Mechanism of Filling and Feeding of Thin-Walled Structures during Gravity Casting

Abstract

:1. Introduction

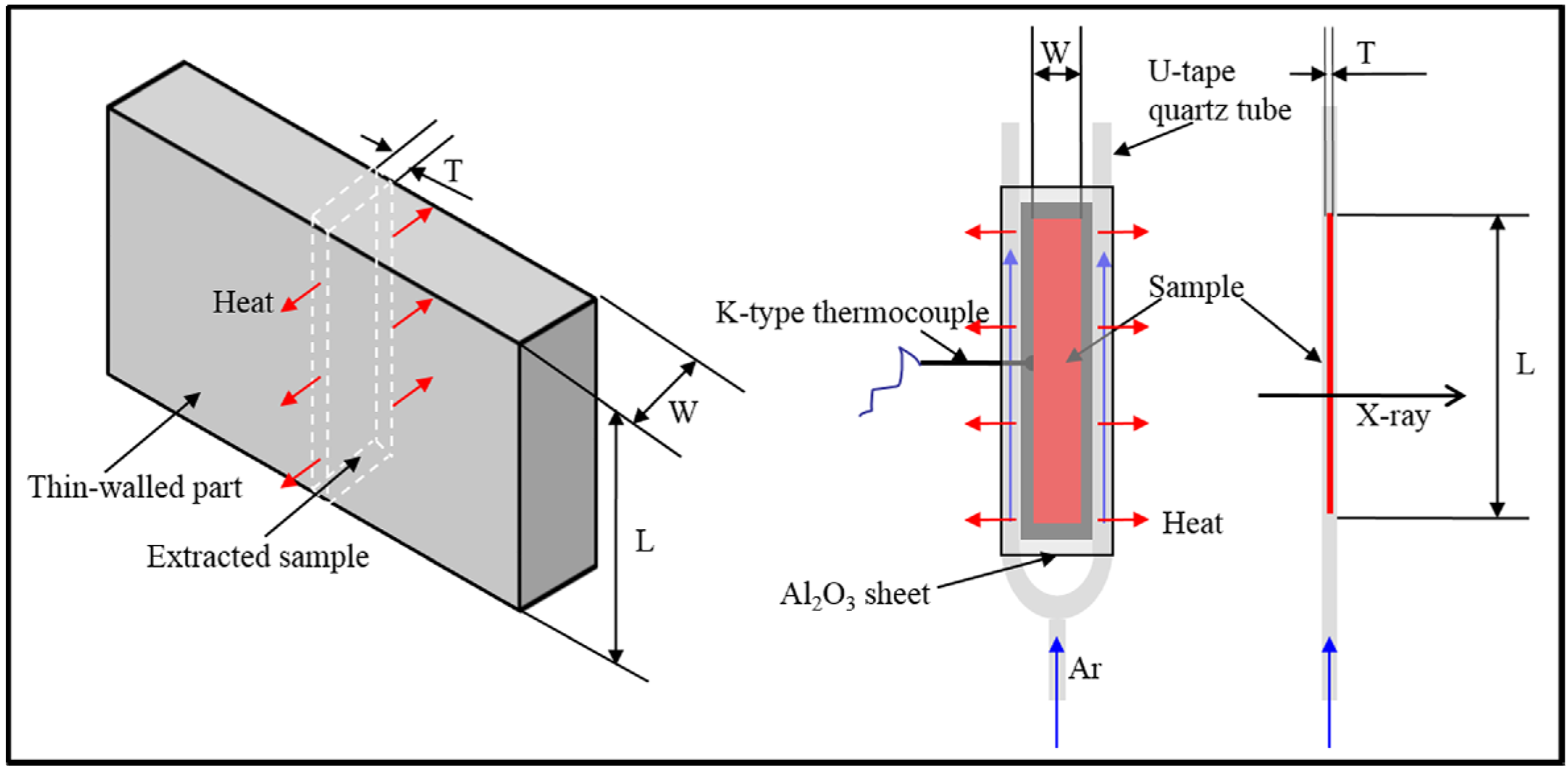

2. Experimental Section

3. Results and Discussion

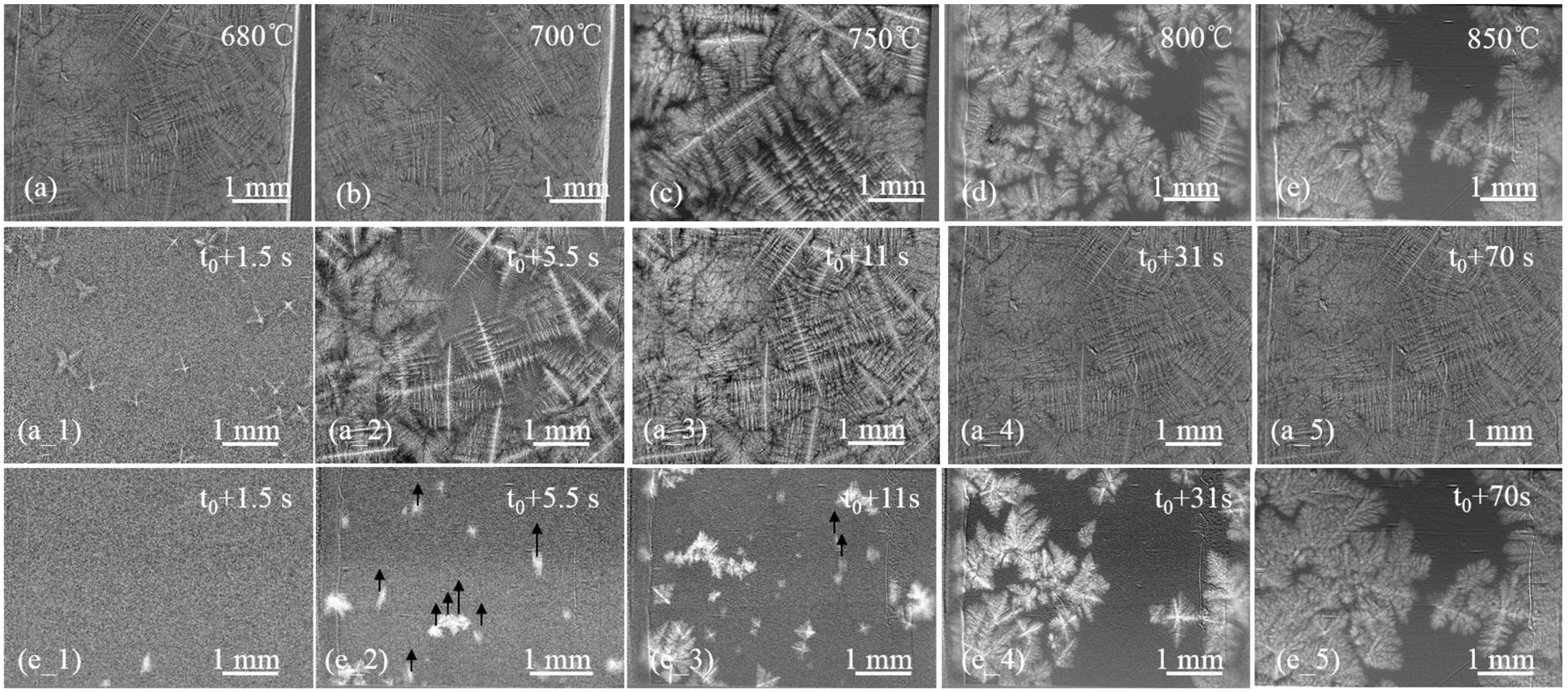

3.1. Solidification Microstructure

3.1.1. Dendrite Structure

3.1.2. Grain Size

| TB, °C | 2 mm | 5 mm | ||

|---|---|---|---|---|

