Comparative Study on Crack Initiation and Propagation of Glass under Thermal Loading

Abstract

:1. Introduction

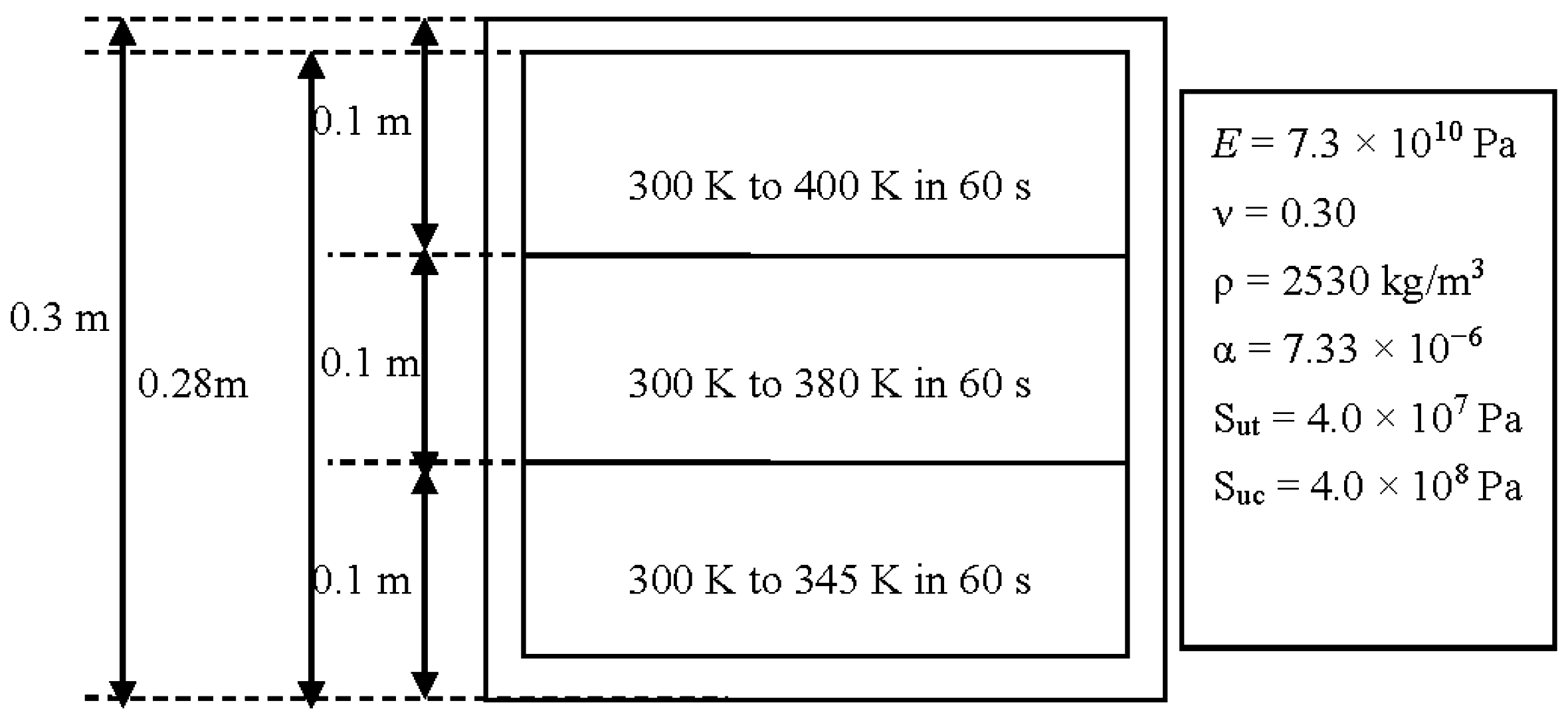

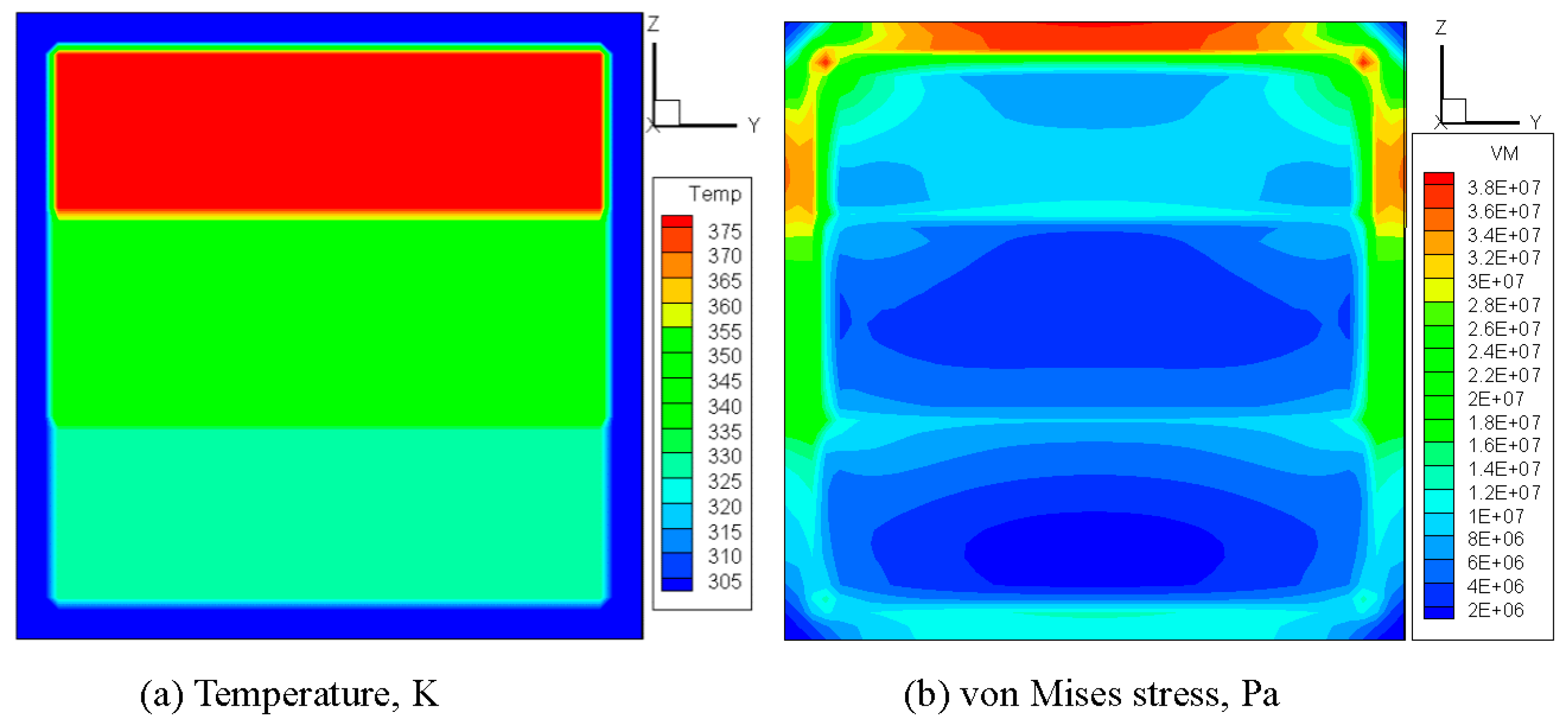

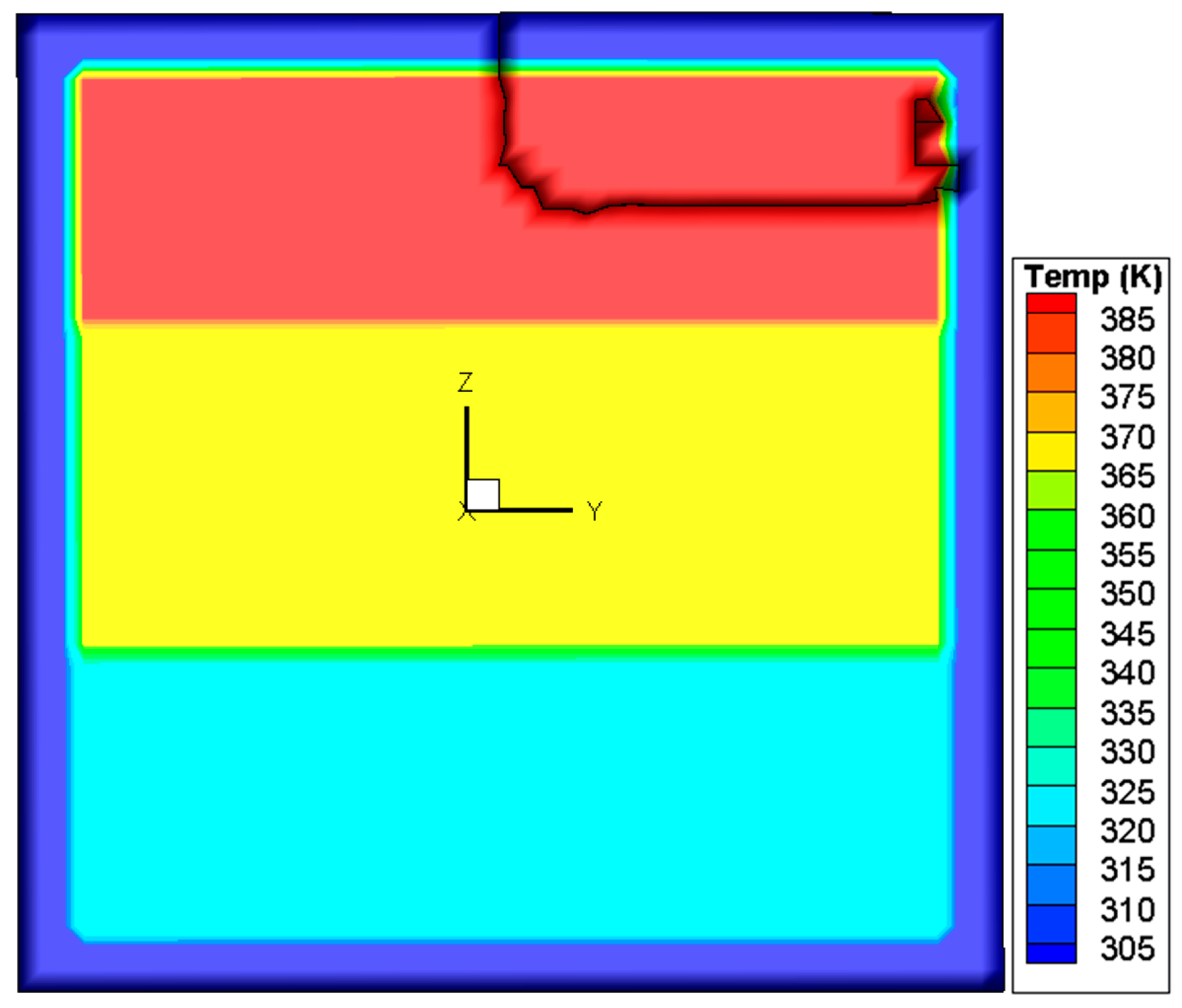

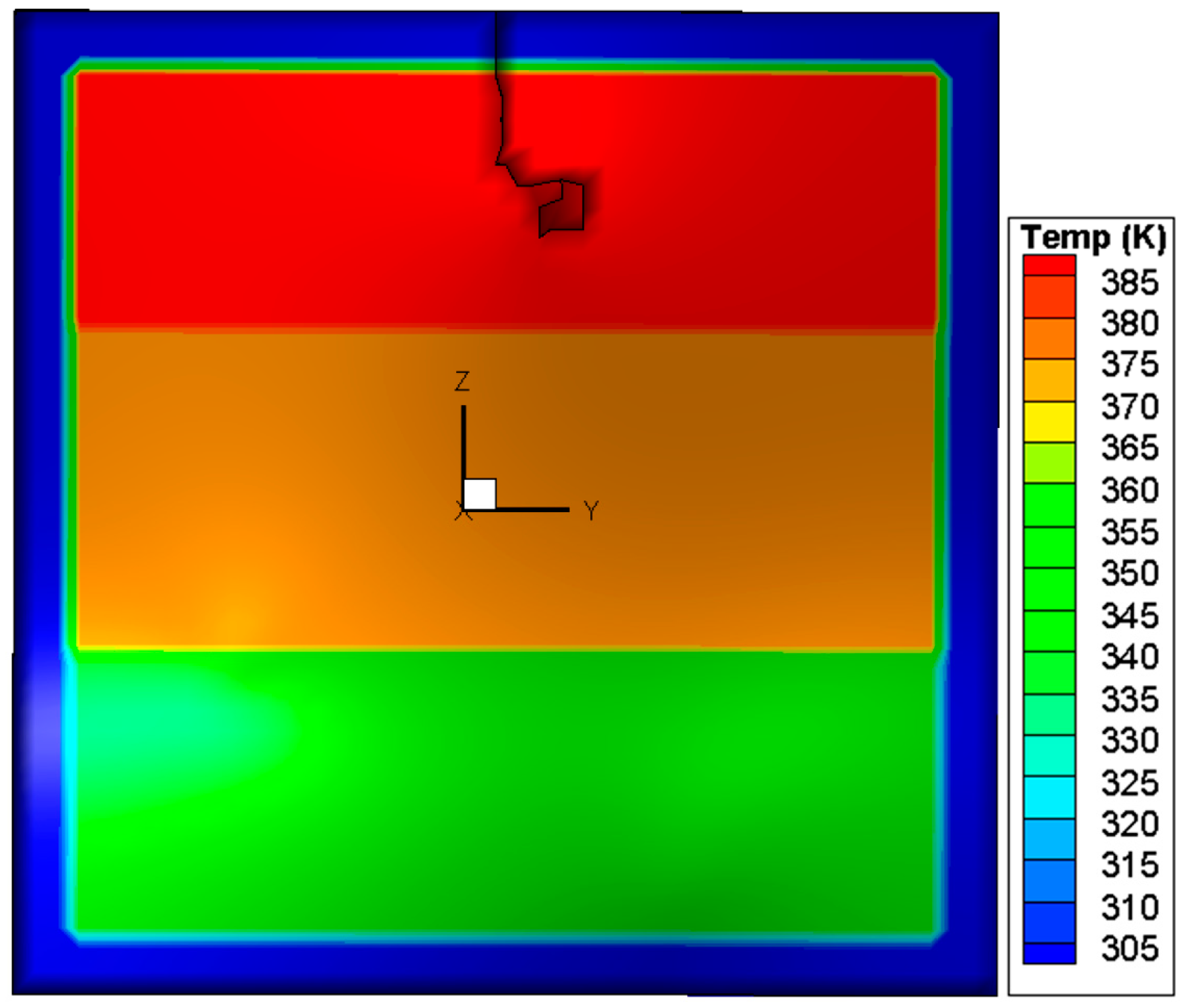

