Chemical Synthesis and Oxide Dispersion Properties of Strengthened Tungsten via Spark Plasma Sintering

Abstract

:1. Introduction

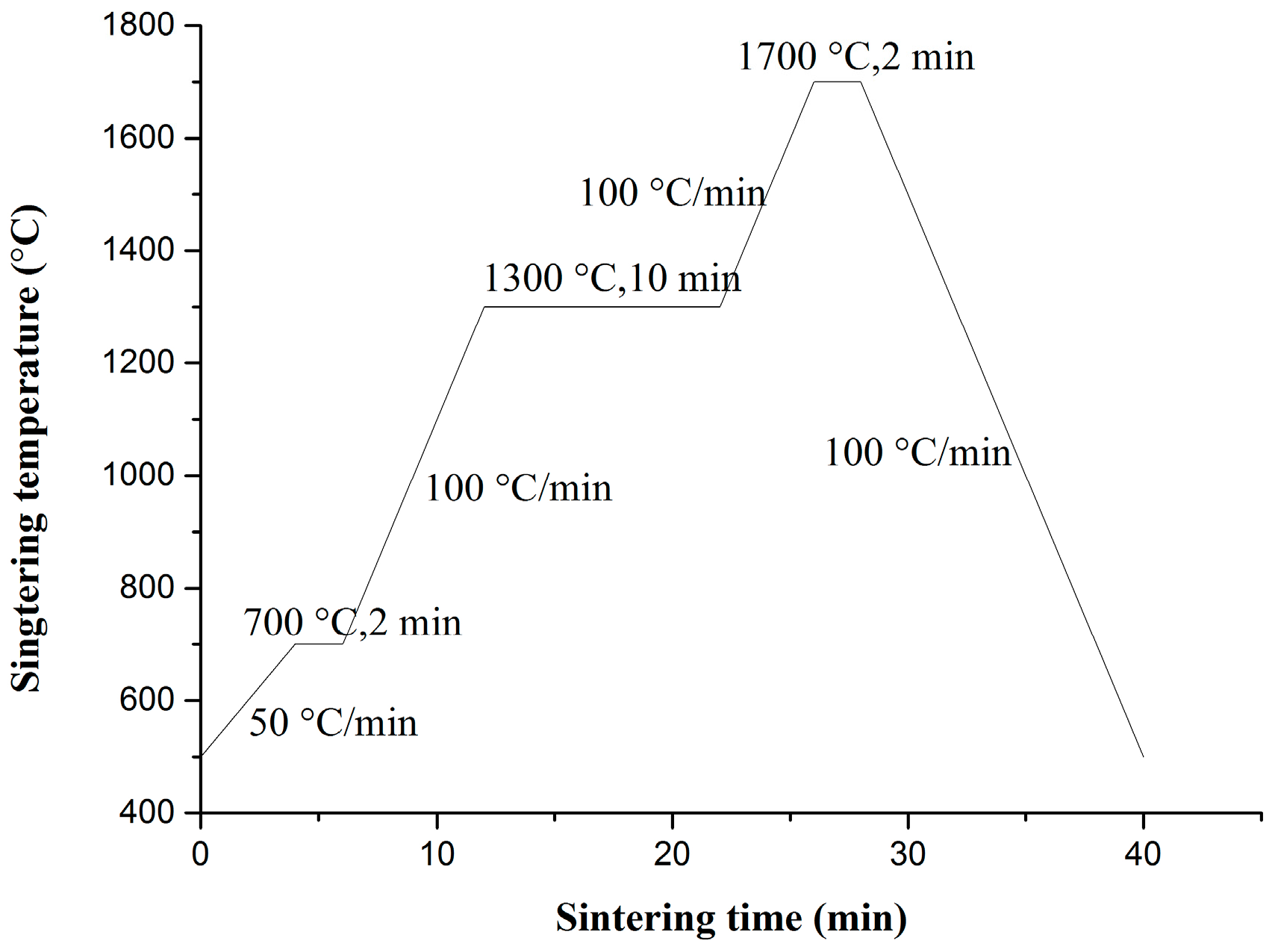

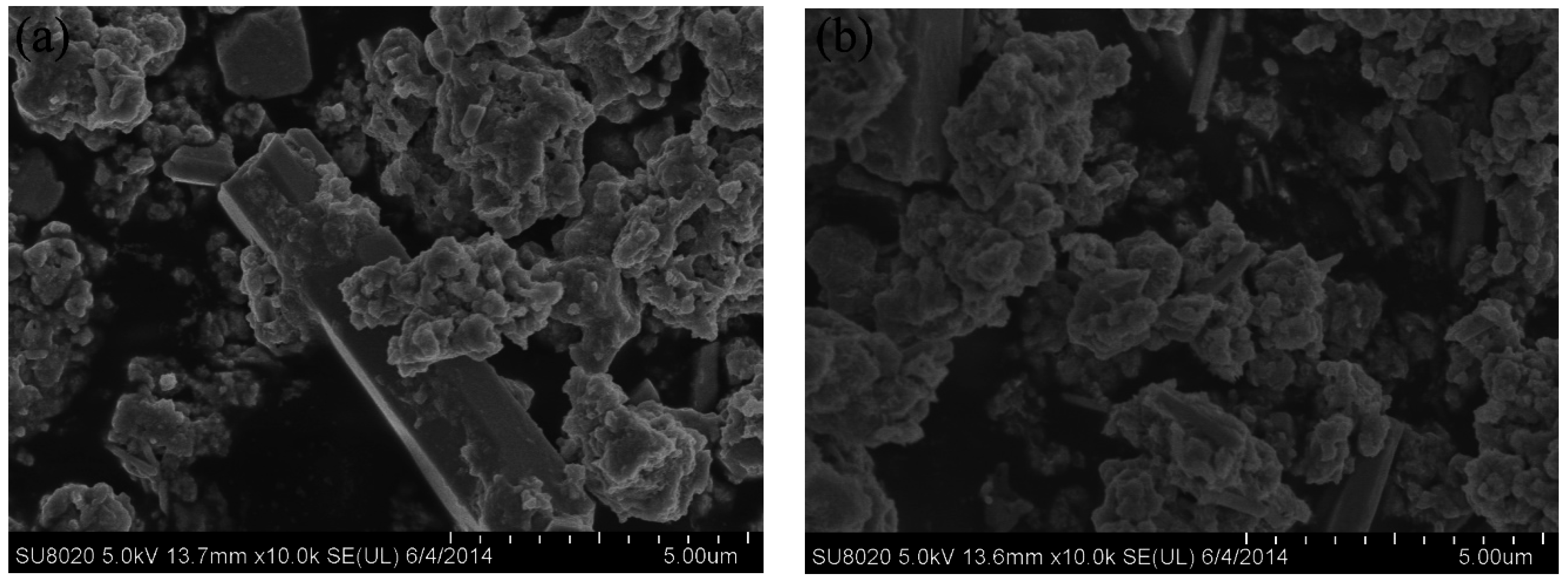

2. Experimental Procedure

