Analytical Modelling and Optimization of the Temperature-Dependent Dynamic Mechanical Properties of Fused Deposition Fabricated Parts Made of PC-ABS

Abstract

:1. Introduction

2. Experimental Producers

2.1. Experimental Work

2.2. Experimental Design

3. Results and Discussion

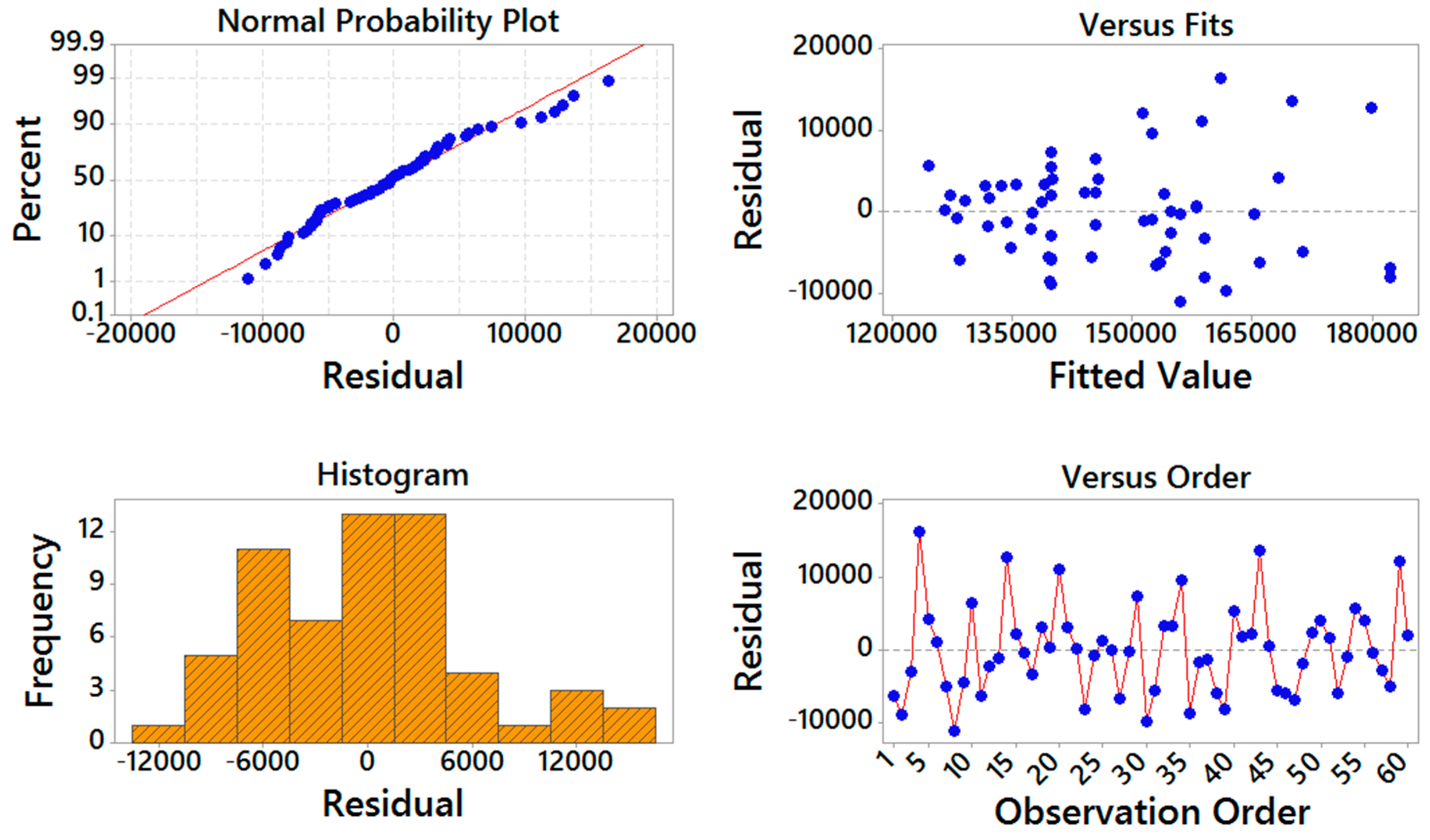

3.1. Multiple Regression Analysis

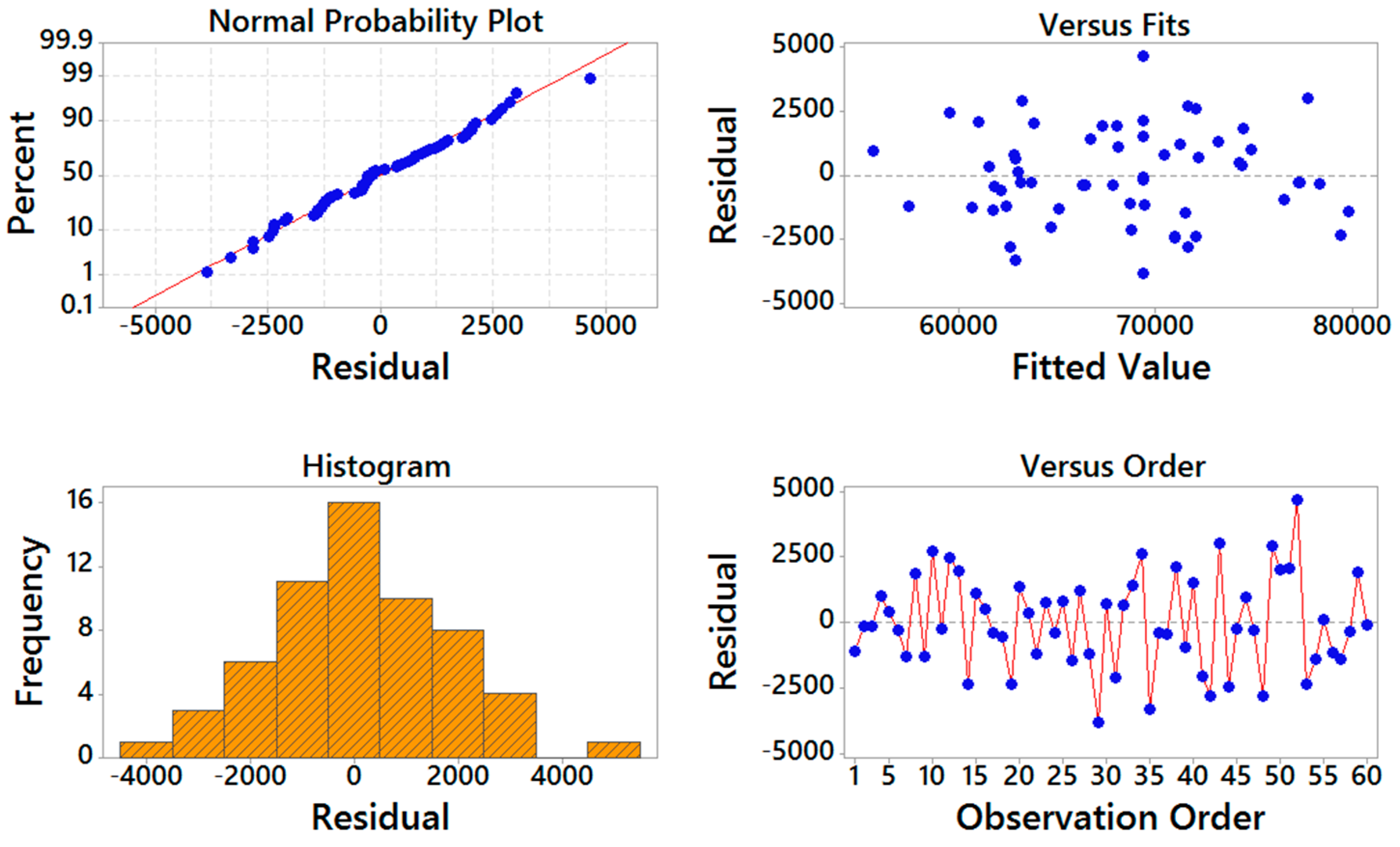

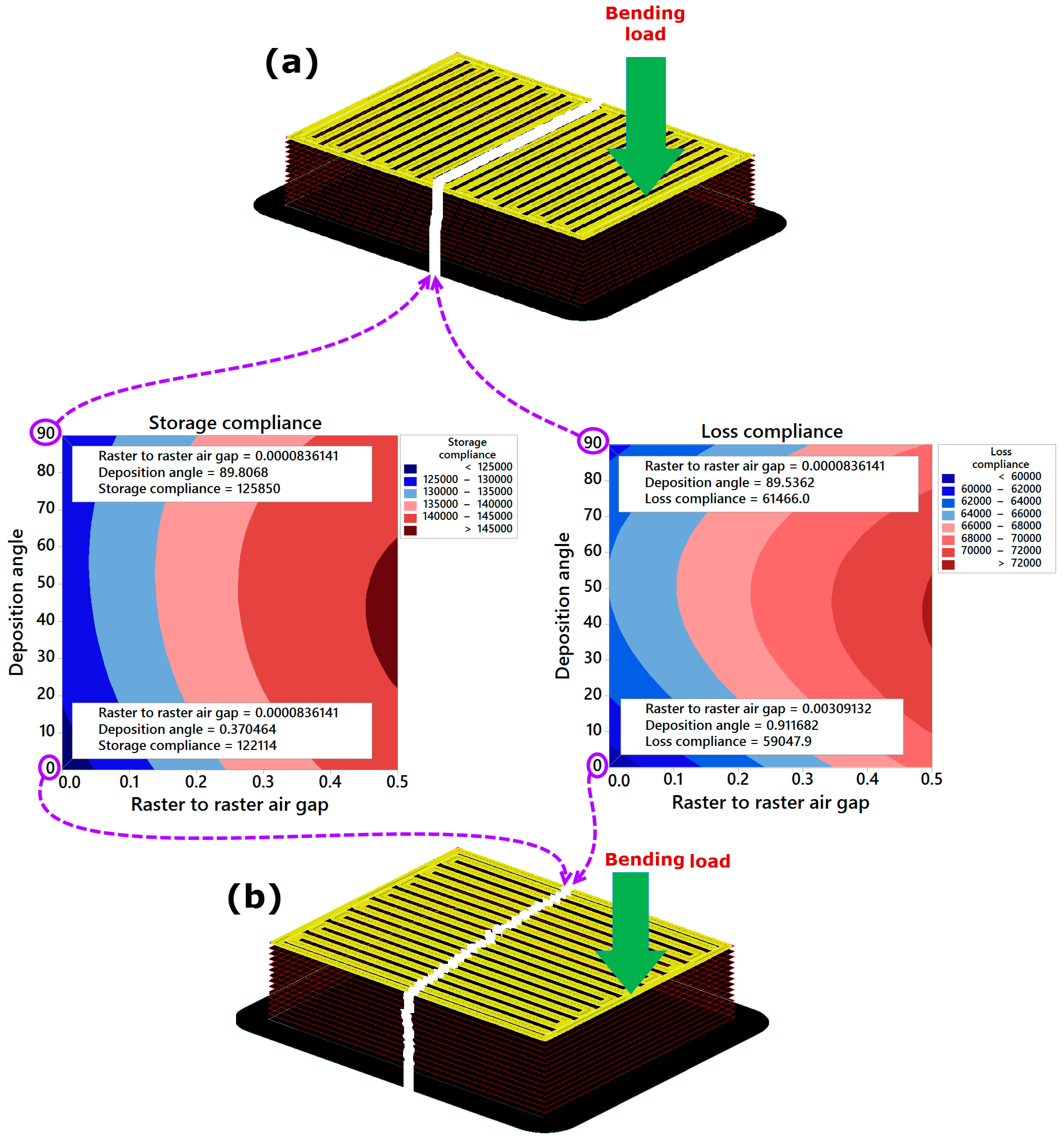

3.2. Influence of Processing Parameters on Storage Compliance and Loss Compliance

