Experimental Investigation on Cutting Characteristics in Nanometric Plunge-Cutting of BK7 and Fused Silica Glasses

Abstract

:1. Introduction

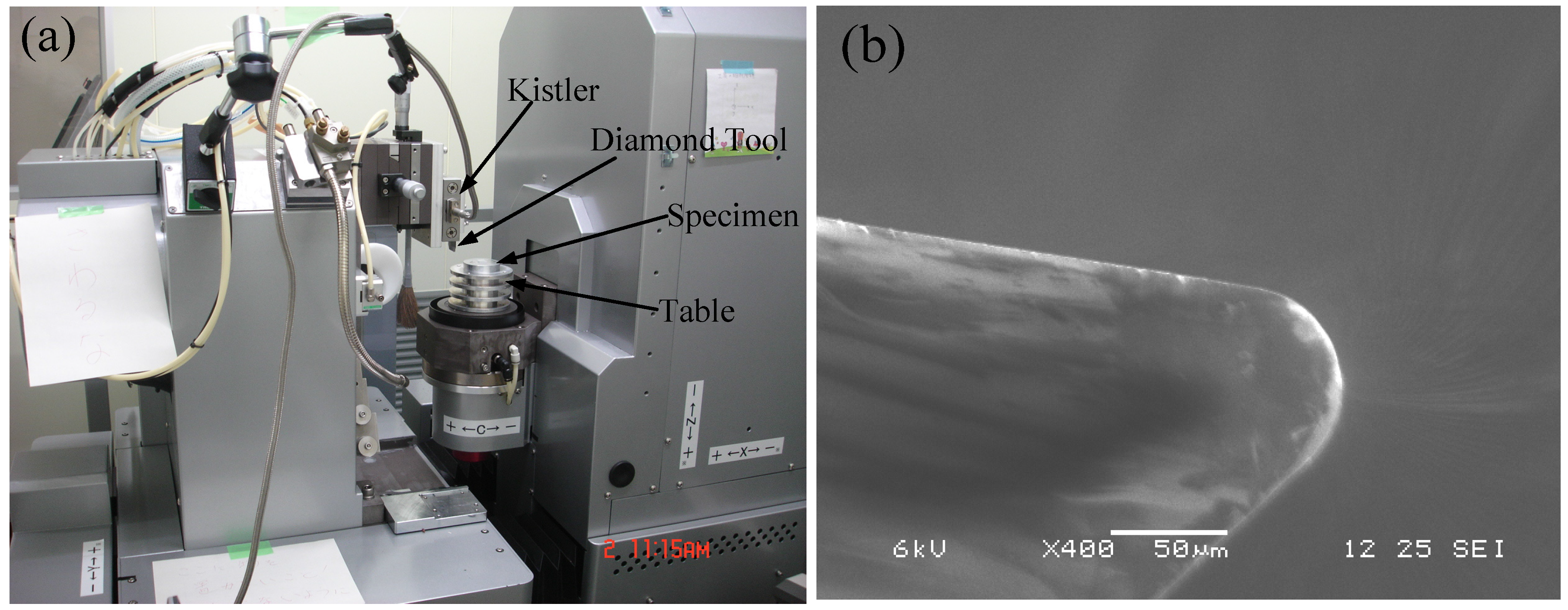

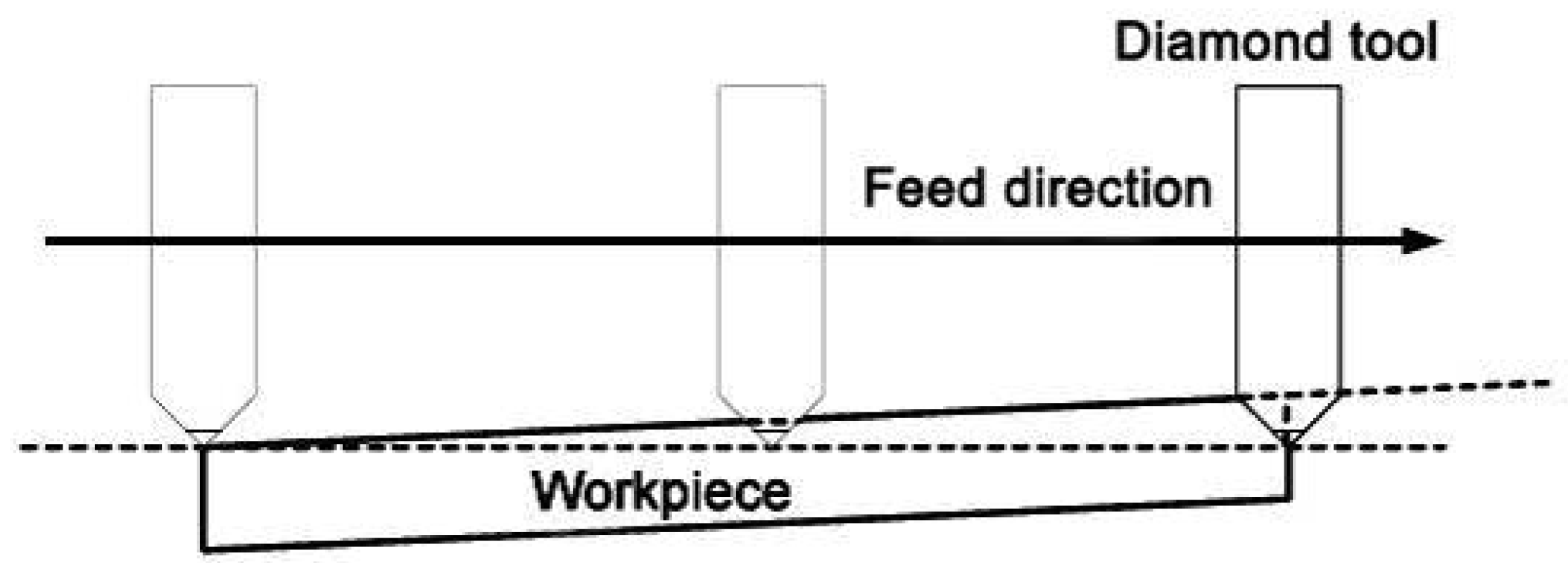

2. Experimental Section

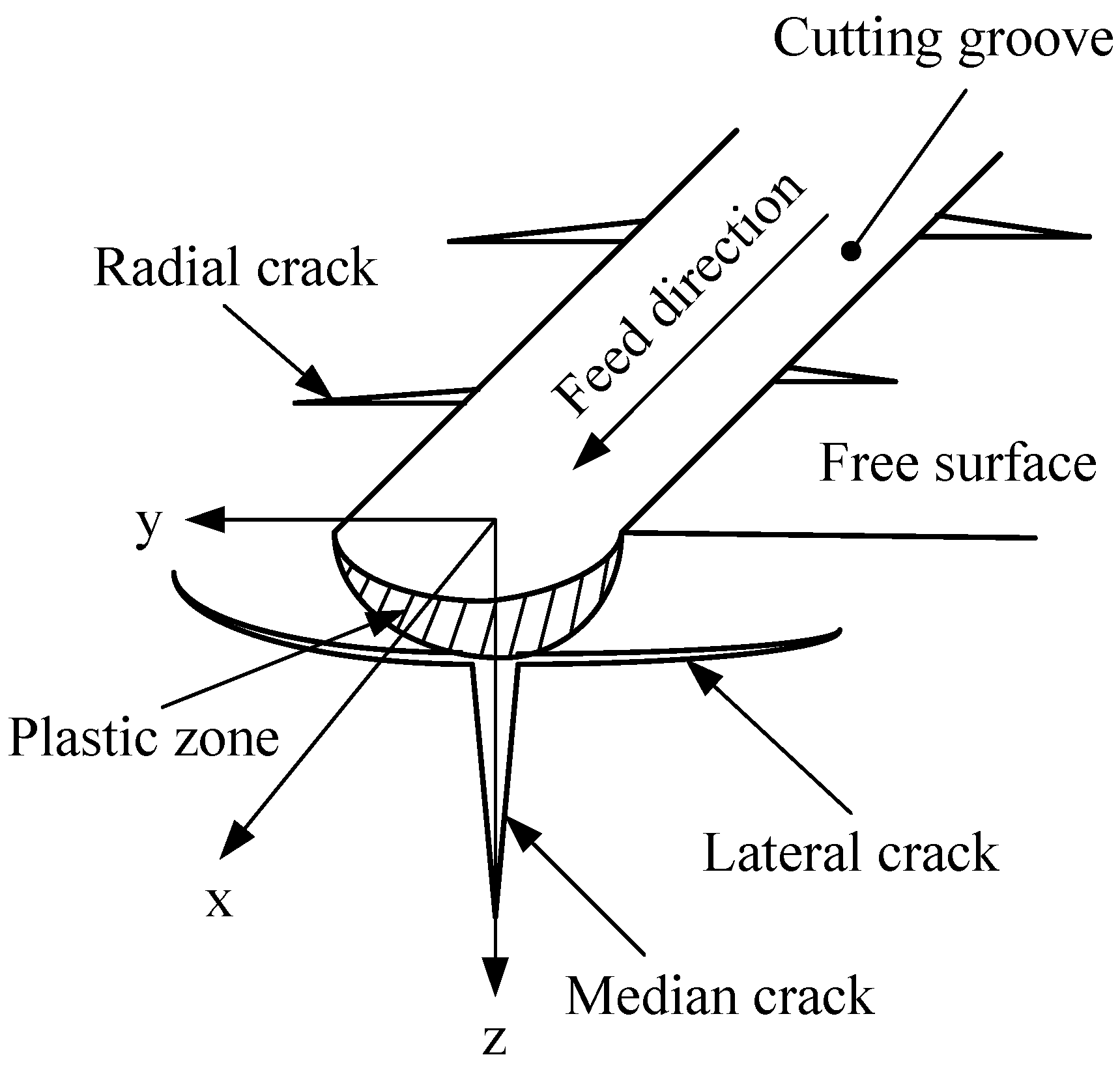

3. Machining Regime of Brittle Materials

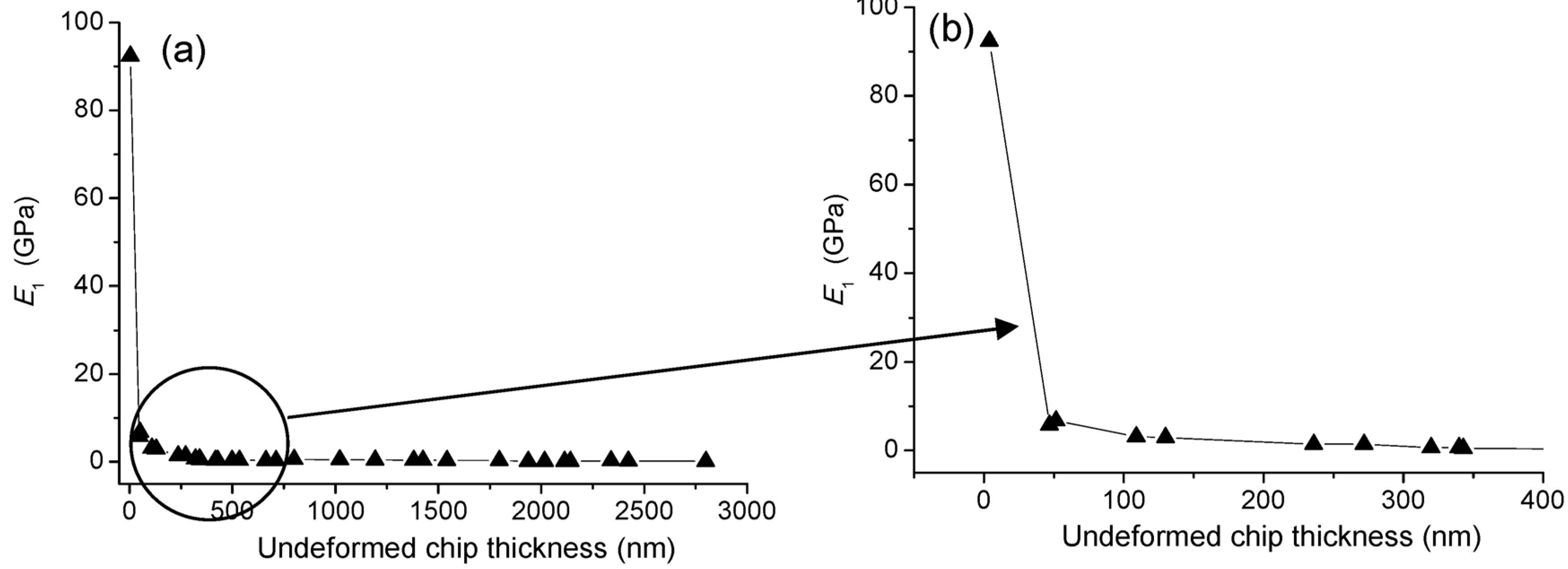

3.1. Specific Cutting Energy

3.2. Critical Undeformed Chip Thickness

4. Results and Discussion

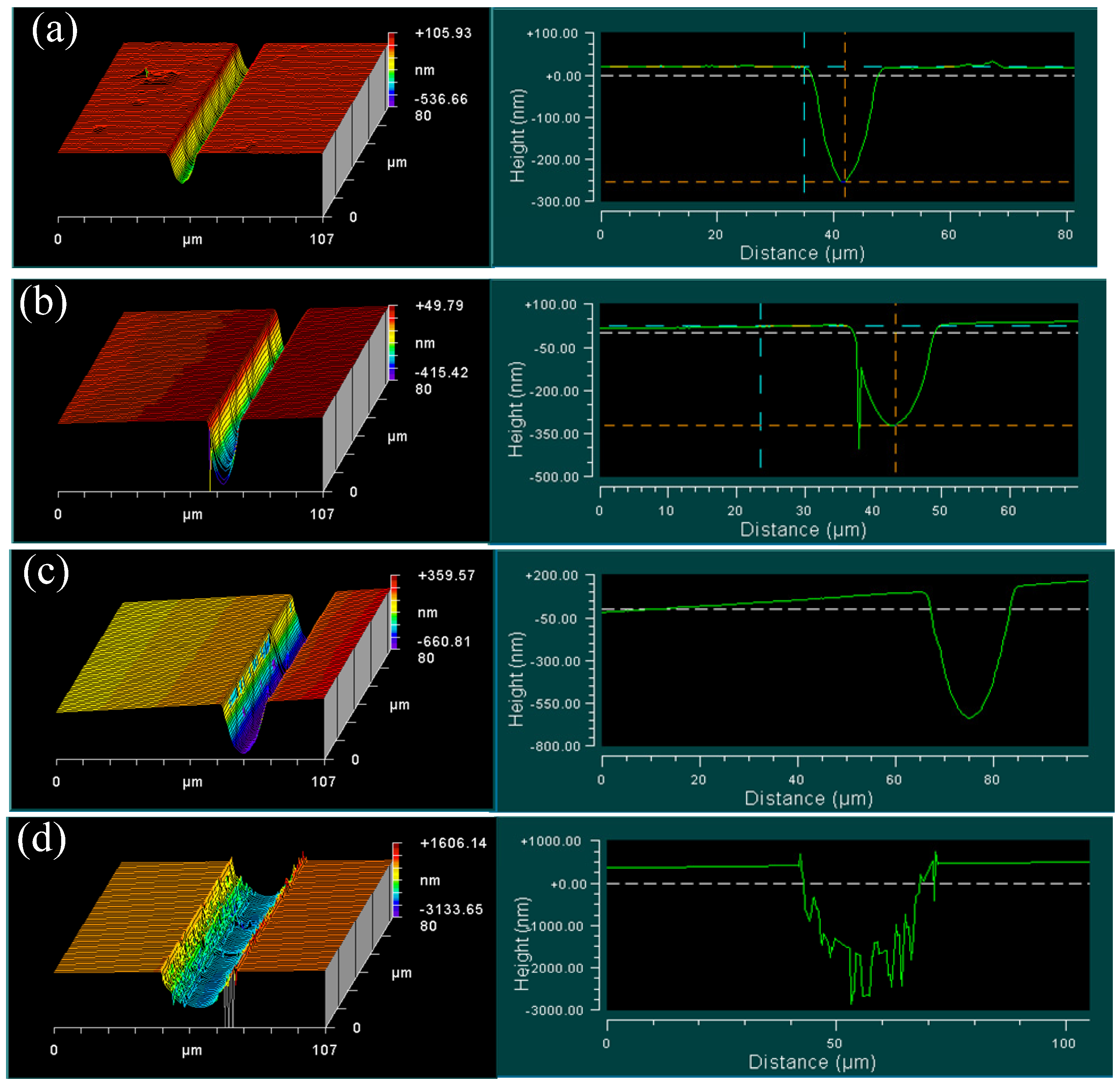

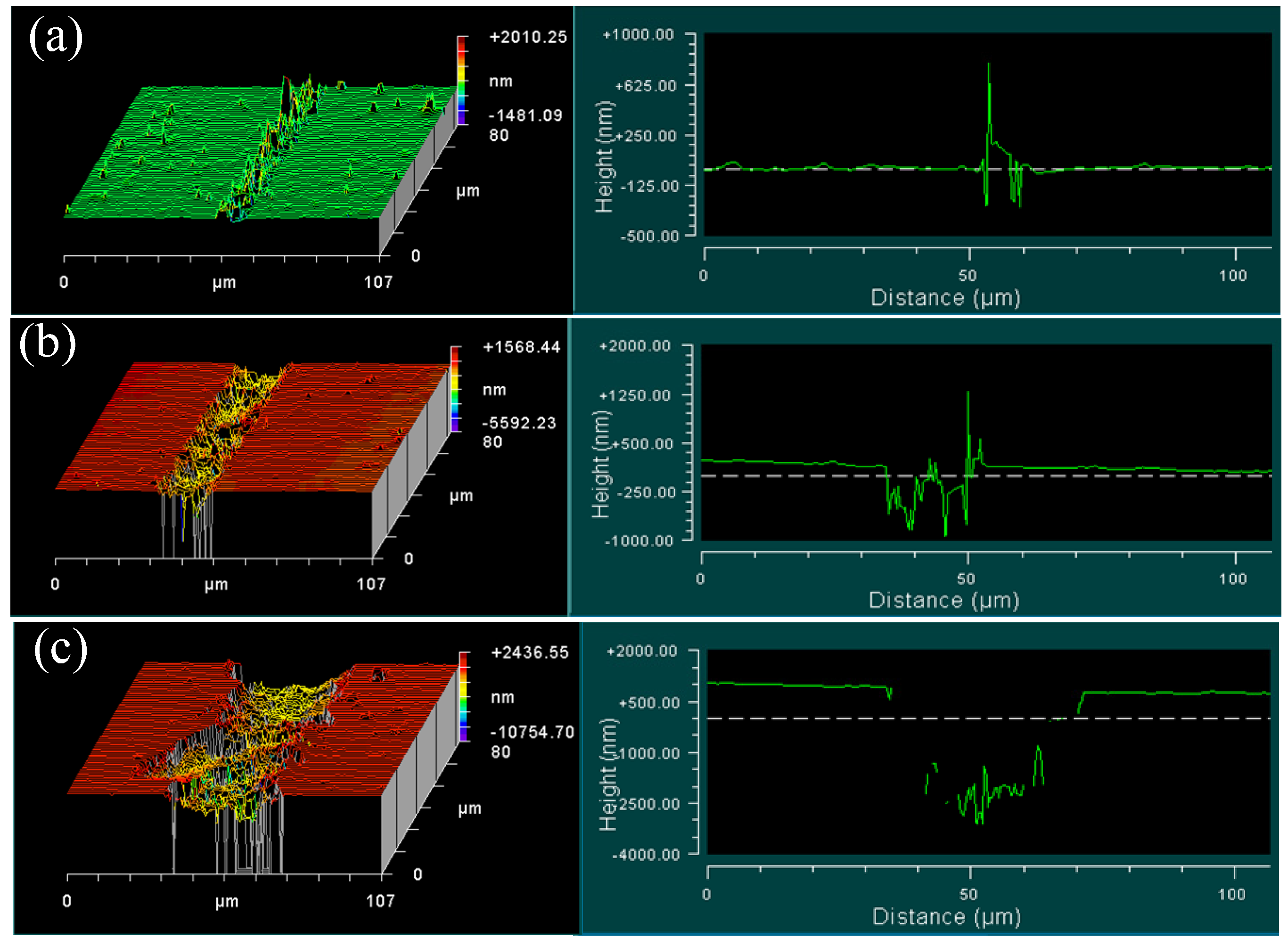

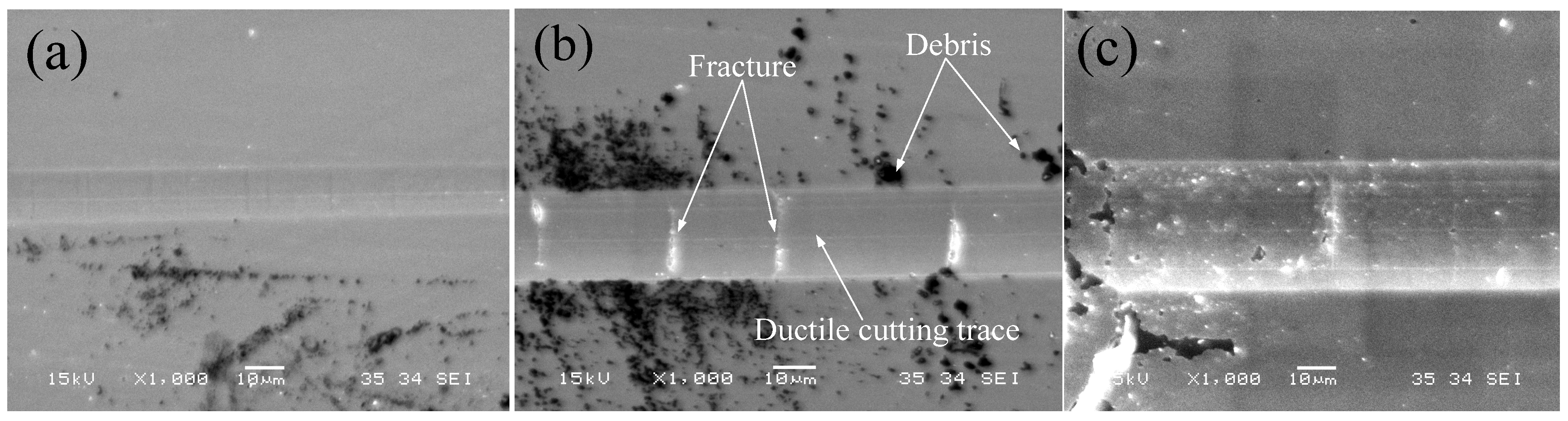

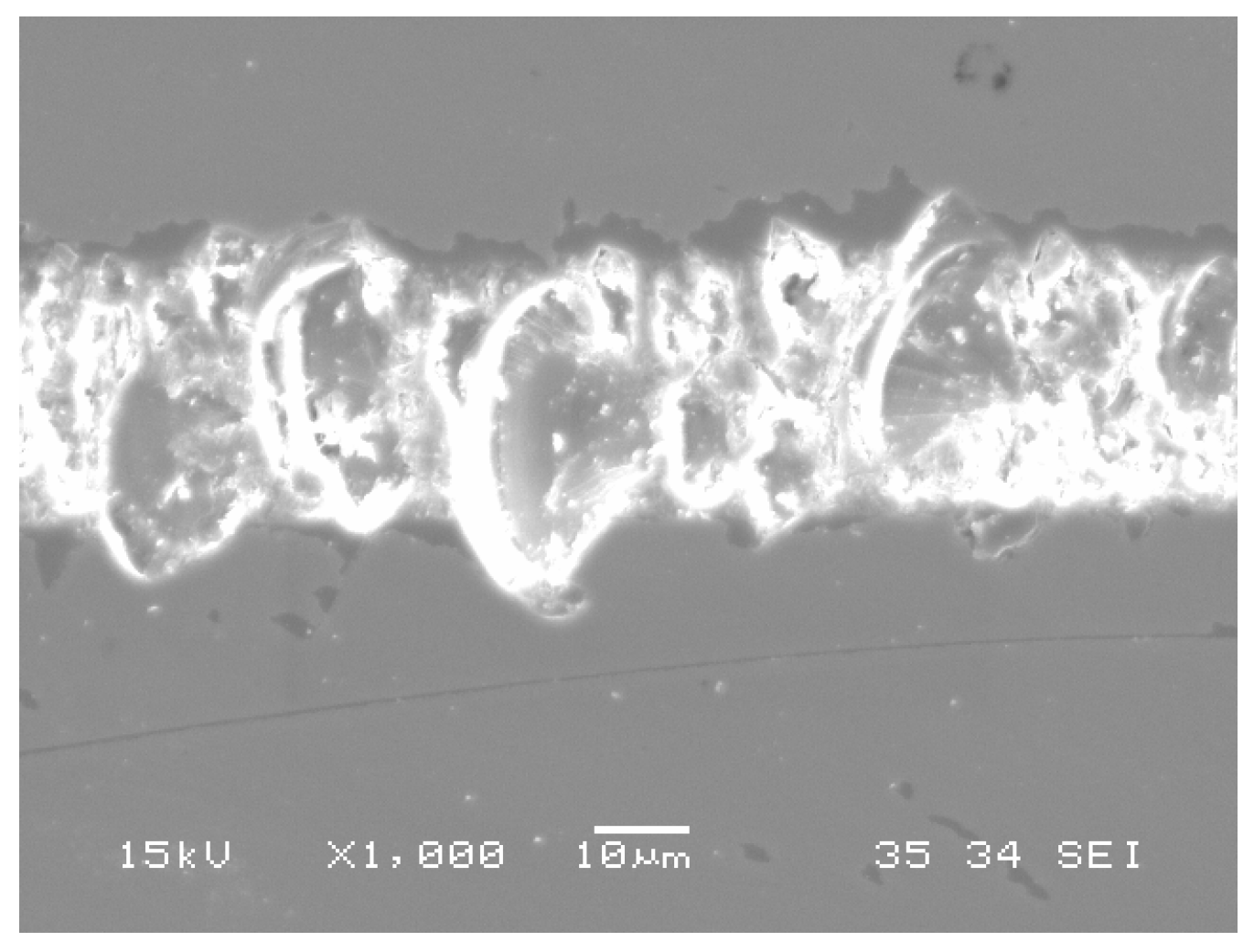

4.1. Machined Surface Morphology

