4.1. Design Concepts

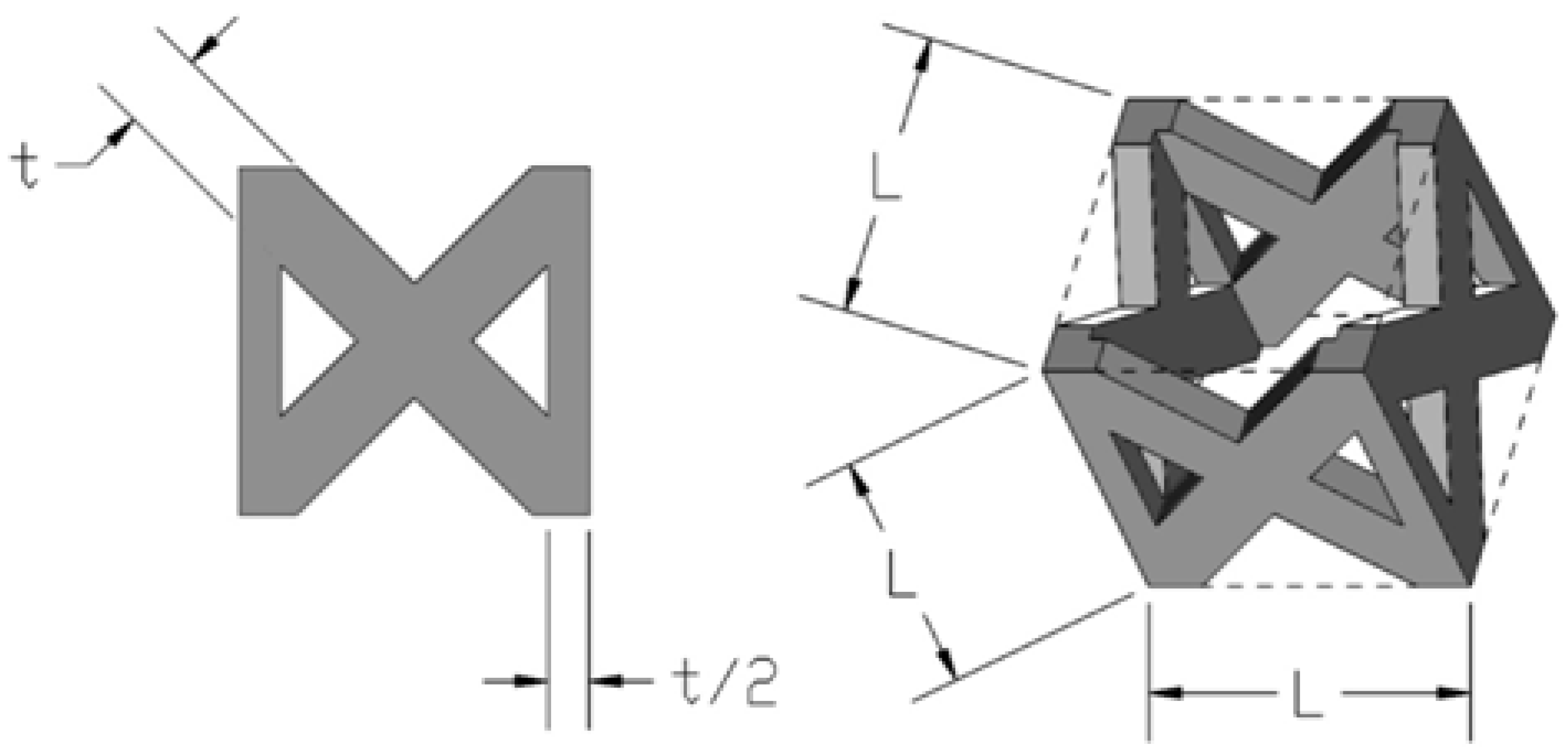

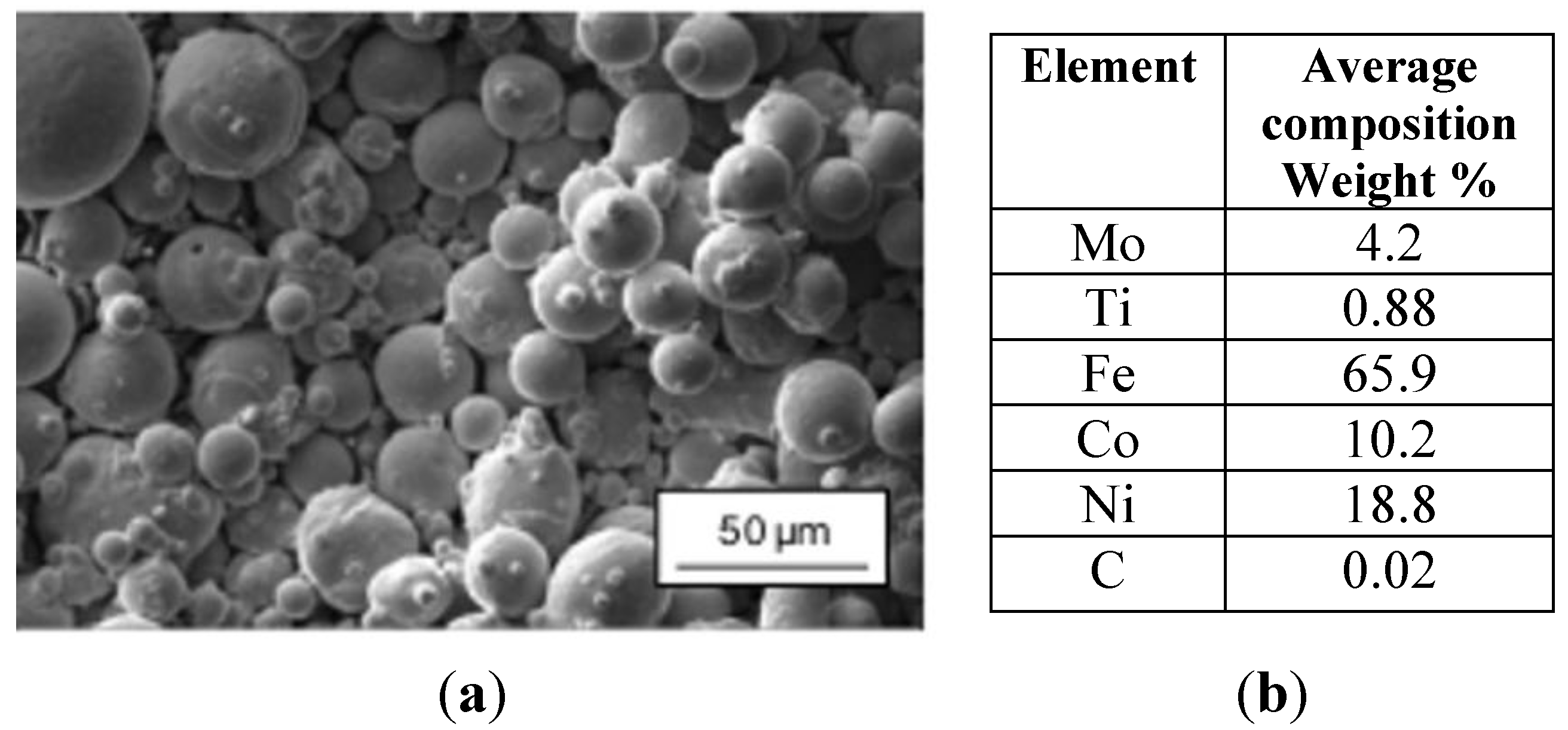

Preliminary experiments were conducted in order to assess the capacity of SLM process to create lattice structures including strut elements as small as possible. The experiments served to find the minimum dimensions of the lattice structure that allow cell geometry to be realized without defects. Results showed that the minimum size of strut edge t must be 500 µm for the samples with cell size L = 2 mm, and 700 µm for the samples with L = 3 mm, respectively.

A more detailed experimental campaign was then carried out in order to compare two design concepts: (i) Design A with cell size L = 3 mm and size of strut edge t = 700 μm; (ii) Design B with cell size L = 2 mm and size of strut edge t = 500 μm. Overall dimensions (D) for designs A and B, respectively, are 24 × 24 × 15 mm3 and 16 × 16 × 16 mm3. Relative density is 0.2456 for design A while design B has a relative density of 0.3562.