2. Thermal Stress Distribution

3. Modeling of Crack Initiation

3.1. Probabilistic Criterion

3.1.1. Two-Parameter Weibull Distribution

3.1.2. Three-Parameter Weibull Distribution

3.2. Deterministic Criterion

3.2.1. Maximum Normal Stress Criterion

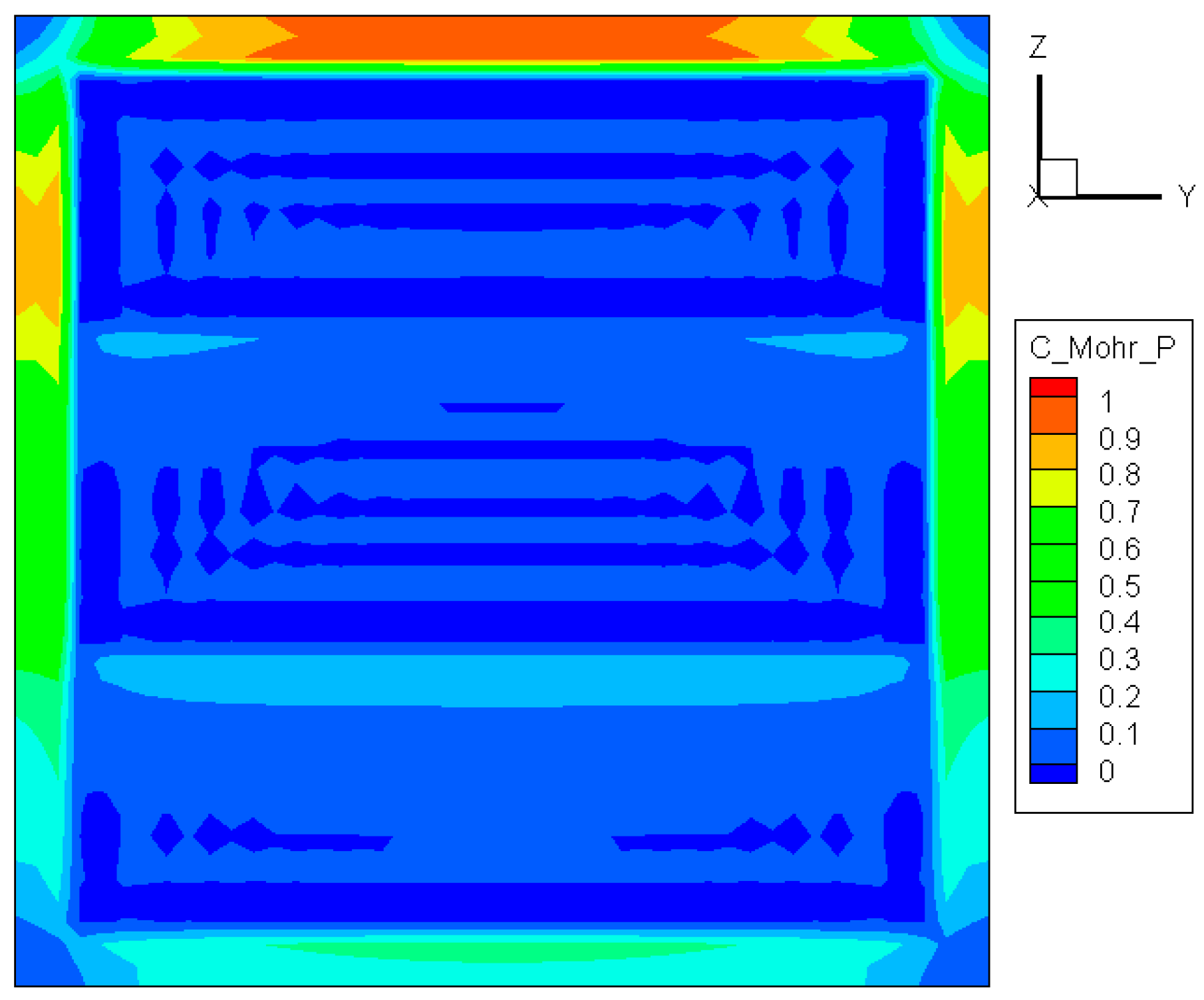

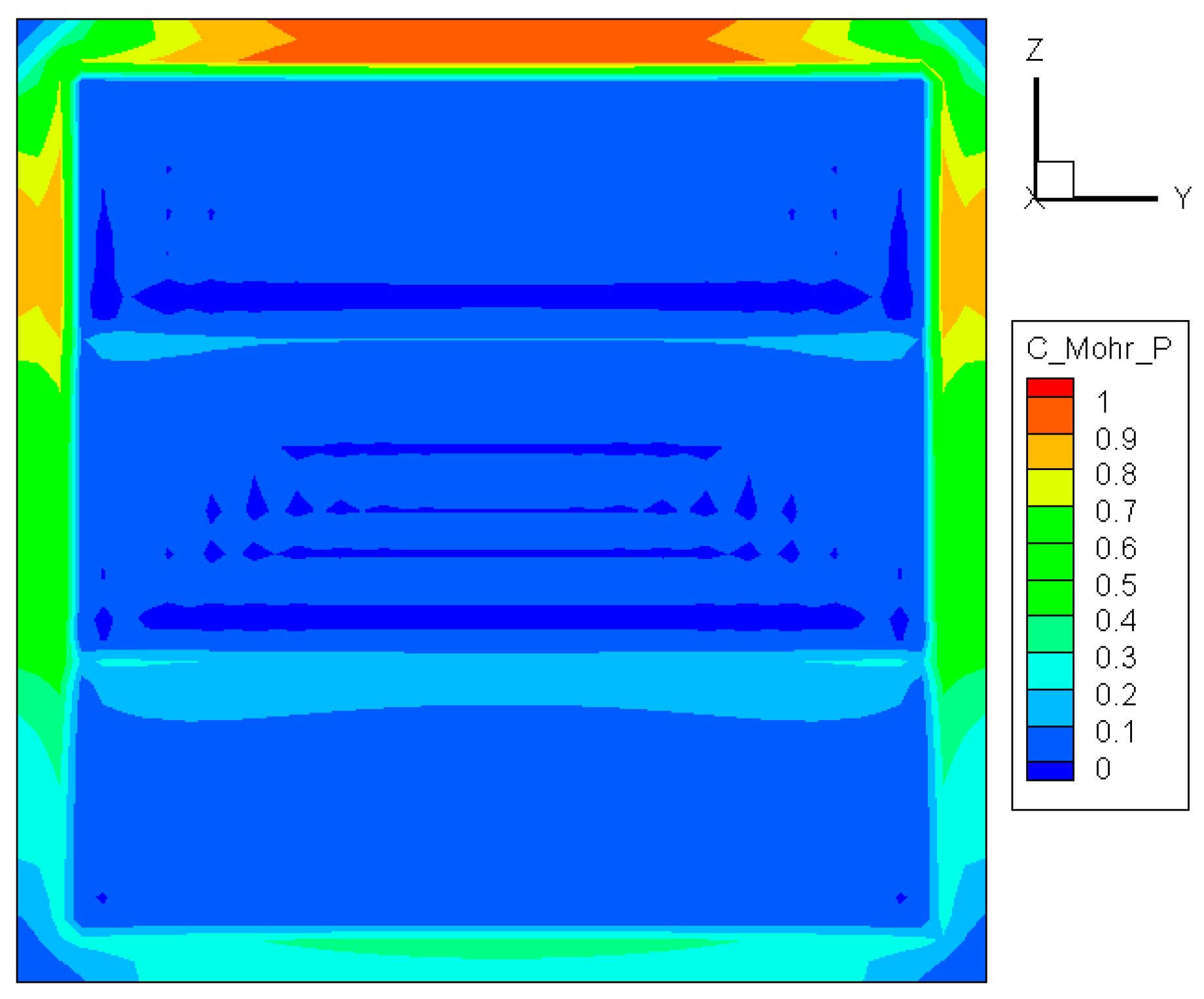

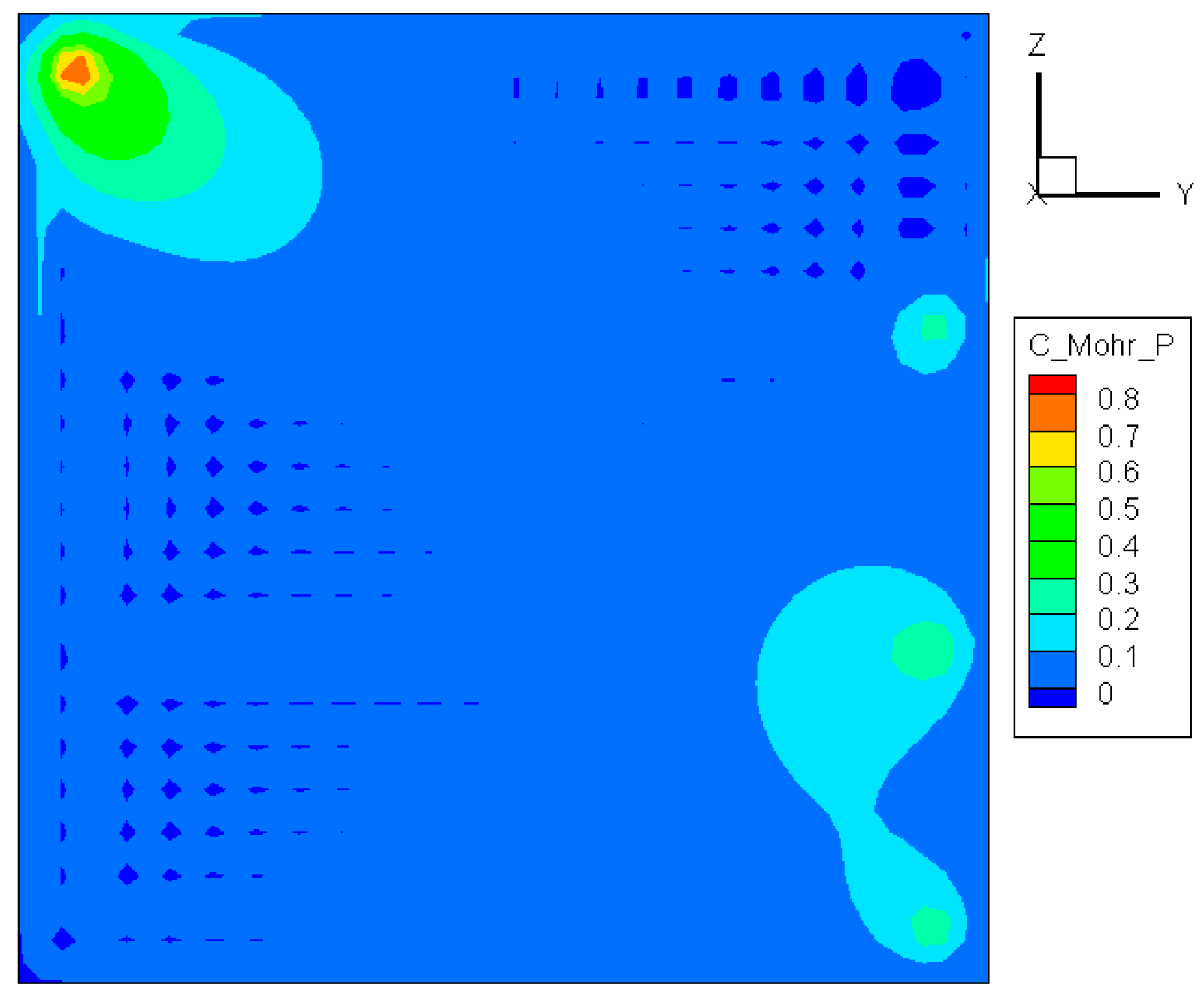

3.2.2. Coulomb-Mohr Criterion

3.2.3. Maximum Principal Stress Criterion

3.2.4. Maximum Mises Stress Criterion

3.2.5. Maximum Shear Stress Criterion