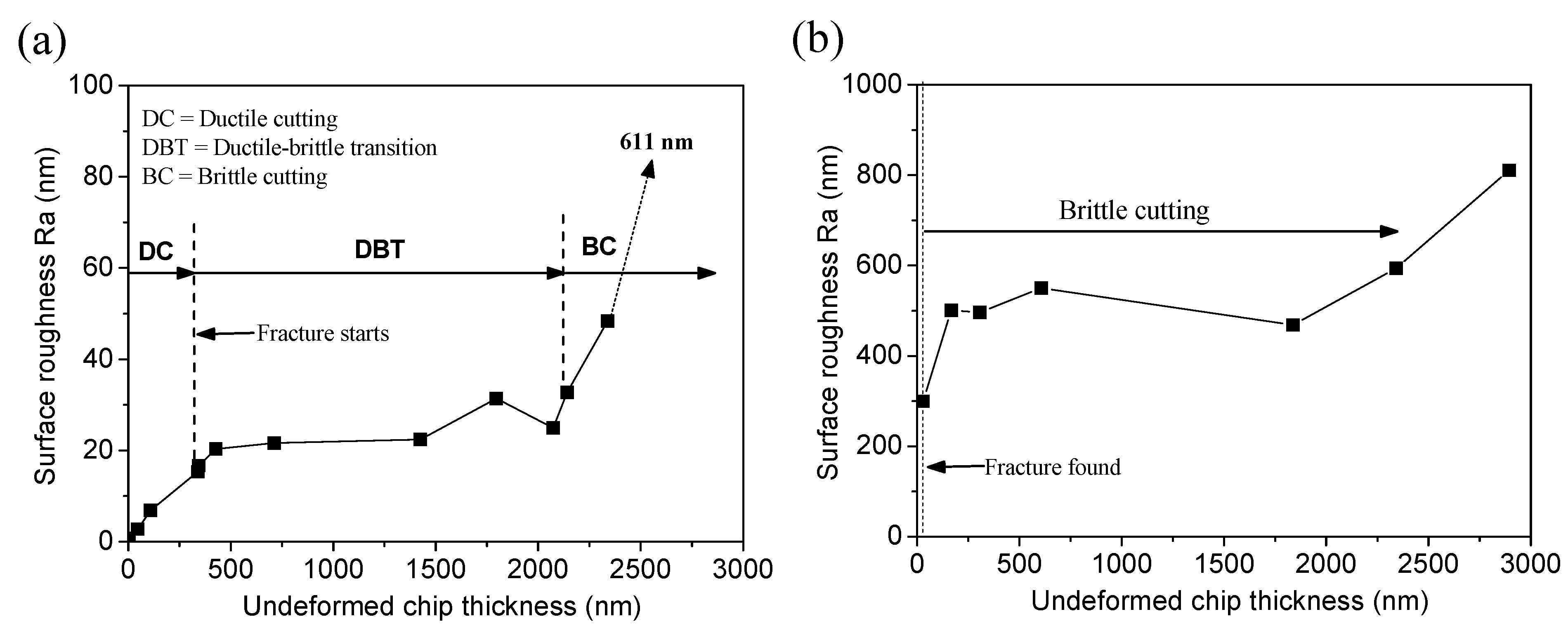

4.2. Surface Roughness

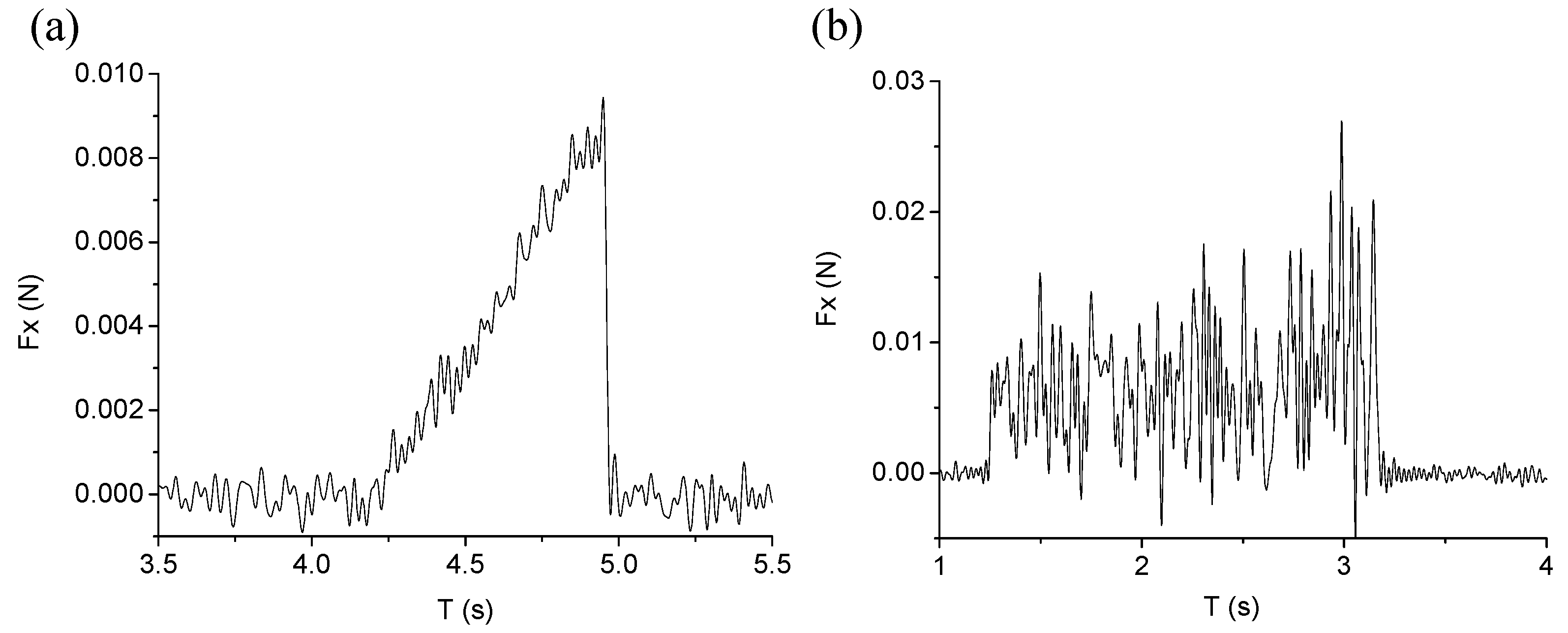

4.3. Cutting Force and Specific Cutting Energy

5. Conclusions

- (1)

- There existed a CUCT of 320 nm in nanometric cutting of BK7, which experienced ductile, ductile-brittle transition and brittle cutting stage successively with increasing undeformed chip thickness. Only brittle cutting was found for fused silica with the same cutting conditions when undeformed chip thickness was above 30 nm, and brittle fractures existed for its high hardness and low fracture toughness compared with BK7.

- (2)