| Rc, K s−1 | Dgr, mm | Rc, K s−1 | Dgr, mm | |

| 680 | 2.48 | 1.04 ± 0.30 | 1.68 | 1.18 ± 0.28 |

| 700 | 2.08 | 1.29 ± 0.16 | 1.04 | 1.33 ± 0.30 |

| 750 | 1.49 | 1.41 ± 0.29 | 0.69 | 1.45 ± 0.40 |

| 800 | 1.16 | 1.58 ± 0.20 | 0.50 | 0.80 ± 0.10 |

| 850 | 0.87 | 1.64 ± 0.20 | 0.33 | 0.75 ± 0.10 |

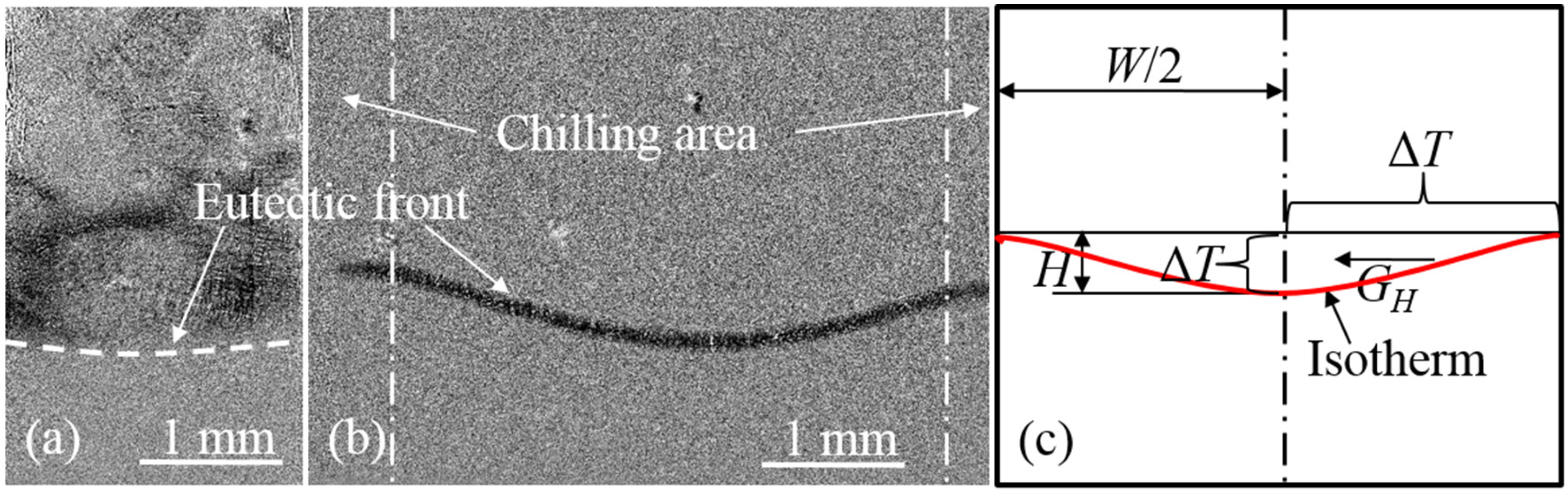

3.2. Thermal and Solute Fields

| TB, °C | 2 mm | 5 mm | ||||

|---|---|---|---|---|---|---|