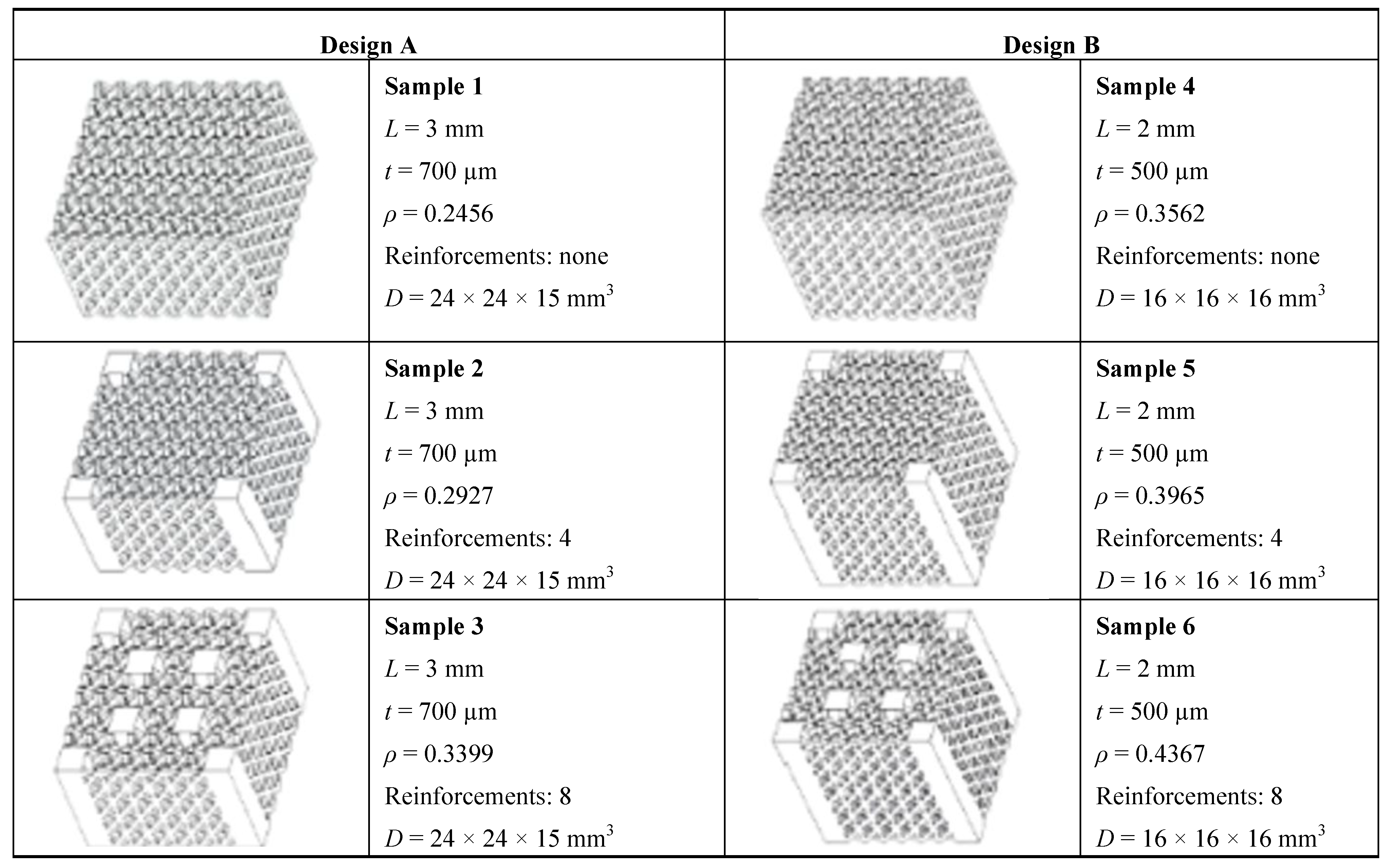

Besides the base designs A and B that reproduce the pillar texile topology, other samples, always with cell sizes of 2 or 3 mm, were studied. These samples, shown in

Figure 6, included vertical reinforcements to improve the overall stiffness of the structure. The dimensions of the cross-sectional area of vertical struts are equal to those of the cell size. Samples 2 and 5 represent structures reinforced only at the four corners. Samples 3 and 6 represent structures reinforced at the four corners and at the centers of the diagonals. The values of relative density, cell size and edge size of strut also are indicated in the figure.

Figure 6.

Schematic of optimized and alternative cell topologies including vertical reinforcements.

Figure 6.

Schematic of optimized and alternative cell topologies including vertical reinforcements.

Figure 6 shows that the relative density of samples changes between 0.2456 and 0.4367. As expected, the introduction of reinforces leads to increase relative density.

4.2. Compression Tests

Figure 7a–c shows design A type samples 1, 2 and 3 manufactured by SLM.

Figure 7d–f shows the corresponding deformed specimens. Similar images were obtained for design B type samples and hence are omitted for the sake of brevity. Typical collapse modes of struts are shown, for example, in

Figure 7g: in particular, this detailed view shows elements located near reinforcement columns.

The six cell variants considered in this study were all tested under uniaxial compression. Mechanical tests were performed under displacement control with a Instron 4467 machine equipped with a 250 kN load cell; end-shortening was supplied to the specimen by setting compression speed to 0.5 mm/min. Five specimens were built and tested for each design variant to obtain statistically significant results. The test protocol was selected according to the collapse mode most likely to occur for the present structures that somehow resemble open-cell foams. Following the theory reported in the classical textbook by Gere and Timoshenko [

28], if the lattice structure is made of a material with positive strain hardening rate, it starts to plastically deform and keeps to withstand increasing levels of stress due to the hardening of the struts that eventually collapse by plastic buckling. In view of this, in the present study, samples were loaded up to the limit of inelastic buckling and compression tests were terminated at 2.5 mm end-shortening. Strut collapse modes observed experimentally (see, for example, the detailed view in

Figure 7g) are consistent with the theoretical collapse behavior described above.

Figure 7.

