1. Introduction

With the rapid increase in the number of motor vehicles worldwide and the associated environmental impact, automobile lightweighting has become an urgent global initiative. As a candidate material class to reduce weight without sacrificing passenger safety, TRIP (Transformation-induced-plasticity)-aided steels have received much attention in recent years due to their outstanding combination of strength and ductility. The excellent performances of this class of steels are closely related to both the multiphase character of their microstructure and the TRIP effect,

i.e., the martensitic transformation of the austenite induced by deformation [

1]. Good ductility results from ductile and soft ferrite and retained austenite (RA), while high strength originates from the martensite induced by martensite transformation from RA [

1,

2,

3]. Martensite transformation leads to an increase of strain hardenability because the mechanical properties difference between retained austenite and martensite results in increasing strain from the shear and dilatation associated with transformation [

4]. The TRIP effect can significantly improve the formability and energy absorption of the material. During intercritical annealing, ferrite inversely transforms into austenite phase, which converts to martensite at the stage of subsequent quenching. The amount and stability of RA at room temperature are closely associated with the intercritical annealing (IA) temperature [

5,

6,

7]. The stability of the austenite at room temperature is mainly controlled by carbon enrichment as a result of the specific heat treatment conditions and parameters. For example, Jacques

et al. focused their investigations on the influence of isothermal bainite holding temperature on the retained austenite volume fraction, carbon content and the overall mechanical properties of the TRIP-assisted steels [

8,

9]. In order to obtain a microstructure with a specific amount and stability of RA, quenching and partitioning (Q&P) treatments [

3,

8] have proven effective in producing high-strength steels with a mixed microstructure of tempered martensite and retained austenite [

3,

8]. The typical Q&P process consists of a first quench (from either full or partial austenization) to a temperature between the martensite start and martensite finish temperature, and a subsequent isothermal treatment at the same or higher temperature to promote the partitioning of carbon from the supersaturated martensite to the retained austenite.

On the other hand, excellent combinations of strength and ductility have been extensively achieved in metals and alloys by engineered microstructure features, including bimodal grain size distribution [

10], nanoscale twin [

11,

12,

13], and dispersed distribution of nanoparticles [

14]. Most of the existing investigations on TRIP steels mainly focus on improving the mechanical properties by adjusting the volume fraction ratio of ferrite to austenite, which can be achieved by controlling chemical compositions and/or heat treatment processes [

15,

16,

17,

18]. Only a handful of works have noted that excellent mechanical properties of TRIP steels can be obtained by controlling the morphology of austenite [

19,

20]. In the current work, we demonstrate that excellent combination of strength and ductility of a medium Mn TRIP steel can be achieved by controlling the volume fraction and the morphology of austenite through hot rolling followed with warm rolling (without the annealing process), replacing the traditional three-stage processes including hot rolling, cold rolling, and annealing.

2. Experimental Methods

2.1. Sample Preparation

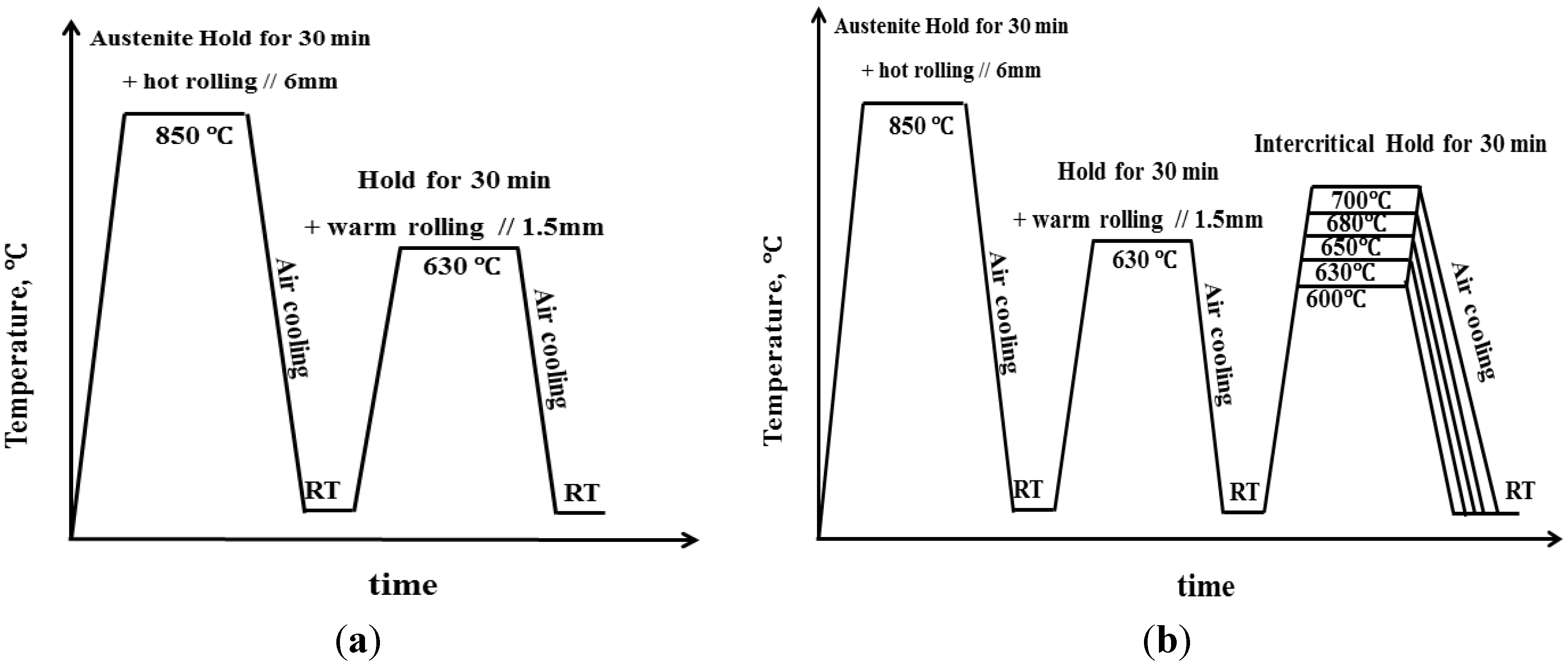

The alloy was melted in a vacuum induction furnace, and an ingot (300 × 200 × 20 mm

