How Properties of Kenaf Fibers from Burkina Faso Contribute to the Reinforcement of Earth Blocks

Abstract

:1. Introduction

2. Materials and Testing Procedures

2.1. Raw Materials

2.2. Procedures

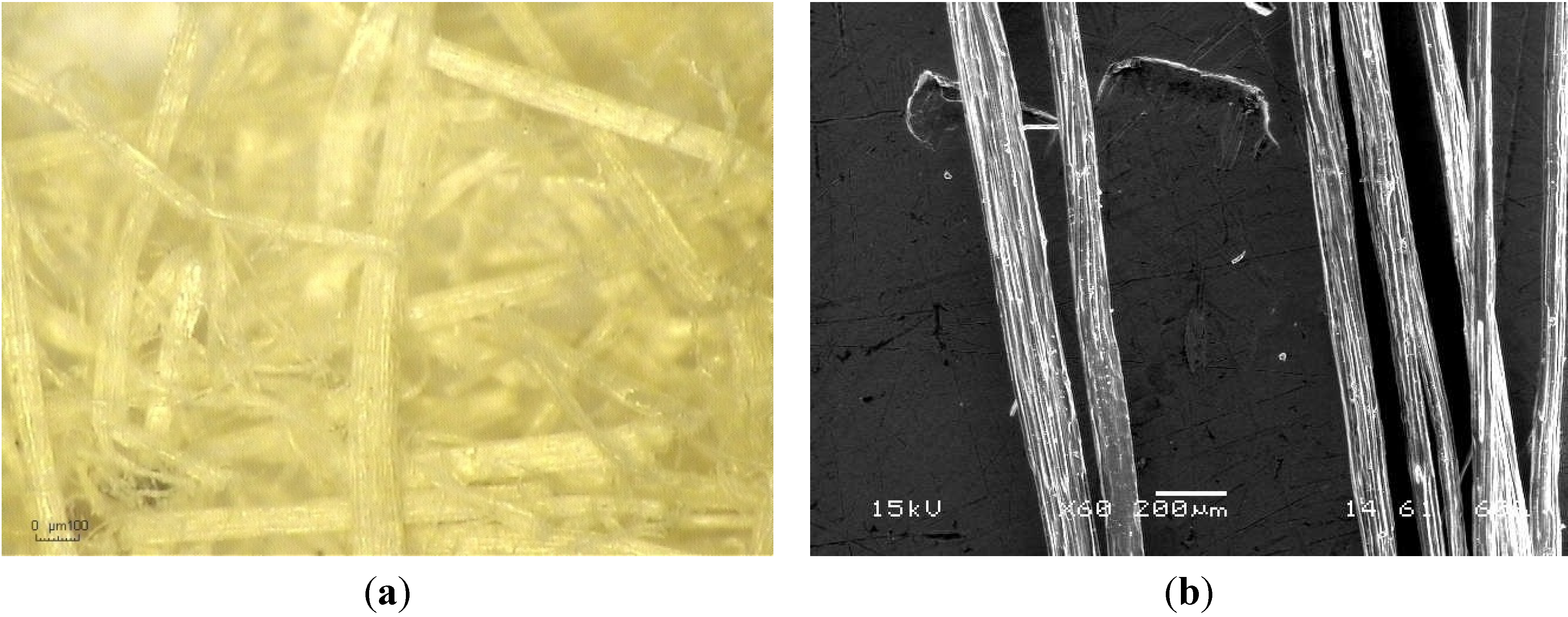

2.2.1. Physicochemical, Mineralogical and Mechanical Characteristics of Fibers

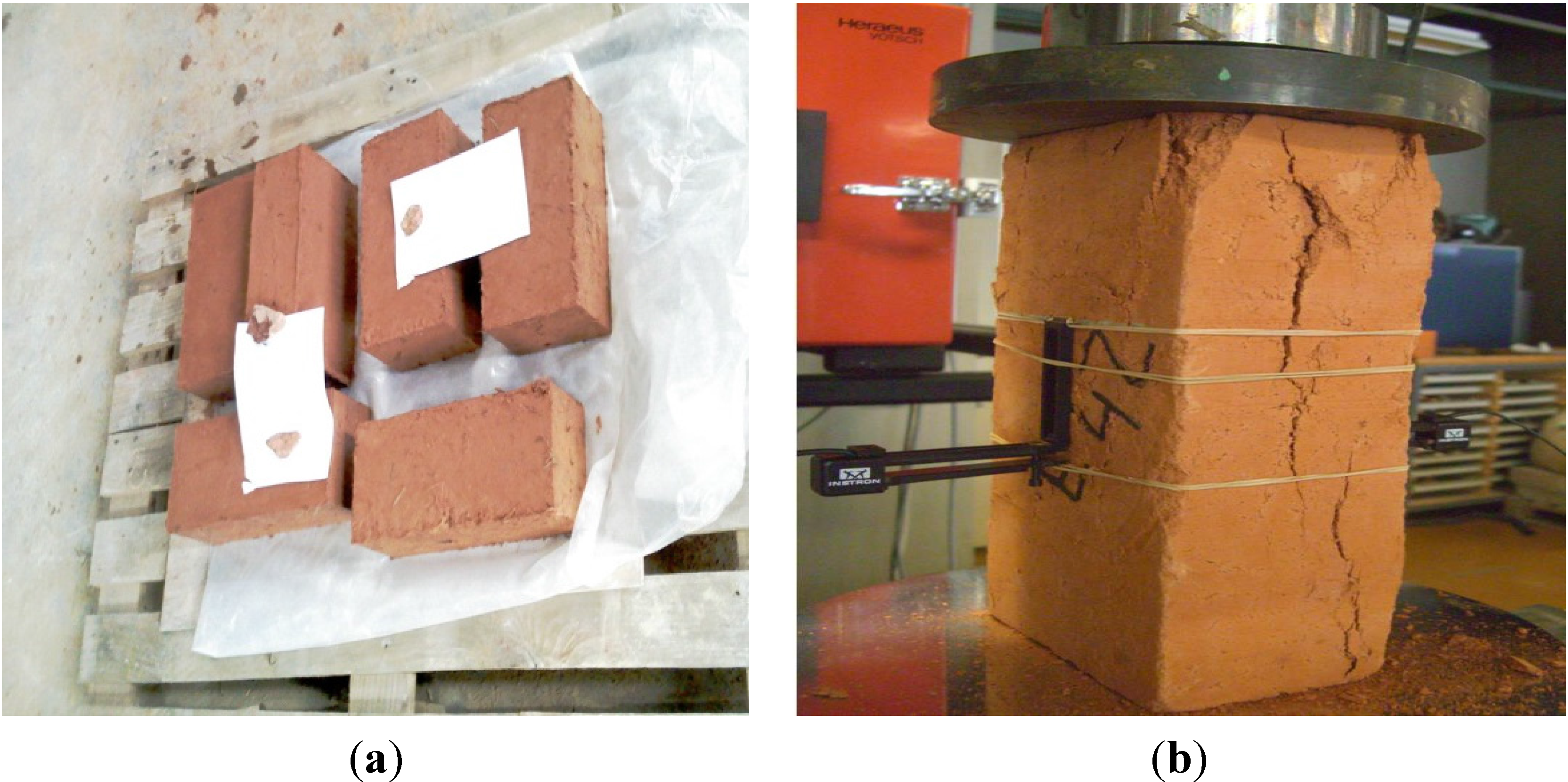

