High Purity and Yield of Boron Nitride Nanotubes Using Amorphous Boron and a Nozzle-Type Reactor

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

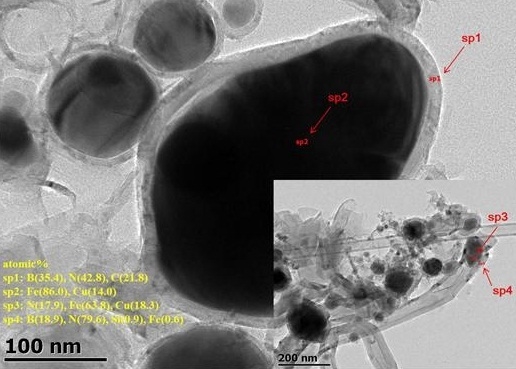

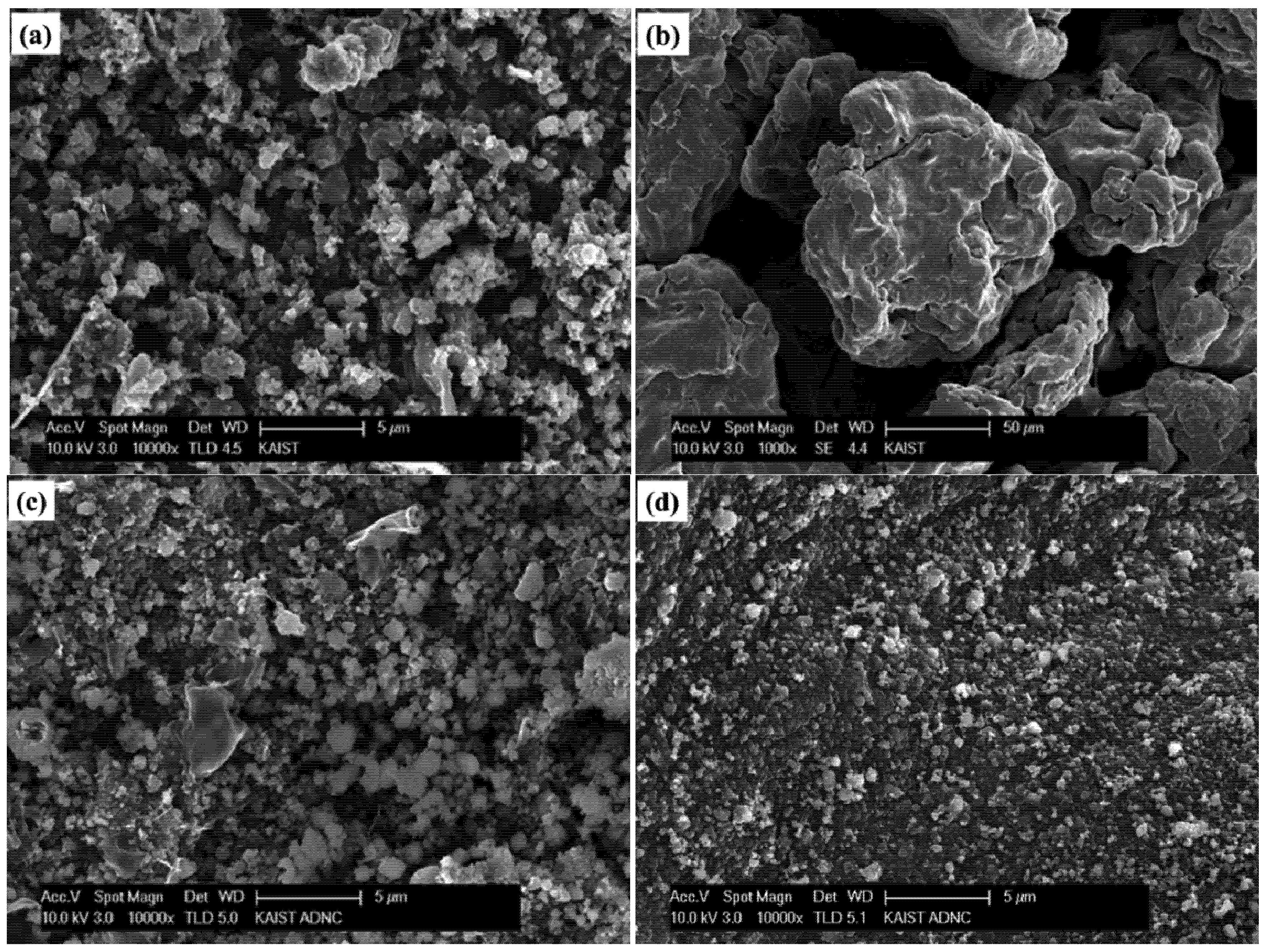

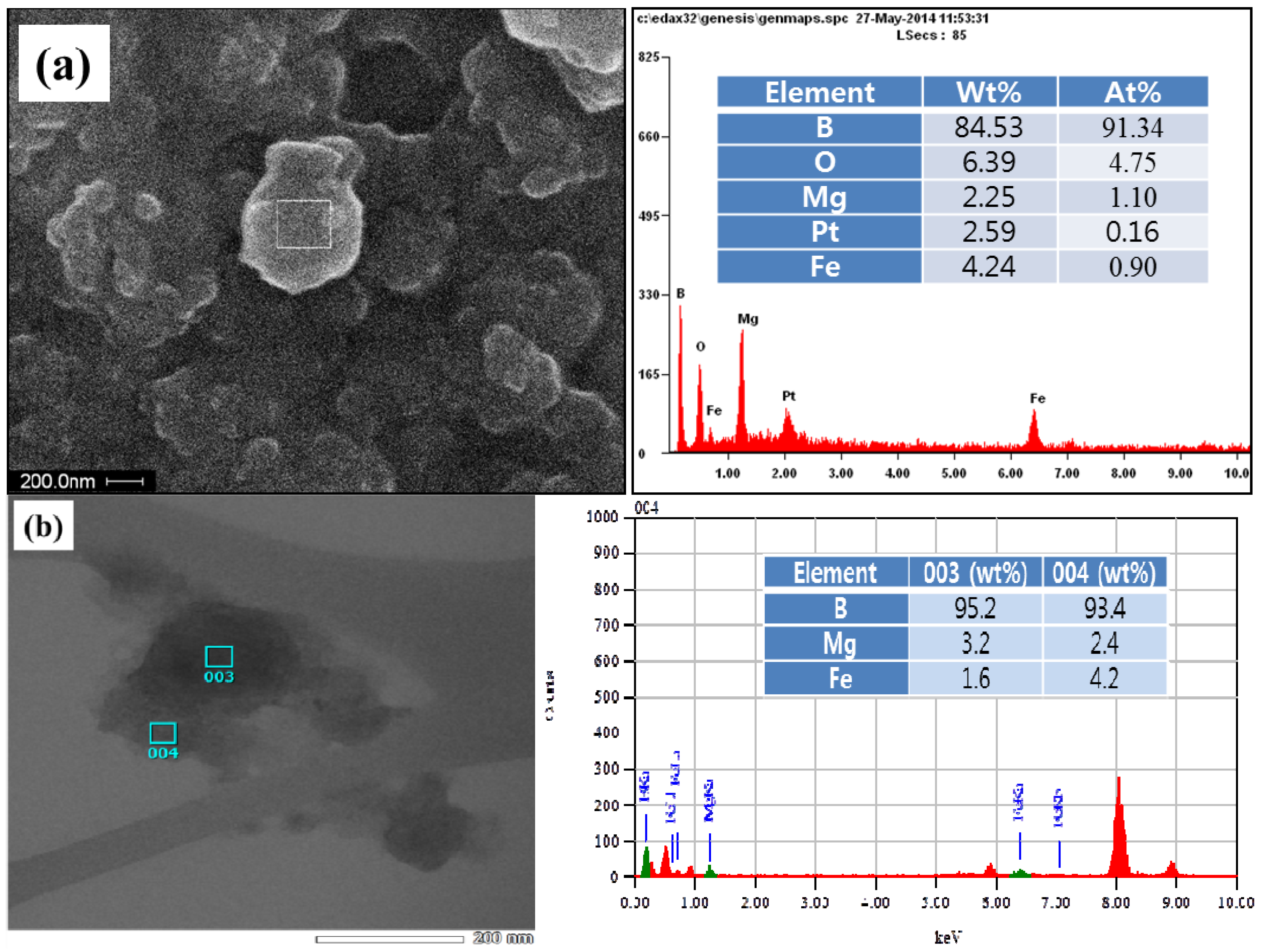

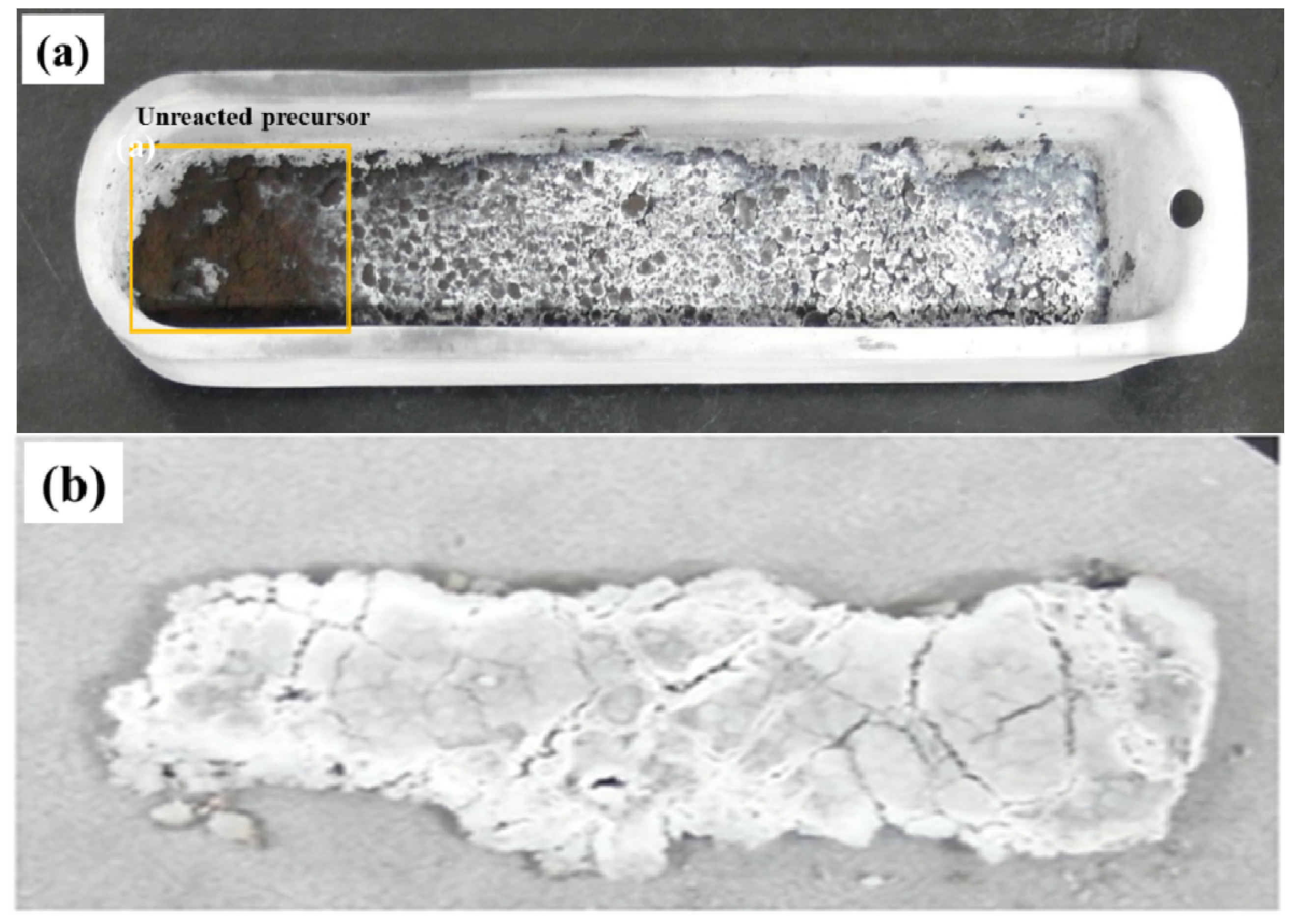

3.1. Preparation of the Precursor for Boron Nitride Nanotubes Synthesis

3.2. Characteristics of Synthesized Boron Nitride Nanotubes