- Low surface roughness value could be obtained in ductile cutting and ductile-brittle transition cutting during BK7 nanometric plunge-cutting test. Brittle cutting process was confirmed to cause the significant increase of machined surface roughness irrespective of BK7 or fused silica. The key reason was attributed to the large amount of cracks and fractures on the machined surface.

- (3)

- The feed cutting force almost increased linearly with elevated undeformed chip thickness for BK7, while the feed cutting force for fused silica fluctuates violently and the amplitude of fluctuation increases when undeformed chip thickness increased. The phenomena were mainly due to the large brittle fractures that led to the high cutting force and fluctuation.

- (4)

- Size effect was found with undeformed chip thickness below 50 nm in ductile cutting of BK7. The appropriate undeformed chip thickness between 50 and 320 nm was expected to get a good surface integrity, when precision machining of BK7 with the similar cutting conditions as used in this research.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hatty, V.; Kahn, H.; Heuer, A.H. Fracture toughness, fracture strength, and stress corrosion cracking of silicon dioxide thin films. Microelectromech. Syst. J. 2008, 17, 943–961. [Google Scholar] [CrossRef]

- Fang, F.Z.; Liu, X.D.; Lee, L.C. Micro-machining of optical glasses—A review of diamond-cutting glasses. Sadhana 2003, 28, 945–955. [Google Scholar] [CrossRef]