2.2.2. Preparation and Mechanical Characterization of Earth Blocks

3. Results and Discussion

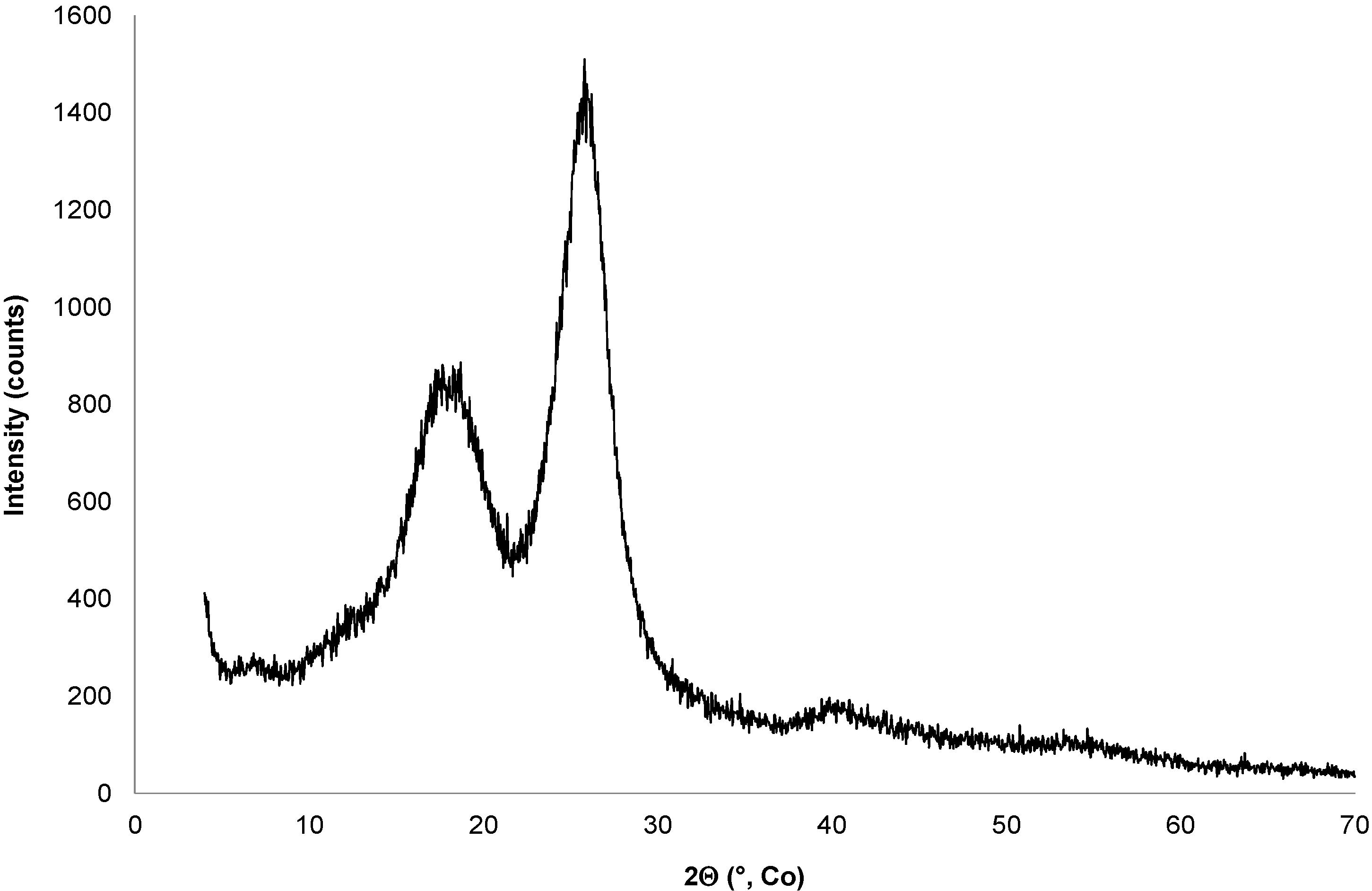

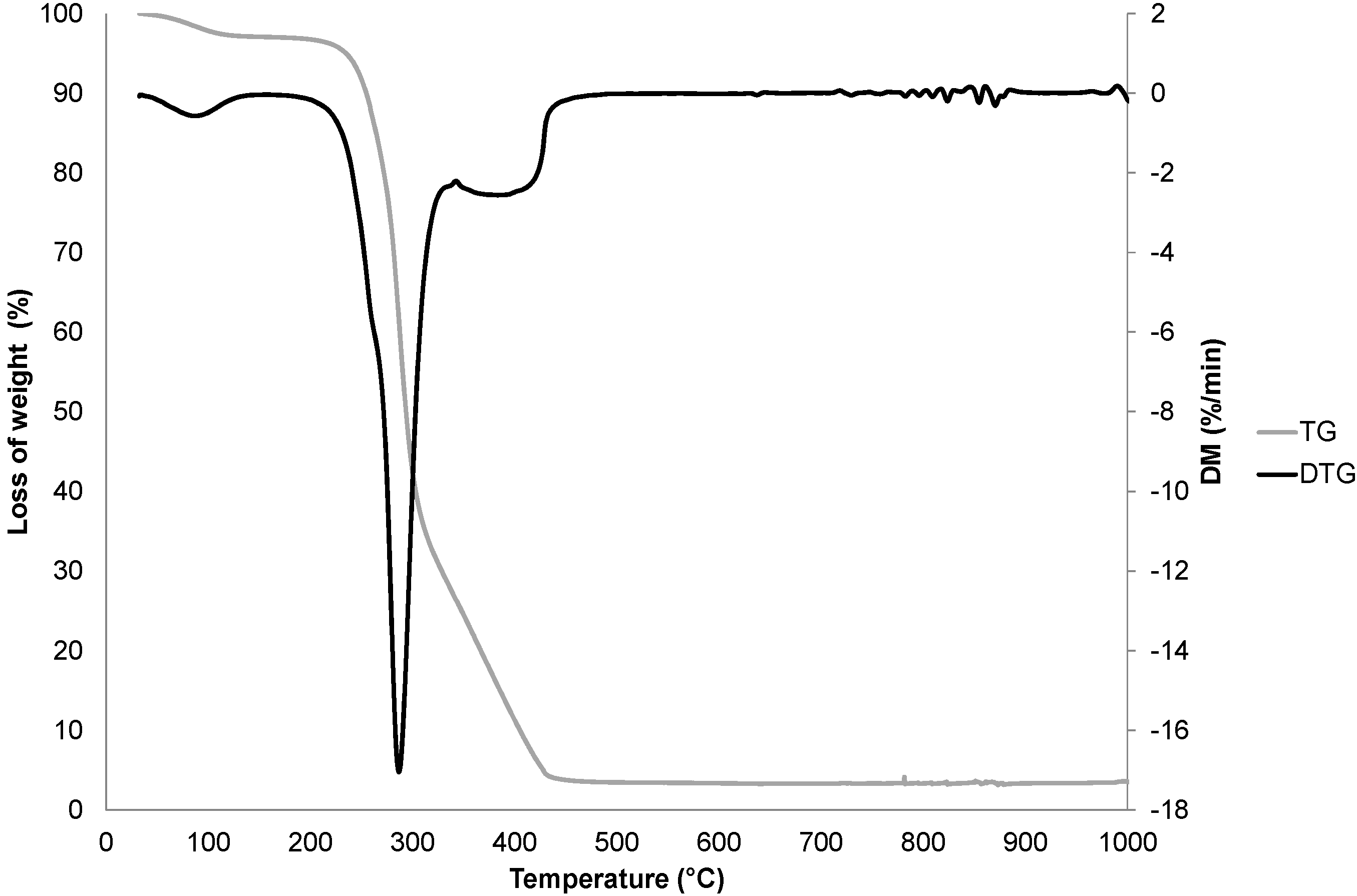

