Polymers have a wide range of applications due to their inherent properties, such light-weight, strength, resistance to chemicals, thermal resistance,

etc. Many processing techniques have been developed to advance the material properties and extend the range of applications. Multilayered polymers have been developed by coextrusion of polymeric systems [

1]. The coextrusion technology was first developed by the Dow Chemical Company in the 1970s [

2,

3,

4,

5,

6]. Multilayered polymers include microlayered and nanolayered polymer depending on the scale of the thickness of layers. Multilayered polymers have been reported to have improved mechanical properties, such as ductility and impact strength, as the layer thickness is reduced [

7,

8,

9]. The microlayered polymer films have been successfully used in industrial applications, such as food packaging and coating [

10,

11,

12]. The 3M Company adopted multilayered polymers for light management in mirrors and the screens of laptop computers. These types of polymer films have some unique properties in their applications. For example, the films can retain the aroma, flavor and freshness of food when used in food packaging. As the coextrusion techniques have advanced in recent years, innovative nanolayered polymer films have been developed, which have more complex hierarchical systems and a truly biomimetic nature [

13,

14]. There are many potential applications for the nanolayered films, such as gas barrier materials, next-generation flat-panel displays and spherical gradient refractive index (GRIN) lenses [

15,

16]. To mimic the structures of eyes in nature, polymer lenses made of nanolayered polymer film with GRIN distributions have been developed in recent years. The GRIN crystalline lenses in biological eyes, such as human being’s eyes, typically contain approximately 22,000 layers [

17,

18]. Layered polymeric optical lenses have been reported to have better optical properties than glass lenses and have been used to replace the traditional glass lens [

17,

18]. Some researchers have studied the physical and mechanical properties, such as transparency and flexibility, of the novel thin films, although the reports are relatively few [

19,

20,

21,

22].

Due to the intrinsic structure of polymers, the mechanical properties of the polymer films can vary widely depending on the material formulation, environmental temperature and time. To facilitate the application of polymers, the deterioration of the material over time, especially at elevated temperature, needs to be studied. We have previously carried out a preliminary investigation to experimentally study the impact of thermal aging on the mechanical behavior of the micro- and nano-layered polymer films [

23]. However, in the previous study, all of the films have various layer thicknesses and film thicknesses. This makes it hard to study the effect of layer thickness and film thickness on the change of properties after aging separately. In the current study, the films have either the same film thickness with various layer thicknesses or the same layer thickness with various film thicknesses. This way, the effect of film and layer thickness on the aging of the film can be studied independently. The effect of aging temperature on a specific nanolayered film has also been studied.

