Analysis of Minimum Quantity Lubrication (MQL) for Different Coating Tools during Turning of TC11 Titanium Alloy

Abstract

:1. Introduction

2. Experimental Details

2.1. Test Material

2.2. Cutting Tools

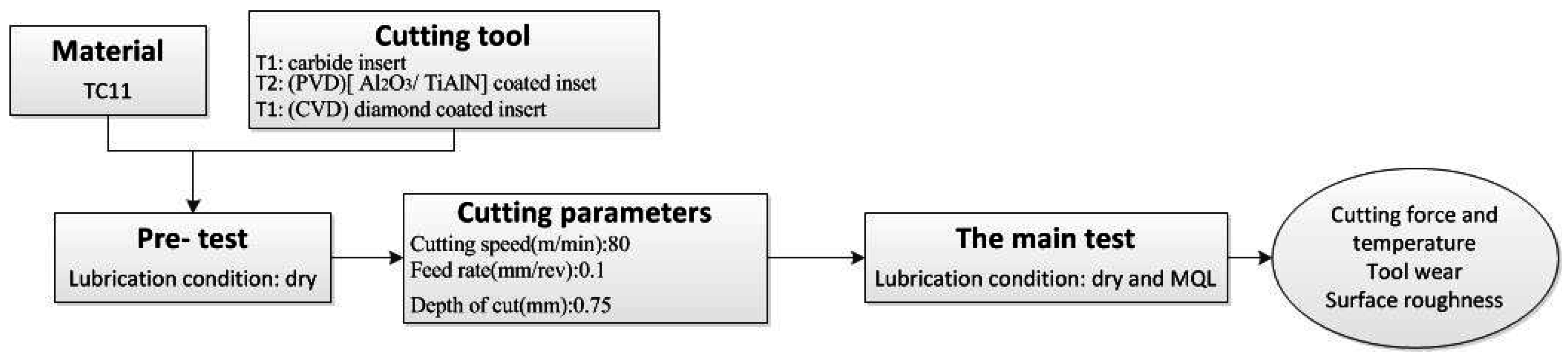

2.3. Global Scheme