- Fang, F.Z.; Chen, L.J. Ultra-precision cutting for ZKN7 glass. CIRP Ann. Manuf. Technol. 2000, 49, 17–20. [Google Scholar] [CrossRef]

- Shibata, T.; Fujii, S.; Makino, E.; Ikeda, M. Ductile-regime turning mechanism of single-crystal silicon. Precis. Eng. 1996, 18, 129–137. [Google Scholar] [CrossRef]

- Fang, F.Z.; Venkatesh, V.C. Diamond cutting of silicon with nanometric finish. CIRP Ann. Manuf. Technol. 1998, 47, 45–49. [Google Scholar] [CrossRef]

- Nakasuji, T.; Kodera, S.; Hara, S.; Matsunaga, H.; Ikawa, N.; Shimada, S. Diamond turning of brittle materials for optical components. CIRP Ann. Manuf. Technol. 1990, 39, 89–92. [Google Scholar] [CrossRef]

- Ikawa, N.; Donaldson, R.R.; Komanduri, R.; König, W.; Mckeown, P.A.; Moriwaki, T.; Stowers, I.F. Ultraprecision metal cutting—The past, the present and the future. CIRP Ann. Manuf. Technol. 1991, 40, 587–594. [Google Scholar] [CrossRef]

- Lv, D.X.; Huang, Y.H.; Wang, H.X.; Tang, Y.J.; Wu, X.C. Improvement effects of vibration on cutting force in rotary ultrasonic machining of BK7 glass. J. Mater. Process. Technol. 2013, 213, 1548–1557. [Google Scholar] [CrossRef]

- Jang, H.S.; Cho, M.W.; Park, D.S. Micro fluidic channel machining on fused silica glass using powder blasting. Sensors 2008, 8, 700–710. [Google Scholar] [CrossRef]

- Bifano, T.G.; Dow, T.A.; Scattergood, R.O. Ductile-regime grinding: a new technology for machining brittle materials. ASME J. Eng. Ind. 1991, 113, 184–189. [Google Scholar] [CrossRef]

- Blake, P.N.; Scattergood, R.O. Ductile-regime machining of germanium and silicon. J. Am. Ceram. Soc. 1990, 73, 949–957. [Google Scholar] [CrossRef]

- Ravindra, D.; Patten, J. Ductile regime single point diamond turning of quartz resulting in an improved and damage-free surface. Mach. Sci. Technol. 2011, 15, 357–375. [Google Scholar] [CrossRef]

- Zhou, M.; Ngoi, B.K.A.; Zhong, Z.W.; Chin, C.S. Brittle-ductile transition in diamond cutting of silicon single crystals. Mater. Manuf. Process. 2001, 16, 447–460. [Google Scholar]