Samples 1, 2 and 3 built by SLM (Design A specimens): (a) Base structure; (b) Structure with 4 reinforcement columns; (c) Structure with 8 reinforcement columns; (d) Deformed base structure; (e) Deformed 4-column reinforced structure; (f) Deformed 8-column reinforced structure; (g) Typical collapse mode of struts observed in the experiments.

Figure 7.

Samples 1, 2 and 3 built by SLM (Design A specimens): (a) Base structure; (b) Structure with 4 reinforcement columns; (c) Structure with 8 reinforcement columns; (d) Deformed base structure; (e) Deformed 4-column reinforced structure; (f) Deformed 8-column reinforced structure; (g) Typical collapse mode of struts observed in the experiments.

Figure 8a,b shows the load-displacement/stress-strain curves, respectively, for design A and B type samples. Following literature, the stress was determined as the ratio between the applied load measured by the load cell and the nominal cross-section of the specimen; strain was determined as the ratio between the measured shortening and nominal height of the specimen. The inelastic buckling limit load corresponds to the peak force recorded in the load-displacement curve (see

Figure 8). Values of stress and strain derived from the load-displacement curves recorded experimentally also are reported in the figure. Since the statistical dispersion of experimental data gathered for each design variant was within ±5%, the relative behavior of different samples can be reliably assessed from the curves shown in

Figure 8.

Figure 8 demonstrates that by introducing the vertical reinforcements (

i.e., for design A type specimens, going from Sample 1 to Sample 3, and from Sample 4 to Sample 6 for design B type specimens) it is possible to increase the load carrying capability of the micro-lattice truss structure by a factor almost equal to 2. Remarkably, the same result was achieved independently of cell dimensions. Although the higher load carrying capability entailed heavier cell structures, it should be noted that by adding reinforcement struts into the cell structure the specific strength of the structure can increase more significantly. In fact, while relative density became only 38.3% or 22.6% higher than for the base (

i.e., unreinforced) structure, respectively, for design A and B samples, the load carrying capability of the cell structure even increased by 70%–80% (see

Figure 8 and peak strength values listed in

Table 1).

Figure 8.

Load-displacement curves for design A type samples (a) and design B type samples (b).

Figure 8.

Load-displacement curves for design A type samples (a) and design B type samples (b).

Table 1.

Comparison of strength peaks measured experimentally and computed by FE analysis.

Table 1.

Comparison of strength peaks measured experimentally and computed by FE analysis.

| Sample | Peak strength [MPa] |

|---|

| Experiments | FE–MELAS | FE–MISO |

|---|

| 1 | 206.0 | 195.7 | 211.1 |

| 2 | 285.6 | 266.7 | 280.3 |

| 3 | 351.8 | 327.3 | 341.4 |

| 4 | 97.0 | 104.4 | 117.4 |

| 5 | 130.6 | 136.0 | 147.4 |

| 6 | 175.4 | 163.7 | 174.4 |

Stress peak values change almost linearly with relative density: the correlation coefficient computed for the linear fitting is 0.9964 and 0.9917, respectively, for designs A and B specimens. Such a behavior was seen for all design variants. Maximum stress values recorded for design A type specimens are just 10% different from their counterpart for design B. Therefore, design A type specimens undergo the same level of stress as design B type specimens but their relative density is on average 30% lower than for design B.

In summary, design A allows the specific strength of the micro-cell structure to be significantly increased with respect to design B. This can be explained by considering that cell failure is driven by buckling. This phenomenon depends on the thickness and length of the strut elements of which the cell structure is comprised. Struts included in design A type samples are 1.4 times thicker than in the case of the samples falling in the design B class (

i.e., 700 μm

vs. 500 μm) but also 1.5 times longer than for design B type specimens (

i.e., 3 mm

vs. 2 mm). The increasing in buckling strength with thickness (strength changes approximately as the fourth power of thickness [

29]) is more significant than the reduction of buckling strength introduced by the presence of longer strut elements (buckling load changes quadratically with length).

The plastic nature of the failure mechanisms observed in the experimental tests is confirmed by the fact that the plastic plateau present in the load-displacement curves is less pronounced for design A type specimens. Furthermore, for a given specimen type, the plateau becomes less significant as the number of reinforcement columns included in the cellular structure increases. Failure begins to develop locally in correspondence of the vertical beams that mostly carry the compressive load. As the peak load is reached, diffuse plasticization of the material occurs and finally structure crushes down.