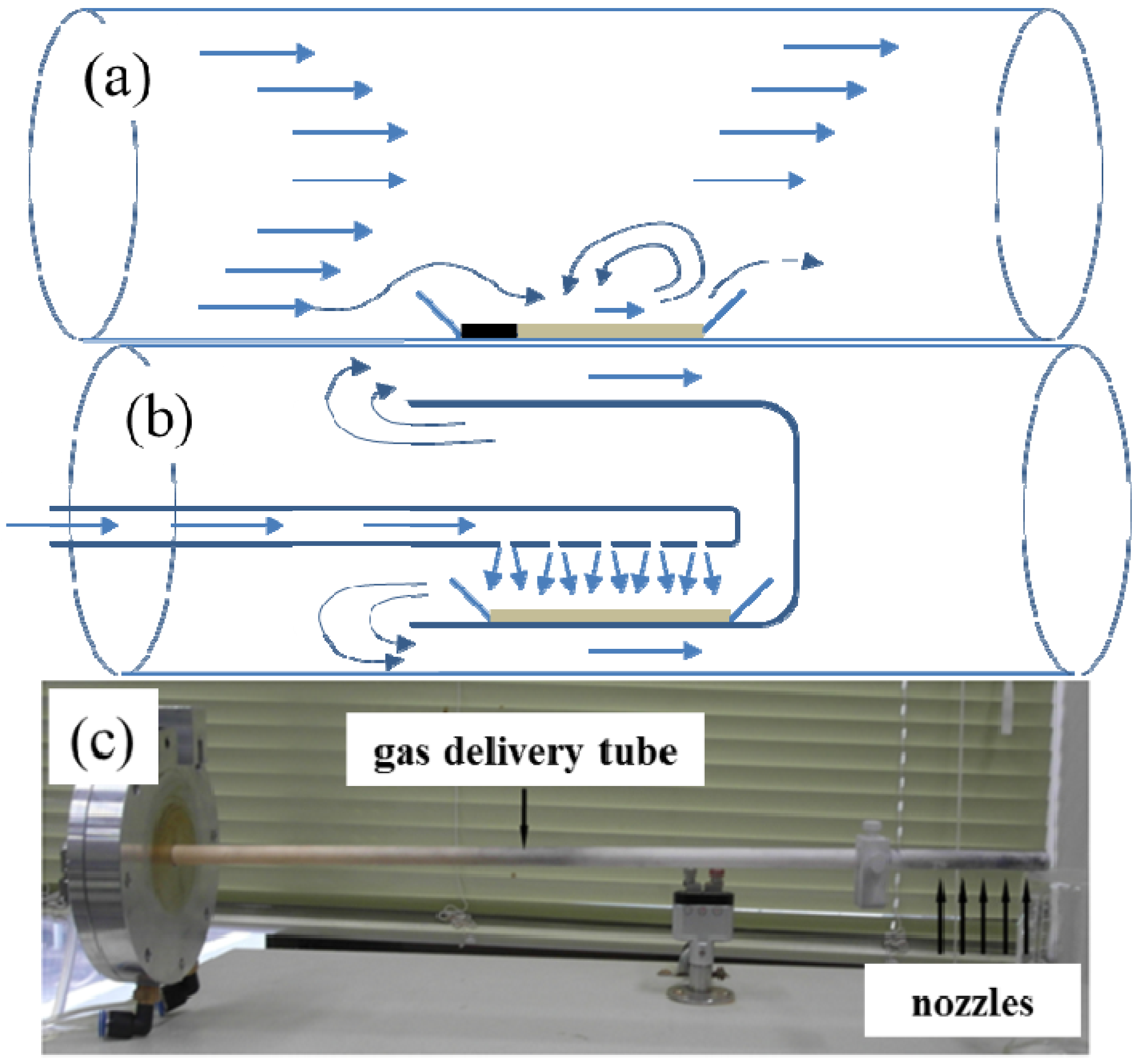

3.2.1. Chemical Reaction Dependent on the Gas Flow Scheme

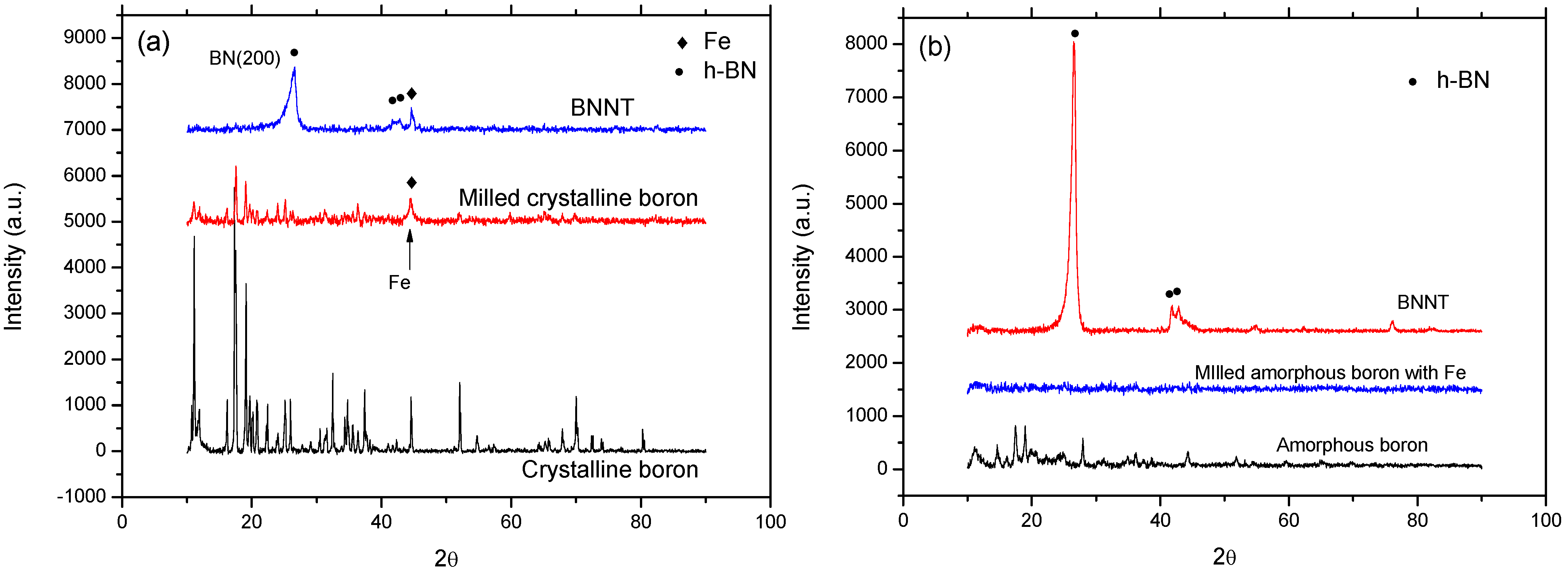

3.2.2. X-ray Diffraction of Annealed Samples

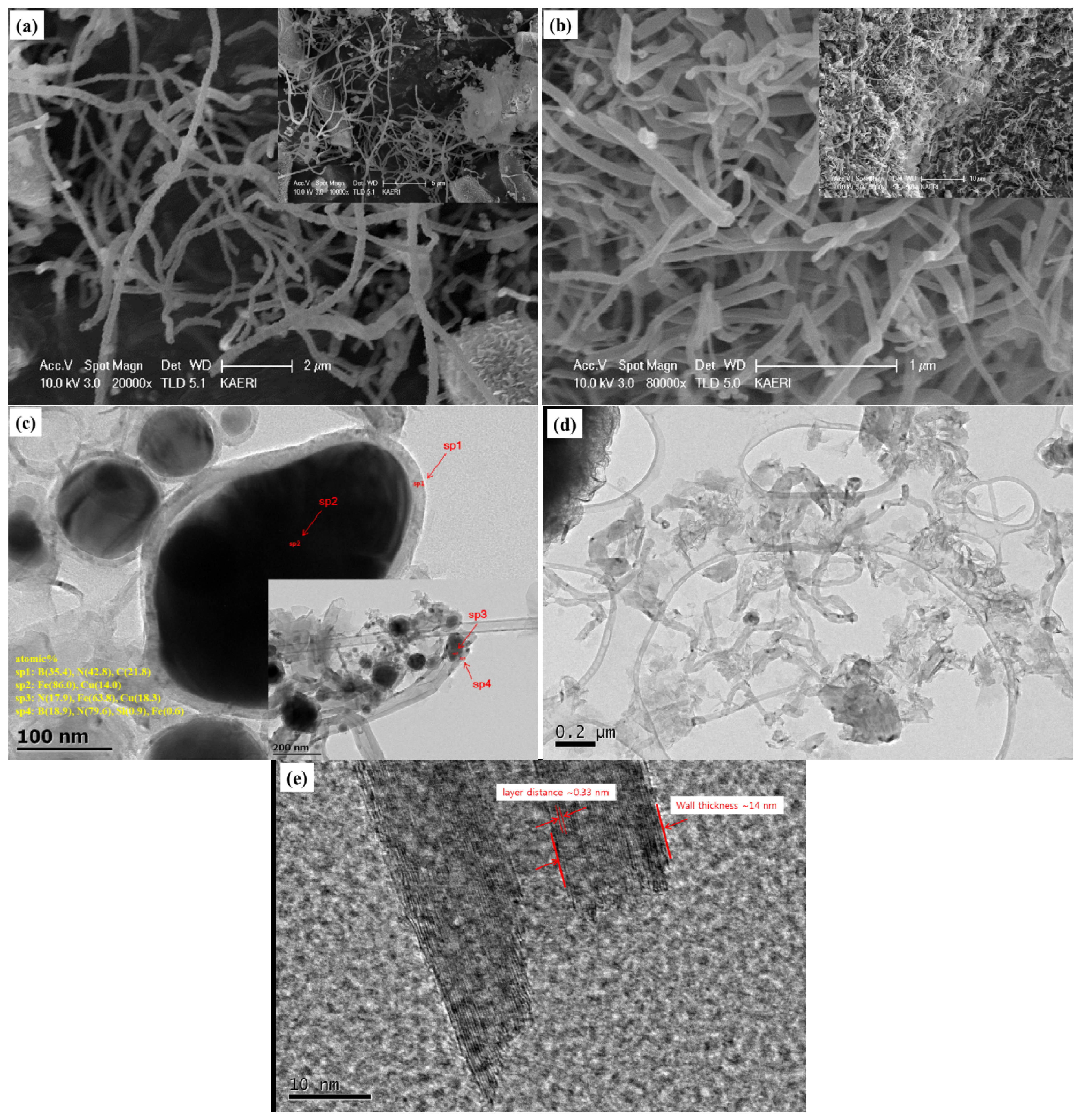

3.2.3. Morphology of Annealed Samples

3.3. Production Yields of Boron Nitride Nanotubes

| Sample No. | Precursor type | Milling condition | Annealing condition | Reactor type |

|---|---|---|---|---|