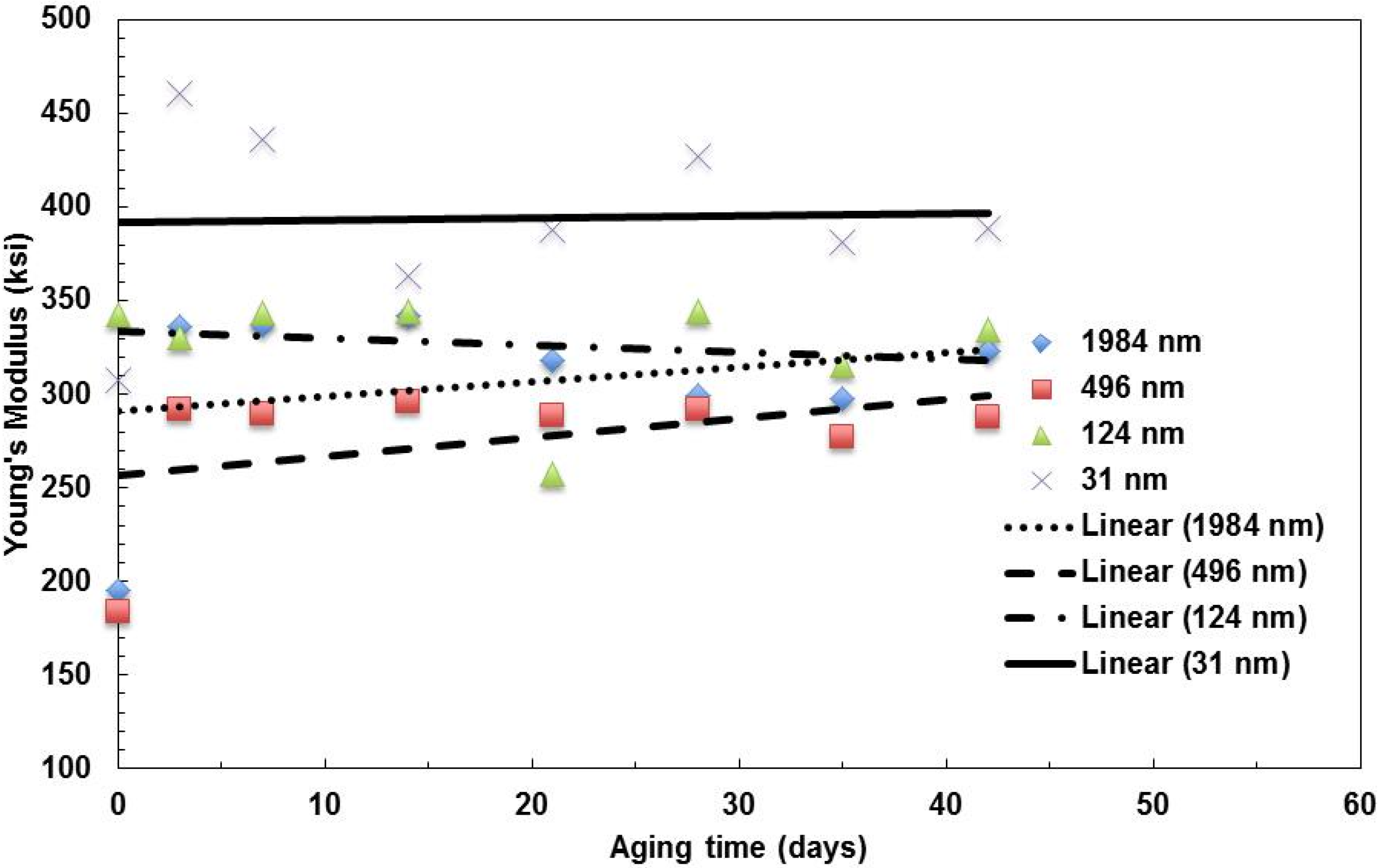

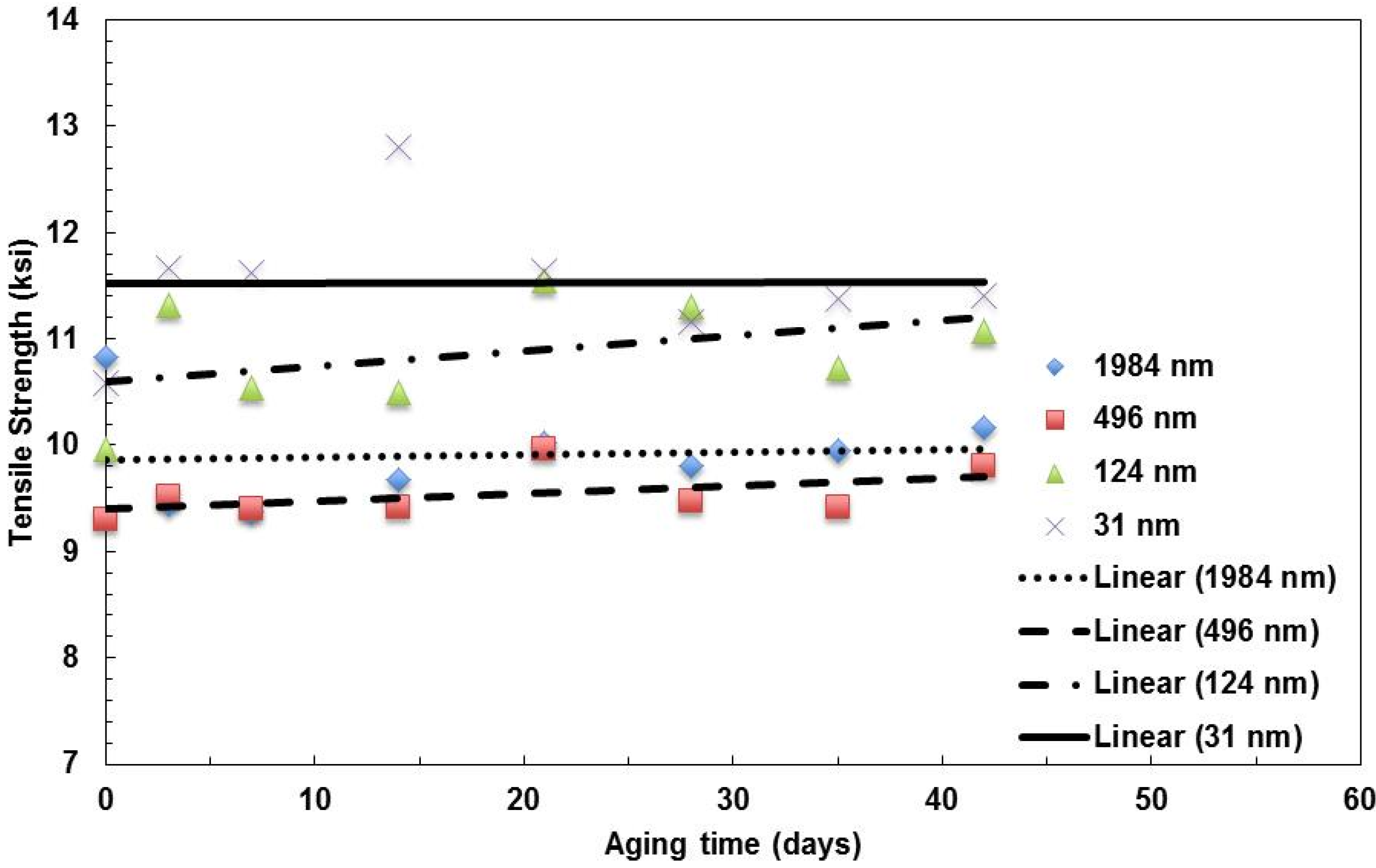

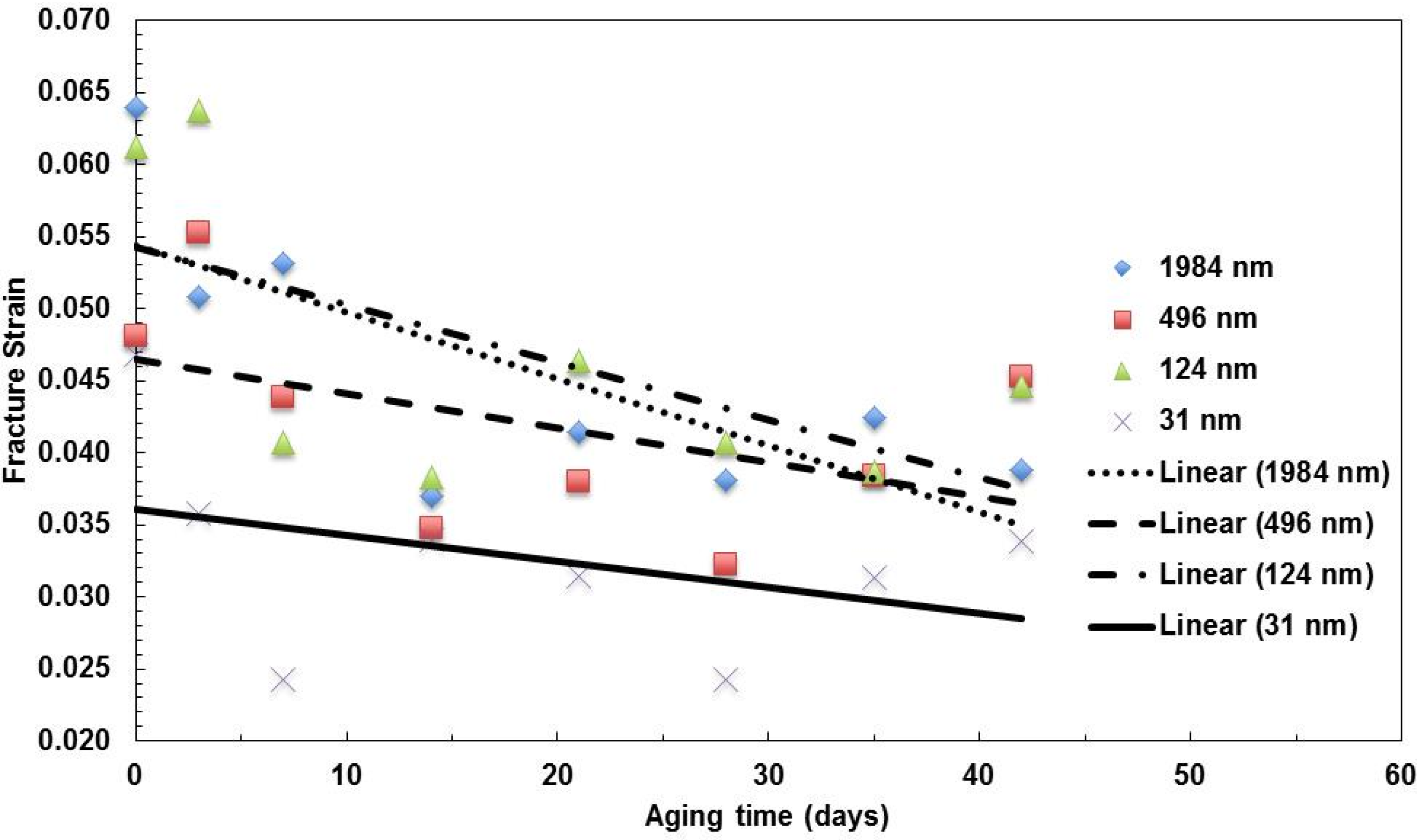

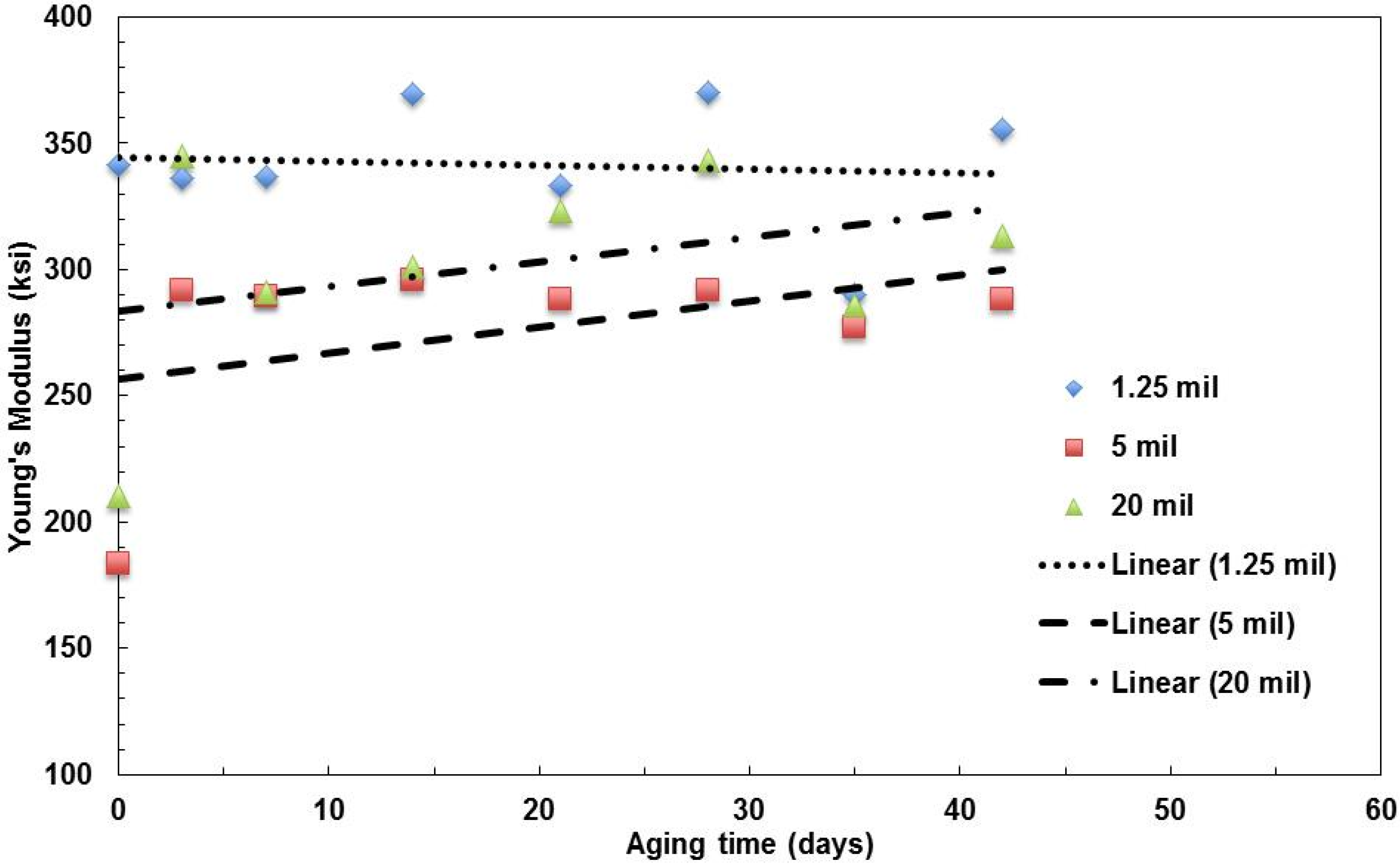

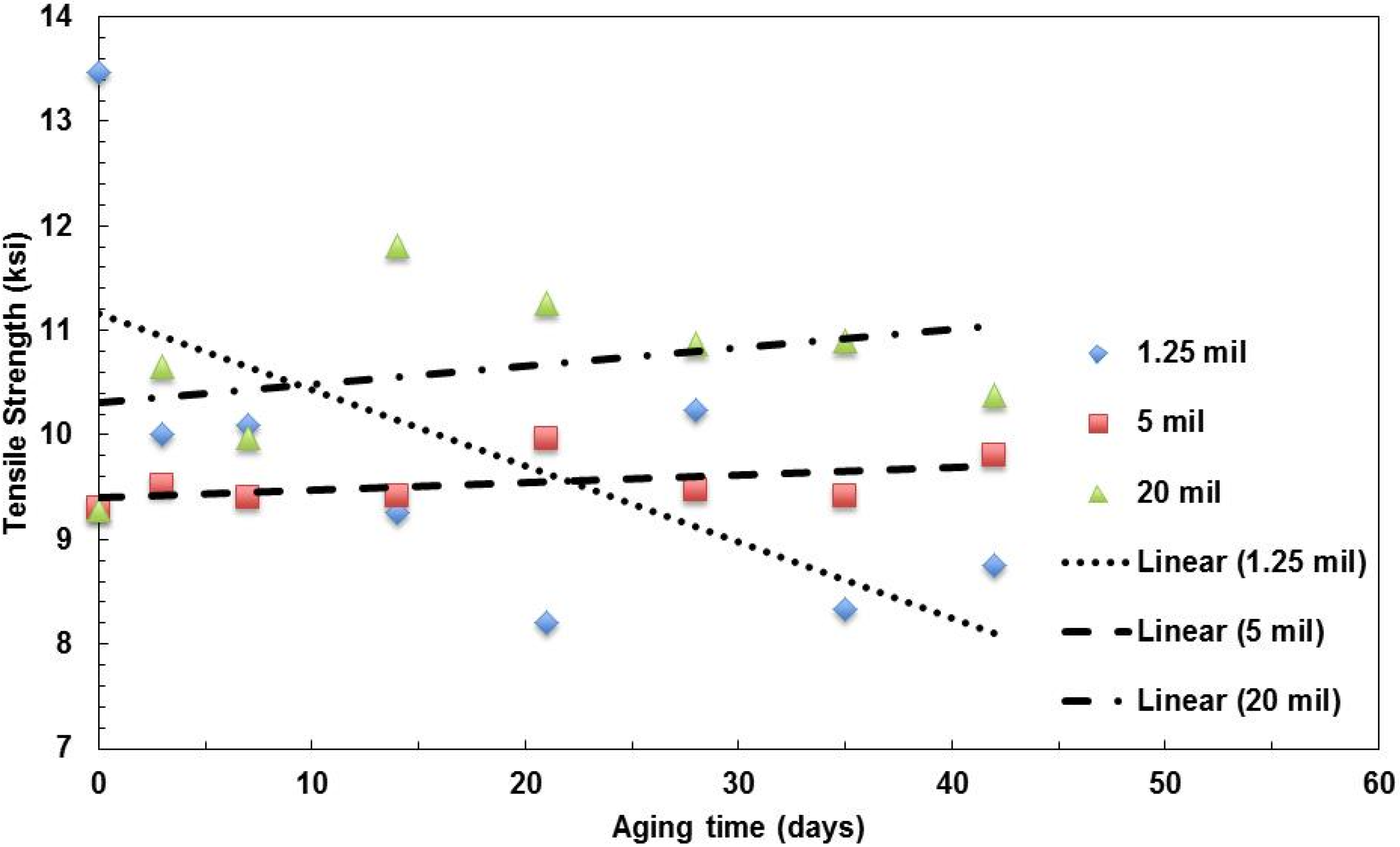

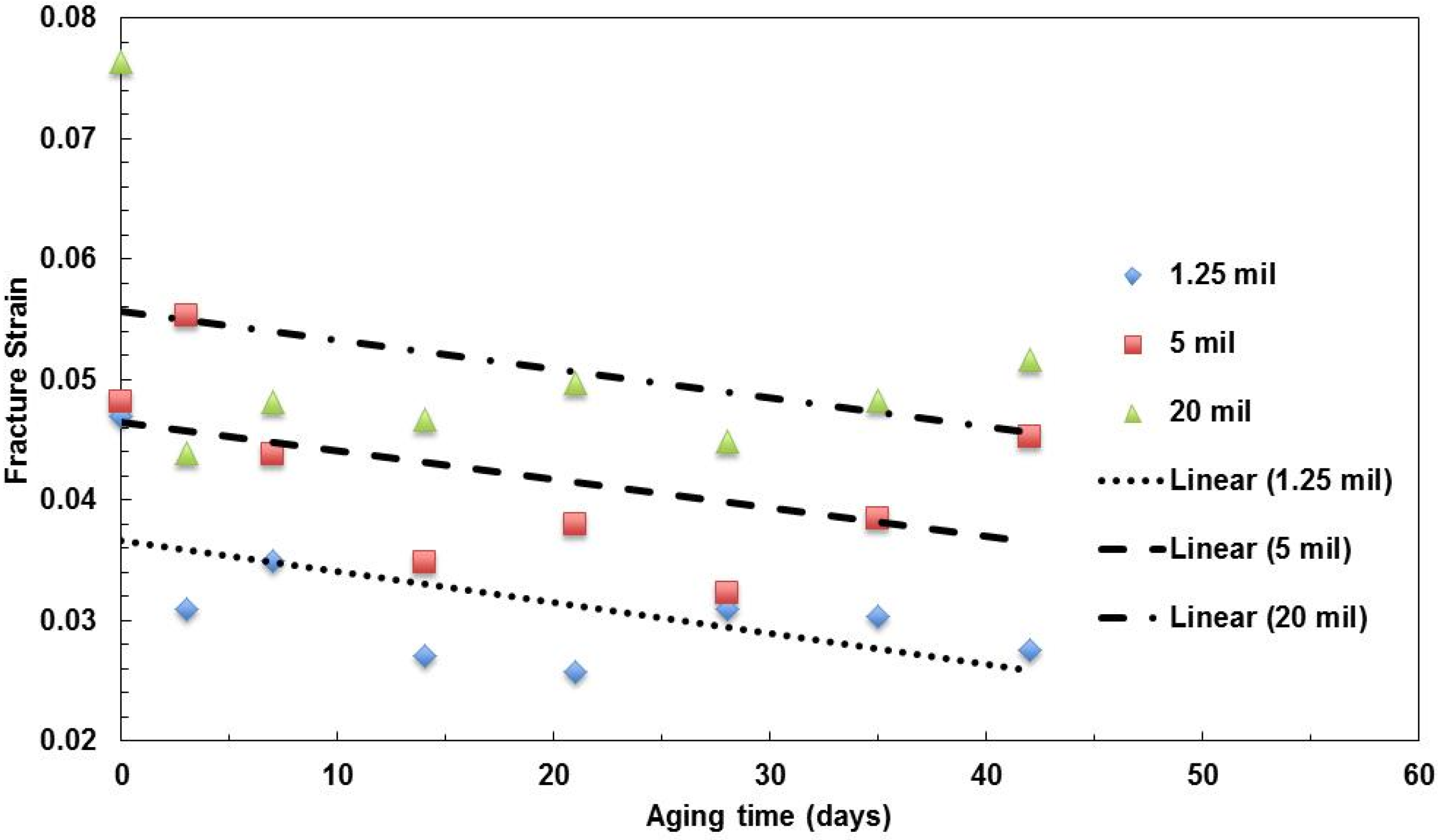