4.3. Finite Element Analysis

Compression tests carried out for the six cell variants were simulated by means of the general purpose finite element code ANSYS

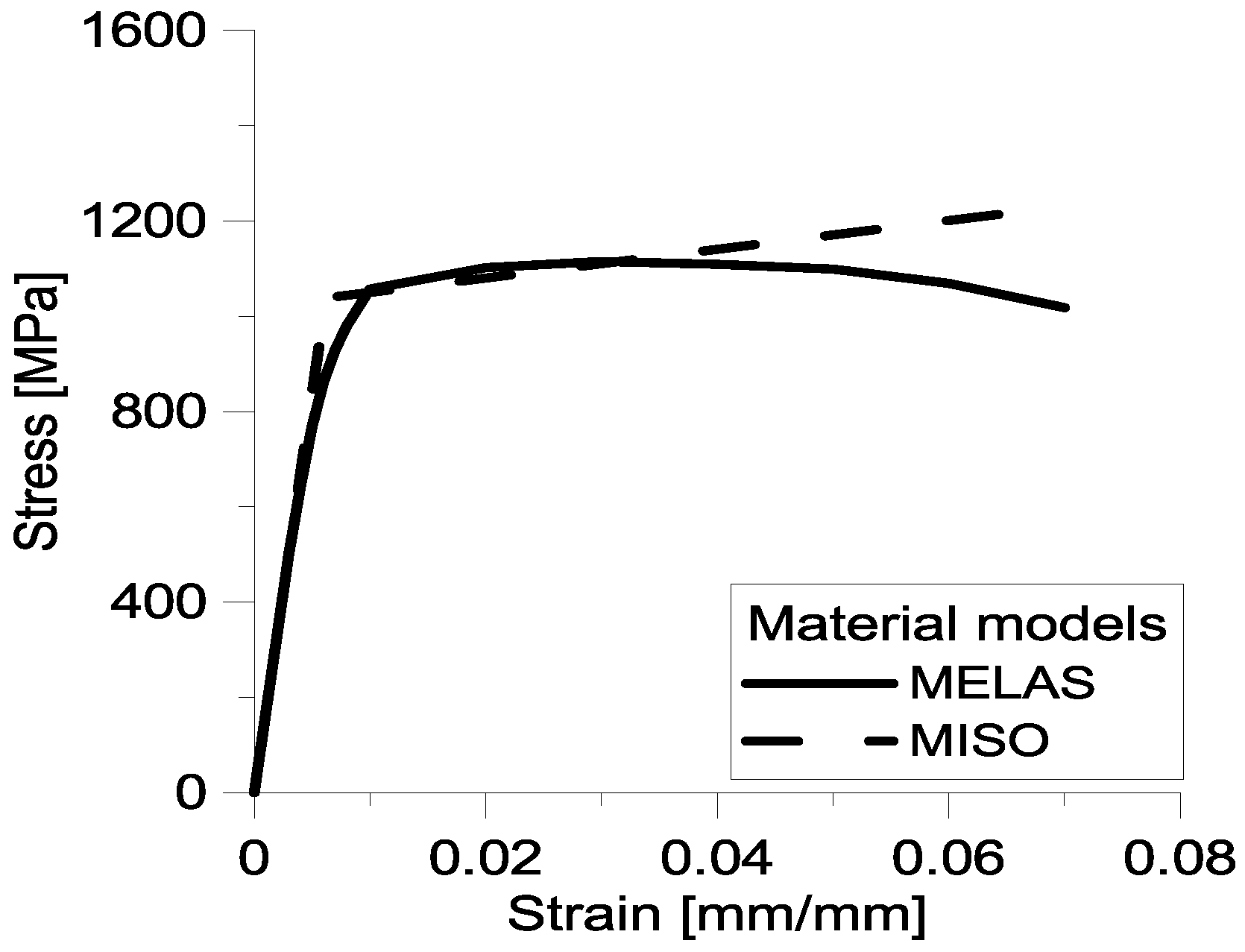

®. FE analysis was basically aimed at assessing the overall constitutive behavior of the micro-cell structures considered in this study. For that purpose, the Multilinear Elastic (MELAS) and Multilinear Isotropic Hardening (MISO) models available in ANSYS were compared.

Figure 9 shows the stress-strain data given in input to the finite element model. These data were obtained from experimental compression tests independently carried out on 18Ni Marage 300 specimens following the ASTM standard E9-09 [

30]. The MISO curve envelopes the ascending branch of the MELAS curve.

Figure 9.

Stress-strain curves corresponding to MELAS and MISO options utilized in the finite element simulations to model the nonlinear constitutive behavior of 18Ni Marage 300.

Figure 9.

Stress-strain curves corresponding to MELAS and MISO options utilized in the finite element simulations to model the nonlinear constitutive behavior of 18Ni Marage 300.

The MELAS model is path independent as it assumes unloading to occur along the same path as loading. Constitutive behavior is described by a piece-wise linear stress-strain curve, with no hysteresis. The MISO model uses the von Mises yield criterion coupled with isotropic work hardening. Constitutive behavior is described by a multilinear stress-strain curve whose initial slope corresponds to the Young’s modulus of the material. This model works well for large strain cycling. The MELAS model is in general much more accurate than the Hookean model but may be less accurate than the MISO model as the latter accounts for plastic deformations and considers the hardening caused by the deformation field imposed to the structure.