| 1 | Crystalline boron based | 600 rpm, 12 h | 1200 °C, 6 h | Conventional flow-through reactor |

| 2 | Amorphous boron based | |||

| 3 | Nozzle-type reactor |

| Sample No. | Initial weight of precursor (g) | Weight increase after annealing (g) | BET (m2/g) | Estimated BNNTs quantity (g) | Estimated yields of BNNTs (%) |

|---|---|---|---|---|---|

| 1 | 1.0 | 0.44 | 21.5 | 0.78 | 54.1 |

| 2 | 1.0 | 0.55 | 40.5 | 0.97 | 62.6 |

| 3 | 1.0 | 0.65 | 54.6 | 1.15 | 69.7 |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhi, C.; Bando, Y.; Terao, T.; Tang, C.; Kuwahara, H.; Golberg, D. Towards thermoconductive, electrically insulating polymer composites with boron nitride nanotubes as fillers. Adv. Funct. Mater 2009, 19, 1857–1862. [Google Scholar]

- Terao, T.; Zhi, C.; Bando, Y.; Mitome, M.; Tang, C.; Golberg, D. Alignment of boron nitride nanotubes in polymeric composite films for thermal conductivity improvement. J. Phys. Chem. C 2010, 114, 4340–4344. [Google Scholar]

- Su, J.; Xiao, Y.; Ren, M. Enhanced thermal conductivity in epoxy nanocomposites with hybrid boron nitride nanotubes and nanosheets. Phys. Status Solidi A 2013, 210, 2699–2705. [Google Scholar]

- Huang, Q.; Bando, Y.; Xu, X.; Nishimura, T.; Zhi, C.; Tang, C.; Xu, F.; Gao, L.; Golberg, D. Enhancing superplasticity of engineering ceramics by introducing BN nanotubes. Nanotechnology 2007, 18. [Google Scholar] [CrossRef]

- Zhi, C.Y.; Bando, Y.; Tang, C.C.; Huang, Q.; Golberg, D. Boron nitride nanotubes: Functionalization and composites. J. Mater. Chem 2008, 18, 3900–3908. [Google Scholar]

- Yue, C.; Liu, W.; Zhang, L.; Zhang, T.; Chen, Y. fracture toughness and toughening mechanisms in a (ZrB2–SiC) composite reinforced with boron nitride nanotubes and boron nitride nanoplates. Scr. Mater 2013, 68, 579–582. [Google Scholar] [CrossRef]