3.3. Interaction Effects

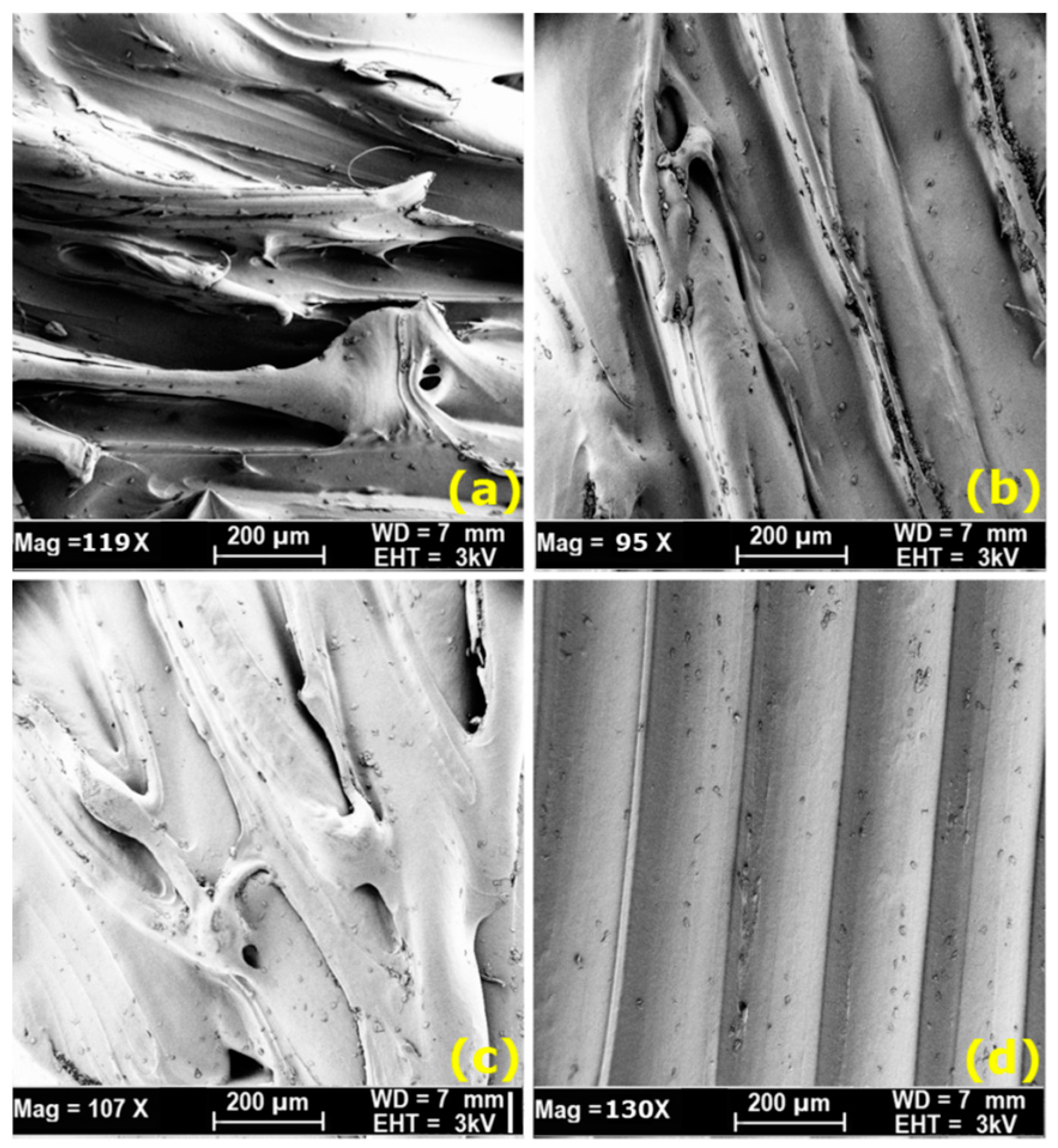

3.4. Morphology

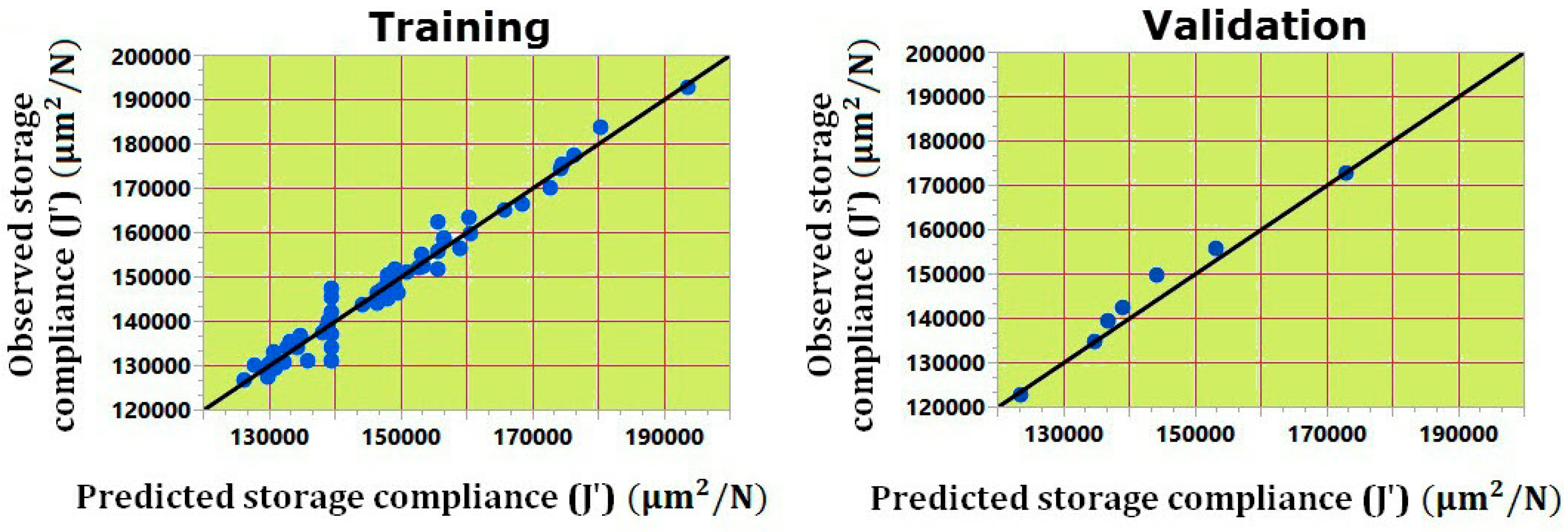

3.5. Modeling with Multilayer Feed-Forward Neural Network (MFNN)

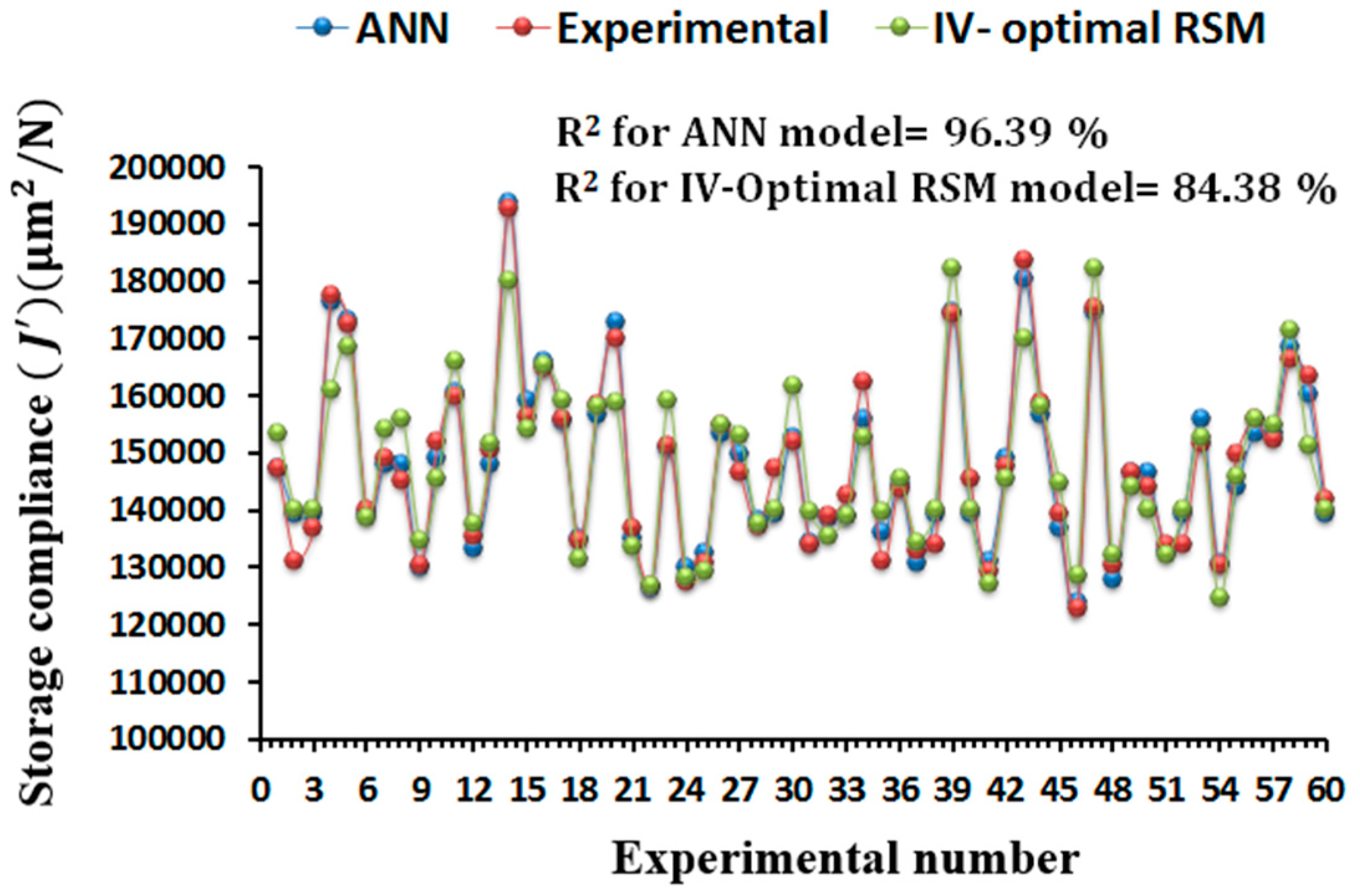

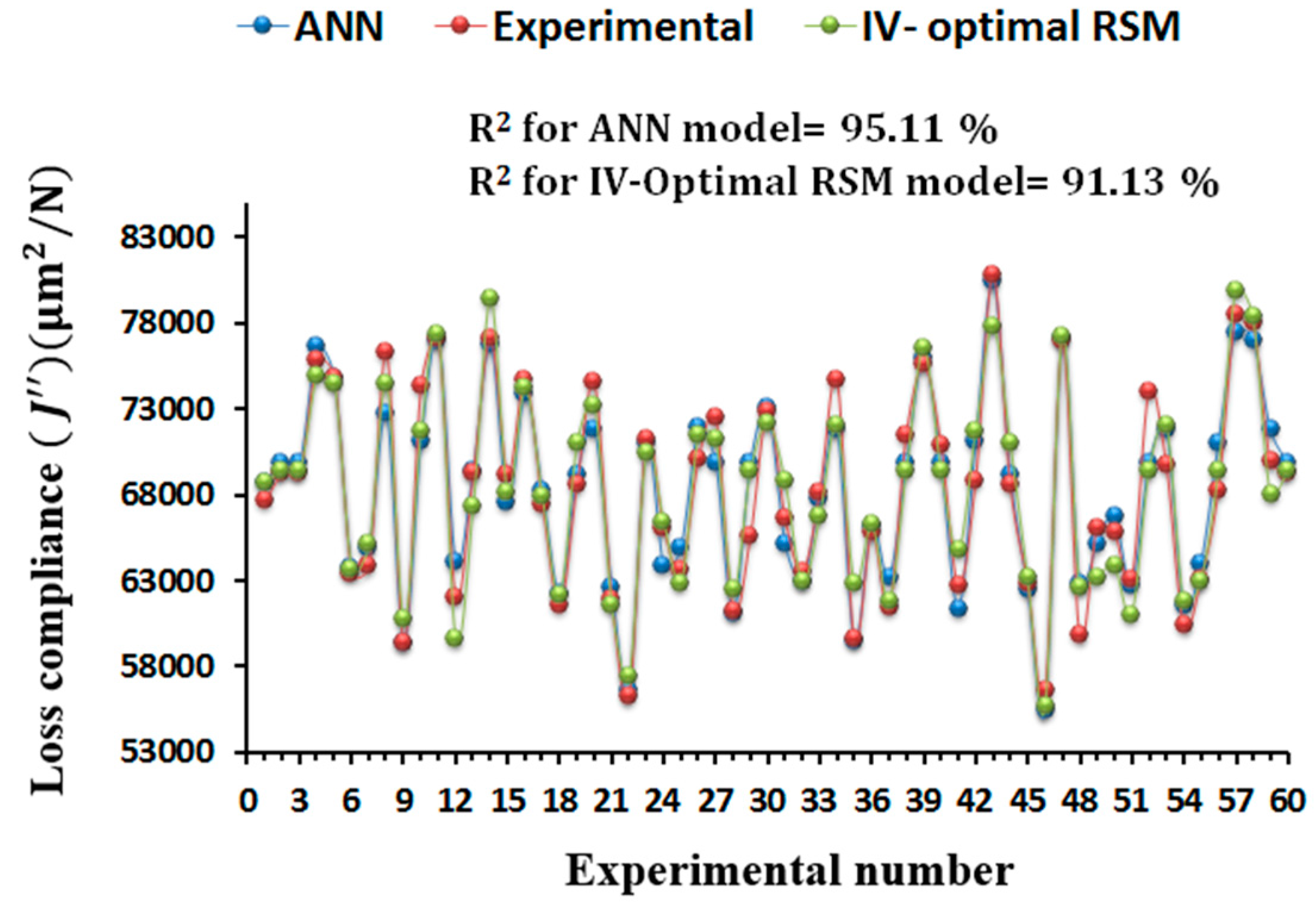

Comparison between ANN and IV-Optimal RSM Models

- 0.1270 mm ≤ ≤ 0.3302 mm

- 0 ≤ ≤ 0.5 mm

- 0° ≤ ≤ 90°

- 0° ≤ ≤ 90°

- 0.4572 mm ≤ ≤ 0.5782 mm

- 1 ≤ ≤ 10

4. Concluding Remarks

- This study has shown for first time that the FDM process conditions have significant influence on the temperature-dependent dynamic mechanical properties of printed PC-ABS parts.

- This work has proposed an effective approach to improve the dynamic mechanical properties as of the FDM fabricated parts as a function of temperature by accurately selecting suitable multi-level process parameters with less number of experiments compared to the traditional response surface designs such as central composite design and face centered composite design when considering the replication of design points.

- The IV-optimality response surface design was found to be an efficient and effective design in process optimization involving many parameters with multiple levels.

- Although MFNN performed slightly better, the IV-Optimal RSM was also found to be a promising design in prediction performance, where good agreement between IV-Optimal RSM models, MFNN models and experimental results was observed.

- It has been observed that storage compliance is more sensitive to slice thickness, raster to raster air gap, and the number of perimeters followed by part print direction and bead width. However, the deposition angle is less effective.

- It has been found that loss compliance is significantly affected by the variables. However, raster to raster air gap, slice thickness and number of perimeters are found to be the most influential variables.

- All parameters can be used effectively for improvement in the dynamic mechanical properties as a function of temperature. The anisotropic behavior of FDM built part was mainly caused by interlayer porosity and weak interlayer bonding.