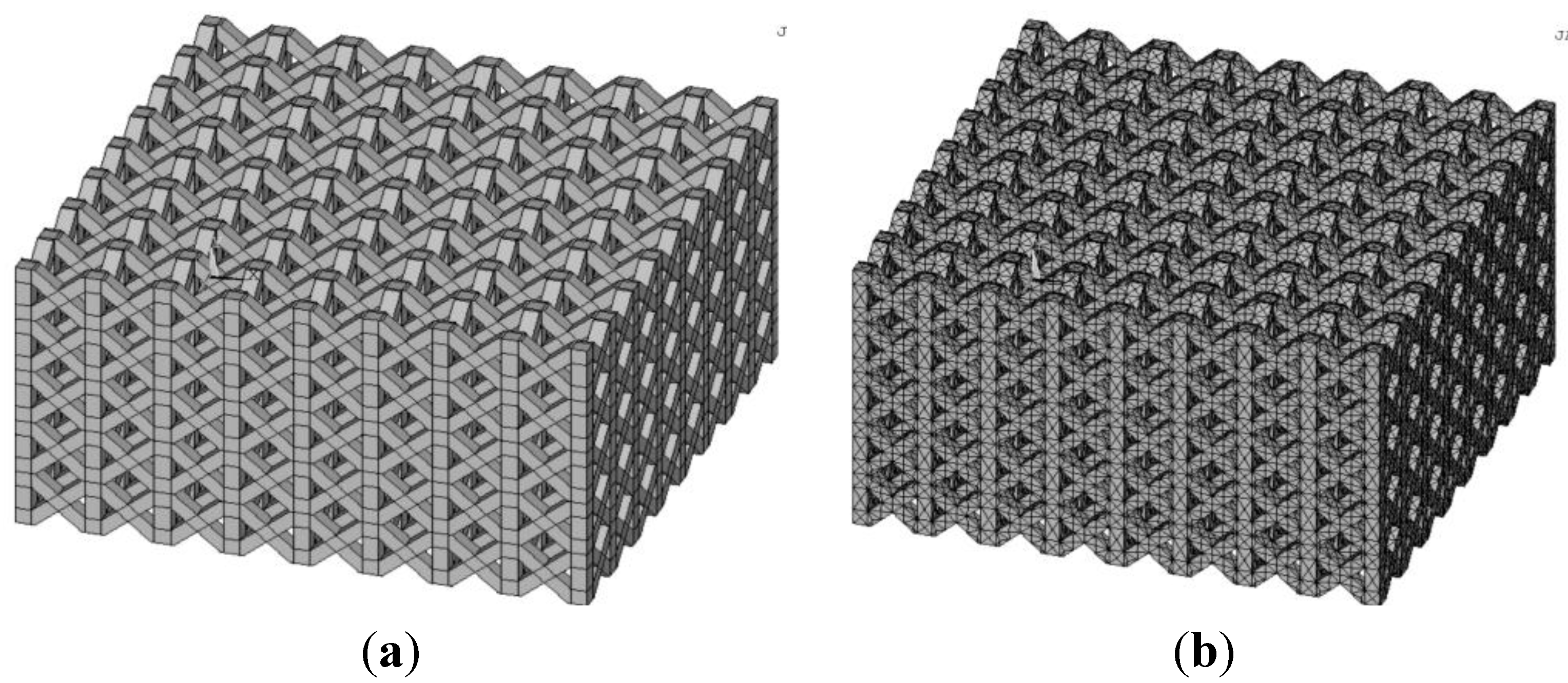

FE element models developed for each of the six design variants were meshed with 12-node pyramidal solid elements. The proper element size was selected on the basis of a convergence analysis carried out in order to obtain mesh independent solutions. FE models included on average 197,000 elements and 406,500 nodes. For example,

Figure 10 shows the 3D model of the structure geometry defined in ANSYS and the corresponding finite element mesh.

Figure 10.

(a) 3D model of the pillar texile micro-cellular structure defined in ANSYS; (b) Finite element mesh of the 3D model.

Figure 10.

(a) 3D model of the pillar texile micro-cellular structure defined in ANSYS; (b) Finite element mesh of the 3D model.

The following kinematic boundary conditions were considered (see

Figure 10): the bottom surface of the model cannot displace while the top surface can only move along the vertical direction.

It should be noted that FE analyses were carried out on 3D CAD models that reproduced the theoretical cell structures. Geometric errors made in the SLM process with respect to 3D CAD models were always smaller than 6%. It was assumed that distortions/errors on cell geometry contribute by the same extent to the global error measured on the external surface of the built samples. In order to assess the effect of these geometric errors on the stress/strain distributions predicted by FE analysis, a “distorted” finite element model including geometric errors was developed. Remarkably, differences in structural response with respect to FE models reproducing theoretical structures were always found to be less than 2%.

