Study on Welding Mechanism Based on Modification of Polypropylene for Improving the Laser Transmission Weldability to PA66

Abstract

:1. Introduction

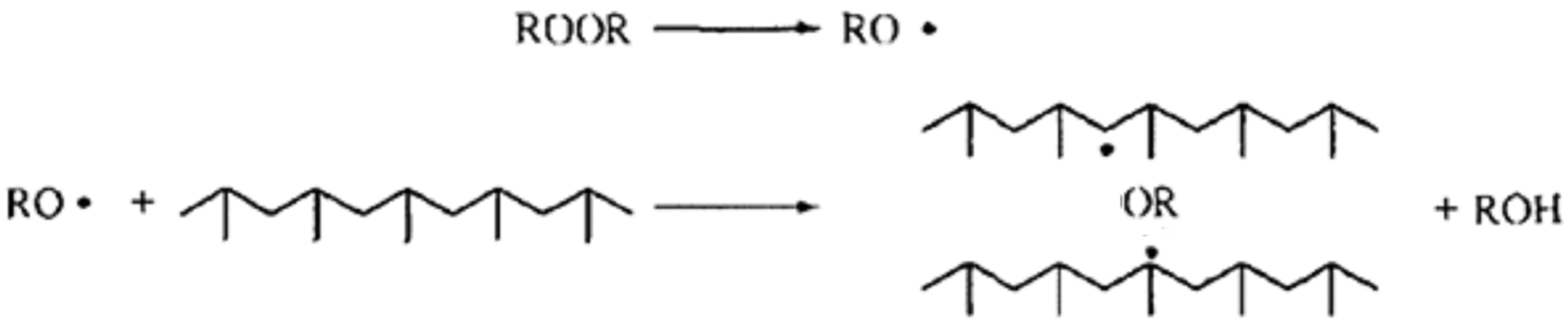

2. The Graft Modified Polypropylene

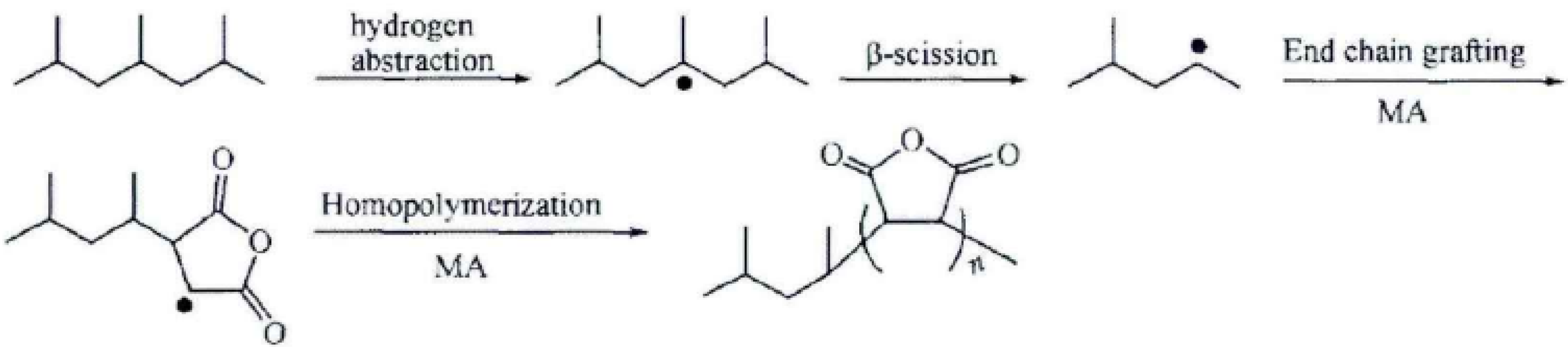

2.1. The Preparation of TGMPP and Its Infrared Spectroscopy

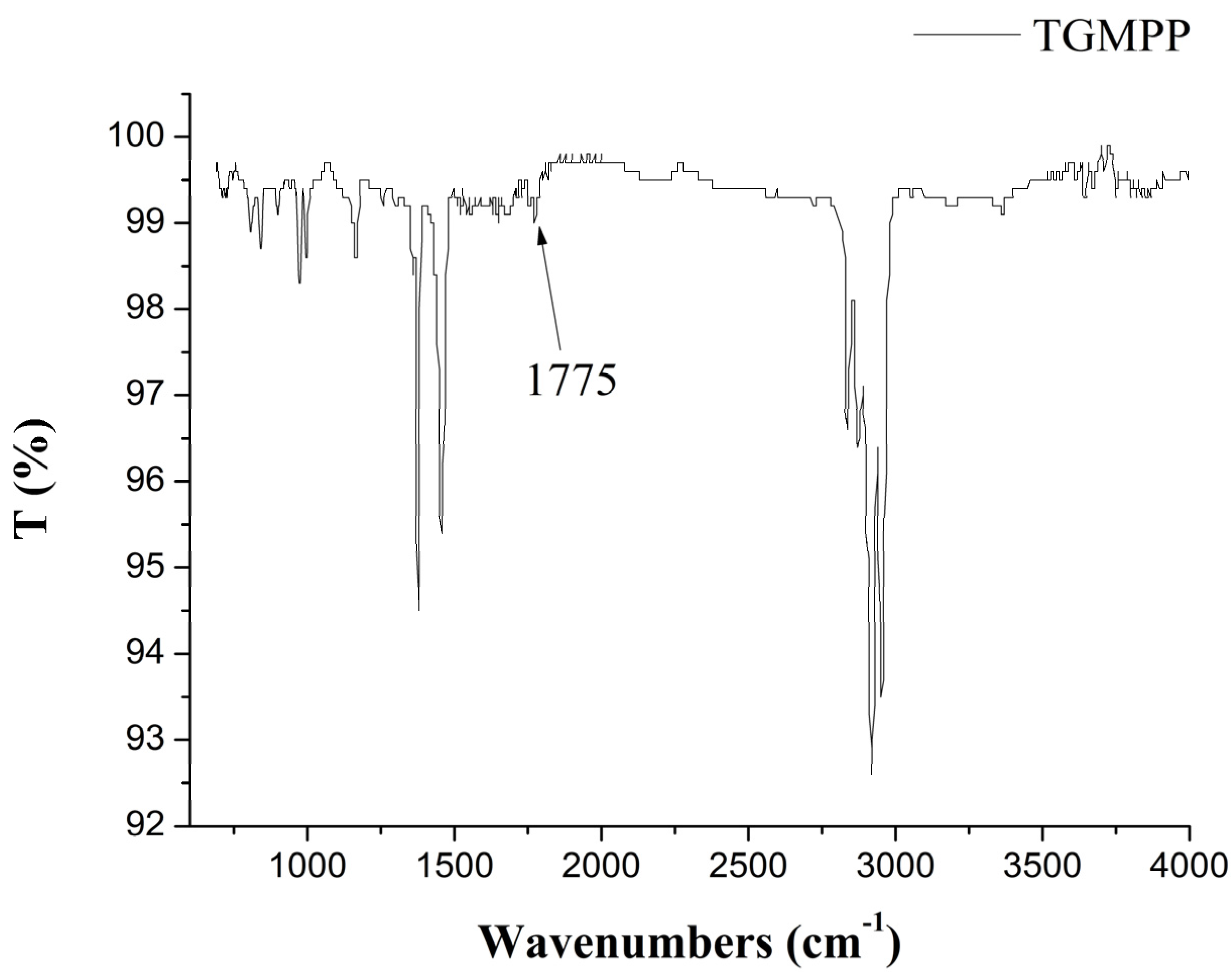

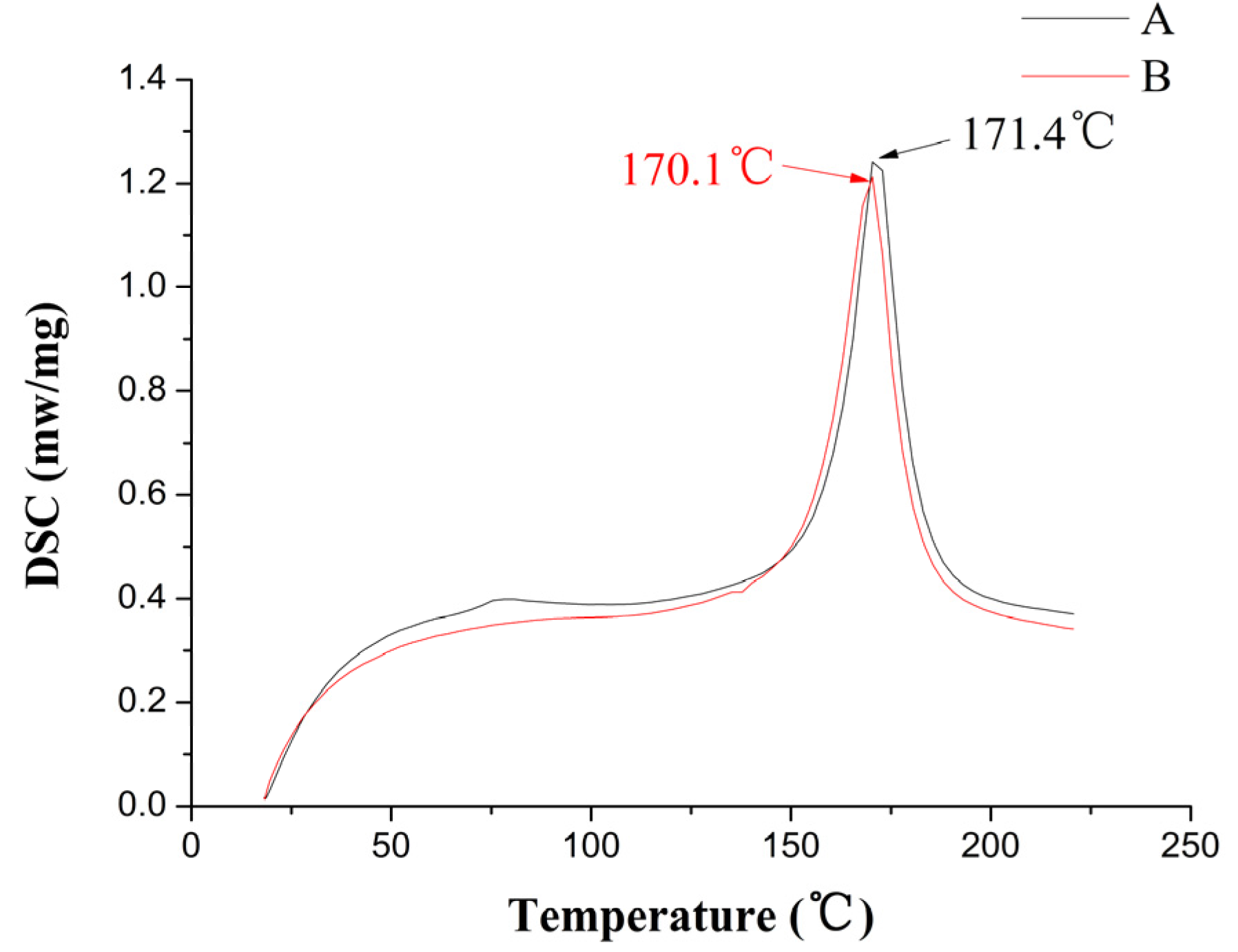