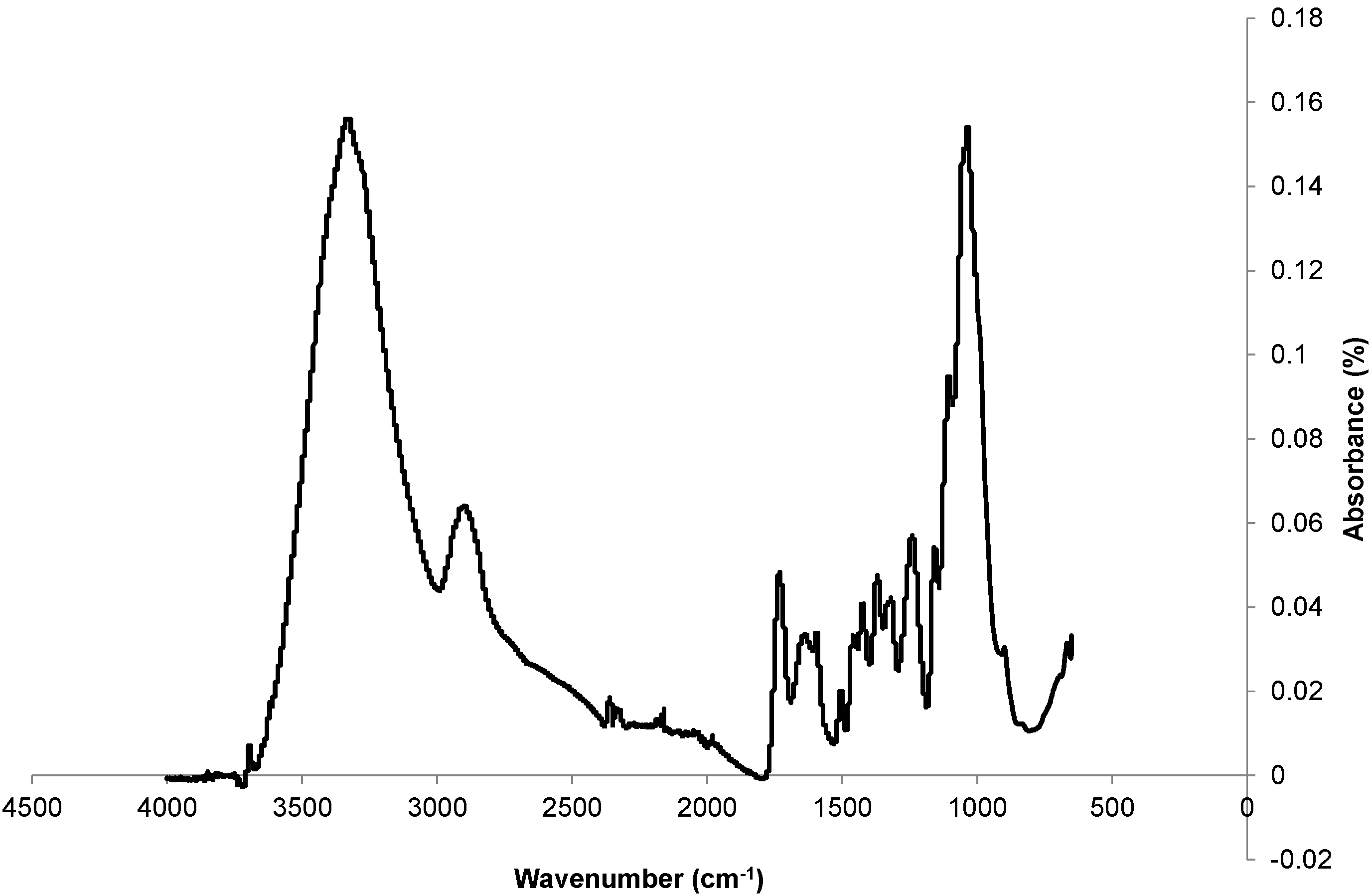

3.1. Physicochemical, Mineralogical and Mechanical Characteristics of Fibers

| Reference | Cellulose (wt%) | Hemicelluloses (wt%) | Lignin (wt%) | Ash (wt%) |