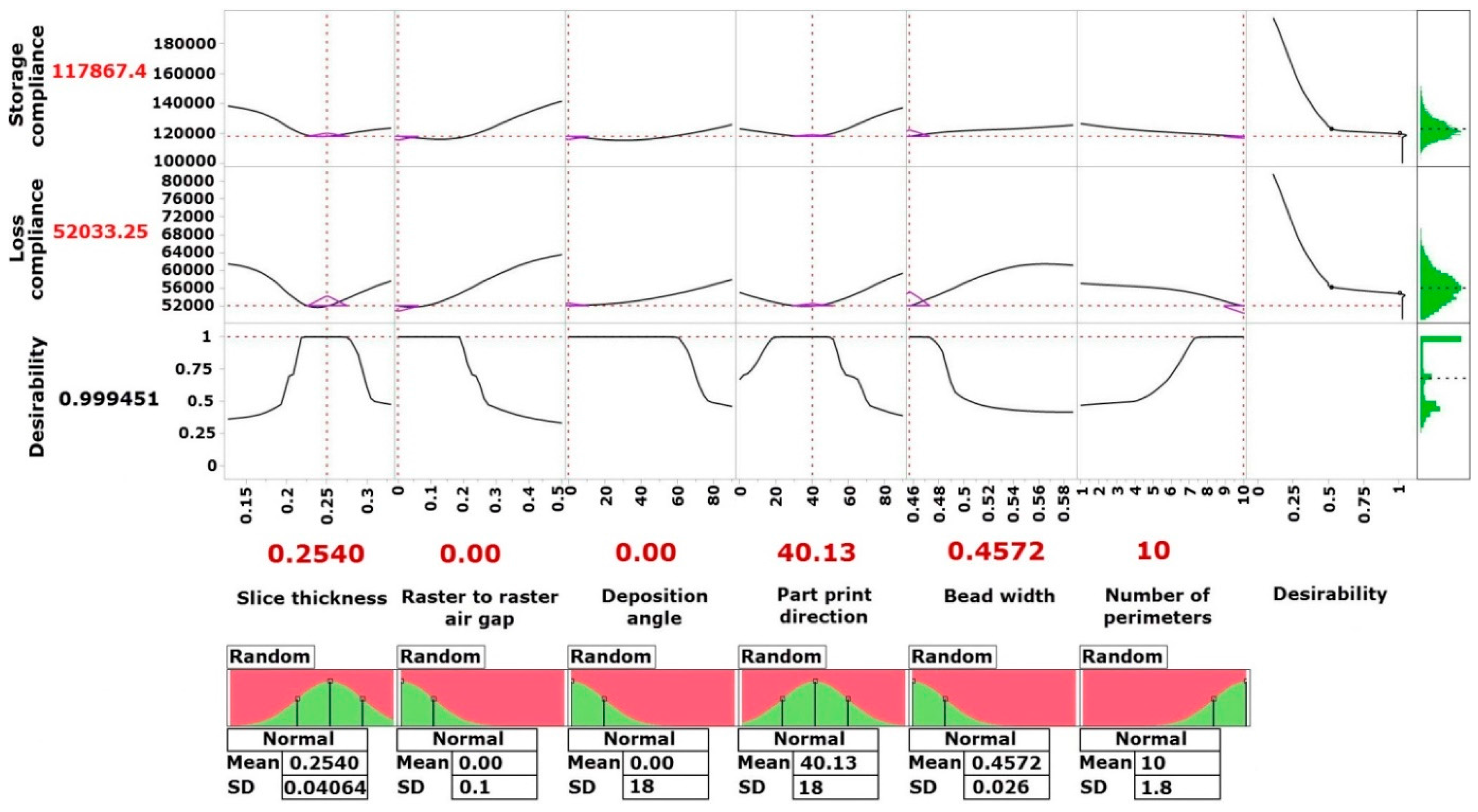

- Based on multi-response optimization process, slice thickness of 0.2540 mm, no raster to raster air gap, disposition angle of 0°, part print direction of 40.13°, bead width of 0.4572 mm and 10 perimeters seem to be the favourable values to improve the temperature-dependent dynamic mechanical properties of the parts printed by FDM.

Author Contributions

Conflicts of Interest

References

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- Chapman, B. Increasing Toughness of 3D-Printed Plastic Using Acetone Vapor. Available online: https://benchapman4.wordpress.com/2014/05/08/increasing-toughness-of-3D-printed-plastic-using-acetone-vapor/ (accessed on 1 November 2016).

- Whelan, A. Polymer Technology Dictionary; Springer: Houten, The Netherlands, 2012. [Google Scholar]

- Ferry, J.D. Viscoelastic Properties of Polymers; John Wiley & Sons: Hoboken, NJ, USA, 1980. [Google Scholar]

- Menard, K.P. Dynamic Mechanical Analysis: A Practical Introduction; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Murayama, T. Dynamic Mechanical Analysis of Polymeric Material; Elsevier: Amsterdam, The Netherlands, 1978. [Google Scholar]

- Arivazhagan, A.; Masood, S. Dynamic mechanical properties of abs material processed by fused deposition modelling. Int. J. Eng. Res. Appl. 2012, 2, 2009–2014. [Google Scholar]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of layer thickness and raster angle on the mechanical properties of 3D-printed PEEK and a comparative mechanical study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef]

- Murphy, C.A.; Collins, M.N. Microcrystalline cellulose reinforced polylactic acid biocomposite filaments for 3D printing. Polym. Compos. Available online: http://onlinelibrary.wiley.com/doi/10.1002/pc.24069/full (accessed on 1 November 2016). [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L.; Nikzad, M.; Azadmanjiri, J. Effect of process parameters on dynamic mechanical performance of fdm PC/ABS printed parts through design of experiment. J. Mater. Eng. Perform. 2016, 25, 2922–2935. [Google Scholar] [CrossRef]

- Zou, R.; Xia, Y.; Liu, S.; Hu, P.; Hou, W.; Hu, Q.; Shan, C. Isotropic and anisotropic elasticity and yielding of 3D printed material. Compos. Part B Eng. 2016, 99, 506–513. [Google Scholar] [CrossRef]