3) was cast. The alloy’s chemical composition, measured by inductively coupled plasma mass spectroscopy, is listed in

Table 1. A plate was cut from the ingot, homogenized in an air furnace at 1250 °C for 1 h to remove any inhomogeneous microstructures evolved during solidification. Subsequently, the plate was heated to 900 °C and held at that temperature for 30 min for full austenization. To obtain a warm-rolled steel, hot rolling was conducted at 850 °C in six passes with a reduction of ~12% each pass to a thickness of 6 mm (ε = 70%). After each pass, necessary reheating was performed to ensure the plate soaked at 850 ± 5 °C for 5min before the next pass. After six passes, the plate was cooled to room temperature in air. The obtained plate was then heated up and kept at 630 °C for 10 min before it was warm-rolled to a thickness of 1.5 mm in seven passes (ε = 75%). Again, after each pass, necessary reheating was performed to ensure the plate soaked at 630 ± 3 °C for 5 min before the next pass. After seven passes, the plate was cooled to room temperature in air (

Figure 1a). Next, to investigate the effect of intercritical annealing, the plate was divided into five equal parts and annealed at 600 °C, 630 °C, 650 °C, 680 °C, 700 °C for 30 min with a continuous annealing machine (CAS30011, General Furnace Manufacturing Co., Ltd., Shenyang, China), followed by air-cooling to room temperature (

Figure 1b).

Table 1.

Chemical composition of the investigated steel (wt.%).

Table 1.

Chemical composition of the investigated steel (wt.%).

| C | Mn | Si | Al | S | P | Fe |

|---|

| 0.07 | 7.9 | 0.14 | 0.05 | 0.002 | 0.003 | Bal |

Figure 1.

Schematic illustration of steps in rolling and heat treatment processes of medium-manganese steels in present work (a) for the warm-rolled steel; and (b) for the warm rolled steels heat-treated with intercritical annealing.

Figure 1.

Schematic illustration of steps in rolling and heat treatment processes of medium-manganese steels in present work (a) for the warm-rolled steel; and (b) for the warm rolled steels heat-treated with intercritical annealing.

In this study, warm rolling was conducted at a relatively high temperature to make the rolling process more easily operable by inhibiting crack/void initiation which is prone in cold rolling. In addition, the reduction of rolling forces with the increase in rolling temperature is also beneficial in prolonging the service life of rollers.

To determine the start point of martensitic transformation, cylindrical dilatometric samples with 3 mm-diameter and 10 mm-length were tested with a push-rod L78-RITA dilatometer (Linseis Messgeraete, Selb, Germany). The sample’s temperature is measured by a thermocouple welded to its surface using a precision welder and the jig supplied by the dilatometer manufacturer. The heating and austenitization treatments were carried out under a vacuum of 5 × 10−2 Pa, and the cooling was achieved using argon gas.

2.2. Mechanical Property Characterization

To examine the effect of heat treatment on the mechanical properties of the steel, the as-treated steel sheets were cut into the dog-bone shaped specimens with a gauge length of 15 mm and a width of 4 mm, and the final sheet thickness is 1.2 mm after polishing. Uniaxial tensile tests were performed on an AG-X plus mechanical testing system at a constant strain rate of 1 × 10

−3·s

−1 under room temperature. A calibrated contactless MTS LX300 laser extensometer (MTS Systems Corporation, Eden Prairie, MN, USA) was used to measure the sample strain upon loading. Note that the dimensions of the tensile specimens in this study do not follow the American Society for testing and materials (ASTM) standard, and the higher length to width ratio may result in slightly overestimated properties in comparison with those reported by other authors [

18,

21].

Micro-hardness of each phase was determined using a Triboindenter (Hysitron Incorporated, Minneapolis, MN, USA) equipped with a diamond Berkovich tip with a pyramidal tip shape and a tip radius of approximately 100 nm. The specimens were loaded to the maximum load of 2 mN and with a loading rate of 0.4 mN/s and held constant for 10 s. The average value for each phase was calculated from 12 indents.

2.3. Microstructure Characterization

Specimens were cut from the heat-treated sheet and the gauge of the deformed samples for X-ray diffraction (XRD) analysis in determining RA volume fractions. The specimens were ground gradually using silicon papers with different grades, chemically cleaned using a mixture of HCl and HNO

3 in 2:1 ratio, further swabbing by few drops of ethanol to improve precision of analysis. The measurement of RA volume was performed on X’Pert PRO diffractometer (PW3040/60, Panalytical B.V., Almelo, The Netherlands) with a sample stage for Co anode (wavelength

k = 0.1789 nm) and X-ray detector, operating at 40 kV and 40 mA. The penetration depth of X-rays (Co radiation) into steel is a few micrometers. Samples were scanned at a step size of 0.02 deg per second and a 2θ ranging from 40 to 100 deg. The volume fraction of retained austenite phase was determined with the integrated intensity of (111)γ, (200)γ and (220)γ, and ferrite peaks (110)α and (200)α with the following Equation [

22]:

Here Vγ is the volume fraction of RA; Iγ and Iα is the integrated intensity of peaks of RA phase and ferrite phase, respectively.