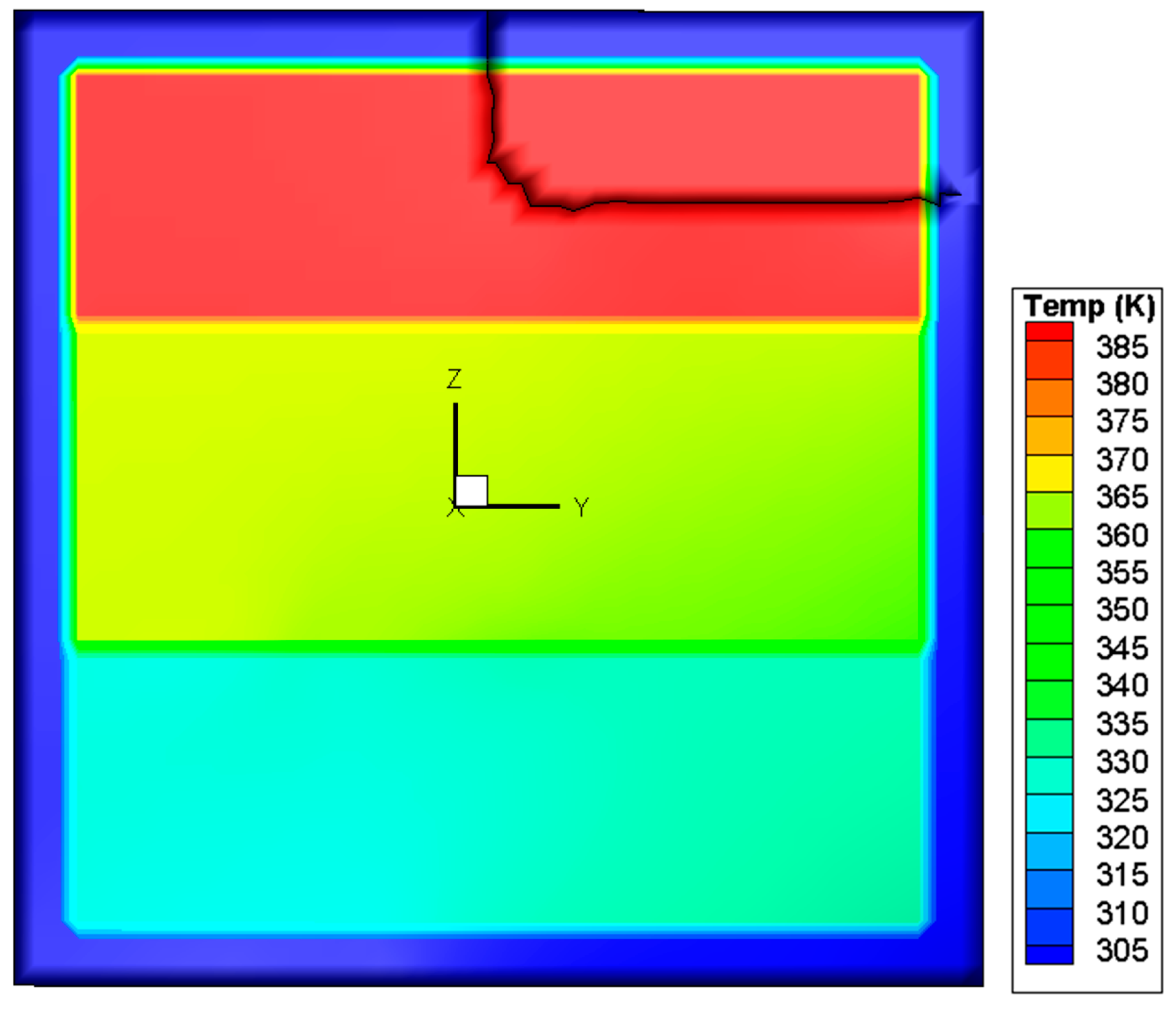

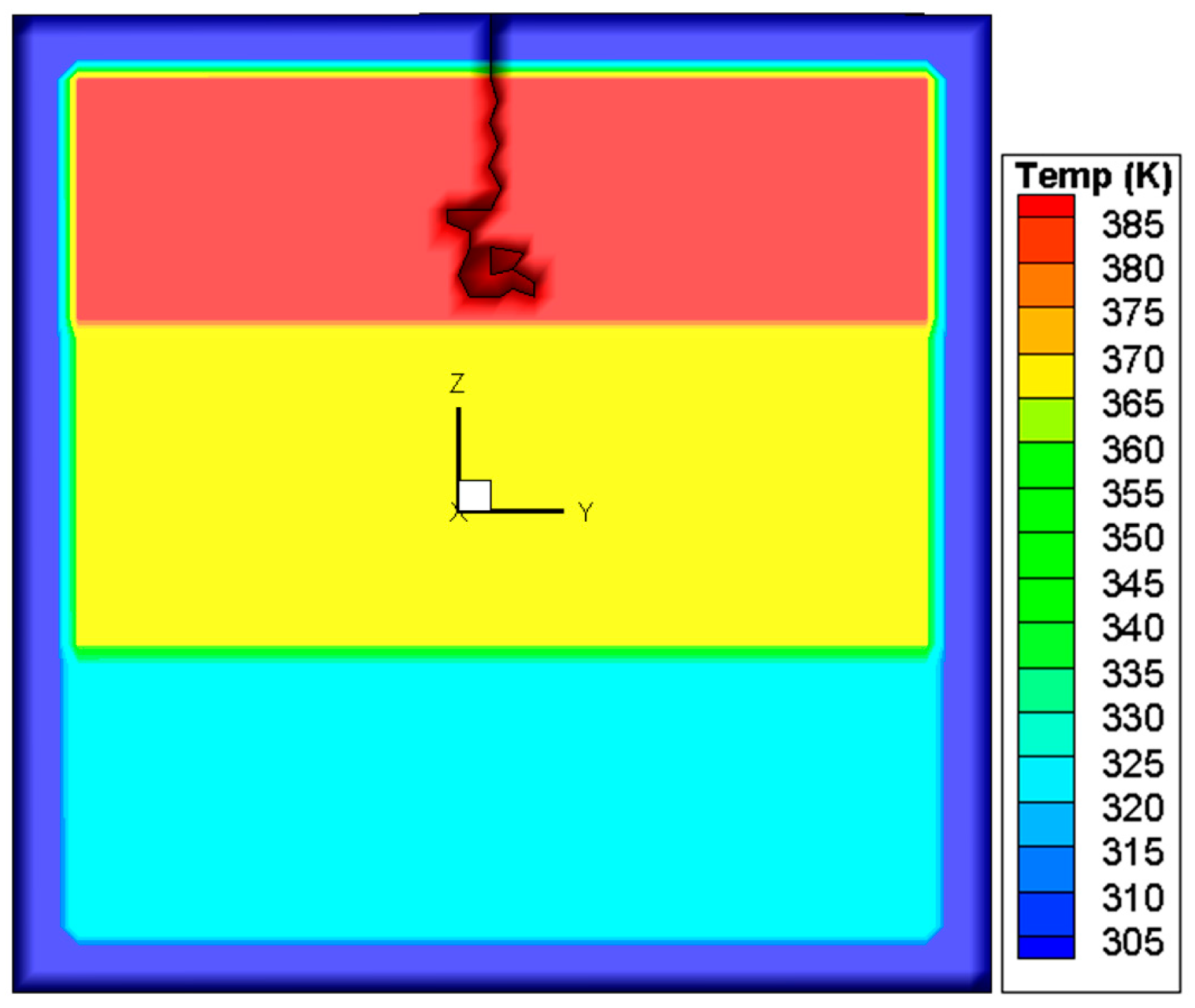

4. Modeling of Crack Propagation

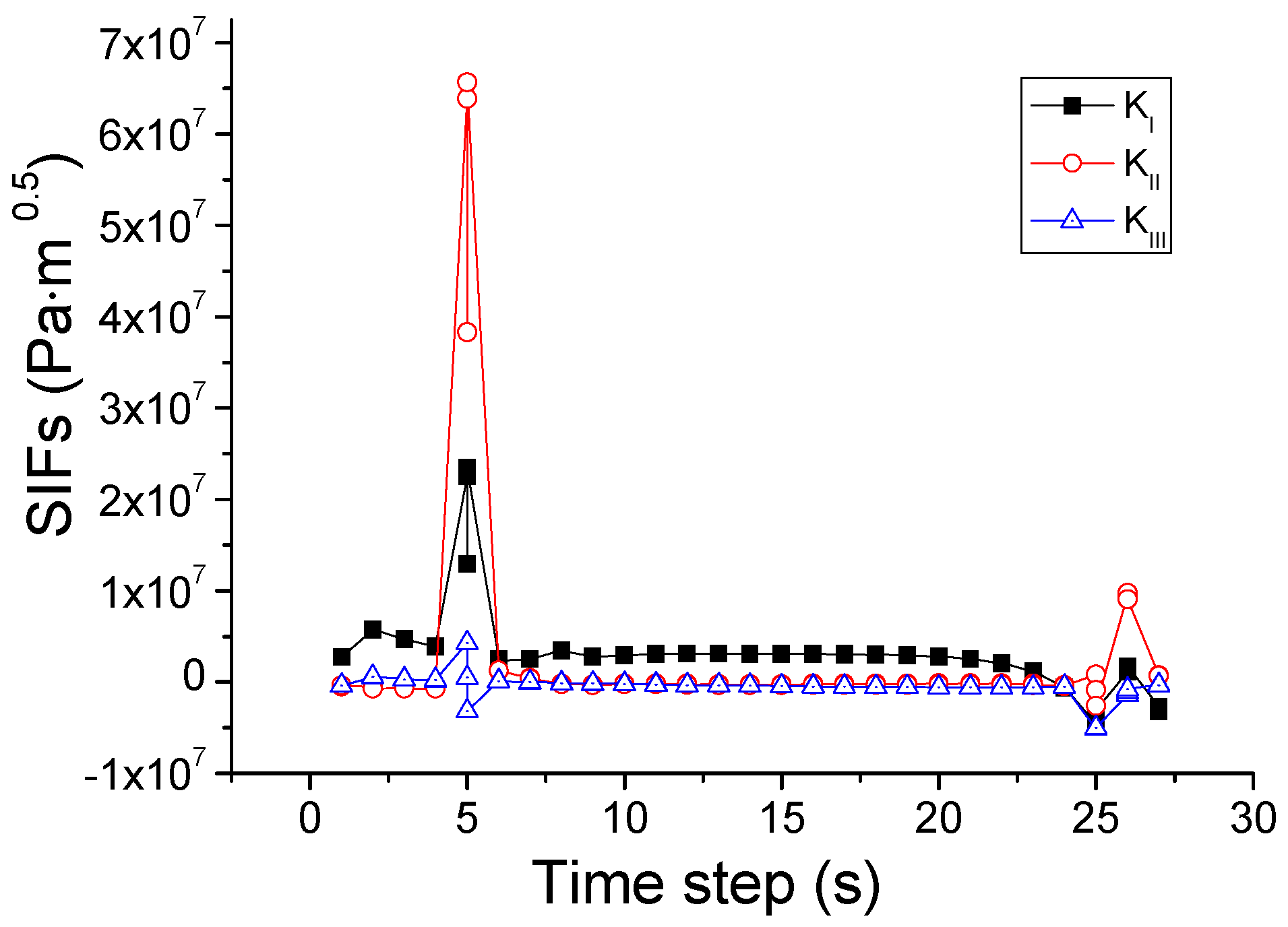

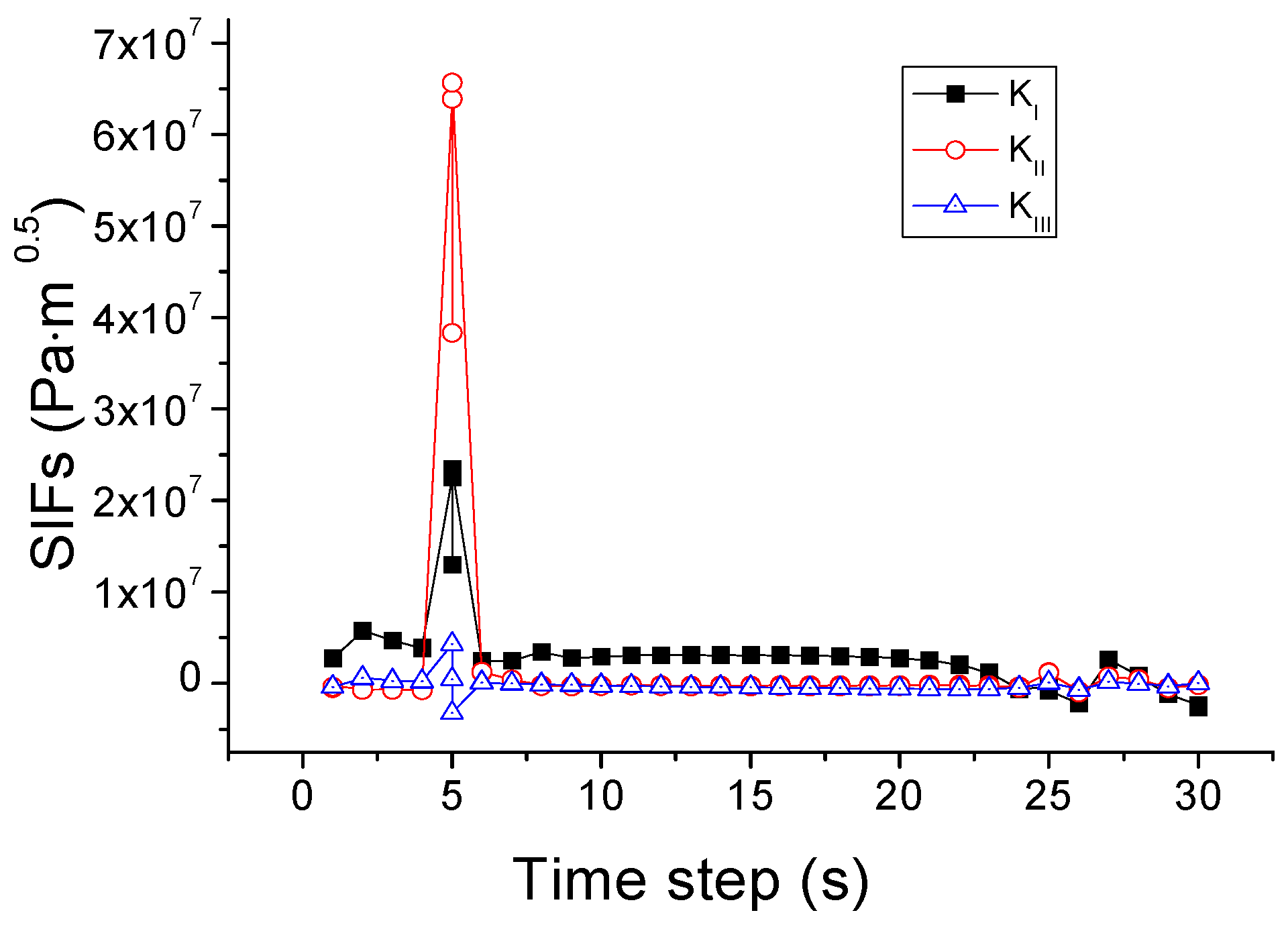

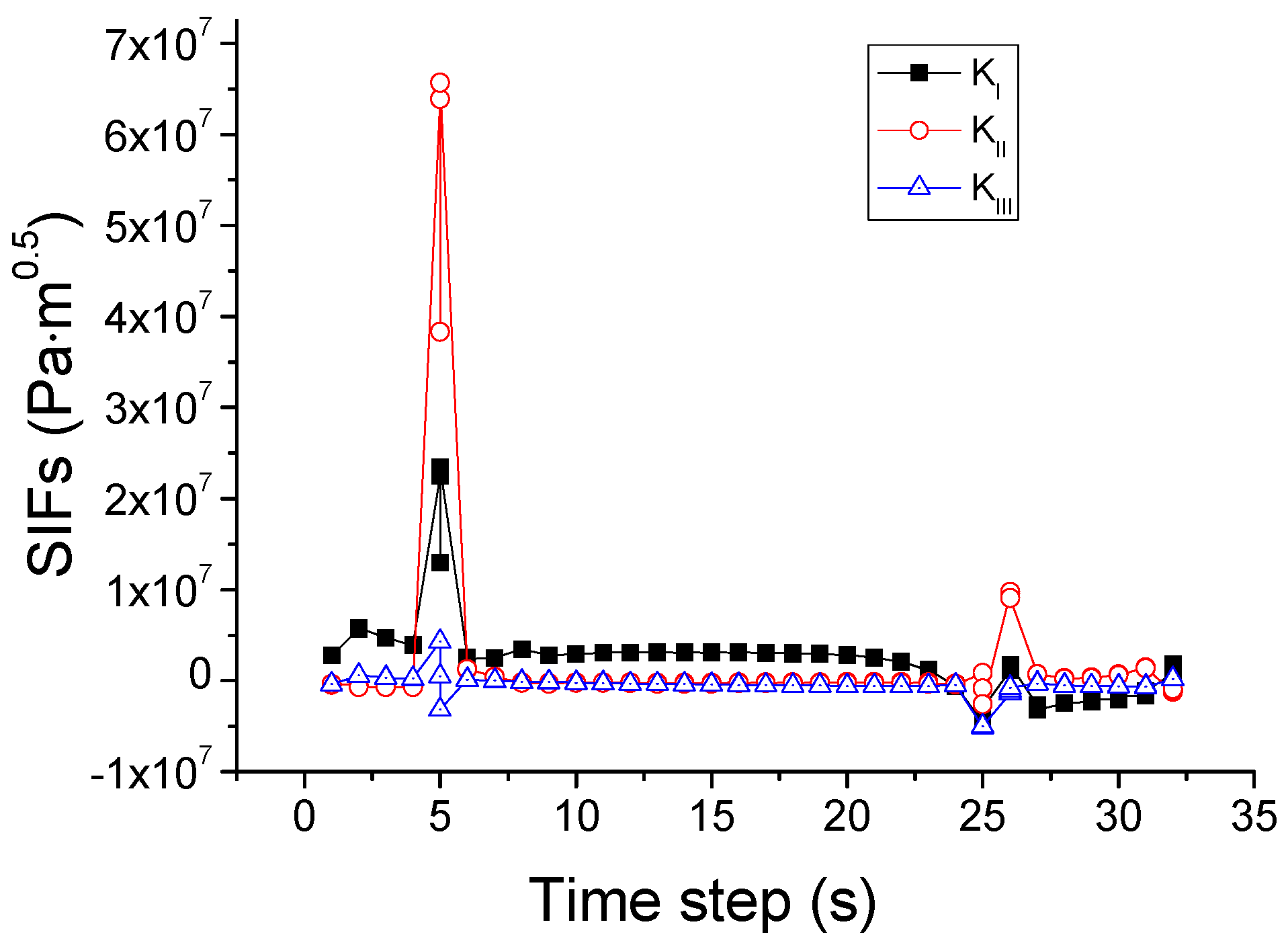

