Paper Sludge Reuse in Lightweight Aggregates Manufacturing

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Experimental Program

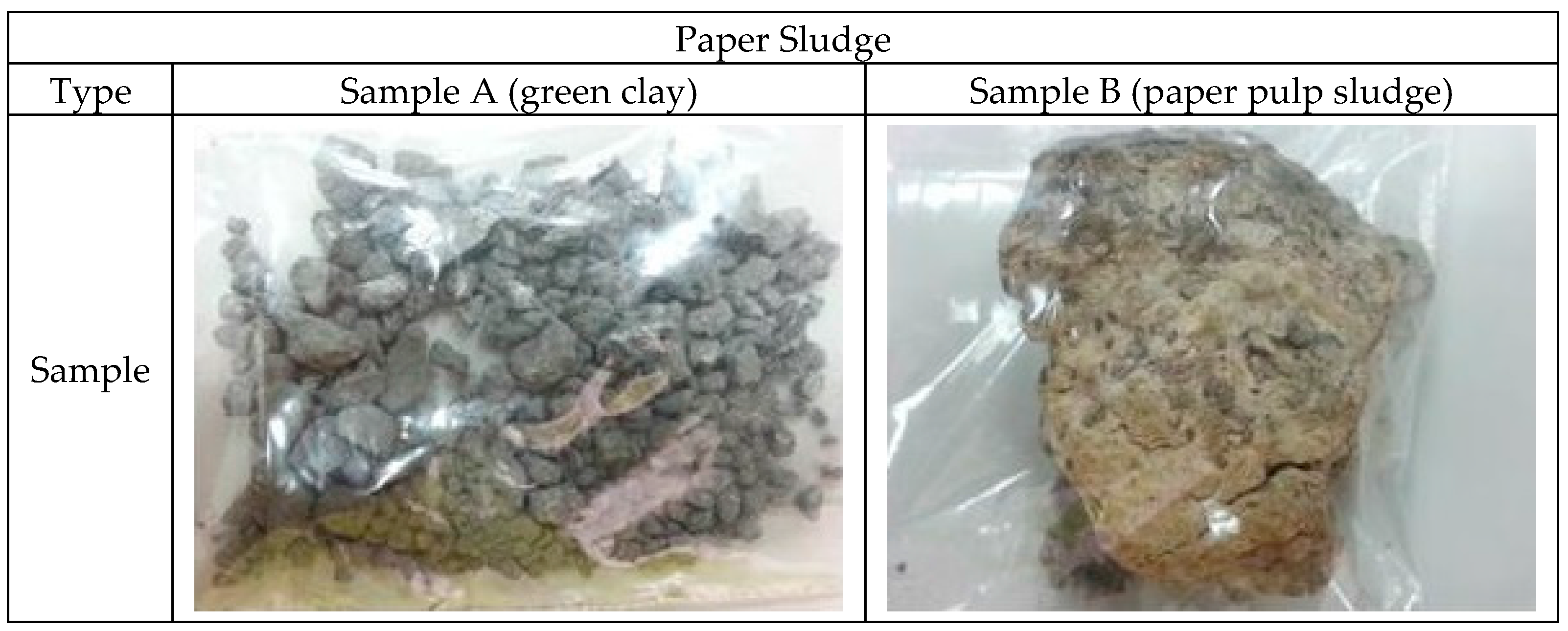

2.2. Materials

3. Results and Discussion

3.1. Chemical Composition of Paper Sludge and Sediment Clay

3.1.1. SiO2, Al2O3, and Fe2O3

3.1.2. Fe2O3, Na2O, K2O, CaO, MgO, and FeO

3.1.3. Mass Ratio of SiO2 and Al2O3 to Fluxing

3.1.4. Three Phase Diagram of Chemical Compounds

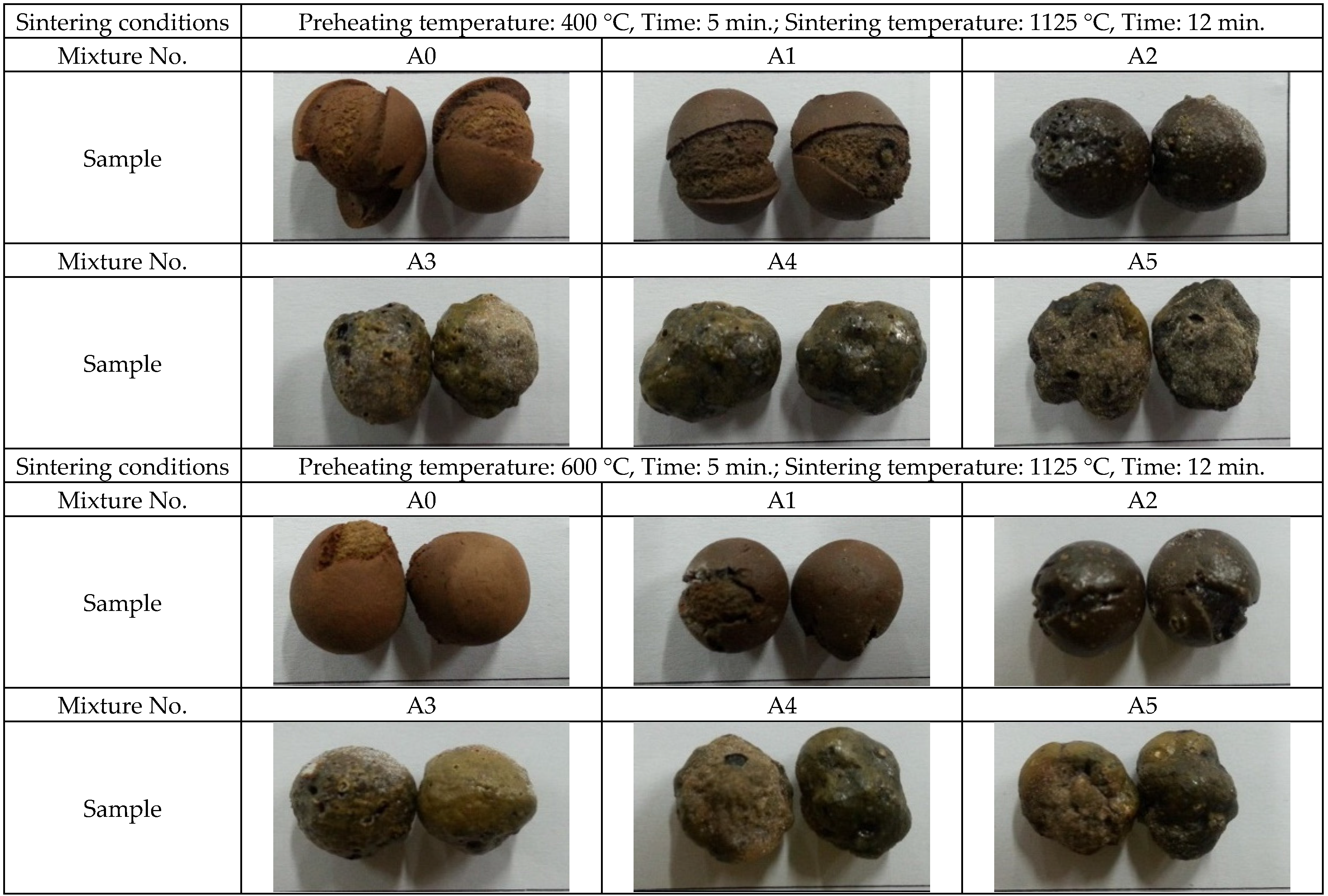

3.2. Sintering of Paper Sludge Lightweight Aggregates

4. Conclusions

- Based on the chemical composition analysis of paper sludge, the paper sludge is not suitable for producing lightweight aggregate. The mixture of sediment clay with a weight ratio of 10%–50% paper sludge, however, should be a potential raw material for lightweight aggregates.

- The sintering temperature can be effectively reduced with the high flux content in green clay series lightweight aggregates. On the other hand, the low flux content in paper pulp sludge series lightweight aggregates is ineffective.