- Panda, B.N.; Shankhwar, K.; Garg, A.; Jian, Z. Performance evaluation of warping characteristic of fused deposition modelling process. Int. J. Adv. Manuf. Technol. 2016. Avalable online: http://link.springer.com/article/10.1007/s00170-016-8914-8 (accessed on 1 November 2016). [Google Scholar] [CrossRef]

- Wendt, C.; Fernández-Vidal, S.R.; Gómez-Parra, Á.; Batista, M.; Marcos, M. Processing and quality evaluation of additive manufacturing monolayer specimens. Adv. Mater. Sci. Eng. 2016, 2016, 5780693. [Google Scholar] [CrossRef]

- Lanzotti, A.; Grasso, M.; Staiano, G.; Martorelli, M.; Pei, E.; Campbell, R.I. The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer. Rapid Prototyp. J. 2015, 21, 604–617. [Google Scholar] [CrossRef]

- Rayegani, F.; Onwubolu, G.C. Fused deposition modelling (FDM) process parameter prediction and optimization using group method for data handling (GMDH) and differential evolution (DE). Int. J. Adv. Manuf. Technol. 2014, 73, 509–519. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties. J. Compos. Mater. 2016. Avalable online: http://jcm.sagepub.com/content/early/2016/04/28/0021998316646169.abstract (accessed on 1 November 2016). [Google Scholar] [CrossRef]

- Impens, D.; Urbanic, R. Assessing the impact of post-processing variables on tensile and compression characteristics for 3D printed components. IFAC PapersOnLine 2015, 48, 652–657. [Google Scholar] [CrossRef]

- Durgun, I.; Ertan, R. Experimental investigation of FDM process for improvement of mechanical properties and production cost. Rapid Prototyp. J. 2014, 20, 228–235. [Google Scholar] [CrossRef]

- Active Standard ASTM D4065. Standard Practice for Determining and Reporting Dynamic Mechanical Properties of Plastics; American Society of Testing and Materials: West Conshohocken, PA, USA, 2001. [Google Scholar]

- DMA2980 Dynamic Mechanical Analysis; Operator’s Manual; TA Instruments: New Castle, DE, USA, 2002; pp. 4–8.

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2009; Volume 705. [Google Scholar]

- Douglas, C.M. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Es-Said, O.; Foyos, J.; Noorani, R.; Mendelson, M.; Marloth, R.; Pregger, B. Effect of layer orientation on mechanical properties of rapid prototyped samples. Mater. Manuf. Process. 2000, 15, 107–122. [Google Scholar] [CrossRef]

- Towell, G.G.; Shavlik, J.W. Knowledge-based artificial neural networks. Artif. Intell. 1994, 70, 119–165. [Google Scholar] [CrossRef]

- Pal, S.K.; Mitra, S. Multilayer perceptron, fuzzy sets, and classification. IEEE Trans. Neural Netw. 1992, 3, 683–697. [Google Scholar] [CrossRef] [PubMed]

- Refaeilzadeh, P.; Tang, L.; Liu, H. Cross-validation. In Encyclopedia of Database Systems; Springer: New York, NY, USA, 2009; pp. 532–538. [Google Scholar]

| Factor | Symbol | Unit | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | Level 6 |

|---|---|---|---|---|---|---|---|---|

| Slice thickness | mm | 0.1270 | 0.1778 | 0.2540 | 0.3302 | - | - | |

| Raster to raster air gap | mm | 0 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | |

| Deposition angle | Degree | 0 | 15 | 30 | 45 | 60 | 90 | |

| Part print direction | Degree | 0 | 30 | 45 | 60 | 75 | 90 | |

| Bead width | mm | 0.4572 | 0.4814 | 0.5056 | 0.5298 | 0.5540 | 0.5782 | |

| Number of perimeters | - | 1 | 3 | 5 | 7 | 8 | 10 |

| S. No | Factors | Responses | S. No | Factors | Responses | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 6 | 6 | 6 | 1 | 1 | 147,118 | 67,605.5 | 31 | 4 | 6 | 4 | 3 | 1 | 6 | 134,002 | 66,648.3 |

| 2 | 3 | 4 | 4 | 3 | 4 | 3 | 131,033 | 69,235.0 | 32 | 4 | 6 | 6 | 6 | 6 | 6 | 138,809 | 63,518.3 |

| 3 | 3 | 4 | 4 | 3 | 4 | 3 | 136,947 | 69,235.0 | 33 | 4 | 6 | 1 | 1 | 6 | 6 | 142,436 | 68,142.8 |

| 4 | 4 | 5 | 6 | 2 | 2 | 1 | 177,380 | 75,885.9 | 34 | 4 | 3 | 5 | 6 | 6 | 1 | 162,230 | 74,662.6 |

| 5 | 1 | 3 | 4 | 6 | 1 | 1 | 172,573 | 74,839.4 | 35 | 3 | 6 | 1 | 6 | 6 | 4 | 131,088 | 59,555.3 |

| 6 | 3 | 3 | 4 | 6 | 1 | 3 | 139,907 | 63,371.1 | 36 | 4 | 3 | 1 | 1 | 6 | 1 | 143,774 | 65,864.4 |

| 7 | 1 | 1 | 1 | 3 | 1 | 3 | 149,156 | 63,814.7 | 37 | 4 | 1 | 1 | 4 | 6 | 3 | 133,017 | 61,386.3 |

| 8 | 4 | 6 | 1 | 6 | 2 | 1 | 144,983 | 76,276.9 | 38 | 3 | 4 | 4 | 3 | 4 | 3 | 134,008 | 71,511.7 |

| 9 | 4 | 1 | 6 | 6 | 1 | 5 | 130,321 | 59,417.7 | 39 | 1 | 6 | 1 | 6 | 6 | 1 | 174,213 | 75,588.2 |

| 10 | 1 | 1 | 4 | 1 | 3 | 4 | 151,821 | 74,398.9 | 40 | 3 | 4 | 4 | 3 | 4 | 3 | 145,352 | 70,910.0 |