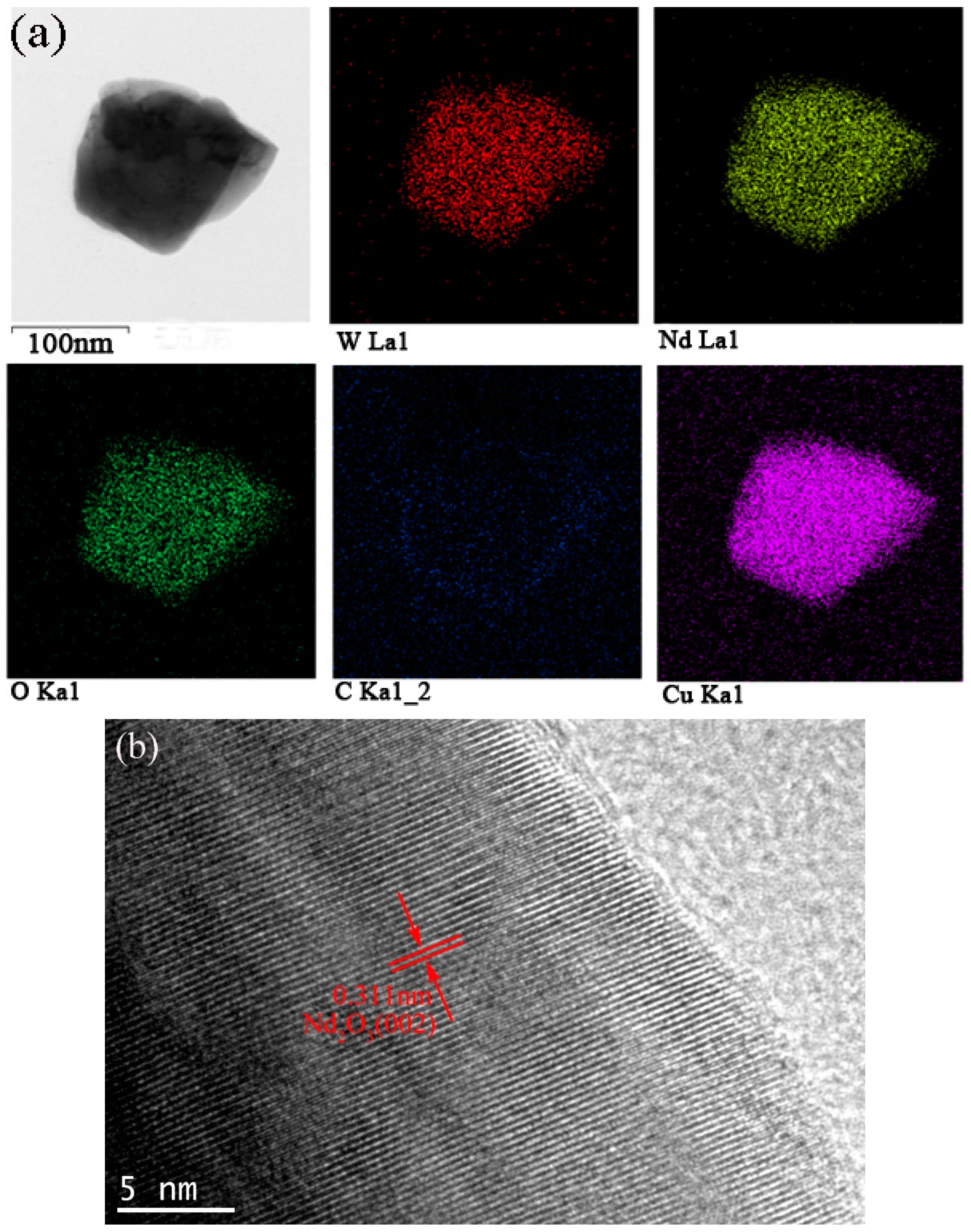

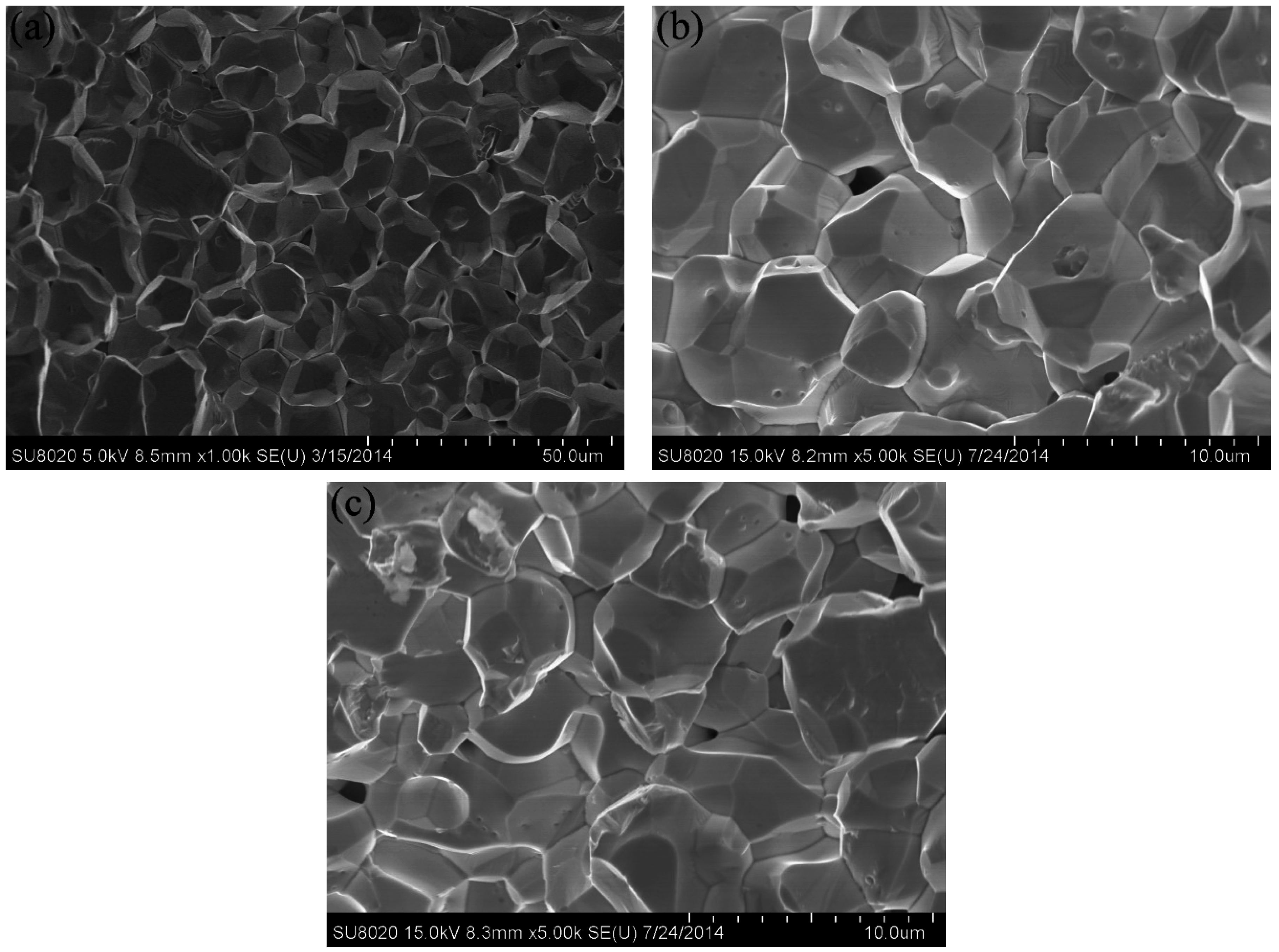

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Terentyev, D.; Dubinko, V.; Bakaev, A.; Zayachuk, Y.; Renterghem, W.V.; Grigorev, P. Dislocations mediate hydrogen retention in tungsten. Nucl. Fusion 2014, 54, 042004. [Google Scholar] [CrossRef]

- Shu, X.Y.; Qiu, H.X.; Huang, B.; Gu, Z.X.; Yang, J.J.; Liao, J.L.; Yang, Y.Y.; Liu, N.; Tang, J. Preparation and characterization of potassium doped tungsten. J. Nucl. Mater. 2013, 440, 414–419. [Google Scholar] [CrossRef]

- Kajita, S.; Temmerman, G.D.; Morgan, T.; Eden, S.; Kruif, T.; Ohno, N. Thermal response of nanostructured tungsten. Nucl. Fusion 2014, 54, 033005. [Google Scholar] [CrossRef]