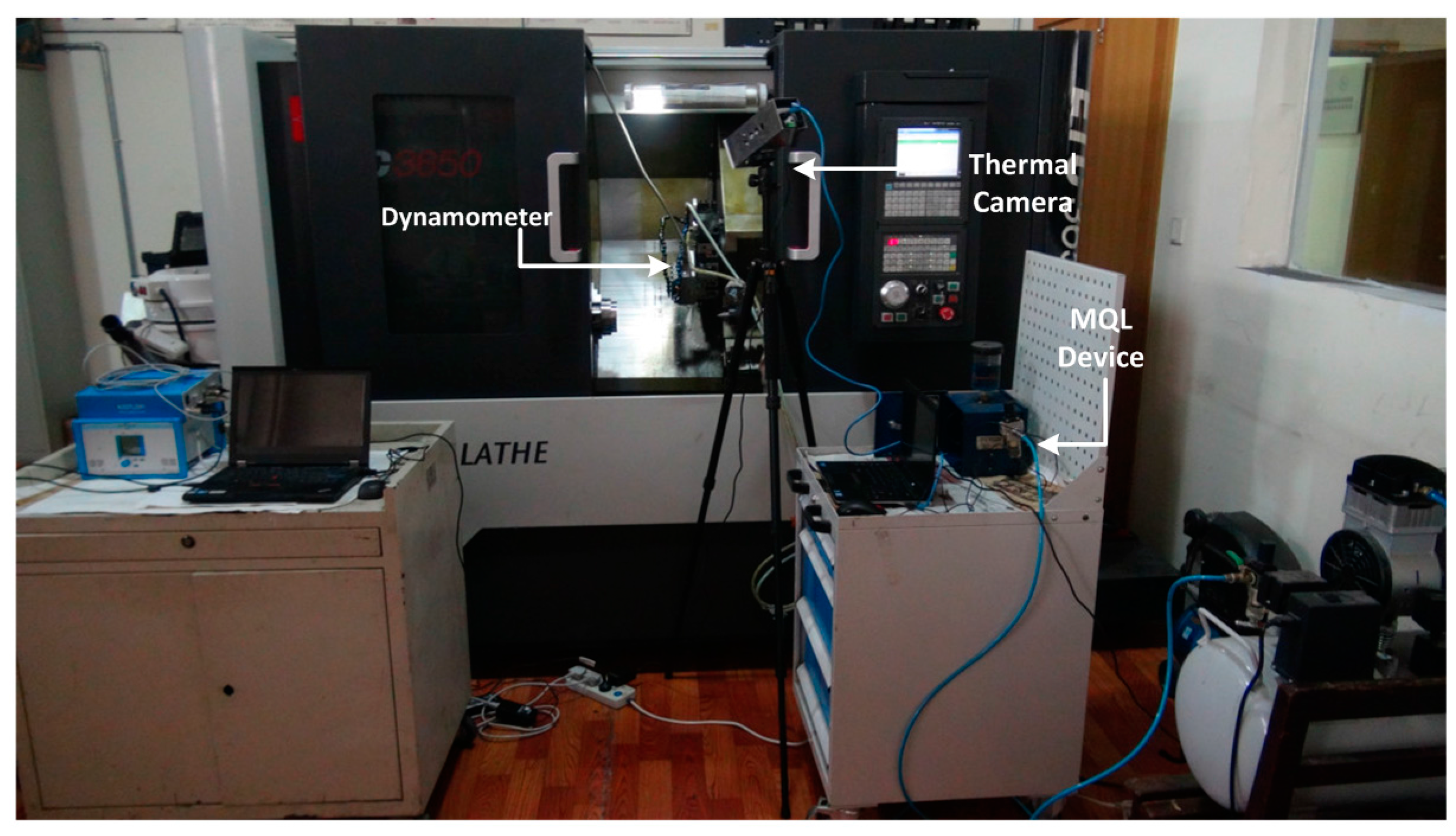

2.4. Experimental Specifications

3. Result and Discussion

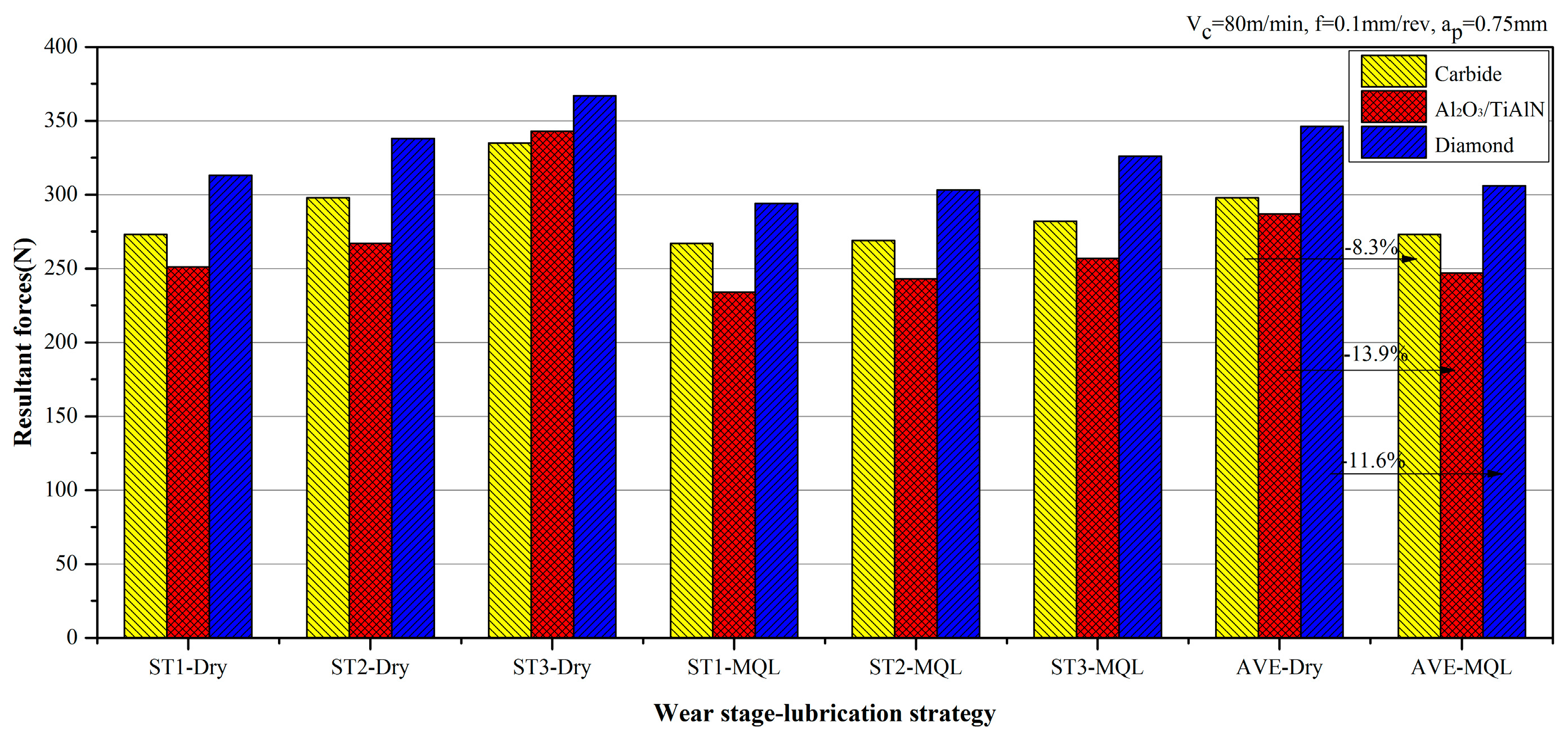

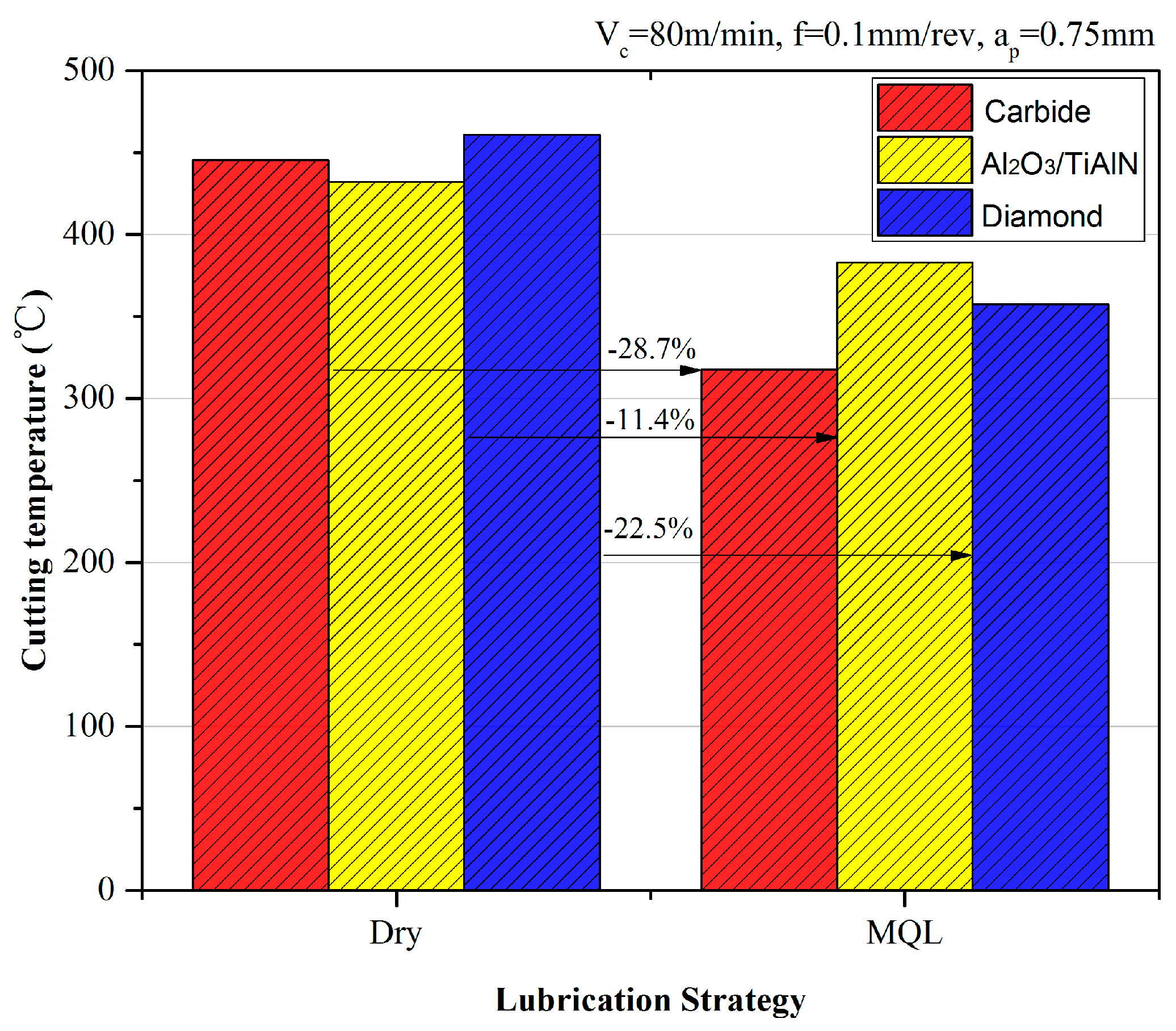

3.1. Cutting Force and Temperature

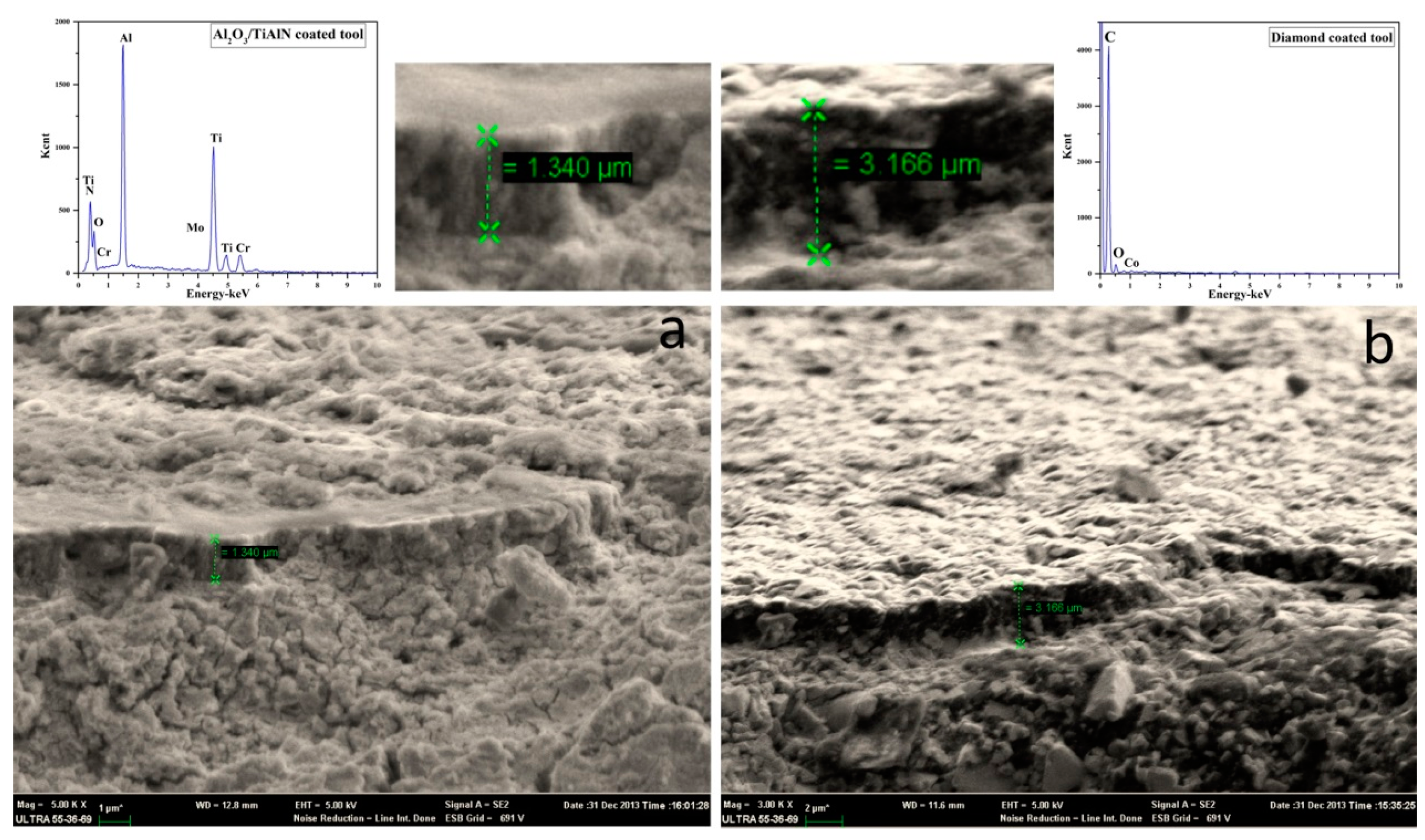

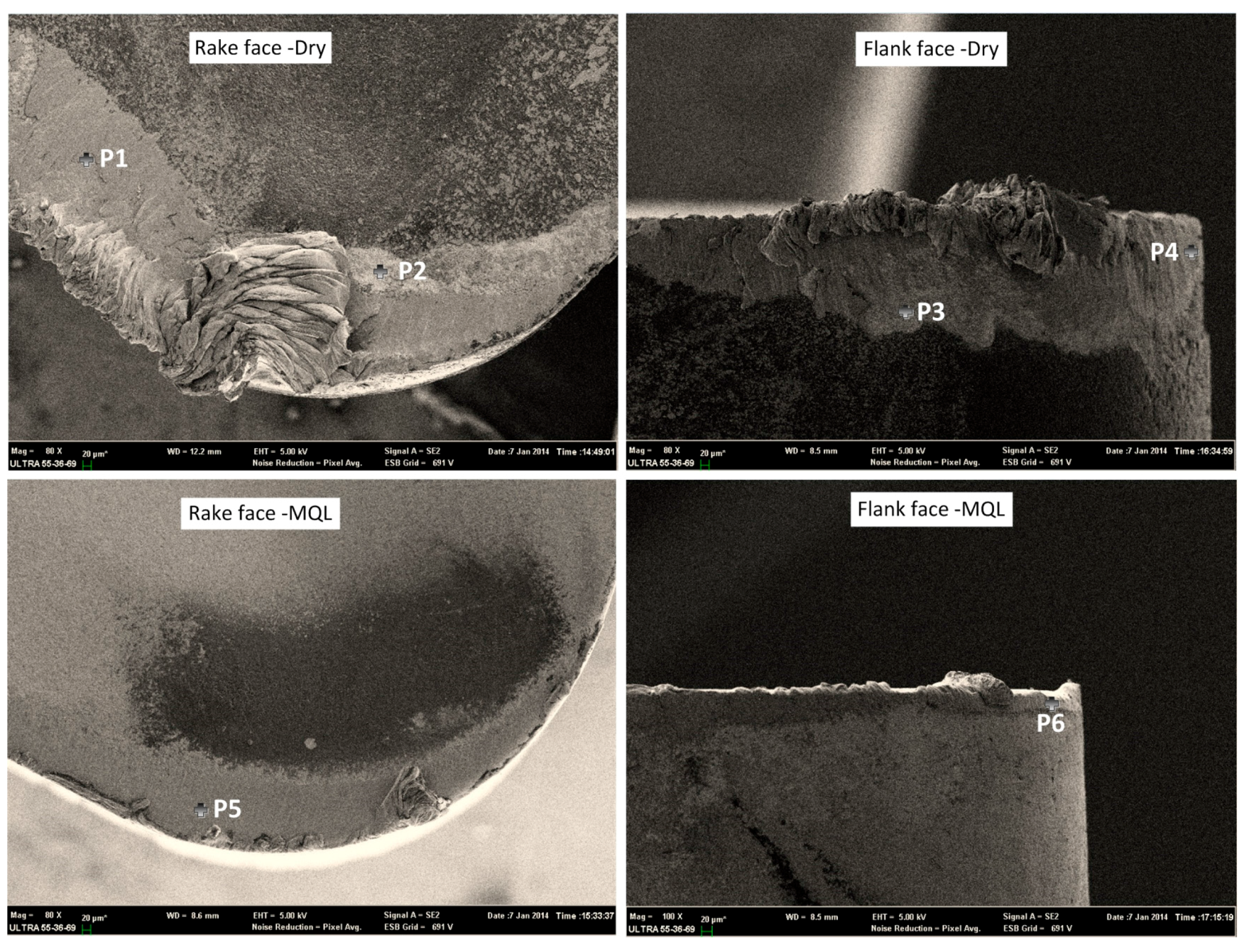