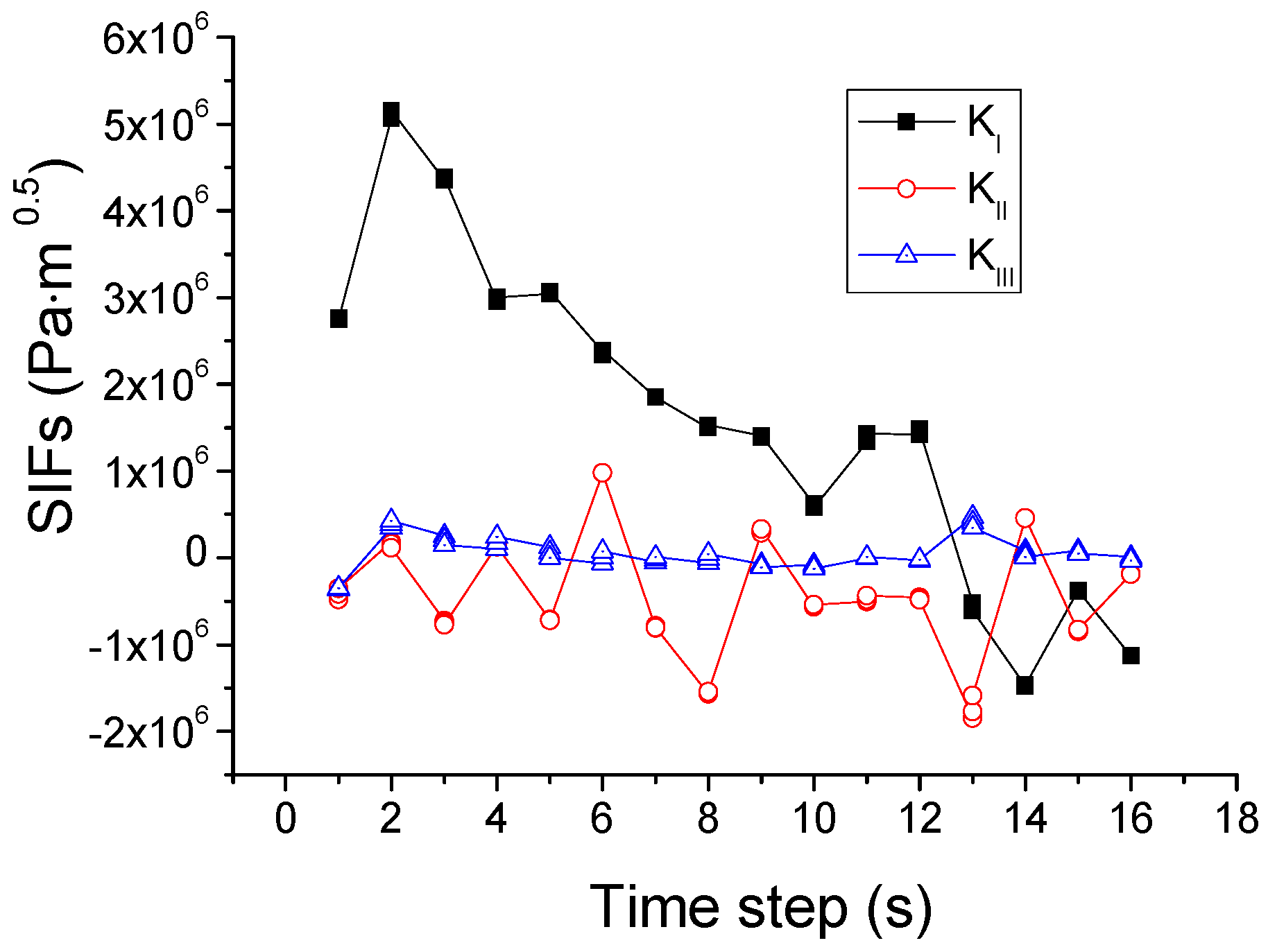

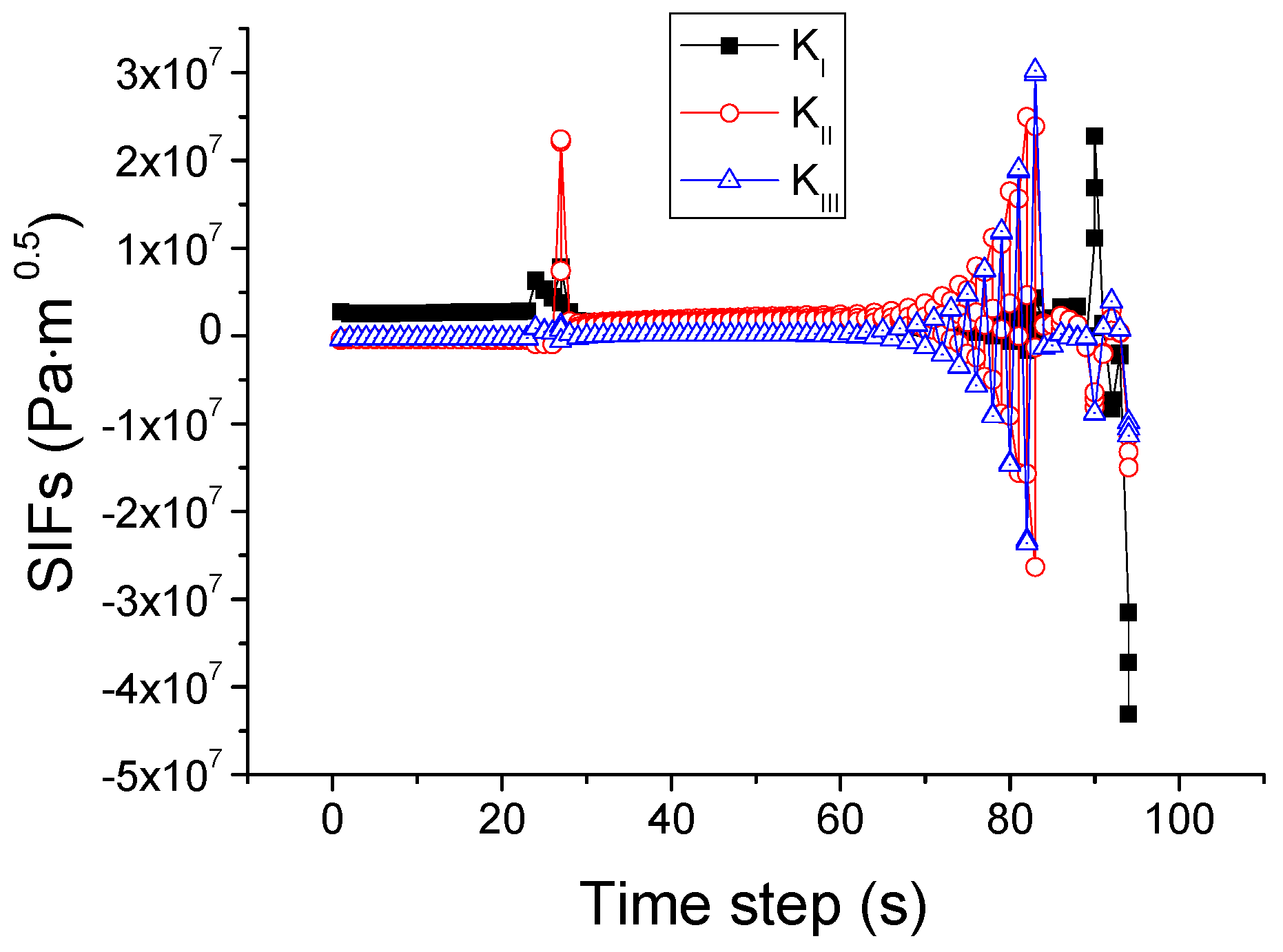

4.1. Mixed-Mode Criterion Based on SIFs

4.2. Mixed-Mode Criterion Based on Energy Release Rates

4.3. SIF-Based Maximum Circumferential Stress Criterion

4.4. Criterion Based on Maximum Principal Stress