|---|---|---|---|---|

| Present Study | 70 | 19 | 3 | 1.3 |

| [29] | 53 ± 4 | 18 ± 1.4 | 8 ± 1.2 | - |

| [13] | 45–57 | 21.5 | 8–13 | - |

| [12] | 58 ± 1 | 22 ± 1 | 17.5 ± 1.3 | 2.4 ± 0.4 |

| [11] | 60.8 | 19.2 | 14.7 | - |

| [30] | 31–39 | 21.5 | 15–19 | - |

| Reference | Cellulose (wt%) | Hemicelluloses (wt%) | Lignin (wt%) |

|---|---|---|---|

| Fibers studied here | 70 | 19 | 3 |

| Flax | 71 | 19–20.6 | 2.2 |

| Hemp | 70–74 | 18–22.4 | 3.7–5.7 |

| Jute | 61–71 | 14–20 | 12–13 |

| Ramie | 68–76 | 13–17 | 0.6–0.7 |

| Sisal | 63–64 | 12.0 | 10–14 |

| Banana | 63–64 | 10 | 5 |

| Cotton | 85–90 | 5.7 | - |

| Coir | 32–43 | 0.15–0.25 | 40–45 |

| Cereal straw | 38–45 | 15–31 | 12–20 |

| OPEFB * fibers | 59 | 2.1 | 25 |

| Groundnut shell | 36 | 19 | 30 |

| Bagasse | 40–46 | 24.5–29 | 12.5–20 |

| Rice husk | 31 | 24 | 14 |

| Coconut coir | 47.7 | 25.9 | 17.8 |

| Properties | Results |

|---|---|

| Diameter (mm) | 0.13 |

| Natural humidity: H (%) | 6.1 |

| Water absorption: W (%) | 307 |

| Specific weight: γ (g/cm3) | 1.04 |

| Elasticity modulus (MPa) | 136 ± 25 |

| Tensile strength: σ (GPa) | 1 ± 0.25 |

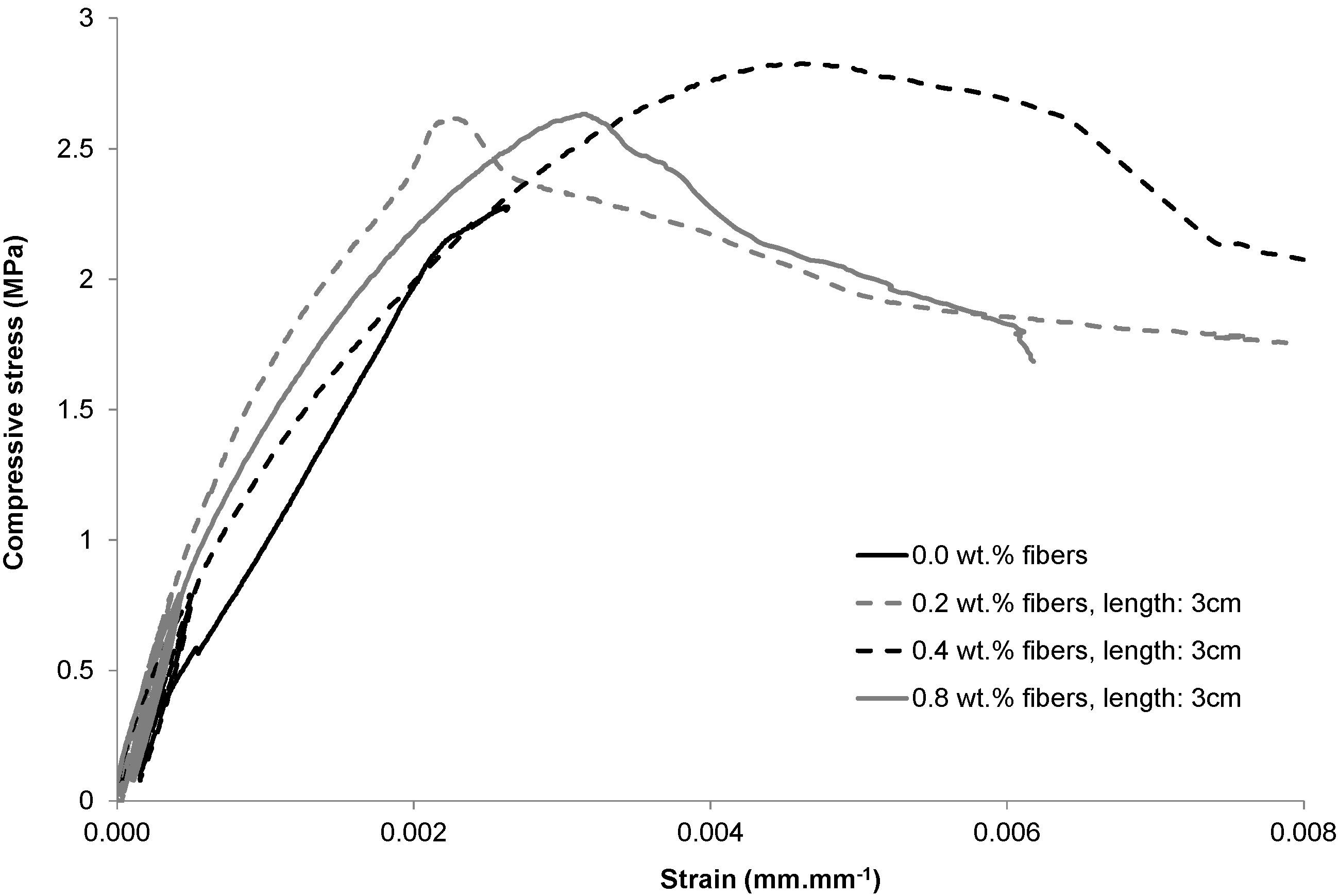

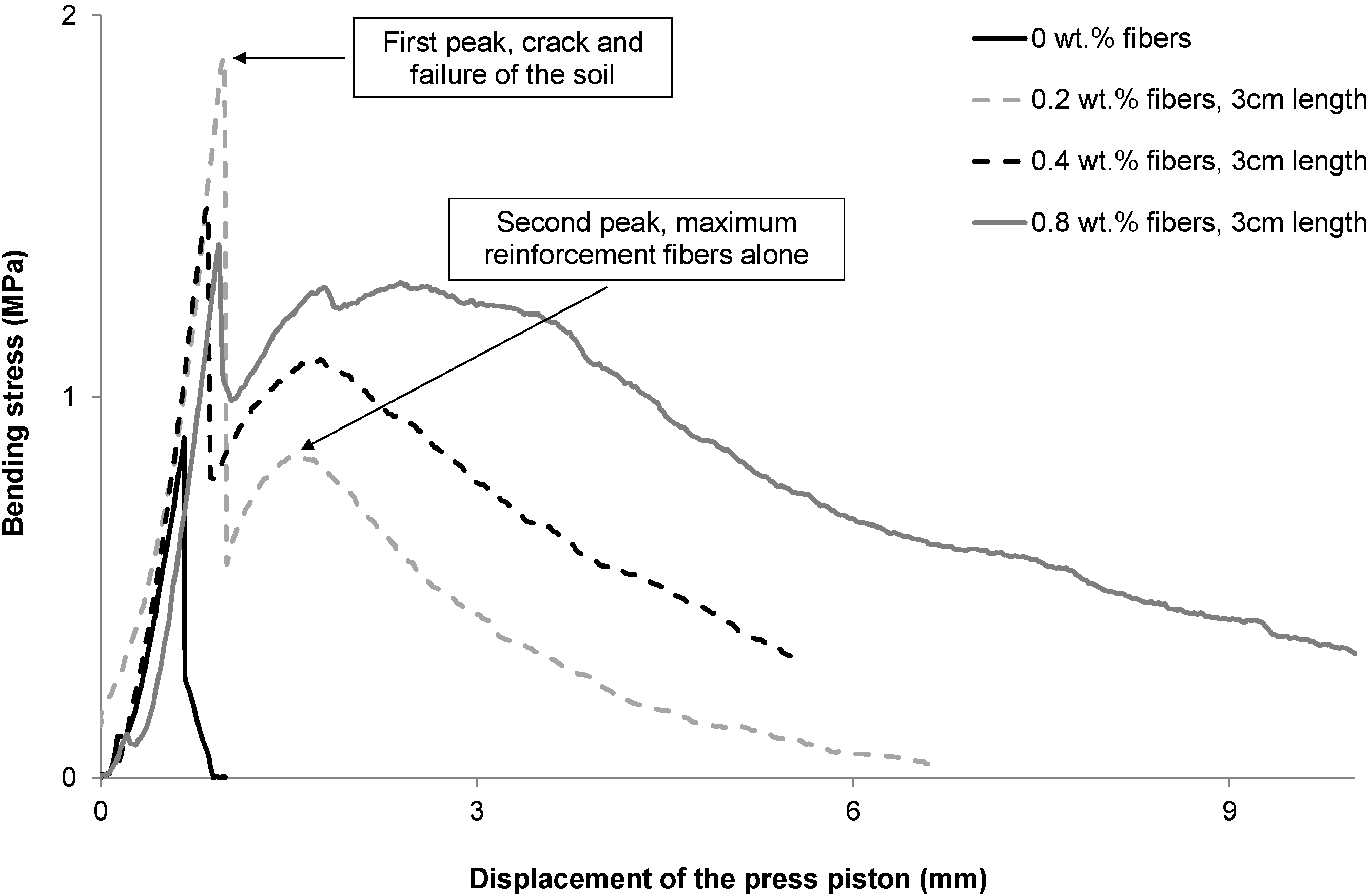

3.2. Mechanical Properties of Earth Blocks

| Case Le < Lme: | (a) fibers with decreasing tensile stress. The fiber is pulled out and its embedded length is decreasing. |

