. Sci. 1997, 32, 3101–3111. [Google Scholar] [CrossRef]

- Thakur, S.K.; Kong, T.S.; Gupta, M. Microwave synthesis and characterization of metastable (Al/Ti) and hybrid (Al/Ti + SiC) composites. Mater. Sci. Eng. A 2007, 452, 61–69. [Google Scholar] [CrossRef]

- Rajkumar, K.; Aravindan, S. Microwave sintering of copper-graphite composites. J. Mater. Process. Technol. 2009, 209, 5601–5605. [Google Scholar] [CrossRef]

- Leparoux, S.; Vaucher, S.; Beffort, O. Assessment of microwave heating for sintering of Al/SiC and for in-situ synthesis of TiC. Adv. Eng. Mater. 2003, 5, 449–453. [Google Scholar] [CrossRef]

- Campanone, L.; Zaritzky, N. Mathematical analysis of microwave heating process. J. Food Eng. 2005, 69, 359–368. [Google Scholar] [CrossRef]

- Ciacci, T.; Galgano, A.; Di Blasi, C. Numerical simulation of the electromagnetic field and the heat and mass transfer processes during microwave-induced pyrolysis of a wood block. Chem. Eng. Sci. 2010, 65, 4117–4133. [Google Scholar] [CrossRef]

- Rosa, R.; Veronesi, P.; Leonelli, C. A review on combustion synthesis intensification by means of microwave energy. Chem. Eng. Process. Process Intensif. 2013, 71, 2–18. [Google Scholar] [CrossRef]

- Mishra, R.R.; Sharma, A.K. Microwave–material interaction phenomena: Heating mechanisms, challenges and opportunities in material processing. Compos. A Appl. Sci. Manuf. 2016, 81, 78–97. [Google Scholar] [CrossRef]

- Porcelli, M.; Cacciapuoti, G.; Fusco, S.; Massa, R.; d’Ambrosio, G.; Bertoldo, C.; De Rosa, M.; Zappia, V. Non-thermal effects of microwaves on proteins: Thermophilic enzymes as model system. FEBS Lett. 1997, 402, 102–106. [Google Scholar] [CrossRef]

- Moshtaghioun, B.; Poyato, R.; Cumbrera, F.; de Bernardi-Martin, S.; Monshi, A.; Abbasi, M.; Karimzadeh, F.; Dominguez-Rodriguez, A. Rapid carbothermic synthesis of silicon carbide nano powders by using microwave heating. J. Eur. Ceram. Soc. 2012, 32, 1787–1794. [Google Scholar] [CrossRef]

- Zhang, H.; Li, F.; Jia, Q.; Ye, G. Preparation of titanium carbide powders by sol-gel and microwave carbothermal reduction methods at low temperature. J. Sol-Gel Sci. Technol. 2008, 46, 217–222. [Google Scholar] [CrossRef]

- Binner, J.G.P.; Hassine, N.A.; Cross, T.E. The possible role of the pre-exponential factor in explaining the increased reaction rates observed during the microwave synthesis of titanium carbide. J. Mater. Sci. 1995, 30, 5389–5393. [Google Scholar] [CrossRef]

- Hassine, N.A.; Binner, J.G.P.; Cross, T.E. Synthesis of refractory metal carbide powders via microwave carbothermal reduction. Int. J. Refract. Met. Hard Mater. 1995, 13, 353–358. [Google Scholar] [CrossRef]

- Holt, J.; Munir, Z. Combustion synthesis of titanium carbide: Theory and experiment. J. Mater. Sci. 1986, 21, 251–259. [Google Scholar] [CrossRef]

- Zeng, L.K.; Liu, Y.C.; Zhu, W.C.; Liu, P.A.; Wang, H.; Cheng, X.S.; Liang, Q.Y. Investigation on the continuous microwave synthesis of nano titanium carbide powder. Adv. Mater. Res. 2014, 1064, 66–70. [Google Scholar] [CrossRef]

- Chen, Y.-F.; Lee, C.-Y.; Yeng, M.-Y.; Chiu, H.-T. The effect of calcination temperature on the crystallinity of TiO2 nanopowders. J. Cryst. Growth 2003, 247, 363–370. [Google Scholar] [CrossRef]

- Colmenares, J.; Aramendia, M.; Marinas, A.; Marinas, J.; Urbano, F. Synthesis, characterization and photocatalytic activity of different metal-doped titania systems. Appl. Catal A Gen. 2006, 306, 120–127. [Google Scholar] [CrossRef]

- Lucarelli, L.; Nadtochenko, V.; Kiwi, J. Environmental photochemistry: Quantitative adsorption and FTIR studies during the TiO2-photocatalyzed degradation of orange II. Langmuir 2000, 16, 1102–1108. [Google Scholar] [CrossRef]

- Diamandescu, L.; Vasiliu, F.; Tarabasanu-Mihaila, D.; Feder, M.; Vlaicu, A.; Teodorescu, C.; Macovei, D.; Enculescu, I.; Parvulescu, V.; Vasile, E. Structural and photocatalytic properties of iron-and europium-doped TiO2 nanoparticles obtained under hydrothermal conditions. Mater. Chem. Phys. 2008, 112, 146–153. [Google Scholar] [CrossRef]

- Jung, Y.-S.; Kim, D.-W.; Kim, Y.-S.; Park, E.-K.; Baeck, S.-H. Synthesis of alumina-titania solid solution by sol-gel method. J. Phys. Chem. Solids 2008, 69, 1464–1467. [Google Scholar] [CrossRef]

- Preiss, H.; Berger, L.-M.; Schultze, D. Studies on the carbothermal preparation of titanium carbide from different gel precursors. J. Eur. Ceram. Soc. 1999, 19, 195–206. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, H.; Li, F.; Lu, L.; Zhang, S. Preparation and characterization of ultrafine ZrB2–SiC composite powders by a combined sol-gel and microwave boro/carbothermal reduction method. Ceram. Int. 2015, 41, 7823–7829. [Google Scholar] [CrossRef]

| TiO2:C (mol:mol/wt:wt) | Composition of Product (wt %) | TiC (200) Peak Position (Degree) | Lattice Constant of TiC (Å) | ||

|---|---|---|---|---|---|

| TiO2 | C | TiC | |||

| 1:3.0/1:0.45 | 15.5 | 4.2 | 80.3 | 41.92 | 4.319 |

| 1:3.2/1:0.48 | 6.7 | 5.7 | 87.6 | 41.86 | 4.320 |

| 1:3.4/1:0.51 | 2.4 | 8.3 | 89.3 | 41.78 | 4.322 |

| 1:3.6/1:0.54 | 0 | 9.4 | 90.6 | 41.70 | 4.324 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zhu, W.; Liu, Y.; Zeng, L.; Sun, L. The Microwave-Assisted Green Synthesis of TiC Powders. Materials 2016, 9, 904. https://doi.org/10.3390/ma9110904

Wang H, Zhu W, Liu Y, Zeng L, Sun L. The Microwave-Assisted Green Synthesis of TiC Powders. Materials. 2016; 9(11):904. https://doi.org/10.3390/ma9110904

Chicago/Turabian StyleWang, Hui, Wencheng Zhu, Yanchun Liu, Lingke Zeng, and Luyi Sun. 2016. "The Microwave-Assisted Green Synthesis of TiC Powders" Materials 9, no. 11: 904. https://doi.org/10.3390/ma9110904