- Lahiri, D.; Hadjikhani, A.; Zheng, C.; Xing, T.; Li, L.H.; Chen, Y.; Agarwal, A. Boron nitride nanotubes reinforced aluminum composites prepared by spark plasma sintering: Microstructure, mechanical properties and deformation behavior. Mater. Sci. Eng. A 2013, 574, 149–156. [Google Scholar]

- Farmanzadeh, D.; Ghazanfary, S. DFT studies of functionalized zigzag and armchair boron nitride nanotubes as nanovectors for drug delivery of collagen amino acids. Struct. Chem 2014, 25, 293–300. [Google Scholar]

- Li, X.; Zhi, C.; Hanagata, N.; Yamaguchi, M.; Bando, Y.; Golberg, D. Boron nitride nanotubes functionalized with mesoporous silica for intracellular delivery of chemotherapy drugs. Chem. Commun 2013, 49, 7337–7339. [Google Scholar]

- Ciofani, G.; Raffa, V.; Menciassi, A.; Cuschieri, A. Folate functionalized boron nitride nanotubes and their selective uptake by giloblastoma multiform cells: Implications for their use as boron carriers in clinical boron neutron capture therapy. Nanoscale Res. Lett 2009, 4, 113–121. [Google Scholar]

- Mpourmpakis, G.; Froudakis, G.E. Why boron nitride nanotubes are preferable to carbon nanotubes for hydrogen storage?: An ab initio theoretical study. Catal. Today 2007, 120, 341–345. [Google Scholar] [CrossRef]

- Leela Mohana Reddy, A.; Tanur, A.E.; Walker, G.C. Synthesis and hydrogen storage properties of different types of boron nitride nanotubes. Int. J. Hydrog. Energy 2010, 35, 4138–4143. [Google Scholar]

- Saner Okan, B.; Kocabaş, Z.O.; Nalbant Ergün, A.; Baysal, M.; Letofsky-Papst, I.; Yürüm, Y. Effect of reaction temperature and catalyst type on the formation of boron nitride nanotubes by chemical vapor deposition and measurement of their hydrogen storage capacity. Ind. Eng. Chem. Res 2012, 51, 11341–11347. [Google Scholar]

- Li, L.H.; Chen, Y.; Lin, M.-Y.; Glushenkov, A.M.; Cheng, B.-M.; Yu, J. Single deep ultraviolet light emission from boron nitride nanotubes film. Appl. Phys. Lett 2010, 97. [Google Scholar] [CrossRef]

- Li, L.H.; Chen, Y. Superhydrophobic properties of nonaligned boron nitride nanotubes films. Langmuir 2010, 26, 5135–5140. [Google Scholar]

- Yu, J.; Chen, Y.; Elliman, R.G.; Petravic, M. Isotopically enriched 10BN nanotubes. Adv. Mater 2006, 18, 2157–2160. [Google Scholar]

- Estevez, J.E.; Ghazizadeh, M.; Ryan, J.G.; Kelkar, A.D. Simulation of hydrogenated boron nitride nanotube’s mechanical properties for radiation shielding applications. Int. J. Chem. Sci. Eng 2014, 8, 63–67. [Google Scholar]

- Chen, H.; Chen, Y.; Yu, J.; Williams, J.S. Purification of boron nitride nanotubes. Chem. Phys. Lett 2006, 425, 315–319. [Google Scholar]

- Choi, J.H.; Kim, J.; Seo, D.; Seo, Y.S. Purification of boron nitride nanotubes via polymer wrapping. Mater. Res. Bull 2013, 48, 1197–1203. [Google Scholar]

- Chen, Y.; Fitz Gerald, J.; Williams, J.S.; Bulcock, S. Synthesis of boron nitride nanotubes at low temperature using reactive ball milling. Chem. Phys. Lett 1999, 299, 260–264. [Google Scholar]

- Li, Y.; Zhou, J.E.; Zhao, K.; Tung, S.; Schneider, E. Synthesis of boron nitride nanotubes from boron oxide by ball milling and annealing process. Mater. Lett 2009, 63, 1733–1736. [Google Scholar]

- Kim, J.; Lee, S.; Uhm, Y.R.; Jun, J.; Rhee, C.K.; Kim, G.M. Synthesis and growth of boron nitride nanotubes by a ball milling-annealing process. Acta Mater 2011, 59, 2807–2813. [Google Scholar]