| Rc, K s−1 | ΔT, K | GH, K mm−1 | Rc, K s−1 | ΔT, K | GH, K mm−1 | |

| 680 | 2.48 | 0.0405 | 0.0405 | 1.68 | 1.9691 | 0.7876 |

| 700 | 2.08 | 0.0416 | 0.0416 | 1.04 | 2.1956 | 0.8782 |

| 750 | 1.49 | 0.0433 | 0.0433 | 0.69 | 3.1516 | 1.2606 |

| 800 | 1.16 | 0.0458 | 0.0458 | 0.50 | 3.8519 | 1.5408 |

| 850 | 0.87 | 0.0472 | 0.0472 | 0.33 | 5.1458 | 2.0583 |

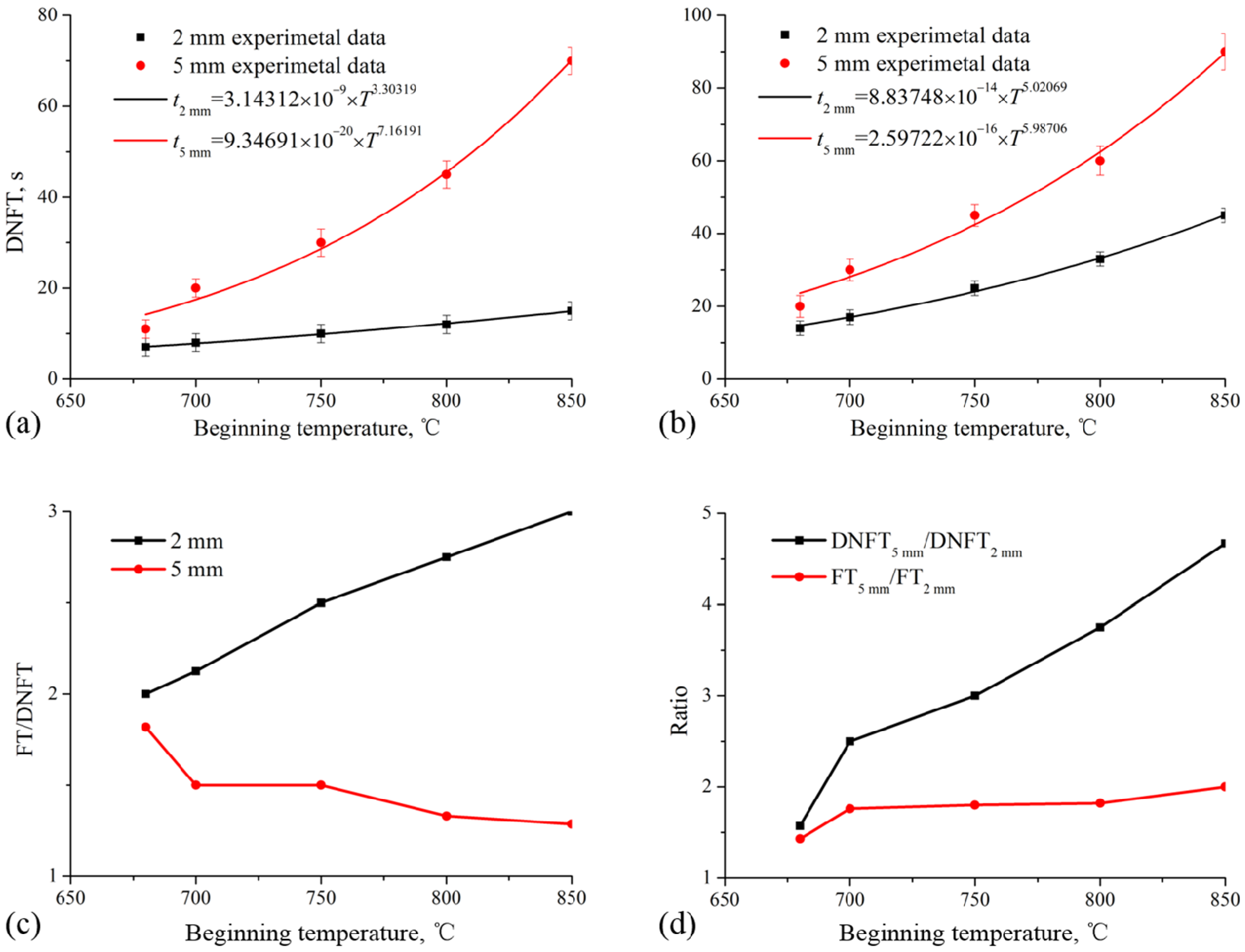

3.3. Influence of Wall Thickness on Filling and Feeding Abilities

3.3.1. Filling Pressure and Feeding Pressure

3.3.2. Filling Time and Feeding Time

4. Conclusions

- The sensitivity of microstructural evolution to wall thickness declines as the thickness decreases. Thinner walls induce greater densification of the dendritic network, which shortens both the filling and feeding times.