The microstructure was characterized using scanning electron microscope (SEM) (FEI Quanta 600, PHILIPS, Hillsboro, OR, USA) operated at a voltage of 20 kV. The last specimen-preparation step was electrolytic polishing with an electrolyte consisting of 15% perchloric acid, 5% distilled water, and 80% ethanol (in v/v) at 20 V for 25 s. The electron-back-scattered-diffraction (EBSD) analysis was conducted with an acceleration voltage of 20 kV, sample tilt angle of 70°, and working distance of 7 mm. To obtain a representative value for the phase fraction, it is important that the EBSD data covers a large area and includes enough points. An area of 1.0 × 1.0 mm2 was covered per specimen. Maps were measured on a hexagonal grid with step sizes of 0.1 µm. The EBSD data was collected on a Ultra-55 field-emission SEM (Zeiss Ltd., Braunschweig, Germany) and evaluated by the orientation imaging microscopy (OIM) software (Oxford Instruments PLC., Oxfordshire, UK).

Transmission electron microscopy (TEM) techniques (Tecnai G2 20, FEI Company, Hillsboro, OR, USA) were used to investigate the micro-structural morphologies associated with the various heat treatment processes and deformation state for the studied steel. Specimens for TEM observation were cut from the annealed samples and the tips of deformed samples close to the fracture surface, mechanically polished from both sides to a final thickness of about 50 µm. Subsequently the samples were polished with diamond paste, and then the foils were thinned using a double jet electrolytic polisher at a voltage of 50 V and a temperature below −10 °C. The electrolyte consists of 10% perchloric acid and 90% (v/v) ethanol. TEM observations were performed in a field-emission-gun (FEG) Tecnai G2 20 microscope operating at an accelerated voltage of 200 kV.

3. Results

Ac1 and Ac3 temperatures of the steel are determined by the dilatometer as 585 °C and 720 °C, respectively. The start point of martensitic transformation occurs at 300 °C for a range of cooling rates of 0.1–60 °C/s.

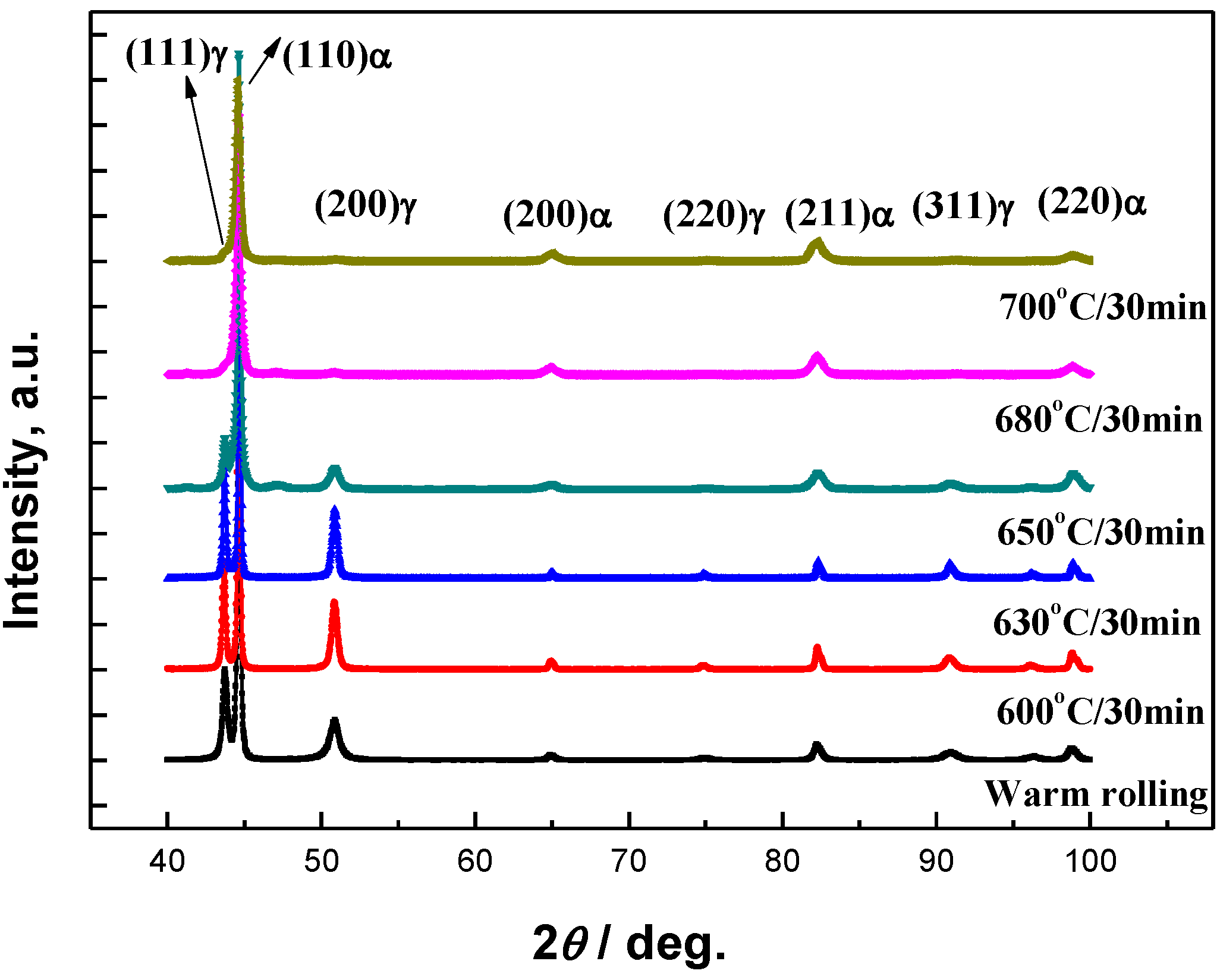

Figure 2 is the XRD patterns of the investigated steels as warm-rolled state along with those annealed under various temperatures for 30 min. The austenite volume fraction is calculated with Equation (1) as 35%, 39%, 36%, 19%, 9% and 7% for the steels as warm-rolled and as annealed at 600 °C, 630 °C, 650 °C, 680 °C, 700 °C for 30 min, respectively. In the range studied, the RA volume fraction decreases with increasing annealing temperature. This is similar to the measured austenite volume fraction reported by Lee and De Cooman [

5] for a 6Mn steel, and the reason may lie in the variations of C and Mn concentration in austenite, affecting austenite’s thermal stability.

