Effects of Medium Temperature and Industrial By-Products on the Key Hardened Properties of High Performance Concrete

Abstract

:1. Research Significance

2. Introduction

3. Experimental Investigation

3.1. Constituent Materials

3.2. Concrete Mix Proportions

| Concrete Type | Coarse Aggregate (kg/m3) | Fine Aggregate (kg/m3) | Binder (B, kg/m3) | Water Content (kg/m3) | SP (%B) | ||

|---|---|---|---|---|---|---|---|

| Cement | Silica Fume | Fly Ash | |||||

| NPCC | 1013 | 675 | 530 | – | – | 185.5 | 1.75 |

| SFC | 1002 | 667 | 477 | 53 | – | 185.5 | 2.25 |

| FAC | 1003 | 668 | 477 | – | 53 | 185.5 | 1.75 |

| SFFAC | 1002 | 668 | 477 | 26.5 | 26.5 | 185.5 | 2.15 |

3.3. Preparation of Fresh Concrete

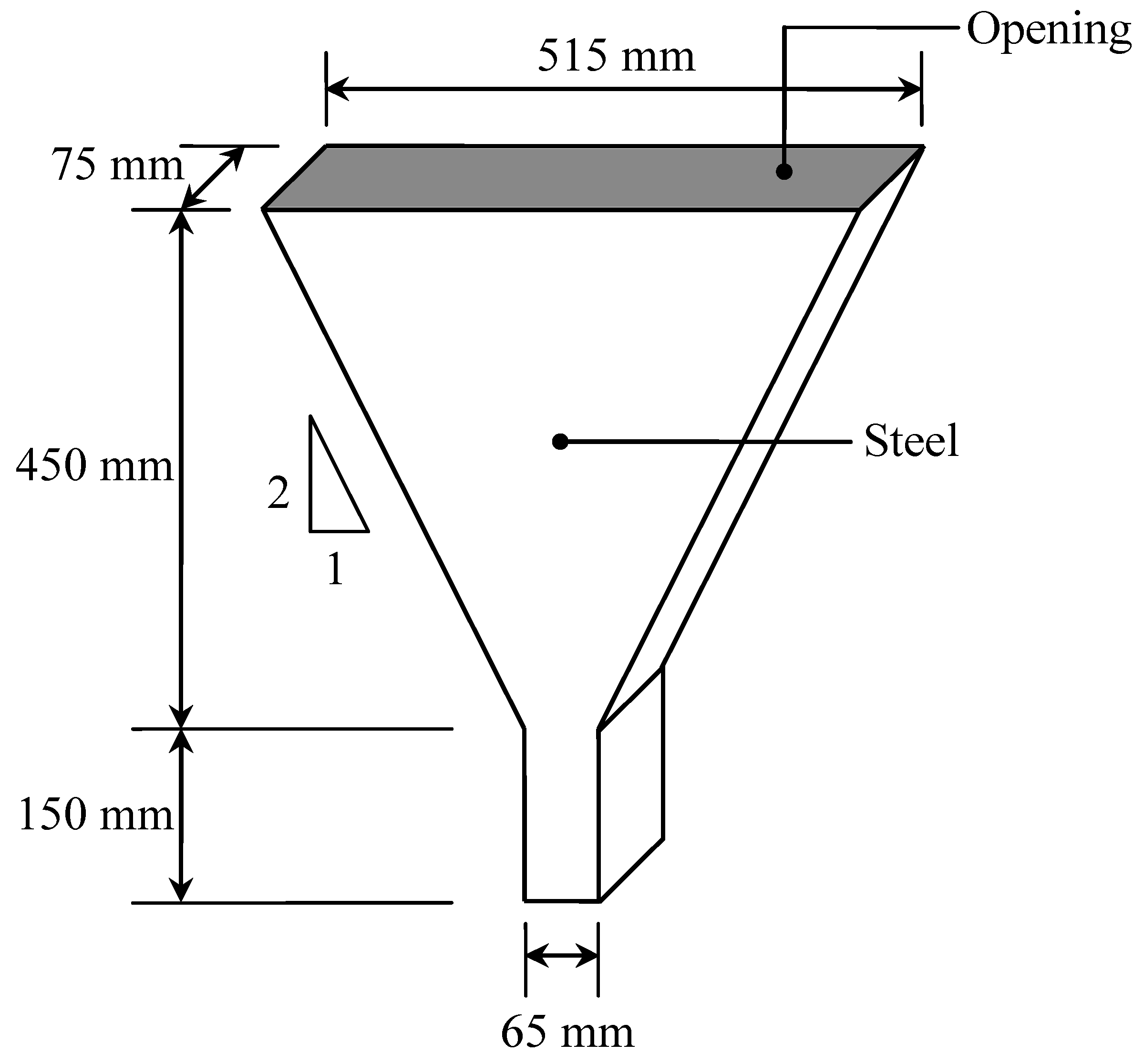

3.4. Testing of Key Fresh Properties of Concrete

3.5. Fabrication of Hardened Test Specimens

3.6. Curing and Conditioning of Hardened Test Specimens

3.7. Testing of Key Hardened Properties of Concrete

4. Results and Discussion

4.1. Fresh Properties of Concrete

| Concrete Type | Water Content (kg/m3) | SP (%B) | Slump (cm) | Slump Flow (cm) | V-Funnel Flow (s) |