- Wall thickness is the vital factor determining the filling time for thin-walled parts. Infinitely increasing the pouring temperature of the molten alloy and the mold can only improve the filling of thin-walled parts to a limited extent. The results showed that the benefits to filling and feeding from increasing the pouring and mold temperatures diminish sharply as the thickness decreases. Suitable filling times under different conditions can be predicted to ensure complete filling of the mold.

- The wall thickness also determines the feeding of thin-walled parts. A proper increase in the pouring temperature and mold temperature while maintaining a certain filling pressure can efficiently improve the feeding ability of thin-walled parts.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ghomashchi, M.R.; Vikhrov, A. Squeeze casting: An overview. J. Mater. Process. Technol. 2000, 101, 1–9. [Google Scholar] [CrossRef]

- Kim, S.-W.; Durrant, G.; Lee, J.-H.; Cantor, B. The effect of die geometry on the microstructure of indirect squeeze cast and gravity die cast 7050 (Al-6.2Zn-2.3Cu-2.3Mg) wrought Al alloy. J. Mater. Sci. 1999, 34, 1873–1883. [Google Scholar] [CrossRef]

- Pedersen, K.M.; Hattel, J.H.; Tiedje, N. Numerical modelling of thin-walled hypereutectic ductile cast iron parts. Acta Mater. 2006, 54, 5103–5114. [Google Scholar] [CrossRef]

- Eskin, D.; Du, Q.; Ruvalcaba, D.; Katgerman, L. Experimental study of structure formation in binary Al-Cu alloys at different cooling rates. Mater. Sci. Eng. A 2005, 405, 1–10. [Google Scholar] [CrossRef]

- Ferguson, J.B.; Meysam, T.-K.; John, C.M.; Pradeep, K.R.; Cho, K.; Kim, C.-S. Predicting the effect of pouring temperature on the crystallite density, remelting, and crystal growth kinetics in the solidification of aluminum alloys. Metall. Mater. Trans. B 2014, 45, 1407–1417. [Google Scholar] [CrossRef]

- Pedersen, K.M.; Tiedje, N.S. Graphite nodule count and size distribution in thin-walled ductile cast iron. Mater. Charact. 2008, 59, 1111–1121. [Google Scholar] [CrossRef]

- Li, X.L.; Hao, Q.T.; Jie, W.Q.; Zhou, Y.C. Development of pressure control system in counter gravity casting for large thin-walled A357 aluminum alloy components. Trans. Nonferrous Metals Soc. China 2008, 18, 847–851. [Google Scholar] [CrossRef]

- Borisov, A.G.; Tarasevich, N.I.; Korniets, I.V.; Semenchenko, A.I. Predicting type of morphology of primary phase in aluminum alloy castings produced in a thin-walled metal mold. Phys. Metals Metallogr. 2013, 114, 242–245. [Google Scholar] [CrossRef]

- Mathiesen, R.H.; Arnberg, L.; Mo, F.; Weitkamp, T.; Snigirev, A. Time resolved x-ray imaging of dendritic growth in binary alloys. Phys. Rev. Lett. 1999, 83, 5062–5065. [Google Scholar] [CrossRef]