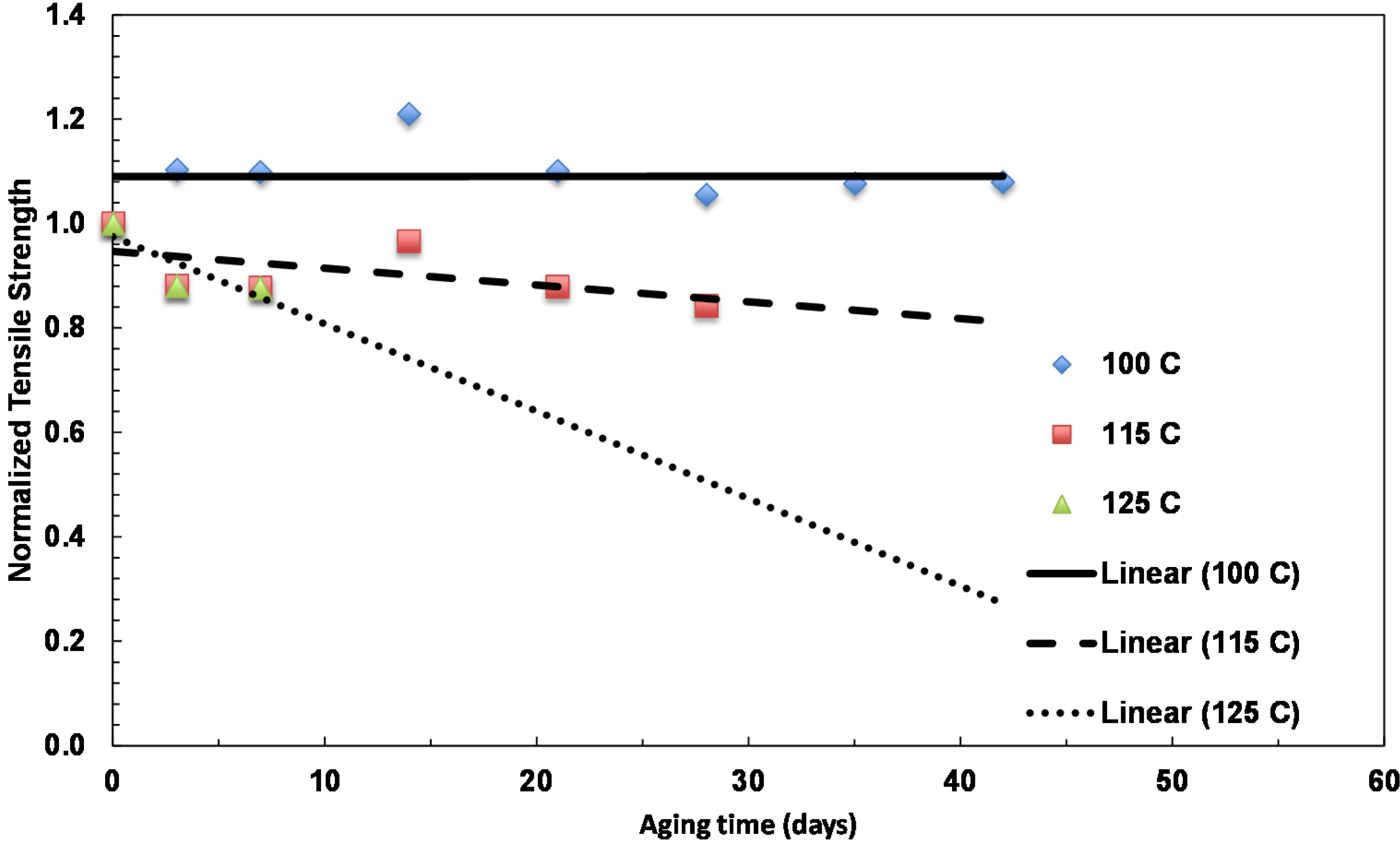

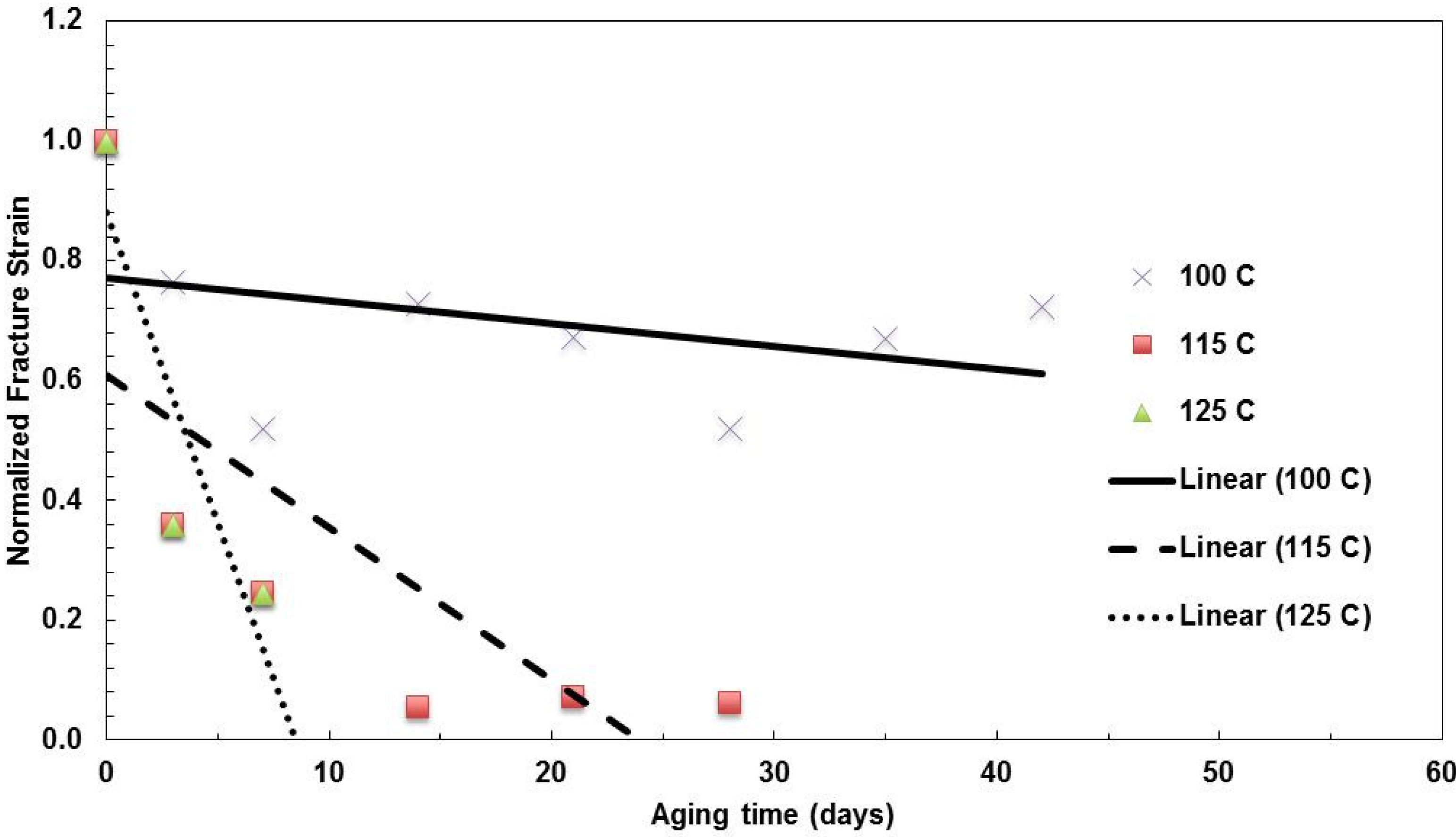

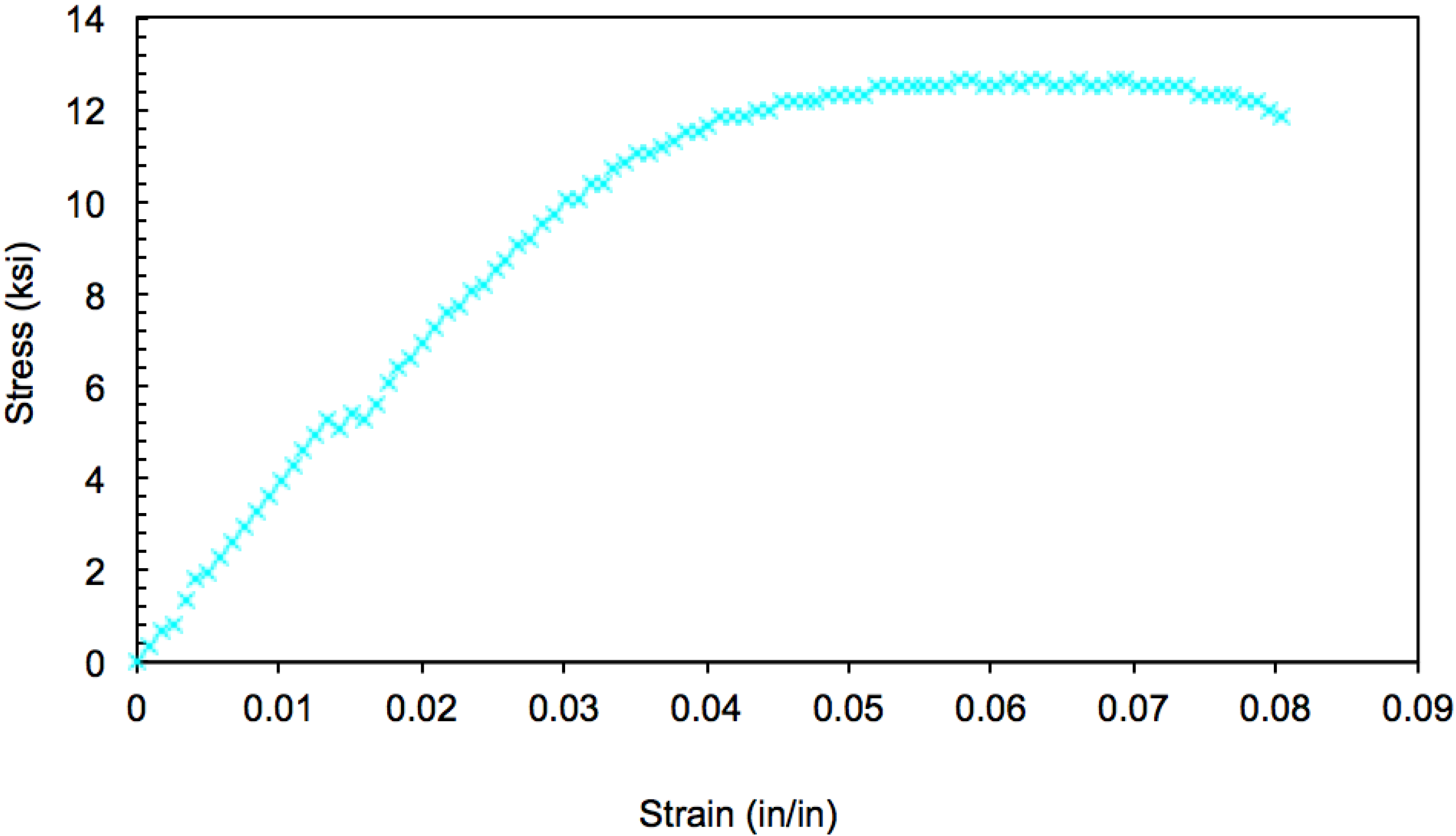

The composition of the polymer films under study is 50 vol% polycarbonate (PC) and 50 vol% poly(methyl methacrylate) (PMMA). The layer thickness ranges from 31 nm to 1,984 nm with a 5-μm film thickness and a film thickness of 31.8 μm to 508 μm with a 496-nm layer thickness. These films were thermally aged at 100 °C in a constant temperature oven for up to six weeks. Their mechanical properties, including the modulus of elasticity, tensile strength and ductility, were compared. It has been observed that the thermal aging temperature and aging time have significant effects on the overall character of the stress-strain responses, and layer and film thickness play important roles. The films with 4,096 layers (31 nm thick for each layer) were aged at 100 °C, 115 °C and 125 °C for up to four weeks to study the effect of aging temperature. It has been observed that the film with a 31-nm layer has relatively stable mechanical properties. The microstructural scale level contributes to the material mechanical properties, such as the mechanical stability and durability. The microstructural features start to play a role as the layer thickness reduces to a certain level, which is very important for applications, such as in GRIN lens designs.