Porosities and surface roughness also may affect the mechanical response of the cellular structure. However, since in the present case almost full density parts were manufactured via SLM, there was no need to include porosity effects in the numerical analysis. As far as it concerns surface roughness, the average ratio of roughness Ra to cell size was about 0.025 (i.e., 15 μm with respect to 500 or 700 μm cell size). Roughness was included as a geometric nonlinearity in the FE model in fashion of surface waviness with an amplitude corresponding to Ra. Differences in structural response with respect to the theoretical CAD model were still smaller than 5%.

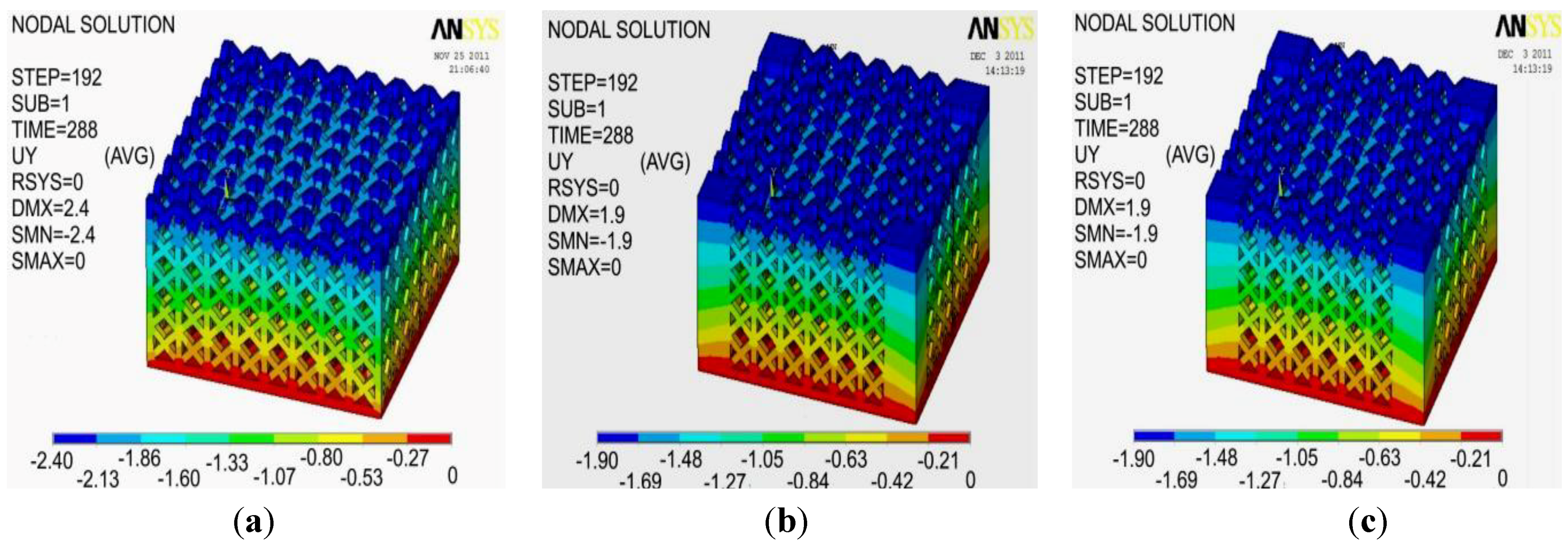

Since the mechanical response evaluated by ANSYS was always insensitive to geometric errors and roughness, having used theoretical 3D CAD models in FE computations is indeed reasonable. For example,

Figure 11 shows the deformed shapes computed by ANSYS for design A type specimens. In particular, the maps of displacement along the loading direction (

i.e., parallel to the height of specimens) are presented. There is a very good agreement between numerical results and the deformed shapes observed experimentally (see

Figure 7d–g). Similar results obtained for design B type specimens will be omitted for the sake of brevity.

Figure 11.

Deformed shapes computed by ANSYS: (a) Specimen 1; (b) Specimen 2; (c) Specimen 3.

Figure 11.

Deformed shapes computed by ANSYS: (a) Specimen 1; (b) Specimen 2; (c) Specimen 3.

Table 1 compared the values of peak strength determined from experiments and numerical simulations as the ratio between the peak load and the cross-sectional area of the specimen. Data reported in the table confirm the good agreement between experiments and FE analysis.