4.5. Criterion Based on Crack Tip Opening Angle (CTOA)

4.6. Criterion Based on Crack Tip Opening Displacement (CTOD)

4.7. Discussion

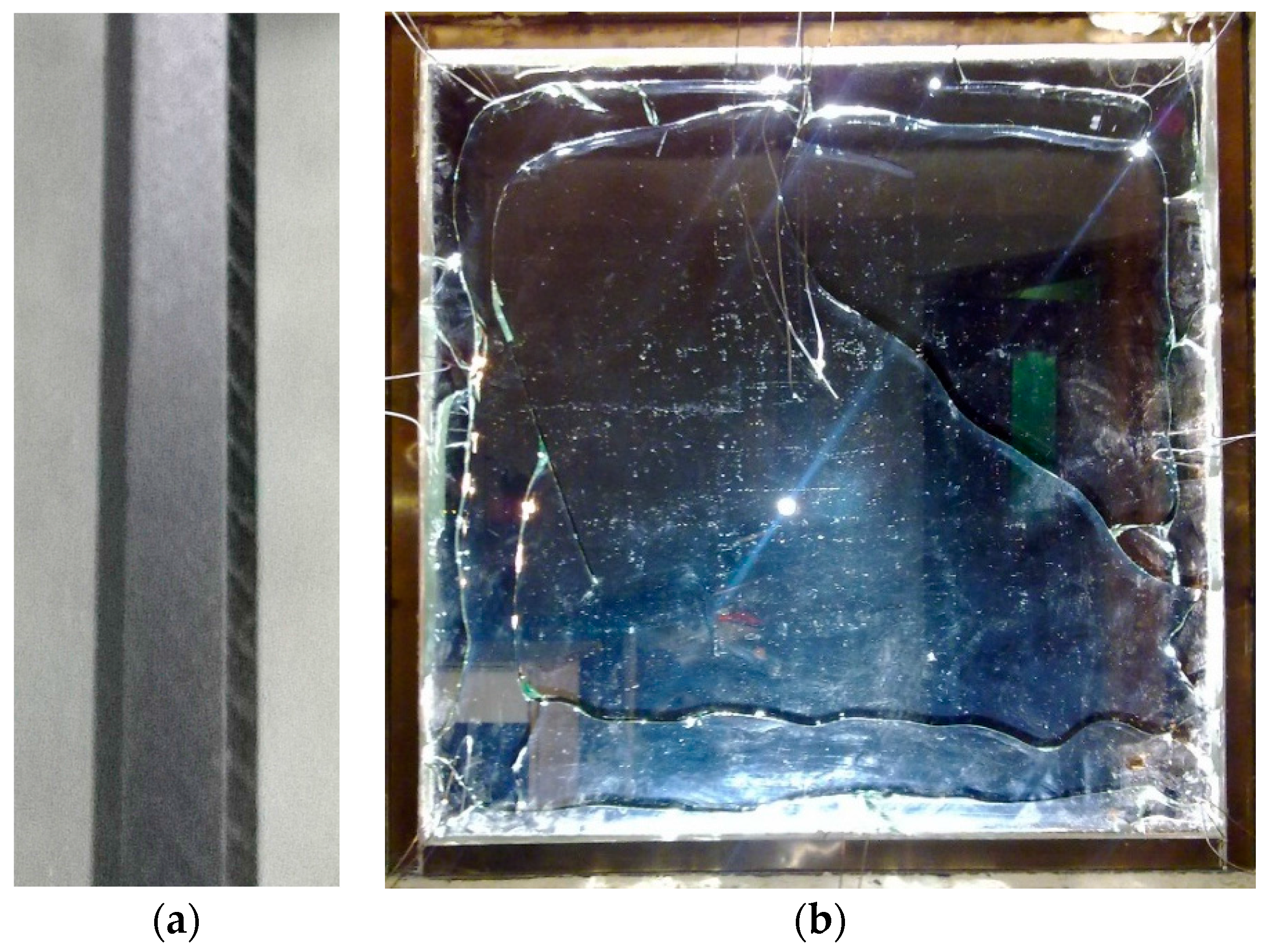

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Keski-Rahkonen, O. Breaking of window glass close to fire. Fire Mater. 1988, 12, 61–69. [Google Scholar] [CrossRef]

- Pagni, P.J.; Joshi, A.A. Glass breaking in fires. In Proceedings of the Third International Symposium on Fire Safety Science, Edinburgh, UK, 8–15 July 1991; pp. 791–802.