- Li, F.G.; Dong, Q.; Zhang, J.; Dai, Y.B.; Fu, Y.N.; Xie, H.L.; Yin, F.C.; Sun, B.D. In situ study on the columnar-equiaxed transition and anaxial columnar dendrite growth of Al-15 wt% Cu alloy by synchrotron radiography. Trans. Nonferrous Met. Soc. Ch. 2014, 24, 2112–2116. [Google Scholar] [CrossRef]

- Dong, Q.; Zhang, J.; Dong, J.F.; Dai, Y.B.; Bian, F.G.; Xie, H.L.; Lu, Y.L.; Sun, B.D. Anaxial columnar dendrites in directional solidification of an Al-15wt% Cu alloy. Mater. Lett. 2011, 165, 3295–3297. [Google Scholar] [CrossRef]

- Ruvalcaba, D.; Mathiesen, R.H.; Eskin, D.G.; Arnberg, L.; Katgerman, L. In situ observations of dendritic fragmentation due to local solute-enrichment during directional solidification of an aluminum alloy. Acta Mater. 2007, 55, 4287–4292. [Google Scholar] [CrossRef]

- Bogno, A.; Nguyen-Thi, H.; Buffet, A.; Reinhart, G.; Billia, B.; Mangelinck-Noël, N.; Bergeon, N.; Baruchel, J.; Schenk, T. Analysis by synchrotron X-ray radiography of convection effects on the dynamic evolution of the solid-liquid interface and on solute distribution during the initial transient of solidification. Acta Mater. 2011, 59, 4356–4365. [Google Scholar] [CrossRef]

- Mathiesen, R.H.; Arnberg, L. Stray crystal formation in Al–20wt% Cu studied by synchrotron X-ray video microscopy. Mater. Sci. Eng. A 2005, 413–414, 283–287. [Google Scholar] [CrossRef]

- Dong, Q.; Zhang, J.; Dong, J.F.; Xie, H.L.; Li, Z.J.; Dai, Y.B.; Liu, Y.; Sun, B.D. In situ observation of columnar-to-equiaxed transition in directional solidification using synchrotron X-radiation imaging technique. Mater. Sci. Eng. A 2011, 530, 271–276. [Google Scholar] [CrossRef]

- Kargl, F.; Engelhardt, M.; Yang, F.; Weis, H.; Schmakat, P.; Schillinger, B.; Griesche, A.; Meyer, A. In situ studies of mass transport in liquid alloys by means of neutron radiography. J. Phys. Condens Matter. 2011, 23. [Google Scholar] [CrossRef] [PubMed]

- Easton, M.A.; StJohn, D.H. Improved prediction of the grain size of aluminum alloys that includes the effect of cooling rate. Mater. Sci. Eng. A 2008, 486, 8–13. [Google Scholar] [CrossRef]

- Andreas, M. On the influence of coarsening on microsegregation. Metall. Trans. A 1989, 20, 247–253. [Google Scholar]

- Kirchheim, R. Grain coarsening inhibited by solute segregation. Acta Mater. 2002, 50, 413–419. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Zhang, J.; Bian, F.; Fu, Y.; Xue, Y.; Yin, F.; Xie, Y.; Xu, Y.; Sun, B. Mechanism of Filling and Feeding of Thin-Walled Structures during Gravity Casting. Materials 2015, 8, 3701-3713. https://doi.org/10.3390/ma8063701

Li F, Zhang J, Bian F, Fu Y, Xue Y, Yin F, Xie Y, Xu Y, Sun B. Mechanism of Filling and Feeding of Thin-Walled Structures during Gravity Casting. Materials. 2015; 8(6):3701-3713. https://doi.org/10.3390/ma8063701

Chicago/Turabian StyleLi, Faguo, Jiao Zhang, Fenggang Bian, Yanan Fu, Yanling Xue, Fucheng Yin, Yu Xie, Yi Xu, and Baode Sun. 2015. "Mechanism of Filling and Feeding of Thin-Walled Structures during Gravity Casting" Materials 8, no. 6: 3701-3713. https://doi.org/10.3390/ma8063701