| 11 | 4 | 6 | 6 | 1 | 6 | 1 | 159,770 | 77,059.7 | 41 | 3 | 1 | 4 | 6 | 3 | 4 | 129,203 | 62,674.9 |

| 12 | 4 | 3 | 1 | 6 | 1 | 6 | 135,250 | 62,019.3 | 42 | 1 | 1 | 4 | 1 | 3 | 4 | 147,701 | 68,863.5 |

| 13 | 4 | 4 | 6 | 1 | 1 | 4 | 150,393 | 69,223.7 | 43 | 2 | 6 | 4 | 2 | 6 | 1 | 183,669 | 80,813.4 |

| 14 | 2 | 6 | 1 | 1 | 1 | 1 | 192,771 | 77,087.9 | 44 | 1 | 3 | 4 | 3 | 6 | 6 | 158,671 | 68,532.9 |

| 15 | 1 | 1 | 6 | 3 | 1 | 6 | 156,206 | 69,187.4 | 45 | 1 | 1 | 1 | 1 | 6 | 1 | 139,286 | 62,858.5 |

| 16 | 1 | 6 | 6 | 5 | 3 | 3 | 164,988 | 74,728.0 | 46 | 3 | 1 | 1 | 1 | 1 | 6 | 122,608 | 56,563.3 |

| 17 | 1 | 6 | 6 | 1 | 6 | 6 | 155,824 | 67,458.0 | 47 | 1 | 4 | 6 | 1 | 1 | 1 | 175,489 | 76,955.9 |

| 18 | 4 | 1 | 6 | 4 | 2 | 1 | 134,693 | 61,586.0 | 48 | 3 | 4 | 6 | 2 | 3 | 6 | 130,149 | 59,779.1 |

| 19 | 1 | 3 | 4 | 3 | 6 | 6 | 158,461 | 68,621.9 | 49 | 2 | 1 | 1 | 6 | 6 | 6 | 146,428 | 66,077.9 |

| 20 | 1 | 6 | 3 | 5 | 5 | 5 | 169,847 | 74,528.4 | 50 | 2 | 4 | 6 | 6 | 4 | 6 | 144,053 | 65,860.6 |

| 21 | 4 | 1 | 3 | 1 | 1 | 1 | 136,729 | 61,905.2 | 51 | 3 | 2 | 6 | 2 | 6 | 3 | 133,867 | 63,086.1 |

| 22 | 3 | 6 | 6 | 6 | 1 | 6 | 126,739 | 56,229.2 | 52 | 3 | 4 | 4 | 3 | 4 | 3 | 134,081 | 74,051.5 |

| 23 | 1 | 1 | 6 | 6 | 6 | 2 | 151,075 | 71,195.6 | 53 | 4 | 3 | 5 | 6 | 6 | 1 | 151,642 | 69,696.0 |

| 24 | 4 | 1 | 3 | 3 | 4 | 6 | 127,379 | 66,034.9 | 54 | 4 | 1 | 6 | 1 | 6 | 6 | 130,200 | 60,367.1 |

| 25 | 2 | 1 | 6 | 1 | 4 | 1 | 130,522 | 63,574.9 | 55 | 3 | 4 | 1 | 3 | 1 | 3 | 149,788 | 63,106.9 |

| 26 | 3 | 6 | 6 | 5 | 5 | 1 | 154,905 | 70,040.4 | 56 | 1 | 4 | 1 | 3 | 3 | 6 | 155,763 | 68,279.9 |

| 27 | 2 | 6 | 5 | 1 | 1 | 6 | 146,426 | 72,460.2 | 57 | 4 | 6 | 4 | 1 | 3 | 3 | 152,173 | 78,448.7 |

| 28 | 2 | 6 | 1 | 6 | 3 | 1 | 137,239 | 61,210.1 | 58 | 1 | 5 | 2 | 4 | 3 | 2 | 166,293 | 78,017.9 |

| 29 | 3 | 4 | 4 | 3 | 4 | 3 | 147,252 | 65,559.7 | 59 | 1 | 6 | 2 | 6 | 1 | 6 | 163,460 | 69,954.7 |

| 30 | 1 | 4 | 1 | 1 | 4 | 4 | 152,018 | 72,879.2 | 60 | 3 | 4 | 4 | 3 | 4 | 3 | 141,899 | 69,298.1 |

| Dependent Variables | Optimal Process Settings | Actual Values | IV-Optimal RSM Model at 95% CI | ANN Model | |||||

|---|---|---|---|---|---|---|---|---|---|

| Storage compliance | 0.2540 | 0 | 0 | 40.13 | 0.4572 | 10 | 118,046.2 | 122,925 | 117,867.4 |

| Loss compliance | 53,334.03 | 53,562.7 | 52,033.25 | ||||||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Analytical Modelling and Optimization of the Temperature-Dependent Dynamic Mechanical Properties of Fused Deposition Fabricated Parts Made of PC-ABS. Materials 2016, 9, 895. https://doi.org/10.3390/ma9110895

Mohamed OA, Masood SH, Bhowmik JL. Analytical Modelling and Optimization of the Temperature-Dependent Dynamic Mechanical Properties of Fused Deposition Fabricated Parts Made of PC-ABS. Materials. 2016; 9(11):895. https://doi.org/10.3390/ma9110895

Chicago/Turabian StyleMohamed, Omar Ahmed, Syed Hasan Masood, and Jahar Lal Bhowmik. 2016. "Analytical Modelling and Optimization of the Temperature-Dependent Dynamic Mechanical Properties of Fused Deposition Fabricated Parts Made of PC-ABS" Materials 9, no. 11: 895. https://doi.org/10.3390/ma9110895