|---|---|---|---|---|---|

| NPCC | 185.5 | 1.75 | 25.0 | 58.0 | 55.3 |

| SFC | 185.5 | 2.25 | 25.0 | 58.0 | 58.3 |

| FAC | 185.5 | 1.75 | 23.5 | 53.0 | 87.5 |

| SFFAC | 185.5 | 2.15 | 24.0 | 55.0 | 65.6 |

4.2. Hardened Properties

4.2.1. Initial Surface Absorption

| Concrete Type | ISA Rate (×10−2 mL/m2/s) after | |||

|---|---|---|---|---|

| 10 min | 30 min | 60 min | 120 min | |

| NPCC | 30 | 21.9 | 16.4 | 12.2 |

| SFC | 25 | 13.2 | 8.7 | 4.3 |

| FAC | 29 | 20.6 | 13.8 | 8.6 |

| SFFAC | 24.3 | 15.5 | 11.0 | 6.9 |

4.2.2. Moisture Movement

| Concrete Type | Rate of Moisture Movement (×10−3 kg/day) after | ||||

|---|---|---|---|---|---|

| 3 Days | 7 Days | 14 Days | 28 Days | 91 Days | |

| NPCC | 7.8 | 5.4 | 3.7 | 2.6 | 0.5 |

| SFC | 3.0 | 2.0 | 1.2 | 0.3 | 0.2 |

| FAC | 6.7 | 3.8 | 2.1 | 1.3 | 0.4 |

| SFFAC | 4.5 | 2.4 | 1.9 | 1.1 | 0.3 |

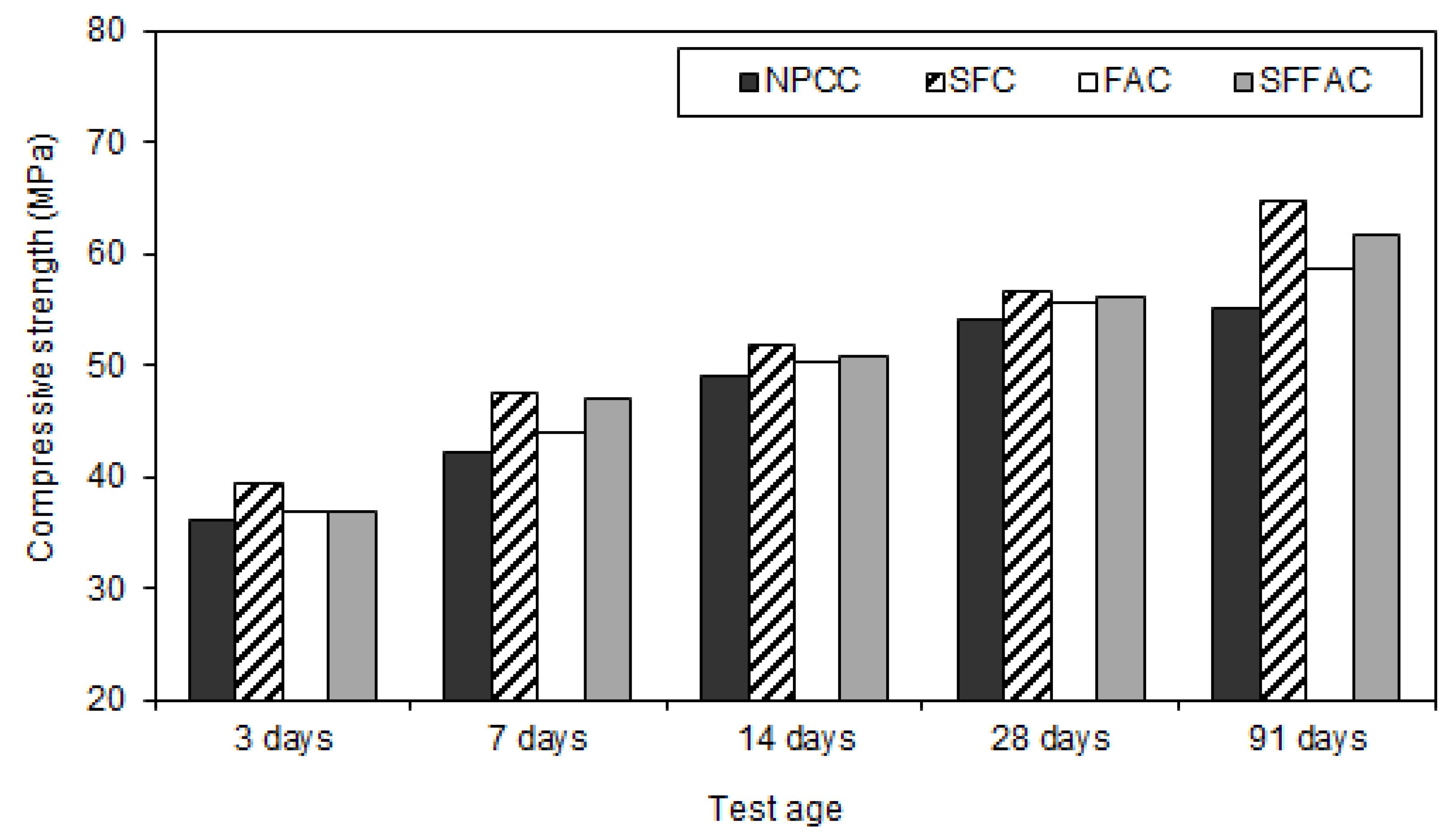

4.2.3. Compressive Strength

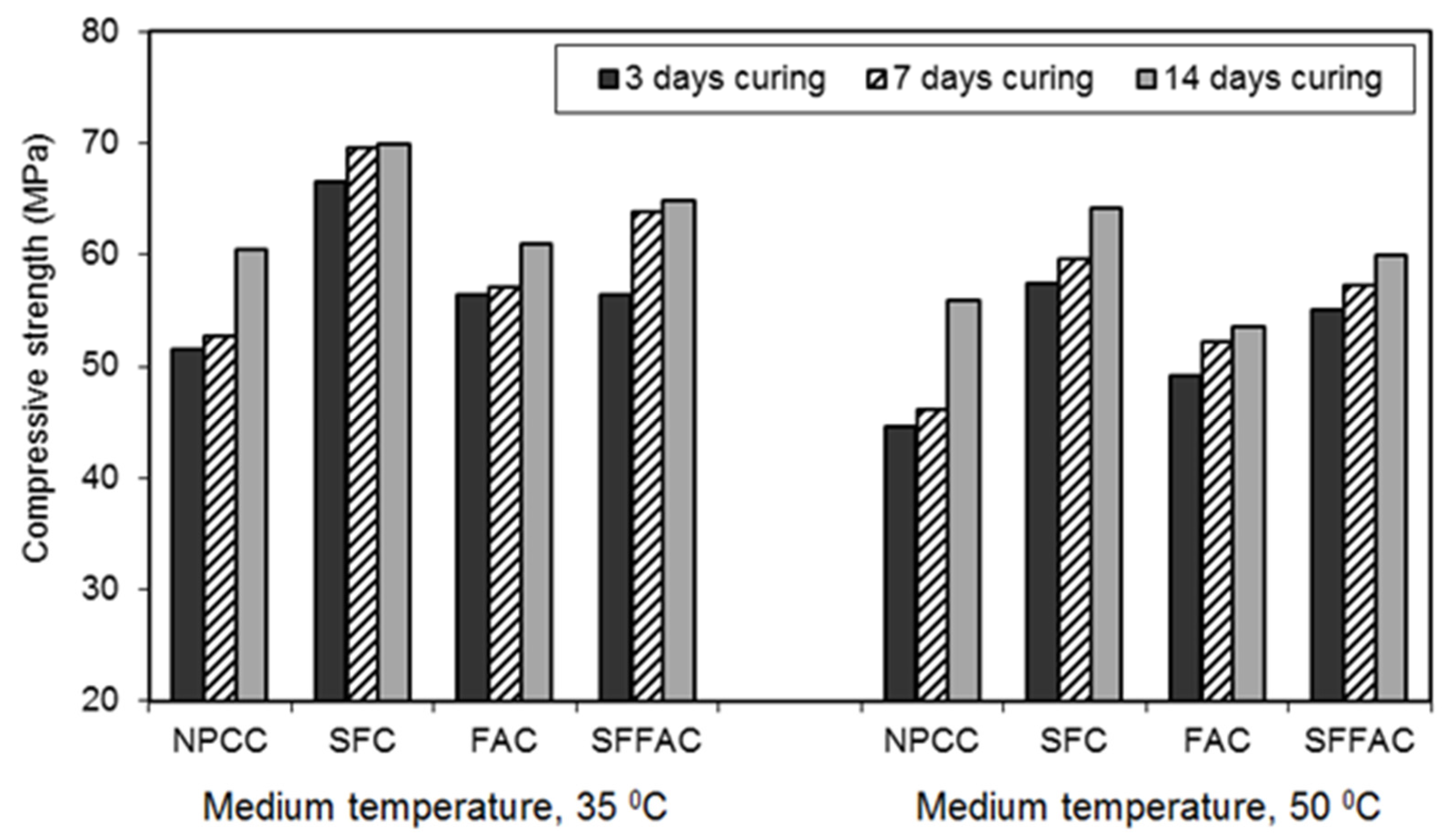

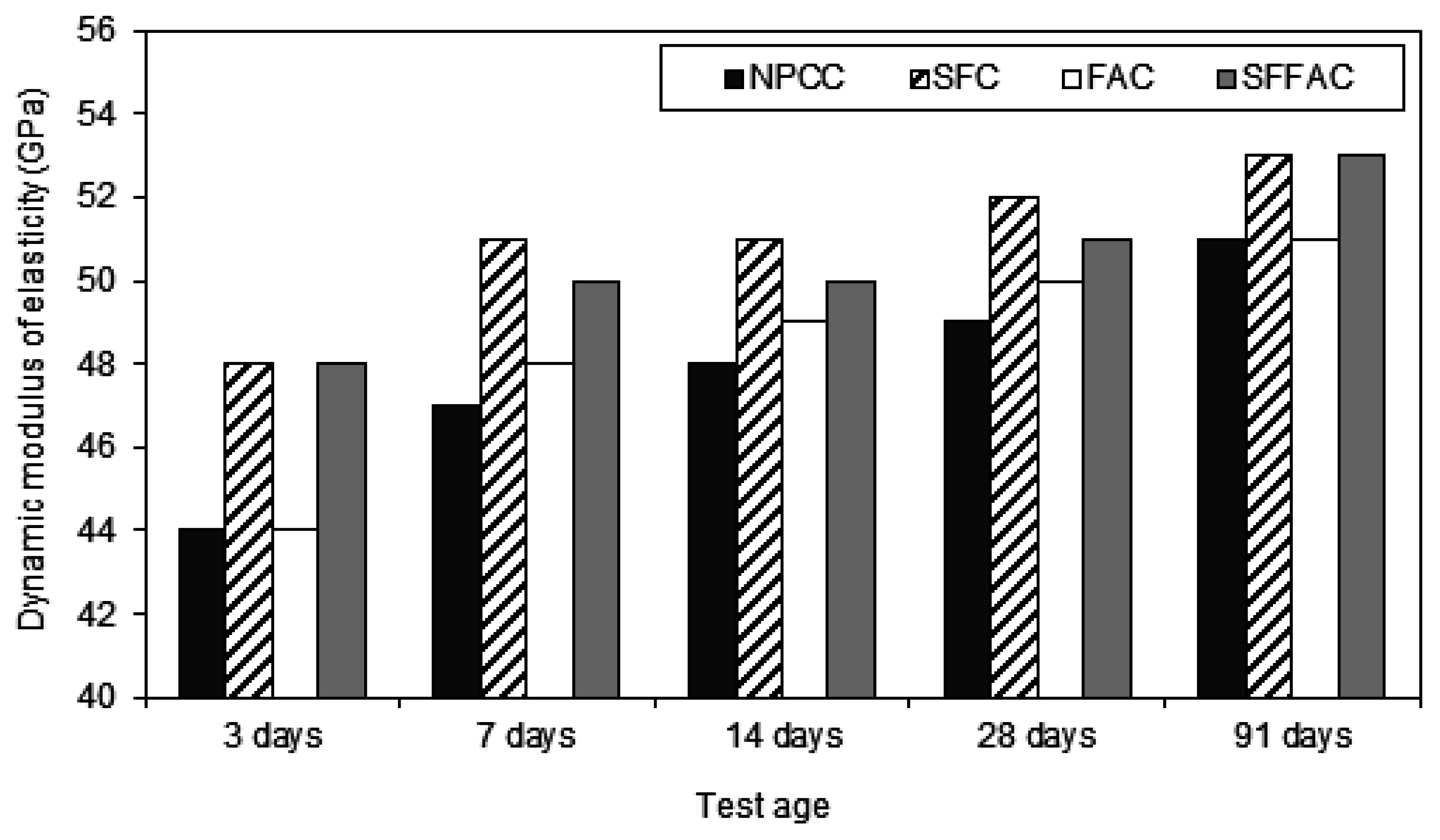

4.2.4. Dynamic Modulus of Elasticity

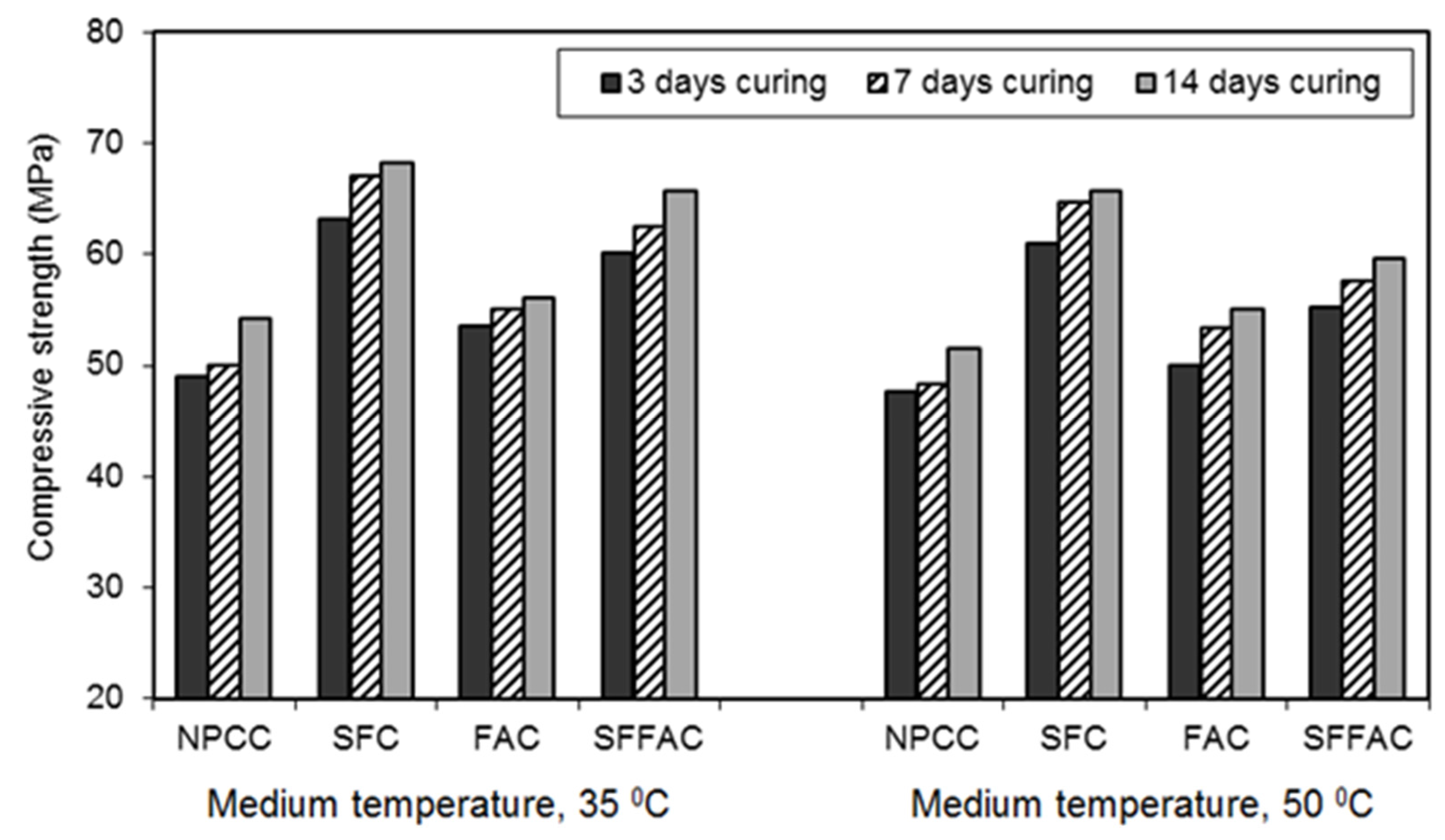

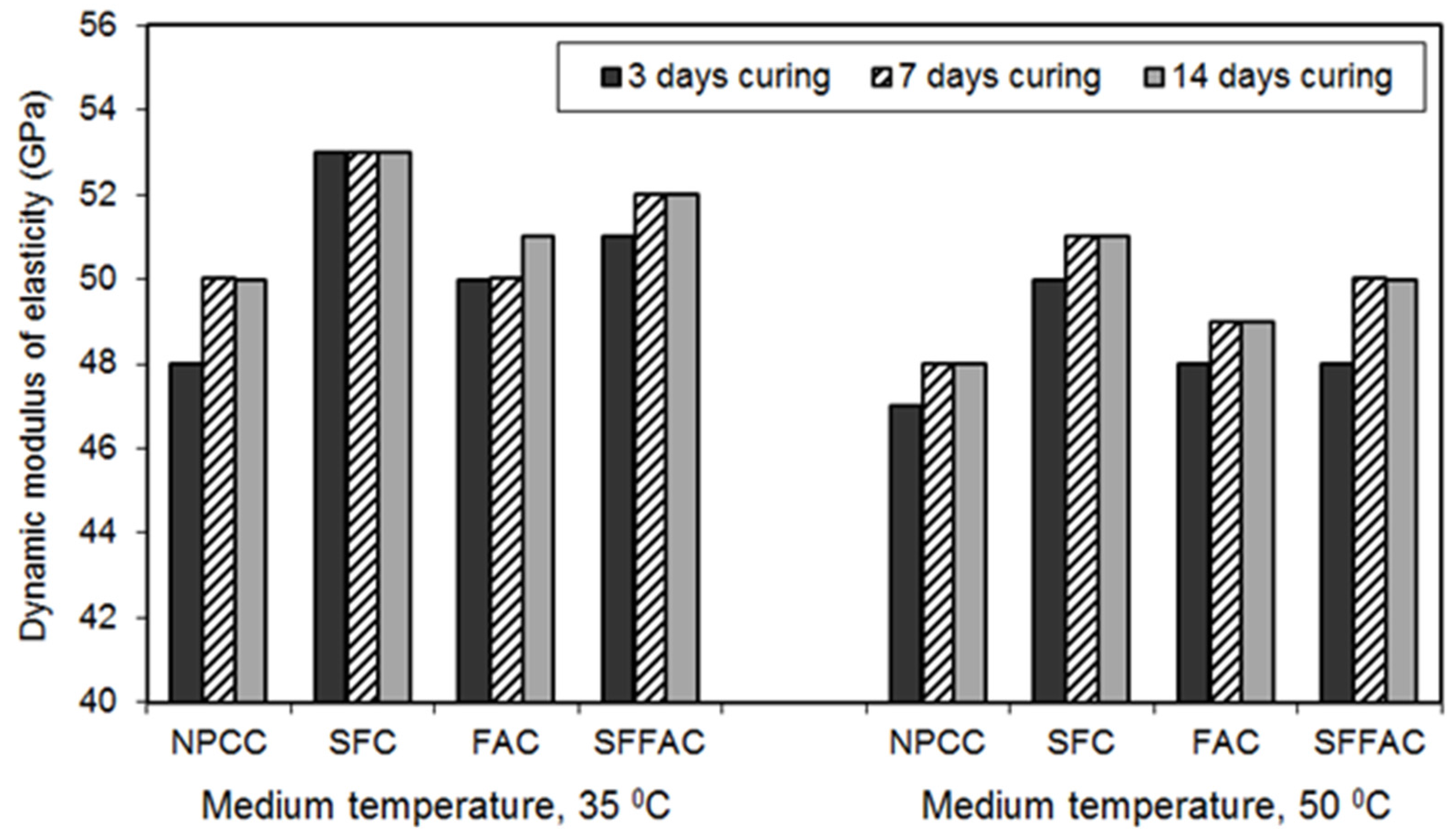

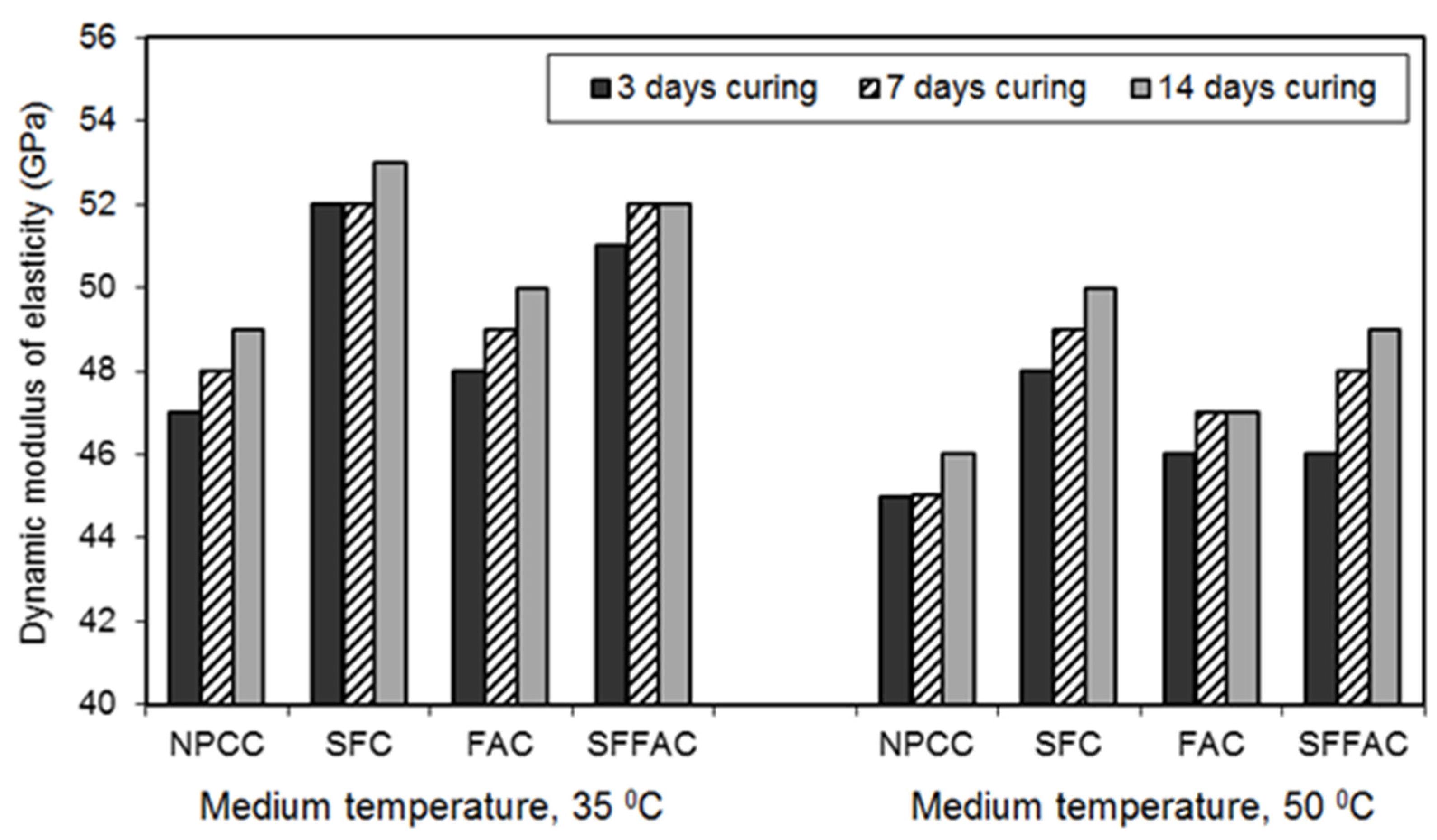

4.3. Effect of Medium Temperature on Hardened Properties