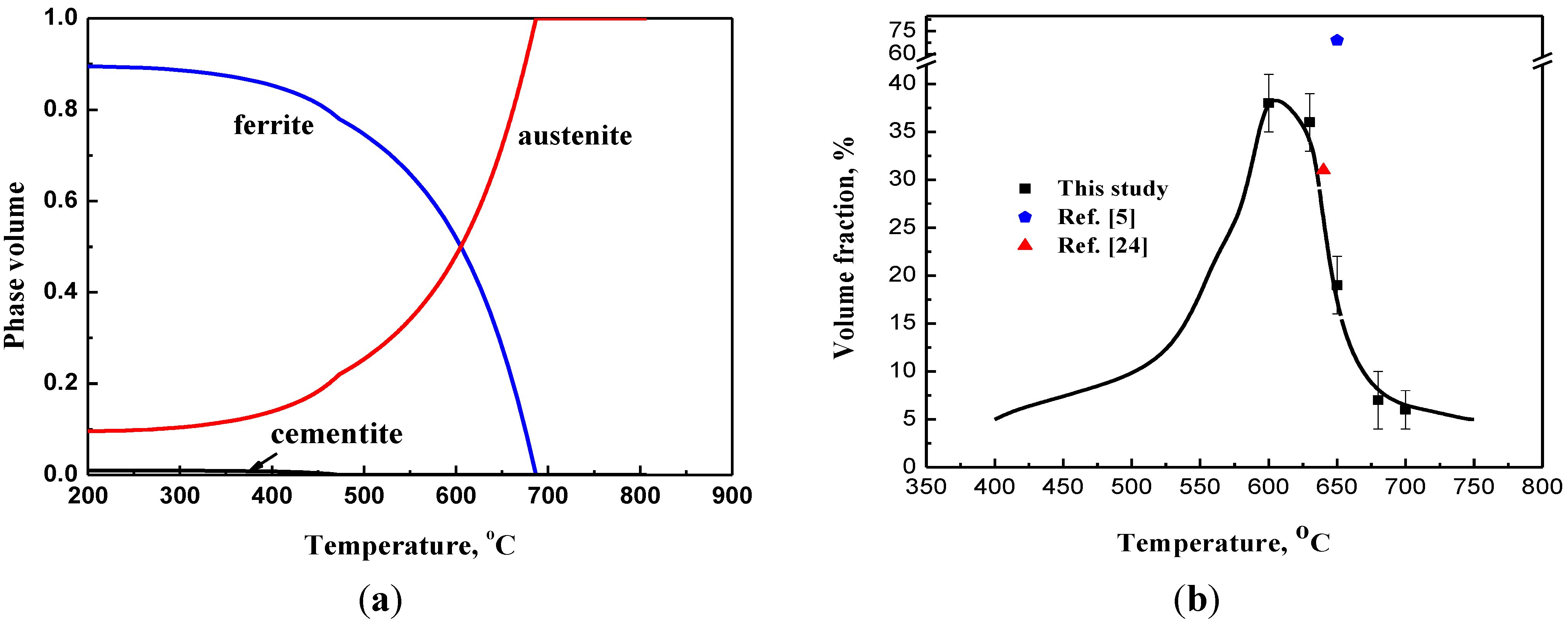

The phase fractions predicted by Thermal-Calc™ using JMatPro database for this steel are shown in

Figure 3a. One can clearly see that the highest austenite fraction is 52% at temperature of 630 °C, balanced with ferrite. Below 450 °C, some cementite (<1%) can been observed. However, the austenite fraction decreased with decreasing temperature and the remaining fraction was stabilized by Mn and C. It has been reported that the diffusion distance of Mn is 280 nm in bcc iron at 640 °C [

6], at which the greatest RA fraction of 31% was obtained for a 0.11C-5.7Mn steel. Meanwhile, a maximum room temperature austenite volume fraction of 69% was obtained at an intercritical annealing temperature of 660 °C in the medium Mn TRIP steel with a nominal chemical composition of Fe-0.3C-6.0Mn (wt%) [

5]. In our study, we used the Thermal-Calc™ using JMatPro database to evaluate the change of final austenite volume fraction with increasing heat treatment temperatures. According to Speer

et al. [

23], the inputs to this calculation include the carbon content of the steel, the Ms temperature, and the cooling rate [

16], assumed that only carbon can reach uniform chemical potential (

i.e., constrained carbon equilibrium (CCE)) at the interface between austenite and martensite whereas other atoms cannot move [

23]. Surprisingly, both the predicted (dark line) and measure results (solid dots) are similar to those obtained from quenching processes, with the highest volume fraction of 39% retained austenite predicted for the sample annealed at 600 °C for 30 min (

Figure 3b).

Figure 2.

XRD patterns for the warm-rolled steel along with those after various heat treatment processes.

Figure 2.