2.2. The Mechanical and Thermal Properties of TGMPP

2.3. The Effect of Grafting Modification on the Optical Properties of Polypropylene

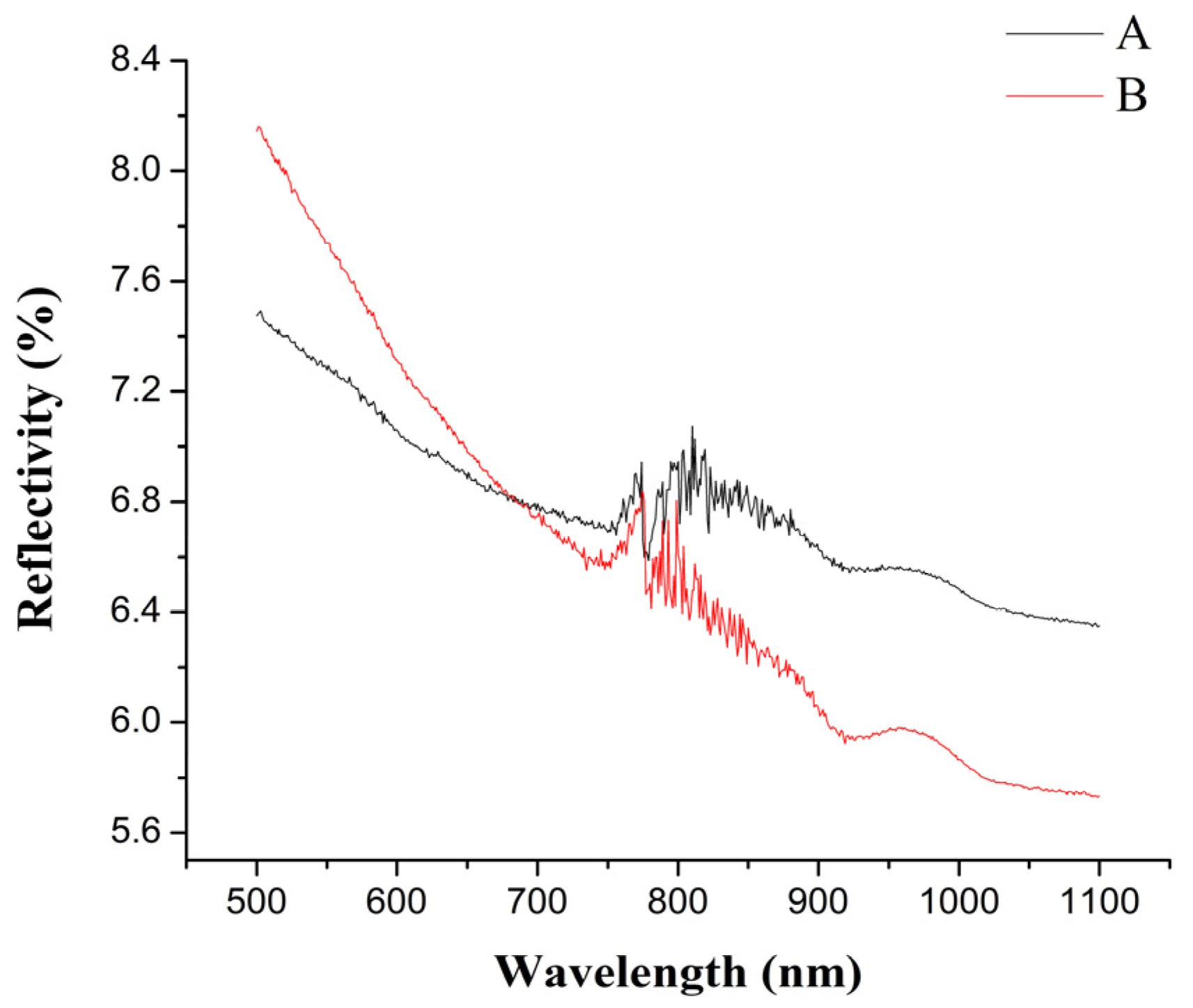

2.3.1. The Effect of Grafting Modification on the Reflectivity of Polypropylene

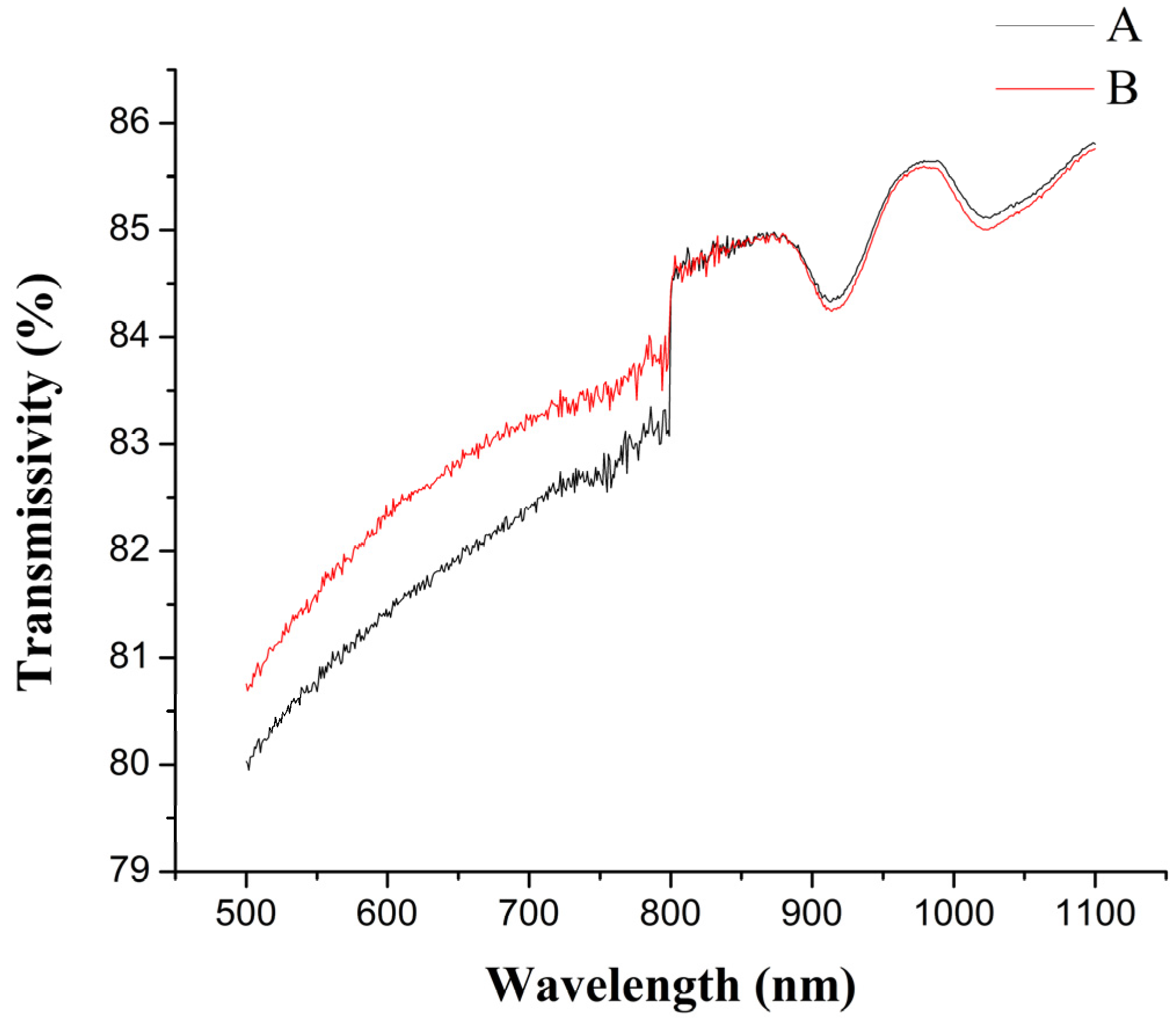

2.3.2. The Effect of Grafting Modification on the Transmissivity of Polypropylene

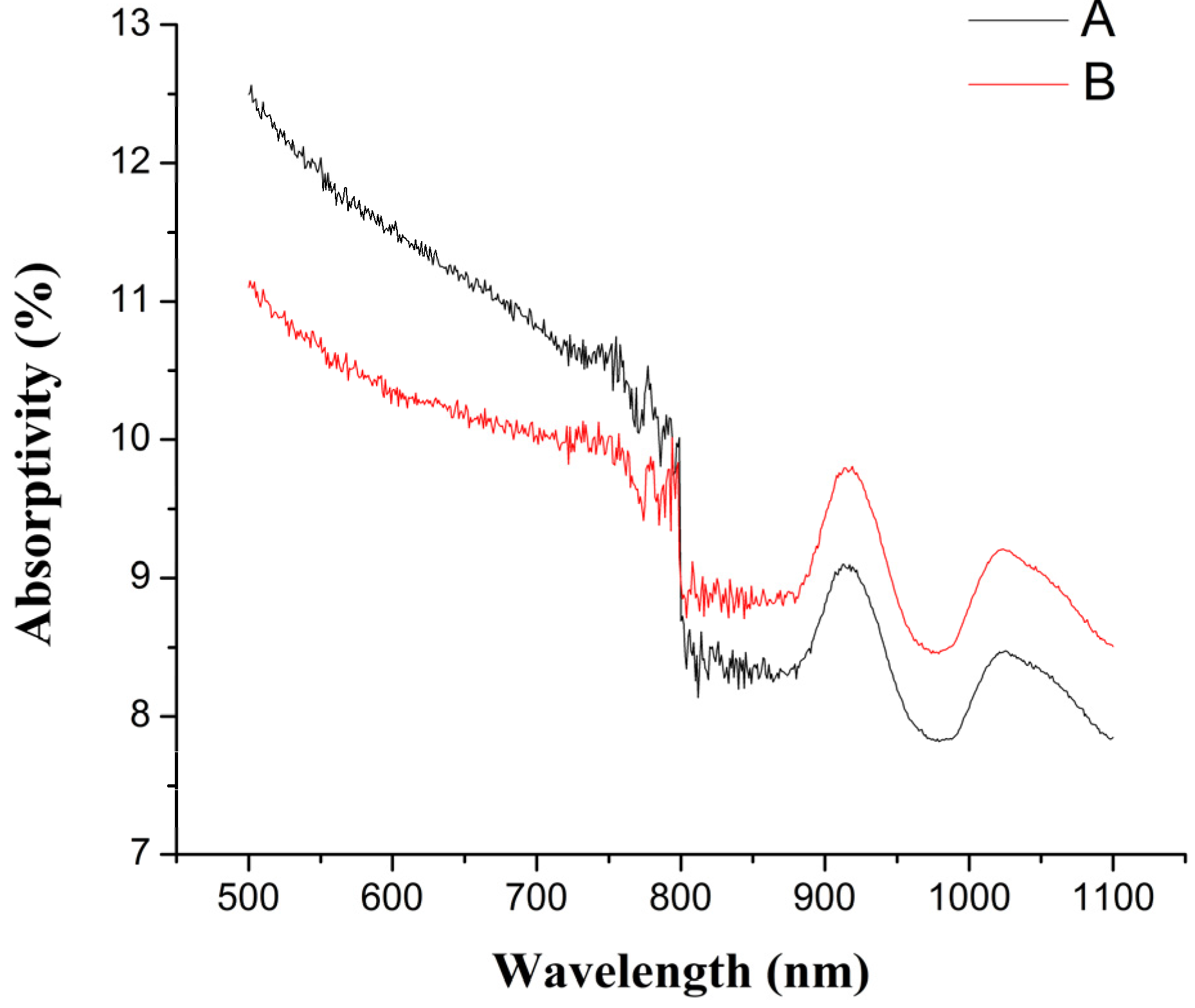