4.4. Effect of Supplementary Cementitious Materials on Hardened Properties

5. Conclusions

- The concrete mixes provided a slump, slump flow, and V-funnel flow as specified for HPC. The addition of silica fume required a higher dosage of SP than any other type of concrete to get the required flowability.

- The period of water curing was a critical factor to reduce the detrimental effect of concrete drying at medium temperature. Fourteen (14) days of water curing before exposure to the medium temperatures of 35 and 50 °C greatly improved the hardened properties of concrete. This is because more moisture was available for additional days to continue cement hydration, thus resulting in more hydration products that further improved the hardened properties of concrete.

- SCM concretes produced lower ISA and moisture movement rate than NPCC. Especially, SFC provided the lowest levels of ISA and moisture movement rate. These results were attributable to the physical (microfilling) and chemical (pozzolanic reaction) effects of silica fume that contribute to produce a refined pore structure and decrease the porosity of concrete.

- SCM concretes produced greater compressive strength and dynamic modulus of elasticity than NPCC. In particular, silica fume concrete provided the highest levels of compressive strength and dynamic modulus of elasticity when exposed to medium temperatures. This indicates that the accelerating pozzolanic reaction of SCM (particularly silica fume) at medium temperatures increases the strength and improves the quality of concrete.

- The compressive strength and dynamic modulus of elasticity of the concretes dried at 35 °C were higher than those of the concretes dried at 50 °C. This indicates that the compressive strength and dynamic modulus of elasticity of concrete decreased as the temperature increased. However, the effect of temperature rise was less detrimental in SCM concretes than NPCC.