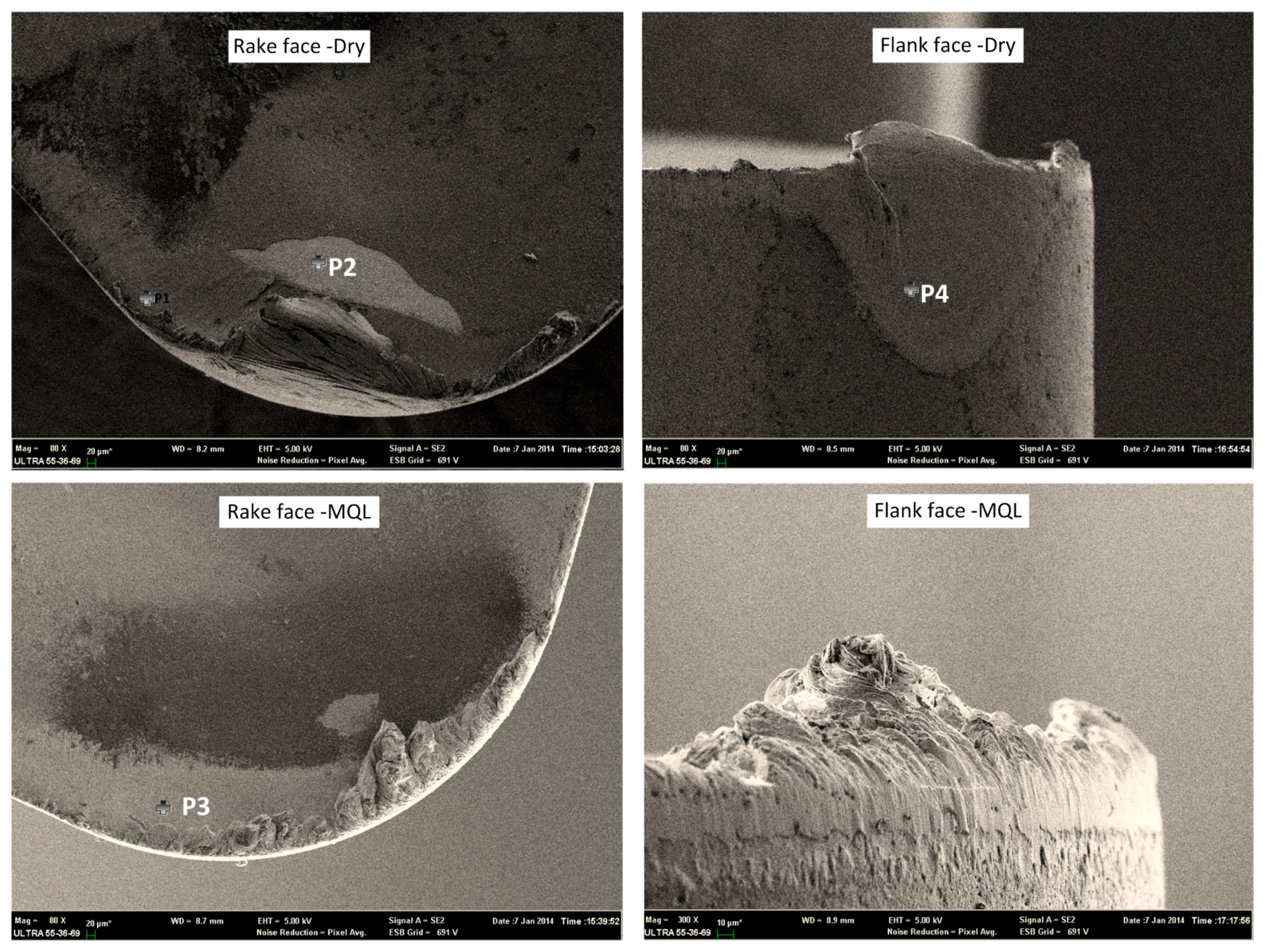

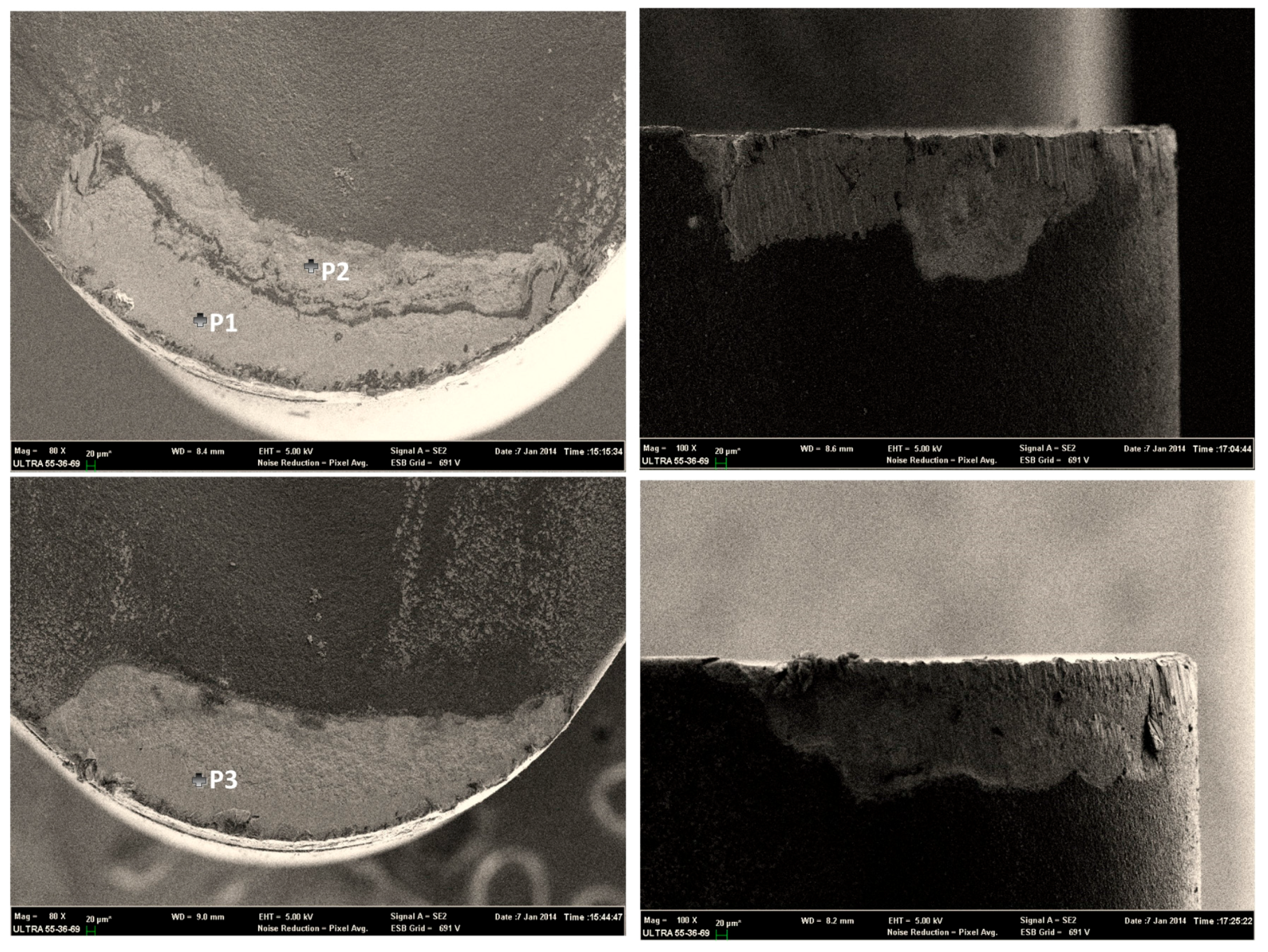

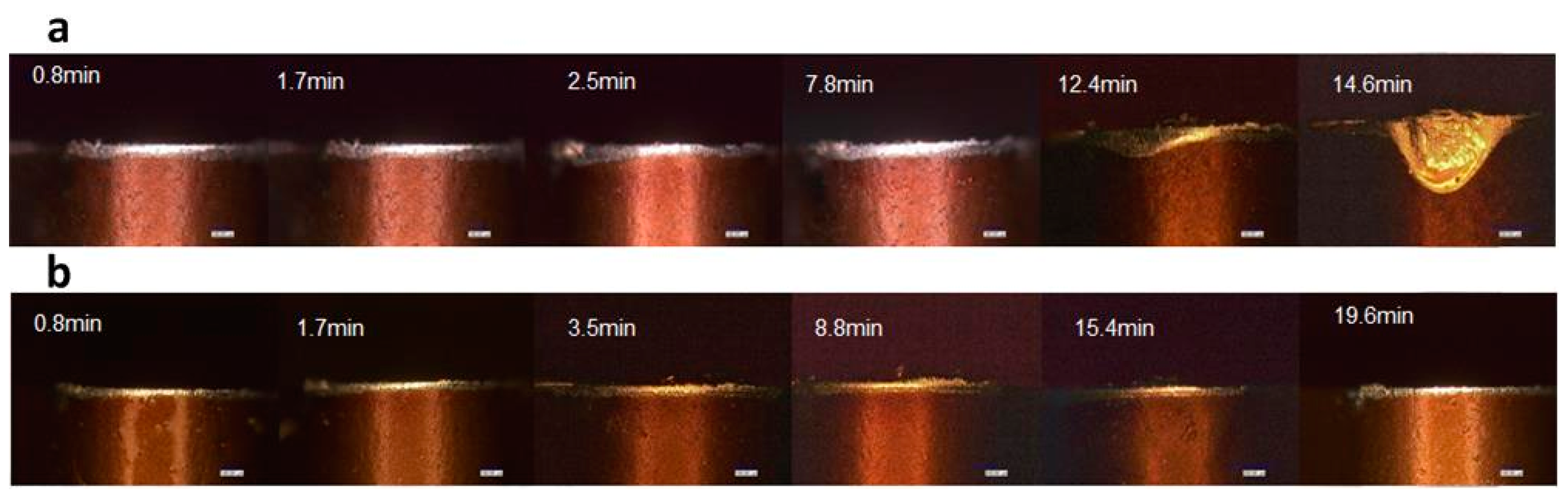

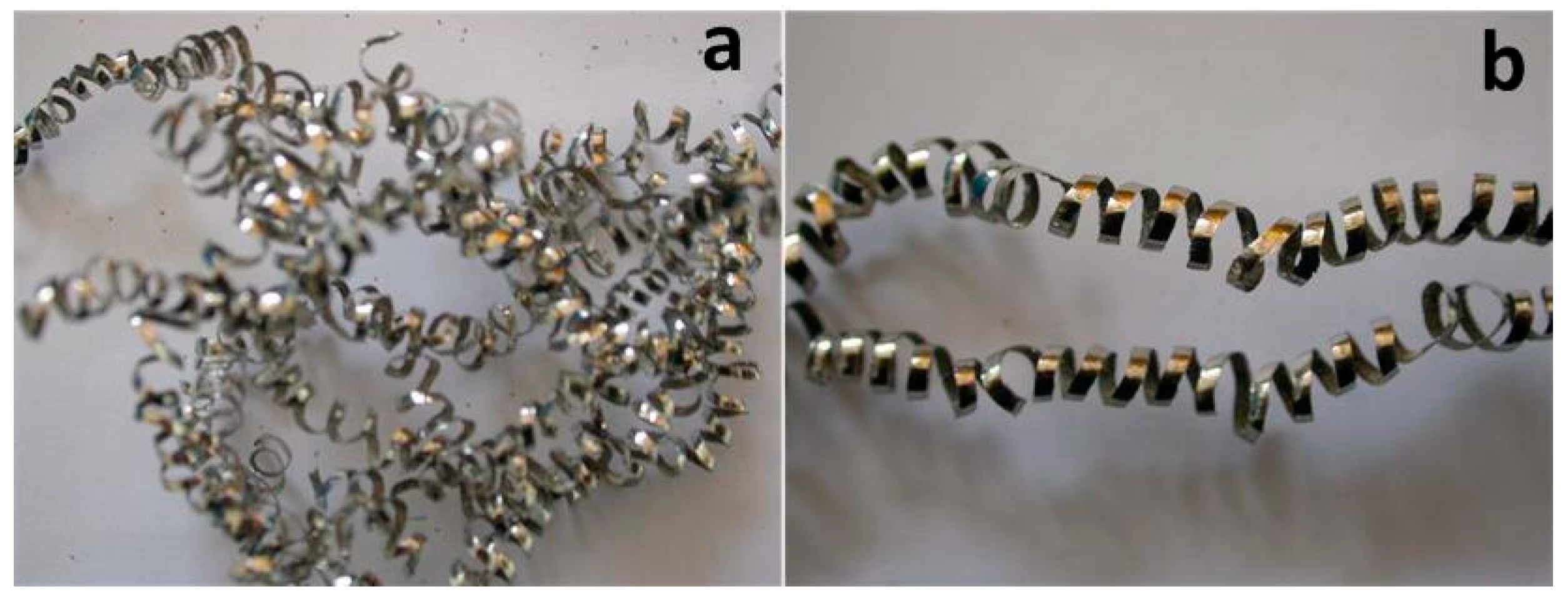

3.2. Tool Wear Mechanism

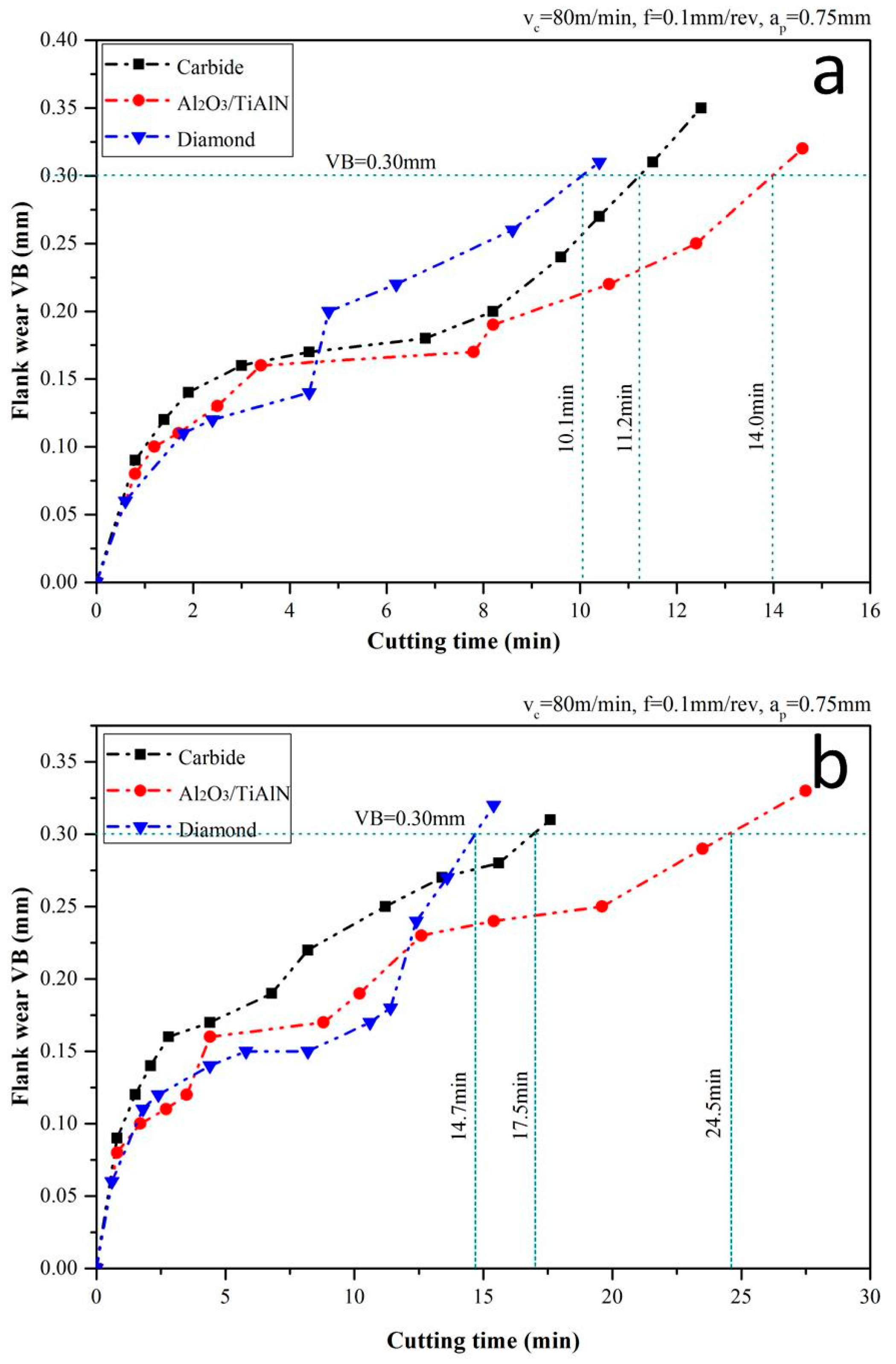

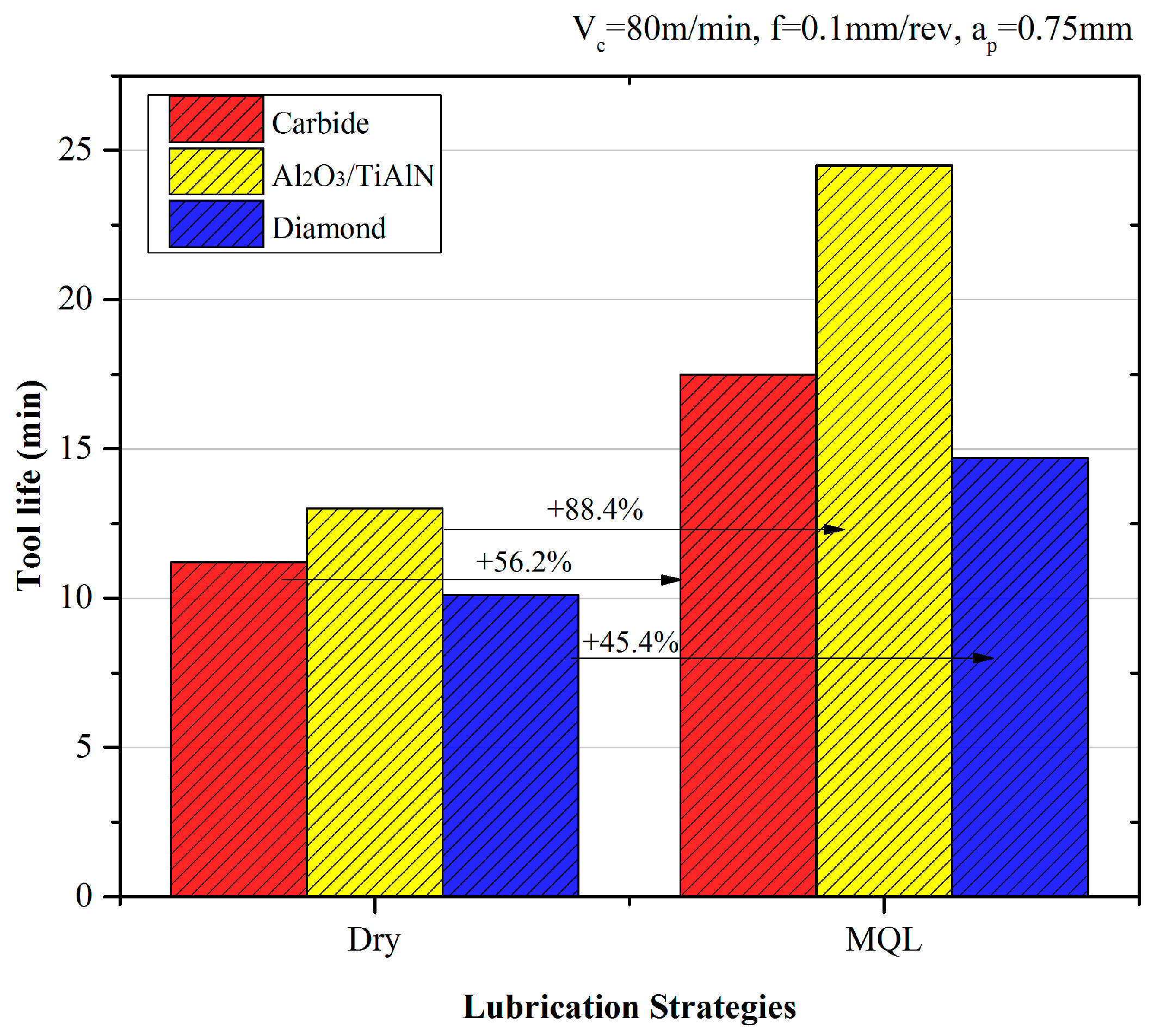