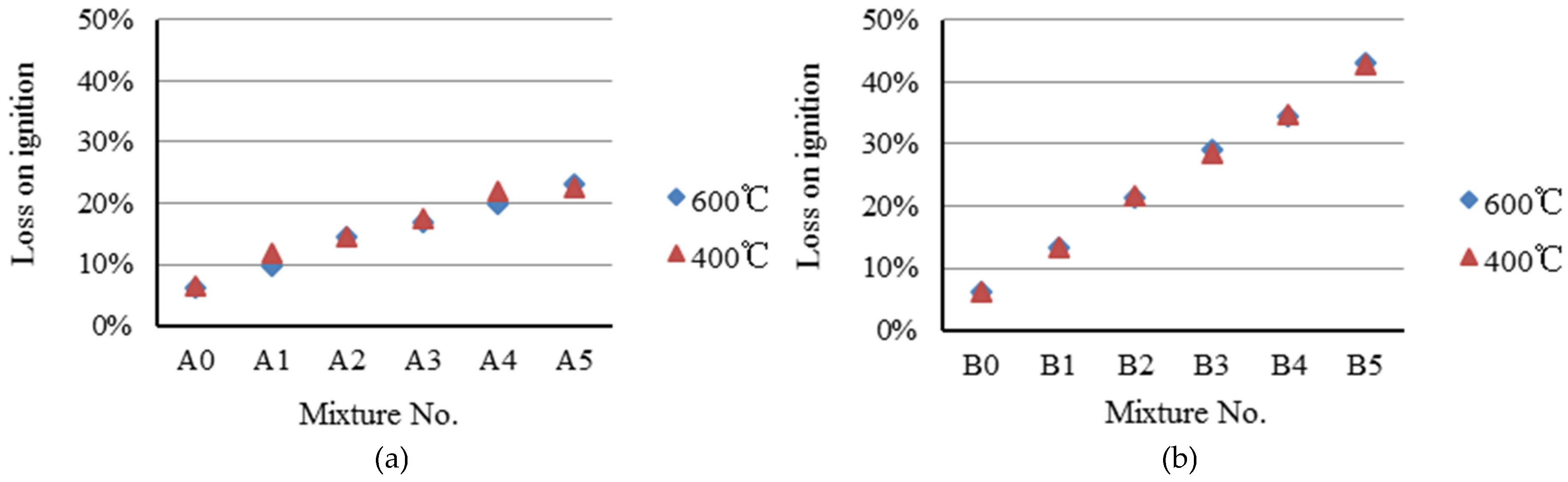

- Green clay lightweight aggregates stay in approximately the same size, and their expansion rates are close. The loss on ignition increases as green clay content increases, resulting in the reduction in particle mass and a decrease in particle density. On the other hand, the particle size and expansion rate of paper pulp sludge lightweight aggregates decreases as the paper pulp sludge content increases. Even though the loss on ignition values increases, resulting in the reduction of particle mass, the paper pulp sludge lightweight aggregates is without significant change in its particle density. The reason is that particle sizes and expansion rates decrease as paper pulp sludge content increases.

- The particle density range of green clay lightweight aggregates is between 1.06 and 1.69; for paper pulp sludge lightweight aggregates, it is between 0.83 and 1.30. This meets the required primary property of recommended specifications of lightweight aggregates.