- Luo, L.M.; Tan, X.Y.; Chen, H.Y.; Luo, G.N.; Zhu, X.Y.; Cheng, J.G.; Wu, Y.C. Preparation and characteristics of W–1 wt.% TiC alloy via a novel chemical method and spark plasma sintering. Powder Technol. 2015, 273, 8–12. [Google Scholar] [CrossRef]

- Bolokang, A.S.; Phasha, M.J.; Maweja, K.; Bhero, S. Structural characterization of mechanically milled and annealed tungsten powder. Powder Technol. 2012, 255, 27–31. [Google Scholar] [CrossRef]

- Xie, Z.M.; Zhang, T.; Liu, R.; Fang, Q.F.; Miao, S.; Wang, X.P.; Liu, C.S. Grain growth behavior and mechanical properties of zirconium micro-alloyed and nano-size zirconium carbide dispersion strengthened tungsten alloys. Int. J. Refract. Met. Hard Mater. 2015, 51, 180–187. [Google Scholar] [CrossRef]

- Xia, M.; Yan, Q.Z.; Xu, L.; Guo, H.Y.; Zhu, L.X.; Ge, C.C. Bulk tungsten with uniformly dispersed La2O3 nanoparticles sintered from co-precipitated La2O3/W nanoparticles. J. Nucl. Mater. 2013, 434, 85–89. [Google Scholar] [CrossRef]

- Kurishita, H.; Matsuo, S.; Arakawa, H.; Kobayashi, S.; Nakai, K.; Takida, T.; Takebe, K.; Kawai, M. Superplastic deformation in W–0.5 wt.% TiC with approximately 0.1 µm grain size. Mater. Sci. Eng. A 2008, 477, 162–167. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, G.J.; Jiang, F.; Ding, X.D.; Sun, Y.J.; Sun, J.; Ma, E. Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility. Nat. Mater. 2013, 12, 344–350. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Yan, Q.Z.; Xia, M.; Zhu, L.X. Preparation of La2O3 doped ultra-fine W powders by hydrothermal-hydrogen reduction process. Int. J. Refract. Met. Hard Mater. 2013, 36, 238–242. [Google Scholar] [CrossRef]

- Wahlberg, S.; Yar, M.A.; Abuelnaga, M.O.; Salem, H.G.; Johnsson, M.; Muhammed, M. Fabrication of nanostructured W–Y2O3 materials by chemical methods. J. Mater. Chem. 2012, 22, 12622–12628. [Google Scholar] [CrossRef]

- Chaudhuri, R.G.; Paria, S. Core/Shell Nanoparticles: Classes, Properties, Synthesis Mechanisms, Characterization, and Applications. Chem. Rev. 2012, 112, 2373–2433. [Google Scholar] [CrossRef] [PubMed]

- Tshephe, T.S.; Olubambi, P.A.; Sigalas, I.; Ozoemena, K.I.; Garrett, J.; Sule, R. Characterization of TiO2–MnO2 composite electrodes synthesized using spark plasma sintering technique. Powder Technol. 2015, 277, 303–309. [Google Scholar] [CrossRef]

- Ding, L.; Xiang, D.P.; Li, Y.Y.; Li, C.; Li, J.B. Effects of sintering temperature on fine-grained tungsten heavy alloy produced by high–energy ball milling assisted spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2012, 33, 65–69. [Google Scholar] [CrossRef]

- Xie, Z.M.; Liu, R.; Fang, Q.F.; Zhou, Y.; Wang, X.P.; Liu, C.S. Spark plasma sintering and mechanical properties of zirconium micro-alloyed tungsten. J. Nucl. Mater. 2014, 444, 175–180. [Google Scholar] [CrossRef]