3.3. Tool Life

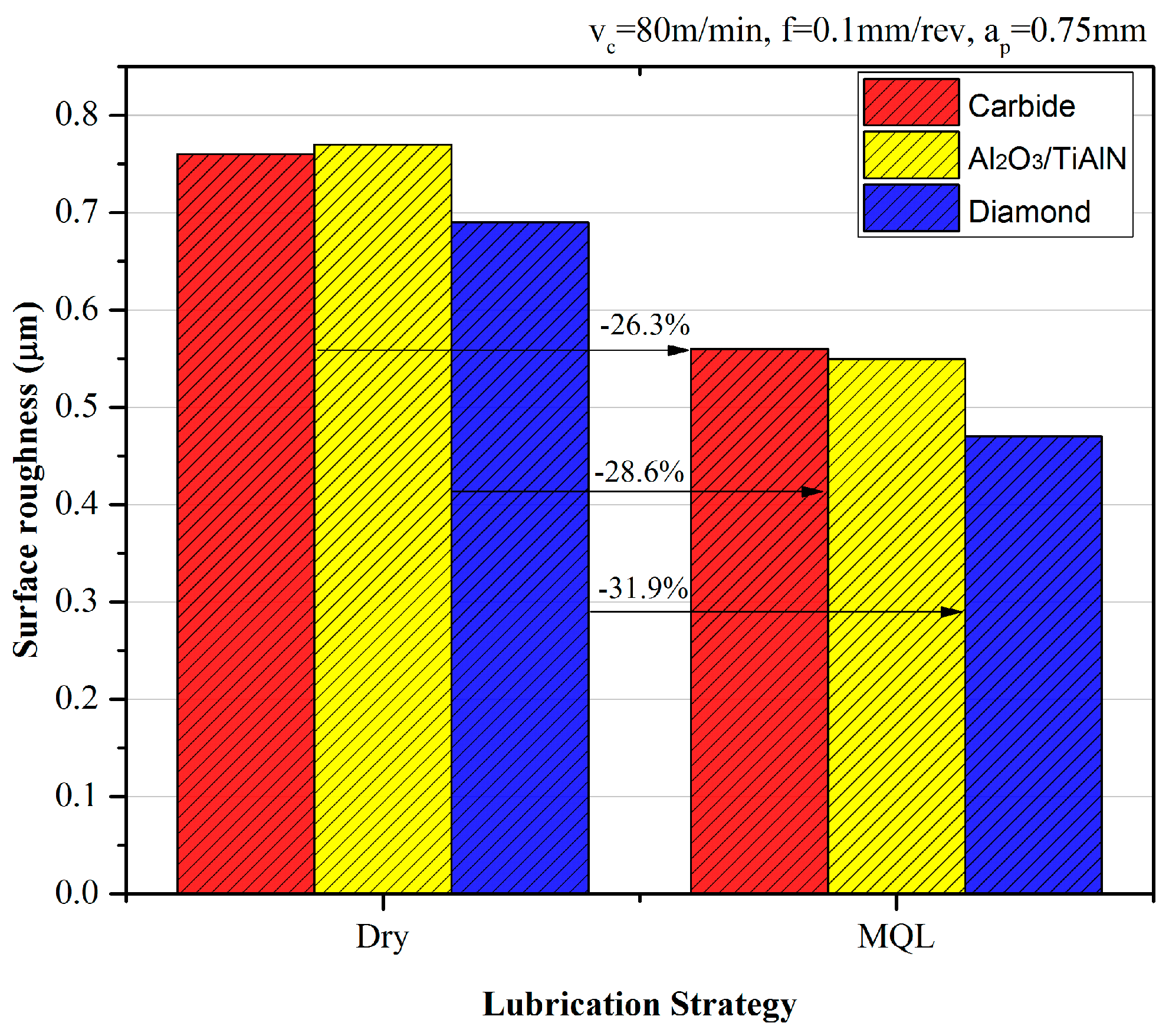

3.4. Surface Roughness

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Çalışkan, H.; Küçükköse, M. The effect of aCN/TiAlN coating on tool wear, cutting force, surface finish and chip morphology in face milling of Ti6Al4V superalloy. Int. J. Refract. Met. Hard Mater. 2015, 50, 304–312. [Google Scholar] [CrossRef]

- Liang, L.; Liu, X.; Li, X.; Li, Y. Wear mechanisms of WC–10Ni3Al carbide tool in dry turning of Ti6Al4V. Int. J. Refract. Met. Hard Mater. 2015, 48, 272–285. [Google Scholar] [CrossRef]

- Rodríguez-Barrero, S.; Fernández-Larrinoa, J.; Azkona, I.; de Lacalle, L.N.L.; Polvorosa, R. Enhanced performance of nanostructured coatings for drilling by droplet elimination. Mater. Manuf. Proc. 2016, 31, 593–602. [Google Scholar] [CrossRef]

- Liu, Z.; An, Q.; Xu, J.; Chen, M.; Han, S. Wear performance of (nc-AlTiN)/(a-Si3N4) coating and (nc-AlCrN)/(a-Si3N4) coating in high-speed machining of titanium alloys under dry and minimum quantity lubrication (MQL) conditions. Wear 2013, 305, 249–259. [Google Scholar] [CrossRef]