- The concrete element exposed to a higher medium temperature should be well-cured to ensure high performance of concrete. The evaporation of water from concrete at an early age must be prevented to avoid the decrease in strength, modulus of elasticity, and other hardened properties of concrete. The suitable medium temperature environment associated with an adequate period of water curing (at least 7 days; preferably 14 days) plays an important role in the hydration process to produce the concrete with desired hardened properties.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Forster, S.W. High performance concrete—Stretching the paradigm. Concr. Int. 1994, 16, 33–34. [Google Scholar]

- Aitcin, P.-C. High Strength Concrete: Current Trends and Applications. In Proceedings of the Fifth International Conference on Concrete Engineering and Technology, Kuala Lumpur, Malaysia, 5–7 May 1997; University of Malaya: Kuala Lumpur, Malaysia, 1997; pp. 37–46. [Google Scholar]

- Nawy, E.G. Fundamentals of High Strength High Performance Concrete; Longman Group Limited: London, UK, 1996. [Google Scholar]

- Aitcin, P.-C. Developments in the application of high performance concrete. Constr. Build. Mater. 1995, 9, 13–17. [Google Scholar] [CrossRef]

- Russel, H. High Strength Concrete in North America. In Proceedings of the Symposium on Utilization of High Strength Concrete, Stavanger, Norway, 15–18 June 1987; pp. 561–572.

- Aitcin, P.-C.; Laplante, P.; Bedard, C. 90 MPa field concrete. In High Strength Concrete, ACI SP-87; American Concrete Institute: Detroit, MI, USA, 1987; pp. 52–70. [Google Scholar]

- Ryell, J.; Bickley, J.A. Scotia Plaza: High Strength Concrete for Tall Buildings. In Proceedings of the Symposium on Utilization of High Strength Concrete, Stavanger, Norway, 15–18 June 1987; pp. 641–653.

- NC News. New challenges. In Technical Documentation; Norwegian Contractors: Stabekk, Norway, 1984; Volume 2. [Google Scholar]

- Helland, S. High strength concrete used in high way pavements. In High Strength Concrete, ACI SP-121; American Concrete Institute: Detroit, MI, USA, 1990; pp. 757–766. [Google Scholar]

- Helland, S. Norwegian Experience with High Strength Concrete. In Proceedings of the International RILEM Workshop held at the University of Paisley, Paisley, Scotland, 2–3 March 1993; E & FN Spon: London, UK, 1993; pp. 131–144. [Google Scholar]

- Levy, C.; Boulicaut, J.-P. High performance concrete supplied by a network of ready mixed concrete plants. In High Performance Concrete: From Material to Structure; Malier, Y., Ed.; E & FN Spon: London, UK, 1992; pp. 63–84. [Google Scholar]

- Farve, R.; Charif, H.; Jaccoud, J.-P. Large reduction of deflections due to high performance concrete. In High Performance Concrete: From Material to Structure; Malier, Y., Ed.; E & FN Spon: London, UK, 1992; pp. 160–185. [Google Scholar]

- Okamura, H.; Ozawa, K. Self-Compactable High Performance Concrete in Japan. In Proceedings of the International Workshop on High Performance Concrete, Bangkok, Thailand, 21–22 November 1994; pp. 31–44.

- Papworth, F.; Ratcliffe, R. High performance concrete-the concrete future. Concr. Int. 1994, 16, 39–44. [Google Scholar]

- Ait-Aider, H.; Hannachi, N.E.; Mouret, M. Importance of W/C ratio on compressive strength of concrete in hot climate conditions. Build. Environ. 2007, 47, 2461–2465. [Google Scholar] [CrossRef]

- Al-Gahtani, A.S. Effect of curing methods on the properties of plain and blended cement concretes. Constr. Build. Mater. 2010, 24, 308–314. [Google Scholar] [CrossRef]

- El-Chabib, H.; Ibrahim, A. The performance of high-strength flowable concrete made with binary, ternary, or quaternary binder in hot climate. Constr. Build. Mater. 2013, 47, 245–253. [Google Scholar] [CrossRef]

- Ibrahim, M.; Shameem, M.; Al-Mehthel, M.; Maslehuddin, M. Effect of curing methods on strength and durability of concrete under hot weather conditions. Cem. Concr. Compos. 2013, 41, 60–69. [Google Scholar] [CrossRef]

- Nassif, A.Y.; Petrou, M.F. Influence of cold weather during casting and curing on the stiffness and strength of concrete. Constr. Build. Mater. 2013, 44, 161–167. [Google Scholar] [CrossRef]

- Nie, Q.; Zhou, C.; Shu, X.; He, Q.; Huang, B. Chemical, mechanical and durability properties of concrete with local mineral admixtures under sulfate environment in Northwest China. Materials 2014, 7, 3772–3785. [Google Scholar] [CrossRef]

- Calado, C.; Camoes, C.; Monteiro, E.; Helena, P.; Barkokebas, B., Jr. Durability indicators comparison for SCC and CC in tropical coastal environments. Materials 2015, 8, 1458–1481. [Google Scholar] [CrossRef] [Green Version]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Xotta, G.; Mazzucco, G.; Salomoni, V.A.; Majorana, C.E.; Willam, K.J. Composite behavior of concrete materials under high temperatures. Int. J. Solids Struct. 2015, 64–65, 86–99. [Google Scholar] [CrossRef]

- Nilsson, L.O. Hygroscopic moisture in concrete—Drying, measurement and related material properties. In Technical Report TVBM 1003; Lund Institute of Technology: Lund, Sweden, 1980. [Google Scholar]

- Tan, K.; Gjorv, O.E. Performance of concrete under different curing conditions. Cem. Concr. Res. 1996, 26, 355–361. [Google Scholar] [CrossRef]

- ASTM C33/C33M-13 Standard Specification for Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM C150/C150M-15 Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C618-12a Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C494/C494M-13 Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2013.