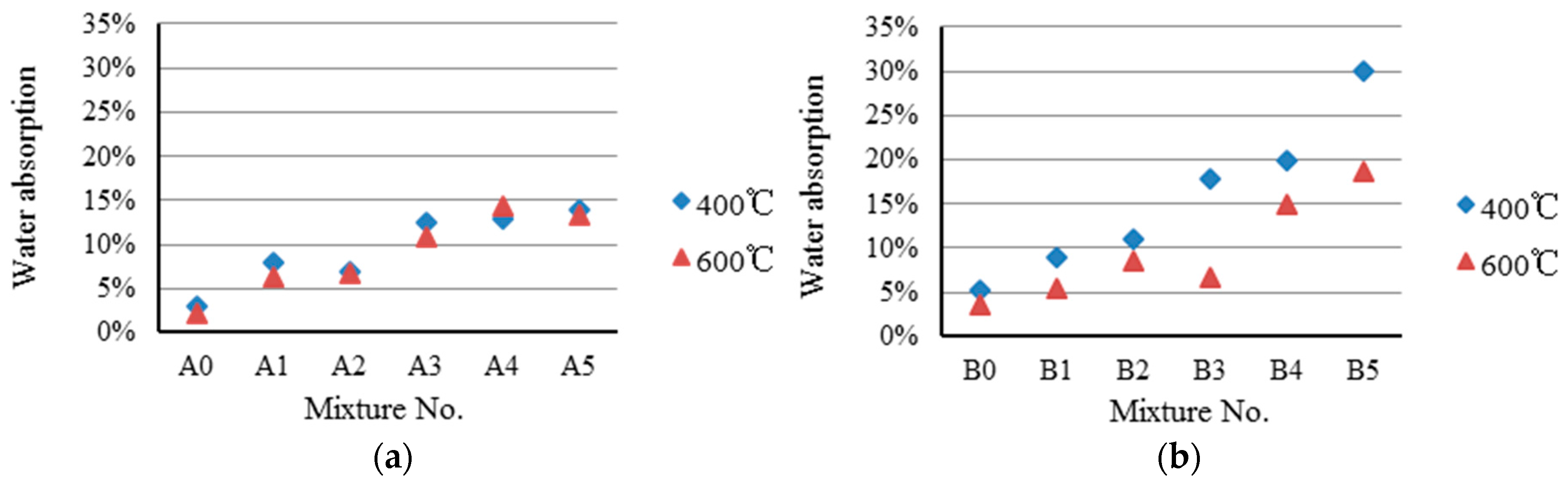

- The 24-h water absorption values of green clay lightweight aggregate range from 6% to 14%, and the water absorption of paper pulp sludge lightweight aggregate range between the values of 5% and 30%. The values increase as paper sludge content increases. For structural concrete engineering applications, the water absorption of lightweight aggregates is usually less than 20%. The results indicate that the lightweight aggregates in this study comply with regulations, except the case of Sample B5.

- Both the green clay and paper pulp sludge can provide good thermal energy under the sintering process and can be used as refuse-derived fuel, as well as raw materials to produce lightweight aggregates.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lee, H.S.; Ismail, M.A.; Woo, Y.J.; Min, T.B.; Choi, H.K. Fundamental study on the development of structural lightweight concrete by using normal coarse aggregate and foaming agent. Materials 2014, 7, 4536–4554. [Google Scholar] [CrossRef]

- Liu, R.; Coffman, R. Lightweight aggregate made from dredged material in green roof construction for stormwater management. Materials 2016, 9, 611. [Google Scholar] [CrossRef]

- Hu, S.C.; Hu, S.H.; Fu, Y.P.; Sie, S.F. Lowered temperature resource recycling of paper sludge using a co-melting technology. BioResources 2012, 7, 2766–2783. [Google Scholar]

- García, C.M.; Palomino, T.C.; Godino, F.J.I.; Iglesias, F.A.C. Porosity of expanded clay manufactured with addition of sludge from the brewing industry. Int. J. Energy Environ. Eng. 2014, 5, 341–347. [Google Scholar] [CrossRef]

- Spathi, C.; Vandeperre, L.J.; Cheeseman, C.R. Production of lightweight fillers from waste glass and paper sludge ash. Waste Biomass Valoriz. 2015, 6, 875–881. [Google Scholar] [CrossRef]

- Ferone, C.; Colangelo, F.; Messina, F.; Iucolano, F.; Liguori, B.; Cioffi, R. Coal combustion wastes reuse in low energy artificial aggregates manufacturing. Materials 2013, 6, 5000–5015. [Google Scholar] [CrossRef] [Green Version]

- Gomathi, P.; Sivakumar, A. Accelerated curing effects on the mechanical performance of cold bonded and sintered fly ash aggregate concrete. Constr. Build. Mater. 2015, 77, 276–287. [Google Scholar] [CrossRef]

- Vasugi, V.; Ramamurthy, K. Identification of design parameters influencing manufacture and properties of cold- bonded pond ash aggregate. Mater. Des. 2014, 54, 264–278. [Google Scholar] [CrossRef]

- Molino, B.; De Vincenzo, A.; Ferone, C.; Messina, F.; Colangelo, F.; Cioffi, R. Recycling of clay sediments for geopolymer binder production. A new perspective for reservoir management in the framework of Italian legislation: The Occhito reservoir case study. Materials 2014, 7, 5603–5616. [Google Scholar] [CrossRef]