- Minton, T.; Ghani, S.; Sammler, F.; Bateman, R.; Fürstmann, P.; Roeder, M. Temperature of internally-cooled diamond-coated tools for dry-cutting titanium. Int. J. Mach. Tools Manuf. 2013, 75, 27–35. [Google Scholar] [CrossRef]

- Le Coz, G.; Marinescu, M.; Devillez, A.; Dudzinski, D.; Velnom, L. Measuring temperature of rotating cutting tools: Application to MQL drilling and dry milling of aerospace alloys. App. Therm. Eng. 2012, 36, 434–441. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Effects of minimum quantity lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: A comprehensive review. J. Clean. Prod. 2016, 127, 1–18. [Google Scholar] [CrossRef]

- Sun, Y.; Huang, B.; Puleo, D.A.; Jawahir, I.S. Enhanced Machinability of Ti-5553 Alloy from cryogenic machining: Comparison with MQL and flood-cooled machining and modeling. Procedia CIRP 2015, 31, 477–482. [Google Scholar] [CrossRef]

- Uysal, A.; Demiren, F.; Altan, E. Applying minimum quantity lubrication (MQL) method on milling of martensitic stainless steel by using nano MoS2 reinforced vegetable cutting fluid. Procedia Soc. Behav. Sci. 2015, 195, 2742–2747. [Google Scholar] [CrossRef]

- Kamata, Y.; Obikawa, T. High speed MQL finish-turning of inconel 718 with different coated tools. J. Mater. Proc. Technol. 2007, 193, 281–286. [Google Scholar] [CrossRef]

- Deiab, I.; Raza, S.W.; Pervaiz, S. Analysis of lubrication strategies for sustainable machining during turning of Titanium Ti-6Al-4V alloy. Procedia CIRP 2014, 17, 766–771. [Google Scholar] [CrossRef]

- Busch, K.; Hochmuth, C.; Pause, B.; Stoll, A.; Wertheim, R. Investigation of cooling and lubrication strategies for machining high-temperature alloys. Procedia CIRP 2016, 41, 835–840. [Google Scholar] [CrossRef]

- Vagnorius, Z.; Sørby, K. Effect of high-pressure cooling on life of SiAlON tools in machining of Inconel 718. Int. J. Adv. Manuf. Technol. 2011, 54, 83–92. [Google Scholar] [CrossRef]

- Bruschi, S.; Bertolini, A.; Medea, F.; Ghiotti, A. Influence of the machining parameters and cooling strategies on the wear behavior of wrought and additive manufactured Ti6Al4V for biomedical applications. Tribol. Int. 2016, 102, 133–142. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.I.; Barreiro, J.; de Lacalle, L.N.L. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Fernandez-Valdivielso, A.; de Lacalle, L.N.L.; Urbikain, G.; Rodriguez, A. Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015. [CrossRef]

| Al | Mo | Mn | Si | Zr | Ti |

|---|---|---|---|---|---|

| 5.8~7.0 | 2.8~3.8 | 0.8~2.0 | 0.2~0.35 | 0.15 | Remainder |

| Tensile Strength (25 °C) | Tensile Strength (500 °C) [MPa] | Yield Strength (25 °C) [MPa] | Elongation (Over 2 Inches) [%] | Hardness | Elastic Moduler [GPa] |

|---|---|---|---|---|---|

| 1030 | 685 | 1000 | 10 | 0.15 | 110 |

| Machine Tool | ETC3650U |

|---|---|

| Cutting Parameters |

|

| Cutting Tool | T1. CNMG120408-SMR H13A; T2. CNMG120408-SMR 1115 T3. CNMG120408-SMR H13A (Coated with diamond) |

| Dynamometer | Kistler 9129AA |

| Thermal Camera | FlirA615 |

| Point | C | Al | Ti | Zr | W | O | S | V | Cr | Co | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3.27 | 4.87 | 88.59 | 1.79 | 0.37 | - | - | - | - | - | - |

| 2 | 6.11 | 1.54 | 31.49 | 0.84 | 57.41 | 1.54 | 0.34 | 0.08 | 0.16 | - | |

| 3 | 5.17 | 0.40 | 5.61 | 1.23 | 77.53 | 0.82 | - | - | - | 0.92 | 0.53 |

| 4 | - | 5.32 | 86.48 | 1.13 | 0.68 | 0.45 | - | 0.35 | - | 0.19 | 2.58 |

| 5 | 1.87 | 1.29 | 19.14 | 1.25 | 72.62 | 0.33 | - | - | - | 1.05 | 2.46 |

| 6 | - | 3.28 | 86.41 | 1.91 | - | - | - | 0.67 | - | 0.26 | 3.56 |

| Point | C | Al | Ti | Zr | W | O | S | V | Cr | Co | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | - | 2.77 | 28.07 | 0.91 | 62.27 | 1.22 | - | 0.16 | - | 4.55 | 1.03 |

| 2 | 8.64 | 0.59 | 1.18 | - | 76.99 | 1.72 | - | 1.12 | 8.59 | - | |

| 3 | 0.98 | 3.25 | 61.70 | 0.46 | 30.85 | - | - | 0.15 | - | 0.93 | 1.67 |

| 4 | 0.01 | 0.67 | 10.74 | 1.02 | 75.01 | 1.72 | - | - | - | 4.40 | 0.51 |

| Point | C | Al | Ti | Zr | W | O | S | V | Cr | Co | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 5.22 | 84.69 | 2.49 | 0.42 | 0.29 | 6.14 | |||||

| 2 | 5.22 | 0.84 | 10.66 | 0.32 | 79.57 | 2.07 | 0.20 | 0.46 | 0.65 | ||

| 3 | 5.11 | 1.02 | 18.80 | 0.85 | 67.75 | 0.23 | 0.12 | 0.30 | 1.08 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, S.; Li, Z.; Guo, G.; An, Q.; Chen, M.; Ming, W. Analysis of Minimum Quantity Lubrication (MQL) for Different Coating Tools during Turning of TC11 Titanium Alloy. Materials 2016, 9, 804. https://doi.org/10.3390/ma9100804

Qin S, Li Z, Guo G, An Q, Chen M, Ming W. Analysis of Minimum Quantity Lubrication (MQL) for Different Coating Tools during Turning of TC11 Titanium Alloy. Materials. 2016; 9(10):804. https://doi.org/10.3390/ma9100804

Chicago/Turabian StyleQin, Sheng, Zhongquan Li, Guoqiang Guo, Qinglong An, Ming Chen, and Weiwei Ming. 2016. "Analysis of Minimum Quantity Lubrication (MQL) for Different Coating Tools during Turning of TC11 Titanium Alloy" Materials 9, no. 10: 804. https://doi.org/10.3390/ma9100804