- Liu, K.; Li, X.P.; Liang, S.Y. Nanometer-scale ductile cutting of tungsten carbide. J. Manuf. Process. 2004, 6, 187–195. [Google Scholar] [CrossRef]

- Arif, M.; Xinquan, Z.; Rahman, M.; Kumar, S. A predictive model of the critical undeformed chip thickness for ductile-brittle transition in nano-machining of brittle materials. Int. J. Mach. Tool. Manuf. 2013, 64, 114–122. [Google Scholar] [CrossRef]

- Sun, X.; Stephenson, D.J.; Ohnishi, O.; Baldwin, A. An investigation into parallel and cross grinding of BK7 glass. Precis. Eng. 2006, 30, 145–153. [Google Scholar] [CrossRef]

- Barsoum, M.W. Fundamentals of Ceramics; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Dahmani, F.; Lambropoulos, J.C.; Schmid, A.W.; Burns, S.J.; Pratt, C. Nanoindentation technique for measuring residual stress field around a laser-induced crack in fused silica. J. Mater. Sci. 1998, 33, 4677–4685. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Schmütz, J. Generation and texture of surfaces in ultraprecision cutting of copper. Mach. Sci. Technol. 1997, 1, 185–193. [Google Scholar] [CrossRef]

- Huang, H.; Zhao, H.; Zhang, Z.; Yang, Z.; Ma, Z. Influences of sample preparation on nanoindentation behavior of a Zr-based bulk metallic glass. Materials 2012, 5, 1033–1039. [Google Scholar] [CrossRef]

- Leung, T.P.; Lee, W.B.; Lu, X.M. Diamond turning of silicon substrates in ductile-regime. J. Mater. Process. Technol. 1998, 73, 42–48. [Google Scholar] [CrossRef]

- Goel, S.; Luo, X.; Agrawal, A.; Reuben, R.L. Diamond machining of silicon: A review of advances in molecular dynamics simulation. Int. J. Mach. Tool. Manuf. 2015, 88, 131–164. [Google Scholar] [CrossRef]

- Patten, J.A.; Gao, W.; Yasuto, K. Ductile regime nanomachining of single-crystal silicon carbide. J. Manuf. Sci. Eng. 2005, 127, 522–532. [Google Scholar] [CrossRef]

- Goel, S. The current understanding on the diamond machining of silicon carbide. J. Phys. D Appl. Phys. 2014, 47. [Google Scholar] [CrossRef]

- Morris, J.C.; Callahan, D.L.; Kulik, J.; Patten, J.A.; Scattergood, R.O. Origins of the ductile regime in single-point diamond turning of semiconductors. J. Am. Ceram. Soc. 1995, 78, 2015–2020. [Google Scholar] [CrossRef]

- Kovalchenko, A.M.; Milman, Y.V. On the cracks self-healing mechanism at ductile mode cutting of silicon. Tribol. Int. 2014, 80, 166–171. [Google Scholar] [CrossRef]

- Ahn, Y.; Farris, T.N.; Chandrasekar, S. Sliding microindentation fracture of brittle materials: Role of elastic stress fields. Mech. Mater. 1998, 29, 143–152. [Google Scholar] [CrossRef]

- Ahn, Y. Deformation about Sliding Indentation in Ceramics and Its Application to Lapping. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 1992. [Google Scholar]

- Wang, J.J.; Liao, Y.Y. Critical depth of cut and specific cutting energy of a microscribing process for hard and brittle materials. J. Eng. Mater. Technol. 2008, 130. [Google Scholar] [CrossRef]

- Lee, J.S.; Lee, D.W.; Jung, Y.H.; Chung, W.S. A study on micro-grooving characteristics of planar light wave circuit and glass using ultrasonic vibration cutting. J. Mater. Process. Technol. 2002, 130, 396–400. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, X.J.; Ngoi, B.; Gan, J. Brittle-ductile transition in the diamond cutting of glasses with the aid of ultrasonic vibration. J. Mater. Process. Technol. 2002, 121, 243–251. [Google Scholar] [CrossRef]

- Zhou, L.; Shiina, T.; Qiu, Z.; Shimizu, J.; Yamamoto, T.; Tashiro, T. Research on chemo-mechanical grinding of large size quartz glass substrate. Precis. Eng. 2009, 33, 499–504. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, Q.; Ming, W.; Chen, M. Experimental Investigation on Cutting Characteristics in Nanometric Plunge-Cutting of BK7 and Fused Silica Glasses. Materials 2015, 8, 1428-1441. https://doi.org/10.3390/ma8041428

An Q, Ming W, Chen M. Experimental Investigation on Cutting Characteristics in Nanometric Plunge-Cutting of BK7 and Fused Silica Glasses. Materials. 2015; 8(4):1428-1441. https://doi.org/10.3390/ma8041428

Chicago/Turabian StyleAn, Qinglong, Weiwei Ming, and Ming Chen. 2015. "Experimental Investigation on Cutting Characteristics in Nanometric Plunge-Cutting of BK7 and Fused Silica Glasses" Materials 8, no. 4: 1428-1441. https://doi.org/10.3390/ma8041428

APA StyleAn, Q., Ming, W., & Chen, M. (2015). Experimental Investigation on Cutting Characteristics in Nanometric Plunge-Cutting of BK7 and Fused Silica Glasses. Materials, 8(4), 1428-1441. https://doi.org/10.3390/ma8041428