| (b) Fibers with an increasing tensile stress; the embedded length of these fibers is greater than the fibers in case (a). | |

| Case Le < Lme: | (c) Broken fibers; the reinforcement is zero. |

| (d) Fibers with an increasing tensile stress, the embedded length of these fibers is smaller than the fibers in case (c). |

4. Conclusions

- 1)

- Kenaf fibers have a tensile strength higher than 750 MPa with a high elasticity modulus (136 ± 25 GPa) compared to other natural fibers.

- 2)

- Kenaf fibers contain large amounts (70 wt%) of cellulose type I (Ic = 40), with hemicelluloses (19 wt%) and lignin (3 wt%).

- 3)

- The incorporation of kenaf fibers in PABs improves mainly the ductility in tension of the blocks thanks to the high mechanical strength of fibers and their strong adherence to the clay matrix.

- 4)

- The incorporation of fibers is particularly beneficial as far as the bending strength of earth blocks is concerned.

- 5)

- In order to obtain optimum mechanical behaviour, an amount smaller than 0.8 wt% of short fibers (30 mm) is recommended.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Binici, H.; Aksogan, O.; Shah, T. Investigation of fibre reinforced mud bricks as a building material. Constr. Build. Mater. 2005, 19, 313–318. [Google Scholar] [CrossRef]

- Ghavami, K.; Toledo Filho, R.D.; Barbosa, N.P. Behaviour of composite soil reinforced with natural fibres. Cem. Concr. Compos. 1999, 21, 39–48. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; Ghavami, K.; England, G.L.; Scrivener, K. Development of vegetable fibre-mortar composites of improved durability. Cem. Concr. Compos. 2003, 25, 185–196. [Google Scholar]

- Mesbah, A.; Morel, J.C.; Walker, P.; Ghavami, K. Development of a direct tensile test for compacted soil blocks reinforced with natural fibers. J. Mater. Civil Eng. 2004, 16, 95–98. [Google Scholar] [CrossRef]

- Bouhicha, M.; Aouissi, F.; Kenai, S. Performance of composite soil reinforced with barley straw. Cem. Concr. Compos. 2005, 27, 617–621. [Google Scholar] [CrossRef]

- Kumar, A.; Walia, S.B.; Mohan, J. Compressive strength of fiber reinforced highly compressible clay. Constr. Build. Mater. 2006, 20, 1063–1068. [Google Scholar] [CrossRef]

- Yetgin, S.; Cavdar, O.; Cavdar, A. The effects of the fiber contents on the mechanic properties of the adobes. Constr. Build. Mater. 2008, 22, 222–227. [Google Scholar] [CrossRef]

- Juárez, C.; Guevara, B.; Durán-Herrera, A. Mechanical properties of natural fibers reinforced sustainable masonry. Constr. Build. Mater. 2010, 24, 1536–1541. [Google Scholar] [CrossRef]

- Ismail, S.; Yaacob, Z. Properties of laterite bricks reinforced with oil palm empty fruit bunch fibres. Pertanika J. Sci. Technol. 2011, 19, 33–43. [Google Scholar]

- Quagliarini, E.; Lenci, S. The influence of natural stabilizers and natural fibres on the mechanical properties of ancient Roman adobe bricks. J. Cult. Herit. 2010, 11, 309–314. [Google Scholar] [CrossRef]

- Shin, H.K.; Jeun, J.P.; Kim, H.B.; Kang, P.H. Isolation of cellulose fibers from kenaf using electron beam. Radiat. Phys. Chem. 2012, 81, 936–940. [Google Scholar] [CrossRef]

- Jonoobi, M.; Harun, J.; Tahir, P.M.; Shakeri, A.; SaifulAzry, S.; Makinejad, M.D. Physicochemical characterization of pulp and nanofibers from kenaf stem. Mater. Lett. 2011, 65, 1098–1100. [Google Scholar] [CrossRef]

- Akil, H.M.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.; Ishak, Z.A.M.; Abu Bakar, A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Kouakou, H.; Morel, J.C. Strength and elasto-plastic properties of non-industrial building materials manufactured with clay as a natural binder. Appl. Clay Sci. 2009, 44, 27–34. [Google Scholar] [CrossRef]