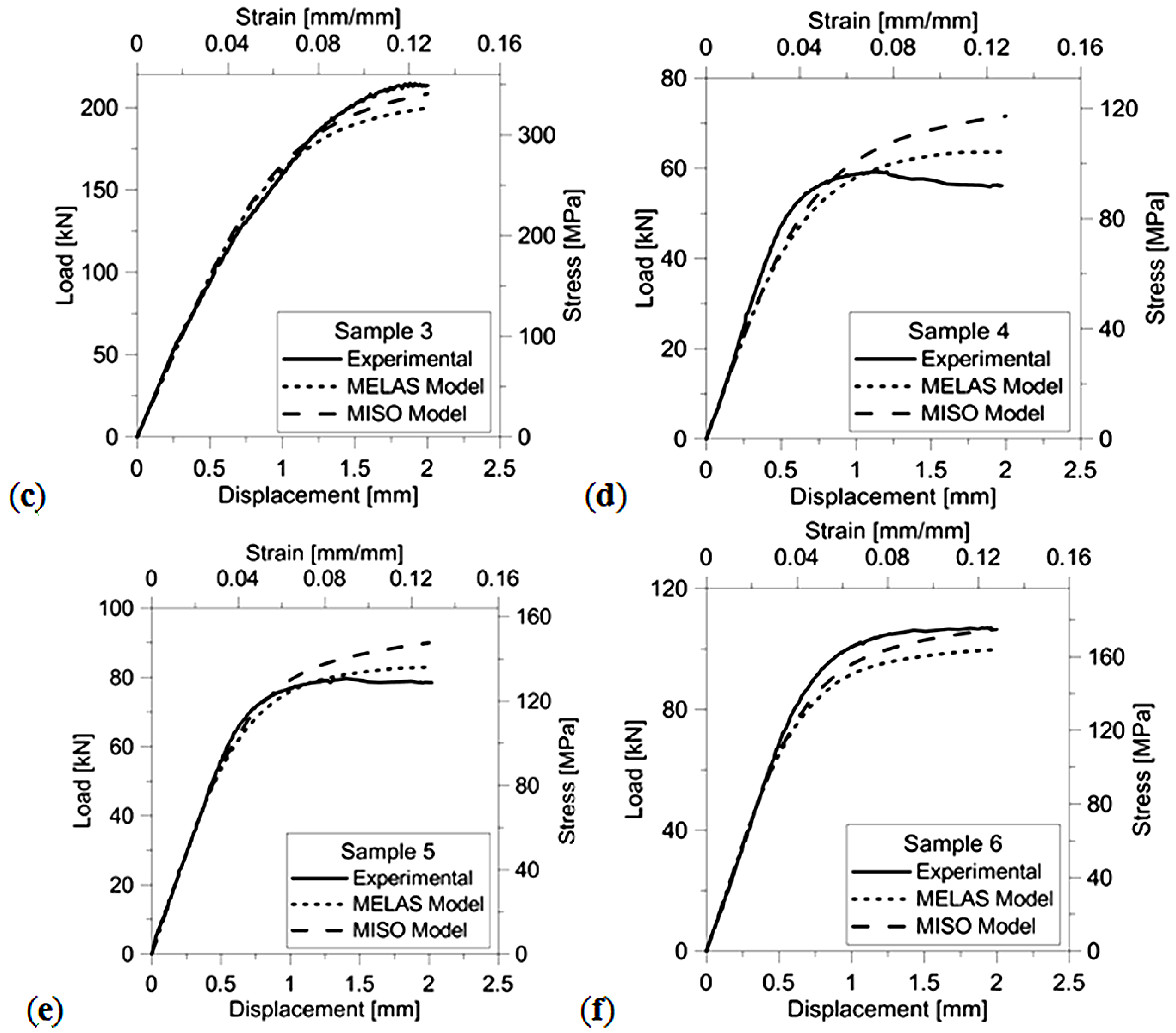

Figure 12 compares the load-displacement and stress-strain curves recorded experimentally with those simulated by ANSYS. The MISO model reproduces more accurately the experimentally observed behavior of the design variants. In the linearly elastic range, both models achieve perfect correspondence with experimental results. The difference between the two models becomes less significant as the number of reinforcement columns increases (see also the corresponding values of peak strength reported in

Table 1). This is because the presence of columns reduces the risk of plastic buckling. Therefore, numerical results are fully consistent with the experimental evidence of structural failure driven by inelastic buckling phenomena.

Figure 12.

Comparison of the load-displacement and stress-strain curves recorded experimentally and simulated numerically: (a) Sample 1; (b) Sample 4; (c) Sample 2; (d) Sample 5; (e) Sample 3; (f) Sample 6.

Figure 12.

Comparison of the load-displacement and stress-strain curves recorded experimentally and simulated numerically: (a) Sample 1; (b) Sample 4; (c) Sample 2; (d) Sample 5; (e) Sample 3; (f) Sample 6.

However, the finite element models developed in this study might not necessarily capture the unstable behavior caused by surface asperities sharper (i.e., higher values of surface roughness) than in the present case. As the compression load increases, surface asperities can locally collapse and the loading cell can record lower load values (i.e., the steps that are typically observed in the plastic plateau).