- Snellings, R.; Cizer, Ö.; Horckmans, L.; Durdziński, P.T.; Dierckx, P.; Nielsen, P.; Vandewalle, L. Properties and pozzolanic reactivity of flash calcined dredging sediments. Appl. Clay Sci. 2016, 129, 35–39. [Google Scholar] [CrossRef]

- Colangelo, F.; Messina, F.; Cioffi, R. Recycling of MSWI fly ash by means of cementitious double step cold bonding pelletization: Technological assessment for the production of lightweight artificial aggregates. J. Hazard. Mater. 2015, 299, 181–191. [Google Scholar] [CrossRef] [PubMed]

- Pipilikaki, P.; Katsioti, M.; Papageorgiou, D.; Fragoulis, D.; Chaniotakis, E. Use of tire derived fuel in clinker burning. Cem. Concr. Compos. 2005, 27, 843–847. [Google Scholar] [CrossRef]

- Li, Z.; Ohnuki, T.; Ikeda, K. Development of paper sludge ash-based geopolymer and application to treatment of hazardous water contaminated with radioisotopes. Materials 2016, 9, 633. [Google Scholar] [CrossRef]

- Meyer, T.; Edwards, E.A. Anaerobic digestion of pulp and paper mill wastewater and sludge. Water Res. 2014, 65, 321–349. [Google Scholar] [CrossRef] [PubMed]

- Gottumukkala, L.D.; Haigh, K.; Collard, F.X.; Rensburg, E.; Görgens, J. Opportunities and prospects of biorefinery-based valorisation of pulp and paper sludge. Bioresour. Technol. 2016, 215, 37–49. [Google Scholar] [CrossRef] [PubMed]

- Wan, H.P.; Chang, Y.H.; Chien, W.C.; Lee, H.T.; Huang, C.C. Emissions during co-firing of RDF-5 with bituminous coal paper sludge and waste tires in a commercial circulation fluidized bed co-generation boiler. Fuel 2008, 87, 761–767. [Google Scholar] [CrossRef]

- Wei, N. Leachability of heavy metals from lightweight aggregates made with sewage sludge and municipal solid waste incineration fly ash. Int. J. Environ. Res. Public Health 2015, 12, 4992–5005. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.J.; Wang, S.Y.; Tang, C.W. Reuse of incineration fly ashes and reaction ashes for manufacturing lightweight aggregate. Constr. Build. Mater. 2010, 24, 46–55. [Google Scholar] [CrossRef]

- Somayaji, S. Civil Engineering Materials; Prentice Hall: Upper Siddle River, NJ, USA, 2001. [Google Scholar]

- Riley, C.M. Relation of chemical properties to the bloating of clays. ACI J. 1951, 34, 121–128. [Google Scholar] [CrossRef]

- Heller-Kallai, L.; Miloslavski, I.; Aizenshtat, Z.; Halicz, L. Chemical and mass spectrometric analysis of volatiles derived from clays. Am. Mineral. 1988, 73, 376–382. [Google Scholar]

- Chen, H.J.; Yang, M.D.; Tang, C.W.; Wang, S.Y. Producing synthetic lightweight aggregates from reservoir sediments. Constr. Build. Mater. 2012, 28, 387–394. [Google Scholar] [CrossRef]

| Mixture No. | A0, B0 | A1, B1 | A2, B2 | A3, B3 | A4, B4 | A5, B5 |

|---|---|---|---|---|---|---|

| Sediment clay | 100 | 90 | 80 | 70 | 60 | 50 |

| Paper sludge | 0 | 10 | 20 | 30 | 40 | 50 |

| Sludge Type | Chemical Compounds (%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | Na2O | MgO | CaO | K2O | SO3 | Others | Organisms | LOI | Total | |

| Sediment clay | 59.31 | 19.97 | 6.53 | 0.01 | 2.02 | 1.41 | 0.08 | 0.07 | – | 2.90 | 7.7 | 100 |

| Sample A | 1.25 | 0.31 | 1.30 | 1.43 | 2.73 | 47.66 | 0.17 | 1.62 | 1.08 | – | 42.5 | 100 |