XRD patterns for the warm-rolled steel along with those after various heat treatment processes.

Figure 3.

(a) Phase fractions were predicted by Thermal-Calc™ using JMatPro database; (b) Final austenite fraction as a function of annealing temperature for a Fe-7.9Mn-0.14Si-0.05Al-0.07C Steel (solid line, predicted, black square, measured data).

Figure 3.

(a) Phase fractions were predicted by Thermal-Calc™ using JMatPro database; (b) Final austenite fraction as a function of annealing temperature for a Fe-7.9Mn-0.14Si-0.05Al-0.07C Steel (solid line, predicted, black square, measured data).

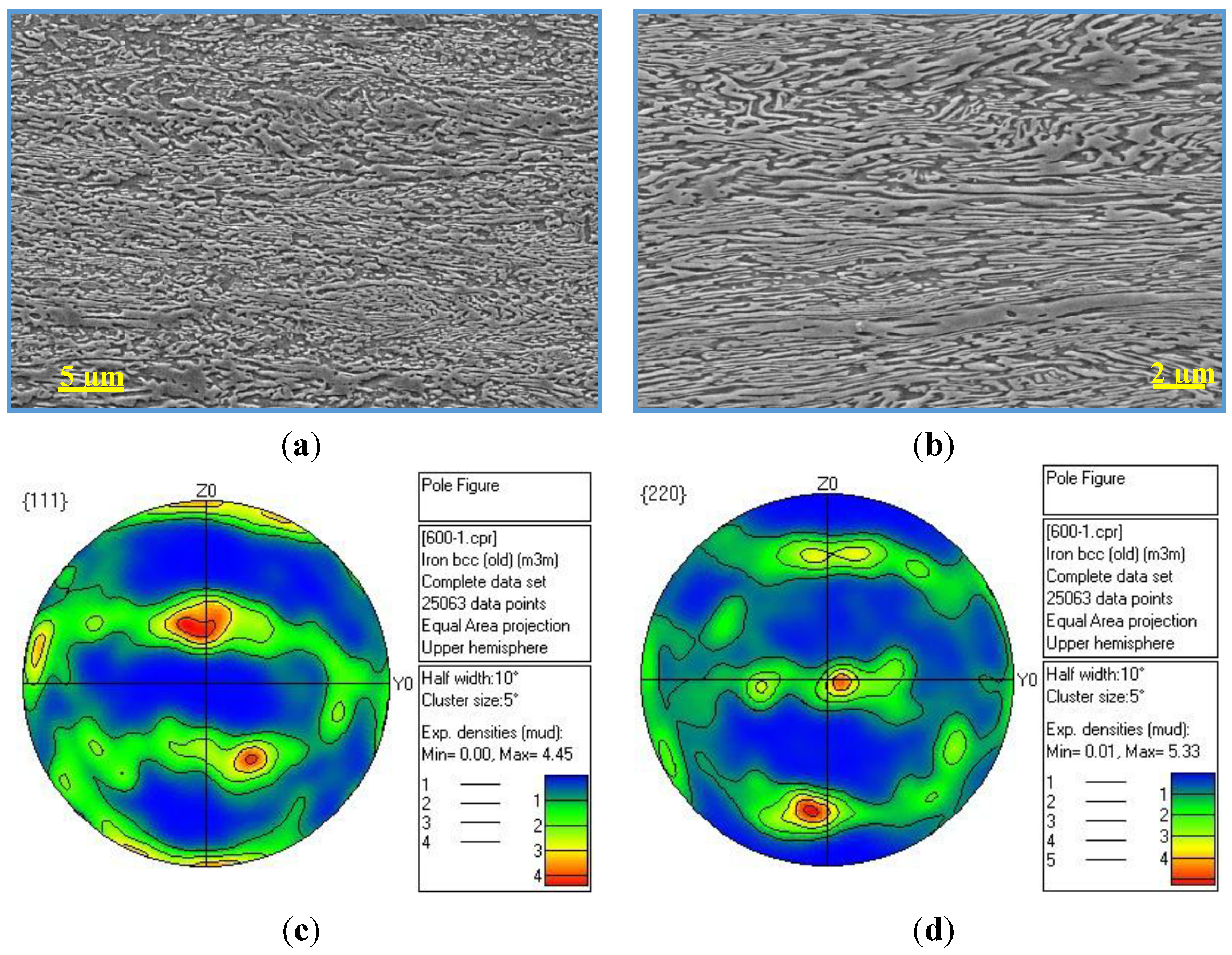

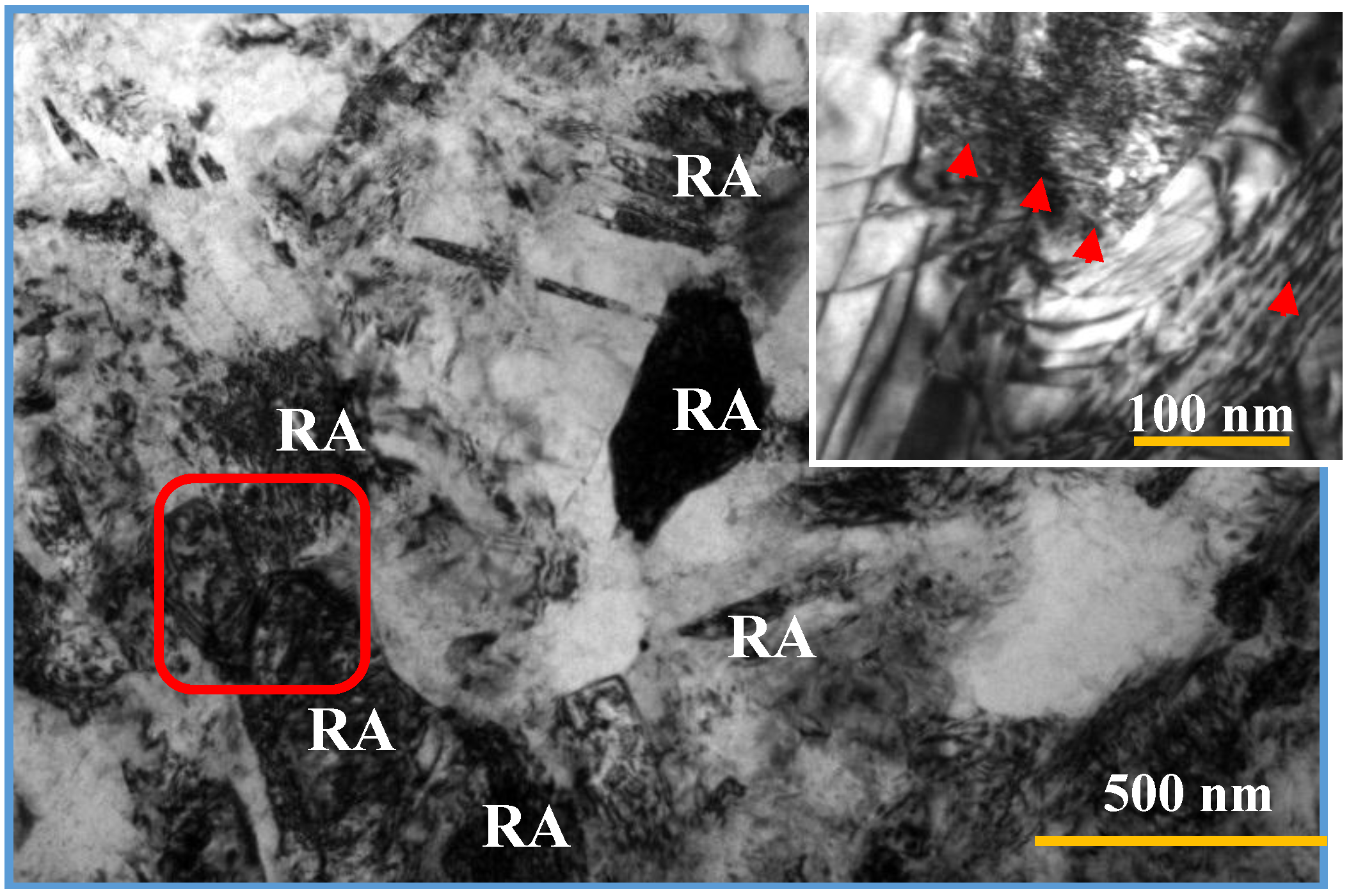

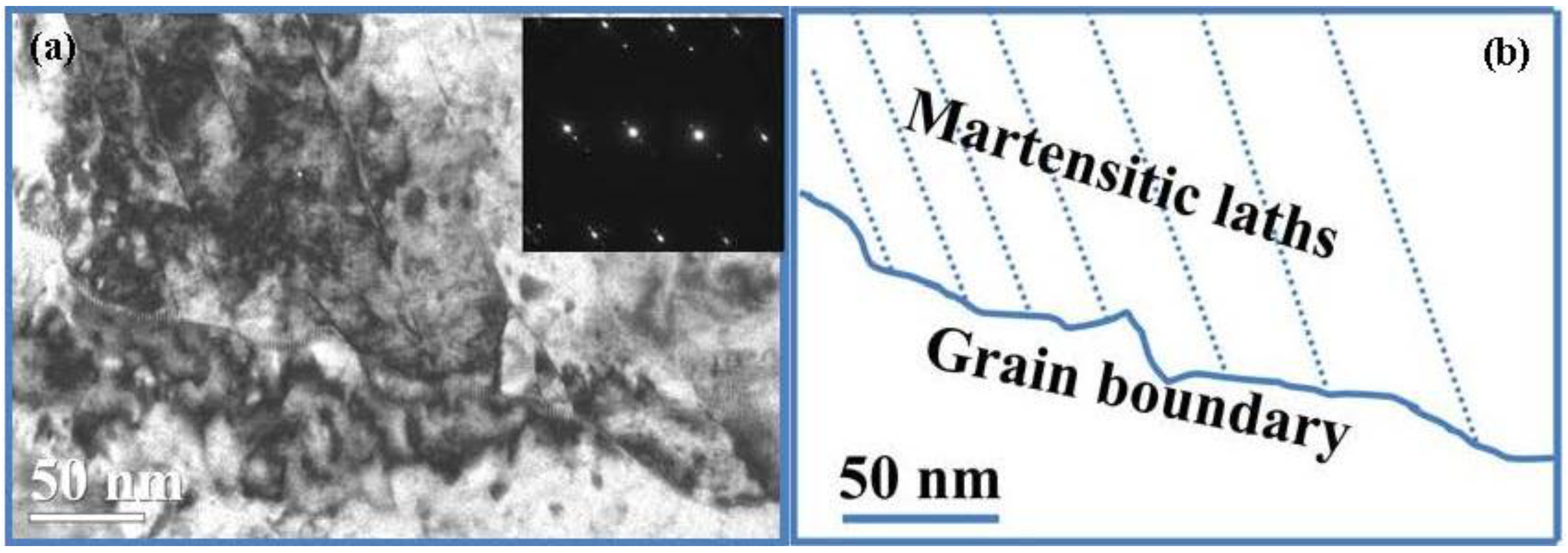

Though the numerous heating and cooling cycles during warm-rolling can strongly affect the microstructures of the warm-rolled steel, postmortem SEM observations proved that the microstructures consist of mainly ferrite and austenite, accompanied with some martensitic packets. Hence, subsequent intercritical annealing was conducted to promote the transformation of martensite into austenite. SEM and TEM observations indicated that, after intercritical annealing at 600 °C for 30 min, the warm-rolled steel mainly consists of light grey ferrite and dark grey austenite (

Figure 4a,b). It is clear from

Figure 4a,b that there is a texture in the warm-rolled plate after annealing at 600 °C for 30 min. Consequently, the texture measurements of were carried out in a plane perpendicular to the transverse direction of the annealed plate, as shown in

Figure 4c,d. One can see that γ-fiber, {111}<112>, is the main component, with an intensity of 5.33 times random. This texture can slightly affect the calculated values of RA by using Equation (1), resulting in an overestimated RA volume fraction in this study.