2.3.3. The Effect of Grafting Modification on the Absorptivity of Polypropylene

3 .The Study of Laser Transmission Welding between TGMPP and PA66

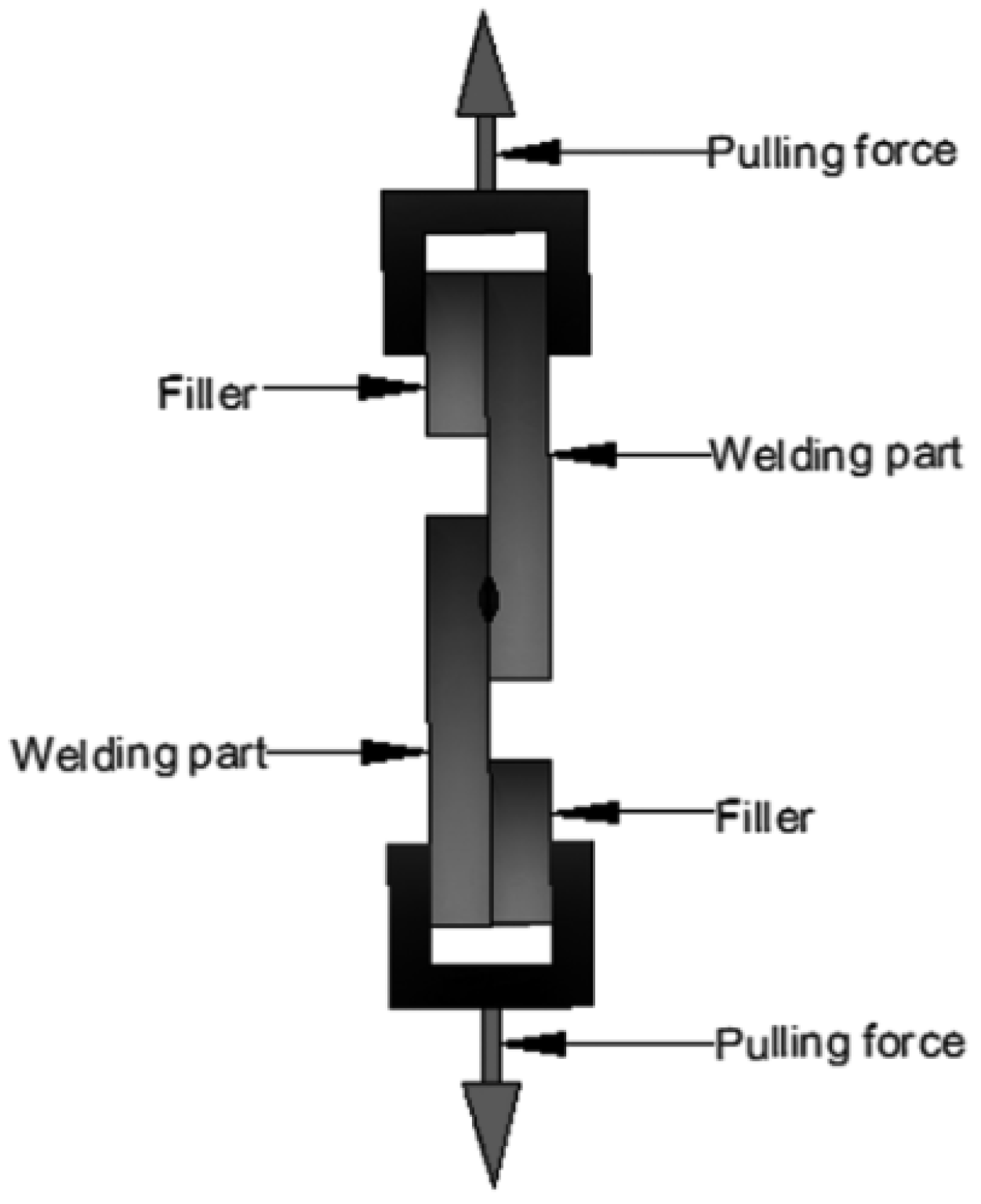

3.1. The Preparation of Specimens and Experimental Equipment

3.2. The Experiments of Laser Transmission Welding between TGMPP and PA66

3.3. Researches on the Mechanism of the Weldability between TGMPP and PA66

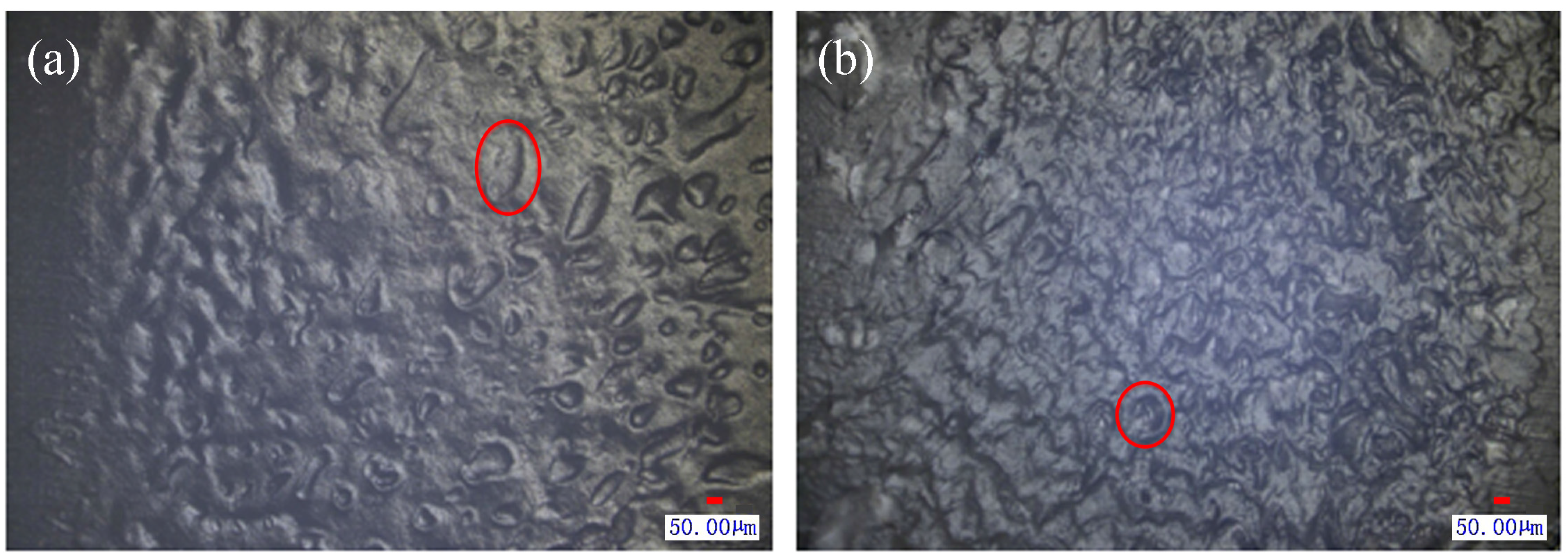