- BS EN 1008 Mixing Water for Concrete; British Standards Institution: London, UK, 2002.

- Aitcin, P.-C. Sherbrook Mix Design Method. In Proceedings of the One-Day Short Course on Concrete Technology/High Performance Concrete: Properties and Durability, Kuala Lumpur, Malaysia, 9 May 1997; University of Malaya: Kuala Lumpur, Malaysia, 1997. [Google Scholar]

- Lessard, M.; Baalbaki, M.; Aitcin, P.-C. Mix design of air entrained high performance concrete. In Concrete under Severe Conditions: Environment and Loading; E & FN Spon: London, UK, 1995; Volume 2, pp. 1025–1034. [Google Scholar]

- ACI Committee 363 Report. In High Strength Concrete; American Concrete Institute: Farmington Hills, MI, USA, 1988.

- De Larrard, F.; Malier, Y. Engineering properties of very high performance concretes. In High Performance Concrete: From Material to Structure; Malier, Y., Ed.; E & FN Spon: London, UK, 1992; pp. 85–114. [Google Scholar]

- BS 1881 Part 125. 2013 Methods for Mixing and Sampling Fresh Concrete in the Laboratory; British Standards Institution: London, UK, 2013.

- ASTM C143/C143M-12 Standard Test Method for Slump of Hydraulic Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2012.

- JIS R 5201 V-Funnel Test for Freshly Mixed Concrete; Japanese Industrial Standards: Tokyo, Japan, 1993.

- BS EN 12390-1 Making and Curing Specimens for Strength Tests; British Standards Institution: London, UK, 2012.

- ASTM C39/C39M-14a Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2014.

- BS 1881: Part 209 Recommendations for the Measurement of Dynamic Modulus of Elasticity; British Standards Institution: London, UK, 1990.

- BS 1881: Part 208 Recommendations for the Determination of the Initial Surface Absorption of Concrete; British Standards Institution: London, UK, 1996.

- Safiuddin, Md.; Raman, S.N.; Zain, M.F.M. Effect of different curing methods on the properties of microsilica concrete. Aust. J. Basic Appl. Sci. 2007, 1, 87–95. [Google Scholar]

- Detwiler, R.I.; Mehta, P.K. Chemical and physical effects of silica fume on the mechanical behavior of concrete. ACI Mater. J. 1989, 86, 609–614. [Google Scholar]

- Siddique, R. Utilization of silica fume in concrete: Review of hardened properties. Resour. Conserv. Recycl. 2011, 55, 923–932. [Google Scholar] [CrossRef]

- Nasser, K.W.; Lohtia, R.P. Mass concrete properties at high temperatures. ACI J. Proc. 1971, 68, 180–186. [Google Scholar]

- Fauzi, M.; Matsufuji, Y. The Influence of Curing Methods on the Physical Properties of High Strength Concrete Exposed to Medium Temperature (20 °C–50 °C). In Proceedings of the Fifth International Conference on Concrete Engineering and Technology, Kuala Lumpur, Malaysia, 5–7 May 1997; University of Malaya: Kuala Lumpur, Malaysia, 1997; pp. 57–66. [Google Scholar]

- Lydon, F.D.; Iacovou, M. Some factors affecting the dynamic modulus of elasticity of high strength concrete. Cem. Concr. Res. 1995, 25, 1246–1256. [Google Scholar] [CrossRef]

- Maltais, Y.; Marchand, J. Influence of curing temperature on cement hydration and mechanical strength development of fly ash mortars. Cem. Concr. Res. 1997, 27, 1009–1020. [Google Scholar] [CrossRef]

- Ellis, W.E. For durable concrete, fly ash does not replace cement. In Durable Concrete, ACI Compilation 24; American Concrete Institute: Farmington Hills, MI, USA, 1992; pp. 24–38. [Google Scholar]

- Fauzi, M. The Study on the Physical Properties of Surface Layer Concrete under the Influence of Medium Temperature Environments. Ph.D. Thesis, Kyushu University, Fukuoka, Japan, 1995. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Safiuddin, M.; Raman, S.N.; Zain, M.F.M. Effects of Medium Temperature and Industrial By-Products on the Key Hardened Properties of High Performance Concrete. Materials 2015, 8, 8608-8623. https://doi.org/10.3390/ma8125464

Safiuddin M, Raman SN, Zain MFM. Effects of Medium Temperature and Industrial By-Products on the Key Hardened Properties of High Performance Concrete. Materials. 2015; 8(12):8608-8623. https://doi.org/10.3390/ma8125464

Chicago/Turabian StyleSafiuddin, Md., Sudharshan N. Raman, and Muhammad Fauzi Mohd. Zain. 2015. "Effects of Medium Temperature and Industrial By-Products on the Key Hardened Properties of High Performance Concrete" Materials 8, no. 12: 8608-8623. https://doi.org/10.3390/ma8125464