Figure 4.

(a) Low-; and (b) high-magnification SEM micrographs show the morphology and arrangement of ferrite (light grey) and austenite (dark grey), in the warm-rolled plate after annealing at 600 °C for 30 min (c); and (d) are the corresponding (111) and (220) pole figures obtained using EBSD analysis.

Figure 4.

(a) Low-; and (b) high-magnification SEM micrographs show the morphology and arrangement of ferrite (light grey) and austenite (dark grey), in the warm-rolled plate after annealing at 600 °C for 30 min (c); and (d) are the corresponding (111) and (220) pole figures obtained using EBSD analysis.

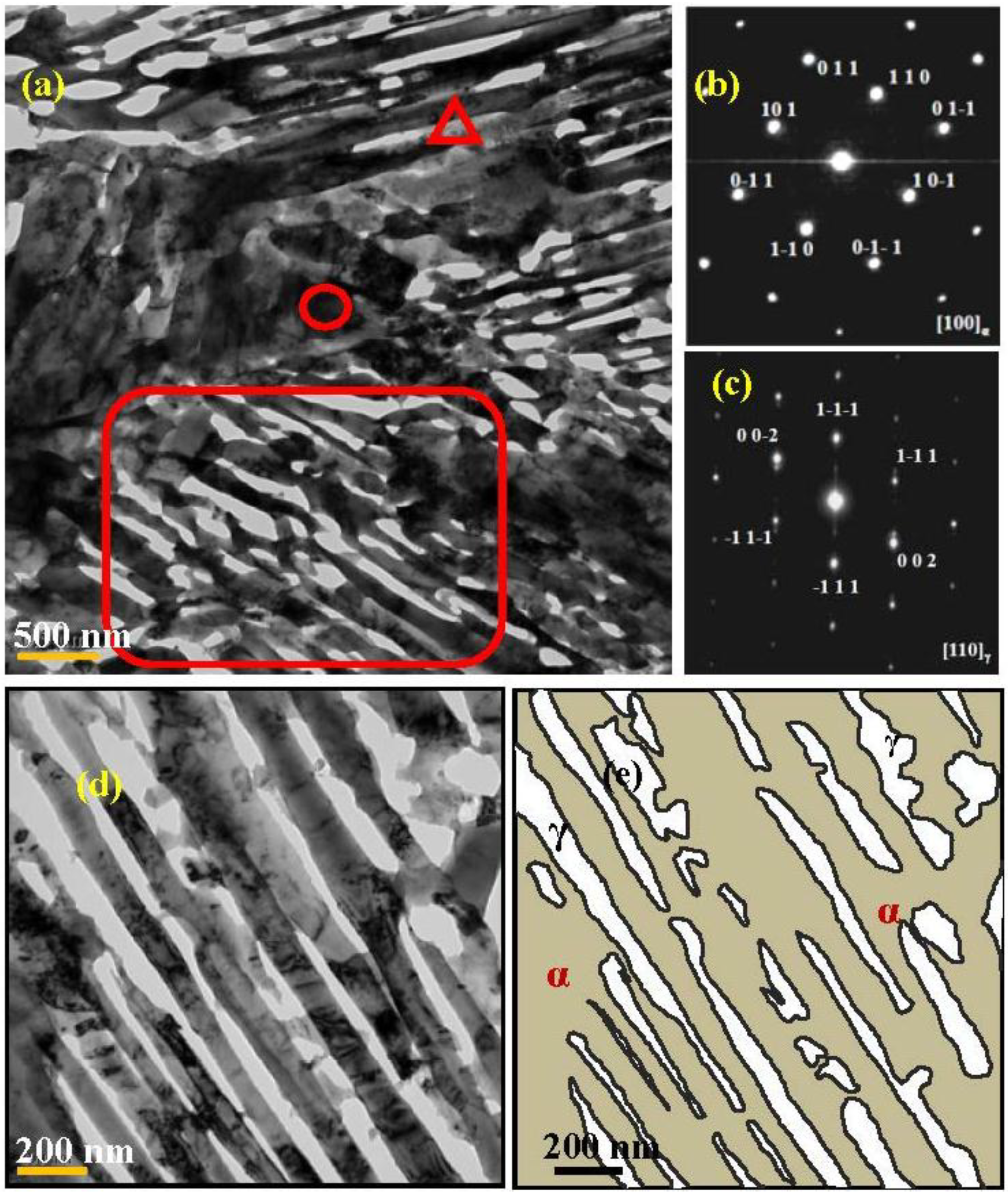

TEM observations reveal that both phases exhibit ultra-fine lamellar microstructures with thickness varying from tens to hundreds of nanometers (

Figure 5). The average lamellae thickness is about 350 nm. In the selected-area-electron-diffraction (SAED) shown in

Figure 5b,c, the dark and bright area were discerned as ferrite and austenite, respectively. Interestingly, one can clearly see two phases alternatively arranged and the majority of austenite have been eroded away (

Figure 5a,d). The key reason can be attributed to the high Mn and C concentrations in austenite. During the electrolytic polishing, the different potential between the ferrite and RA would result in a difference in the erosion sequence.