- Millogo, Y.; Morel, J.C.; Aubert, J.E.; Ghavami, K. Experimental analysis of pressed adobe blocks reinforced with Hibiscus cannabinus fibers. Constr. Build. Mater. 2014, 52, 71–78. [Google Scholar] [CrossRef]

- Toledo Filho, R.D. Natural Fibre Reinforced Mortar Composites: Experimental, Characterisation. Ph.D. Thesis, DEC-PUC/Imperial College, London, UK, 1997; p. 472. [Google Scholar]

- Van Soest, P.D.; Wine, R.H. The use of detergents in the analysis of fibrous feed II. A rapid method for determination of fiber and lignin. J. Assoc. Off. Agric. Chem. 1967, 50, 50–55. [Google Scholar]

- Fulgencio, S.C.; Jaime, C.; Juan, G.R. Determination of hemicelluloses, cellulose, and lignin contents of dietary fibre and crude fiber of several seed hulls. Data Comp. 1983, 177, 200–202. [Google Scholar]

- Ciblac, T.; Morel, J.C. Sustainable Masonry: Stability and Behavior of Structures; Wiley: Hoboken, NJ, USA, 2014; p. 280. [Google Scholar]

- Aubert, J.E.; Maillard, P.; Morel, J.C.; Al Rafii, M. Towards a simple compressive strength test for earth bricks? Mater. Struct. 2015. [Google Scholar] [CrossRef]

- Aubert, J.E.; Fabbri, A.; Morel, J.C.; Maillard, P. A soil block with a compressive strength higher than 45 MPa! Constr. Build. Mater. 2013, 47, 366–369. [Google Scholar] [CrossRef]

- Olivier, M.; Mesbah, A. Modèle de comportement pour sols compactés. In Proceedings of the First International Conference on unsaturated soils, Paris, France, 6–8 September 1995.

- Bui, Q.B.; Morel, J.C.; Hans, S.; Walker, P. Effect of moisture content on the mechanical characteristics of rammed earth. Constr. Build. Mater. 2014, 54, 163–169. [Google Scholar] [CrossRef]

- Morel, J.C.; Pkla, A. A model to measure compressive strength of Compressed Earth Blocks with the “3 points bending test”. Constr. Build. Mater. 2002, 16, 303–310. [Google Scholar] [CrossRef]

- Morel, J.C.; Pkla, A.; di Benedetto, H. Interprétation en compression ou traction de l’essai de flexion en trois points. Rev. Fr. Génie Civil 2003, 7, 221–237. [Google Scholar]

- El-Shekeil, Y.A.; Sapuan, S.M.; Abdan, K.; Zainudin, E.S. Influence of fiber content on the mechanical and thermal properties of Kenaf fiber reinforced thermoplastic polyurethane composites. Mater. Des. 2012, 40, 299–303. [Google Scholar] [CrossRef]

- Morān, J.I.; Alvarez, V.A.; Cyras, V.P.; Vāsquez, A. Extraction of cellulose and preparation of nanocellulose. Cellulose 2008, 15, 149–159. [Google Scholar] [CrossRef]

- Ivanova, N.V.; Korolenko, E.A.; Korolik, E.V.; Zhbankov, R.G. IR spectrum of cellulose. J. Appl. Spectrosc. 1989, 51, 847–851. [Google Scholar] [CrossRef]

- Godin, B.; Ghysel, F.; Agneessens, R.; Schmit, T.; Gofflot, S.; Lamaudière, S.; Sinnaeve, G.; Goffart, J.P.; Gerin, P.A.; Stilmant, D.; et al. Détermination de la cellulose, des hemicelluloses, de la lignine et des cendres dans diverses cultures lignocellulosiques dédiées à la production de bioéthanol de deuxième génération. Biotechnol. Agron. Soc. Environ. 2010, 14, 549–560. [Google Scholar]

- Morel, J.C.; Gourc, J.P. Behavior of sand reinforced with mesh elements. Geosynth. Int. 1997, 4, 481–508. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Millogo, Y.; Aubert, J.-E.; Hamard, E.; Morel, J.-C. How Properties of Kenaf Fibers from Burkina Faso Contribute to the Reinforcement of Earth Blocks. Materials 2015, 8, 2332-2345. https://doi.org/10.3390/ma8052332

Millogo Y, Aubert J-E, Hamard E, Morel J-C. How Properties of Kenaf Fibers from Burkina Faso Contribute to the Reinforcement of Earth Blocks. Materials. 2015; 8(5):2332-2345. https://doi.org/10.3390/ma8052332

Chicago/Turabian StyleMillogo, Younoussa, Jean-Emmanuel Aubert, Erwan Hamard, and Jean-Claude Morel. 2015. "How Properties of Kenaf Fibers from Burkina Faso Contribute to the Reinforcement of Earth Blocks" Materials 8, no. 5: 2332-2345. https://doi.org/10.3390/ma8052332