| Sample B | 20.10 | 11.90 | 0.30 | – | 2.20 | 0.80 | – | – | 2.50 | – | 62.2 | 100 |

| Proper proportion * | 53–79 | 12–26 | 8–24 | – | – | – | – | – | ||||

| Chemical Composition | A- Mixture No. | ||||||

| Sample A | Sediment Clay (A0) | A1 | A2 | A3 | A4 | A5 | |

| SiO2 | 2 | 66 | 60 | 53 | 47 | 40 | 34 |

| Al2O3 | 1 | 23 | 21 | 19 | 16 | 14 | 12 |

| Fluxing | 97 | 11 | 20 | 28 | 37 | 45 | 54 |

| Total | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| (SiO2 + Al2O3)/Fluxing | 0.03 | 8.09 | 4.10 | 2.55 | 1.72 | 1.20 | 0.85 |

| Chemical Composition | B- Mixture No. | ||||||

| Sample B | Sediment Clay (B0) | B1 | B2 | B3 | B4 | B5 | |

| SiO2 | 57 | 66 | 65 | 64 | 63 | 62 | 62 |

| Al2O3 | 34 | 23 | 24 | 25 | 26 | 27 | 29 |

| Fluxing | 9 | 11 | 11 | 11 | 10 | 10 | 10 |

| Total | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| (SiO2 + Al2O3)/Fluxing | 10.11 | 8.09 | 8.26 | 8.43 | 8.62 | 8.80 | 9.00 |

| Mixture No. | Preheating Conditions | Sintering Conditions | Loss On Ignition (%) | Water Absorption (%) | Oven Dry Particle Density (G/Cm3) | ||

|---|---|---|---|---|---|---|---|

| Temperature (°C) | Time (min) | Temperature (°C) | Time (min) | ||||

| A0 | 400 | 5 | 1125 | 12 | 6 | 3 | 1.55 |

| A1 | 12 | 8 | 1.24 | ||||

| A2 | 14 | 7 | 1.45 | ||||

| A3 | 17 | 13 | 1.33 | ||||

| A4 | 22 | 13 | 1.06 | ||||

| A5 | 23 | 14 | 1.40 | ||||

| A0 | 600 | 5 | 1125 | 12 | 6 | 2 | 1.93 |

| A1 | 10 | 6 | 1.69 | ||||

| A2 | 14 | 7 | 1.61 | ||||

| A3 | 17 | 11 | 1.39 | ||||

| A4 | 20 | 14 | 1.24 | ||||

| A5 | 23 | 13 | 1.28 | ||||

| B0 | 400 | 5 | 1225 | 15 | 6 | 5 | 0.66 |

| B1 | 13 | 9 | 0.83 | ||||

| B2 | 22 | 11 | 1.18 | ||||

| B3 | 28 | 18 | 1.29 | ||||

| B4 | 35 | 20 | 1.11 | ||||

| B5 | 43 | 30 | 1.14 | ||||

| B0 | 600 | 5 | 1225 | 15 | 6 | 4 | 0.86 |

| B1 | 13 | 5 | 1.19 | ||||

| B2 | 21 | 8 | 1.06 | ||||

| B3 | 29 | 6 | 1.30 | ||||

| B4 | 35 | 15 | 0.97 | ||||

| B5 | 43 | 14 | 1.15 | ||||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.-J.; Hsueh, Y.-C.; Peng, C.-F.; Tang, C.-W. Paper Sludge Reuse in Lightweight Aggregates Manufacturing. Materials 2016, 9, 876. https://doi.org/10.3390/ma9110876

Chen H-J, Hsueh Y-C, Peng C-F, Tang C-W. Paper Sludge Reuse in Lightweight Aggregates Manufacturing. Materials. 2016; 9(11):876. https://doi.org/10.3390/ma9110876

Chicago/Turabian StyleChen, How-Ji, Ying-Chih Hsueh, Ching-Fang Peng, and Chao-Wei Tang. 2016. "Paper Sludge Reuse in Lightweight Aggregates Manufacturing" Materials 9, no. 11: 876. https://doi.org/10.3390/ma9110876