- Chopra, N.G.; Luyken, R.J.; Cherry, K.; Crespi, V.H.; Cohen, M.L.; Louie, S.G.; Zettle, A. Boron nitride nanotubes. Science 1995, 269, 966–967. [Google Scholar]

- Lee, C.M.; Choi, S.I.; Choi, S.S.; Hong, S.H. Synthesis of boron nitride nanotubes by arc-jet plasma. Curr. Appl. Phys 2006, 6, 166–170. [Google Scholar]

- Tang, C.; Bando, Y.; Sato, T.; Kurashima, K. A novel precursor for synthesis of pure boron nitride nanotubes. Chem. Commun 2002, 12, 1290–1291. [Google Scholar]

- Lee, C.H.; Wang, J.; Kayatsha, V.K.; Huang, J.Y.; Yap, Y.K. Effective growth of boron nitride nanotubes by thermal chemical vapor deposition. Nanotechnolgy 2008, 19. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Yin, Y.; Chen, Y.; Bi, X. Water-assisted chemical vapor deposition synthesis of boron nitride nanotubes and their photoluminescence property. Nanotechnology 2013, 24. [Google Scholar] [CrossRef]

- Enouz, S.; Stéphan, O.; Cochon, J.-L.; Collies, C.; Loiseau, A. C-BN patterned single-walled nanotubes synthesized by laser vaporization. Nano Lett 2007, 7, 1856–1862. [Google Scholar]

- Smith, M.W.; Jordan, K.C.; Park, C.; Kim, J.-W.; Lillehei, P.T.; Crooks, R.; Harrison, J.S. Very long single- and few-walled boron nitride nanotubes via the pressurized vapor/condenser method. Nanotechnology 2009, 20. [Google Scholar] [CrossRef]

- Wen, G.; Zhang, T.; Huang, X.X.; Zhong, B.; Zhang, X.D.; Yu, H.M. Synthesis of bulk quantity BN nanotubes with uniform morphology. Scr. Mater 2010, 62, 25–28. [Google Scholar]

- Bi, X.; Yin, Y.; Li, J.; Chen, Y.; Li, J.; Su, Q. A co-precipitation and annealing route to the large-quantity synthesis of boron nitride nanotubes. Solid State Sci 2010, 25, 39–44. [Google Scholar]

- Li, L.; Li, L.H.; Chen, Y.; Dai, X.J.; Xing, T.; Petravic, M.; Liu, X. Mechanically activated catalyst mixing for high-yield boron nitride nanotube growth. Nanoscale Res. Lett 2012, 7. [Google Scholar] [CrossRef]

- Li, L.H.; Chen, Y.; Glushenkov, A.M. Boron nitride nanotube film grown from boron ink painting. J. Mater. Chem 2010, 20, 9679–9683. [Google Scholar]

- Kim, J.; Lee, S.; Seo, D.; Seo, Y.S. Synthesis of multiwalled boron nitride nanotubes dependent on crystallographic structure of boron. Mater. Chem. Phys. 2012, 137, 182–187. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Kim, J.; Seo, D.; Yoo, J.; Jeong, W.; Seo, Y.-S.; Kim, J. High Purity and Yield of Boron Nitride Nanotubes Using Amorphous Boron and a Nozzle-Type Reactor. Materials 2014, 7, 5789-5801. https://doi.org/10.3390/ma7085789

Kim J, Seo D, Yoo J, Jeong W, Seo Y-S, Kim J. High Purity and Yield of Boron Nitride Nanotubes Using Amorphous Boron and a Nozzle-Type Reactor. Materials. 2014; 7(8):5789-5801. https://doi.org/10.3390/ma7085789

Chicago/Turabian StyleKim, Jaewoo, Duckbong Seo, Jeseung Yoo, Wanseop Jeong, Young-Soo Seo, and Jaeyong Kim. 2014. "High Purity and Yield of Boron Nitride Nanotubes Using Amorphous Boron and a Nozzle-Type Reactor" Materials 7, no. 8: 5789-5801. https://doi.org/10.3390/ma7085789

APA StyleKim, J., Seo, D., Yoo, J., Jeong, W., Seo, Y.-S., & Kim, J. (2014). High Purity and Yield of Boron Nitride Nanotubes Using Amorphous Boron and a Nozzle-Type Reactor. Materials, 7(8), 5789-5801. https://doi.org/10.3390/ma7085789