- Joshi, A.A.; Pagni, P.J. Fire-Induced Thermal Fields in Window Glass I—Theory. Fire Saf. J. 1994, 22, 25–43. [Google Scholar] [CrossRef]

- Joshi, A.A.; Pagni, P.J. Fire-Induced Thermal Fields in Window Glass II—Experiments. Fire Saf. J. 1994, 22, 45–65. [Google Scholar] [CrossRef]

- Skelly, M.J.; Roby, R.J.; Beyler, C.L. An experimental investigation of glass breakage in compartment fires. J. Fire Prot. Eng. 1991, 3, 25–34. [Google Scholar] [CrossRef]

- Shields, T.J.; Silcock, G.W.H.; Hassani, S.K.S. The behavior of single glazing in an enclosure fire. J. Appl. Fire Sci. 1998, 7, 145–163. [Google Scholar] [CrossRef]

- Klassen, M.S.; Sutula, J.A.; Holton, M.M.; Roby, R.J.; Izbicki, T. Transmission through and breakage of multi-pane glazing due to radiant exposure. Fire Technol. 2006, 42, 79–107. [Google Scholar] [CrossRef]

- Wondraczek, L.; Mauro, J.C.; Eckert, J.; Kühn, U.; Horbach, J.; Deubener, J.; Rouxel, T. Towards ultrastrong glasses. Adv. Mater. 2011, 23, 4578–4586. [Google Scholar] [CrossRef] [PubMed]

- Hietaniemi, J. Probabilistic Simulation of Glass Fracture and Fallout in Fire; VTT: Vuorimiehentie, Finland, 2005; p. 18. [Google Scholar]

- Wang, Q.S.; Zhang, Y.; Wang, Y.; Sun, J.H.; He, L.H. Three dimensional dynamic stress prediction of window glass under thermal loading. Int. J. Therm. Sci. 2012, 59, 152–160. [Google Scholar] [CrossRef]

- Tofilo, P.; Delichatsios, M. Thermally Induced Stresses in Glazing Systems. J. Fire Prot. Eng. 2010, 20, 101–116. [Google Scholar] [CrossRef]

- Mai, Y.; Jacob, L. Thermal stress fracture of solar control window panes caused by shading of incident radiation. Mater. Struct. 1980, 13, 283–288. [Google Scholar] [CrossRef]

- Chowdhury, H.; Cortie, M.B. Thermal stresses and cracking in absorptive solar glazing. Constr. Build. Mater. 2007, 21, 464–468. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Y.; Wang, Q.; Liew, K.M.; Chen, H.; Sun, J.; He, L. Numerical study on fire response of glass facades in different installation forms. Constr. Build. Mater. 2014, 61, 172–180. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Q.; Shao, G.; Chen, H.; Sun, J.; He, L.; Liew, K.M. Experimental study on critical breaking stress of float glass under elevated temperature. Mater. Des. 2014, 60, 41–49. [Google Scholar] [CrossRef]

- McLellan, G.W.; Shand, E.B.; MacLellan, G. Glass Engineering Handbook; McGraw-Hill: New York, NY, USA, 1984. [Google Scholar]

- Pagni, P.J. Thermal Glass Breakage. In International Association for Fire Safety Science, Proceedings of the Seventh International Symposium on Fire Safety Science, Worcester, MA, USA, 16–21 June 2003; Evans, D., Ed.; pp. 3–22.

- Guy, N.; Seyedi, D.M.; Hild, F. A probabilistic nonlocal model for crack initiation and propagation in heterogeneous brittle materials. Int. J. Numer. Methods Eng. 2012, 90, 1053–1072. [Google Scholar] [CrossRef]

- Alqam, M.; Bennett, R.M.; Zureick, A.H. Three-parameter vs. two-parameter Weibull distribution for pultruded composite material properties. Compos. Struct. 2002, 58, 497–503. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.B. A criterion study for non-singular stress concentrations in brittle or quasi-brittle materials. Eng. Fract. Mech. 2006, 73, 505–523. [Google Scholar] [CrossRef]

- Sun, X.F. Mechanics of Materials, 5th ed.; Higher Education Press: Beijing, China, 2011. [Google Scholar]

- Pokluda, J.; Šandera, P. Micromechanisms of Fracture and Fatigue. In A Multi-scale Context; Springer: Berlin, Germany, 2010. [Google Scholar]

- SolidWorks Help. Web Help Content Version: SolidWorks 2012 SP02; SolidWorks Corp: Waltham, MA, USA, 2012. [Google Scholar]

- Tabiei, A.; Wu, J. Development of the DYNA3D simulation code with automated fracture procedure for brick elements. Int. J. Numer. Methods Eng. 2003, 57, 1979–2006. [Google Scholar] [CrossRef]

- Wu, E.M. Application of fracture mechanics to anisotropic plates, Transactions of the ASME. J. Appl. Mech. 1967, 34, 967–974. [Google Scholar] [CrossRef]

- Irwin, G.R. Analysis of stresses and strains near the end of a crack traversing a plate, Transactions of the ASME. J. Appl. Mech. 1957, 24, 361–364. [Google Scholar]

- Carloni, C.; Nobile, L. Maximum circumferential stress criterion applied to orthotropic materials. Fatigue Fract. Eng. Mater. 2005, 28, 825–833. [Google Scholar] [CrossRef]

- Jung, S.; Lee, H. Crack-tip field characterization of crack-tip opening angle-based crack growth—Plane strain single-edge cracked specimen subject to pure extension. J. Mech. Sci. Technol. 2011, 25, 1207–1213. [Google Scholar] [CrossRef]

- Daniewicz, S.R.; Newman, J.C.; Schwalbe, K.H. Fatigue, Fracture, E.S.I. Society. In Proceedings of the ASTM International Symposium on Fatigue and Fracture Mechanics, Tampa, FL, USA, 19–21 Novmber 2005.

- Sutton, M.A.; Deng, X.; Ma, F.; Newman, J.C., Jr.; James, M. Development and application of a crack tip opening displacement-based mixed mode fracture criterion. Int. J. Solids Struct. 2000, 37, 3591–3618. [Google Scholar] [CrossRef]

- Nunes, L.C.S.; Reis, J.M.L. Estimation of crack-tip-opening displacement and crack extension of glass fiber reinforced polymer mortars using digital image correlation method. Mater. Des. 2012, 33, 248–253. [Google Scholar] [CrossRef]

- Ravi-Chandar, K.; Yang, B. On the role of microcracks in the dynamic fracture of brittle materials. J. Mech. Phys. Solids 1997, 45, 535–563. [Google Scholar] [CrossRef]

- Yuse, A.; Sano, M. Transition between crack patterns in quenched glass plates. Nature 1993, 362, 329–331. [Google Scholar] [CrossRef]

- Yang, B.; Ravi-Chandar, K. Crack path instabilities in a quenched glass plate. J. Mech. Phys. Solids 2001, 49, 91–130. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Y.; Zhang, Y.; Chen, H.; Sun, J.; He, L. A stochastic analysis of glass crack initiation under thermal loading. Appl. Therm. Eng. 2014, 67, 447–457. [Google Scholar] [CrossRef]

| Weibull Function | m | σ0 (MPa) | σu (MPa) |

|---|---|---|---|

| Two-parameter | 3.20 | 74.1 | – |

| Three-parameter | 1.21 | 33.0 | 35.8 |

| No. | Criteria | ΔT, °C | σy, MPa | σvm, MPa | σ1, MPa | Time, s |

|---|---|---|---|---|---|---|

| 1 | Two-parameter Weibull | 94 | 67.78 | 67.23 | 67.79 | 44.0 |

| 2 | Three-parameter Weibull | 93 | 60.50 | 59.80 | 60.50 | 43.0 |

| 3 | Maximum normal stress | 76.8 | 40.03 | 39.48 | 40.03 | 23.5 |

| 4 | Coulomb-Mohr | 76.8 | 40.03 | 39.48 | 40.03 | 23.5 |

| 5 | Maximum principle stress | 76.8 | 40.03 | 39.48 | 40.03 | 23.5 |

| 6 | Maximum von Mises stress | 78.0 | 40.72 | 40.14 | 40.73 | 25.0 |

| 7 | Maximum shear stress | no crack | – | – | – | – |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wang, Q.; Chen, H.; Sun, J.; He, L. Comparative Study on Crack Initiation and Propagation of Glass under Thermal Loading. Materials 2016, 9, 794. https://doi.org/10.3390/ma9100794

Wang Y, Wang Q, Chen H, Sun J, He L. Comparative Study on Crack Initiation and Propagation of Glass under Thermal Loading. Materials. 2016; 9(10):794. https://doi.org/10.3390/ma9100794

Chicago/Turabian StyleWang, Yu, Qingsong Wang, Haodong Chen, Jinhua Sun, and Linghui He. 2016. "Comparative Study on Crack Initiation and Propagation of Glass under Thermal Loading" Materials 9, no. 10: 794. https://doi.org/10.3390/ma9100794