3.3.1. Micro Morphology Analysis of the Welding Zone

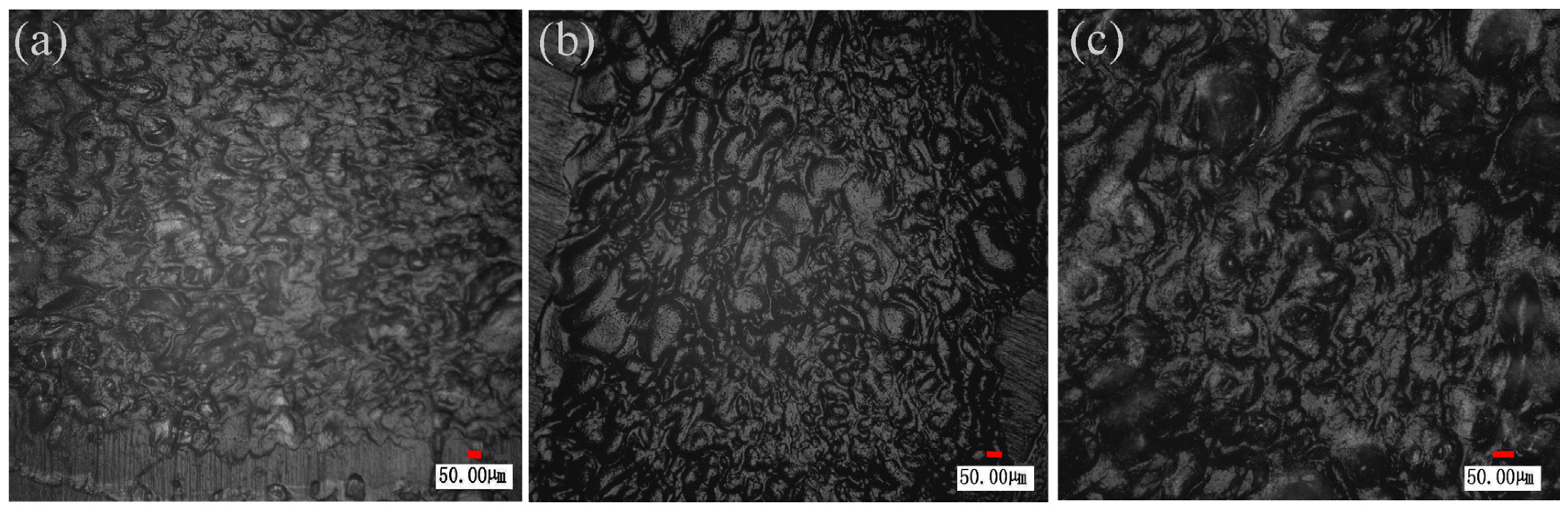

3.3.2. The Effect of the Bubbles in the Welding Zone on the Welding Quality

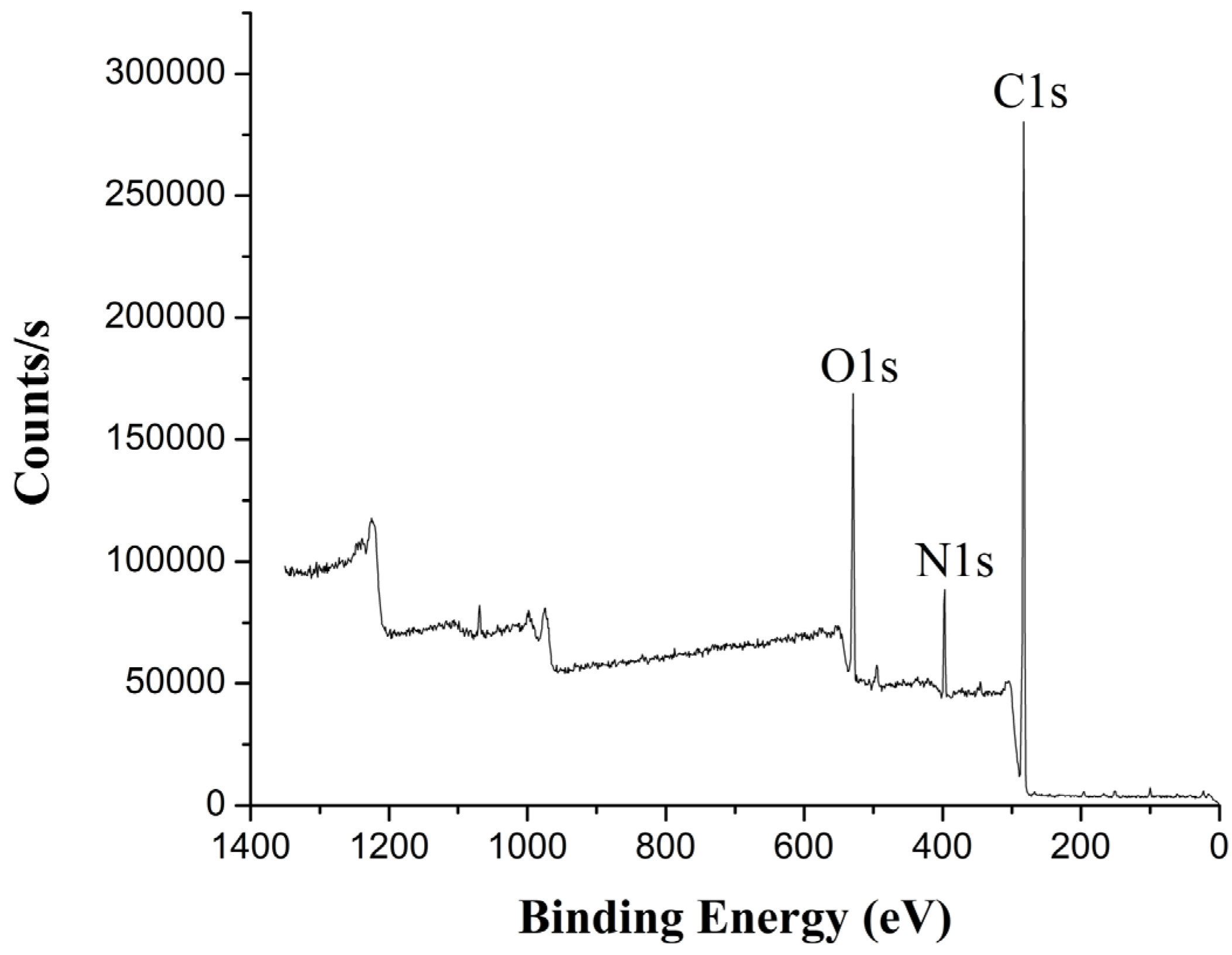

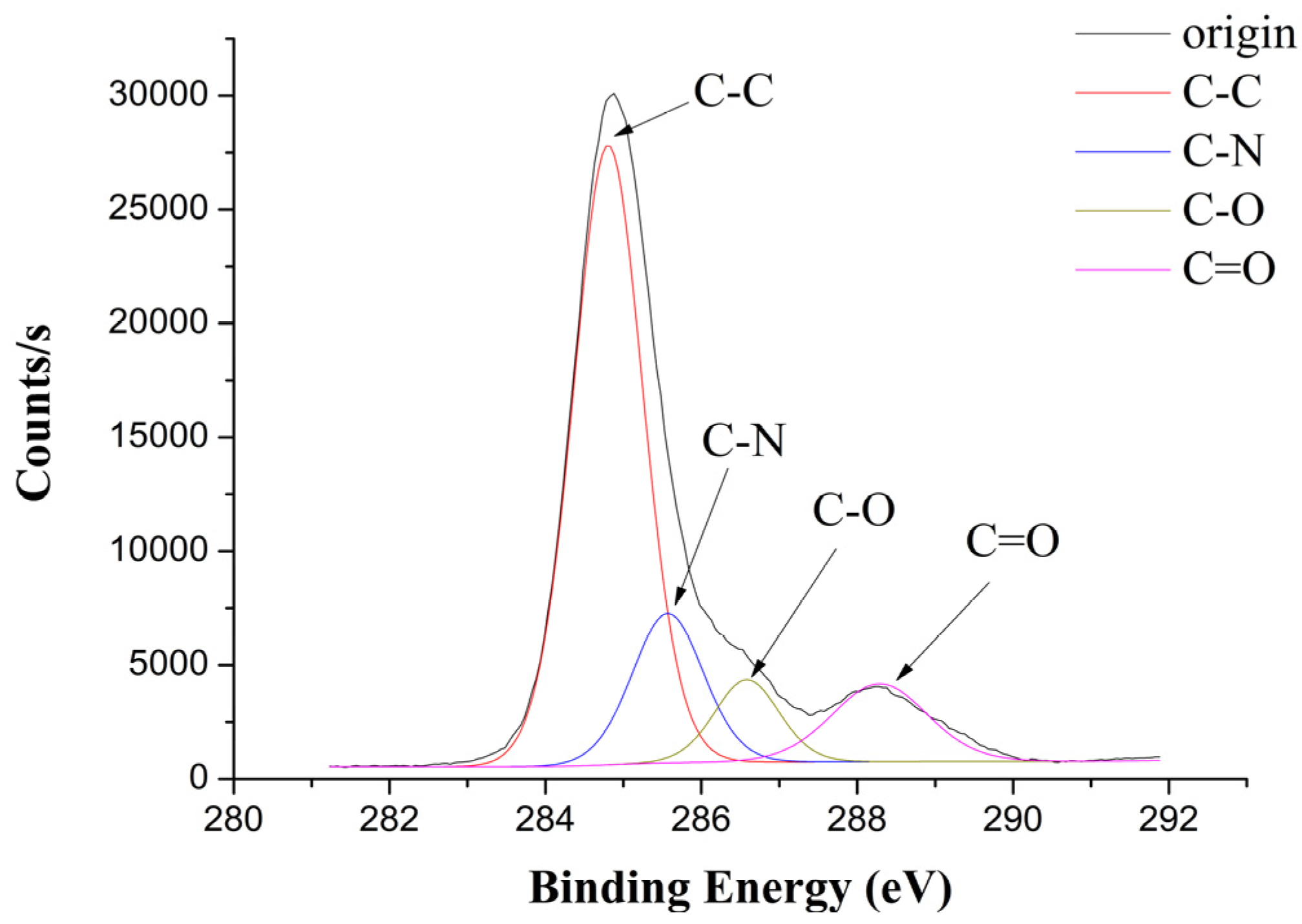

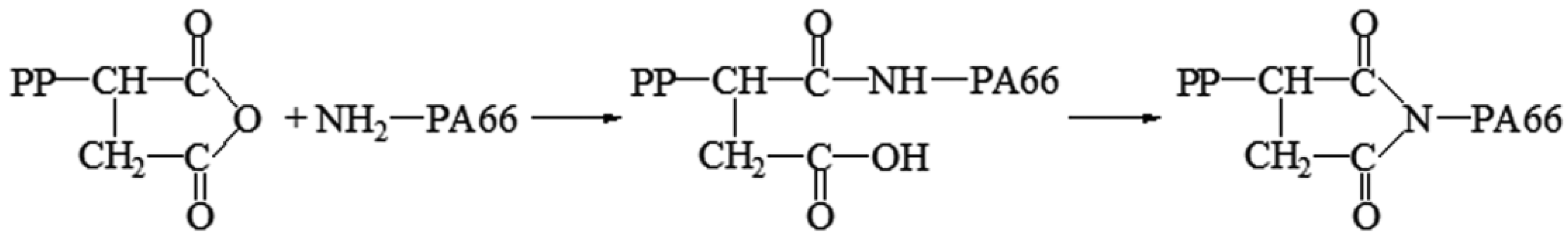

3.3.3. X-ray Photoelectron Spectroscopy Analysis of the Welding Zone

| Binding Energy (eV) | FWHM | Chemical Bonds |

|---|---|---|

| 284.8 | 1.11 | C–C |

| 285.68 | 0.96 | C–N |

| 286.39 | 1.03 | C–O |

| 287.88 | 1.26 | C=O |

| Binding Energy (eV) | FWHM | Chemical Bond |

|---|---|---|

| 399.73 | 1.38 | N–C |

4. Conclusions

- (1)

- Through grafting reactions, MAH with strong reactivity and polarity can be grafted to the side chain of PP to improve the welding performance of PP and PA66.

- (2)

- In general, the grafting modification has certain influence on the mechanical and thermal properties of PP. However, the original properties of PP change little.

- (3)

- The grafting modification has little influence on the optical properties of PP. The grafting modification causes the reflectivity and transmissivity of PP to decrease slightly and makes the absorptivity of PP increase slightly.

- (4)

- TGMPP and PA66 can be welded well. The micro morphology of the welding zone displays that because of the grafting modification, the affinity and the compatibility between PP and PA66 are improved and a large number of locking structures as similar to the rivet lock are formed, which is one of the reasons why the welding performance is so high.

- (5)

- Proved by the X-ray photoelectron spectroscopy (XPS), PA66 may react with the MAH of the side chain of TGMPP under the heating effect of laser, which is another reason for the high welding performance.