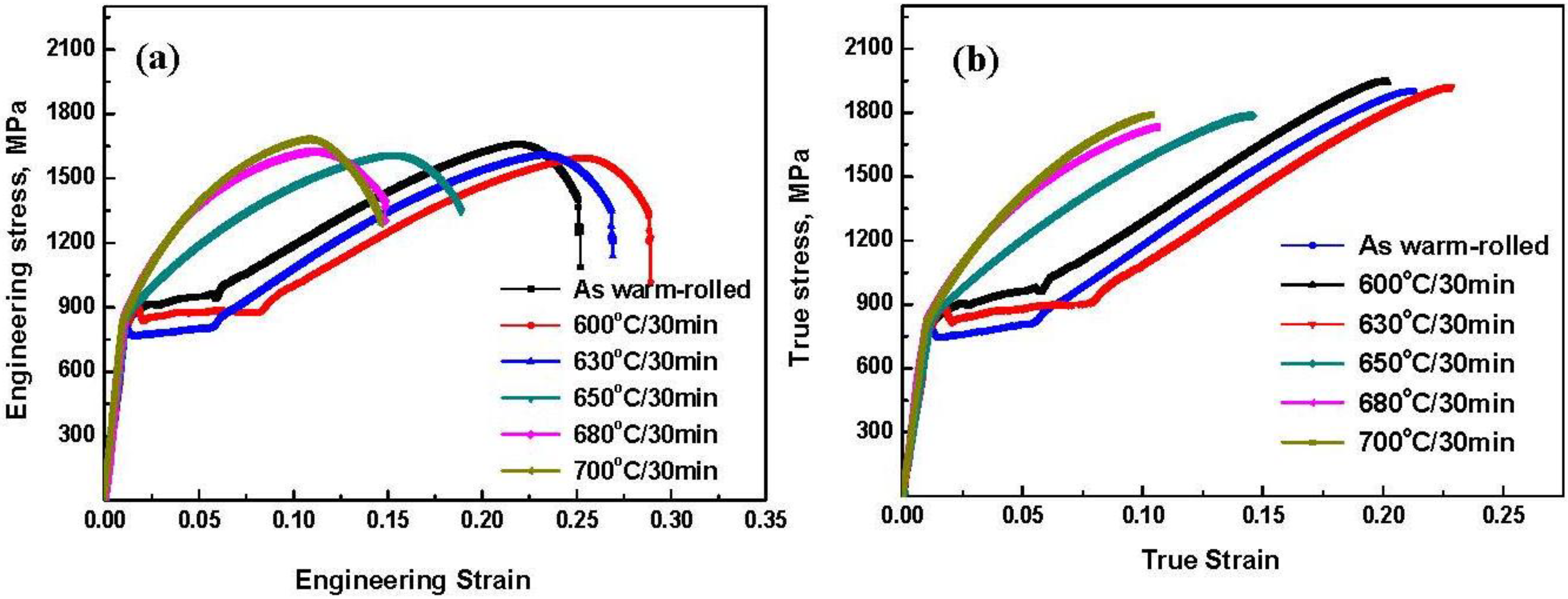

Tensile testing results reveal that the annealing temperature dramatically influences the mechanical properties of the studied steels. All engineering stress-strain and true stress-strain curves for the investigated samples are presented in

Figure 6. Several significant observations can be made from

Figure 6. First, the as warm-rolled steel exhibits an ultimate tensile strength (σ

UTS) of 1670 MPa and a moderate elongation-to-failure (ε

f) of 0.24. The samples show obviously different behaviors with increasing annealing temperatures. At the lowest annealing temperature of 600°C, the sample exhibits the highest ε

f of 0.29 and a slightly decreased σ

UTS of 1600 MPa. With increasing annealing temperature to 630 °C, the ε

f decreases to 0.27 while the σ

UTS remains the same. Finally, when the annealing temperatures go beyond 630 °C, the ε

f significantly decreases to ≤ 0.18 due to the increasing amount of martensite and reduced amount of RA in the samples. Notice that the σ

UTS is almost the same for all the samples. From

Figure 6 one can clearly see the warm-rolled sample with 600 °C annealing temperature has the best combination of ultimate tensile strength and elongation to failure. It is worthwhile pointing out that the warm-rolled specimens after annealing at the lower temperature for 30min exhibit good ductility (ε

f ≥ 0.27), high yield strength and extremely high σ

UTS of 1600 MPa, which is over two times higher than that reported for the martensitic 8Mn steel with the same amount of Mn [

25].

Figure 5.

(a) TEM micrograph, and selected-area-electron-diffraction (SAED) patterns for the circle; (b) and triangle; (c) indicated areas in the warm-rolled plate after annealing at 600 °C for 30 min; (d) shows the close observation to the square indicated area in (a); (e) A schematic illustration of (d) to help differentiate and measure the thicknesses of ferrite and austenite. α: ferrite; γ: austenite.

Figure 5.

(a) TEM micrograph, and selected-area-electron-diffraction (SAED) patterns for the circle; (b) and triangle; (c) indicated areas in the warm-rolled plate after annealing at 600 °C for 30 min; (d) shows the close observation to the square indicated area in (a); (e) A schematic illustration of (d) to help differentiate and measure the thicknesses of ferrite and austenite. α: ferrite; γ: austenite.

Figure 6.

The engineering stress—strain (a) and true stress—strain curves (b) for the samples obtained by various heat treatment processes.

Figure 6.

The engineering stress—strain (a) and true stress—strain curves (b) for the samples obtained by various heat treatment processes.