- Yar, M.A.; Wahlberg, S.; Bergqvist, H.; Salem, H.G.; Johnsson, M.; Muhammed, M. Spark plasma sintering of tungsten–yttrium oxide composites from chemically synthesized nanopowders and microstructural characterization. J. Nucl. Mater. 2011, 412, 227–232. [Google Scholar] [CrossRef]

- Yar, M.A.; Wahlberg, S.; Bergqvist, H.; Salem, H.G.; Johnsson, M.; Muhammed, M. Chemically produced nanostructured ODS–lanthanum oxide–tungstencomposites sintered by spark plasma. J. Nucl. Mater. 2011, 408, 129–135. [Google Scholar] [CrossRef]

- Veleva, L.; Oksiuta, Z.; Vogt, U.; Baluc, N. Sintering and characterization of W–Y and W–Y2O3 materials. Fusion Eng. Des. 2009, 84, 1920–1924. [Google Scholar] [CrossRef]

- Kiran, U.R.; Kumar, M.P.; Sankaranarayana, M.; Singh, A.K.; Nandy, T.K. High energy milling on tungsten powders. Int. J. Refract. Met. Hard Mater. 2015, 48, 74–81. [Google Scholar] [CrossRef]

- Liu, R.; Xie, Z.M.; Hao, T.; Zhou, Y.; Wang, X.P.; Fang, Q.F.; Liu, C.S. Fabricating high performance tungsten alloys through zirconium micro-alloying and nano-sized yttria dispersion strengthening. J. Nucl. Mater. 2014, 451, 35–39. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, Y.; Hao, T.; Zhang, T.; Wang, X.P.; Liu, C.S.; Fang, Q.F. Microwave synthesis and properties of fine–grained oxides dispersion strengthened tungsten. J. Nucl. Mater. 2012, 424, 171–175. [Google Scholar] [CrossRef]

- Battabyal, M.; Spätig, P.; Murty, B.S.; Baluc, N. Investigation of microstructure and microhardness of pure W and W–2Y2O3 materials before and after ion-irradiation. Int. J. Refract. Met. Hard Mater. 2014, 46, 168–172. [Google Scholar] [CrossRef]

| Materials | Density (g/cm3) | Relative Density (%) | Grain Size (μm) | Hardness (HV200g) |

|---|---|---|---|---|

| W | 18.5 | 95.8 | 10 | 270 |

| W–1 wt % Nd2O3 | 18.3 | 96.5 | 4 | 349 |

| W–1 wt % CeO2 | 18.2 | 95.9 | 4 | 305 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, X.-Y.; Luo, L.-M.; Chen, H.-Y.; Zhu, X.-Y.; Zan, X.; Cheng, J.-G.; Wu, Y.-C. Chemical Synthesis and Oxide Dispersion Properties of Strengthened Tungsten via Spark Plasma Sintering. Materials 2016, 9, 879. https://doi.org/10.3390/ma9110879

Ding X-Y, Luo L-M, Chen H-Y, Zhu X-Y, Zan X, Cheng J-G, Wu Y-C. Chemical Synthesis and Oxide Dispersion Properties of Strengthened Tungsten via Spark Plasma Sintering. Materials. 2016; 9(11):879. https://doi.org/10.3390/ma9110879

Chicago/Turabian StyleDing, Xiao-Yu, Lai-Ma Luo, Hong-Yu Chen, Xiao-Yong Zhu, Xiang Zan, Ji-Gui Cheng, and Yu-Cheng Wu. 2016. "Chemical Synthesis and Oxide Dispersion Properties of Strengthened Tungsten via Spark Plasma Sintering" Materials 9, no. 11: 879. https://doi.org/10.3390/ma9110879

APA StyleDing, X.-Y., Luo, L.-M., Chen, H.-Y., Zhu, X.-Y., Zan, X., Cheng, J.-G., & Wu, Y.-C. (2016). Chemical Synthesis and Oxide Dispersion Properties of Strengthened Tungsten via Spark Plasma Sintering. Materials, 9(11), 879. https://doi.org/10.3390/ma9110879