- (6)

- The evenly distributed bubbles caused by the thermal degradation are good for the high welding strength. However, when the laser power is too high, the serious thermal degradation causes many large bubbles to be formed in the welding zone, which account for a wide area in the welding zone and cause the poor welding strength.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Amanat, N.; James, N.L.; McKenzie, D.R. Welding methods for joining thermoplastic polymers for the hermetic enclosure of medical devices. Med. Eng. Phys. 2010, 32, 690–699. [Google Scholar] [CrossRef] [PubMed]

- Ageorges, C.; Ye, L.; Hou, M. Advances in fusion bonding techniques for joining thermoplastic matrix composites: A review. Compos. Part A Appl. Sci. Manuf. 2001, 32, 839–857. [Google Scholar] [CrossRef]

- Qiu, J.; Takahata, H.; Huang, Y.; Pan, Y. The relationship between interfacial structure and welding strength of hot plate welding crystalline polymer. Kobunshi Ronbunshu 2008, 65, 235–241. [Google Scholar] [CrossRef]

- Liu, H.; Wang, K.; Li, P.; Zhang, C.; Du, D.; Hu, Y.; Wang, X. Modeling and prediction of transmission laser bonding process between titanium coated glass and PET based on response surface methodology. Opt. Lasers Eng. 2012, 50, 440–448. [Google Scholar] [CrossRef]

- Wang, X.; Chen, H.; Liu, H.; Li, P.; Yan, Z.; Huang, C.; Zhao, Z.; Gu, Y. Simulation and optimization of continuous laser transmission welding between PET and titanium through FEM, RSM, GA and experiments. Opt. Lasers Eng. 2013, 51, 1245–1254. [Google Scholar] [CrossRef]

- Acherjee, B.; Kuar, A.; Mitra, S.; Misra, D. Modeling of laser transmission contour welding process using FEA and DoE. Opt. Laser Technol. 2012, 44, 1281–1289. [Google Scholar] [CrossRef]

- Hadriche, I.; Ghorbel, E.; Masmoudi, N.; Casalino, G. Investigation on the effects of laser power and scanning speed on polypropylene diode transmission welds. Int. J. Adv. Manuf. Technol. 2010, 50, 217–226. [Google Scholar] [CrossRef]

- Ghorbel, E.; Casalino, G.; Abed, S. Laser diode transmission welding of polypropylene: Geometrical and microstructure characterisation of weld. Mater. Des. 2009, 30, 2745–2751. [Google Scholar] [CrossRef]

- Wang, X.; Chen, H.; Liu, H. Investigation of the relationships of process parameters, molten pool geometry and shear strength in laser transmission welding of polyethylene terephthalate and polypropylene. Mater. Des. 2014, 55, 343–352. [Google Scholar] [CrossRef]

- Acherjee, B.; Kuar, A.; Mitra, S.; Misra, D.; Acharyya, S. Experimental investigation on laser transmission welding of PMMA to ABS via response surface modeling. Opt. Laser Technol. 2012, 44, 1372–1383. [Google Scholar] [CrossRef]

- O’Connor, C.P.J.; Martin, P.J.; Sweeney, J.; Menary, G.; Caton-Rose, P.; Spencer, P.E. Simulation of the plug-assisted thermoforming of polypropylene using a large strain thermally coupled constitutive model. J. Mater. Process. Technol. 2013, 213, 1588–1600. [Google Scholar] [CrossRef]

- Zhao, R.; Luo, W.; Xiao, H.; Wu, G. Water-absorptivity and mechanical behaviors of PTFE/PA6 and PTFE/PA66 blends. Trans. Nonferrous Metal Soc. China 2006, 16, S498–S503. [Google Scholar] [CrossRef]

- Ghorbel, E.; Hadriche, I.; Casalino, G.; Masmoudi, N. Characterization of thermo-mechanical and fracture behaviors of thermoplastic polymers. Materials 2014, 7, 375–398. [Google Scholar] [CrossRef]

- Sultana, T.; Newaz, G.; Georgiev, G.; Baird, R.; Auner, G.; Patwa, R.; Herfurth, H. A study of titanium thin films in transmission laser micro-joining of titanium-coated glass to polyimide. Thin Solid Films 2010, 518, 2632–2636. [Google Scholar] [CrossRef]

- Juhl, T.; Christiansen, J.; Jensen, E. Investigation on high strength laser welds of polypropylene and high-density polyethylene. J. Appl. Polym. Sci. 2013, 129, 2679–2685. [Google Scholar] [CrossRef]

- Braun, E.; Levin, B. Nylons: A review of the literature on products of combustion and toxicity. Fire Mater. 1987, 11, 71–88. [Google Scholar] [CrossRef]

- Liu, F.C.; Liao, J.; Nakata, K. Joining of metal to plastic using friction lap welding. Mater. Des. 2014, 54, 236–244. [Google Scholar] [CrossRef]

- Katayama, S.; Kawahito, Y. Laser direct joining of metal and plastic. Scr. Mater. 2008, 59, 1247–1250. [Google Scholar] [CrossRef]

- Gorga, R.; Narasimhan, B. Fracture behavior at partially miscible polymer interfaces. Polym. Eng. Sci. 2004, 44, 929–939. [Google Scholar] [CrossRef]

- Lo, C.; Narasimhan, B. A new kinetic model for interdiffusion at semicrystalline polymer interfaces. Polymer 2005, 46, 2266–2275. [Google Scholar] [CrossRef]

- Horiuchi, S.; Nakagawa, A.; Liao, Y.; Ougizawa, T. Interfacial entanglements between glassy polymers investigated by nanofractography with high-resolution scanning electron microscopy. Macromolecules 2008, 41, 8063–8071. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Jiang, H.; Guo, D.; Chen, G.; Yan, Z.; Li, P.; Zhu, H.; Chen, J.; Wang, X. Study on Welding Mechanism Based on Modification of Polypropylene for Improving the Laser Transmission Weldability to PA66. Materials 2015, 8, 4961-4977. https://doi.org/10.3390/ma8084961

Liu H, Jiang H, Guo D, Chen G, Yan Z, Li P, Zhu H, Chen J, Wang X. Study on Welding Mechanism Based on Modification of Polypropylene for Improving the Laser Transmission Weldability to PA66. Materials. 2015; 8(8):4961-4977. https://doi.org/10.3390/ma8084961

Chicago/Turabian StyleLiu, Huixia, Hairong Jiang, Dehui Guo, Guochun Chen, Zhang Yan, Pin Li, Hejun Zhu, Jun Chen, and Xiao Wang. 2015. "Study on Welding Mechanism Based on Modification of Polypropylene for Improving the Laser Transmission Weldability to PA66" Materials 8, no. 8: 4961-4977. https://doi.org/10.3390/ma8084961